Page 1

Installation Manual

IOM-VAB-00 06-30-04

VAB Vertical Air Handler Belt Drive

Installation, Operation, and Maintenance Manual

Contents Page

General ....................................................................1

Introduction.............................................................1

Safety .......................................................................1

Inspection................................................................1

Product Description ............................................... 1

Model Number Specification .............................................1

Dimension Specification .................................................... 1

Unit Cabinet Dimensions...................................................2

Coil Specifications ............................................................. 2

Dimensional Drawings.......................................................2

Installation...............................................................4

Ductwork ...........................................................................4

Duct Insulation and Vapor Proofing................................... 4

Motors and Drives .............................................................4

Sound Attenuation............................................................. 4

Electrical Connections....................................................... 4

Condensate Drain .............................................................5

Water Piping......................................................................5

Installation of Options............................................5

Discharge / Return Air Plenum..........................................5

Electric Heater................................................................... 6

Startup ..................................................................... 6

Operation and Maintenance ..................................7

Return Air Filters ...............................................................7

Coil .................................................................................... 7

Belt and Pulley ..................................................................7

Motor ................................................................................. 7

Blower ...............................................................................7

Abbreviations.......................................................... 7

General

This document provides installation, operation, and

maintenance information for the Titus Vertical Air Handler

Belt Drive (VAB) models.

Additional information may be found at the Titus website,

www.titus-hvac.com.

Introduction

The following information is to be used by the installer as a

guide. Since each installation is unique unto itself, only

general topics are covered. The order in which topics are

presented may not be those required by the actual

installation.

This guide does NOT supersede or circumvent any

applicable national, state, or local codes.

The installation is to be performed only by individuals

whose experience meets or exceeds the requirements of

the work involved.

The installer must read the entire contents of

and develop a thorough understanding before beginning

installation.

Due to a continuing program of product research, Titus

reserves the right to discontinue or change without notice,

any or all specifications or designs without incurring

obligations.

this guide

Safety

The installation and/or servicing of comfort conditioning

equipment can be hazardous due to system pressures

and electrical devices.

Caution: Only trained and qualified personnel

should perform service and/or installation.

Observe all precautions and warnings in product

data or attached to the unit.

Follow all safety codes. Wear eye protection and gloves.

Have a fire extinguisher readily avai

Caution: Disconnect all power supplies before

accessing equipment.

Disconnecting more than one power supply may

be required to de-energize some equipment.

DANGER

ELECTRIC SHOCK CAN CAUSE DEATH.

lable.

Inspection

Thoroughly inspect all packages upon receipt. Ensure

carton(s) have not been dropped, crushed or punctured.

Inspect all contents for damage. If damage is found,

immediately file a claim with the delivering carrier.

Product Description

This section provides model number nomenclature,

various unit dimensions, and coil specification.

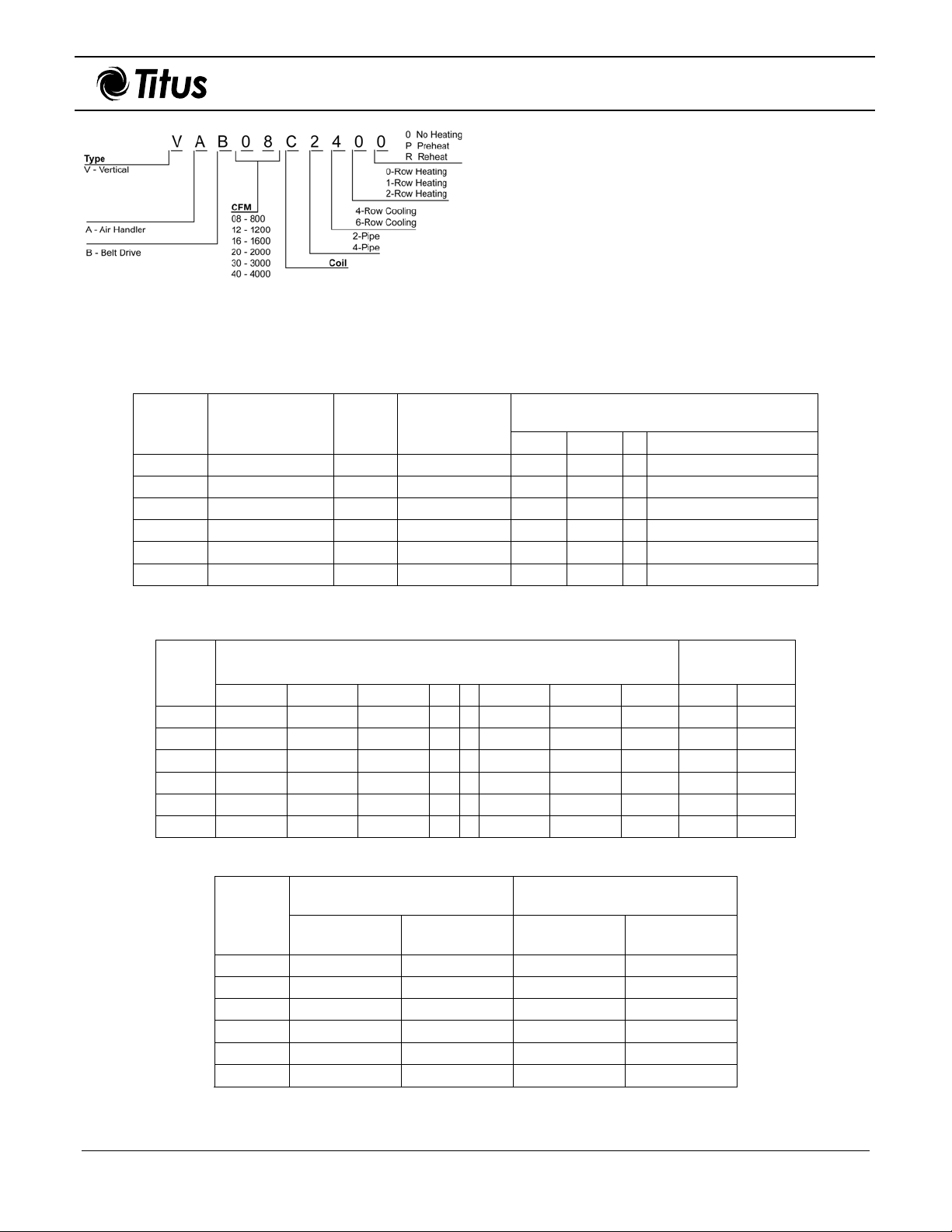

Model Number Specification

Figure 1 defines model number nomenclature specifics.

Dimension Specification

Table 1 provides VAB model dimension specifics such as

tonnage, blower, filter dimensions, optional discharge or

return air plenum, and shipping weight of plenum.

605 Shiloh Road • Plano, Texas 75074 • 972- 212-4800

All rights reserved. No part of this work may be reproduced or transmitted in any form or any means, electronic or mechanical, including photocopying and recording, or by any information storage retrieval system without permission in writing from Air Distribution Technologies.

Page 2

VAB Installation Manual

IOM-VAB-00 06-30-04

Unit Cabinet Dimensions

Table 2 provides the cabinet dimensions for each VAB

model along with the blower-opening outlet.

Coil Specifications

Table 3 provides VAB model specifics for the chilled and hot

water coil outside diameter and shipping weight based on

the number of coils (weight for 4-row chilled water coil

includes weight for entire unit).

Figure 1. Air Handler Model Number

Nomenclature

Table 1. VAB Model Dimensions

Model

VAB08 2 9 x 9 20 x 20 22 23-1/2 12 23

VAB12 3 9 x 9 20 x 20 22 23-1/2 12 23

VAB16 4 10 x 10 22-1/2 x 22-1/2 25 23-1/2 14 30

VAB20 5 12 x 12 (2) 16 x 25 29-1/4 25-1/2 16 35

VAB30 7-1/2 15 x 15 (3) 16 x 25 39 27 24 41

VAB40 10 15 x 15 (4) 20 x 25 51-1/2 27 24 41

Nominal Rating in

Tons

Blower

Filter Size

(inches)

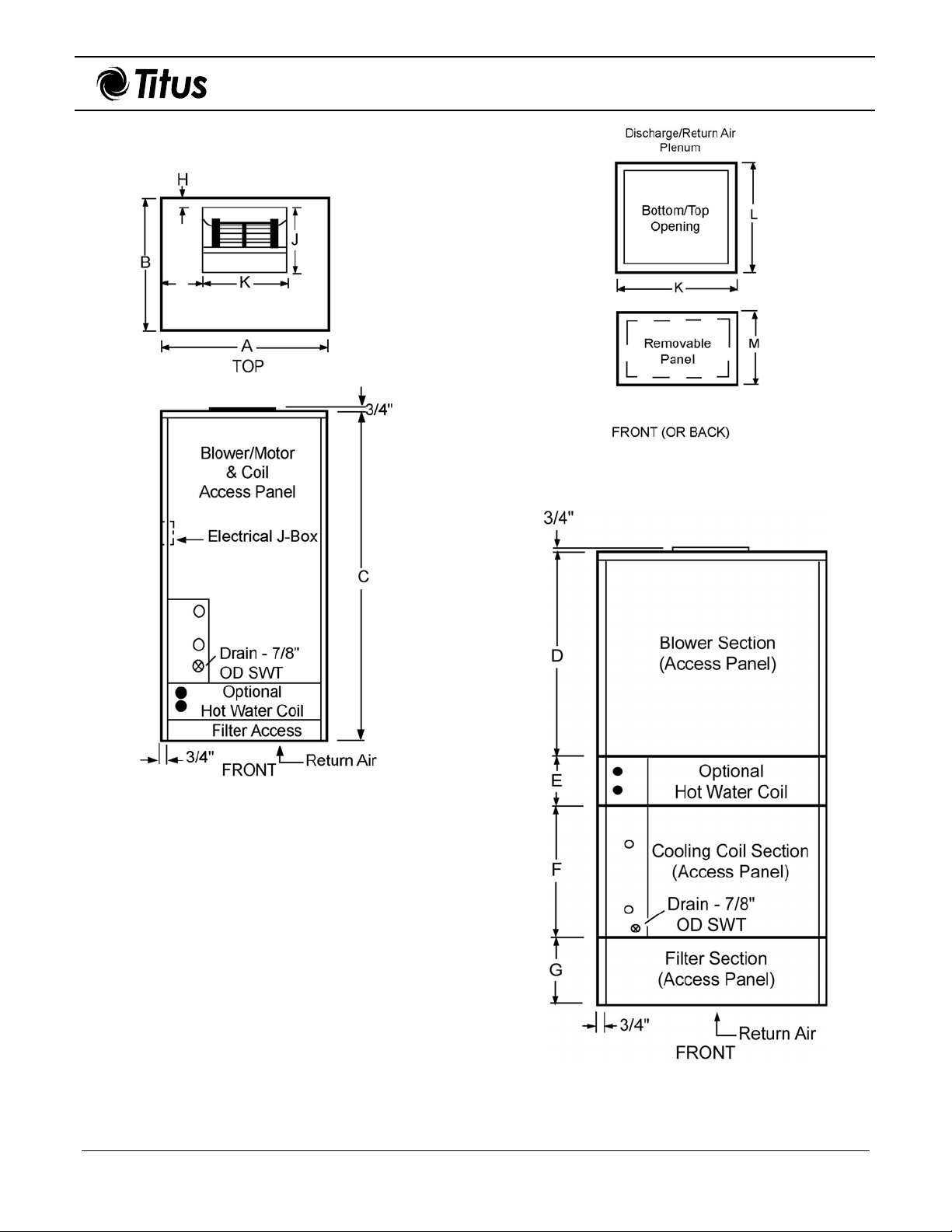

Dimensional Drawings

Figures 2 through 4 provide dimensional callouts with letters

corresponding to letters used in Tables 1 through 3.

Optional Discharge or Return Air Plenum

Dimensions (inches)

K L M Shipping Wgt. (lbs.)

Table 2. Cabinet Dimensions

Model

A B C D E F G H J K

VAB08 22 23-1/2 50 - - - - 3 12 8-3/4

VAB12 22 23-1/2 50 - - - - 3 12 8-3/4

VAB16 25 23-1/2 56-1/2 - - - - 1-1/2 14 9-1/2

VAB20 29-1/4 23-1/2 59-5/8 - - - - 1 14 13

VAB30 39 27 - 34 9 19-1/2 15-1/2 1 16-3/4 13-1/4

VAB40 51-1/2 27 - 34 9 19-1/2 20-1/2 1 16-3/4 13-1/4

Model

VAB08 3/4" OD SWT 164 7/8" OD SWT 14

VAB12 3/4" OD SWT 170 7/8" OD SWT 14

VAB16 7/8" OD SWT 200 7/8" OD SWT 17

VAB20 1-1/8" OD SWT 253 1-1/8" OD SWT 21

VAB30 1-1/8" OD SWT 364 1-1/8" OD SWT 81

VAB40 1-3/8" OD SWT 462 1-1/8" OD SWT 102

Note 1: Weight for entire unit.

Note 2: Weight for heating coil only.

Cabinet Dimensions (inches)

Table 3. Coil Dimensions

4-Row Unit 2-Row Heating Coil

Connection

Size

Shipping Wgt.

(lbs) Note 1

Connection

Size

Shipping Wgt.

Blower Opening

Outlet (inches)

(lbs) Note 2

2 of 7

Page 3

VAB Installation Manual

Figure 3. Optional Discharge or Return Air

IOM-VAB-00 06-30-04

Plenum

Figure 2. VAB08, 12, 16, and 20

Figure 4. VAB30 and 40

3 of 7

Page 4

VAB Installation Manual

IOM-VAB-00 06-30-04

Installation

Basic installation procedure covers verifying and/or

installing the following items.

• Ductwork

• Duct insulation and vapor proofing

• Motors and drives

• Sound attenuation

• Electrical connections

• Condensate drain

• Water piping

Ductwork

Use accepted industry practices and design guidelines of

the ASHRAE Fundamentals Handbook. Ductwork must

comply with all building codes and the National Fire

Protection Association’s pamphlet 90A and 90B.

Carefully inspect any previously installed ductwork to

determine suitability.

Note: Ductwork should be of a size meeting

requirements of the installation. Ductwork should

transition gradually from

required duct run size to avoid excessive loss of air

velocity.

When return air duct connection is smaller than return air

inlet opening, construct the transition piece so the vertical

and horizontal dimensions of transition do not increase

more than one inch for every seven inches of length.

Allow a minimum of three feet of straight ductwork

following an equipment outlet.

a smaller size blower outlet to

Electrical Connections

Each unit has a mounted control box, and typically, the

motor is to be wired to this box. Only ODP, single- and

three-phase motors on 800 t

wired to junction box. All other motors require field wiring

to junction box located on side of the unit cabinet.

Note 1: Unit must be permanently grounded in

accordance with NEC and local codes and ordinances.

See the typical wiring diagrams shown in Figure 5.

Note 2: Not all installations require a starter (some

motors utilize a contactor).

o 2000 CFM units are factory-

Duct Insulation and Vapor Proofing

Previously installed heating supply ductwork may already

have adequate insulation against excessive heat loss.

This insulation may be satisfactory for protection against

heat gain from summer cooling. Depending upon

application, additional

Externally insulated ductwork must have adequate vapor

seal for summer operation, especially where duct is

exposed to high humidity conditions.

insulation may be required.

Motors and Drives

Units are normally shipped with motor and drive installed.

However; when mounting a motor on the adjustable base

in the field, use extreme care to ensure proper alignment

and belt tension.

Sound Attenuation

Flexible duct connections should be used between the unit

and both the supply and return ducts.

Figure 5. Wiring Diagrams

4 of 7

Page 5

VAB Installation Manual

Condensate Drain

Install unit with 1/8-inch pitch toward condensate drain

opening.

Condensate drain must consist of a minimum of ¾-inch

copper tubing, ¾-inch galvanized pipe, or ¾-inch PVC

pipe. Figure 6 shows condensate drain setup. The drain

trap must be properly configured to ensure the removal of

all condensate runoff. Ensure drain pitches downward at a

slope of one inch every 10 feet.

Note 1: Incorrect trapping can hold water in pan,

causing overflow.

Note 2: Consult local codes for additional precautions

before installing condensate drain.

Water Piping

All piping must be supported, independent of coils. Swing

joints or flex

expansion and contraction strains. Rigid piping reduces

the effectiveness of vibration isolators. The water supply

should always be connected so the entering water is on

the leaving airside of the coil. Coils must be adequately

vented in order to prevent air binding.

Note 1: Freeze-ups due to low air temperatures are

not covered under the warranty agreement.

Note 2: Titus recommends a freeze-stat (by others) be

installed when a hot water coil is used and mounted in

the reheat position.

ible fittings must be provided to absorb

IOM-VAB-00 06-30-04

Figure 6. Condensate Drain

Installation of Options

In addition to the standard equipment, the following

optional equipment may require attention du

installation.

• Discharge plenum.

• Return air plenum.

• Two-row hot water heating coil (reheat or preheat

location).

• Electric heat.

• Motor and drive selections.

ring

Discharge / Return Air Plenum

The plenum can be used for either the discharge or return

air as shown in Figure 7. The construction consists of

three permanent sides and one removable panel attached

by screws. This panel may be removed to attach a grille

(not provided) or ductwork and then re-attached to the

plenum. If required, field technicians may choose to cut an

opening in one of the other three sides of the plenum.

Note: The contractor in the field determines the

opening size and

since they are field cut.

location for the grille or ductwork

Figure 7. Optional Plenum Locations

5 of 7

Page 6

VAB Installation Manual

IOM-VAB-00 06-30-04

Electric Heater

Figure 8 shows electric heater components and their

placement and orientation to a VAB unit.

Preparation

Some items to consider prior to installing electric heat are

as follows:

• Duct materials must be suitable for 250º F operation.

See NFPA 90A and 90B pamphlet.

Note: Electric heaters are incompatible with discharge

equipment.

• Ensure ample room exists in the ductwork. Electric

heat must have at least 24 inches of straight duct

clearance before an elbow. If 24 inches are

unavailable, devices such as turning vanes or baffles

may be required.

Installation

Use the following information to install electric heat on

VAB models.

Position heater element section over the blower

1.

wheel of the VAB unit.

Note: Heater baffle must align with blower cutoff scroll. If necessary, rotate heater 180

degrees to align. This ensures proper blower

discharge of air over the heater elements.

Attach electric heat plenum to VAB unit using #6 or

2.

larger sheet metal screws.

Note: Ensure plenum securely attaches to VAB

unit only and not just to blower wheel

extension.

Add insulation, if necessary, to outside of heater

3.

plenum section.

Warning: Do not insulate duct heater.

Startup

Check the following items before startup.

• Ensure all

plus, ensure all other bolts and screws are tight.

• Verify the voltage and phase on the unit nameplate,

and ensure it is the same as the motor wired.

• Check the alignment of the sheaves (pulley wheels)

and ensure the setscrews are tight.

• Check for proper rotation of the blower pulley.

• Check motor phase and rotation.

− Exchanging two of the three leads at the unit

− Exchanging leads inside the motor junction box

− Not all installations require a starter (some

• Ensure all filters are installed.

• Make sure all doors and panels are in place.

• Check the amperage draw of the motor. The

amperage draw should not exceed the nameplate

amps shown on the motor serial plate.

shipping bolts and screws are removed;

junction box can reverse three-phase motor

rotation.

can reverse the rotation of single-phase motors.

Refer to the motor nameplate.

motors utilize a contactor).

Figure 8. VAB Unit with Electric Heater

Components

6 of 7

Page 7

VAB Installation Manual

IOM-VAB-00 06-30-04

Operation and Maintenance

Read and observe the following statements before

operation or maintenance.

DANGER

DISCONNECT ELECTRICAL POWER TO ALL

CIRCUITS BEFORE SERVICING UNIT.

FAILURE TO DO SO MAY RESULT IN PERSONAL

INJURY FROM ELECTRICAL SHOCK OR MOVING

PARTS.

Return Air Filters

Inspect return air filters on a regular basis (at least

monthly). Clean or replace filter(s). Filter can be accessed

from either side of unit.

Caution: Never operate unit without a filter or with

filter access door removed. Damage to blower

motor may result.

Coil

The coil is easily cleaned when dry. To check or clean,

remove blower access panel, filter access door and

filter(s). Use accepted industry methods for cleaning.

Remove all foreign matter from pan and condensate drain

line. Check for rust and holes.

Belt and Pulley

Proper pulley alignment and belt tension must be

maintained at all times.

Reduce speed by adjusting pu

further apart.

Increase speed by moving the faces closer together.

Check pulley setscrews and bolts.

lley faces so the faces are

Abbreviations

The following table lists the abbreviations found within this

document.

Abbrev. Term

ANSI American National Standard Institute

ASHRAE

ASTM

CFM cubic feet per minute

CW chilled water

ETL Environmental Testing Laboratory

fpi fins per inch

fpm feet per minute

HW hot water

IAQ Indoor Air Quality

J-Box Junction Box

lbs pounds

NEC National Electric Code

OD outside diameter

ODP open-drip proof

PSI pounds per square inch

PVC polyvinyl chloride

rpm revolutions per minute

SAE Society of Automotive Engineers

SWT sweat

UL Underwriters Laboratory

wgt. weight

American Society of Heating

Refrigeration Air-Conditioning

Engineers

American Society for Testing and

Materials

Motor

Proper lubrication is essential to long motor life. Use

electric motor oil or SAE20 non-detergent oil. Tighten

motor mount bracket and base bolts.

Note: Avoid over-oiling the motor. If a motor is overoiled, the oil may run down the motor shaft and

splatter.

Blower

Periodically check bearing for wear. Replace as required.

Check wheel for dirt accumulation and clean as required.

7 of 7

Page 8

Air Handler

Terms and Conditions

Warranty

The following terms and conditions apply to and govern

the sale of the air handling equipment and parts

manufactured by Titus.

EXCLUSIVE TERMS OF SALE – Titus quotes and sells its

goods on the expressed condition that the buyer assents to

the terms and conditions set forth herein, regardless of any

inconsistent or additional terms that may be embodied in

any purchase order. Titus’ sale of its goods is expressly

conditional on the buyer’s acceptance and receipt of the

goods shall constitute the buyer’s assent to such terms and

conditions.

ACCEPTANCE – All orders are subject to Credit and Sales

Department approval and acceptance. Titus reserves the

right, among other remedies, to terminate or suspend

further delivery against an order in the event the buyer fails

to pay any portion of the order when it becomes due.

Should buyer’s financial condition become

Titus, cash payment or satisfactory security may be required

by Titus for further deliveries or for goods already delivered.

CANCELLATION – Buyer shall not cancel the order without

prior written consent of Titus. In the event buyer cancels the

order with the prior written consent of Titus after the buyer’s

offer to purchase is received and acknowledged in writing,

Titus shall be entitled to receive from the buyer Titus’ cost

plus 15% administrative overhead and liquidated damages

in the amount of 10%. Furthermore, for goods released for

production but prevented by buyer from shipping upon

completion or by the acknowledged shipping date,

whichever is later, Titus may, at its option, in addition to all

other remedies, invoice buyer to be payable within 30 days

and store the goods at buyer’s

DELIVERIES – Any stated shipping date of the goods is

Titus’ best estimate based upon the volume of orders for the

goods Titus has received or expects to receive at the time it

receives buyer’s order. TITUS MAKES NO GUARANTEE

OF SHIPMENT BY THE ESTIMATED DATE AND SHALL

HAVE NO LIABILITY OR OTHER OBLIGATION,

INCLUDING, BUT NOT LIMITED TO INCIDENTAL OR

CONSEQUENTIAL DAMAGES THE BUYER OR ANY

THIRD PARTY MAY INCURE, FOR ITS FAILURE TO

SHIP BY SUCH DATE, REGARDLESS OF CAUSE.

SHIPMENTS –Titus shall not be bound to deliver any goods

for which buyer has not given shipping instructions. ALL

PRODUCTS ARE SOLD F.O.B. SELLER’

TO GOODS PASSES TO THE BUYER UPON DELIVERY

BY TITUS TO THE FREIGHT LINE. All goods are shipped

at buyer’s risk. Buyer should examine shipments carefully

for loss or damage and should have same noted by

transportation agent on the freight bill upon accepting

delivery. In the event of concealed damage, buyer has 10

days from receipt of the goods in which to call the freight

line for an inspection.

In either case, the equipment cannot be returned to Titus

until after a freight inspection has been completed. In

absence of shipping instructions, Titus shall use its own

discretion in choice of carrier.

TAXES – Sales, use, consumption, storage or other taxes, if

applicable, shall be paid by the buyer.

sole expense.

unsatisfactory to

S PLANT. TITLE

RETURN GOODS – New and unused goods returned for

credit will not be accepted unless a Return Goods

Authorization number has bee

must be securely packed to reach Titus without damage and

properly identified with the Return Goods Authorization

number. RGA numbers are valid for only 30 days after

issuance. A minimum 20% fee will be charged on all stock

products cleared for return that can be returned to stock

after inspection. Build-to-order products manufactured and

shipped cannot be returned and a 100% cancellation fee

applies to any order that has been released for production

but has not shipped. All goods must be returned freight

prepaid by the buyer.

ALL PRODUCTS LIMITED WARRANTY – Titus warrants

that its goods will be free from defects in material and

workmanship under normal use and maintenance for a

period of one year from the date of original installation or 18

months from the date of shipment whichever comes first. A

new or rebuilt part to replace any defective part w

provided without charge, PROVIDED the defective part is

returned to Titus. The replacement part assumes the

unused portion of the warranty.

THIS WARRANTY DOES NOT INCLUDE LABOR or other

costs incurred for identifying, repairing, removing, installing,

shipping, servicing, or handling of either defective parts or

replacement parts.

TITUS WILL NOT BE RESPONSIBLE FOR:

1. Normal maintenance.

2. Damage or repairs required as a consequence of faulty

installation or application by others.

3. Failure to start due to voltage conditions, blown fuses,

open circuit breakers, or other damages due to the

inadequacy or interruption of electrical service.

4. Damage or repairs required as a consequence of any

misapplication, abuse, improper servicing,

unauthorized alteration, or improper operation.

5. Damage as a result of floods, winds, fires, lightning,

accidents, corrosive atmosphere, or other conditions

beyond the control of

6. Parts not supplied or designated by Titus.

7. Titus products installed outside the United States and

Canada.

FOR SERVICE OR REPAIR FOLLOW THESE STEPS IN

ORDER:

FIRST: Contact the installing contractor.

SECOND: Contact the distributor or nearest authorized

Titus representative.

THIRD: Contact

TITUS

990 Secur

Richardson, TX 75080

972.699.1030

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

n issued by Titus. Goods

ill be

Titus.

ity Row

1 of 2

Page 9

Terms and Conditions

Warranty

BUYER’S EXCLUSIVE REMEDY – The buyer’s acceptance

of the goods shall confirm the buyer’s review and

acceptance of Titus’ All Products Limited Warranty,

notwithstanding any other written or oral warranty of the

goods that may be given to the buyer. THE BUYER’S

EXCLUSIVE REMEDY AGAINST TITUS SHALL BE

LIMITED TO TITUS’ ALL PRODUCT LIMITED

WARRANTY. NO OTHER REMEDY, INCLUDING, BUT

NOT LIMITED TO, RECOVERY FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES FOR LOST PROFITS,

LOST SALES, INJURY TO PERSON OR PROPERTY, OR

ANY OTHER INCIDENTAL OR CONSEQUENTIAL LOSS,

SHALL BE AVAILABLE TO THE BUYER.

LD MODIFICATIONS – Should the installing contractor

FIE

believe that the goods do not meet the requirements of the

original submittal or do not operate according to the

submittal, the buyer should immediately contact the selling

distributor or authorized Titus representative as outlined in

the All Products Limited Warranty section. Upon Titus’

acceptance of responsibility to make modifications to the

goods, Titus will, at its sole discretion, either direct the

contractor to make the modifications, send its own field

service technicians to make the modifications, or engage

another contractor to make the modifications. If Titus directs

the installing contractor to make the modifications, Titus will

issue a Field Repair Order (FRO) specifying the work to be

done and the price to be paid. DO NOT BEGIN ANY

MODIFICATIONS WITHOUT AN FRO NUMBER. Titus will

not be responsible

goods, unless it has approved the modifications in advance.

for any costs incurred in modifying the

EXCUSE OF PERFORMANCE – Titus shall not be liable for

its failure to perform due to causes beyond its reasonable

control, including but not limited to strikes, fire, war, acts of

God, whether such events occur at or about Titus’ plant or

at the plant of its suppliers.

CREDIT AND TERMS OF PAYMENT – Unless otherwise

specified, terms of payment are net cash, thirty (30) days

after shipment. Interest at the legal rate applicable to

judgments will be charged on past due accounts

commencing after the last day of the first calendar month

following the date of invoice. Seller may suspend credit and

refuse shipment whenever seller in its sole discretion

believes buyer’s credit is unsatisfactory unless buyer then

makes arrangements for

seller.

MISCELLANEOUS – THESE TERMS AND CONDITIONS

FOR THE SALE OF THE GOODS SHALL BE

CONSTRUED ACCORDING TO THE LAWS OF THE

STATE OF TEXAS. ALL SUMS DUE TITUS FOR THE

SALE OF ITS GOODS ARE PAYABLE, AND ALL

MATTERS ARISING PURSUANT TO SUCH SALE ARE

PERFORMABLE, IN DALLAS COUNTY, TEXAS. The

terms and conditions state herein constitute the full

understanding between Titus and the buyer, and no terms,

conditions, understanding or agreement purporting to

modify or vary these terms shall be binding unless hereafter

made in writing and signed by Titus and the buyer.

Titus has a policy of continuous product improvement,

and reserves the right to cha

specification without notice. Titus has no system

design or application responsibility to buyer or any

third party.

payment which are satisfactory to

nge design and

2 of 2

Loading...

Loading...