Page 1

Installation Manual

Installation, Operation & Maintenance of the ZECV

Analog Pressure Controller

General Description

When applying Zcom diusers in an changeover/

bypass application with a constant volume rooftop

unit, provisions must be made to control duct static

pressure. The duct static pressure is typically

controlled by a system bypass damper installed o

of the supply duct, and controlled from a static

pressure tap installed 2/3 down the main duct.

Figure 2 illustrates a re commended installation of

the bypass damper to maximize mixing of the

bypass air with the return air. This location of the

bypass minimizes the opportunity for developing

hot or cold spots in the rooftop.

Installation Instructions

ZECV-IOM-1.0 3-1-03

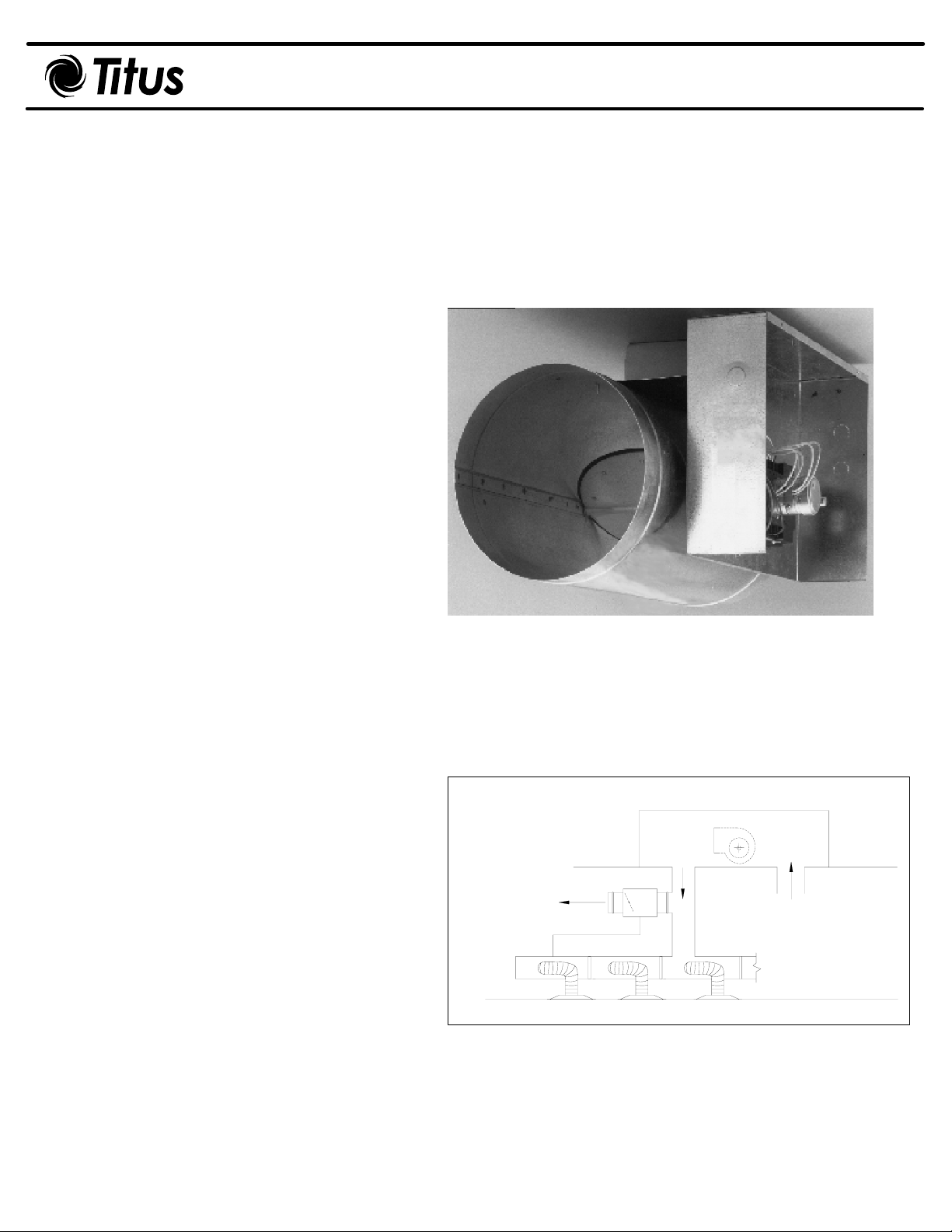

Figure 1. ZECV

These instructions are intended only as a basic

guide for the installer. They do not assure

compliance with local codes. Consult the

authorities having jurisdic tion be

terminal.

fore installing this

Receiving Inspection

After unpacking the pressure controller, check it for

shipping damage. If any shipping damage is found,

report it immediately to the delivering carrier.

Supporting the Terminal

The basic control is light enough so that it can be

supported by the duct work in which it is installed.

Where the accessory modules such as coils,

attenuators or multiple outlets are included, the

assembly should be supported directly. Use the

support method prescribed for rectangular duct in

the job specications.

Duct Connections

Slip the inlet duct over the inlet collar.

The diameter of the inlet duct in inches must be

equal to the listed size if the terminal: e.g., a duct

that actually measures 8 in ches must be tted to a

size 8 terminal. Attach the

by using standard SMACNA slip and drive

connection method. Fasten and seal all

connections by the method prescribed by the job

specications.

rectangular outlet duct

Figure 2.

Static

Pressure

Tap

Bypass

Air

Constant Volume Rooftop Unit

Supply

Air

ZECV

Return

Air

Zcom

Page 2

ZECV-IOM-2.0 3-1-03

Field Wiring Instructions

Inspection

Factory mounted controls and accessories are mounted

inside the sheet metal enclosure located on the side of

the terminal. Remove the cover and inspect all

components for visual damage.

Power and Supply

Analog electronic controls require 24 VAC -15/+20

percent power supply. Allow 14 VA for the controller.

Factory supplied transformers are available with supply

voltages of 277V, 240V, 208V, or 120V. Field supplied

transformers can be mounted inside the control box.

Attach the 24 volt leads to terminals 9 and 10 on the

controller (See Figure 3).

Single Transformer Wiring

The same 24 VAC transformer may be used to power

the controller plus control relays, contractors and/or

valves on a terminal. For single transformer wiring see

figure 3.

Multiple Loop Wiring

If multiple controllers are looped together in a single

circuit using a common transformer, wire all #9

connections together, and all #10 connections together.

If the transformer secondary is connected to earth

ground, this lead must also be connected to terminal #9.

ALWAYS OBSERVE PHASING!

CAUTION: NEVER connect power to the controls until

all wiring has been installed. ALWAYS disconnect power

to the controls before servicing the unit controls or

accessories. DO NOT connect line voltage to the

controller or other unit components.

Balancing

The following guidelines are recommended when

balancing a constant volume rooftop unit and Zcom

diffuser system.

1. Adjust rooftop to supply cooling or heating during

the balance. The Zcom diffuser has three modes of

operation; cooling, heating and ventilation. If the

supply air temperature is between the heating and

cooling setpoints, the Zcom will operate in the

ventilation mode and go to the ventilation damper

position of 50% closed. Therefore, to properly

balance the system, the rooftop unit must be in either

cooling or heating.

2. Drive the Zcom diffusers fully open with the

Zapper, shown on the Zapper as “CL Open” or “HT

Open” (CL for cooling mode and HT for heating

mode), or power down all Zcom diffusers which will

return the Zcom’s to the fully open position.

3. Balance each diffuser for the required design air

flow.

The next steps apply to balancing the bypass damper to

maintain duct static pressure.

1. Command all Zcom diffusers to the minimum

position except one Zcom master, which is to remain

fully open. The Zapper is used to command the Zcom

to the minimum position by pushing the down arrow

selector button until “CL Close” or “HT Close” (CL for

cooling mode and HT for heating mode) is displayed

on the Zapper.

2. Set the bypass damper by adjusting the ZECV

constant volume module to the desired static

pressure as measured at the static pressure tap

installed 2/3 down the main duct. The TITUS ZECV

has a time delay of approximately five minutes before

reacting to any adjustment.

NOTES:

Consult local codes for specific types of wires and

enclosures required for low voltage wiring.

Troubleshooting information is found on page.

All wiring diagrams shown in this manual show single

transformer wiring.

Page 3

Figure 3.

POWER

SUPPLY

CONDUCTORS ONLY

{

12

COM

WHT

24 VAC

USE COPPER

L1

N

RED

GREEN

13

RED - CCW - GRN

CLOSE

GRN - CW - RED

ZECV-IOM-3.0 3-1-03

BLACK

WHITE

DISC SWITCH

(OPTIONAL)

14

BLACK

WHITE

208V

240V

TRANSFORMER

BLK

RED

ORN

240V TRANSFORMER

CAP UNUSED

TRANSFORMER LEAD

YELLOW

24V120/277V

BLUE

YELLOW

24V

BLUE

BLUE

YELLOW

SEE MOTOR DETAIL BELOW

CONTROLLER/ACTUATOR

LINK DAMPER CLOSED, CW TO OPEN

HI LO

8

9

10

11

12

13

{

14

7

6

5

4

3

2

1

BLUE #18

WHITE #18

ORANGE #18

WIRING DETAIL FOR CLOCKWISE TO OPEN ROTATION

FOR PRESSURE CONTROL

RED

GREEN

14

13

12

RED - CCW - GRN

COM

CLOSE

WHT

24 VAC

GRN - CW - RED

WIRING DETAIL FOR CLOCKWISE TO OPEN ROTATION

FOR BYPASS CONTROL

TUBE W/RED STRIPE (HI)

INLINE FILTER

CLEAR TUBING

TEE

STATIC PRESSURE

TAP (FIELD INSTALLED)

BYPASS PRESSURE CONTROL OR

LOCATED DOWNSTREAM FOR

DISCHARGE PRESSURE CONTROL

STATIC PRESSURE TAP:

LOCATED UPSTREAM FOR

Replacement Parts

DESCRIPTION MODEL # TITUS PART #

Controller-Actuator-Sensor

(Sizes 4–10) CEP-4011 100277-01

(Sizes 12–16) CEP-4012 100277-02

System Control Modules

Constant Volume

Pressure Controller REE-1004 101711-01

INCR

R456

CONSTANT VOLUME

MODULE

ORANGE #18

BLUE #18

WHITE #18

CAUTION:

ELECTRIC SHOCK MAY RESULT.

DISCONNECT POWER SUPPLY

PRIOR TO SERVICING UNIT.

DESCRIPTION TITUS PART #

Transformers

120/24V 50VA 100058-01

208/24V 50VA 100575-01

240/24V 50VA 100575-01

277/24V 50VA 100066-01

480/24V 50VA 101003-01

24V/24V 50VA 101066-01

NOTES:

Vendor part numbers may vary by date of manufacture. Series 4000 controls

and accessories began with TITUS Factory No. 37337 (1988). Series 4000

controllers and modules must be matched together. All other series are

interchangeable.

All valve sizes are National Pipe Thread (NPT). Valves include one female

and one male union.

Proportional control water valves may be used as proportional with above

listed modules or as two-position with standard reheat module.

Water control valves and actuators are shipped separately from terminal unit

to reduce damage.

Primary Damper Assy.

Size 4–5–6” 301820-01

Size 7” 301820-02

Size 8” 301820-03

Size 9” 301820-04

Size 10” 301820-05

Size 12” 301820-06

Size 14” 301820-07

Size 16” 301820-08

Damper Shaft Extension

Short Stub-ALL 703003-01

Long Extension

Sz. 4–6, 14, 16 703003-02

Sz. 7–12 703003-03

Shaft Bearing 703249-01

Page 4

ZECV-IOM-4.0 3-1-03

Service Procedure Check Sheet

Voltage Range

Terminal Connectors #9, #10 #11, #12 #13, #14

Tag Location

I. Verify all wires are tightly secured to the proper terminals. CAUTION: Do NOT touch terminals with a screwdriver while

power is on.

II. Verify CONTOLLER/ACTUATOR operation:

A. Observe motor operation through observation window. It should be rotating frequently and rocking back and forth in

response to changes in air flow.

B. Observe arrow on the end of the damper shaft. Verify that damper rotates a full 90 degrees on call from full

pressure.

C. Verify the setscrew is secure to the damper shaft at the proper location. Do NOT alter factory setting. CAUTION:

Motor may be hot to the touch. (May be up to 150° F).

III. PROBLEMS AND POSSIBLE SOLUTIONS:

A.Power supply (#9 and #10) out of range -

- If ZERO, turn power on the read again.

- If power is on, determine reason for damage,

Repace faulty or undersized transformer.

B. Damper remains full OPEN-

- Verify sufficient primary air flow to terminal.

- Check for loose damper set screw.

- Verify damper is positioned correctly.

- Verify limits are not set too high at the thermostat.

C. Damper remains full CLOSED-

- Check continuity for broken sensor wires.

- Verify damper set screw is secure.

- Verify damper position is correct.

- Verify damper is free to turn.

D. Damper remains STOPPED (won’t open or close)

- Verify 24 VAC on motor that should be rotating.

- Reset thermostat slider and check opposite motor for 24 VAC.

- Verify damper is free to turn.

- Replace faulty controller/actuator.

Thermostat

Setting

20.4-28.8 0 or 24 0 or 24

Power Supply

Supply Voltage, AC

CCW

Motor

CW

Motor

Loading...

Loading...