Page 1

Installation Manual

Linear Slot Ceiling Diffusers

Aluminum • Modulinear

Models: ML-37 •

ML-38 •

ML-39 • 1” Slot • Supply

MLR-37 •

MLR-38 •

MLR-39 • 1” Slot • Return

1

/2” Slot • Supply

3

/4” Slot • Supply

1

/2” Slot • Return

3

/4” Slot • Return

D-ML-IM 2-28-13

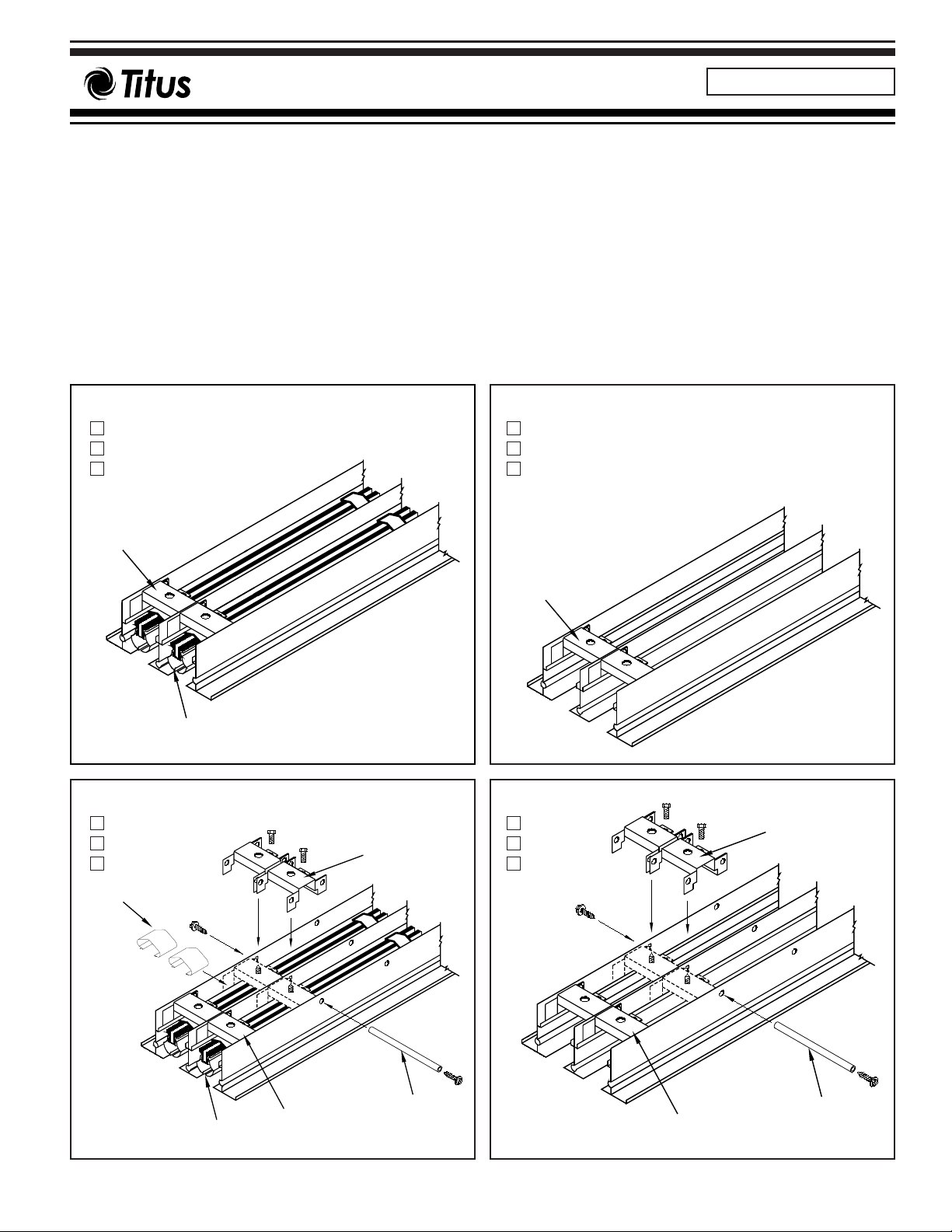

Factory Cut Supply

ML-37

ML-38

ML-39

Factory

Spacer

Pattern

Conrtoller

Factory Cut Supply

ML-37

ML-38

ML-39

Field

Spacer

Factory Cut Return

MLR-37

MLR-38

MLR-39

Factory

Spacer

Factory Cut Return

MLR-37

MLR-38

MLR-39

Field

Spacer

Spring Clips

Pattern

Conrtoller

Factory

Spacer

Tube

Dimensions are in inches.

Factory

Tube

Spacer

Y-?.0-S

Page 2

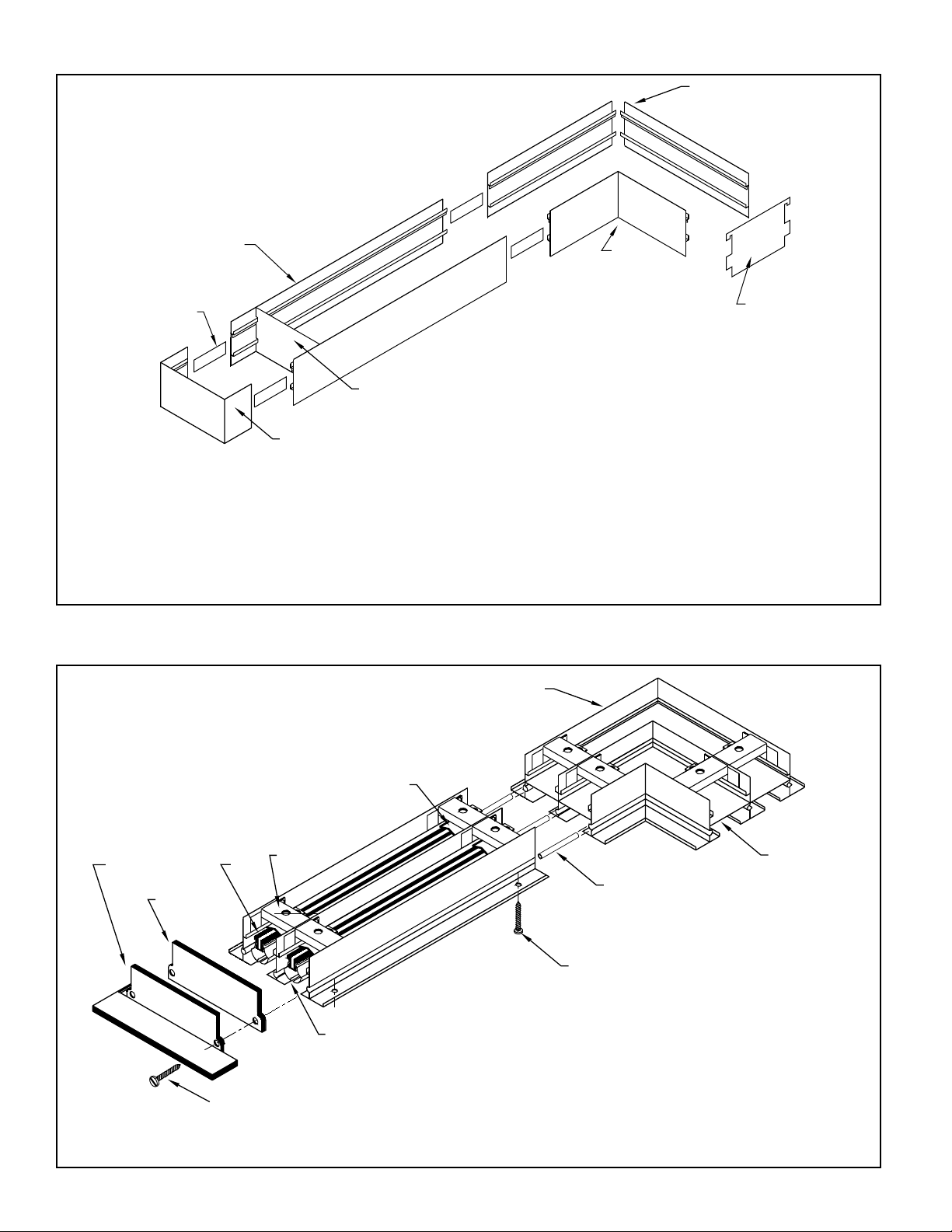

End Fabrication

(Factory Welded)

End Frame

Strip

Alignment

Rail

Side

Assembled

Gauge

Temporary

Corner

Field

Temporary

Gauge

Corner

Field Assembled

Diffuser Assembly Instructions

#8 x 1 1/4 Oval Head Screw

(Border Type 1A only)

(Welded)

Factory

Spacer

#6 x 1/2 SMS

Optional

End Cap

End Border

Optional

Blade

Bar

Support

Controller

Pattern

Spring Clip

Alignment

Pins

Corner

Mitered

Blank-Offs

Optional

1. Determine size of duct opening. Duct width depends upon model,

frame & border type and number of slot. See Duct Dimensions D’

table (Page 7). Duct length is as ordered.

2. First install end frames and field assembled corner pieces in ceiling

opening. Then cut side rails to length and install. Use alignment strips

furnished with frame parts to connect side rails, corners and end

frames to each other.

Note: When end borders are not to be used with diffuser, mounting

frame ends are not furnished.

3. Use removable gauges furnished with frame parts to ensure

proper fit of diffuser into mounting frame. Gauges snap into place

between side rails as shown above. If mounting frame is to be plastered into place, use wood blocks to stiffen side rails and maintain

correct inside dimensions.

1. Assemble diffuser with alignment pins as shown above. End

borders or caps, where ordered, are attached at factory.

2. Install diffuser in ceiling. See Hanger Bracket Mounting

Instructions (Page 4).

Note: Mounting frame is used only on

Frame & Border Types 3, 4, 6, 7A, 7B, 11.

2

Page 3

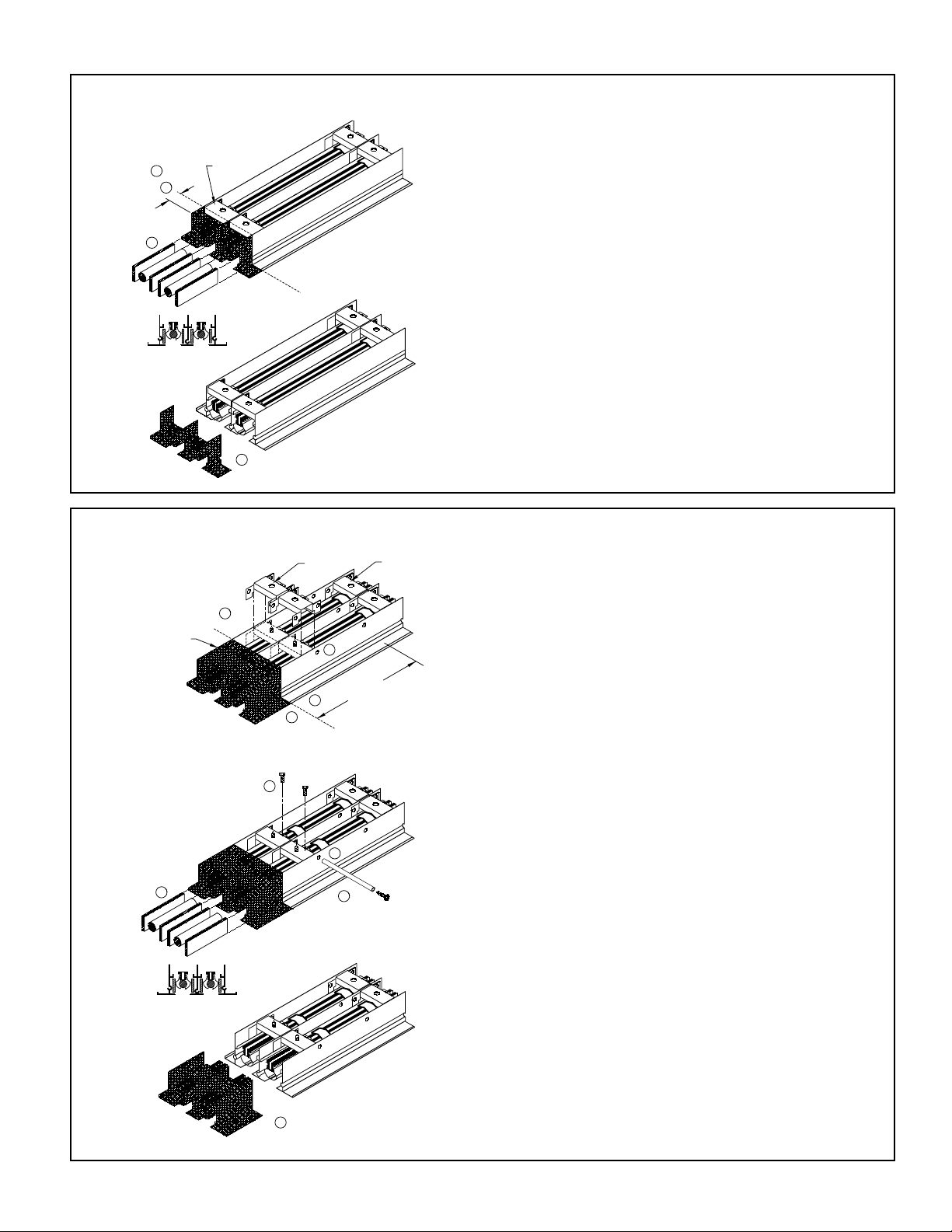

Field Cut Diffuser

3

Field Cutting Instructions

Factory Cut Diffuser (Trimming)

1. Message length of diffuser to be cut.

2. Mark ML or MLR for cut. You can cut as much as 3” on each

end for a maximum of 6”. Do not cut passed weld spacer.

3. Insert 1/2” dowel into center of each pattern controller. Insert

wood blocks or dowels on outside of pattern controller. Wood will

support pattern controller when cutting through diffuser.

4. Cut ML or MLR with circular saw. Recommended metal cutting saw blade:

14 x 152 teeth or

10 x 80 teeth

3/32 “ thickness.

Apply lubricant while cutting.

1. Message length of diffuser to be cut.

2. Mark MLF or MLRF for field cut. NOTE: If 6” or less is to be cut off,

use Trimming instructions shown above. To ensure proper support of

pattern controller deflector blades, there should be 7” or less between

end of diffuser and next spacer. If after marking their is more than 7”

between the field cut mark and the factory spacer, install field spacer.

If field spacer is required

3. Line up wholes on side of field spacer with predrilled holes in diffuser. Make sure field cut is between factory weld spacer and field

spacer.

4. Installed tube through diffuser field spacer. Next install screws in

both ends of the tube and tighten.

5. For MLF with pattern controllers, install screw through lower tab

hole of field spacer and tighten into threaded channel on blade support

bar.

6. For MLF with pattern controllers install additional spring clips on top

of blade support bar. Place clip 2” from edge or directly behind spacer

if space is in the way. See spring clip for detail, Page 4.

7. Insert 1/2”dowel in center of each controller. Insert wood blocks or

dowels on outside of pattern controller. Wood support pattern controller

when cutting through diffuser.

8.Cut MLF or MLRF with circular saw. Recommended metal cutting

saw blade:

14 x 152 teeth or

10 x 80 teeth

3/32” thickness

Apply lubricant while cutting.

Spacer

Factory

1

3

Spacer

Field

Spacer

Factory

1

Field Cut

use field spacer

If more than 7"

2

7

5

4

6

8

3" Max

3

2

1

Spacer

Factory

Do not cut

past spacer

Trim

4

Page 4

4

Spring Clip - Attaching to Field Cut Diffuser

1

2

To attach spring clip to field cut diffuser:

1. Start spring clip on side of blade support bar.

2. Use needle nose pliers or screwdriver to

expand spring clip until it hooks over other side of

blade support bar.

Hanger Bracket Mounting Instructions

1

1. Drill through top of blade support with

7/32” drill. Use hole in top of field spacer

as guide for drill.

Note: Blade supports are pre-drilled

under factory spacers at at end of

diffusers

2. Hole in blade support will be used as

clearance hole for inserting screw

through face of diffuser, upward into

hanger bracket.

Field Cut Diffuser Only - All Frame & Border Types

1. Insert #10 screw through face of

diffuser, through hole in blade support

and into foot of hanger bracket above

diffuser.

2. Attach hanger wires (by others).

1. Insert #10 screw through face of

diffuser, through hole in blade support.

Start screw in top of hanger bracket

above diffuser.

Note: See submittal Y-ML for duct

dimension D’.

2. Side diffuser up into duct until

hanger bracket ends are above hem of

duct.

3. Tighten screws to draw diffuser

border snug against ceiling.

Caution: Do not overtighten.

1. Insert #10 screw through face of

diffuser, through hole in blade support.

Start screw in top of hanger bracket

above diffuser.

2. Side diffuser up into mounting

frame until hanger bracket ends are

above channel on inside of mounting

frame.

3. Tighten screws to draw diffuser

border snug against ceiling.

Hanger Bracket

for Border

Types 9A, 9B, 12, 15

Hanger Bracket

for Border

Types 2A, 2B

Hanger Bracket

for Frame & Border

Types 3, 4, 6, 7A, 7B, 11

2

1

2

1

3

2

1

3

2

Page 5

Horizontal Left

5

Pattern Controller Blade Settings

Frame & Border Types, Dimensions

for #8 SMS (5/16 from Edge)

Countersunk Screw Holes

O’= D’+ 7/8

3/4

S

D’=Duct Size

1/8

1 1/8

1 3/4

Supply

Model ML-37 S=1/2”

ML-38 S=3/4”

ML-39 S=1”

Return

Model MLR-37 S=1/2”

MLR-38 S=3/4”

MLR-39 S=1”

Border Type 1A

With

• Flange Border

• Screw Mounting

Border Type 1B

With

• Flange Border

• Duct Mounting

Border Type 2A

Border Type 2B

Both with

• Flange Border

• Concealed Mounting

Type A O’

2A 1 1/8D’+ 3/

4

2B

7

/8D’+ 1/

4

† See Page 7

Horizontal Right

Dampered

Horizontal Left

Vertical Fully Dampered

Opposed

One Way Vertical & Horizontal

Opposed Unequal Flow

(One Slot Dampered)

S

S

S

S

D’=Duct Size

D’=Duct Size

3 5/16"

3/4

O’= D’+ 7/8

1 3/4

S

1/8

1 1/8

1/8" to 1/2"

3/4"

O’

S

1 3/4"

1/8"

A

Page 6

Frame & Border Types, Dimensions (Continued)

† See Page 7

Frame & Border Type 3

With

• Flush Border

• Concealed Mounting

Frame & Border Type 4

With

• Flange Border

• Concealed Mounting

Frame & Border Type 6

With

• Plaster & Tile Mounting Frame

• Flush Border

• Concealed Mounting

Frame & Border Type 7A

Frame & Border Type 7B

Both with

• Plaster & Tile Mounting Frame

• Flange Border

• Concealed Mounting

Border Type 9A

Border Type 9B

Both with

• Flange Border

• Ceiling Hangers

Border Type II

With

• Perimeter Plaster & Tile

Mounting Frame

• Flush Border

• Concealed Mounting

Border Type 12

With

• Spline Border

• Ceiling Hangers

Border Type 15

With

• Flush Border

• Ceiling Hangers

Border Type 16

With

• Curved Flange Border

• Concealed Mounting

• Equalizing Grid

Border Type 16 standard selections:

ML-38 only

1 slot: duct diameters 10, 14, 18, 22, 24”

2 slot: duct diameter 14, 18, 22, 24”

6

Type A O’

7A 1 1/8D’+ 3/

4

7B

7

/

8

D’+ 1/

4

Type A O’

9A

3

/4D’+ 3/

4

9B 1 7/8D’+ 1 3/

8

D’=Duct Size

3/4"

S

O’=D’minus1/8"

3/4"

D’+1 1/4

D’+1/2

D’=Duct Size

3/4

S

O’

1/8

A

1 7/8"

1 1/16

9/16

3 5/16"

1 15/16

3 5/16

D’=Duct Size

3/4

O’=D’+3/4

D’=Duct Size

3/4"

S

O’

3 5/16

1 15/16

1 1/8

1/8

S

D’+1 1/4

D’+1/2

D’=Duct Size

3/4

S

O’=D’-1/8

3/4

1/2

1

3 5/16

1 7/8

Hanger

3 1/8"

1 3/4"

1/16"

A

D’=Duct Size

3/4

O’=D’-1/8

3/4

3 5/16

1 7/8

1

1/2

S

3/4

1 3/16

1/4

D'=Duct Size

S

3/4

7/16

O'=D'-1/16

Hanger

3 1/8

1 3/4

7/16

1 1/16

D'=Duct Size

S

3/4

O'=D'-1/16

Hanger

3 1/8

1 3/4

7/16

DUCT BY OTHERS

1/2 X 1/2 X 1/2

ALUMINUM

EQUALIZING GRID

3/4

1 1/8

Page 7

D = Duct Size

O

C

End Fabrication

Overall Length for Various End Fabrications

Duct Dimensions D’ (Width) for Various Frame & Border Types

X End Border Y Open End Z End Cap

Frame

and/or

Border

Type

XXXYXZYYYZZZ

X-X X-Y X-Z Y-Y Y-Z Z-Z

CO CO CO CO CO CO

1A, 1B, 9B D - 1

3

/8D + 3/4D - 11/16D + 3/8D + 5/8D + 7/

16

D D D + 1/16D + 1/16D + 1/8D + 1/

8

2A, 4, 7A, 16 D - 1 3/8D + 3/4D - 11/16D + 3/8D + 5/8D + 7/

16

D D D + 1/16D + 1/16D + 1/8D + 1/

8

3, 6, 11 D - 1 3/

8

DD - 11/

16

DD + 5/8D + 1/

16

D D D + 1/16D + 1/16D + 1/8D + 1/

8

2B, 7B D - 1 3/8D + 1/4D - 11/16D + 1/8D + 5/8D + 3/

16

D D D + 1/16D + 1/16D + 1/8D + 1/

8

9A D - 1 3/

8

DD - 11/

16

DD + 5/8D + 1/

16

D D D + 1/16D + 1/16D + 1/8D + 1/

8

12, 15 D - 1 11/

16

DD - 5/

16

DD + 1/4D + 1/

16

D D D + 1/16D + 1/16D + 1/8D + 1/

8

Types 1A, 1B Types 2A, 2B, 4, 7A, 7B, 16 Types 3, 6, 11 Types 9A, 9B Types 12, 15

ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR ML/MLR

37 38 39 37 38 39 37 38 39 37 38 39 37 38 39

S =

1

/2S = 3/4S = 1 S = 1/2S = 3/4S = 1 S = 1/2S = 3/4S = 1 S = 1/2S = 3/4S = 1 S = 1/2S = 3/4S = 1

11 7/

8

2 1/

8

2 3/

8

22

1

/

4

2 1/

2

2 1/

8

2 3/

8

2 5/

8

1 3/

8

1 5/

8

1 7/

8

1 3/

8

1 5/

8

1 5/

8

23 1/

8

3 5/

8

4 1/

8

3 1/

4

3 3/

4

4 1/

4

3 3/

8

3 7/

8

4 3/

8

2 5/

8

3 1/

8

3 5/

8

2 5/

8

3 1/

8

3 5/

8

34 3/

8

5 1/

8

5 7/

8

4 1/

2

5 1/

4

64

5

/

8

5 3/

8

6 1/

8

3 7/

8

4 5/

8

5 3/

8

3 7/

8

4 5/

8

5 3/

8

45 5/

8

6 5/

8

7 5/

8

5 3/

4

6 3/

4

7 3/

4

5 7/

8

6 7/

8

7 7/

8

5 1/

8

6 1/

8

7 1/

8

5 1/

8

6 1/

8

7 1/

8

56 7/

8

8 1/

8

9 3/

8

78

1

/

4

9 1/

2

7 1/

8

8 3/

8

9 5/

8

6 3/

8

7 5/

8

8 7/

8

6 3/

8

7 5/

8

8 7/

8

68 1/

8

9 5/

8

11 1/88 1/

4

9 3/

4

11 1/

4

8 3/

8

9 7/811 3/

8

7 5/

8

9 1/810 5/87 5/

8

9 1/

8

10 5/

8

79 3/

8

11 1/812 7/89 1/

2

11 1/

4

13 9 5/

8

11 3/813 1/

8

8 7/

8

10 5/812 3/88 7/

8

10 5/812 3/

8

8 10 5/812 5/814 5/810 3/412 3/414 3/410 7/812 7/814 7/810 1/812 1/814 1/810 1/812 1/814 1/

8

7

No.

of

Slots

D = Duct Size

C

C

D = Duct Size

O

O

Page 8

Accessories (Optional) Check if provided

Optional Miter Corner

MLF-37 • 1/2” Slot

MLF-38 • 3/4” Slot

MLF-39 • 1” Slot

O

D = Duct Size

Optional Mitered Corner

MC-37 • 1/2” Slot

MC-38 • 3/4” Slot

MC-39 • 1” Slot

D = Duct Size

O

Check if provided

MC-37 • 1/2” Slot

MC-38 • 3/4” Slot

MC-39 • 1” Slot

No.

1A, 1B 2A, 4, 7A 2B, 7B 3, 6, 11 9A 9B 12, 15

of

Slots

O D O D O D O D O D O D O D

7

1, 2 12

3-8 24 7/1624 24 3/824 24 1/824 23 7/824 24 5/1624 24 11/1624 24 24

All dimensions are in inches.

/1612 12 3/812 12 1/812 11 7/812 12 5/1612 12 11/1612 12 12

Note:

• MP and MPI are available for all frames

and border types.

• Standard nominal length are 2, 3, 4 and

5 feet.

• Request Submittal Y-MP for details.

• Option MP-SP available with maximum

spread pattern.

Optional

MP-SP Design

Optional Blank-offs

BLKS • Cold Rolled Steel • Fit over Neck

BLKS • Vinyl • Fits in Slot

All rights reserved. No part of this work may be reproduced or transmitted in any form or any means, electronic or mechanical, including photocopying and recording, or by any information storage retrieval system without permission in writing from Air Distribution Technologies.

605 Shiloh Road • Plano, Texas 75074 • 972- 212- 4800

Part #719687-08

Loading...

Loading...