Page 1

Installation Manual

IOM-MAB-00 08-15-04

MAB Modular Air Handler Belt Drive

Installation, Operation, and Maintenance Manual

Contents Page

Introduction.............................................................1

General ....................................................................1

Safety .......................................................................1

Inspection................................................................1

Product Description ...............................................1

Model Number Specification .............................................1

Dimension Specification .................................................... 2

Blower and Plenum Information ........................................2

Standard Installation ..............................................4

Ductwork ...........................................................................4

Duct Insulation and Vapor Proofing................................... 5

Sound Attenuation............................................................. 5

Condensate Drain .............................................................5

Water Piping...................................................................... 5

Motors and Drives .............................................................6

Electrical Connections.......................................................6

Installation of Options............................................6

Grille Plenum..................................................................... 6

Mixing Box.........................................................................7

Electric Heat......................................................................8

Air Handler Startup.................................................8

Operation and Maintenance ..................................9

Return Air Filters ...............................................................9

Coil ....................................................................................9

Belt and Pulley ..................................................................9

Motor ................................................................................. 9

Blower ...............................................................................9

Abbreviations..........................................................9

The installation is to be performed only

whose experience meets or exceeds the requirements of

the work involved.

The installer MUST read the entire contents of this guide

and develop a thorough understanding before beginning

installation.

Due to a continuing program of product research, Titus

reserves the right to discontinue or change without notice,

any or all specifications or designs without incurring

obligations.

by individuals

Safety

The installation and/or servicing of comfort conditioning

equipment can be hazardous due to system pressures

and electrical devices.

Caution: Onl

should perform service and/or installation.

Observe all precautions and warnings in product

data or attached to the unit.

Follow all safety codes. Wear eye protection and gloves.

Have a fire extinguisher readily available.

Caution: Disconnect all power supplies before

accessing equipment.

Disconnecting more than one power supply may

be required to de-energize some equipment.

ELECTRIC SHOCK CAN CAUSE DEATH.

y trained and qualified personnel

DANGER

Introduction

This document provides installation, operation, and

maintenance information for the Titus Modular Air Handler

Belt Drive (MAB) models.

Additional information may be found at the Titus website,

www.titus-hvac.com.

Inspection

Thoroughly inspect all packages upon receipt. Ensure

carton(s) have not been dropped, crushed or punctured.

Inspect all contents for damage. If damage is found,

immediately file a claim with the delivering carrier.

Product Description

General

The following information is to be used by the installer as a

guide. Since each installation is unique unto itself, only

general topics are covered. Topic order may not be the

same as required by actual installation.

This guide is not intended to supersede or circumvent any

applicable national, state, or local codes.

605 Shiloh Road • Plano, Texas 75074 • 972- 212-4800

All rights reserved. No part of this work may be reproduced or transmitted in any form or any means, electronic or mechanical, including photocopying and recording, or by any information storage retrieval system without permission in writing from Air Distribution Technologies.

This section provides model features, number

nomenclature, various unit dimensions, and coil

specification.

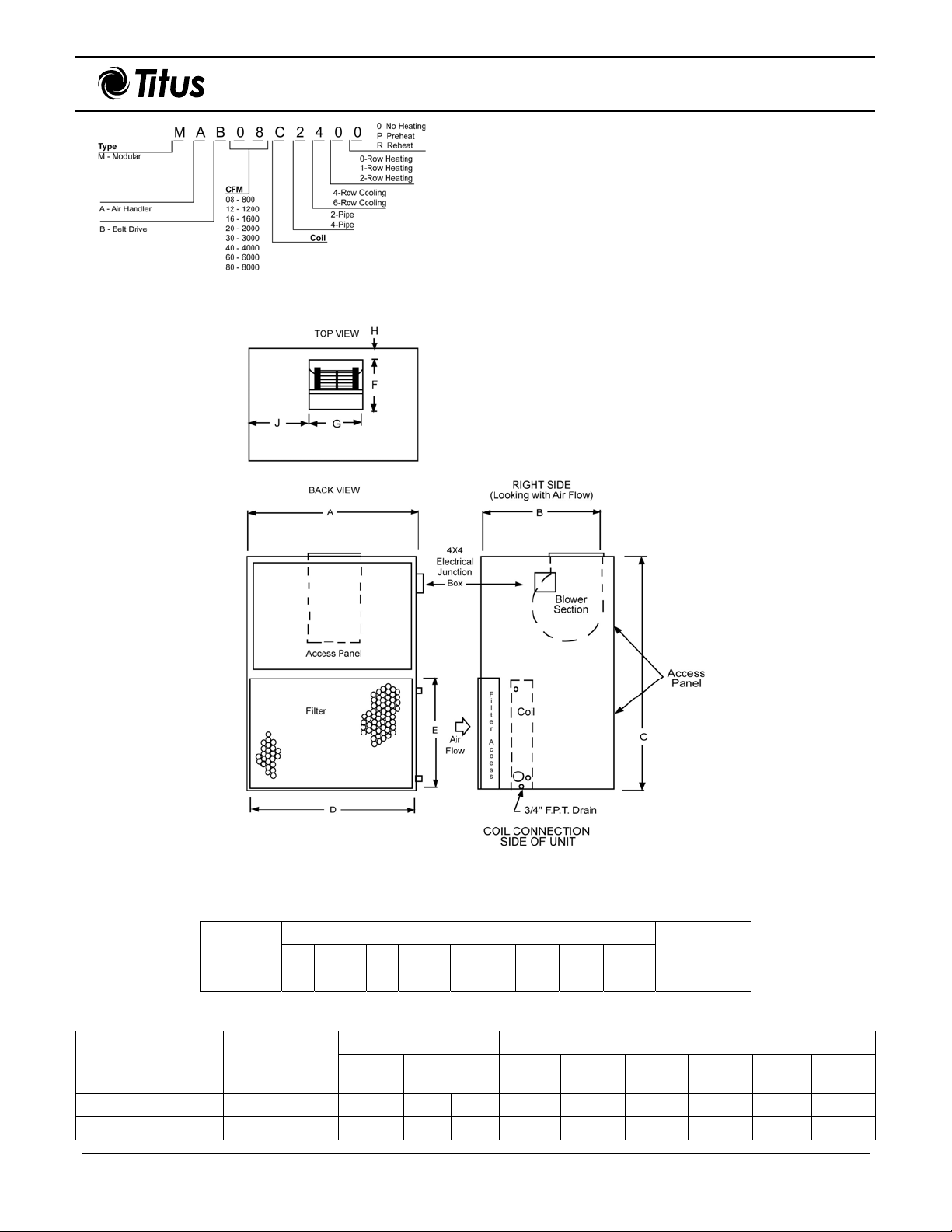

Model Number Specification

The following figure defines model number nomenclature

specifics.

Page 2

MAB Installation Manual

Figure 1. Air Handler Model Number

Nomenclature

IOM-MAB-00 08-15-04

Dimension Specification

Figures 2 and 3 show dimensional callouts for all sides of an

MAB unit. Tables 1 and 3 provide MAB model dimensional

specifics such as tonnage, blower, filter dimensions, optional

discharge or return air plenum, and shipping weight of

plenum.

Blower and Plenum Information

Tables 2 and 4 provide the blower coil and/or plenum

specifics for MAB models. Table 5 provides water

connection sizes based on model.

Figure 2. MAB08 & MAB12 Dimensional Views

Table 1. Cabinet Dimensions (MAB08 & MAB12)

Model

MAB08/12 37 31.75 36 27.50 16 12 8.50 1.13 14.25 16 x 32

Model

MAB08 800 2 2/10 4/10 6/10 0.625 13 0.75 145 0.75 156

MAB12 1200 3 2/10 4/10 6/10 0.625 18 0.75 171 0.875 190

Nominal

CFM

A B C D E F G H J

Table 2. Blower Coil Specifics (MAB08 & MAB12)

Nominal

Capacity

(Tons)

Water

Dimensions (inches)

Rows/Fins Per Inch Coil Connection (OD Sweat)

Hot

Chilled

Water

2 of 9

Two-

Row

Ship.

Wgt.

1-inch Filter

Four-

Row

Ship.

Wgt.

Six-

Row

Ship.

Wgt.

Page 3

MAB Installation Manual

IOM-MAB-00 08-15-04

Figure 3. Dimensional View

Table 3. Cabinet Dimensions

Model A B C D E F G H J K

MAB16/20 40 26 27.5 36 25.5 11.88 13.63 1.13 13.13 21.25

MAB30/40 50 34 34.5 48 32 16.38 19 1.13 15.44 27

MAB60/80 72 34 47.5 66 45 16.38 16.38 1.13 14 34

Note: All dimensions in inches.

3 of 9

Page 4

MAB Installation Manual

Table 4. Blower Coil and Plenum Dimensions (MAB16 through MAB80)

Model

MAB16 1600 4 10 x 10 (2) 20 x 25 75 23 16 x 24

MAB20 2000 5 10 x 10 (2) 20 x 25 75 23 16 x 24

MAB30 3000 7.5 15 x 15 (4) 16 x 25 90 26-1/2 18 x 48

MAB40 4000 10 15 x 15 (4) 16 x 25 90 26-1/2 18 x 48

MAB60 6000 15

MAB80 8000 20

Nominal

CFM

Model

MAB16 7/8" 321 1-1/8" 377 7/8" 30

MAB20 1-1/8" 344 1-1/8" 400 1-1/8" 34

MAB30 1-1/8" 584 1-3/8" 637 1-1/8" 49

MAB40 1-3/8" 584 1-5/8" 637 1-1/8" 53

MAB60 1-3/8" 844 1-5/8" 930 1-1/8" 86

MAB80 (2) 1-5/8" 890 (2) 1-5/8" 996 (2) 1-1/8" 106

Nominal

Capacity

(Tons)

Table 5. MAB Water Coil Connection Size (OD SWT)

4-Row 6-Row 2-Row

Coil Size

Blower 2” Filter

(2) 16 x 20

(2) 15 x 12

Ship

Weight

(lbs)

(2) 16 x 25

(2) 20 x 20

(2) 20 x 25

Coil Size

Ship

Weight

(lbs)

Optional Discharge Grille Plenum

Weight (lbs)

240 36 (4) 12 x 30

Coil Size

IOM-MAB-00 08-15-04

Height

(inches)

Ship

Weight

(lbs)

Grille Size

(inches)

Standard Installation

Basic installation procedure covers verifying and/or

installing the following items.

• Ductwork

• Duct insulation and vapor proofing

• Unit placement

• Sound attenuation

• Condensate drain

• Water piping

• Motors and drives

• Electrical connections

Note: If mixing boxes form part of the unit, install the

mixing boxes prior to installing unit. See Mixing Box

installation instructions within this document.

Ductwork

Use accepted industry practices and design guidelines of

the ASHRAE Fundamentals Handbook. Ductwork must

comply with all building codes and the National Fire

Protection Association’s pamphlet 90A and 90B

Carefully inspect any previously installed ductwork to

determine suitability.

Note: Ductwork should be

requirements of the installation. Ductwork should

transition gradually from a smaller size blower

outlet to required duct run size to avoid excessive

loss of air velocity.

4 of 9

of a size meeting

Page 5

MAB Installation Manual

DANGER

BEFORE INSTALLING UNIT, DETERMINE IF THE UNIT

WEIGHT CAN BE SAFELY SUPPORTED.

POSSIBLE INJURY AND DAMAGE MAY RESULT DUE

TO JOIST/TRUSS OVERLOADING.

1. When return air duct connection is smaller than return

air inlet opening, construct the transition piece so the

horizontal and vertical dimensions of transition does

not increase more than one inch for every seven feet

of length.

2. Allow a minimum of three feet of straight ductwork

following an equipment outlet.

3. Install unit with 1/8-inch pitch toward condensate

drain opening.

Duct Insulation and Vapor Proofing

Previously installed heating supply ductwork may already

have adequate insulation against excessive heat loss.

This insulation may be satisfactory for protection against

heat gain from summer cooling. Depending upon

application, additional

Externally insulated ductwork must have adequate vapor

seal for summer operation, especially where duct is

exposed to high humidity conditions.

insulation may be required.

IOM-MAB-00 08-15-04

Water Piping

All piping must be supported, independent of coils. Swing

joints or flexible fittings must be provided to absorb

expansion and contraction strains. Rigid piping reduces

the effectiveness of vibration isolators. The water supply

should always be connected so the entering water is on

the leaving airside of the coil. See Figure 6. Coils must be

adequately vented in order to prevent air binding.

Note: Freeze-ups due to low air temperatures are not

covered under the warranty agreement.

Figure 4. Condensate Drain

Sound Attenuation

Flexible duct connections should be used between the unit

and both the supply and return ducts.

Both suspended and base-mounted units require unit

vibration isolation.

Condensate Drain

Condensate drain must consist of a minimum of ¾-inch

copper tubing, ¾-inch galvanized pipe, or ¾-inch PVC

pipe. Figure 4 shows condensate drain setup. The drain

trap must be properly configured to ensure the removal of

all condensate runoff. Ensure drain pitches down

slope of one inch every 10 feet.

Note 1: Incorrect trapping can hold water in pan,

causing overflow.

Note 2: Consult local codes for additional precautions

before installing condensate pan.

Caution: If unit location is above an occupied

space or where damage may result from

condensate overflow, install a watertight pan

of corrosion-resistant metal beneath unit to

catch overflow. If this condition exists a

separate ¾-inch condensate drain must be

provided for this added pan. See Figure 5.

ward at a

Figure 5. Occupied Space Condensate Pan

Installation

Figure 6. Blower Coil Connections

5 of 9

Page 6

MAB Installation Manual

IOM-MAB-00 08-15-04

Motors and Drives

Units are normally shipped with motor and drive installed.

However; when mounting a motor on the adjustable base

in the field, use extreme care to ensure proper alignment

and belt tension.

Electrical Connections

Each unit has a mounted control box, and typically, the

motor is to be wired to this box. Only ODP, single- and

three-phase motors on 800 to 2000 CFM units are factorywired to junction box. All other motors require field wiring

to junction box located on side of the unit cabinet.

Note 1: Unit must be permanently grounded in

accordance with NEC and local codes and

ordinances. See the typical wiring diagrams shown in

Figure 7.

Note 2: Not all installations require a starter (some

motors utilize a contactor).

Installation of Options

In addition to the standard equipment, the following

optional equipment may require consideration during

installation.

• Discharge grille plenum.

• Mixing box.

• Electric heat.

• Motor and drive selections.

Grille Plenum

The discharge grille plenum is designed for a freestanding

configuration set in an open area with a requirement for a

90° turn of the discharge air. See Figure 8. This option is

available on models MAB16 through 80.

1. Check plenum alignment with unit. Remove screws

aligning with the smaller plenum cutouts. Retain

screws for later.

Note: Screws aligning with the larger cutouts

remain in place.

2. Remove grille from the plen

3. Position plenum so discharge is directed toward

the back or front of unit, as desired.

4. Align the ½-inch holes in the plenum with the unit’s

protruding screw heads.

5. Align the smaller ¼-inch holes in plenum and unit

together.

6. Square up plenum and unit; then reach through

grille opening to insert screws into the smaller ¼inch holes.

7. Tighten all screws to secure plenum.

8. Reinsert grille in plenum opening and secure with

screws retained previously. Adjust grille louvers

manually.

um.

Figure 7. Wiring Diagrams

Figure 8. Grille Plenum Installation

6 of 9

Page 7

MAB Installation Manual

IOM-MAB-00 08-15-04

Mixing Box

Preparation

Inspect desired installation location and determine if

space provides sufficient work and safety clearances. If

space allows, make all sheet metal connections and

attachments prior to moving complete assembly to duct

connection site. Figure 9 and Table 6 provide unit, mixing

boxes, and damper dimensional information.

One side of mixing box has two plastic plugs. These

1.

plugs may be removed and placed on the opposite

end to seal the unused 7/8-inch holes at the opposite

cabinet end where the 5/6-inch linkage rods do not

extend outward.

Choose the cabinet side most accessible for

2.

servicing to mount damper motor. Remove

each damper shaft and extend shaft until second

hole in shaft aligns with hole in damper blade. Insert

bolt. Connect two shafts with the two crank arms and

the 5/16-inch linkage rod (furnished with mixing box).

Mount damper motor on the selected side of mixing

3.

box cabinet by drilling necessary holes and securing

with screws or nuts and bolts.

bolt for

Installation

Attach mixing box to unit return-air duct flange.

1.

Vertical duct flange connections at unit rear are prepunched to match pre-punched holes in mixing

boxes. Mixing boxes may be mounted for top-rear or

bottom-rear connections.

2.

After bolting vertical flange, drill holes in horizontal

duct flanges. Secure flanges with screws or nuts and

bolts.

Use field-supplied hardware to connect motor shaft

3.

to one of the damper shafts.

Connect duct to the 1-inch

4.

mixing box for return and fresh air locations as

needed.

Note: Installation steps 1, 2, and 3 may follow

Preparation steps 1 and 2, if preferred.

duct flange provided on

Figure 9. Mixing Box Dimensions

Table 6. Mixing Box Dimensions

Model

MAB16/20 8 25.5 16 8 9.5 36 (2) 34 x 8 75 2000 0.07

MAB30/40 12 32 20 10 10 48 (2) 46 x 12 131 4000 0.03

MAB60/80 14 45 22 15 16 66 (2) 56 x 14 201 8000 0.04

Note: All dimensions in inches.

A B C D E F

Mixing Box Dimensions

Damper

7 of 9

Ship Wgt.

(lbs)

Nominal

CFM

SP Loss

Page 8

MAB Installation Manual

Electric Heat

Preparation

Some items to consider prior to installing electric heat are

as follows:

• Duct materials must be suitable for 250ºF operation.

See NFPA 90A and 90B pamphlet.

• Ensure ample room exists in the ductwork. Electric

heat must have at least 24 inches of straight duct

clearance before an elbow. If 24 inches are

unavailable, devices such as turning vanes or baffles

may be required.

Note: Electric heaters are incompatible with discharge

grille plenum.

Installation

Use the following information to install electric heat on

MAB models.

Position heater element section over the blower

1.

wheel of the MAB unit.

Note: Heater baffle must be alig

blower cut-off scroll. Heater should be rotated

180 degrees, if necessary to align. This

ensures proper blower discharge of air over

the heater element.

Attach electric heat plenum to MAB unit using #6 or

2.

larger sheet metal screws.

Note: Ensure plenum is securely attached to

MAB unit only and not to blower wheel

extension.

3. Add insulation, if necessary to outside of plenum.

Warning: Do not insulate heater box.

Figure 10 shows MAB and electric heat components.

ned with the

Air Handler Startup

Check the following items before startup.

• Ensure all shipping bolts/screws are removed and all

other bolts and screws are tight.

• Never assume

nameplate is the same as the motor wired.

• Check the alignment of the sheaves and ensure the

setscrews are tight.

• Check for proper rotation of the blower pulley.

the voltage and phase on the unit

IOM-MAB-00 08-15-04

Figure 10. Modular Unit with Electric Heater

Components

• Check motor phase and rotation.

− Exchanging two of the three leads at the unit

junction box can reverse three-phase motor

rotation.

− Exchanging leads inside the motor junction box

can reverse the rotation of single-phase motors.

Refer to the motor nameplate.

− Not all installations require a starter (some

motors utilize a contactor).

• Ensure all filters are installed. Perform filter check

with all doors and panels in place.

• Check the amperage draw of the motor. The

amperage draw should not exceed the nameplate

amps shown on the motor serial plate.

8 of 9

Page 9

MAB Installation Manual

IOM-MAB-00 08-15-04

Operation and Maintenance

Read and heed warning and danger notices before

operation and maintenance

DANGER

DISCONNECT ELECTRICAL POWER TO ALL

CIRCUITS BEFORE SERVICING UNIT. FAILURE TO DO

SO MAY RESULT IN PERSONAL INJURY FROM

ELECTRICAL SHOCK OR MOVING PARTS.

Return Air Filters

Inspect return air filters on a regular basis (at least

monthly). Clean or replace filter(s). Filter can be accessed

from either side of unit.

Caution: Always operate unit with a filter and/or

filter access door closed to avoid blower motor

damage.

Coil

The coil is easily cleaned when dry. To check or clean,

remove unit access panel, filter access door and filter(s).

Use accepted industry methods for cleaning. Remove all

foreign matter from pan and condensate drain line. Check

for rust and holes.

Belt and Pulley

The following list highlights items to consider for belt and

pulley maintenance and adjustment.

• Proper pulley alignment and belt tension mu

maintained at all times.

• Reduce speed by adjusting pulley faces so the faces

are further apart.

• Increase speed by moving the faces closer together.

• Check pulley setscrews and bolts.

st be

Motor

Proper lubrication is essential to long motor life. Use

electric motor oil or SAE20 non-detergent oil. Tighten

motor mount bracket and base bolts.

Note: Avoid over-oiling the motor. If a motor is overoiled, the oil may run down the motor shaft and

splatter.

Blower

Periodically check bearing for wear. Replace as required.

Check wheel for dirt accumulation and clean as required.

Abbreviations

The following table lists the abbreviations found within this

document.

bbrev. Term

A

CFM cubic feet per minute

F.P.T. Female pipe thread

lbs pounds

OD outside diameter

PVC polyvinyl chloride

SAE Society of automotive Engineers

SP static pressure

SWT sweat

wgt. weight

9 of 9

Loading...

Loading...