Page 1

STE-8001 and STE-8201 sensors

Set

Point

7O

12O2

Installation Guide

Section 1

Introduction to STE-8000 sensors

Specifications ...........................................................................................................................4

Safety considerations .............................................................................................................6

Section 2

Installing STE-8000 sensors

Planning for motion sensing .................................................................................................7

Rough-in preparation ............................................................................................................8

Installing the sensors ..............................................................................................................8

Maintenance ............................................................................................................................9

Section 3

User functions

Operating the STE-8000 .......................................................................................................11

Changing setpoints ...............................................................................................................12

Section 4

Commissioning functions

The commissioning sequence .............................................................................................14

Enter the commissioning mode ..........................................................................................14

Setting up network communications .................................................................................15

Box options ............................................................................................................................16

Setting commissioning setpoints ........................................................................................20

Setting the airflow setpoints ...............................................................................................23

Balancing airflow ..................................................................................................................27

Advanced options ................................................................................................................31

RevisionA

Page 2

KMC Controls

Important notices ©2012, KMC Controls, Inc.

WinControl XL Plus, NetSensor, and the KMC logo are registered trademarks of

KMC Controls, Inc.

BACstage and TotalControl are trademarks of KMC Controls, Inc.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any

form by any means without the written permission of KMC Controls, Inc.

Printed in U.S.A.

Disclaimer The material in this manual is for information purposes only. The contents and

the product it describes are subject to change without notice. KMC Controls, Inc.

makes no representations or warranties with respect to this manual. In no event

shall KMC Controls, Inc. be liable for any damages, direct or incidental, arising

out of or related to the use of this manual.

KMC Controls

P. O . B o x 4 9 7

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 1.574.831.5250

FAX: 1.574.831.5252

E-mail: info@kmccontrols.com

Revision A2

Page 3

SECTION 1

Note

Set

Point

7O

12O2

Set

Point

7O

12O2

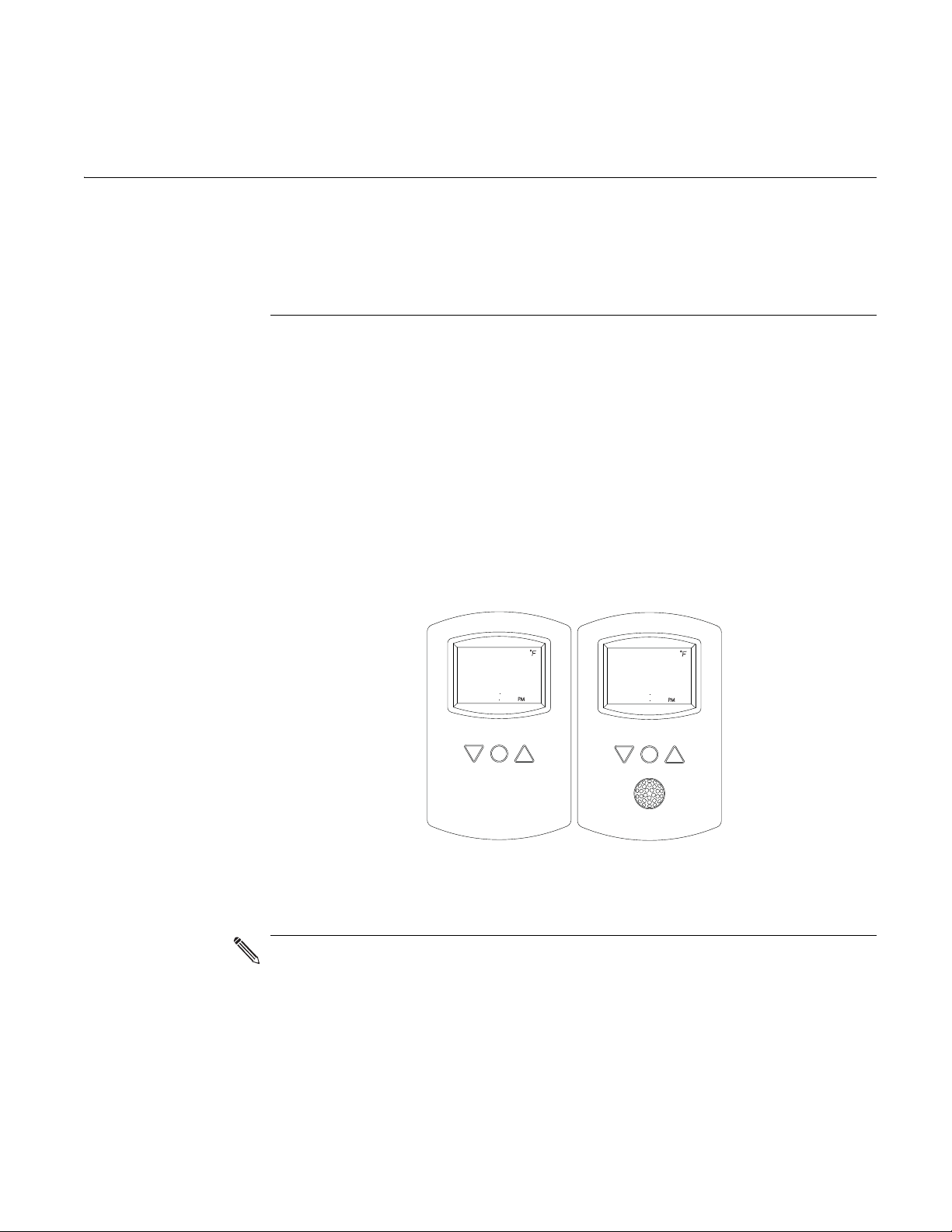

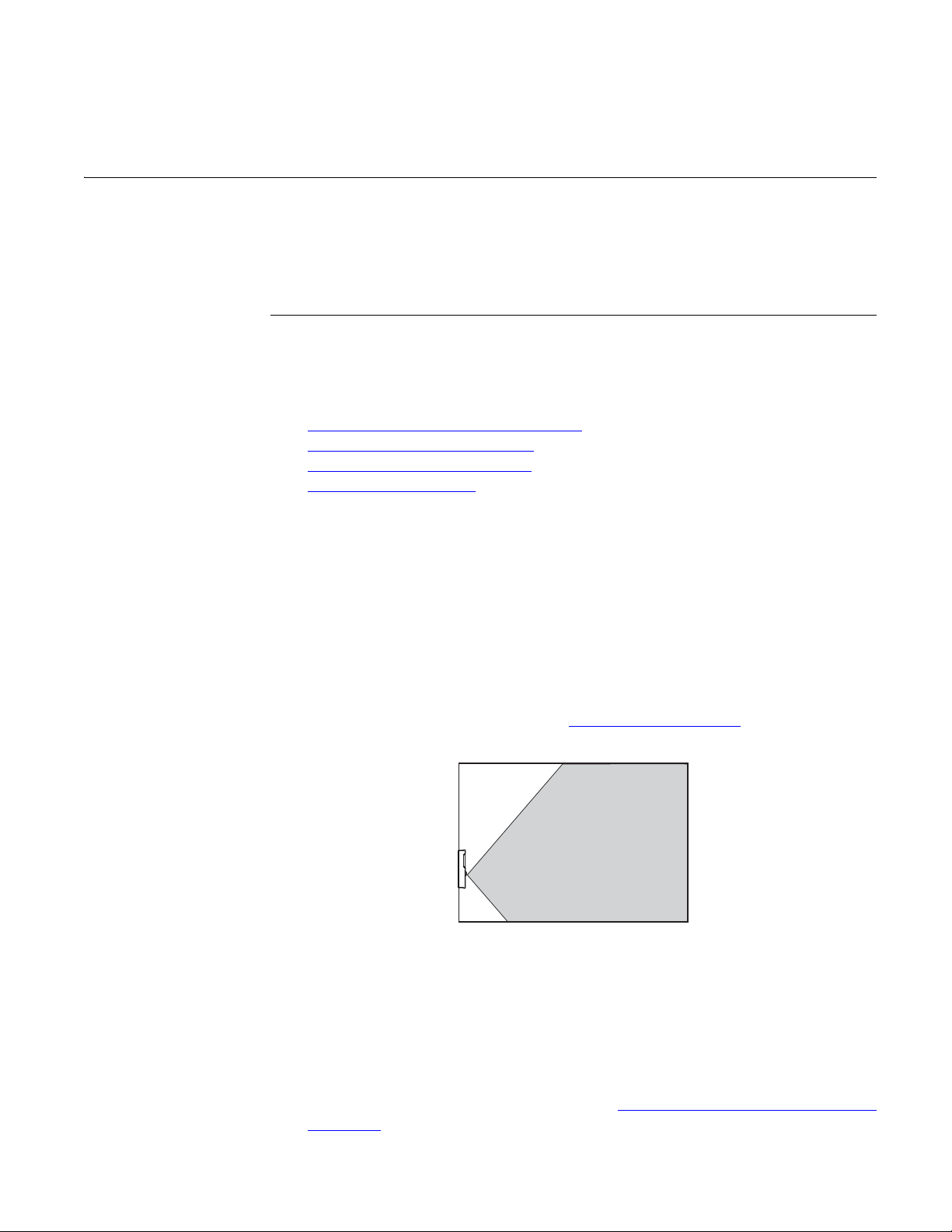

STE-8001

STE-8201

Introduction to STE-8000 sensors

This section provides a description of the KMC Controls STE-8001

and STE-8201 wall sensors. It also introduces safety information.

Review this material before installing or operating the sensors.

Models STE-8001 and STE-8201 are wall-mounted, temperature sensor for use

with KMC BAC-8000 series VAV controllers. Key features include the following:

◆ Integrated operator interface ready to use with BAC-8000 series VAV

◆ Large LCD display

◆ Simple three-button interface

◆ Continuously displays temperature and time

◆ Separate password protection for user and commissioning functions

◆ Use as a service tool to set up BAC-8000 series VAV controllers

◆ Optional motion sensor to detect space occupancy

controllers

Revision A 3

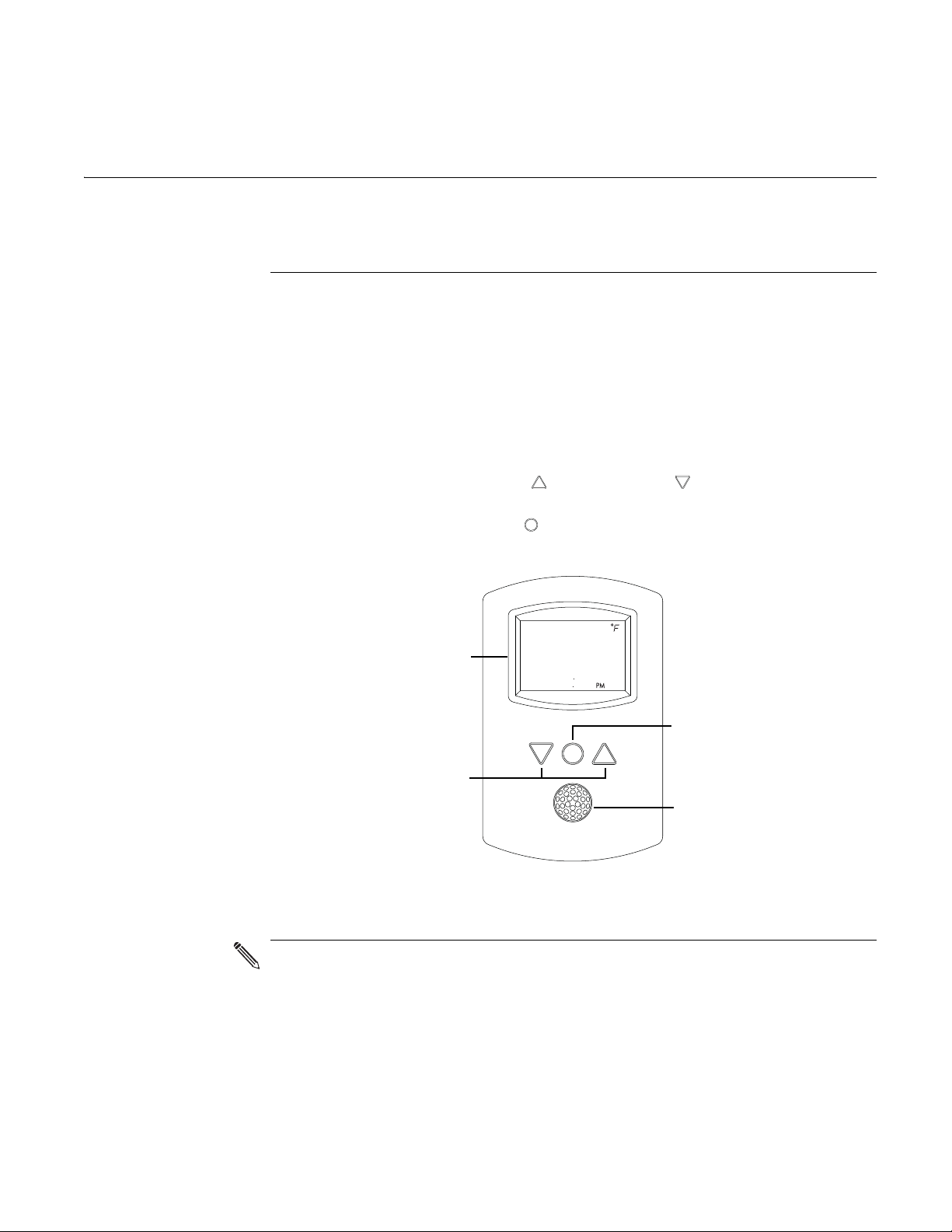

Illustration 1-1 STE-8001 and STE-8201

An STE-8000 series sensor will display time if the controller to which it is

attached has been synchronized with system time within the previous 24

hours.

Page 4

Introduction to STE-8000 sensors

Specifications

Specifications

Display Multifunctional LCD

Compatibility BAC-8000 series VAV controllers

Controller Connection

Connector type Eight-wire RJ-45 modular jack

Cable type and length Standard Ethernet cable up to 75 feet (22.9 meters)

Power Supplied by connected controller

Mounting Surface mount directly to any flat surface or to a

Weight 2.8 ounces (80 grams)

KMC Controls

1.88 x 1.25 in. (48 x 32 mm)

x 4 inch or 4 x 4 inch handy-box. Mounting on a

2

x 4 inch box requires a mounting backplate.

4

Material Flame retardant plastic

Accessories

Mounting backplate HMO-1161W

Gasket HPO-116

Replacement Allen screwsHPO-0044 (package of 10)

Environmental Limits

Operating Temperature 34° to 125° F (1.1 to 51.6° C)

Shipping –40° to 140° F (–40°C to 60° C)

Humidity 0 to 95% relative humidity

non-condensing

4

Revision A

Page 5

STE-8001 and STE-8201 sensors

55

°

10 m

32.8 ft

10 m

32.8 ft

X

0°

10 m

32.8 ft

10 m

32.8 ft

0°

46.5

°

Y

Top view

Side view

7O

12O2

C

B

A

D

E

F

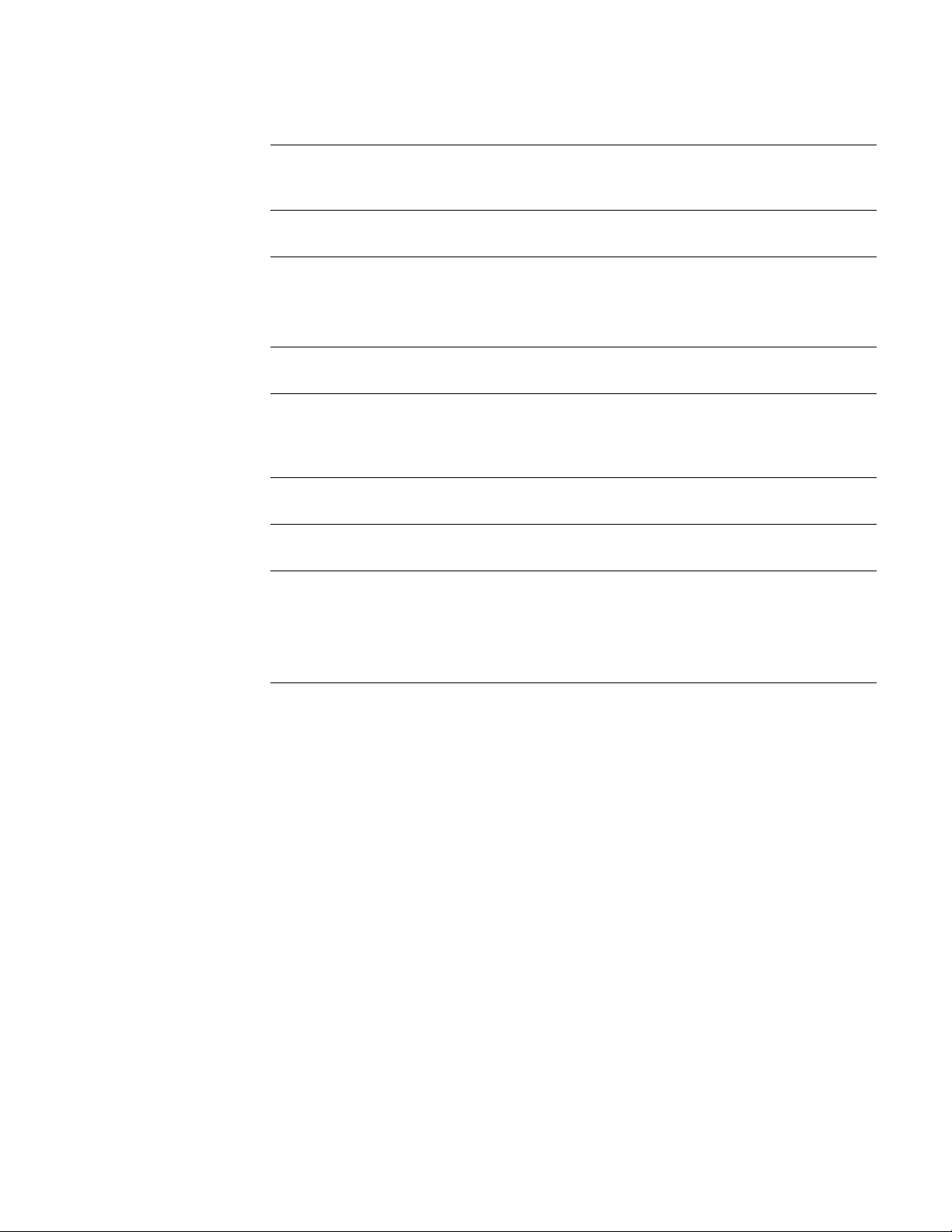

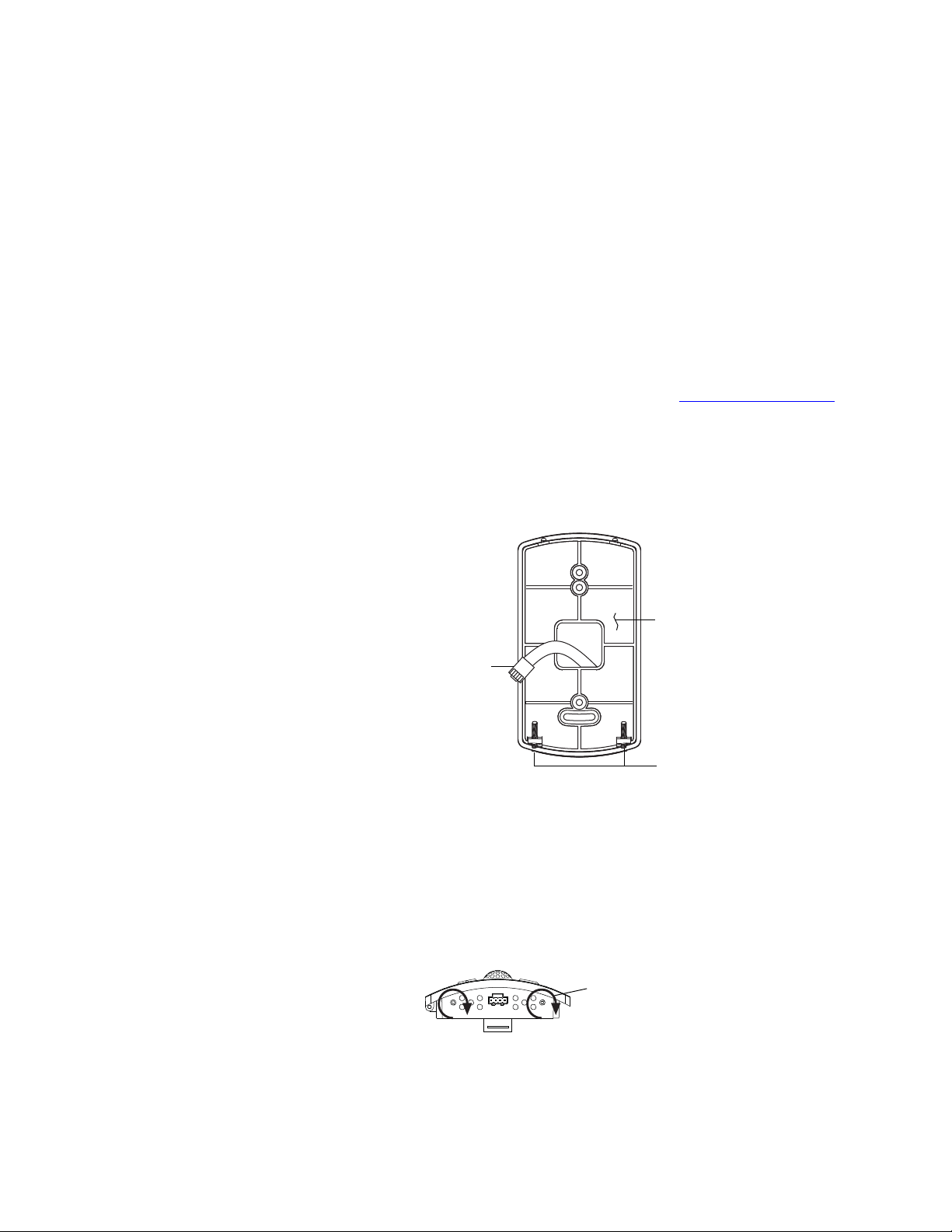

Motion sensor range Model STE-8201 only

Introduction to STE-8000 sensors

Specifications

Detector type Passive infrared

Range 33 feet (10 meters). See diagrams

Dimensions

ABCDE F

3.25 in. 5.16 in. 2.58 in. 3.25 in. 0.87 in. 1.07 in.

83 mm 116 mm 66 mm 83 mm 22 mm 27 mm

Revision A

5

Page 6

Introduction to STE-8000 sensors

Danger

Warning

Caution

Note

Detail

Safety considerations

Models

Safety

considerations

KMC Controls assumes the responsibility for providing you a safe product and

safety guidelines during its use. Safety means protection to all individuals who

install, operate, and service the equipment as well as protection of the

equipment itself. To promote safety, we use hazard alert labeling in this manual.

Follow the associated guidelines to avoid hazards.

Danger represents the most severe hazard alert. Bodily harm or death will

occur if danger guidelines are not followed.

KMC Controls

Temperature sensor only STE-8001

Temperature and motion STE-8201

Warning represents hazards that could result in severe injury or death.

Caution indicates potential personal injury or equipment or property damage

if instructions are not followed.

Notes provide additional information that is important.

Provides programing tips and shortcuts that may save time.

6

Revision A

Page 7

SECTION 2

Installing STE-8000 sensors

Installing the sensors includes the following topics that are covered in this

section.

Planning for motion sensing

For STE-8201 only—Mount the STE-8201 sensor on a wall that will have an

unobstructed view of the typical traffic in the coverage area. When choosing a

location, do not install the sensor in the following areas.

This section provides important instructions and guidelines for

installing the STE-8000 series sensors. Carefully review this

information before installing the controllers.

◆ Planning for motion sensing on page 7

◆ Rough-in preparation on page 8

◆ Installing the sensors on page 8

◆ Maintenance on page 9

◆ Behind curtains or other obstructions

◆ In locations that will expose it to sunlight or heat sources

◆ Near a heating/cooling duct.

For details on the coverage pattern, see Specifications

on page 4.

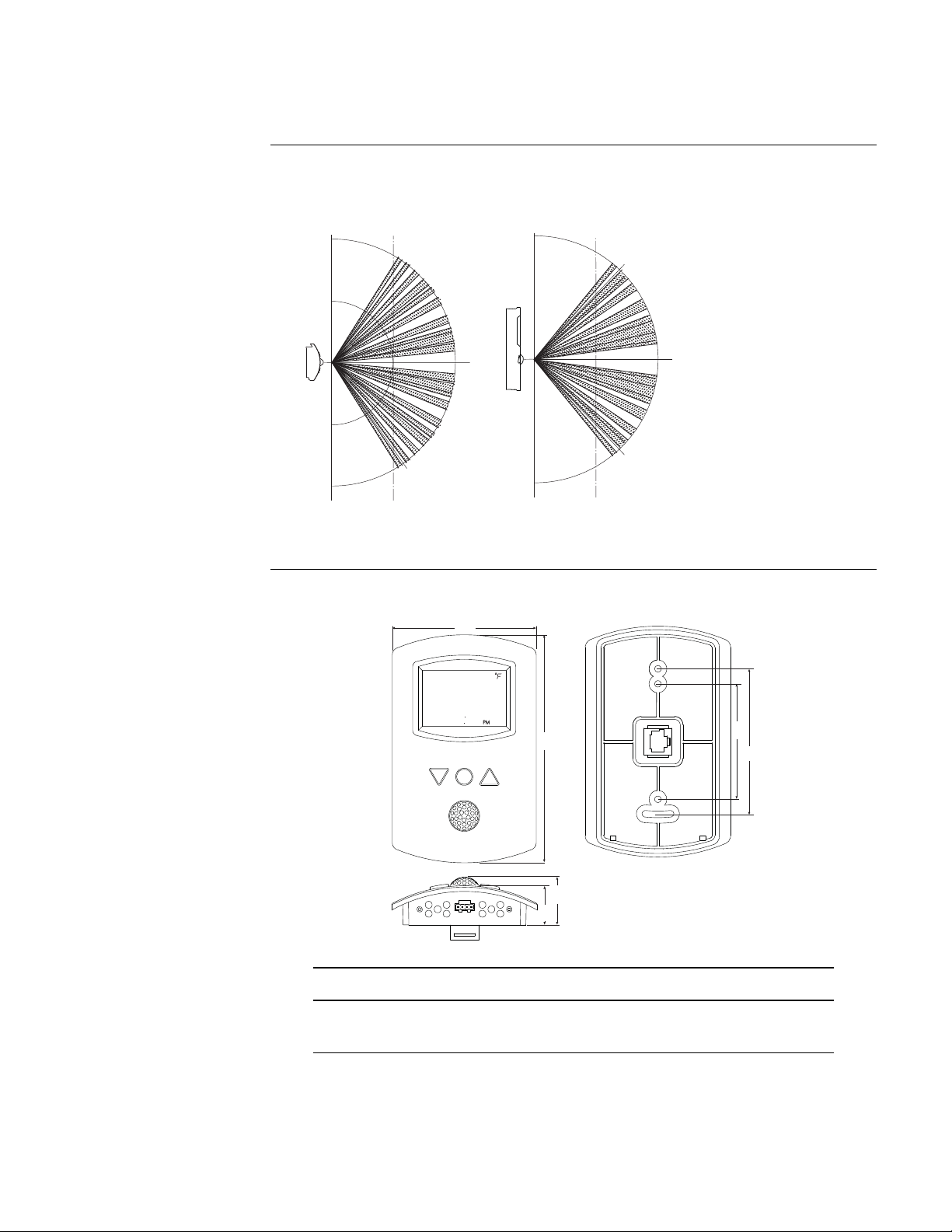

Illustration 2-1 Typical motion sensing coverage area

The effective detection range is approximately 10 meters or 33 feet. Factors that

may reduce the range include:

◆ The difference between the surface temperature of the object and the

background temperature of the room is too small.

◆ Object movement in a direct line toward the sensor.

◆ Very slow or very fast object movement.

◆ Obstructions as shown in the illustration Typical motion sensing coverage area

on page 7.

Revision A 7

Page 8

Installing STE-8000 sensors

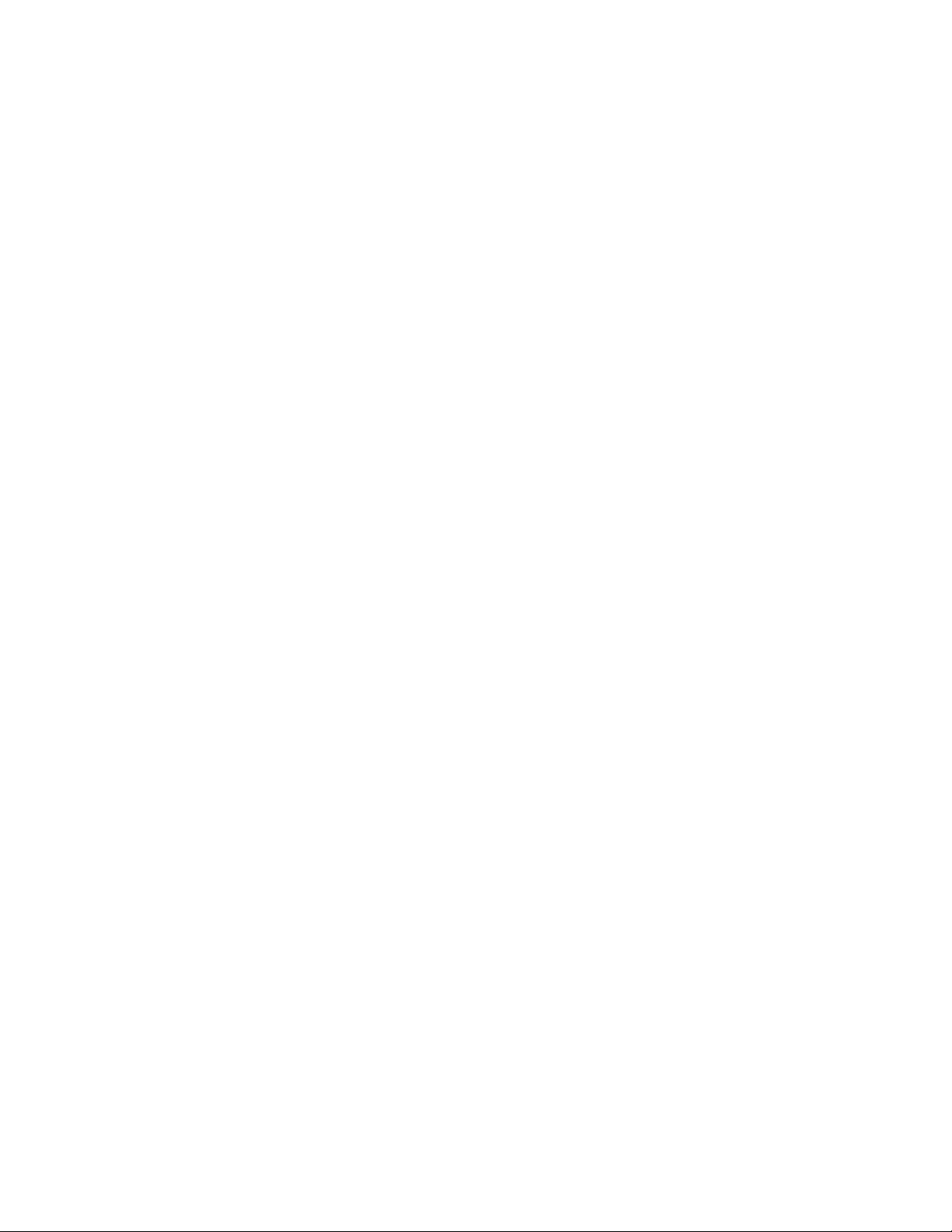

Connecting cable

Maximum 75 feet

or 22.9 meters

Allen

screws

Mounting

base

Turn clockwise to

remove from base.

Rough-in preparation

Rough-in

KMC Controls

False detections may be triggered by:

◆ The temperature inside the detection range suddenly changes because of

the entry of cold or warm air from an air-conditioning or heating unit.

◆ The sensor being directly exposed to sunlight, an incandescent light, or

other source of far-infrared rays.

◆ Small animal movement.

preparation

Complete rough-in wiring at each sensor location prior to sensor installation.

This includes the following.

◆ Routing the connecting cable from the sensor to a controller.

◆ If required, install the appropriate backplate. See Accessories on page 4 for

model numbers.

Connect the STE-8000 series sensor to a controller with a standard Ethernet cable

with RJ-45 connectors on each end. Maximum cable length is 75 feet (22.9

meters). Plenum-rated preassembled cables are recommended.

Installing the sensors

8

To install the sensor on a backplate, do the following:

Illustration 2-2 Sensor mounting details

1. Turn the Allen screws in the base of the NetSensor clockwise until they

clear the cover. Swing the sensor away from the mounting base to remove

it.

2. Route the Ethernet cable through the mounting base.

Illustration 2-3 Mounting screws

3. Fasten the mounting base directly to a 2 x 4 inch outlet box or a backplate

with the Allen screws toward the floor.

Revision A

Page 9

STE-8001 and STE-8201 sensors

Installing STE-8000 sensors

Maintenance

4. Insert the Ethernet cable coming from the base into the sensor.

5. Place the top of the sensor over the top of the mounting base and swing it

down over the Allen screw brackets. Be careful not to pinch any wiring.

6. Back the Allen screws out of the brackets until they engage the sensor cover

and hold it in place.

Maintenance Remove dust as necessary from holes in top and bottom. Clean the display with

soft, damp cloth and mild soap.

Revision A

9

Page 10

Installing STE-8000 sensors

Maintenance

KMC Controls

10

Revision A

Page 11

SECTION 3

Note

Set

Point

Set

Point

7O

12O2

LCD display with

temperature and time

UP and down

buttons

Setpoint button

Motion sensor

(STE-8201 only)

User functions

User functions are limited to changing the occupied temperature setpoints from

the STE-8000.

Operating the STE-8000

The functions are accessible through an STE-8000 series sensor. The functions are

entered or changed using the buttons and display on the front of the STE-8000.

This section covers topics for the end user in a facility.

◆ Pressing either the up button or down button changes a selection,

setting, or value.

◆ Pressing the setpoint button saves the setting or value. Typically saving

an entry also advances to the next display.

Revision A 11

Illustration 3-1 The STE-8000 series display and buttons

An STE-8000 series sensor will display time if the controller to which it is

attached has been synchronized with system time within the previous 24

hours.

Page 12

User functions

72

12S1

Set

Point

Set

Point

PSW1

OOOO

Set

Point

7SO

COOLING

Set

Point

68O

HEATING

Changing setpoints

Changing

KMC Controls

setpoints

Enter occupied setpoints

To enter or change the occupied setpoints you will need a Level 1 password.

Procedure Steps STE display

Starting display

Enter the level one

password

Start from the temperature display.

1. Press the button.

2. Press the or buttons to change

the first digit.

3. Press the button to select the next

digit. Repeat for all four digits.

4.

Note: If a Level 1 password has not

previously been entered, the display

will change to the occupied cooling

setpoint display after Step 1.

Set the occupied

cooling setpoint

1. Press the or buttons to change

the cooling setpoint temperature. The

setpoint changes in increments of 0.5

degrees.

2. Press the button to save the value.

The display advances to set the

heating setpoint.

Set the occupied

heating setpoint

1. Press the or buttons to change

the heating setpoint temperature.

The setpoint changes in increments

of 0.5 degrees.

2. Press the button to save the value.

The display returns to the

temperature display.

12

Revision A

Page 13

SECTION 4

Note

Commissioning functions

This topics in this section are advanced topics for control technicians

and engineers.

The commissioning functions that are accessible through an STE-8000 series

sensor are values and settings that are entered during the installation and

commissioning of a VAV terminal unit. Typically these functions do not change

after the installation and commissioning process.

To set up the commissioning functions, you will need the following:

◆ Information about the VAV terminal unit including the configuration for

◆ The installation and operation manual supplied with the controller to

◆ The building automation system plans.

fans and reheat

which the STE-8000 series sensor is connected.

Users may change the occupied heating and cooling setpoints without accessing

the commissioning functions. This procedure is covered in

page 11.

The instructions for commissioning functions cover all of the functions that an

STE-8000 sensor can set up in the BAC-8000 series of controllers. Not all

functions are available on every model of controller. Consult the installation

and operation manual supplied with the controller to verify the functions and

options that are available.

User functions on

Revision A 13

Page 14

Commissioning functions

72

12S1

Set

Point

Set

Point

PSW2

OOOO

COMM

The commissioning sequence

The

commissioning

KMC Controls

sequence

Enter the commissioning mode

Enter the commissioning mode

Procedure Steps STE display

Starting display Start from the temperature display.

Set the commission functions in the following sequence.

1. Enter the commissioning mode on page 14

2. Setting up network communications on page 15

3. Box options on page 16

4. Setting commissioning setpoints on page 20

5. Setting the airflow setpoints on page 23

6. Balancing airflow on page 27

For access to the commissioning functions you will need a Level 2 password.

◆ If the controller has not been previously set up, no password is required.

◆ A new Level 2 password can be entered in the advanced commissioning

functions. See the topic Advanced options

on page 31.

Enter the

commissioning

password

Select a

commissioning

function

1. Press the and buttons together

and hold them down until the

display changes to PSW2.

2. Press the or button to change

the first digit.

3. Press the button to select the next

digit. Repeat for all four digits.

4. When the button is pushed for the

fourth correct digit, the display

changes to COMM.

Note: If a Level 2 password has not

previously been entered the display

will change to the COMM display after

Step 1.

Access to the commissioning

functions always start at the COMM

display.

14

Revision A

Page 15

STE-8001 and STE-8201 sensors

72

12S1

PSW2

OOOO

Set

Point

COMM

Set

Point

Set

Point

D ID

OO72O69

Set

Point

MAC

11

Set

Point

BAUD

384OO

Set

Point

COMM

Setting up

network

Commissioning functions

Setting up network communications

communications

Procedure to set up network communications

Procedure Steps STE display

Starting display 1. Start at the temperature display.

Select the COMM

display

Set the network communication settings before placing a controller on the

network. Setting network settings requires entering the Level 2 password which

is described in the topic Enter the commissioning mode

on page 14.

2. Enter the Level 2 password. The

display changes to the COMM.

Press the button. The display changes

to DI D.

Enter the device

instance.

Enter the MAC

address.

Enter the baud

Advance or exit

1. Press the or buttons to change

the first digit.

2. Press the button to select the next

digit. Repeat for all seven digits.

3. When the button is pressed for the

last digit, the display changes to MAC.

1. Press the or buttons to change

the MAC address.

2. Press the button to save the

selected MAC address.

The display changes to BAUD.

1. Press the or buttons to select a

new baud.

2. Press the button is save the

selected baud.

The display returns to COMM.

1. Press the or buttons to select

one of the following:

• BLNC or CNFG options

• EXIT to return to the temperature

display.

2. Press the button to select the next

function.

Revision A

15

Page 16

Commissioning functions

72

12S1

PSW2

OOOO

Set

Point

Set

Point

COMM

CNFG

STPT

BOX

Set

Point

9O4

PKFT

Set

Point

9O4

SKFT

Box options

KMC Controls

Box options The box options set up the controller for the specific mechanical installation of

the VAV terminal unit. Setting the box options requires entering the Level 2

password which is described in the topic Enter the commissioning mode

page 14.

Procedure to set the box functions

Procedure Steps STE display

Starting display 1. Start at the temperature display.

2. Enter the Level 2 password. The

display changes to the COMM.

on

Select the box

settings display.

Set the primary

VAV te r m i na l u n it

K-factor.

1. From the COMM display, press the

or buttons to show the CNFG

display.

2. Press the button to select the CNFG

options. The display changes to

STPT.

3. Press the or buttons to change

the display to BOX.

4. Press the button to select BOX.

1. Press the or buttons to set the

primary K-factor.

2. Press the button to save the entry

and advance to the next function.

16

Set the secondary

VAV te r m i na l u n it

K-factor.

1. Press the or buttons to set the

secondary K-factor.

2. Press the button to save the entry

and advance to the next function.

Revision A

Page 17

STE-8001 and STE-8201 sensors

Set

Point

NONE

REHT

Set

Point

NONE

FAN

Procedure to set the box functions (Continued)

Procedure Steps STE display

Commissioning functions

Box options

Set the mode of

reheat for the

terminal unit

Set the fan option

1. Press the or buttons to choose

one of the following reheat options.

None—Reheat is not enabled.

Staged—Enables two or three stage

reheat. If lighting is enabled the

staged reheat is set to two stages. If

lighting is not enabled, three reheat

stages are available.

Modulating—The reheat output

varies from 0-10 volts.

Floating—The reheat outputs control

a tristate actuator.

Time proportional—Controls a

thermal wax valve with a 24-volt

triac output.

2. Press the button to save the reheat

option and advance to the next

function.

1. Press the or buttons to choose

one of the following fan options.

None—No fan is connected to the

controller.

Series—The VAV unit includes a

series fan.

Parallel—The VAV unit includes a

parallel fan.

2. Press the button to save the fan

option and advance to the next

function.

Revision A

17

Page 18

Commissioning functions

Set

Point

CCW

DDIR

Set

Point

VAV

DUAL

Box options

Procedure to set the box functions (Continued)

Procedure Steps STE display

KMC Controls

Set the damper

direction to close

Set the dual duct

mode

1. Press the or buttons to which

direction to damper moves to close.

CCW—The actuator turns

counterclockwise to close the

damper.

CW—The actuator turns clockwise to

close the damper.

2. Press the button to save the

damper option and advance to the

next function.

1. Press the or buttons to choose

the dual duct mode of operation.

VAV—The system maintains space

temperature with variable air volume

control.

CAC—The system maintains space

temperature with constant air

volume control.

Supply exhaust offset—The system

maintains space temperature with

the primary VAV controller. The

secondary controller controls the

exhaust unit. Supply/exhaust

tracking is controlled as an offset

percentage.

Supply exhaust differential—The

system mantains space temperature

with the primary VAV controller. The

secondary controller controls the

exhaust unit. Supply/exhaust

tracking controlled by differential

pressure.

Indoor air quality—Room

temperature is maintained with

primary VAV unit and CO2 levels

controlled by secondary VAV unit.

2. Press the button to save the dual

duct option and advance to the next

function.

18

Revision A

Page 19

STE-8001 and STE-8201 sensors

Set

Point

BOX

Procedure to set the box functions (Continued)

Procedure Steps STE display

Commissioning functions

Box options

Advance or exit

1. Press the or buttons to select

one of the following:

• STPT, FLOW, or ADVC options

• BACK to choose another

commissioning function

• EXIT to return to the temperature

display.

2. Press the button to select the next

function.

Revision A

19

Page 20

Commissioning functions

PSW2

OOOO

Set

Point

Set

Point

COMM

CNFG

STPT

Set

Point

MIN

68O

Set

Point

MAX

78O

Setting commissioning setpoints

Setting

commissioning

KMC Controls

setpoints

Procedure to set the commissioning setpoints

The commissioning setpoints set the operational parameters and limits for the

VAV terminal unit. Setting configuration setpoints requires entering a Level 2

password which is described in the topic Enter the commissioning mode

page 14.

Procedure Steps STE display

Starting display

Select the setpoint

display.

Enter the Level 2 password. The display

changes to the COMM.

1. From the COMM display, press the

or buttons to show the CNFG

display.

2. Press the button to select the CNFG

options. The display changes to

STPT.

on

Set the minimum

cooling setpoint

Set the maximum

heating setpoint

3. Press the button to select the STPT

options.

1. Press the or buttons to set the

minimum cooling setpoint. The

setpoint will change in 0.5°

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

maximum heating setpoint. The

setpoint will change in 0.5°

increments.

2. Press the button to save the

setpoint and advance to the next

function.

20

Revision A

Page 21

STE-8001 and STE-8201 sensors

Set

Point

OCCL

74O

Set

Point

OCHT

7OO

Set

Point

UNCL

8OO

Set

Point

UNHT

62O

Set

Point

74

CHNG

Procedure to set the commissioning setpoints (Continued)

Procedure Steps STE display

Commissioning functions

Setting commissioning setpoints

Set the occupied

cooling setpoint

Set the occupied

heating setpoint

Set the unoccupied

cooling setpoint

Set the unoccupied

heating setpoint

Set the supply air

temperature

changeover setpoint

1. Press the or buttons to set the

occupied cooling setpoint. The

setpoint will change in 0.5°

increments.

2. Press the button to save the

setpoint and advance to the next

function.

Note: This setpoint can also be changed as

described in the section

User functions on

page 11.

1. Press the or buttons to set the

occupied heating setpoint. The

setpoint will change in 0.5°

increments.

2. Press the button to save the

setpoint and advance to the next

function.

Note: This setpoint can also be changed as

described in the section

User functions on

page 11.

1. Press the or buttons to set the

unoccupied cooling setpoint. The

setpoint will change in 0.5°

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

unoccupied heating setpoint. The

setpoint will change in 0.5°

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

changeover setpoint. The setpoint

will change in 1° increments.

2. Press the button to save the

setpoint and advance to the next

function.

Revision A

21

Page 22

Commissioning functions

Set

Point

O5

DIFF

Set

Point

OS

Set

Point

OO

DDOF

Set

Point

OO5

DDDP

Set

Point

1OOO

C2SP

Set

Point

STPT

Setting commissioning setpoints

Procedure to set the commissioning setpoints (Continued)

Procedure Steps STE display

KMC Controls

Set the minimum

temperature

differential

setpoint

Set the standby

differential

setpoint

Set the supply

exhaust offset

Set the supply

exhaust differential

pressure setpoint

1. Press the or buttons to set the

differential setpoint. The setpoint

will change in 1° increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

standby differential setpoint. The

setpoint will change in 1° increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

supply exhaust offset setpoint. The

setpoint will change in 1%

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

supply exhaust differential pressure

setpoint.The setpoint will change in

increments of 0.01 inches of water.

2. Press the button to save the

setpoint and advance to the next

function.

22

Set the CO2

setpoint.

Advance or exit

1. Press the or buttons to change

CO2 setpoint. The setpoint changes

increments for 1 part per million.

2. Press the button to save the

setpoint and complete the setpoint

changes.

The display returns to STPT.

1. Press the or buttons to select

one of the following:

• FLOW, BOX, or ADVC options

• BACK to choose another

commissioning function

• EXIT to return to the temperature

display.

2. Press the button to select the next

function.

Revision A

Page 23

STE-8001 and STE-8201 sensors

Note

72

12S1

PSW2

OOOO

Set

Point

Set

Point

COMM

CNFG

STPT

FLOW

Setting the

Commissioning functions

Setting the airflow setpoints

airflow setpoints

Procedure to set the airflow setpoints

Procedure Steps STE display

Starting display 1. Start at the temperature display.

The airflow setpoints configure the airflow limits for the VAV terminal unit.

Setting the airflow setpoints requires entering a Level 2 password which is

described in the topic

If the VAV unit is a heat only or cooling only unit, the airflow setpoints for the

unused mode must be set within the range of the mode in use. Failure to set the

unused setpoints correctly will result in unpredictable or erroneous air

balancing settings.

2. Enter the Level 2 password. The

display changes to the COMM.

Enter the commissioning mode on page 14.

Select the flow

setpoint display.

1. From the COMM display, press the

or buttons to show the CNFG

display.

2. Press the button to select the CNFG

options. The display changes to

STPT.

3. Press the or buttons to change

the display to FLOW.

4. Press the button to select FLOW.

Revision A

23

Page 24

Commissioning functions

Set

Point

O O

MNCL

Set

Point

3SO

MXCL

Set

Point

OO

MNHT

Set

Point

3SO

MXHT

Set

Point

2O

MIN

Set

Point

1OO

MAX

Setting the airflow setpoints

Procedure to set the airflow setpoints (Continued)

Procedure Steps STE display

KMC Controls

Set the cooling

minimum airflow

limit

Set the cooling

maximum airflow

limit

Set the heating

minimum airflow

limit

Set the heating

maximum airflow

limit

Set the minimum

limit for fan speed

Set the maximum

limit for fan speed

1. Press the or buttons to set the

minimum limit for cooling airflow.

The setpoint will change in 1 CFM

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

maximum limit for cooling airflow.

The setpoint will change in 1 CFM

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

minimum limit for heating airflow.

The setpoint will change in 1 CFM

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

maximum limit for heating airflow.

The setpoint will change in 1 CFM

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

minimum limit for the fan speed. The

setpoint will change in 1%

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

maximum limit for the fan speed.

The setpoint will change in 1%

increments.

2. Press the button to save the

setpoint and advance to the next

function.

24

Revision A

Page 25

STE-8001 and STE-8201 sensors

Set

Point

O O

MNCL

Set

Point

3SO

MXCL

Set

Point

OO

MNHT

Set

Point

3SO

MXHT

Set

Point

2O

MIN

Set

Point

1OO

MAX

Procedure to set the airflow setpoints (Continued)

Procedure Steps STE display

Commissioning functions

Setting the airflow setpoints

Set the cooling

minimum airflow

limit

Set the cooling

maximum airflow

limit

Set the heating

minimum airflow

limit

Set the heating

maximum airflow

limit

Set the minimum

limit for fan speed

Set the maximum

limit for fan speed

1. Press the or buttons to set the

minimum limit for cooling airflow.

The setpoint will change in 1 CFM

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

maximum limit for cooling airflow.

The setpoint will change in 1 CFM

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

minimum limit for heating airflow.

The setpoint will change in 1 CFM

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

maximum limit for heating airflow.

The setpoint will change in 1 CFM

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

minimum limit for the fan speed. The

setpoint will change in 1%

increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

maximum limit for the fan speed.

The setpoint will change in 1%

increments.

2. Press the button to save the

setpoint and advance to the next

function.

Revision A

25

Page 26

Commissioning functions

Set

Point

OO

MNC2

Set

Point

3SO

MXC2

Set

Point

FLOW

Setting the airflow setpoints

Procedure to set the airflow setpoints (Continued)

Procedure Steps STE display

KMC Controls

Set the minimum

limit for indoor air

quality ventilation

Set the maximum

limit for indoor air

quality ventilation

Advance or exit

1. Press the or buttons to set the

minimum limit for ventilation

airflow. The setpoint will change in 1

CFM increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

maximum limit for ventilation

airflow. The setpoint will change in

1 CFM increments.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to select

one of the following:

• STPT, BOX, or ADVC options

• BACK to choose another

commissioning function

• EXIT to return to the temperature

display.

2. Press the button to select the next

function.

26

Revision A

Page 27

STE-8001 and STE-8201 sensors

Note

Note

72

12S1

PSW2

OOOO

Set

Point

Set

Point

COMM

BLNC

PRI

Commissioning functions

Balancing airflow

Balancing airflow The airflow balancing method described in this section requires a flow hood or

other accurate method to measure airflow. The airflow balancing procedure

requires entering the Level 2 password which is described in the topic

commissioning mode on page 14.

If the VAV unit is a heat only or cooling only unit, the airflow setpoints for the

unused mode must be set within the range of the mode in use. Failure to set the

unused setpoints correctly will result in unpredictable or erroneous air

balancing settings. See Setting the airflow setpoints

to adjust the setpoints.

Starting the balancing procedure erases all previous airflow correction factors.

The airflow readings displayed by the STE-8000 are the actual uncorrected

airflow readings as measured by the controller.

on page 23 for the procedure

Enter the

The airflow balancing procedure

Procedure Steps STE display

Starting display 1. Start at the temperature display.

2. Enter the Level 2 password. The

display changes to the COMM.

Select the COMM

display

1. From the COMM display, press the

or buttons to show the BLNC

display.

2. Press the button to select BLNC.

The display advances to PRI.

Revision A

3. Press the button to select PRI.

27

Page 28

Commissioning functions

Set

Point

Set

Point

PMAX

OO

Set

Point

Set

Point

PMIN

OO

Balancing airflow

The airflow balancing procedure (Continued)

Procedure Steps STE display

KMC Controls

Measure and enter

the actual

maximum primary

airflow

Measure and enter

the actual

minimum primary

airflow

The display begins flashing PMAX

and also displays the actual airflow

at the bottom.

Note: The airflow will attempt to stabilize

on the highest value for either the cooling

or heating maximum airflow even if only

one mode is operational.

Note: The airflow displayed by the

STE-8000 in this step is the actual,

uncorrected airflow.

1. Wait for the maximum airflow value

to stabilize.

2. With a flow hood, measure the actual

airflow.

3. Press the button to advance to the

entry display. PMAX stops flashing.

4. Press the or buttons to enter the

measured airflow.

5. Press the button to save the

measured airflow. The display

changes to PMIN.

The display begins flashing PMIN

and also displays the actual airflow

at the bottom.

Note: The airflow will attempt to stabilize

on the lowest value for either the cooling

or heating minimum airflow even if only

one mode is operational.

28

Note: The airflow displayed by the

STE-8000 in this step is the actual,

uncorrected airflow.

1. Wait for the minimum airflow value

to stabilize.

2. With a flow hood, measure the actual

airflow.

3. Press the button to advance to the

entry display. PMIN stops flashing.

4. Press the or buttons to enter the

measured airflow.

5. Press the button to save the

measured airflow. The display

advances to PRI.

Revision A

Page 29

STE-8001 and STE-8201 sensors

Set

Point

PRI

SEC

Set

Point

Set

Point

SMAX

OO

The airflow balancing procedure (Continued)

Procedure Steps STE display

Commissioning functions

Balancing airflow

Advance or exit

Measure and enter

the actual

maximum

secondary airflow

1. Press the or buttons to select

one of the following:

• SEC to balance the secondary VAV

for dual duct systems

• BACK to choose another

commissioning function

• EXIT to return to the temperature

display.

2. Press the button to select the next

function.

The display begins flashing SMAX

and also displays the actual airflow

at the bottom.

Note: The airflow displayed by the

STE-8000 in this step is the actual,

uncorrected airflow.

1. Wait for the maximum airflow value

to stabilize.

2. With a flow hood, measure the actual

airflow.

3. Press the button to advance to the

entry display. SMAX stops flashing.

4. Press the or buttons to enter the

measured airflow.

5. Press the button to save the

measured airflow. The display

advances to SMIN.

Revision A

29

Page 30

Commissioning functions

Set

Point

Set

Point

SMIN

OO

Set

Point

SEC

Balancing airflow

The airflow balancing procedure (Continued)

Procedure Steps STE display

KMC Controls

Measure and enter

the actual

minimum

secondary airflow

Advance or exit

The display begins flashing SMIN

and also displays the actual airflow

at the bottom.

Note: The airflow displayed by the

STE-8000 in this step is the actual,

uncorrected airflow.

1. Wait for the minimum airflow value

to stabilize.

2. With a flow hood, measure the actual

airflow.

3. Press the button to advance to the

entry display. SMIN stops flashing.

4. Press the or buttons to enter the

measured airflow.

5. Press the button to save the

measured airflow. The display

advances to SEC.

1. Press the or buttons to select

one of the following

• PRI to balance the primary VAV

for dual duct systems

• BACK to choose another

commissioning function

• EXIT to return to the temperature

display.

2. Press the button to select the next

function.

30

Revision A

Page 31

STE-8001 and STE-8201 sensors

72

12S1

PSW2

OOOO

Set

Point

Set

Point

COMM

CNFG

STPT

ADVC

Set

Point

Set

Point

PSW1

OOOO

Commissioning functions

Advanced options

Advanced

options The advanced options set up passwords and special features in the controller.

Setting the advance options requires entering the Level 2 password which is

described in the topic Enter the commissioning mode

Procedure to set the advanced options

Procedure Steps STE display

Starting display 1. Start at the temperature display.

2. Enter the Level 2 password. The

display changes to the COMM.

on page 14.

Select the

advanced display.

Enter a new

Level

1 password

1. From the COMM display, press the

or buttons to show the CNFG

display.

2. Press the button to select the CNFG

options. The display changes to

STPT.

3. Press the or buttons to change

the display to ADVC.

4. Press the button to select ADVC.

Note: Entering four zeros (0000) removes

the password.

Revision A

1. Press the or buttons to change

the first digit.

2. Press the button to select the next

digit. Repeat for all four digits.

3. When the button is pressed for the

last digit, the new password is saved

and the display advances.

31

Page 32

Commissioning functions

Set

Point

Set

Point

PSW2

OOOO

Set

Point

3O

OVRD

Set

Point

15

Set

Point

DISABLE

DAT

Set

Point

OO

CALIB

Advanced options

Procedure to set the advanced options (Continued)

Procedure Steps STE display

KMC Controls

Enter a new

2 password

Level

password

Set the local

unoccupied

override timer

Set the standby

time

Note: Entering four zeros (0000) removes

the password.

1. Press the or buttons to change

the first digit.

2. Press the button to select the next

digit. Repeat for all four digits.

3. When the button is pressed for the

last digit, the new password is saved

and the display advances.

Note: This function applies only to

controllers that will use an STE-6017

sensor.

1. Press the or buttons to set the

local unoccupied override timer. The

value will change in 1 minute

increments.

2. Press the button to save the

setpoint and advance to the next

function.

Note: This function applies only to

controllers that will use an STE-8201

sensor.

Set discharge air

temperature

limiting

Set the STE-8000

temperature sensor

calibration

constant

3. Press the or buttons to set the

time for the standby time. The value

will change in 1 minute increments.

4. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to enable or

disable discharge air temperature

limiting.

2. Press the button to save the

setpoint and advance to the next

function.

1. Press the or buttons to set the

calibration constant. The setpoint

will change in 0.1 minute increments.

2. Press the button to save the

setpoint and advance to the next

function.

32

Revision A

Page 33

STE-8001 and STE-8201 sensors

Set

Point

ADVC

Procedure to set the advanced options (Continued)

Procedure Steps STE display

Commissioning functions

Advanced options

Advance or exit

1. Press the or buttons to select

one of the following:

• STPT, FLOW, or BOX options

• BACK to choose another

commissioning function

• EXIT to return to the temperature

display.

Press the button to select the next

function.

Revision A

33

Page 34

Commissioning functions

Advanced options

KMC Controls

34

Revision A

Loading...

Loading...