Page 1

Underfloor Products

INSTALLATION MANUAL

Underfloor Products

LHK

PFC

TAF-D

TAF-G

TAF-HC

TAF-R

TAF-V

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 2

LHK and PFC Underfloor Fan Powered Terminals

Underfloor Products IOM

Receiving Inspection

After unpacking the terminal, check it for shipping damage. If any shipping damage is found, report it immediately to the delivering carrier.

Store units in a clean dry location and do not stack more than four high.

Caution: Do not use the inlet collar, damper shaft, flow sensor or

air tubing (available on LHK only) as a handle to lift or move assembly. Damage to the unit or controls may result.

Before installation, remove fan packing and all foreign material from the

unit. Check the blower wheel for free rotation.

Floor Supports

The units can be mounted directly on the slab. If isolation from the slab is

necesary, the unit can be placed on a rubber or cork pad.

Access to the motor, blower,and damper assebmly is on the top of

the unit. The access and control enclosure doors are sectioned so

that each door is aligned with a floor panel.

Note: If equipped with pneumatic controls the terminal must be mounted

right side up. It must be level within ±10 degrees of horizontal, both

parallel to the air flow and at the right angle of air flow. The control side

of the terminal is labeled with an arrow indicating UP.

Minimum Access

Fan Powered terminals require sufficient clearance to service the fan

blower assembly, low voltage controls and line voltage motor controls or

electric heat section from the top of the unit.

For top access panel removal, 2” minimum vertical clearance above the

unit is recommended, plus sufficient horizontal clearance to slide the access panel clear of the top of the unit. Horizontal clearance is dependent

on access panel dimensions as indicated on product submittals.

Low voltage control enclosure doors are “L” shaped to allow access from

the top and sides. For low voltage control enclosure access, a minimum

of 18” clear is recommended. Specific control enclosure location is indicated on product submittals. Panel for low voltage enclosures are removable (not hinged). For line voltage motor controls or electric heat control

access, a minimum of 36” should be provided to allow full opening of

hinged access doors. Specific location is indicated on product submittals.

Important: These recommendations do not preclude NEC or local

codes that may be applicable, which are the responsibility of the

installing contractor.

Duct Connections for LHK

Slip each inlet duct over the inlet collar of the terminal. Fasten and seal

the connection by the method prescribed by the job specification.

The diameter of the inlet duct “D” in inches must be equal to the listed

size of the terminal; e.g. a duct that actually measures 8 inches must be

fitted to a size 8 terminal. The inlet collar of the terminal is made 1/8”

smaller than listed size in order to fit inside the duct.

Important: Do not insert duct work inside the inlet collar of the

assembly.

Inlet duct should be installed in accordance with SMACNA guidelines.

Rectangular discharge opening is designed for flanged duct connections.

Fasten and seal by method prescribed in the job specification.

If single-point electronic velocity sensor is used, 3 to 5 inlet duct diameters of straight duct should be provided at the terminal inlet.

2

Installation Manual - Underfloor Products

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 3

LHK and PFC Underfloor Fan Powered Terminals

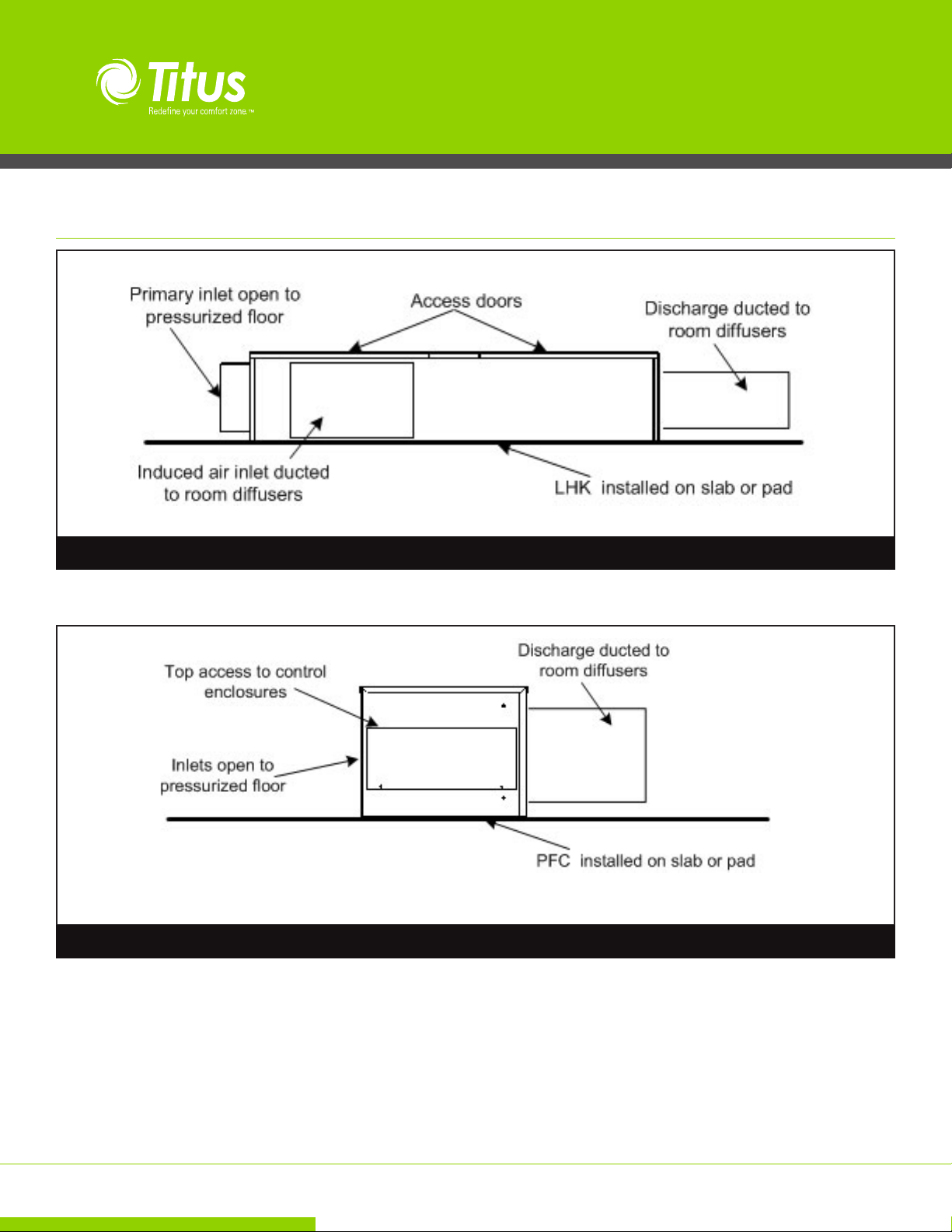

Figure 1. LHK

Underfloor Products IOM

Figure 1. PFC

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - Underfloor Products

3

Page 4

Field Wiring

Underfloor Products IOM

All field wiring must comply with the local codes and with the National

Electrical Code (ANSI/NFPA 70-1996). Disconnect switches are optional

equipment. Electrical, control, and piping diagrams are shown on the

exterior labeling or on a diagram on the inside of the control and high

voltage enclosure covers. Unless specified otherwise in the order writeup, all units are wired for a single point electrical connection to the fan

and optional electrical heater. All electric heaters if provided by Titus

are balanced by kW per stage. The installing electrician should rotate

incoming electric service by phase in order to help balance the building

electric load.

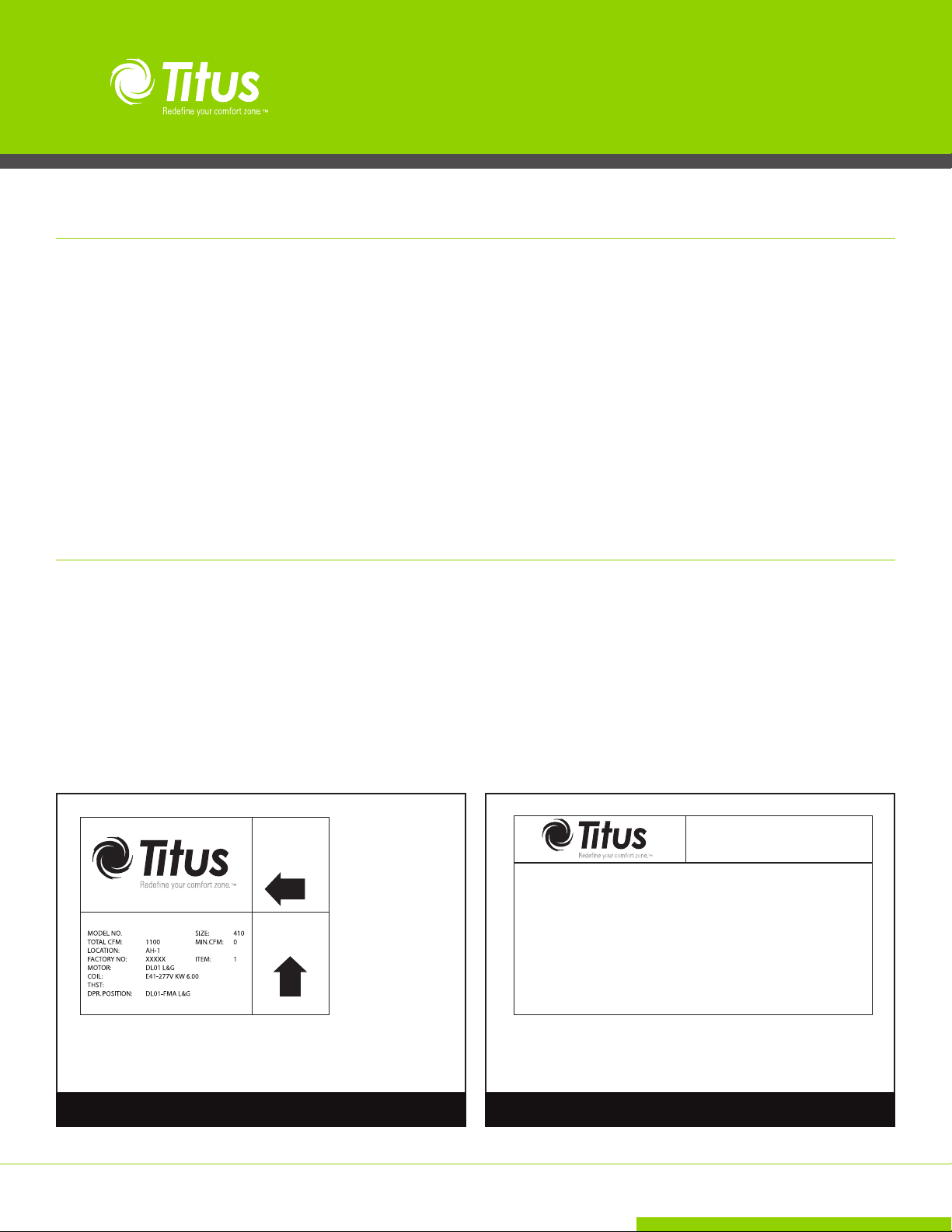

Unit Labeling

Each unit will have two main labels attached to the casing. The FAN UNIT

label (Figure 3) lists the Model Number, Supply Voltage requirements,

Motor Horsepower, and Overcurrent Protection requirements. The AIR

FLOW label (Figure 4) lists the Model Number, Unit Size, Factory Order

Number, and Location. The Location (or “Tag”) indicates the engineer’s

planned location for the unit to be installed. There may be other labels

attached to the unit, as options or codes may require.

Caution—Electrical Requirement:

1. Provide a safety disconnect per NEC 424-19, 20 & 21.

2. Disconnect all incoming power before wiring or servicing unit. All

disconnect switches on the terminal (if so equipped) should be in

OFF position while making power connections.

3. All field wiring must be in accordance with NEC and local code

requirements. All units with electric heat should have copper wires

for 125% of Nameplate Amperage.

4. Observe wiring diagram and instructions mounted on the unit. 480

V/3 phase units require a 4th (neutral) wire in addition to the full

sized ground wire. All units must be grounded as required by NEC

424-14 and 250.

Please read all labels on a typical unit, before beginning installation. If you have any questions, please contact the local Titus Rep-

resentative for clarification. Have the key points from the AirFlow label

available for reference before calling.

DLHK

4

Installation Manual - Underfloor Products

AIR

FLOW

UP

303155001015

FAN UNIT

MODEL NO.: DLHK CODE: 88-XXXXX-A 2 REV: 02

MOTOR VOLT: 277 PHASE: 1 HZ 60

HP: 1/3 FLA(EA) 1.4

HEAT VOLT 277 PHASE 1 HZ 60

KW 6.0 AMPS 21.66

MOTOR (S) ARE THERMALLY PROTECTED

MIN. SUPPLY CIRCUIT AMPS: 24 AMP

MAX. FUSE OR OVERCURRENT PROTECTION: 30 AMP

MAX. OUTLET AIR TEMPERATURE: 200F

UNIT DESIGNED TO OPERATE AT NO LESS THAN 0.2 IWG STATIC PRESSURE

ZERO CLEARANCE FROM UNIT, CONNECTED DUCT AND/OR PLENUM

TO COMBUSTIBLE MATERIAL

Figure 3. Figure 4.

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 5

Control Start-up, Operation

Detailed information regarding power, accessory and communications

connections, start-up and operating procedures for the Titus TD-1 controller (digital) or pneumatic and analog controls are available from your

local Titus representative. For specific information on controls by other

manufacturers contact that manufacturer’s local branch or dealer.

Note: Controllers may incorporate specific communication addresses

based on Building Management Systems Architecture, and original engineering drawings. Installing the terminal in a different location than

noted on unit label may result in excessive start-up labor.

Fan Flow Adjustment

Underfloor Products IOM

Note: Before starting fan motor, follow steps 1 and 2.

1. Discharge ductwork should be connected. The minimum

recommended discharge static pressure is 0.2” wg. Be sure fan

packing is removed!

2. All foreign materials should be removed from duct system. Filters

should be installed where required.

3. Motor is shipped from factory at full speed setting. Allow motor to

run-in at least 15 minutes before adjusting speed. During initial runin, check ductwork connections for leaks and repair if necessary.

(Do not adjust fan speed down if ductwork is not connected).

4. Unit is equipped with manual fan speed control, mounted on

the side of the line voltage motor enclosure. Turning the control

counterclockwise will reduce the fan speed; clockwise will increase

speed.

5. Set the unit to full heating (maximum induction). Adjust and set

remote balancing dampers, if present. Adjust the speed control to

deliver the required CFM by measuring air quantity at the room

outlets.

6. Proceed to primary air adjustment procedure (LHK only), detailed

in control installation information. Fan should be re-adjusted with

primary air and ventilation air at maximum setpoint, to insure that

no supply air is discharged at the induction port.

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - Underfloor Products

5

Page 6

Maintenance Procedures, Fan and Motor

Underfloor Products IOM

Motor is equipped with permanently lubricated bearings. Inspect fan and

motor assembly for accumulation of dust and dirt as required by operating environment. Clean as necessary.

If fan motor does not run:

a. Free rotation of blower wheel fan packing removed. freight or

installation damage.

b. Check for proper unit power Disconnects should be ON .Check

optional fusing.

c. Check for proper control signal, P/E switch setting, proper air control

24 vac at fan contactor, coil energized.

If fan motor runs, excessive noise:

a. Clearance problems on blower. All components securely attached.

b. Verify integrity of ductwork. Leaks or loose connections. Rattling

diffusers or balancing dampers.

c. Maximum CFM too high, or discharge static pressure too low

If fan motor runs, insufficient airflow:

a. Check for ductwork restrictions. Dirty air filters. Clogged water coils.

b. Re-adjust fan speed control.

c. Discharge static pressure too high.

If repair or replacement is required:

Motor and fan should be removed as an assembly. Disconnect all power

before servicing. Remove the four hex nuts from the mounting lugs holding the fan assembly to the discharge panel, and lower the assembly. Do

not allow assembly to hang from wiring.

If removing motor from blower, first loosen the set screw holding the

blower wheel to the motor shaft. Remove the three screws holding motor

to the fan housing, and slide motor and fan housing apart.

Reverse the procedure for assembly.

Note: Over tightening motor mounting screws may crush isolation bushings, causing excessive fan noise.

6

Installation Manual - Underfloor Products

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 7

Primary Air Damper

Underfloor Products IOM

LHK Model:

To replace the damper blade and/or shaft assemblies:

a. Disconnect power before servicing. Remove control enclosure cover

to access actuator.

b. Note position of damper shaft, using indicating arrow. Loosen

linkage or actuator collar to allow damper to rotate freely.

c. Remove bottom access door to expose damper assembly. Rotate

damper to fully closed position, exposing rivets holding damper

blade to shafts.

Replacement Parts List

Description Part Number

Multipoint Velocity Sensors

Size 9” 3151520005

Size 10” 3151520006

Damper Shaft Bearing

Shaft Bearing – All 70324901

Primary Damper Assembly (LHK)

Size 9 31171304

Size 10 31171305

Unit Size Filter Size Part Number

Induced Air Filters

Model LHK

3 18 x 10 1026491810

4 18 x 14 1026491814

Model PFC

10 18 x 10 1026491810

14 16 x 14 1026491614

16 14 x 16 1026491614

Control Tube

Red Stripe .25” O.D. 61510035

Green Stripe .25” O.D. 61510034

Red Stripe .38” O.D. 61510279

Green Stripe .38” O.D. 61510280

Tees for Sensor Taps

Plastic .25” 42150011

Plastic .38” 42150020

d. Drill out rivets using 1/2” drill, rotate damper to fully open position,

and slide damper and/or shaft assemblies out of the duct.

e. Fit new damper and/or shaft assemblies in place, using 1/4-20

screws with lock nuts to replace rivets.

f. Reverse procedure in steps c, b, and a, for assembly. When locking

down actuator linkage or collar, position indicating arrow on damper

in the same location as before the repair.

Description Part Number

Plugs for Tees

.25” 42160081

.38” 10015601

Fan Motor Fuse (SC-CL-G 300V)

1 Amp 10048301

3 Amp 10048501

4 Amp 10048601

6 Amp 10048801

8 Amp 10049001

10 Amp 10049101

12 Amp 10049201

15 Amp 10049301

20 Amp 10105201

Disconnects

Fan Toggle (All) 10027801

Door Interlock 3P/40A (All)

10053201

Door Knob 40 Amp 100532011

Door Interlock 3P/80A (All)

10054601

Door Knob 80 Amp 100546011

Replacement Parts List

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - Underfloor Products

7

Page 8

Replacement Parts List (continued)

Underfloor Products IOM

Description Part Number

Fan Relays

1 Pole, 24V Coil 10156901

2 Pole, 24V Coil 10161801

Contactors, Magnetic

2P/20A, 24V coil 10054401

2P/20A, 120V coil 10054402

2P/20A, 208/240V coil 10054404

2P/20A, 277V coil 10054403

Safety Devices

Auto Reset Thermal Cutout for Elec. Coils

10052101

Air Flow Switch (AFS) 10269501

AFS Sensor 4” length 10057201

AFS Sensor 6” length 10057202

P.E. Switch, 1 step 10000901

P.E. Switch, 2 step 10199801

P.E. Switch, 3 step 10199802

Control Transformers

120/24V, 50 VA 10029301

208/240/24V, 50 VA 10057501

277/24V, 50 VA 10006601

Description Part Number

Fan Speed Controllers (SCR)

120V 10055301

208/240V 10057601

277V 10053301

Fan Motor Capacitors (120V,208/240V, 277V)

1/4 Hp Motor 5 MFD

10053002

1/3 Hp Motor 10 MFD

10053003

3/4 Hp Motor 20 MFD

10055701

Mounting Bracket (all)

10054501

Description Part Number

ECM Motor Components

ECM Motor Mounting Assembly

31484401

PWM (Manual Operation)

10334801

PWM (Remote Operation)

10334801

277V Power Cable, 8 ft.

10320501

277V Power Cable, 5 ft.

10320520

24V Comm. Cable, 8 ft.

10334901

24V Comm. Cable, 5 ft.

10334902

LHK Inductor

277V:

Inductor 3.0 Amp (Size 3)

10335101

Inductor 5.5 Amp (Size 4)

10335001

120V:

Inductor 11 Amp (All)

10348001

PFC Inductor

277V:

Inductor 5.5 Amp (All)

10335001

120V:

Inductor 11 Amp (All)

10348001

Replacement Parts List

8

Installation Manual - Underfloor Products

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 9

Fan Motors

Underfloor Products IOM

Model

LHK

PFC

LHK

w/ECM

Motor

PFC

w/ECM

Motor

Unit Size

3

4

10

14

16

3

4

10

14

16

HP

1/4

1/3

1/4

1/3

3/4

1/3

1/3

1/3

1/2

120V/1

10095303

10151201

10095303

10151201

10051401

31535224

31535225

31535234

31535226

1

31535227

208/240V/1

10150103

10151203

10150103

10151203

10057003

N/A

N/A

315352138

315352131

315352132

277V/1

10096703

10151202

100967-03

10151202

10051402

31535209

31535210

31535233

31535211

31535212

Blower Assembly

10045501

10045501

10045001

10346201

10261701

10045501

10045501

10045001

10346201

10261701

Fan Motors

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - Underfloor Products

9

Page 10

Open/close indicator

is raised from the trim

ring and diffuser core.

TAF-R / TAF-R-FR Diffusers and TAF-G Grommet

The TAF-R / TAF-R-FR diffuser and TAF-G grommet were designed to install easily in the floor without the need to remove the floor tile. The

TAF-R / TAF-R-FR and TAF-G should be installed after the installation of

carpet. The TAF-R / TAF-R-FR and TAF-G install using the mounting ring

spring clip assembly.

Installation requires a 8 5/8” mounting hole cut into the access floor tile.

It is recommended that the tile is pre-cut from the tile manufacturer to

ensure a consistent, round 8 5/8” hole.

Note: The trim ring should be able to move freely in the mounting hole.

Irregular shaped holes may bind the trim ring and force it to not properly

seat in the mounting hole.

Underfloor Products IOM

Figure 6. Position Indicator

Figure 5. TAF-R Diffuser

Pivot Cover

Grommet Cover

Grommet Seal (optional)

Trim Ring

Mounting Ring

Figure 7. TAF-G Grommet

10

Installation Manual - Underfloor Products

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 11

TAF-R / TAF-R-FR Diffusers and TAF-G Grommet (continued)

Place trim ring above the mounting hole. Press the trim ring into the floor

by using your weight to press down on the trim rings so the clips engage

below the floor tile (Figure 8).

Place the inner damper basket in the outer dirt basket and insert the

baskets into the trim ring (Figure 9). The outer basket has three tabs

which are keyed to the trim ring so that the baskets will only install flush

in one position.

For the TAF-R / TAF-R-FR, place the diffuser in the trim ring (Figure 8) and

align the open / closed position indicator (Figure 6). For the TAF-G, snap

the grommet cover into the trim ring (not shown).

For the TAF-R / TAF-R-FR with the optional actuator, the actuator interconnect diagram can be seen on page 12 of this document.

Underfloor Products IOM

Figure 8. Trim ring installation

Redefine your comfort zone. ™ | www.titus-hvac.com

Figure 9. Basket installation

Figure 10. Face installation

Installation Manual - Underfloor Products

11

Page 12

Underfloor Products IOM

Notes:

1. All referenced part numbers in the interconnect diagram below can be found on the TAF-R/TAF-R-FR ordering procedure

2. A maximum of six actuators may be daisy chained between the thermostat and transformer. After that, a maximum of six more actuators may be

daisy chained on the opposite side of the transformer. A maximum of 12 actuators may be supplied from one transformer and controlled from one

thermostat.

3. The transformer must have an internal circuit breaker or equivalent breaker or equivalent 2.25A external fuse in the secondary circuit.

Actuated TAF-R / TAF-R-FR Interconnect Wiring Diagram

Actuated TAF-R/TAF-R-FR Interconnect Wiring Diagram

12

Installation Manual - Underfloor Products

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 13

Underfloor Products IOM

Replacement Parts List (See pages 13-15 for interconnect part details)

Part Number Description Part Number Description

31898201 Thermostat for Actuated Flow Regulator 31898301 Transformer Cable RJ12 Length (12in)

72541702 TAF-R Black Grille 31898450 Thermostat Cable Length (50 ft)

10304502 TAF-R Black Trim Ring 31898701 3-Way Modular Connector

10304602 TAF-R Black Flow Regulator (Inner Basket) 31898412 Actuactor RJ12 Jumper Cable Length (12 ft)

10304802 TAF-R Black Dust Basket (Outer Basket)

72541701 TAF-R Grey Grille

10304501 TAF-R Grey Trim Ring

Actuated TAF-R / TAF-R-FR Interconnect Components

31898201 Thermostat

◊ Specifications

◊ Supply Voltage: 14-19 VDC

◊ Set Point Range: 60-85F (15.6-29.4C) (Power on Default: 70F/21.1C)

◊ Temperature Sensor Type: Thermstor

◊ Accuracy: +/- 36F (2C)

◊ Display Degrees F or C: Selectable (Factory Setting: Degrees F)

◊ Direct Acting Output: 0-10 VDC

◊ Min/Max Limits: Adjustable 0-100% (Factory Settings: Min = 20,

Max = 100)

◊ Proportional Band: 2-6F (1.1-3.3C) (Factory Setting: 4F)

◊ Integration Time: 15-60 Minutes (0 = Off) (Factory Setting: 30)

◊ Unoccupied Setpoint Modes: Off or Deadband (Factory Setting: Off)

◊ Off Mode: Output Voltage = 0.0 Volts (Safety Override: Output

Cycles 0.0 Volts to 2.0 Volts to maintain 50F to 55F)

◊ Deadband Mode: Integral Action Disabled & Setpoint set to default

+/- 10F Deadband. Deadband output midway between max. & min.

◊ Temperature Offset: Adjustable +/- 2F (+/- 1.1C) (Press min & int

together)

◊ Operating Ambient: 34-125F (1.1-51.6C)

◊ Shipping Ambient: -40-140F (-40-60C)

◊ Humidity: 0-95% non condensing

◊ Case Material: Light almond abs, UL Flame Class 94HB

◊ RJ-12 Female Connector:

PIN1 NC PIN2 COM PIN3 SUPPLY

PIN4 OUT PIN5 COM PIN5 NC

31898201 Thermostat

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - Underfloor Products

13

Page 14

Actuated TAF-R / TAF-R-FR Interconnect Components (continued)

31898301 Transformer Cable

Underfloor Products IOM

31898301 Transformer Cable

31898450 Thermostat Cable

31898450 Thermostat Cable

14

Installation Manual - Underfloor Products

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 15

Actuated TAF-R / TAF-R-FR Interconnect Components (continued)

31898701 3-Way Modular Connector

Underfloor Products IOM

31898701 3-Way Modular Connector

31898412 Actuator Jumper Cable

31898412 Actuator Jumper Cable

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - Underfloor Products

15

Page 16

Actuated TAF-R / TAF-R-FR Interconnect Components (continued)

RJ-12 Connector Pinout Diagram

Underfloor Products IOM

Detail applies to “ALL” RJ-12 cables used on actuated TAF-R/TAF-R-FR

16

Installation Manual - Underfloor Products

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 17

TAF-R Mounting Clip Replacement

Underfloor Products IOM

TAF-R Mounting Clip Replacement

Notes:

1. “Old Mounting Method” detail above illustrates the previous installation method of the TAF-R which utilized a mounting ring & gasket as shown

in the above view. The mounting ring & gasket can be discarded in place of the new mounting clips shown in the “New Mounting Method” view

above.

2. Detail “A” shows the location for the replacement clip. There are 3 slotted features on the trim ring that will require the replacement clip be

located adjacent to this slotted feature as shown in Detail “A”.

3. The mounting clip replacement part number is 72821301. This part number should be ordered for a quantity of 3 clips per unit being replaced.

For example, if 5 TAF-R units need to have the mounting ring & gasket replaced, then a quantity of 15 clips should be ordered.

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - Underfloor Products

17

Page 18

TAF-HC, TAF-D and TAF-V Diffusers with Plenum

Underfloor Products IOM

The TAF-HC, TAF-V and TAF-D diffuser plenums were designed to install

easily in the floor without the need to remove the floor tile.

Installation requires a 8 5/8” by 16 5/8”mounting hole cut into the access floor tile.

Attach the CT-TAF grille frame to the TAF-HC / TAF-V / TAF-D plenum using sheet metal screws prior to installation in the floor. For the TAF-HC

and TAV-V, the actuator and thermostat must be wired before the unit is

installed in the floor tile. Once the CT-TAF frame is attached to the plenum, slide the assembly into the hole in the floor tile. (Figure 11).

The wiring for the TAF-HC and TAF-V is shown in (Figure 12).

Figure 11. TAF-HC, TAF-D and TAF-V Installation

18

Installation Manual - Underfloor Products

Figure 12. TAF-HC and TAF-V Wiring

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 19

Notes

Underfloor Products IOM

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - Underfloor Products

19

Page 20

UnderFloor systems are not just for computer rooms anymore. Access floor construction has gained significant popularity

around the world due to changing occupant requirements. There are already several million square feet installed in the

United States alone. Many building owners are recognizing the versatility and economics of access floor air distribution.

TAF-V

The TAF-V is an UnderFloor Variable Volume Diffuser plenum

that integrates with the CT-TAF linear bar diffuser to provide

air distribution in underfloor applications.

605 Shiloh Rd

Plano TX 75074

ofc: 972.212.4800

fax: 972.212.4884

Loading...

Loading...