Page 1

T3SQ-1-IOM-1.0 6-6-09

Installation, Operation & Maintenance of the T3SQ Analog

VAV Diffuser

Step 1

The units should be shipped assembled except for the backpan. The thermal T

additional packaging to protect the actuator assembly. Remove all packaging from the components.

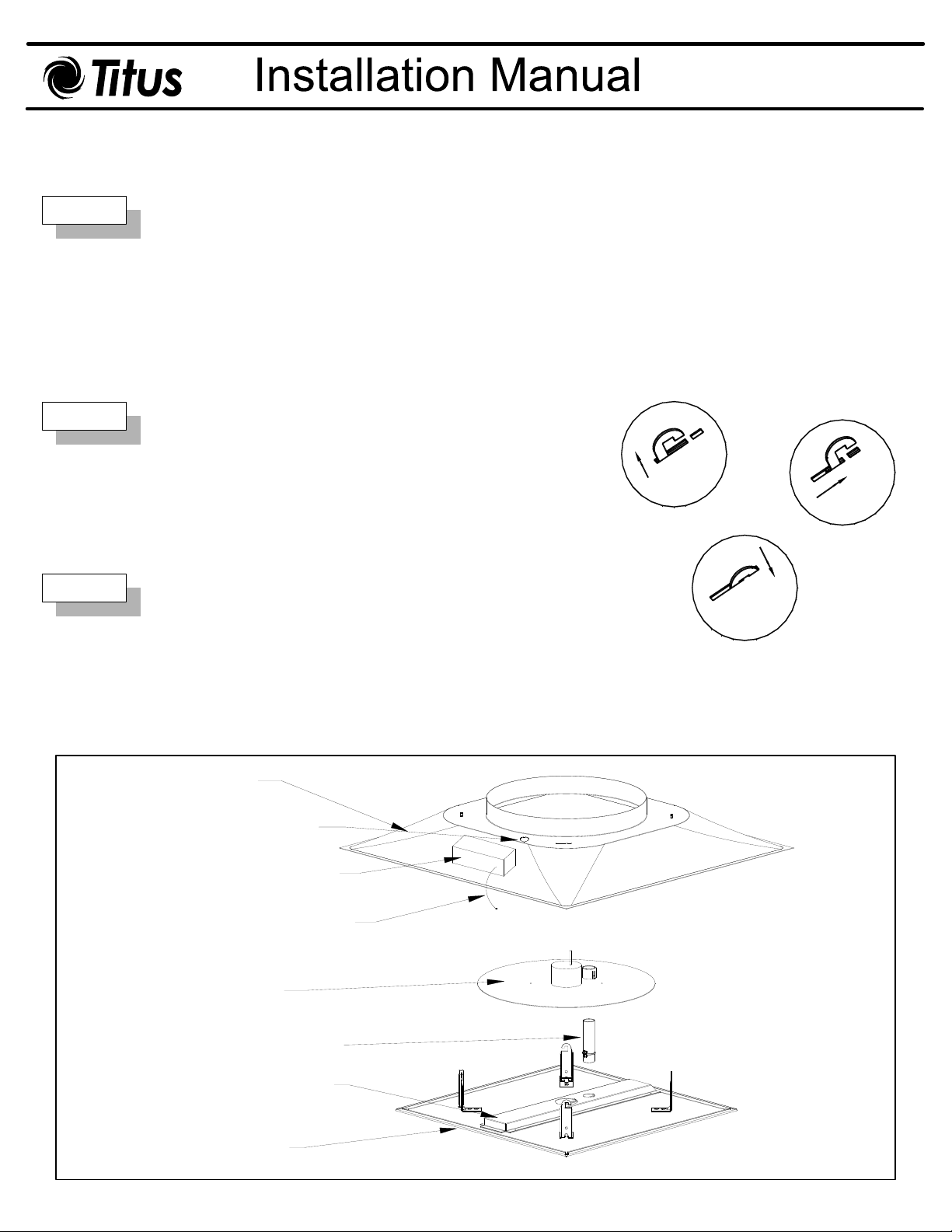

If the unit is not assembled, follow the steps below before proceeding (see Figure 1):

1. Insert the control disc guide into the control disc.

2. Screw the bottom of the actuator / control disc assembly into the mounting channel.

SQ is shipped with

3

Note: The T3SQ-1 diffuser is shipped as a dummy unit. Master and drone operation is

determined by the wiring – discussed in Step 3. Master and drone locations are not needed

at this point in installation.

Step 2

Step 3

Place the back pan into ceiling grid. Connect duct work to back

pan. Insert the supply air temperature sensor into the supply

duct. If the unit has an optional inlet heater, the supply air

sensor must be positioned above the heater in the supply duct.

Set minimum airflow by adjusting

actuator shaft. 0.5" down from the top of the shaft allows the

diffuser to go to the full closed position.

Installation is completed by lining up the hooks on the face

plaque assembly with the corresponding slot. Insert the RJ-45

cable on actuator / control disc assembly through wiring conduit.

The hooks are inserted and the face plaque assembly is rotated

clockwise, and lowered so that each hook is firmly in place. (See

Figure 2)

the brass nuts at the top of the

1.

2.

3.

Figure 2. Face Panel Installation

Plug the RJ-45 cable on actuator / control disc assembly into

any RJ-45 jack on the wiring interface box on the backpan.

Backpan

Conduit for Wiring

Wiring Interface Box

Supply Air Temperature

Sensor

Actuator / Control Disc

Assembly

Control Disc Guide

Mounting Channel

Face Plaque

Figure 1. T3SQ-1 Assembly

Page 2

T3SQ-1-IOM-2.0 6-6-09

Step 4

Wiring Instructions:

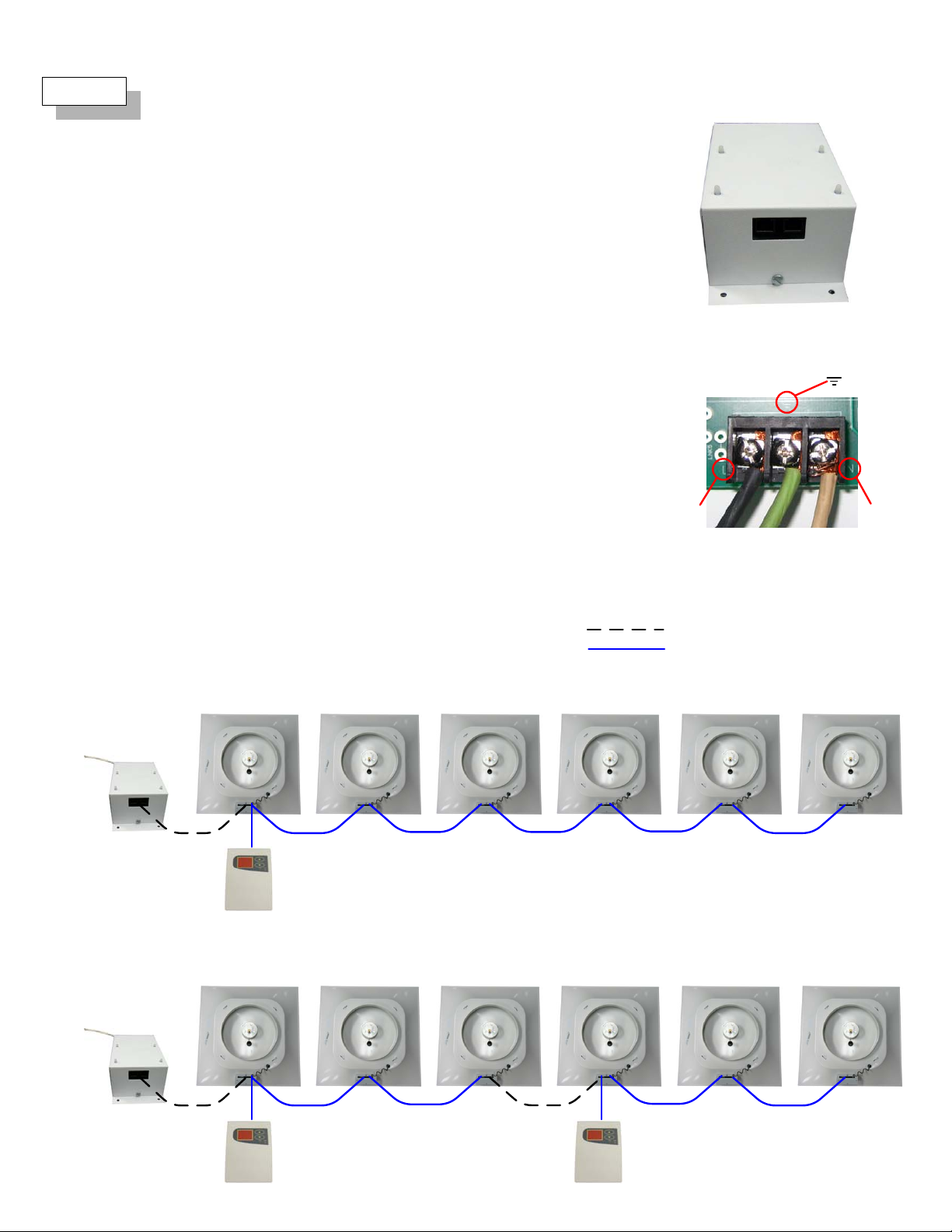

T3SQ-1 diffusers are all shipped as dummy units. Determination of

master and drone units is made through plug and play cable

connections.

One power module is required for every six (6) diffusers without electric

reheat or every five (5) diffusers with electric reheat. (See Figure 3)

Power module requires 120VAC line voltage input – hardwired by

others. (See Figure 4)

Master diffusers must be connected to a controller / thermostat. (See

Master Controller / Thermostat section on next page for details.) Drone

diffusers must be connected to a master diffuser. Disconnect the

supply air temperature sensor on all drone units.

White RJ-12 6-pin cables provide 24VAC power between diffusers.

RJ-12 cables should be used between the power module and the first

diffuser and to connect a master unit to another master unit. The RJ-12

jacks are interchangeable – either RJ-12 jack may be used during

installation. (See Example below)

Blue RJ-45 8-pin cables provide 24VAC power and control signal

between diffusers. RJ-45 cables should be used between diffuser and

master controller / thermostat and between master and drone units.

Disconnect the supply air temperature sensor on all drone units.

Figure 3. T3PM Power Module

al

d

r

t

n

L

Figure 4. T

t

o

H

Grou

PM Power Module Wiring

3

u

e

N

N

The RJ-45 jacks are interchangeable – any open RJ-45 jack may be

used during installation. (See Example below)

Examples:

One master unit controlling 5 drone units:

Master unit Drone unit Drone unit Drone unit Drone unit Drone unit

120V input, field

wiring by others

24V output

to diffusers

Two master units controlling 2 drone units each:

Master unit Drone unit Drone unit Drone unit Drone unit

120V input, field

wiring by others

RJ-12 24V power only

RJ-45 power and control signal

Master unit

24V output

to diffusers

Page 3

Master Controller / Thermostat Operation

When power is supplied to the diffusers and the controller / thermostat, the

controller / thermostat will drive the diffusers to full closed to calibrate the

movement of the master and drone units. During this startup operation the

controller / thermostat will display “ST”.

The controller / thermostat normally displays room temperature.

The Cool and Heat indicator lights show the mode of operation that the unit

is in. If the zone is above setpoint, the Cool indicator will be lit to show that

the zone requires more cooling. If the zone is below setpoint, the Heat

indicator will be lit to show that the zone requires more heating.

To adjust the setpoint adjustment press either button. An audible sound will

let you know the button was pressed. The current setpoint value will flash

on the display. Default setpoint is 71º F (22º C). Press the up or down

arrow buttons to increase or decrease the setpoint. The setpoint

adjustment function will exit after 5 seconds of no user input.

T3SQ-1-IOM-3.0 6-6-09

To drive the damper full open or full closed, you must put the controller /

thermostat into override mode. Override mode should be used for

commissioning. Press the down arrow for 5 seconds until display will read

“LI” to indicate the override mode.

Pressing the up arrow will drive the damper to the closed position. Pressing

the down arrow will drive the damper to the open position. Pressing both

buttons simultaneously will take the unit out of override mode.

Press the up arrow on the controller / thermostat for 5 seconds to display

supply air temperature. A display of “00” denotes that a changeover sensor

is not being used. The display will revert back to zone temperature after 5

seconds.

Optional Inlet Heater Operation

The optional SCR controlled inlet electric heater is mounted in the neck of

SQ-1 diffuser. (Line voltage must be supplied to the electric heaters.)

the T

3

If the inlet heater is used with the T

through the wiring interface board on the heater assembly instead of the

wiring interface board on the diffuser backpan. The wiring interface board

on the diffuser may be discarded or ignored. The power wiring to the heater

has to be connected by removing the face from the wiring interface board

enclosure per Figure 7. The wires must be routed through the grommets,

connected to L & N, and then re-attach the face of the enclosure.

SQ-1, all wiring should be connected

3

Figure 5. Master Controller / Thermostat

Figure 6. Optional Inlet Heater

The controller / thermostat will energize the inlet heater when the zone

temperature is 1

a time pulsed signal from minimum output to full output over a 2

temperature range. At 3

An airflow switch and two thermal cutouts protect the heater from operation

without airflow or at temperatures above 200

o

F below setpoint. The SCR heater controller will modulate

o

F over setpoint the heater will be at full output.

o

F.

o

F

Figure 7. Optional Inlet Heater Wiring

Page 4

Replacement Parts

T3SQ-1-IOM-4.0 6-6-09

Description Part Number

Master Controller / Thermostat

PM - 120V/24VAC Power Module

T

3

Blue RJ-45 Power and Control Cable

White RJ-12 Power Cable

Actuator / Control Disc Assembly

Supply Air Temperature Changeover Sensor

Wiring Interface Box

Venturi Tube

Venturi Tube Guide

Control Disc Sleeve

Analog Induction Channel

Plaque / Actuator / Control Disc Assembly for T3SQ-1

18200601

31673701

31623701

31623601

31623301

31625601

31623401

72540201

72540301

72540401

31623101

31625201

Inlet

Size

6

8

10

12

120V Inlet Heater

kW

0.75

31633501

1.0

31633504

1.25

31633507

1.25

31633510

277V Inlet Heater

kWPart Number

Part Number

0.75

31633503

1.0

31633506

1.5

31633509

2.0

31633512

208V Inlet Heater

kW Part Number

0.75

1.0

1.5

2.0

Master / Drone Control Parts Worksheet

This worksheet is to be used to calculate the quantity of Master Controllers / Thermostats, Cables, and Power Modules needed to

make operational T

# of Master Controller / Thermostats

# of total T

SQ masters and drones. See the Wiring section of this IOM for wiring information.

3

# of Master units

= # of Master Controller / Thermostats needed

= # of White RJ-12 Power Cables needed

# of total T

SQ-1 diffusers divided by 6 = # of T3PM Power Modules needed – FOR NON-ELECTRIC REHEAT UNITS

3

SQ-1 diffusers = # of Blue RJ-45 Power and Control Cables needed

3

OR

# of total T

SQ-1 diffusers divided by 5 = # of T3PM Power Modules needed – FOR ELECTRIC REHEAT UNITS

3

Troubleshooting

31633502

31633505

31633508

31633511

Symptom Action

No display on master

controller / thermostat

or

Dim display on master

controller / thermostat

Control disk will not move

Control disk will not go to

full closed

Occupant uncomfortable,

control disc closed

Supply air temperature

reading is incorrect

Verify power module wiring.

Verify cables are correct.

RJ-12, 6-pin, straight through pinout from power module to first T

and RJ-45, 8-pin, straight through pinout from T

SQ diffuser to master controller / thermostat.

3

SQ diffuser or between master T3SQ units

3

Verify cable continuity with a cable tester.

Note: The Power Module has integral circuit protection that protects it from shorts in the RJ-12 and RJ-45 cabling by

shutting down the Power Module. During this process, the Power Module may heat up enough that the component

coatings emit a smell much like burnt electronics, but the transformer is NOT damaged. Replace the bad cable and

cycle power to the Power Module.

Verify that control disk cable has been properly inserted through conduit and plugged into wiring interface box on

backpan.

Verify that master units is properly connected with RJ-45 to master controller / thermostat or verify that drone units are

properly connected with RJ-45 to a master unit.

Adjust brass nuts at the top of the actuator shaft to desired minimum position.

Adjust setpoints on master controller / thermostat.

Check supply air temperature by pushing and holding top arrow for 5 seconds.

If supply air is warmer than setpoint and setpoint is below zone temperature, damper will close to reduce

supply air volume into space.

If supply air is cooler than setpoint and setpoint is above zone temperature, damper will close to reduce

supply air volume into space.

Verify that the supply air temperature sensor is securely connected on all master units – thermostat display will show

“00” if the supply air temperature sensor is not connected.

Verify that the supply air temperature sensor has been disconnected from all drone units – thermostat display will read

incorrectly if drone units has a supply air temperature sensor.

Unit is operating in reverse

Follow steps in “Occupant uncomfortable” above to ensure proper setpoints and verify supply air temperature.

(closing when it should be

opening, etc.)

Note: This IOM is meant to demonstrate general dimensions of this product. The drawings on this IOM are not meant to detail every aspect of the product with exactness. Drawings are not to scale.

All rights reserved. No part of this work may be reproduced or transmitted in any form or by any means, el ectronic or mechanical, including photocopying and recording, or by any information stor age retrieval system without permission in writing from Air Distribution Technologies.

Follow steps in “Supply air temperature reading is incorrect” above to ensure supply air temperature is correct.

TITUS reserves the right to make changes without written notice.

Page 5

Troubleshooting (cont.)

Symptom Action

T3SQ-1-IOM-5.0 6-6-09

Thermostat not operating

properly

Thermostat display codes

No Power

Check main power supply to power pack.

Check two power supplies not on same circuit. This will definitely be a problem if the two power supplies are

driven from different phases.

Check thermostat cable

If cable fine check drone cable between drone board and master controller

Replace with another wall thermostat

Replace with another power supply.

Display 00

Unit is in special supply sensing mode, but no supply sensor is fitted.

This function will be activated when the top button is pressed for 5 seconds. It will automatically reset to

control position.

If the unit do not automatically reset to control position, the button is damaged, and the wall

thermostat needs to be replaced

Display Li

Unit is in Special commissioning mode.

This function will be activated when the bottom button is pressed for 5 seconds.

The unit will reset to control position when both buttons are pressed simultaneously.

If the unit do not reset to control position when both buttons are pressed simultaneously, the unit is

faulty.

Display Flashing digits

Unit is in Room Setpoint adjustment mode.

This function is activated when the top or bottom buttons is pressed at short intervals for up and down

adjustment of Room Setpoint

The display will automatically reset to control position.

Inlet Heater not operating

properly

Display 88 or 56 or possibly other numbers

Two Wall thermostats are possibly connected on the same loop. Make sure that an RJ45 cable does not loop

between two Masters. Use an RJ12 cable instead.

If unit is in supply sensing mode, more than one supply air sensor (Change over sensor is plugged into the

same loop. Every master and it’s drones can have only one CO sensor plugged in. Unplug all CO sensors

from the drones.

Heater not working

Check to see if the motor is working. If the motor is working, wait at least 120 seconds for the damper to get

to minimum. The heater will only be activated 120 seconds after heating mode is activated.

If motor is not working, check RJ11 and RJ45 cabling through to master.

Check to see if the main power is available to connection point of Triac on the drone board.

Check to see if the heating mode light is on the front of wall display.

If the heating mode light is on, check to see if the difference between the Set-point and room temp is big

enough to keep the heater on full time. The proportional band of the heater is between -1°F and -3°F. The

heater will therefore only be on full time if the room temperature is 3°F lower than setpoint. If the room

temperature is 1°F lower than setpoint, the heater will not fire at all.

Check RJ11 and RJ45 cabling through to master.

Check to see if another wall stat is connected to triac and will activate the heater.

If yes replace wall stat

If no, replace triac

Heater remains on

Triac failed in open position.

Master heater operates, drone heater does not

Check Cabling

Note: This IOM is meant to demonstrate general dimensions of this product. The drawings on this IOM are not meant to detail every aspect of the product with exactness. Drawings are not to scale.

TITUS reserves the right to make changes without written notice.

Page 6

Troubleshooting (cont.)

Symptom Action

Erratic driving

T3SQ-1-IOM-6.0 6-6-09

Check if controller is in proportional band. The motor will start pulsing when room is 1°F from setpoint and the

motor will only drive full time when the room 3°F away from setpoint.

Check to see if only one master controller is connected to diffusers in the same control loop.

Motor not operating

properly

Not driving open or close

Check if controller is in proportional band. The motor will start pulsing when room is 1°F from setpoint and the

motor will only drive full time when the room 3°F away from setpoint.

Check cabling.

Check to see if the master is connected to the control loop.

Disconnect diffuser from control loop and test with external master.

Last resort change motor.

Only drives open

If change over sensor is fitted then motor will drive open when it normally would have driven closed when

supply air is higher than setpoint.

If change over not fitted, check to see if the room temperature is at least 3°F higher than setpoint.

Only drives close

If change over sensor is fitted then motor will drive closed when it normally would have driven open when

supply air is higher than setpoint.

If change over not fitted check to see if the room temperature is at least 3°F lower than setpoint.

Continuous driving up and down

Check if two master controllers are connected to the same control loop.

Master unit driving while drone unit non-responsive

Check drone RJ45 cabling

Check motor RJ45 cabling

Check to see if the motor is faulty

Noisy motor

Voltage too low

Faulty motor

Note: This IOM is meant to demonstrate general dimensions of this product. The drawings on this IOM are not meant to detail every aspect of the product with exactness. Drawings are not to scale.

TITUS reserves the right to make changes without written notice.

Loading...

Loading...