Page 1

ADVANCED TECHNICAL MANUAL

Part #: 265888

Universal Control Card

Page 2

Table of Contents

Part #: 265888

Universal Control Card

ADVANCED TECHNICAL MANUAL

PRODUCT OVERVIEW..............................................................................3

FEATURES............................................................................................3

CONTROL MODES....................................................................................4

ELECTRICAL SPECIFICATIONS.................................................................6

Test Probe Jacks......................................................................................6

LED Indicators..........................................................................................6

Signal Details...........................................................................................6

RJ-45 Network Cable Connections......................................................6

COMMUNICATION SPECIFICATIONS......................................................7

Overview...............................................................................................7

MODBUS Register Specifications............................................................7

Universal Control Card

Page 3

Part #: 265888

Universal Control Card

ADVANCED TECHNICAL MANUAL

PRODUCT OVERVIEW

Titus’s ENV1028 Universal Control Card provides MODBUS network and analog control capabilities to a Titus Fan Filter Unit

equipped with an electrically commutated motor. Three different control modes provide installation versatility by allowing the FFU

to be controlled via MODBUS RTU network, analog 0-10 VDC control signal, or by adjusting the onboard potentiometer. The

ENV1028 Universal Control Card is fully compatible with all of Titus’s plug & play System Control Consoles using MODBUS RTU.

Additional details of the controls modes are provided on page 4.

FEATURES

• Networkable Via MODBUS RTU

• 0-10 VDC Analog Control

• Manual Control Via Onboard Potentiometer

• Simple Connections

• RJ45 For Networking Connection

• Screw Terminals For Analog Control

• Test Probe Jacks For DC mV Signal Output Of The Following:

• RPM

• Motor Control Set Point

• LED Diagnostics

• Support for external LED (10mA) remote status notification via 2 Pin MTA connector

• Onboard green LED for Board Status notification

• Onboard red LED for Network Traffic

• Powered from Network or Local Supply

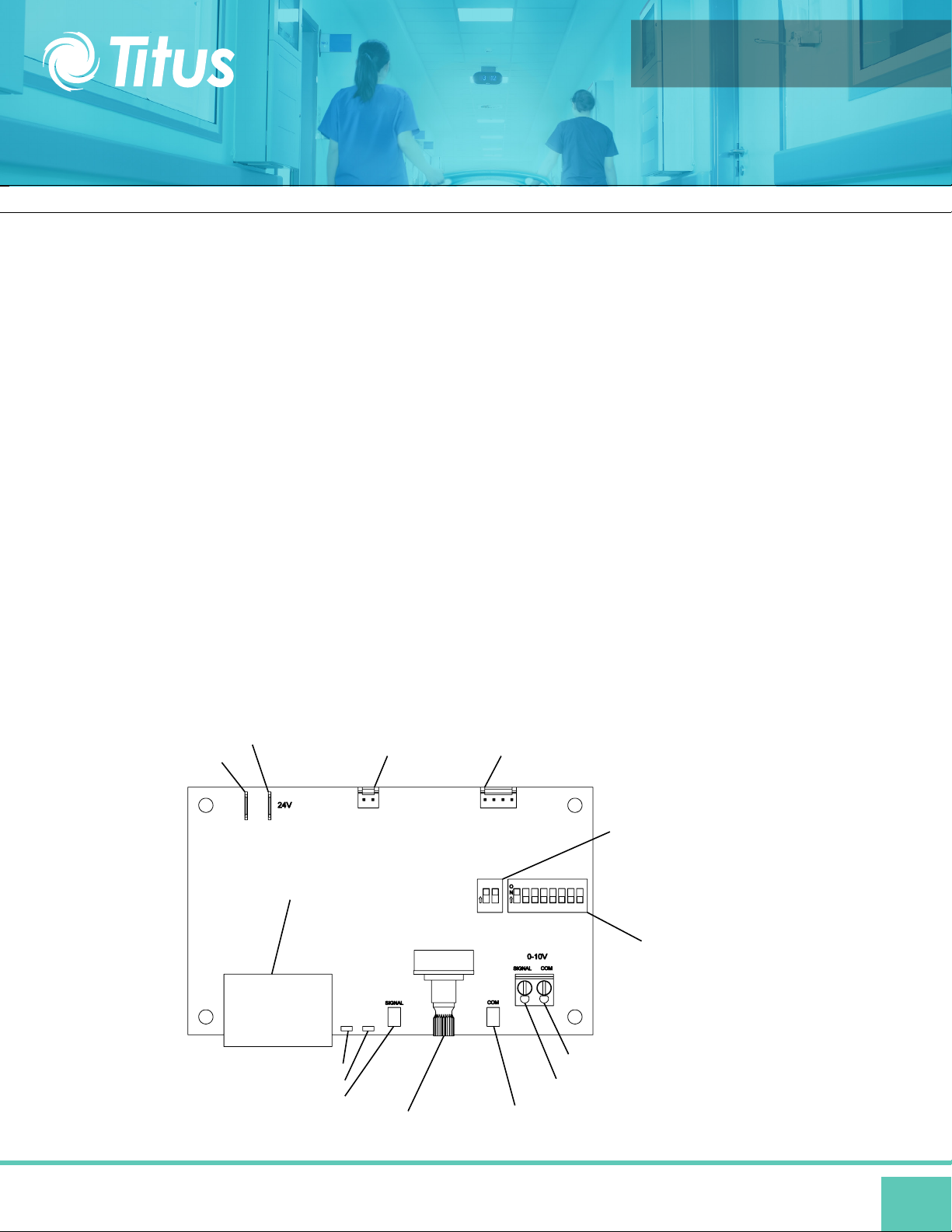

INCOMING POWER 24VAC

COMMON

DUAL RJ-45 JACKS FOR CAT 5 CABLE

RED LED FOR NET ACTIVITY

GREEN LED FOR SYSTEM/RPM STATUS

RPM TEST PROBE JACK "SIGNAL"

MANUAL SPEED POT

LED CONNECTOR

CONTROL HARNESS CONECTOR

CONTROL DIP SWITCH

11 23 45 67 82

ANALOG INPUT "COM"

ANALOG INPUT "SIGNAL"

RPM TEST PROBE JACK "COM"

ADDRESSING DIP SWITCH

Universal Control Card

3

Page 4

A D V ANCE D T E CHN I CAL MAN U A L

CONTROL MODES

The ENV1028 operates in one of three selectable modes. The Mode is selected using DIP Switch S1.

• MANUAL control, on-board potentiometer

• ANALOG control, Remote 0-10 VDC

• NETWORK control, MODBUS RTU

Manual Mode = 1 OFF 2 OFF

Part #: 265888

Universal Control Card

ON ADE02

1 3 4 5 6 7 8

O

N

1

2

Analog Mode = 1 ON 2 OFF

ON ADE02

1 3 4 5 6 7 8

O

N

1

2

Network Mode = 1 OFF 2 ON

ON ADE02

1 3 4 5 6 7 8

O

N

2

2

2

1

2

Network Mode = 1 ON 2 ON

ON ADE02

1

2

Note: Network mode can be using either DIP switch setting shown above.

1 3 4 5 6 7 8

2

O

N

Universal Control Card

4

Page 5

Part #: 265888

Universal Control Card

A D V ANCE D TECHNICAL MANU A L

Manual Control Mode:

In Manual control mode, the motor speed is set using the onboard potentiometer. Onboard potentiometer rotation is CW to increase

the motor output.

Analog Control Mode:

In ANALOG control mode, the motor output is set using an external 0-10 VDC demand signal.

Network Control Mode:

In NETWORK control mode, the motor output is set using MODBUS Register 2. Motor output is specified as a value from 0 to 100

representing a percentage of motor torque output. Each ENV1028 in a MODBUS network must be set to a unique address. The address

value is set in binary using the eight DIP switches of switch bank (S2). A maximum of 200 ENV1028 devices is

recommended per local area network(LAN). If an Titus ACC Control Console is the MODBUS master, then addresses should be

assigned within the address range supported by the Control Console. Address zero should not be used as it is reserved for global

commands. Ad-dress switch settings are only checked by the ENV1028 at power-up. Power must be cycled (OFF/ON) before

affected changes take place.

ON ADE02

1 3 4 5 6 7 8

O

N

1

2

Control Mode

DIP Switches

Registers relevant to this mode:

• Register 1 “Start/Stop” (R/W)

– To enable motor, write a value of 1; To disable motor, write a value of 0

• Register 2 “Motor Set Speed” (R/W)

– Motor Target speed value. Values may be written from 0 to 100

• Register 6 “RPM” (R)

– Motor RPM. Read from the motor

• Register 12 “Actual Motor Speed Instruction” (R)

– Speed control signal applied to the motor by the ENV1028.

(R/W) = Read/Write, (R) = Read Only

2

Addess DIP Switches

Universal Control Card

5

Page 6

Part #: 265888

Universal Control Card

ADVANCED TECHNICAL MANUAL

ELECTRICAL SPECIFICATIONS

Control and Interface Signals:

1. External Speed 0-10V Input

• Input impedance 20k Ohms.

• MIN ON-to-OFF threshold: 190mV*

• MAX OFF-to-ON threshold: 240mV*

• ON (~215mV) to 9.89V linearly scales 1 to 99% speed.

• 9.89V or more deadbands to 100% speed.

2. External LED Output

• 10mA regulated

• LED forward voltages up to 5V

3. RPM Signal

• Signal Value: mVDC = RPM

• Ex: 900mV = 900RPM

• RPM Output Range: ~ 0, 5 to 2000 RPM (0, 5mV to 2000 mV DC)

• RPM Output Resolution: 5RPM (Zero, 400 steps from 5 to 2000 RPM inclusive)

Electrical and Environmental

Specification

Input Voltage

Supply Frequency

Input Power Consumption

Ambient Operating Temperature

Test Probe JacksPoints:

The test probe jacks may be used to measure the motor rpm or the PWM signal that is being output to the motor.

• In Manual or Analog Control Mode with an Address setting of 1 or greater, the test probe jacks output 0-2000 mVDC representing

motor RPM. By changing the address DIP switches to 0, the test probe jacks will output 0-1000 mVDC representing

0-100% demand signal to the motor. The address may be changed without interrupting power to the control card.

• In Network Control Mode, 0-2000 mVDC always represents RPM.

LED Indicators:

• Onboard Status LED:

The Onboard Status LED is software controlled by the unit microcontroller. The Status LED is solid ON when RPM reported by

the motor is greater than zero and OFF when RPM reported by the motor is zero.

• External Status LED:

Support for an external Status LED (10mA current-controlled driver), via a 2-pin MTA connector, for remote system status notification.

The external Status LED operates in the same manner as the Onboard Status LED.

• Onboard Net LED:

The Onboard Net LED is driven directly by the receive data signal. The NET LED shows all network traffic on a 2-wire network.

The NET LED is intended to confirm low-level network connectivity, independent of microcontroller or firmware functionality. If

A/B network wires are swapped, the NET LED will be normally on, providing quick diagnostics of this common condition.

Min

22

50

na

0

24

50/60

na

25

Max

42

60

0.5

50

UnitsTypical

VAC

Hz

VA

C

Net LED Status Definition

LED OFF

LED Flickering

LED ON

RJ45 Network Cable Connections:

Power Lost or No Communications

Network Data Traffic In Progress

A/B network wires are swapped

Red Network LEDG reen Status LED

1 2 3 4 5 6 7 8

Bus Power

Pass Through

0V (GND) RS-485 0V (GND) Bus Power

+

NC NC -

Universal Control Card

Pass Through

6

Page 7

Part #: 265888

Universal Control Card

A D V ANCE D TECHNICAL MANU A L

COMMUNICATION SPECIFICATIONS

Overview:

• MODBUS RTU protocol over RS485 (serial)

• 9600 baud rate, word length is 8, parity is none(n), stop bits=1

• 255 unique address values selectable by DIP switch settings

• (recommended network node capacity 200 nodes)

• Slew rate limited transceivers for improved network performance MODBUS Register Summary Table

• DO NOT USE CROSSOVER CABLES. THIS MAY DAMAGE THE CONTROL CARD OR RENDER IT NON-OPERATIONAL.

MODBUS Register Specifications

Register Name R/W Values & Defaults Units Origin Comments

1 RUN/STOP RW 0,1 1 RAM power up from REG 14

2 DEMAND RW 0-100 % RAM power up from REG 10

6 SPEED R 0,5-2000 RPM LIVE

7 ANA1 R 0-1000 - LIVE Onboard Pot 0-1000=0-100%

9 STATUS R see detail - LIVE

10 DEFAULT SPEED RW 0-100 50 EEPROM applies to network only

12 CURRENT SPEED R 0-100 - LIVE

14 DEFAULT RUN/STOP RW 0,1 1 EEPROM applies in network mode only

24 ANA2 R 0-1000 - LIVE 0-10V input 0-1000=0-10VDC

To reset non-volatile registers to factory default values, write 170 (AA hex) to Register 14, and then cycle power.

Note: Register 24 may be read in network mode to determine the value of 0-10VDC signal that may be connected.

For example, a pressure transducer may be connected to indicate unit interal static pressure.

Universal Control Card

7

Loading...

Loading...