Page 1

Installation Manual

Single Duct VAV Terminals

SD-IOM-1.0 6-15-02

Receiving Inspection

After unpacking the terminal, check it for

shipping damage. If any shipping

damage is found, report it immediately

to the delivering carrier. Store units in a

clean, dry location prior to installation.

Caution: Do not use the ow sensor,

connecting tubing, or damper shaft

linkage as a handle to lift o r mo ve

assembly. D amage to the ow

sensor or controls may result.

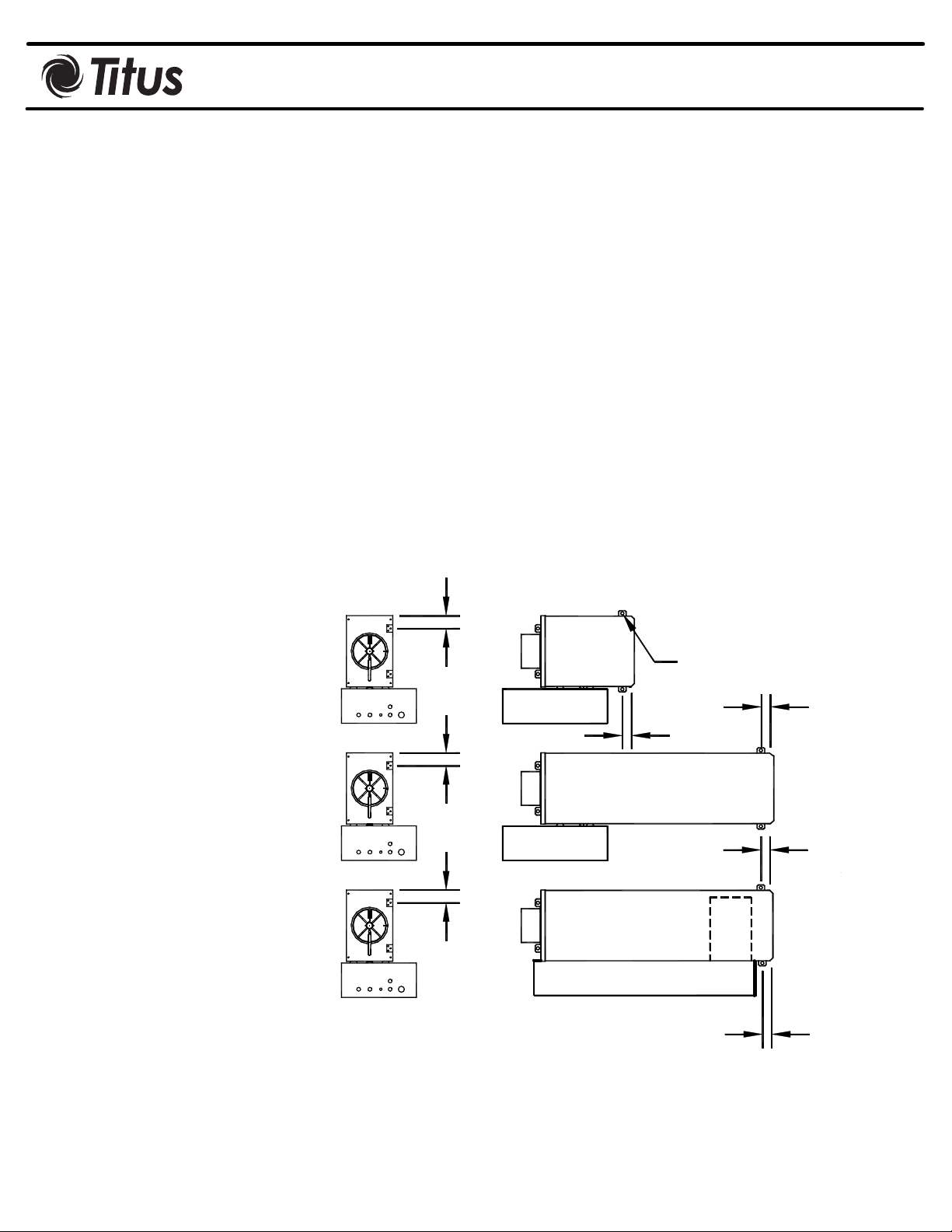

Supporting the Assembly

Many basic single duct terminals are

light enough to be supported by the duct

work itself. Where heavier access ory

modules, such as DDC controls, coils,

attenuators, or multiple outlets are

included, the terminal should be

supported directly. Straps screwe d

directly into the side of the terminal,

threaded rod through the opti onal

hanger brackets (see Figure 1), or the

method prescribed for the rect angular

duct on the job specications m ay be

used.

Important: If equipped with pneumatic

controls, the terminal must be mounted

right side up. It must be level wi thin

+ or - 10 degrees of hori zon

parallel to the air ow and at the right

angle of air ow. The control side of the

term inal i s l abeled wi th an arrow

indicating UP. The rst let te r of th e

model number (P) indicates pneumatic

controls. Most electronic units (A- analog

controls and D-digital controls) can be

installed in any orientation. Check with

the local TITUS representative for

verication.

tal, both

Duct Connections

Slip each inlet duct over the inlet collar

of the terminal. Fasten and seal the

connection by the method prescri bed by

the job specication.

The diameter o f t he i nl et duct "D " in

inches must be equal to the listed size

of the terminal; e.g. a duct that actually

measures 8 inches must be tted to a

size 8 terminal. The inlet collar of the

terminal is made 1/8 inch smaller than

listed size in order to t inside the duct

(see Figure 1).

Note: Do not insert duct work inside

the inlet collar of the assembly. Inlet

duct should be installed in accordance

with SMACNA guidelines.

2" TYP

2" TYP

W / ATTENUATOR

2" TYP

W / ELECTRIC HEAT

The outlet end of the terminal is

designed for use with slip and drive duct

connections. A rectangular duct the size

o f the t e r m inal o utlet should be

attached.

If single-point electronic velocity sensor

is used, 3 to 5 inlet duct diameters of

straight duct should be provided at the

terminal inlet; for specic guidelines,

consult the manufacturer’s installation

material. Sensor(s) may be attached to

the inside of control enclosu re fo r

protection during shipping. Sensor must

be i nse rte d in inlet duct of terminal

before operation. R em o ve any

protective plastic devices fr om ti p o f

sensor before installation.

Optional

Hanger Bracket

70738001

1 1/2" TYP

1 1/2" TYP

1 1/2" TYP

Figure 1. Single Duct Recommended Hanger Bracket Locations

1 1/2" TYP

Page 2

SD-IOM-2.0 6-15-02

Field Wiring

All field wiring must comply with the local codes and

with the National Electrical Code (ANSI/NFPA 70-1981).

Electrical, control and piping diagrams are shown on the

exterior labeling or on the diagram on the inside of

control enclosure cover. All electric heaters if provided

by TITUS are balanced by kW per stage. The installing

electrician should rotate these heater stages by phase

in order to help balance the building electric load.

Control Start-up, Operation

Detailed information regarding power, accessory and

communications connections, start-up and operating

procedures for the controls provided by TITUS are

available from your local TITUS representative. For

specific information on controls by other manufacturers,

contact that manufacturer’s local branch or dealer.

Important: Units with digital controllers may incorporate

specific communication addresses based on Building

Management Systems Architecture, and original

engineering drawings. Installing the terminal in a

different location than noted on unit label may result in

excessive start-up labor.

Replacement Parts

Description Part Number

Primary Damper Assembly

Size 4-5-6" 31171301

Size 7" 31171302

Size 8" 31171303

Size 9" 31171304

Size 10" 31171305

Size 12" 31171306

Size 14" 31171307

Size 16" 31171308

Damper Shaft Extension

Short Stub all sizes 70300301

Long Ext. Sz. 4-6, 14, 16 70300302

Long Ext. Sz. 7-12 70300303

Shaft Bearing - All 70324901

Control Tube

Red Stripe 1/4" O.D. 61510035

Green Stripe 1/4" O.D. 61510234

Red Stripe 3/8" O.D. 61510279

Green Stripe 3/8" O.D. 61510280

Yellow Stripe 1/4" O.D. 61510260

White Stripe 1/4" O.D. 61510261

Blue Stripe 1/4" O.D. 61510262

Calibration Instructions

For Pneumatic Controls, see PNEU-IOM: Operations

Manual for Pneumatic Controls.

For Analog Controls: Titus TA1, see ANA-IOM: Analog

Controller Calibration.

For Digital Controls: see control manufacturer's manual

Tees for sensor taps

Plastic 1/4" 42150011

Plastic 3/8" 42150020

Plugs for tees

1/4" 42160081

3/8" 10015601

AeroCrossTM Multipoint Velocity Sensors

Size 4" 3151520001

Size 5" 3151520001

Size 6" 3151520002

Size 7" 3151520003

Size 8" 3151520004

Size 9" 3151520005

Size 10" 3151520006

Size 12" 3151520007

Size 14" 3151520008

Size 16" 3151520009

Size 24" x 16" 3151520009

Loading...

Loading...