Page 1

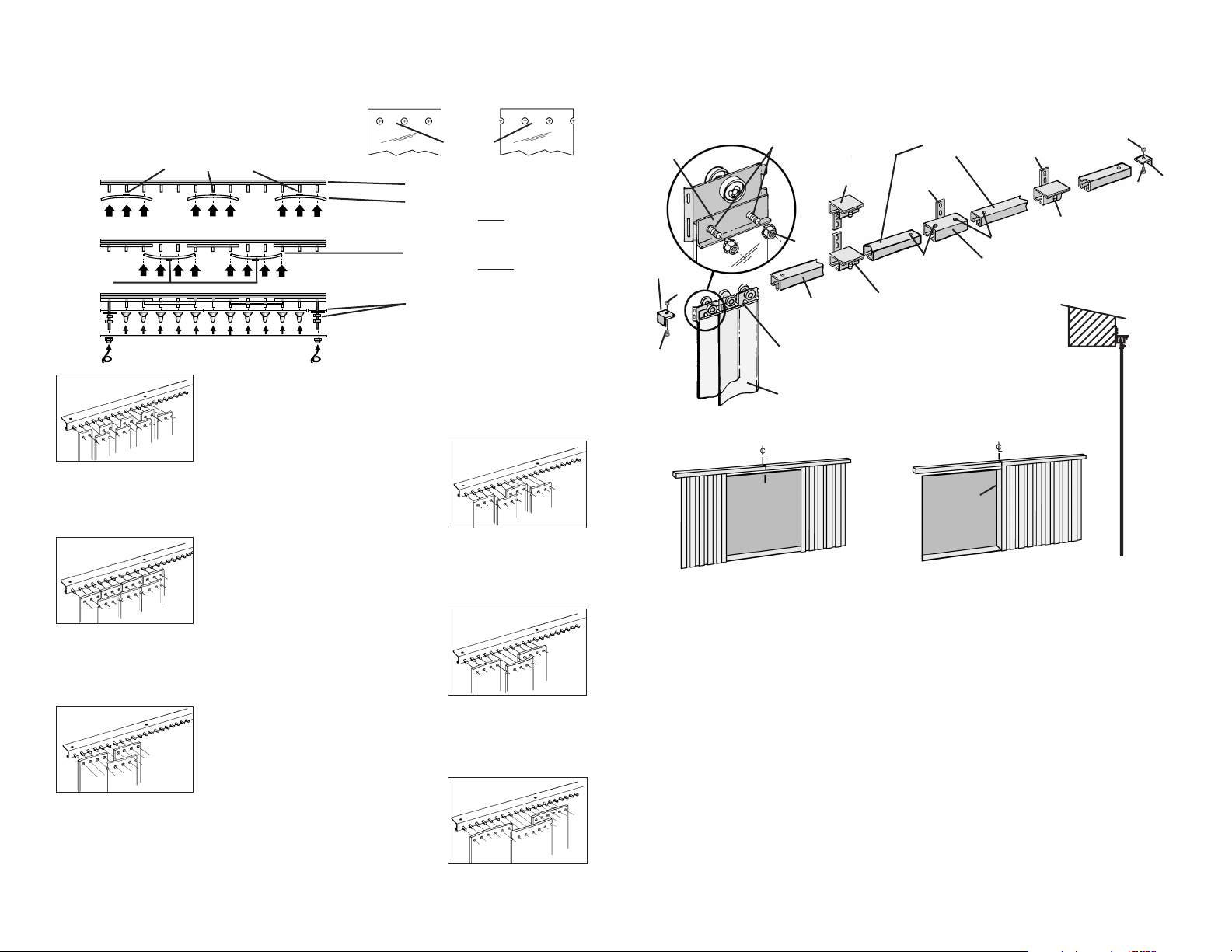

STANDARD TRACK MOUNTING SYSTEMS

5 6

4” wide strips - 50% overlap

Hang the first strip with the blue stickers to the far left, skip 2”, hang

the second strip with the blue stickers, skip 2” and repeat to the far

right. Center the remaining strips with green stickers over 2” gaps.

4 - 50

6 - 33

6” wide strips - 33% overlap

Hang the first strip with the blue stickers to the far left, skip 4”, hang

the second strip with the blue stickers, skip 4” and repeat to the far

right. Center the remaining strips with green stickers over 4” gaps.

8” wide strips - 75% overlap

Hang the first strip with the blue stickers to the far left, skip 2” hang the

second strip with the blue stickers, skip 2” and repeat to the far right.

Center the remaining strips with green stickers over 2” gaps.

8 - 75

12 - 50

12” wide strips - 50% overlap

Hang the first strip with the blue stickers to the far left, skip 6” hang

the second strip with the blue stickers, skip 6” and repeat to the far

right. Center the remaining strips with green stickers over 6” gaps.

6” wide strips - 100% overlap

Hang the first strip with the blue stickers to the far left, align the second strip with the front strip, and repeat to the far right. Center the

remaining strips with green stickers over the seams.

6 - 100

8 - 25

8” wide strips - 25% overlap

Hang the first strip with the blue stickers to the far left, skip 6” hang

the second strip with the blue stickers, skip 6” and repeat to the far

right. Center the remaining strips with green stickers over 6” gaps.

SPECIAL OVERLAP CONFIGURATIONS

Special overlaps use half of the strips with standard

holes and half off-set holes (see Fig. 4). Also, Blue

Stickers are used for the first row and Green Stickers

are used for the second row (see the illustration below).

•

•

Fig. 4

BLUE STICKERS

STICKERS

GREEN

STICKERS

Installed Mounting Bars

Place 1st row of strips on studs

with sticker away

from installer.

After 1st row is completed . . .

Place 2nd row of strips on studs

with sticker toward

the installer.

After 2nd row is completed . . .

Place retaining bars over studs,

attach lock-nuts and tighten.

If partial width strips are includ-

ed, see bottom illustration on

page 4.

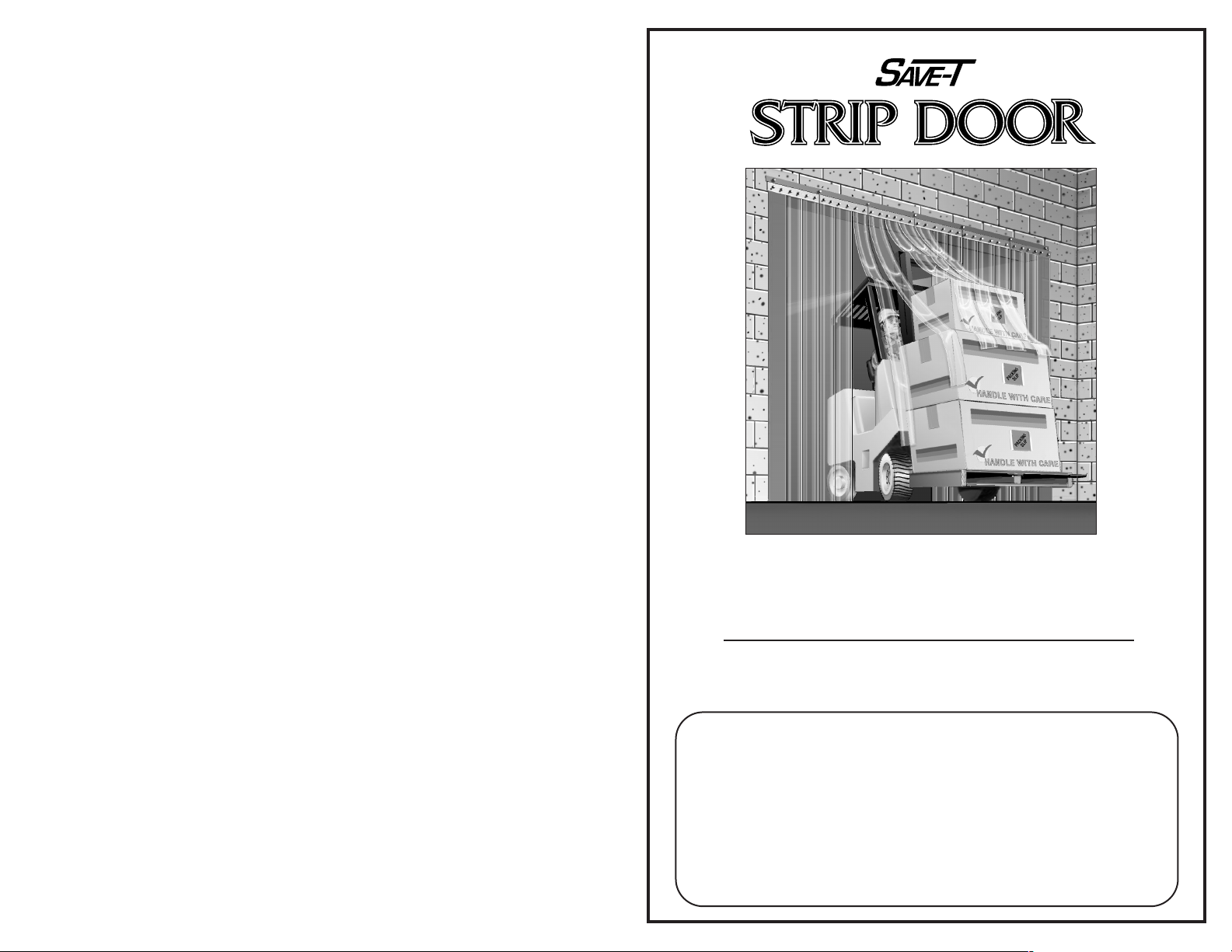

STRAIGHT

TRACK

P. V.C. STRIPS

BI-PARTING WALL MOUNT

(BP-WM)

END

STOP

END

STOP

SECTIONAL HINGED

TROLLEY

WALL MOUNT TRACK

CONNECTOR – UP

WALL MOUNT

TRACK

CONNECTOR

– DOWN –

SPLICE CONNECTOR – UP

WALL MOUNT TRACK

CONNECTOR – UP

THREADED

STUDSRETAINING

BAR

NUT

NUT

NUT

BOLT

BOLT

MOUNTING

LUG

MOUNTING

LUG

SET

SCREWS

SET

SCREWS

STRAIGHT

TRACK

WALL MOUNT

SIDE VIEW PROFILE

STANDARD HOLES OFF-SET HOLES

Please study these drawings to familiarize yourself with part names and mounting methods.

ONE-SIDED WALL MOUNT

OS-WM

(Right side shown)

DOORWAY

CENTER

DOORWAY

EDGE

First, determine if your sliding door system is a bi-parting wall mount system (BPWM) or

a one-sided wall mount system (OSWM). If it is an OSWM system, you will also need to

determine to which side of the doorway opening the track will be extended (above illustration shows right-side extension). If you are not sure of which system you have purchased, please refer to the model number indicated on the front cover of this booklet.

FOR SINGLE TRACK (ONE PIECE) SYSTEMS

1. For BPWM models only, mark the center of the doorway opening.

2. Mark the center of the straight track section.

3. Loosely attach all wall mount track connectors to the straight track section. All the

connector’s anchor hole tabs should be in the up or down position, depending on

which connectors were shipped.

4. Position the far left connector 4” from the left end of the track and position the far

right connector 4” from the right end of the track. Then, evenly distribute the remaining connectors across the straight track section and tighten all the connectors.

5. Connect three hinged trolley sections and slide the trolley sections into one end of

the straight track.

Page 2

IMPORTANT

Carefully examine the carton(s) for damage.

If the carton is damaged, immediately notify the

shipping company.

YOUR MODEL NUMBER IS . . .

STRIP WIDTH STRIP OVERLAP TYPE OF HARDWARE

PLEASE READ ALL INSTRUCTIONS BEFORE

PROCEEDING WITH INSTALLATION.

7

INSTALLATION

INSTRUCTIONS

INSTALLATION

INSTRUCTIONS

❏ 4”

❏ 6”

❏ 8”

❏ 12”

❏ 16”

❏ 25%

❏ 33%

❏ 50%

❏ 67%

❏ 75%

❏ 100%

❏ SL

❏ UL

❏ UM

❏ BPWM

❏ OSWM

6. Place the end stops at both ends of the track.

7. Take one P.V.C. strip and temporarily attach the strip to the threaded studs on the

hinged trolley sections.

8. Raise and level the track assembly above the doorway opening, aligning the center

point of the track with the center point of the doorway opening (BPWM models) or the

center point of the track with the edge of the doorway opening (OSWM models).

Adjust until the bottom of P.V.C. strip is 1/2” above the floor.

9. Mark all the wall mount track connector mounting lug anchor holes and remove track

assembly.

10. Drill anchor holes and place anchors (supplied by others) into those holes.

11. Place anchors in each hole and attach the track assembly with lag screws.

12. Remove just one end stop from the assembly and slide the three hinged trolley sections with P.V.C. strip from the track assembly.

13. Connect and slide all of the individual hinged trolley sections into the open end of the

track assembly. The studs should be facing away from the wall.

14. Replace the end stop that was removed in step 12.

15. The final step is to attach the P.V.C. strips to the hinged trolley sections using one of

the three methods illustrated on pages 3, 4 and 5.

DOOR WIDTHS GREATER THAN 5’

Multiple tracks are used for these units and wall mount track splice connectors are utilized at the joints. If multiple tracks are required, they should be assembled in numerical

order from left to right. All joints must be aligned and butted together perfectly.

1. For BP-WM models only, mark the center of the doorway opening.

2. Lay out and assemble all track components on the floor at the base of the doorway.

All joints should be butted together tightly with splice connectors.

3. Attach all wall mount track connectors to the unit. All the connector’s mounting lugs

and splice connector’s mounting lugs should be in the up or down position, depending

on which units were shipped. Position the end connectors 4” from each end of the

track assembly.Then, evenly distribute the remaining connectors across the straight

track section and tighten all the connectors.

4. Measure and mark the center point of the track assembly and disassemble the

straight track sections at the splice joints.

5. Connect four hinged trolley sections and slide these sections into one end of the

straight track that has the marked center point.

6. With that one section, follow steps 7 through 10, “FOR SINGLE TRACK SYSTEMS”.

7. Using a level, attach the remaining track sections to the wall, one at a time, making

sure that each joint’s splice connector and track connectors are firmly attached to the

wall and the set screws are firmly tightened.

8. Once the assembly is completed, install one end stop.

9. Connect and slide all of the individual hinged trolley sections into the open end of the

track assembly. The studs should be facing away from the wall.

10. Install the remaining end stop.

11. The final step is to attach the P.V.C. strips to the hinged trolley sections using one of

the three methods illustrated on pages 4 and 5.

®

Catalog No. SD-II-06/07

©

Copyright 2007 TMI, LLC

Page 3

GETTING STARTED . . .

Open all carton(s) and remove all door hardware. Do not remove the P.V.C. strips

from the carton(s) until ready for installation.

NOTE: When multiple strip doors are ordered, all carton(s) will be properly

tagged.

All strip doors are shipped complete with the following:

• Mounting Bars (excluding support anchors)

• Retaining Bars, 1/4” strip fastening nuts and individual P.V.C. strips with

custom pre-punched holes

NOTE: Support anchors (provided by others) and mounting surface must be

capable of supporting the total weight of the strip door or the sliding strip

door. If you have any questions please refer to a registered architect or structural engineer.

Pre-studded galvanized steel Mounting Bars and Retaining Bars are standard

(aluminum and stainless steel optional). Depending on the door width, more than

one mounting bar might be supplied.

Wall Mount Hardware (SL)

The top edge of this steel hardware is

attached 4

3

/8” above the edge of the lintel, directly to the wall. Attach by conventional anchors or by welding (see Fig. 1).

Header Mount Hardware (UL

This steel hardware is attached directly to

the door header (lintel). Attach by conventional anchors or by welding (see Fig. 2).

Universal Hardware (UM)

The top edge of this steel hardware can

be attached 4

3

/8” above the edge of the

lintel, directly to the wall or can be

attached directly to the door header (lintel). Attach by conventional anchors or by

welding (see Fig. 3).

Sliding Track Hardware (BPWM or

OSWM)

Please refer to Page 6 for this type of

installation.

1 2

FIRST. . .

SECOND. . .

. . . determine which type of hardware and mounting procedure you will be

using by referring to YOUR MODEL NUMBER found on the front page of

this booklet. The checked boxes will let you know what strip width you

ordered, the percent overlap and the type of hardware & mounting procedure needed.

. . install the Mounting Bar(s) either on the wall above the doorway opening (WALL MOUNT)

or the under surface of the lintel (HEADER MOUNT). See Figures 1, 2 or 3.

Note: If multiple bars are required, start with Bar

➀

to the far left and continue to the

right in numerical order (

➁, ➂

, etc.). All joints must be aligned and butted together

perfectly.

Fig. 2

Fig. 1

Fig. 3

Retaining Bar

Header Mount (UL)

Header

Mount (UM)

Wall Mount (SL)

Wall

Mount (UM)

Retaining Bar

Retaining Bar

Mounting Bar

Mounting Bar

Mounting Bar

Doorway

Opening

P. V.C.

Strips

Mounting Bar

WALL MOUNT HARDWARE INSTALLATION (SL)

Pre-studded galvanized steel Mounting Bars and Retaining Bars are standard

(aluminum and stainless steel optional). Depending on the door width, more than

one mounting bar might be supplied.

HEADER MOUNT HARDWARE INSTALLATION (UM)

1. Temporarily attach a

P. V.C. strip to either

end of the Mounting

Bar(s).

2. Remove the Bar(s)

and drill the anchor

holes.

3. Place anchors in each

hole and attach the

Mounting Bar(s) with

lag screws.

2. Center and level the

bar(s) above the

opening so the strips

are 1/2” above the

floor.

3. Mark Mounting

Bar(s) anchor

holes and remove

the bar.

4. Drill anchor holes

and place anchors

(supplied by others)

into those holes.

5. Take the temporary

strips off the

Mounting Bar(s)

and attach the

Bar(s) with lag

screws.

1/2”

IMPORTANT

If attaching to wood, anchors are not

necessary. If attaching to steel, welding could be used.

1. Center the Mounting

Bar(s)on the underside of the lintel. Mark

the mounting holes.

SIDE VIEW

Centered

➀

➁➂

Align and Butt Joints Perfectly

Align and Butt Joints Perfectly

Page 4

. . . place the P.V.C. strips on the pre-studded hardware that has just been installed.

Before you start, refer to YOUR MODEL NUMBER found on the front page of this booklet to determine the width of your strips and overlap configuration.

3 4

THIRD. . .

STANDARD OVERLAP CONFIGURATIONS

Note: All strips are provided with a round colored sticker at the location of the

pre-punched holes. See SPECIAL OVERLAP diagrams on page 4.

Installed Mounting Bars

Installed Mounting Bars

Place 1st row of strips on studs with sticker

away

from installer.

After 1st row is Completed . . .

Place 2nd row of strips on studs with sticker

toward

the installer.

After 2nd row is completed . . .

Place retaining bars over studs, attach lock-

nuts and tighten.

Place 1st row of strips on

studs with sticker away

from

installer.

After 1st row is completed . . .

Place 2nd row of strips on

studs with sticker toward

the

installer.

After 2nd row is completed . .

.

Place retaining bars over

studs, attach lock nuts and

tighten.

STICKERS

STICKERS

STICKERS

STANDARD OVERLAP

STANDARD OVERLAP WITH SMALLER WIDTH END STRIPS

STICKERS

There are 3 overlap configurations used. The STANDARD OVERLAP (all strips are the

same width), the STANDARD OVERLAP WITH PARTIAL END STRIPS (one or two

strips are a smaller width and are placed at the ends) and SPECIAL OVERLAP (half the

strips have been specially punched and have a blue or green sticker affixed, see Page 5).

4” wide strips - 100% overlap

Hang the first strip to the far left, align the second strip with the first strip,

repeat to the far right. Center the remaining strips over the seams.

4 - 100

6 - 67

6” wide strips - 67% overlap

Hang the first strip to the far left, skip 2”, hang the second strip, skip 2” and

repeat to the far right. Center the remaining strips over 2” gaps.

16” wide strips - 25% overlap

Hang the first strip to the far left, skip 12”, hang the second strip, skip

12” and repeat to the far right. Center the remaining strips over 12”

gaps.

16 - 25

16 - 50

16” wide strips - 50% overlap

Hang the first strip to the far left, skip 8”, hang the second strip, skip

8” and repeat to the far right. Center the remaining strips over 8” gaps.

16” wide strips - 75% overlap

Hang the first strip to the far left, skip 4” , hang the second strip, skip

4” and repeat to the far right. Center the remaining strips over 4” gaps.

16 - 75

16 - 100

16” wide strips - 100% overlap

Hang the first strip to the far left, align the second strip with the first

strip. Repeat to the far right. Center the remaining strips over the

seams.

12” wide strips - 33% overlap

Hang the first strip to the far left, skip 8”, hang the second strip, skip 8”

and repeat to the far right. Center the remaining strips over 8” gaps.

12 - 33

12” wide strips - 100% overlap

Hang the first strip to the far left, align the second strip with first strip.

Repeat to the far right. Center the remaining strips over the seams.

12 - 100

12 - 67

12” wide strips - 67% overlap

Hang the first strip to the far left, skip 4”, hang the second strip, skip 4”

and repeat to the far right. Center the remaining strips over 4” gaps.

8” wide strips - 50% overlap

Hang the first strip to the far left, skip 4”, hang the second strip, skip 4” and

repeat to the far right. Center the remaining strips over 4” gaps.

8 - 50

8 - 100

8” wide strips - 100% overlap

Hang the first strip to the far left, align the second strip with the first strip.

Repeat to the far right. Center the remaining strips over the seams.

IMPORTANT: All P.V.C. strips have a natural curve across

the width of the material. When hung properly (row 1 concaved – row 2 convexed), it creates a barrier against drafts.

Row 1 - Concaved

Row 2 - Convexed

Draft Barrier Draft Barrier

SMALLER STRIPSMALLER STRIP

Loading...

Loading...