Page 1

Installation Manual

IOM-MBC-00 08-30-04

Mixing Box Control Systems

Installation, Operation, and Maintenance Manual

Contents Page

Introduction.............................................................1

General ....................................................................1

Safety .......................................................................1

Inspection................................................................1

Mixing Box Control Systems.................................2

Integrated Economizer System Operation.........................2

Diagnostic Equipment .......................................................2

Three-Position Control System.............................2

Three-position Damper Motor – M8405A ..........................2

Logic Module – W7459C ................................................... 4

Solid-State Enthalpy Sensor - C7400A .............................5

Verification and Troubleshooting.......................................6

Modulating Control System...................................8

Modulating Damper Motor – M7415A................................8

Logic Module – W7459A .................................................10

Solid-State Enthalpy Sensor - C7400A ...........................12

Air Temperature Sensor – C7150B .................................12

Verification and Troubleshooting.....................................15

Abbreviations........................................................15

Introduction

This document provides installation, operation, and

maintenance information for the mixing box control

systems.

General

The following information is to be used by the installer as a

guide. Since each installation is unique unto itself, only

general topics are covered. The order in which topics are

presented may not be required by the actual installation.

This guide is not intended to supersede or circumvent any

applicable national, state, or local codes.

The installation is to be performed only by individuals

whose experience meets or exceeds the requirements of

the work involved.

The installer MUST read the entire contents of this guide

and develop a thoroug

installation.

Due to a continuing program of product research, Titus

reserves the right to discontinue or change without notice,

any or all specifications or designs without incurring

obligations.

h understanding before beginning

Safety

Titus requests the following information be read and

understood prior to installation.

The installation and/or servicing of comfort conditioning

equipment can be hazardous due to system pressures

and electrical devices.

Caution: Only trained and qualified personnel

should perform service and/or i

Observe all precautions and warnings in the

product data or attached to the unit.

Follow all safety codes. Wear eye protection and gloves.

Have a fire extinguisher readily available.

Caution: Disconnect all power supplies before

accessing equipment.

Disconnecting more than one power supply may

be required to de-energize some equipment.

DANGER

ELECTRIC SHOCK CAN CAUSE DEATH.

Caution: Read these instructions carefully. Failure

to follow them could result in damage to the

product or cause a hazardous condition.

• Check the ratings given in the instructions and on the

product to ensure the product is suitable for your

application.

• Only trained and qualified personnel should perform

service and/or installation.

• After installation is complete, checkout product

operation as provided within this document.

nstallation.

Inspection

Thoroughly inspect all packages upon receipt. Ensure

carton(s) have not be

Inspect all contents for damage. If damage is found,

immediately file a claim with the delivering carrier.

en dropped, crushed or punctured.

605 Shiloh Road • Plano, Texas 75074 • 972- 212-4800

All rights reserved. No part of this work may be reproduced or transmitted in any form or any means, electronic or mechanical, including photocopying and recording, or by any information storage retrieval system without permission in writing from Air Distribution Technologies.

Page 2

Mixing Box Control Installation Manual

IOM-MBC-00 08-30-04

Mixing Box Control Systems

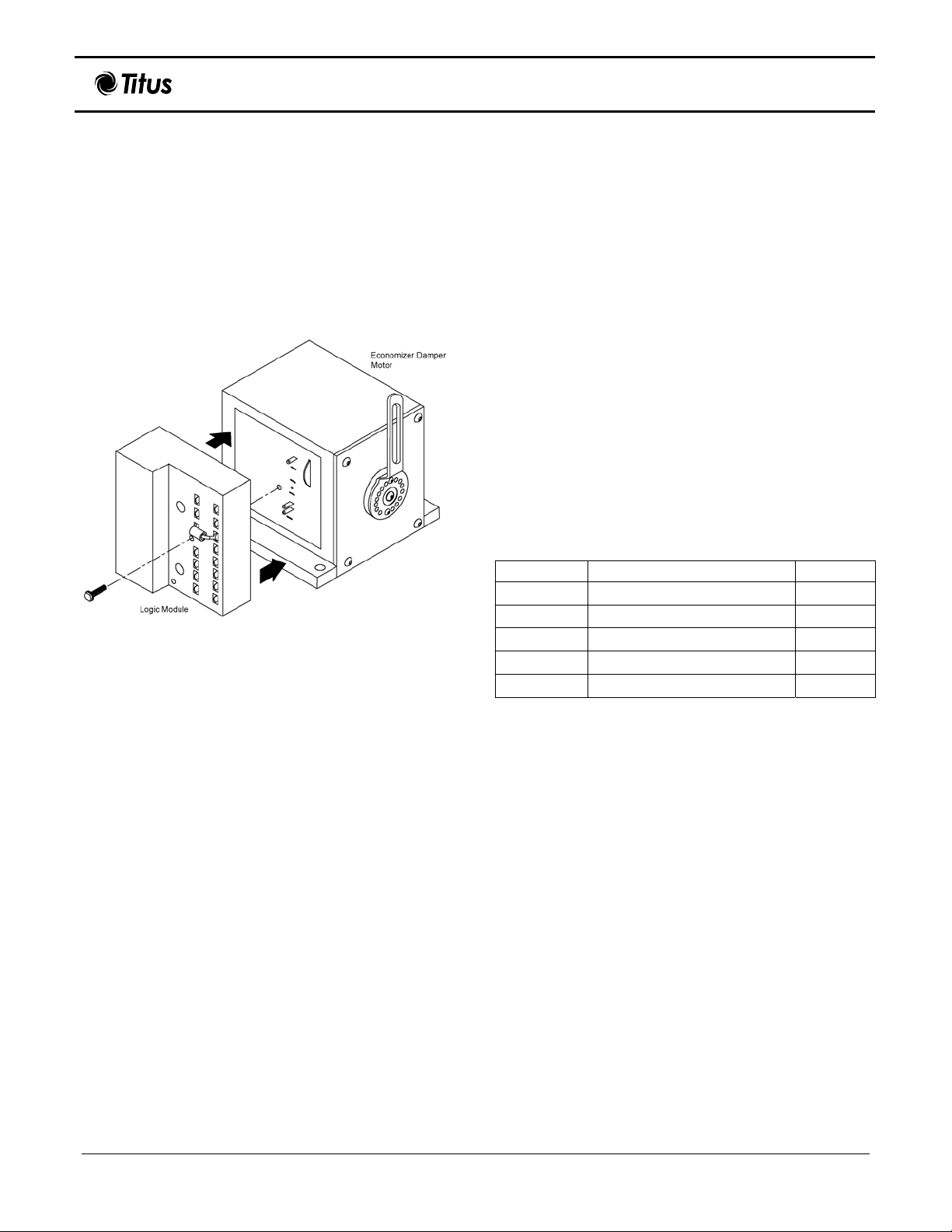

Titus offers two types of mixing box control system

packages, they are:

• Three-Position Control System.

• Modulating Control System.

The following segments discuss each system and its

components in detail, with the exception of the ball joints

and pushrods. The setup shown in Figure 1 is logic

module connected to a damper motor in a dedicated

arrangement.

Figure 1. Dedicated Logic Module and Damper Motor

Arrangement

Integrated Economizer System Operation

The purpose of an economizer is to use outdoor air for

cooling, whenever possible, to reduce compressor

operation. An economizer control system includes a

cooling thermostat and a solid-state enthalpy changeover

sensor. This allows it to respond to both dry bulb

temperature and humidity, allowing the use of outdoor air

temperatures for free cooling when humidity is low.

The

economizer functions as a first stage of cooling and

provides maximum economy during the cooling cycle. The

economizer is automatically locked out during heating by

holding the outdoor air damper at the minimum position

setting.

On a call for cooling by the space thermostat, the system

operates as follows:

When the sensed enthalpy of the outdoor air is below the

set point, the outdoor air damper is modulated open (and

return air damper is modulated closed) to maintain

between 50 and 56º Fahrenheit at the

sensor. The second stage cooling uses the mechanical

cooling during the economizer operation.

mixed/discharge air

When the sensed enthalpy of the outdoor air is above the

set point, the outdoor air damper closes to its minimum

position. On a call for cooling from the space thermostat

brings on mechanical cooling.

During the unoccupied period, the damper motor will

spring return the outdoor air damper to full closed position.

Diagnostic Equipment

In addition to either control system package, the following

diagnostic equipment (supplied

beneficial to the installation, verification, and/or

troubleshooting processes.

• 1.2k ohm checkout resistor

• Remote minimum position potentiometer

• Minimum position potentiometer

• Remote bulb control for low ambient lockout

• Board for panel mounting logic module

by others) may be

Three-Position Control System

Components list of the three-position control system is as

follows:

Table 1. Package Contents

Part Code Description Quantity

M8405A Three-position Damper Motor 1

W7459C Logic module 1

C7400A Solid state enthalpy sensor 1

27518 Ball joints 2

27520E 18-inch pushrods 2

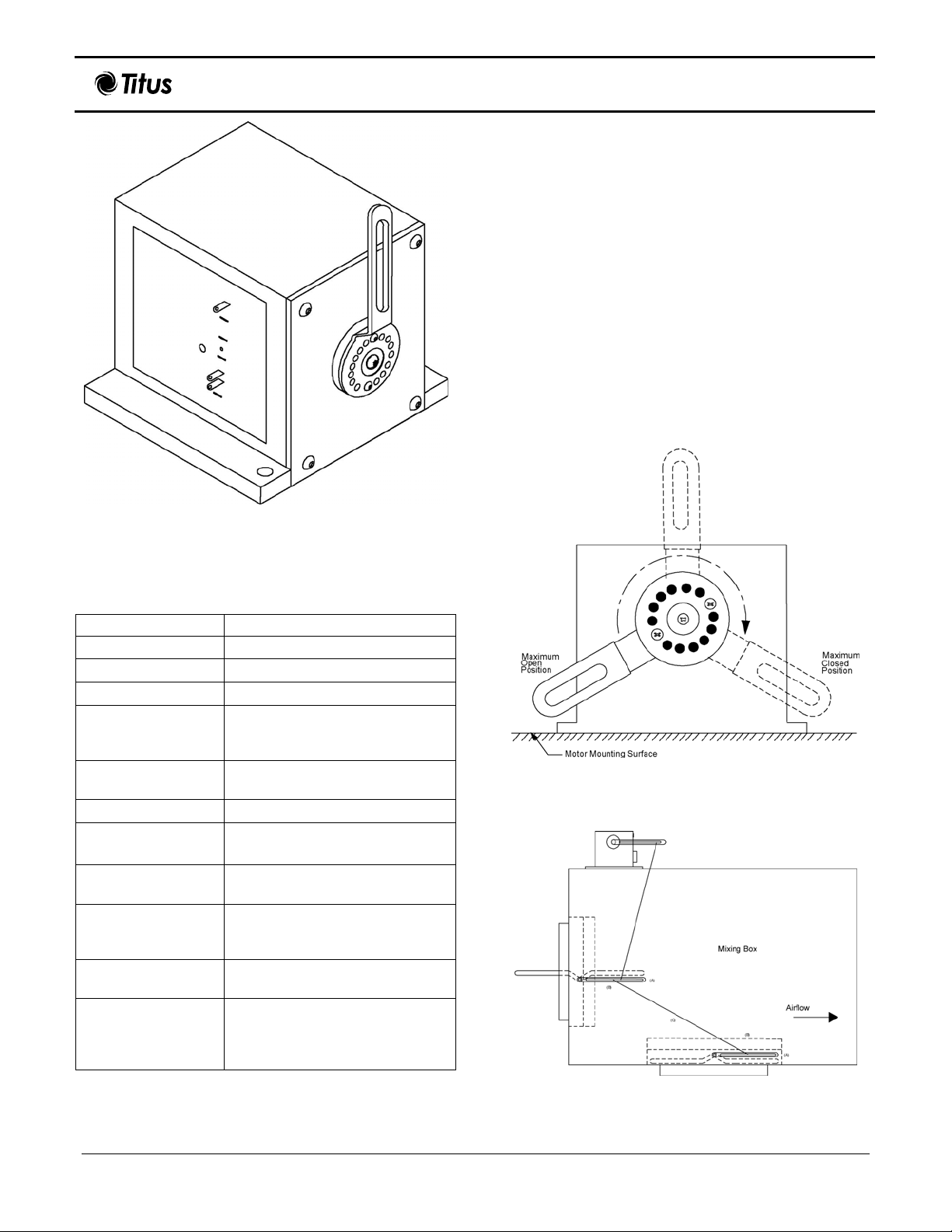

Three-position Damper Motor – M8405A

Spring-return, 25-inch/pound damper motor (actuator)

provides three-position control of economizer systems or

ventilation dampers. Spring returns motor shaft to normal

position on power interruption. The following figure depicts

a damper motor.

Note: Damper motors may be referred to as

actuators.

2 of 15

Page 3

Mixing Box Control Installation Manual

Figure 2. Three-Position Damper Motor

IOM-MBC-00 08-30-04

Installation

When planning the installation, allow ample clearance for

maintenance and service. Ensure the location is protected

from rain and snow. The following steps provide basic

instructions to install a damper motor.

Position damper motor on mixing box where

1.

mounting is desired.

Note: Motor placement may restrict crank arm

rotation. Position motor to allow widest range

of crank arm rotation, see Figure 3.

Use the damper motor holes as guides and

2.

drill four holes into mixing box.

Secure the damper motor to mixing box using

3.

four screws. Figure 4 shows a typical damper

motor to mixing box installation.

Operation Ratings

The following table highlights operational information.

Table 2. Operating Ratings

Operation Rating

Synchronous Normally closed

Power VA 7

Timing (sec.) 90

Stroke

Application

Timing 90 seconds

Voltage and

frequency

Maximum operating

torque

Ambient temperature

rating

Shaft

Approximate

dimensions

Component recognized by Underwriters Laboratories, Inc.

90 degrees, opens counterclockwise as viewed from power

end.

Three-position, with adjustable

minimum position control

24 Vac, 50/60 hertz

25-inch/pound (2.8N-M)

-25° to +125° Fahrenheit (-32° to

+52° Celsius) at 25 percent duty

cycle.

Single-ended drive with crank arm

supplied.

4.5 inches (114 millimeter) high; 5

inches (127 millimeters) wide, and

5.188 inches (132 millimeter)

deep.

Note: Possible 90 degree arm rotation, based on

motor positioning.

Figure 3. Crank Arm Rotation Limits

Figure 4. Typical Damper Motor to Mixing Box

Installation

3 of 15

Page 4

Mixing Box Control Installation Manual

IOM-MBC-00 08-30-04

Settings and Adjustments

Connect 24 Vac to motor at terminals T and X

1.

(Terminal D is not connected).

Adjust thumbwheel on motor for desired minimum

2.

position.

Operation

A single-pole, single-throw (SPST) low-voltage controller

is used to control the three-position Damper Motor.

• Fully open – when controller provides 24 Vac to D

and T, motor is energized and drives fully open.

• Fully closed – when power is removed from

terminals T and D, and the motor spring returns to the

fully closed position.

• Mid-position – when controller provides 24 Vac to T

and X, motor is energized and drives to the adjustable

mid-position (minimum position)

An adjustable minimum position can be reached from

either the fully closed or fully open position. From fully

closed, the motor drives open to the minimum position;

from fully open the motor spring returns to the minimum

position.

.

Verification

Operate the motor through its complete open-close stroke.

If necessary, release one of the previously tightened

linkage connections to prevent damage. Check for proper

operation, ensuring the linkage does not bind and the

motor travels smoothly throughout its fully open and full

closed positions. This motor checkout ensures:

1. The motor operates the load.

2. The motor responds properly to the controller.

There is no binding of the linkage or

3.

at any point of travel.

If motor does not operate properly, check for proper

voltage or mechanical binding in linkage or damper.

If questions arise regarding this product, contact your

distributor or Titus representative.

motor stalling

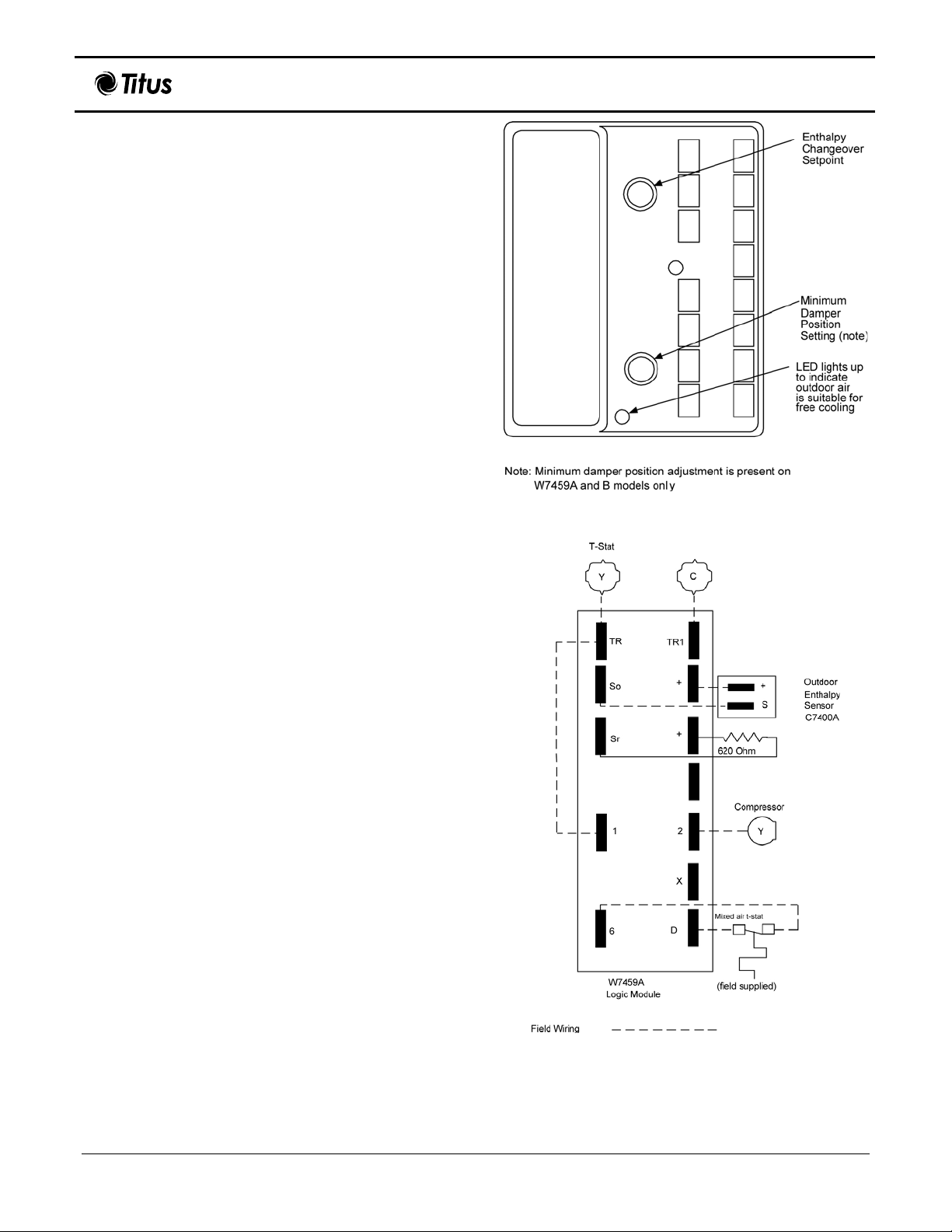

Logic Module – W7459C

The logic module provides control for the damper motor.

Use the enthalpy set point of the logic module to select air

temperature and humidity suitable for free cooling. Figure

5 depicts the logic module.

Remote Minimum Position Control

Remote control of the outdoor air dampers can be used, if

temporary additional ventilation is required. The

potentiometer in the logic module – W7459 controls the

minimum position of the dampers.

Operation

Table 4 provides operational information.

Figure 5. Three-Position Logic Module

Table 4. Operational Ratings

Operation Rating

Operating ambient

temperature

Humidity

Input voltage

Relay contact rating

at 24 Vac

Application

Discharge air

temperature input

Minimum position

potentiometer

adjustment

Terminals for remote

minimum damper

position

Output relays 2 single-pole, dual-throw (spdt)

25º Fahrenheit t

Fahrenheit (32 to +52º Celsius)

5 to 95 percent relative humidity

24 Vac, 50/60 hertz

1.5 A run, 3.5 A inrush

Use with three-position Damper

Motor - M8405A

Single-pole, single-throw (spst)

None

(Minimum position adjustment is

built into Damper Motor M8405)

None

to +125º

p

4 of 15

Page 5

Mixing Box Control Installation Manual

Installation

The logic module mounts on the side of the three-position

damper motor (M8405A). When planning the installation,

allow enough clearance for maintenance and service.

Ensure the location is protected from rain and snow.

1. Align logic module to prongs of the Damper Motor.

2. Press logic module and Damper Motor together.

Secure logic module to damper motor using the

3.

supplied mounting screw.

Settings and Adjustments

The minimum position potentiometer keeps the outdoor air

damper from closing completely during system operation

to provide ventilation. Figure 6 shows potentiometer

adjustment slots. Use a screw

Connect 24 Vac at terminals TR and X (D is not

1.

connected).

Adjust thumbwheel on motor for desired minimum

2.

position.

Wiring

Disconnect power supply before connecting wiring to

prevent electrical shock or equipment. All wiring must

comply with applicable local codes, ordinances, and

regulations. See Figure 7 for wiring diagram depicting the

three-position control system.

driver to make adjustments.

IOM-MBC-00 08-30-04

Figure 6. Enthalpy Set Point Potentiometer (Three-

Position System)

Solid-State Enthalpy Sensor - C7400A

The solid-state enthalpy sensor – the C7400A has a solidstate element that senses temperature and humidity. It

combines solid-state enthalpy changeover control,

minimum damper position potentiometer and compressor

staging relays.

The solid-state enthalpy sensor – C7400A when

the Solid State Economizer Logic Module – W7459 and

three-position damper motor – M8405 helps to position

outdoor and return air dampers in economizer systems.

Figure 8 depicts the solid-state enthalpy sensor.

Use for enthalpy control as follows:

• One sensor in outdoor air for single enthalpy control.

• Two sensors, one in return air and one in outdoor air,

for differential enthalpy control. Contact a Titus

representative, if specifications call for differential

enthalpy control.

The enthalpy set point of the logic module selects the air

temperature and humidity suitable for free cooling.

Operational Ratings

Table 6 highlights operational ratings.

used with

Figure 7. Three-position Control System Circuit

5 of 15

Page 6

Mixing Box Control Installation Manual

Verification and Troubleshooting

The following table provides the actions and responses to

verify the installation of W7459C logic module installed on

an M8405 Actuator.

DISCONNECT POWER SUPPLY BEFORE

CONNECTING WIRING TO PREVENT ELECTRICAL

SHOCK OR EQUIPMENT DAMAGE

Caution: Exercise care when adjusting the

enthalpy changeover and minimum damper

position control. Use a small screwdriver for

these adjustments. Excessive force may damage

the controls.

IOM-MBC-00 08-30-04

DANGER

Figure 8. Solid-State Enthalpy Sensor

Table 6. Operating Ratings

Specific Description

Case

Temperature Sensing

Duct-mounted

Thermistor

Element:

Output Signal

4 to 20 mA current signal;

increases from 4 to 20 mA as

enthalpy decreases

Operating ambient

temperature

Shipping temperature

rating:

Maximum power

-40 to 125° Fahrenheit (-40 to

+52° Celsius)

-40 to 150° Fahrenheit (-40 to

+66° Celsius)

0.45 Vac

consumption

Maximum supply

18 to 24 Vdc

voltage

Electrical connection

Two ¼-inch quick-connect

terminals

Listed by Underwriters Laboratories Inc.

Location and Mounting

The sensor mounts in any position up to 200 feet (61

meters) away from the logic module – W7459C and may

be used for the following operational circumstances.

• Proportional damper control: Attach the logic

module to the Damper Motor’s side.

• Outdoor air sensing: Mount in any orientation where

it is exposed to freely circulating air, but is protected

from rain, snow, and direct sunlight.

• Return air sensing: For differential enthalpy control,

a second C7400A enthalpy sensor can be connected

to the W7459 and mounted in the return air duct.

Note: Contact your Titus representative if

specificat

ions call for differential enthalpy control.

Perform verification and troubleshooting steps in

order.

Table 7. Three-Position Control Verification

and Troubleshooting

esnopseR noitcA

A. Power

Disconnect power at

1.

terminals TR and TR1.

Disconnect wires from

2.

terminals 6, X and D.

3. Jumper TR and 1.

4. Jumper 6 and D.

If connected, remove

5.

C7400A enthalpy sensor

from terminals S

and +.

O

Factory-installed 620-ohm

resistor should be

connected to S

Apply 24 Vac power to

6.

terminals TR and TR1.

and +.

R

LED should be off.

Motor is in closed

position.

Disconnect factory-

7.

installed 620-ohm resistor

from terminals S

B. Enthalpy Simulation

To simulate high and low

1.

and +.

R

LED should be on.

Motor drives toward

open.

enthalpy (single enthalpy

sensor)).

Reconnect factory-

2.

installed 620-ohm resistor

across terminals S

Connect 1.2k ohm

3.

and +.

R

checkout resistor across

terminals S

and +.

O

6 of 15

Page 7

Turn enthalpy set

4.

potentiometer to “A”.

Turn enthalpy set point

5.

potentiometer to “D”.

Disconnect the 1.2k ohm

6.

checkout resistor.

C. Sensor

Reconnect the + lead of

1.

outdoor enthalpy sensor

to the + terminal of

W7459.

Connect a DC multi-meter

2.

or voltmeter between

terminals S

of the W7459

O

and terminal S of the

enthalpy sensor. (Positive

meter lead to terminal S of

enthalpy sensor.)

If using differential

3.

enthalpy, the return air

enthalpy sensor may be

checked by connecting a

DC multi-meter or

voltmeter between

terminal S

of the W7459

R

and terminal S of the

return air enthalpy sensor.

(Position meter lead to

terminal S of return air

enthalpy sensor.

Mixing Box Control Installation Manual

esnopseR noitcA

LED should be on,

indicating low enthalpy.

Motor drives toward

open.

LED should be off,

indicating high enthalpy.

Motor spring returns to

fully closed position.

Multi-meter or voltmeter

should indicate between

3 and 25 mA, if sensor

is operating properly.

If multi-meter or

voltmeter indicates

zero, the sensor may be

wired backwards.

Multi-meter or voltmeter

should indicate between

3 and 25 mA, if sensor

is operating properly.

If multi-meter or

voltmeter indicates

zero, the sensor may be

wired backwards.

IOM-MBC-00 08-30-04

7 of 15

Page 8

Mixing Box Control Installation Manual

Modulating Control System

Package contents of the modulating (enthalpy) system are

as follows:

Table 8. Modulating (Enthalpy) System Package

Part Code Description Quantity

M7415A Modulating damper motor 1

W7459A Logic module 1

C7400A Solid state enthalpy sensor 1

C7150B Sensor 1

27518 Ball joints 2

27520E 18-inch pushrods 2

IOM-MBC-00 08-30-04

Modulating Damper Motor – M7415A

Spring-return, 25-inch/pound damper motor provides

modulating control of economizer systems or ventilation

dampers. Spring returns motor shaft to normal position on

power interruption. Figure 9 depicts a damper motor.

Operation

Tables 9 and 10 provide operating ratings and motor

performance respectively.

A single Damper Motor – M7415 accepts the thermistor

sensor input from the air temperature sensor, mounted in

the discharge or mixed air duct. See Figure 10.

During the occupied period, on a call for cooling, when the

outdoor air temperature is low, the damper motor – M7415

modulates to maintain between 50 and 56° Fahrenheit at

the thermistor.

If the mixed or discharge air temperature is above 56°

Fahrenheit, the damper motor opens to admit additional

outdoor air until the temperature returns to between 50

and 56° Fahrenheit. If the mixed or discharge air

temperature is below 50° Fahrenheit, the damper motor

modulates close, shutting the outdoor air damper until the

temperature returns to between 50 and 56° Fahrenheit.

During the occupied period, the damper will not close past

the minimum position.

If the fully open damper motor cannot satisfy the space

demand, mechanical cooling is sequenced on.

During the unoccupied period, the damper motor overrides

the minimum position setting and drives fully closed. On a

loss of power,

position.

When in heating operation, outdoor air temperature or

enthalpy conditions are high, economizer operation is

locked out, and the damper motor is held at minimum

position.

the damper spring returns to a fully closed

Figure 9. Fully Modulating Damper Motor

Table 9. Operation Ratings

Specification Performance

Stroke

Timing 90 seconds

Voltage and

frequency

Maximum operating

torque

Ambient temperature

rating

Synchronous Normally closed.

Power VA 8

Application

Shaft

Approximate

dimensions

Component recognized by Underwriters Laboratories, Inc.

Fixed 90 degrees, opens counterclockwise as viewed from power

end.

24 Vac, 50/60 hertz

25 inch/pound (2.8N-M)

-25° to +125° Fahrenheit (-32° to

+52° Celsius) at 25 percent duty

cycle.

Modulating, use with thermistor

mixed-air or discharge sensor

(C7150B)

Single-ended drive with crank arm

supplied.

4.5 inches (114 millimeter) high; 5

inches (127 millimeters) wide, and

5.188 inches (132 millimeter)

deep.

8 of 15

Page 9

Mixing Box Control Installation Manual

Figure 10. Economizer Control System Schematic

IOM-MBC-00 08-30-04

Installation

When planning the installation, allow ample clearance for

maintenance and service. Ensure the location is protected

from rain and snow. The following steps provide basic

instructions to install a damper motor.

Position damper motor on mixing box where

1.

mounting is desired. Figure 11 shows possible crank

arm rotation.

Use the damper motor holes as guides and drill four

2.

holes into mixing box.

Secure the damper motor to mixing box using four

3.

screws. Figure 12 shows a typical damper motor to

mixing box installation.

Settings and Adjustments

Once installed, review system requirements and settings.

Then make necessary adjustments using the following

information.

1. Run motor to fully closed position and disconnect 24

Vac from terminals TR and TR1.

2. Connect minimum position potentiometer to terminals P

and P1 (T and T1 are disconnected).

3. Reconnect 24 Vac to terminals TR and TR1 and adjust

potentiometer for desired minimum position.

Note: Possible 90 degree arm rotation, based on motor

positioning.

Figure 11. Crank Arm Rotation Limits

4. When an actuator mounted minimum position

potentiometer is used and a remote potentiometer is

NOT connected in series, utilize jumper terminals P

and P1 on the minimum position potentiometer.

9 of 15

Page 10

Mixing Box Control Installation Manual

IOM-MBC-00 08-30-04

Figure 12. Typical Damper Motor to Mixing Box

Installation

Verification

Operate the motor through its complete open-close stroke.

If necessary, release one of the previously tightened

linkage connections to prevent damage. Check for proper

operation, making sure that the linkage does not bind and

that the motor travels smoothly throughout its fully open

and fully closed positions. This motor checkout ensures:

• The motor operates the load.

• The motor responds properly to the controller.

• There is no binding of the linkage or motor stalling at

any point of travel.

If motor does not operate properly, check for proper

voltage or mechanical binding in linkage or damper.

If questions arise regarding this product, contact your

distributor or Titus representative.

Logic Module – W7459A

The logic module provides the operation control to the

Damper Motor. Use the enthalpy set point of the logic

module to select air temperature and humidity suitable for

free cooling. Figure 13 depicts the logic module.

Remote Minimum Position Control

Remote control of the outdoor air dampers is desirable

when temporary additional ventilation may be required.

The potentiometer in the logic module controls the

minimum position of the dampers.

Operation

Tables 11 and 12 provide operating rating and specific

information.

Figure 13. Fully Modulating Logic Module

Table 11. Operational Ratings

gnitaR noitarepO

Operating ambient

temperature

Humidity

Input voltage 24 Vac, 50/60 hertz

Relay contact rating at 24 Vac 1.5 A run, 3.5 A inrush

Discharge air temperature

input

Minimum position

potentiometer adjustment

Terminals for remote

minimum damper position

Output relays

Application To be used with

25º Fahrenheit tp to

+125º Fahrenheit (32 to

+52º Celsius)

5 to 95 percent relative

humidity

Single-pole, single-throw

(spst)

None

(Minimum position

adjustment is built into

damper motor M7415A)

None

2 Single-pole, doublethrow (spdt)

• Solid-state enthalphy

sensor C7400A

• Modulating damper

motor M7415A

Installation

The logic module mounts on the side of the Modulating

Damper Motor (W7415A). When planning the installation,

allow ample clearance for maintenance and service.

Ensure the location is protected from rain and snow.

Align logic module to prongs of the Damper Motor

1.

and press module and motor together.

Secure logic module to damper motor using the

2.

supplied mounting screw.

10 of 15

Page 11

Mixing Box Control Installation Manual

IOM-MBC-00 08-30-04

Settings and Adjustments

The face of the logic module has two potentiometers with

slots for adjustment. Use a slotted screwdriver to adjust

the potentiometers. Figures 14 and 15 show potentiometer

adjustment slots.

Minimum Damper Position

The minimum position potentiometer keeps the outdoor air

damper from closing completely during system operation

to provide ventilation.

Ensure the factory-installed jumper is in place

1.

across terminals P and P1 (T and T1 are

disconnected).

If remote control of dampers is desired, connect the

2.

remote potentiometer and turn it fully clockwise

before adjusting the minimum position. See Figure

14.

Connect 24 Vac at terminal TR and TR1 and adjust

3.

the potentiometer on the logic module face with a

screwdriver for desired minimum position.

Wiring

Disconnect power supply before connecting wiring to

prevent electrical shock or equipment. All wiring must

comply with applicable local codes, ordinances, and

regulations. Figure 16 shows a modulating circuit.

Figure 14. Enthalpy Set Point Potentiometer Location

Figure 15. Meter Location for Verification and

Troubleshooting

11 of 15

Figure 16. Modulating Control Circuit

Page 12

Mixing Box Control Installation Manual

Solid-State Enthalpy Sensor - C7400A

Use the Solid State Enthalpy Sensor – C7400A and Solid

State Logic Module W7459A with Modulating Damper

Motor - M7415 to proportion outdoor and return air

dampers in economizer systems.

C7400A solid-state element senses temperature and

humidity. Sensor mounts in any position up to 200 feet (61

meters) away from the W7459. Use one sensor in outdoor

air for single enthalpy control. Use two sensors, one in

return air and one in outdoor air, for differential enthalpy

control. W7459A attaches to the damper motor’s side for

proportional control of damper. Combines solid-state

entha

lpy changeover control, minimum damper position

potentiometer and compressor staging relays. To select

air temperature and humidity suitable for free cooling, use

enthalpy set point on W7459.

Table 13 and 14 list application operational specifics,

respectively. Figure 17 depicts a solid-state enthalpy

sensor.

Table 13. Application Specifics

tnemmoC noitacilppA

Sensor Used With C7400A

For use with actuator M7415

Discharge Air Temperature Input

Minimum Position Potentiometer

Adjustment

Terminals for Remote Minimum

Damper Position

Output Relays 2 spdt

Table 14. Operating Specifics

Specific Description

Case Duct-mounted

Temperature

Sensing Element:

Output Signal

Operating ambient

temperature

Shipping

temperature rating:

Maximum power

consumption

Maximum supply

voltage

Electrical connection

Listed by Underwriters Laboratories Inc.

Thermistor

4-20 mA current signal; increases

from 4 mA to 20 mA as enthalpy

decreases

-40 to 125° Fahrenheit (-40 to

+52° Celsius)

-40 to 150° Fahrenheit (-40 to

+66° Celsius)

0.45 Vac

18 to 24 Vdc

Two ¼-inch quick-connect

terminals

Thermistor sensor

C7150B or C7046

YES

YES

IOM-MBC-00 08-30-04

Figure 17. Solid-State Enthalpy Sensor

Location and Mounting

Outdoor air sensing: The Enthalpy Sensor may be

mounted in any orientation where it is exposed to freely

circulating air, but protected from rain, snow, and direct

sunlight.

Return air sensing: For differential enthalpy control, a

second C7400A enthalpy sensor is connected to the

W7459. It is mounted in the return air duct. Contact Titus

if specifications call for differential enthalpy control.

Air Temperature Sensor – C7150B

Use the air temperature sensor – C7150B and the singlezone system – W973 with the damper motor – M7415A to

sense mixed or discharge air in rooftop packaged

conditioning equipment. See Figure 18.

Figure 18. Air Temperature Sensor

air

12 of 15

Page 13

Mixing Box Control Installation Manual

IOM-MBC-00 08-30-04

The sensor consists of thermistor sensor element used in

ventilation duct systems. Negative temperature coefficient

(NTC) causes the resistance to decrease as the sampled air

temperature increases. This resistance change is used to

control the W973 and W7415A. Setting and calibration not

required.

Operation

Table 15 highlights operational ratings of the air temperature

sensor.

Enthalpy Changeover Set Point

With single enthalpy the enthalpy changeover set point is set to

return the outdoor air damper to minimum position when the

enthalpy rises above its set point. The enthalpy set point scale

markings, located on W7459, are

A, B, C, and D in Figure 20.

Table 15. Operation Ratings

Specification Performance

Maximum ambient

temperature

Operating temperature

range

Resistance/ Temperature

(NTC)

Resistance sensitivity per

degree at midrange

Electrical connections

250º Fahrenheit (125º

Celsius)

-30 to 150º Fahrenheit (-34 to

65º Celsius)

300 ohms at 77º Fahrenheit

(25º Celsius)

70 ohms per degree

Fahrenheit

¼-inch quick-connect

terminals

Figure 20. Performance Characteristics for Enthalpy Changeover Settings A, B, C, and D

13 of 15

Page 14

Mixing Box Control Installation Manual

See Figure 20 for the corresponding control point. The

factory-installed 620 ohm jumper must be in place across

terminals + and S

Single M7415 actuator accepts the thermistor sensor input

from C7150B mounted in discharge or mixed air duct. See

Figure 10.

During the occupied period, on a call for cooling, when

outdoor air temperature or enthalpy conditions are low, the

M7415 economizer actuator will proportion to maintain

between 50-56º Fahrenheit at thermistor sensor.

If the mixed or discharge air temperature is above 56º

Fahrenheit, M7415 actuator will open to admit additional

outdoor air until the temperature returns to the 50 to 56º

Fahrenheit

will not close past minimum position.

If the fully open M7415 actuator cannot satisfy the space

demand, mechanical cooling is sequenced on.

During the unoccupied period, the M7415 actuator will

override minimum position setting and drive fully closed.

On a loss of power, the actuator will spring return fully

closed.

When in heating operation, or outdoor air temperature or

enthalpy conditions are high, economizer operation is

locked out, and M7415 actuator is held at minimum

position.

R.

range. During the occupied period, the actuator

IOM-MBC-00 08-30-04

Figure 21. Increasing the Air Temperature Sensor

Setpoint

Discharge Air Temperature Setpoint

Adjustment

The air temperature sensor – C7150B maintains the

discharge or mixed air duct temperature between 50 and

56º Fahrenheit. If the mixed air discharge temperature is

outside the 50 to 56º Fahrenheit range, the damper motor

will proportion open or closed until the temperature returns

to between 50 and 56º Fahrenheit.

This temperature range can be adjusted either up or down

by wiring a resistor in series or parallel with the C7150B

depending on the application. Refer to Figures 21 and 22

for details.

Figure 22. Decreasing the Air Temperature Sensor

Setpoint

14 of 15

Page 15

Mixing Box Control Installation Manual

IOM-MBC-00 08-30-04

Verification and Troubleshooting

The following table provides the actions and responses to

verify the installation of W7459A installed on an M7415

Actuator.

DANGER

DISCONNECT POWER SUPPLY BEFORE

CONNECTING WIRING TO PREVENT ELECTRICAL

SHOCK OR EQUIPMENT DAMAGE

Caution: Exercise care when adjusting the

enthalpy changeover and minimum damper

position control. Use a small screwdriver for

these adjustments. Excessive force may damage

the controls.

Perform verification and troubleshooting steps in

order.

Table 16. Modulating Control Verification

and Troubleshooting

esnopseR noitcA

A. Power

Disconnect power at

1.

terminals TR and TR1.

Disconnect jumper

2.

across P and P1.

3. Jumper TR and 1.

4. Jumper T1 to T.

If connect, remove

5.

C7400A Enthalpy Sensor

from terminals S

Verify Factory-installed

6.

620 ohm resistor is

connected to S

Apply 24 Vac power to

7.

terminals TR and TR1

Disconnect factory-

8.

installed 620 ohm

resistor from terminals S

and +.

B. Enthalpy Simulation

Reconnect factory-

1.

installed 620-ohm

resistor across terminals

S

and +.

R

Connect 1.2k ohm

2.

checkout resistor across

terminals S

R

and +.

O

and +.

O

and +.

LED should be off.

Motor is in closed

position.

LED should be on,

indicating low enthalpy.

R

Motor drives toward

open.

esnopseR noitcA

Set enthalpy set point

3.

potentiometer to “A”.

LED should come on,

indicating low enthalpy.

Motor drives toward

open.

Set enthalpy set point

4.

potentiometer to “D”.

LED should go off,

indicating high enthalpy.

Motor drives toward

closed.

C. Sensor

Reconnect the + lead of

1.

outdoor enthalpy sensor

to the + terminal of

W7459.

Connect a DC multi-

2.

meter or voltmeter

between terminals S

the W7459 and terminal

S of the enthalpy sensor.

(Positive meter lead to

terminal S of enthalpy

sensor.)

If using differential

3.

enthalpy, the return air

enthalpy sensor may be

checked by connecting a

DC multi-meter or

voltmeter between

terminal S

of the W7459

R

and terminal S of the

O

Multi-meter or voltmeter

should indicate between

of

3 and 25 mA, if sensor

is operating properly.

If multi-meter or

voltmeter indicates

zero, the sensor may be

wired backwards.

Multi-meter or voltmeter

should indicate between

3 and 25 mA, if sensor

is operating properly.

If multi-meter or

voltmeter indicates

zero, the sensor may be

wired backwards.

return air enthalpy

sensor. (Position meter

lead to terminal S of

return air enthalpy

sensor.

Abbreviations

The following table lists the abbreviations found within this

document.

Abbrev. Term

A Ampere

BTU British Thermal Units

DC Direct Current

LED Light Emitting Diode

mA Milliampere

NTC Negative temperature coefficient

RH Relative Humidity

spdt Single-pole, double -throw

spst Single-pole, single-throw

Vac Volts Alternating Current

Vdc Volts Direct Current

15 of 15

Loading...

Loading...