Titus Pneumatic User Manual

Installation Manual

TITUS I, II, and IIA Pneumatic Controls

Installation, Operation, and Maintenance Manual

Adjusting Minimum and Maximum Air Flow

PNEU-IOM-1.0 5-2-05

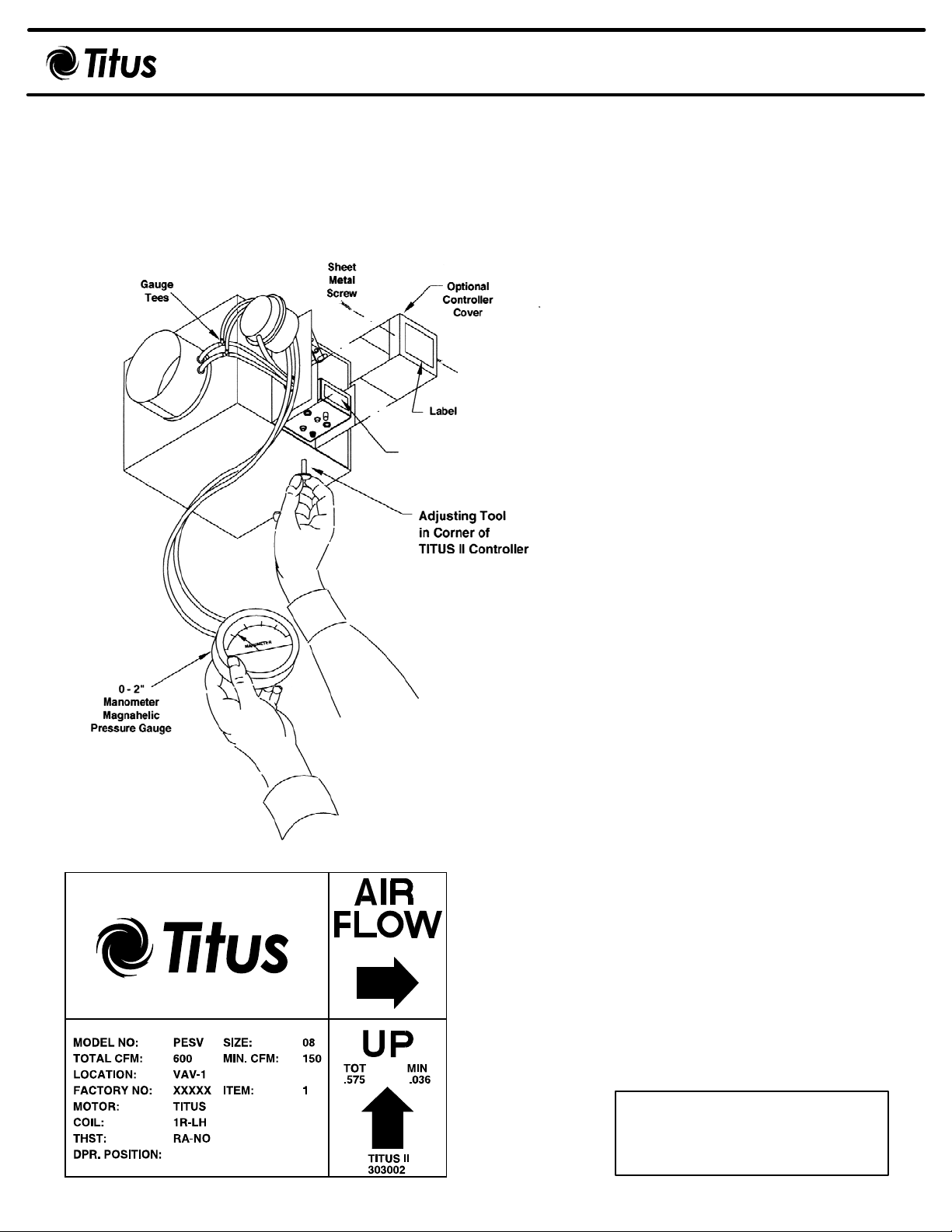

Airflow limits are printed on the label on the

optional controller cover (or the side of the

terminal) and the side of the controller (Figures

2 and 3).

If field adjustment becomes necessary, follow

the procedure outlined below.

AIR FLOW ADJUSTING PROCEDURES FOR

ALL CONTROLLERS

Figure 1. Adjusting Air Flow

(See Figure

3)

(Label, See Figure 3)

1. Remove the optional controller cover

(Figure 1).

2. The action of the controller must match the

settings printed on the labels (Figures 2

and 3).

a. TITUS I—Direct acting, normally

open, (control color—beige).

b. TITUS I—Reverse acting, normally

closed, (control color—gray).

c. TITUS IIA—Direct or reverse acting

thermostat. No adjustment necessary.

d. TITUS IIA—Verify setting on damper

dial is correct (N.O. or N.C.).

e. TITUS II—Check thermostat and

damper compatibility selectors, verify

that settings are as marked on the

label.

3 Remove the caps from the tees in the HI

and LO tubes (red and green stripe).

Connect a manometer gauge to both tees

(gauge with a 0 to 2 inch scale is

recommended).

4. Refer to the calibration curve for

terminal being serviced (Page 8). From the

curve read the differential pressure across

the sensor for the required airflow.

5. For instructions to readjust the control refer

to:

a. TITUS I See page 3.

b. TITUS IIA See page 4-5.

c. TITUS II See page 6-7.

d. For dual duct terminals, see document

PNEU-DD-IOM.

e. Quick-Check. See page 2.

6. After the flow rates are adjusted:

a. Replace the thermostat connection to

the controller.

b. Remove the gauge and replace the

caps on the tees.

c. Replace the optional controller cover.

the size

Figure 2. Unit Label

MODEL NO: PESV

TOTAL CFM: 600

TITUS II NO RA COOL

MIN. CFM: 160

FACTORY NO:XXXXX

Figure 3. Controller Label

SIZE: 08

VP: .410

VP: .030

ITEM: 1

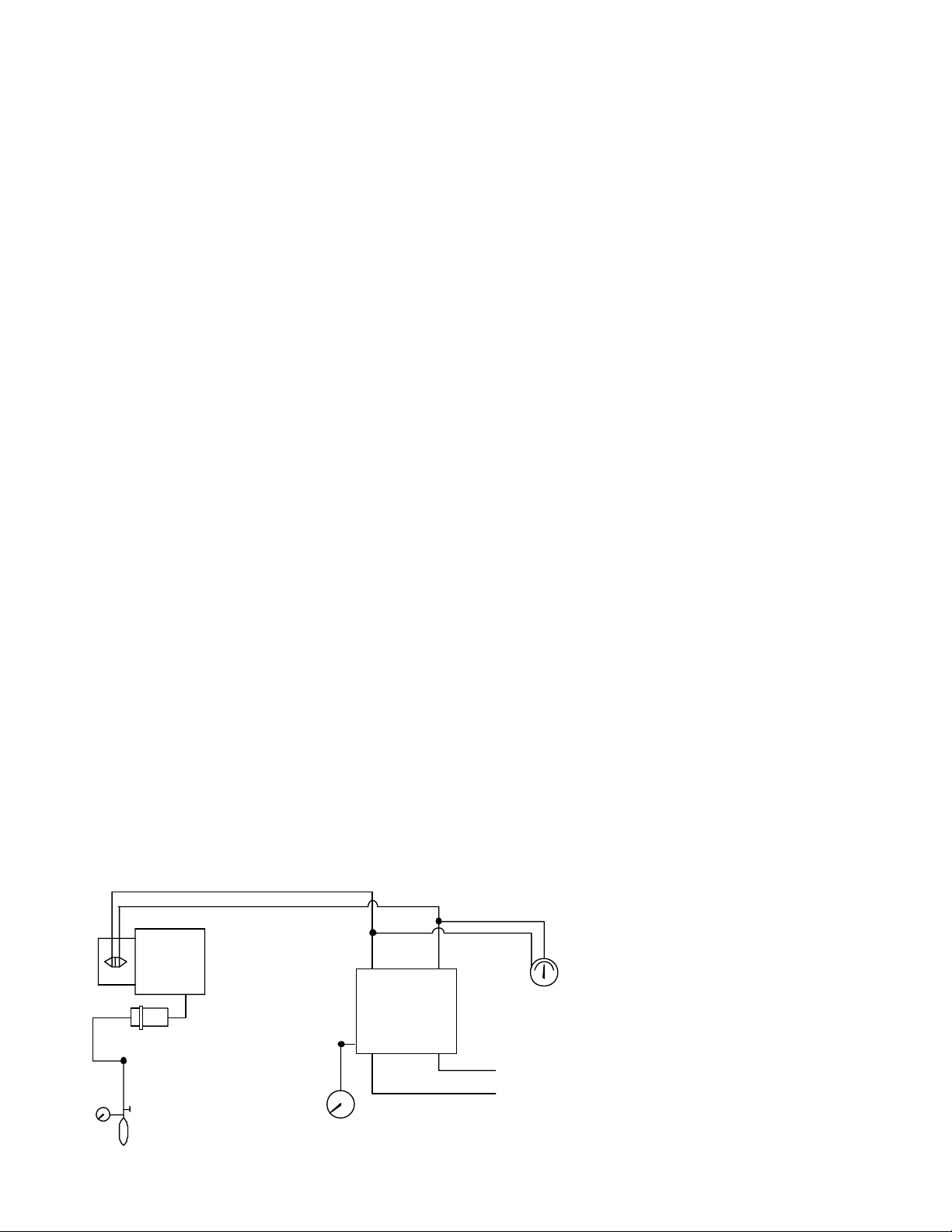

Quick-Check Procedure for TITUS I, II, and IIA Controllers

PNEU-IOM-2.0 5-2-05

Preparing for Calibration

1. Disconnect the actuator tube

(yellow stripe) from controller

Port B.

2. Connect squeeze bulb with 0 to 25

PSI gauge to the actuator.

3. Connect 0 to 25 PSI gauge to

controller Port B (Figure 4).

A. Direct Acting Cooling or Reverse

Acting Heating

1. Apply zero PSI to thermostat

Port T.

2. Read the differential pressure for

the desired Minimum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

3. Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

4. Adjust the LO knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

5. Read the differential pressure for

the desired Maximum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

6. Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

7. Adjust the HI knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

8. Remove gauges and reconnect

actuator to controller Port B.

NOTE: If the actuator fails to respond,

see Guide to Service Procedures.

RED

GR EEN

LOHI

ESV

SENSOR

YELLOW

YELLOW

GAUGE

0-25 PSI

SQUEEZE

BULB

5-10 PSI

ACTUATO R

Figure 4. Controller Setup

B. Reverse Acting Cooling or Direct

Acting Heating

For TITUS I Controllers

1. Apply zero PSI to thermostat

Port T.

2. Read the differential pressure for

the desired Maximum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

3. Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

4. Adjust the HI knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

5. Read the differential pressure for

the desired Minimum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

6. Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

7. Adjust the LO knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

8. Remove gauges and reconnect

actuator to controller Port B.

NOTE: If the actuator fails to respond,

see Guide to Service Procedures.

For TITUS II Controllers

1. Apply 15 to 25 PSI to thermostat

Port T.

2. Read the differential pressure for

the desired Minimum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

WHI TE

LO

BLUE

MAIN AIR

(15-25 PSI)

ROOM THERMOSTAT

(0-15 PSI)

HI

PNEUMATIC

CONTROLLER

B

TM

GAUGE

0-25 PSI

0-2" W.G.

MANOMETER

calibrated (Page 8).

3. Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

4. Adjust the LO knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

5. Read the differential pressure of the

desired Maximum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

6. Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

7. Adjust the HI knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

8. Remove gauges and reconnect

actuator to controller Port B.

NOTE: If the actuator fails to respond,

see Guide to Service Procedures.

For TITUS IIA Controllers

1. Apply zero PSI to thermostat Port T.

2. Read the differential pressure for

the desired Maximum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

3. Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

4. Adjust the LO knob on the face of

the controller until the gauge on

Port B 7.5 PSI ± 1.0 PSI.

5. Read the differential pressure for

the desired Minimum CFM from the

calibration curve corresponding to

the inlet size of the terminal being

calibrated (Page 8).

6. Pump the squeeze bulb until the

desired differential pressure is read

on the manometer gauge.

7. Adjust the HI knob on the face of

the controller until the gauge on

Port B reads 7.5 PSI ± 1.0 PSI.

8. Remove gauges and reconnect

actuator to controller Port B.

NOTE: If the actuator fails to respond

see Guide to Service Procedures.

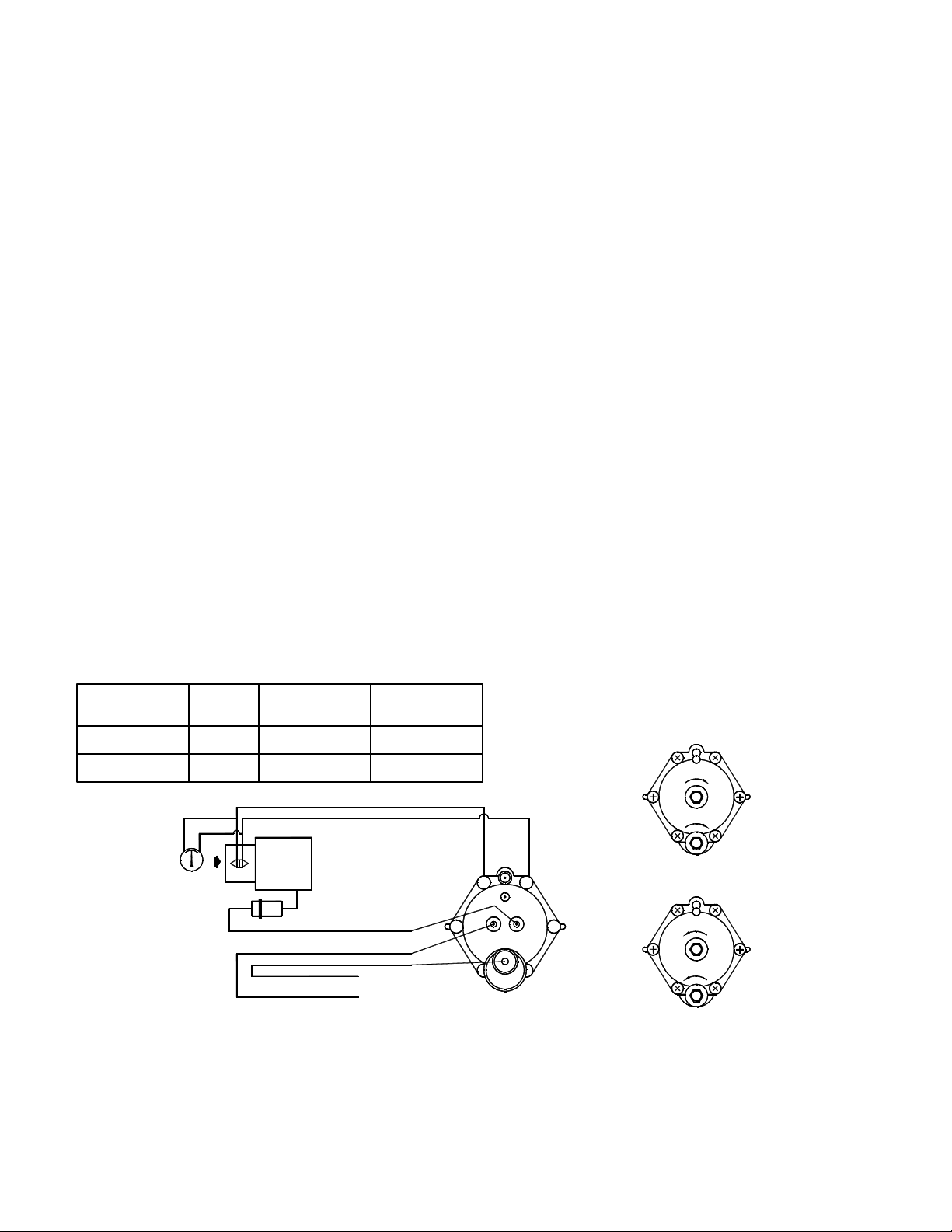

Calibration Procedure for TITUS I Controller

PNEU-IOM-3.0 5-2-05

A. Direct Acting (Beige). (N.O.)

b. Refer again to the calibration

curve (Page 8) to determine

1. Adjusting minimum air flow:

a. Apply zero PSI signal to Port T

on the controller.

b. If the minimum CFM equals

zero, the damper should

assume a closed

position (observe the indicator

on the end of the damper

the differential pressure

necessary for the required

maximum CFM.

c. Adjust the HI knob on the

controller until the manometer

gauge reads the required

differential pressure from the

curve.

shaft). If not, adjust LO knob on

the controller until the

compressed air drives the

NOTE: If actuator fails to respond,

see Guide to Service Procedure.

damper closed.

c. If a non-zero minimum CFM is

B. Reverse Acting (Gray). (N.C.)

required, read the differential

pressure for the desired CFM

from the calibration curve

corresponding to the inlet size

of the terminal being calibrated

(Page 8).

d. Adjust the LO knob until the

desired differential pressure is

read on the manometer gauge.

Allow several seconds for the

controls to react to system

pressure and stabilize.

1. Adjusting maximum air flow:

a. Apply zero PSI signal to Port T

on the controller.

b. Refer to calibration chart (Page

8). Read the differential

pressure for the desired

maximum CFM from the curve

corresponding to the inlet size

of the terminal being

calibrated.

c. Adjust the HI knob on the

controller until the desired

2. Adjusting maximum air flow:

differential pressure is read on

a. Apply 15-25 PSI signal to

Port T on the controller.

the manometer gauge. Allow

several seconds for the

controls to react to the system

and stabilize.

2. Adjusting minimum air flow:

a. Apply 15-25 PSI signal to

Port T on the controller.

b. If minimum CFM equals zero,

the damper should assume a

closed position (observe

indicator on the end of the

damper shaft). If not, adjust the

LO knob until the damper

closes.

c. If a non-zero minimum CFM is

required, read the differential

pressure for the required CFM

from the curve (Page 8).

d. Adjust the LO knob on the

controller until the manometer

gauge reads the desired

differential pressure from the

curve.

NOTE: If actuator fails to respond,

see Guide to Service Procedures.

Table 1.

Thermostat

Action

Color Low Port Signal

Direct Beige Y X

Reverse Grey X Y

HI

SENSOR

LO

ACTUATOR

YELLOW

BLUE

WHITE

ROOM THERMOSTAT

(0-15 PSI)

MAIN AIR (20-25 PSI)

H L

MAGNAHELIC

GAUGE

(0-20" WG)

Figure 5. Titus I Controller

High Port

Signal

RED

GREEN

LO

INCREASE

LOLO

HI

INCREASE

HI

M

LO

DIRECT ACTING CONTROLLER

X

Y

B

T

REVERSE ACTING CONTROLLER

HI

BEIGE

HI

INCREASE

LO

LO

INCREASE

HI

GRAY

Loading...

Loading...