Page 1

Titus Proportional Lynergy

W/ Discharge Temperature Limit

Start-Up, Operation and Service Instructions

SAFETY NOTE

Air-handling equipment will provide safe and reliable service when operated within design specifications. The equipment

should be operated and serviced only by authorized personnel who have a thorough knowledge of system operation, safety

devices, and emergency procedures. Good judgment should be used in applying any manufacturer’s instructions to avoid injury

to personnel or damage to equipment and property.

WARNING

power is not disconnected. Electrical shock and personal injury could result.

WARNING

control box and/or heat sinks may be hot.

LineaHeat is an electronic, time proportional electric heat system. The heat output of the heater is modulated utilizing quiet,

rapid performing solid state relays. The relays are switched off and on to allow the heating of electrical resistance elements.

The proportion of time the relay is on dictates the proportion of maximum heat the electric heater can produce. The solid state

relays are switched off and on by a supplied Electric Heat Module (EHM). The EHM accepts an input signal from the terminal

unit controller or thermostat for the amount of heat desired. The EHM can accept a variety of different input signals when

interfacing with controls. The type of input the EHM will accept is modified by changing the position of one or two jumpers

easily accessible on the board.

The LineaHeat is available with an optional discharge temperature sensor. When used with the discharge sensor option, the

LineaHeat will modulate outgoing temperature from the unit between the maximum temperature setting and initial temperature

of incoming air before heating began. The discharge temperature set point is easily adjusted in the field by rotating the

temperature dial on the EHM. The EHM will not allow temperatures over the set point so as to prevent overheating,

stratification, and energy waste from heated air lost through overhead returns.

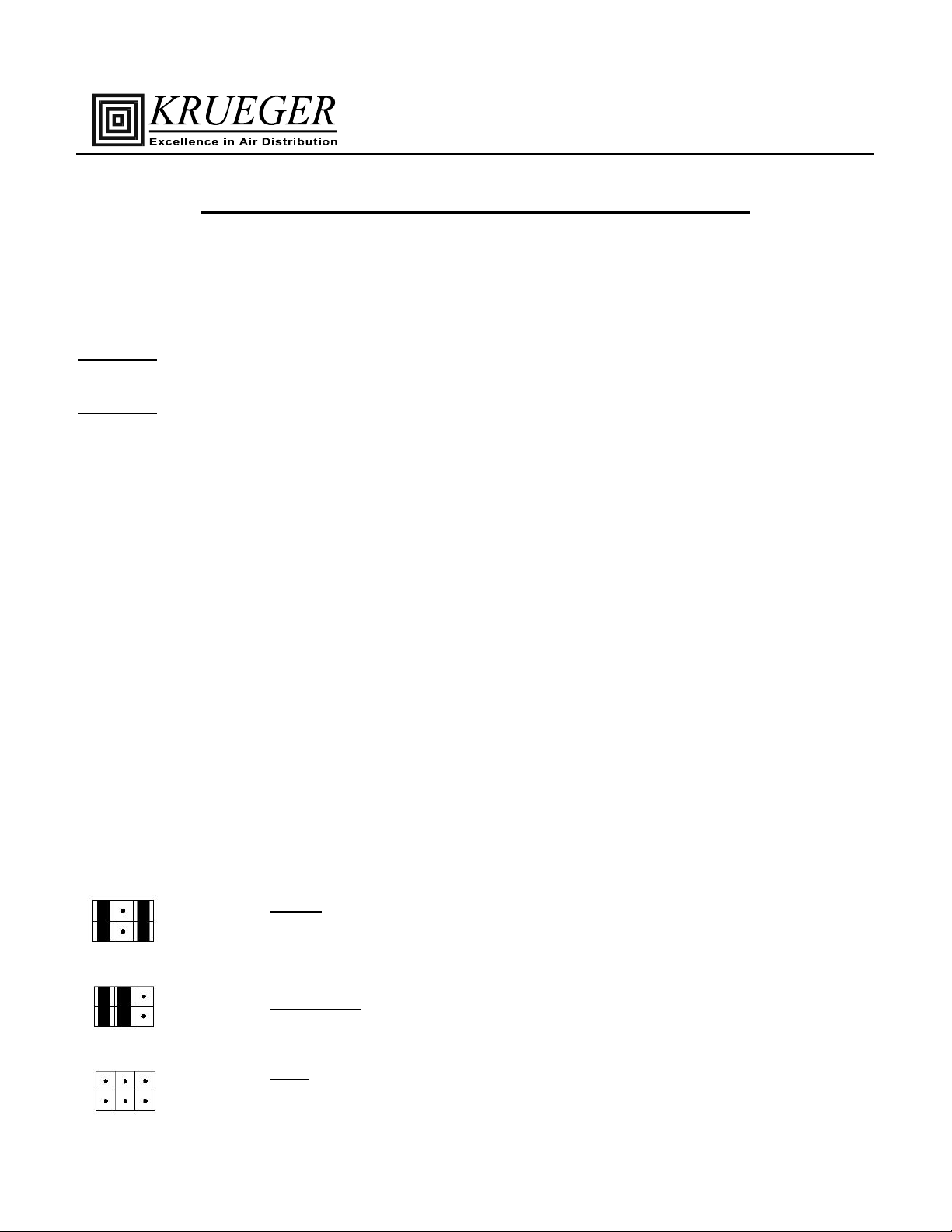

INPUT SETTING. The LineaHeat board is capable of being controlled and operated 7 different ways. The units are ordered

with an LXY code, where “X” is coded for unit power and “Y” is coded for the application. This “Y” application can be

changed in the field. The application desired is chosen by placement of jumpers in the corner of board (See Drawing 1 on page

2). Jumper settings below are representative of pins at bottom left of control board as shown in drawing. Wiring diagrams for

each are on pages 5 & 6.

: Disconnect all power to the unit before performing maintenance or service. Unit may automatically start if

: Units with LineaHeat use Solid State relays, which generate heat when used. The temperature of the

OVERVIEW

START-UP

LX1) On/Off: This application accepts one 24 Vac input at “Inc” to step the heater output from

OFF to 100% heater kW rating. The signal may be pulsed off and on over a small time

period to provide proportional heat. For example, a signal that is on for 4.5 seconds every

10 seconds would produce 45% of the heater’s kW rating.

LX2) 2 Stage (2Stg): This two stage application accepts two 24 Vac inputs to step the heater

LX3) 0-10V: This application accepts a 0-10 Vdc (0-20mA) signal to modulate the heater

output from off to 50% or 100% heater kW rating. A signal to “Inc” is 50% and a signal

to “Dec” is 100%

output. The output is proportional to input signal (i.e., 4.5 volts sets the heater to 45% of

kW rating).

1

Page 2

LX4) 2-10V: This application accepts a 2-10 Vdc (4-20 mA) signal to modulate the heater

output. The output is proportional to input voltage above 2 volts (i.e., 4.5 volts sets the

heater to 25% of kW rating).

LX5) Incremental (Incr): This application accepts one 24 Vac input to modulate heater output.

An increase signal will increase the heater output from 0% to 100% over a 4 minute 15

second interval, staying at 100% afterward. When the signal is removed, the heater output

will decrease to 0% over the same time period. This application mirrors a Normally

Closed hot water valve.

LX6) Bininary (Bin): This application accepts two 24 Vac inputs to step the heater from off to

33%, 67%, or 100% of the heater’s kW rating. A signal to “Inc” is 33%, a signal to “Dec”

is 67%, and a signal to both is 100%.

LX7) 3 Point Floating (Float)

: This floating input application accepts two 24 Vac inputs to

increase or decrease the heater output. As the increase signal is sent, the heater output will

increase from 0% to 100% over a 2 minute 15 second interval. If the increase signal is

removed, or decrease signal is also added, the heater output will stay constant at present

point. When only the decrease signal is received, the heater output will decline from the

present level to 0% over the same time period. This application mirrors a Three-Point

floating hot water valve.

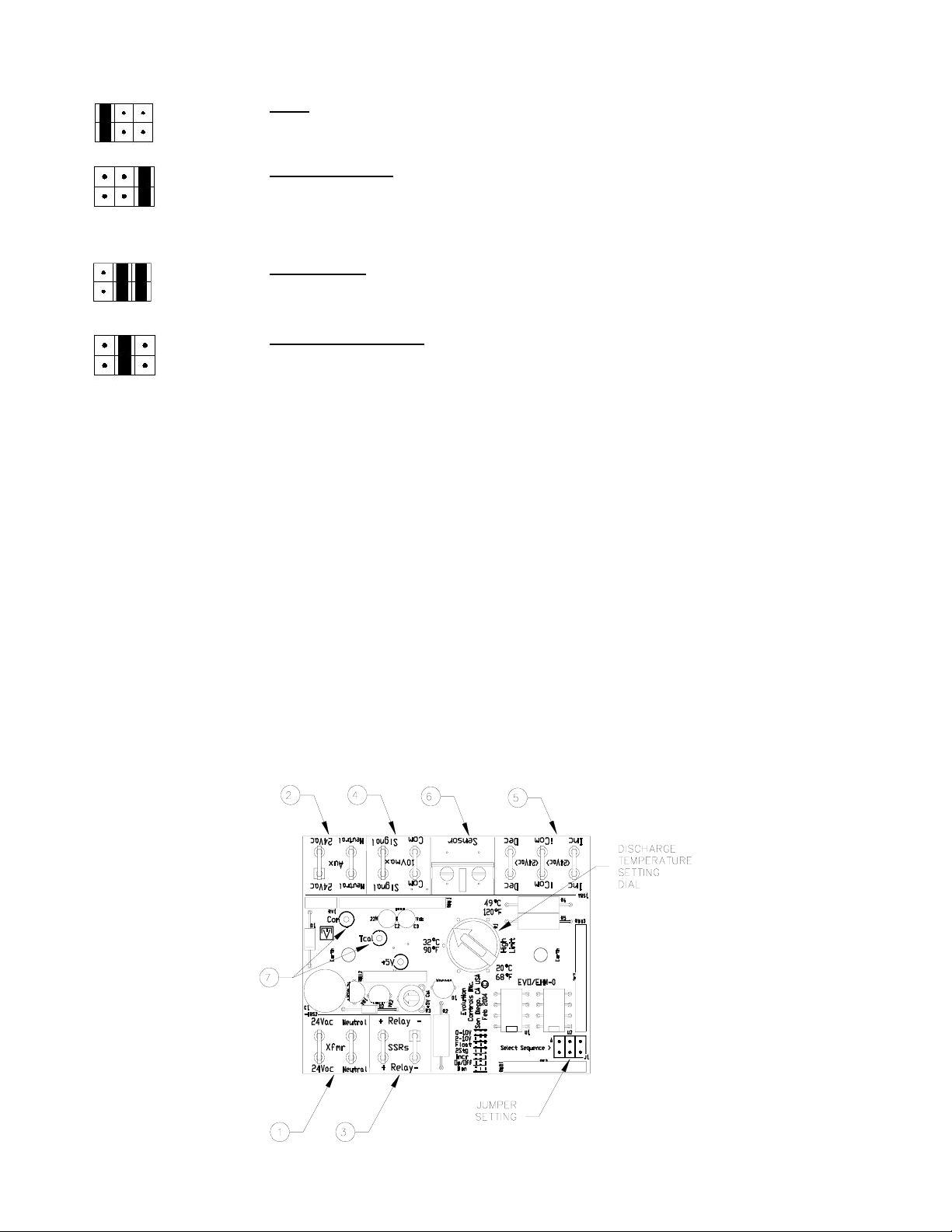

WIRING. The EHM control board is powered by 24Vac (1) from the transformer in the electric heater. The EHM has

auxiliary 24Vac outputs (2) that can be used to power the unit’s electrical controls. Next to the “Xfmr” inputs are the “+” and

“-“ Relay connections (3) that control the solid state relays by sending pulses of ~25Vdc.

There are two terminations to use for dc Volt control (4) of the electric heat (applications LX3 and LX4 from above). These

are polar sensitive. The “+” signal from the controller must be connected to “Signal” on the EHM Control Board. The “-“

from the controller must be connected to “Com” next to “Signal (Note: NOT “iCom”). A termination to “-“ is possible, but not

necessary to measure mA signals to the board.

There are three terminations for 24 Vac control (5) of the electric heat (applications LX1, LX2, LX5, LX6, and LX7 from

above). “Inc” is for the increase signal in applications LX5 and LX7, as well as the first stage heat signal in applications LX1,

LX2, and LX6. “Dec” is for the decrease signal in application LX7, as well as the second stage heat signal in applications LX2

and LX6. A connection to “iCom” is necessary for all of these 24 Vac applications. If the unit’s controller does not have a

Common output, a jumper to the correct “Aux” terminal can be used. If the unit controller outputs the “24Vac” side from it’s

input power, a jumper should be made from “Neutral” to “iCom” (See sample diagram on page 7). If the unit controller

outputs the “Neutral” side of it’s input power, a jumper should be made from “24Vac” to “iCom”.

2

Page 3

DISCHARGE TEMPERATURE SET POINT. LineaHeat comes with a discharge temperature set point (DTS) option. This

option allows a maximum temperature to be set at the board to prevent overheating of discharge air. When the unit receives a

signal to start heating, the board will take an initial temperature reading and modulate heat from that point to the maximum

temperature. For example, if a thermostat requires only a 10% heating output of air that was initially 60°F and has a maximum

temperature setting of 90°F, the EHM will modulate the heater’s output temperature to 63°F (the additional 3 degrees coming

from (90-60)*10%). This allows heaters to be sized for morning warm up in the winter and still comfortably operate on those

days when the inlet temperatures are slightly warmer.

The discharge temperature sensor comes with a 9’ cable for mounting in the downstream ductwork. The sensor should be

mounted a minimum of 36” from the discharge of the unit and be vertically centered in the ductwork. The sensor can be

mounted by drilling a 1/2” hole into the ductwork, inserting the sensor, and securing it with 2 sheet metal screws. The sensor is

6” long, and the tip should not touch any part of the ductwork.

Neither the jumper settings nor the controls wiring needs to be changed when this option is ordered. The EHM control board

will detect if a sensor has been connected, and it will adjust the control function accordingly. The sensor wires are connected

to the screw terminals at the “Sensor” (6) location on the EHM. The connection at this termination is not polar sensitive and

the two wires may be switched with no effect.

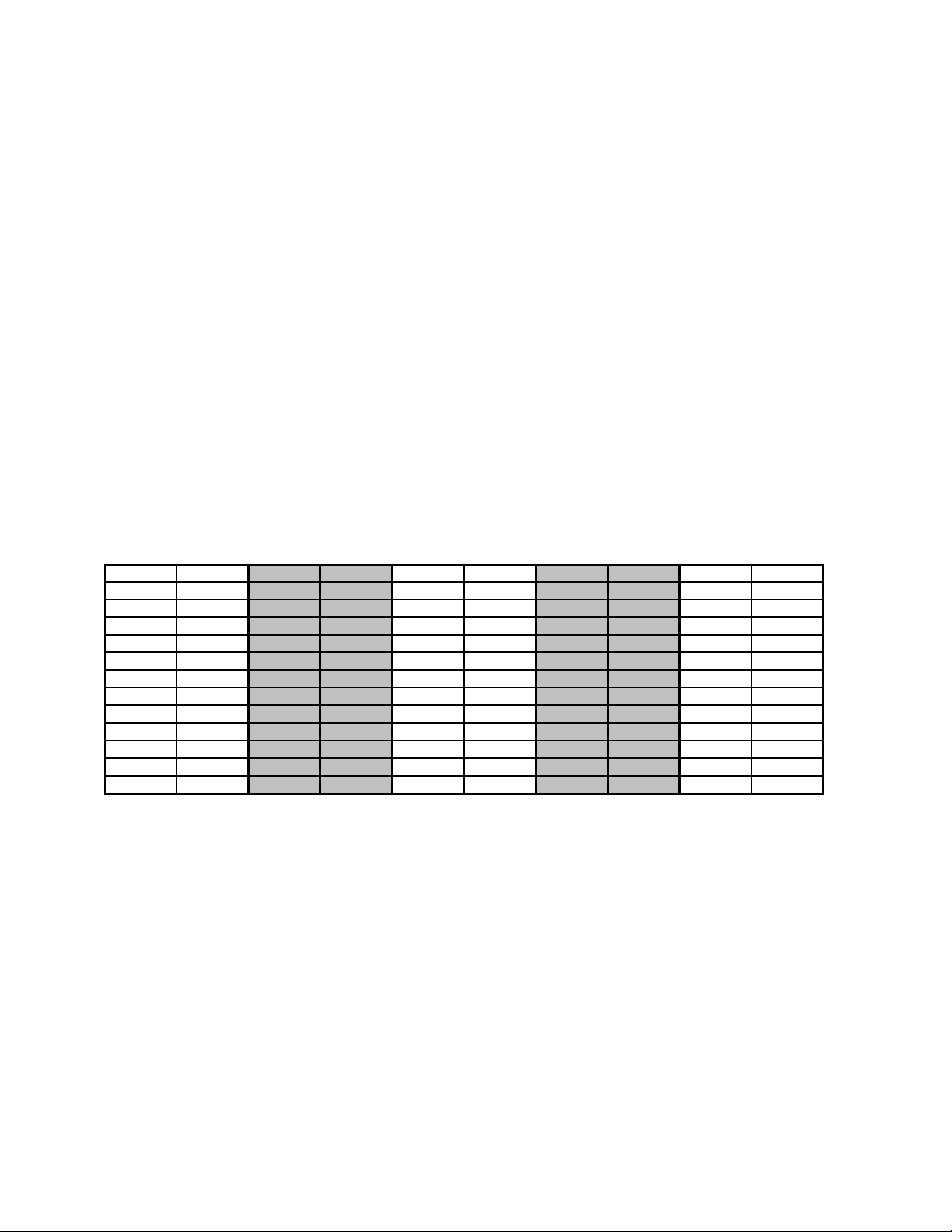

The desired discharge temperature is set by rotating the discharge temperature set point dial arrow to the maximum outlet

temperature desired. To fine tune the discharge temperature set point, connect the positive and negative leads of a multimeter

to “Tcal” and “Com” (7), respectively, on the EHM. Then place a jumper between the two screw heads on the sensor

termination. Rotate the discharge temperature set point dial until the desired voltage per temperature is obtained. After the

voltage is obtained, the EHM board must be reset. To reset the board, remove the jumpers and then place back in correct

position.

TEMP dc VOLT TEMP dc VOLT TEMP dc VOLT TEMP dc VOLT TEMP dc VOLT

68 0.00 80 0.58 90 0.95 100 1.23 110 1.44

69 0.05 81 0.62 91 0.98 101 1.25 111 1.46

70 0.10 82 0.66 92 1.01 102 1.27 112 1.48

71 0.15 83 0.70 93 1.04 103 1.30 113 1.50

72 0.20 84 0.74 94 1.07 104 1.32 114 1.51

73 0.26 85 0.77 95 1.10 105 1.34 115 1.53

74 0.30 86 0.81 96 1.12 106 1.36 116 1.55

75 0.35 87 0.85 97 1.15 107 1.38 117 1.56

76 0.40 88 0.88 98 1.18 108 1.40 118 1.58

77 0.44 89 0.91 99 1.20 109 1.42 119 1.60

78 0.49 120 1.61

79 0.53

It should be noted that ASHRAE Fundamentals Handbook (Chapter 31) states that discharging air at a temperature more than

15°F above the room (90°F in a 75°F room) will likely result in significant unwanted air temperature stratification.

It is recommended that heater output is ramped or staged when switching from cooling to heating modes. On initial call for

maximum or near maximum heat, from cooling mode, the heater may overshoot the desired temperature by up to 20°F for 10

to 20 seconds (on oversized heaters). As the EHM begins modulating heater output, the discharge temperature will quickly

drop to the desired set point. Temperatures within ±2°F of desired set point are reached within 90 seconds with oversized

heaters.

3

Page 4

TROUBLESHOOTING

Problem: No Heat when called for.

1) Confirm the jumper setting is correct for the input given.

a) If the controls are outputting Vdc, the jumper should be set as shown on page 1 for applications LX3, and

LX4.

b) If the controls are outputting 24Vac, the jumper setting should be set as shown on pages 1 & 2 for

applications LX1, LX2, LX5, LX6, & LX7. (Also see diagrams on page 6 & 7)

2) Check that wiring to the EHM is correct.

a) If using applications LX3 and LX4, confirm the positive Vdc connection is wired to the “Signal” terminal,

and the negative Vdc connection is wired to the “Com“ terminal.

b) If using 24Vac, confirm the wires are terminated correctly at (5) with a connection at “iCom”. If an “Aux”

terminal (2) on the EHM has been jumpered to “iCom”, make sure that the opposite 24Vac input is what is

outputted at the controls (See page 7 for one example).

3) Check that airflow is above minimum. Terminal units with electric heat come with pressure switches to insure that

heater elements have airflow over them. See catalog for minimum airflow required for specific size terminal units.

Fan boxes must have minimum downstream static of 0.2”.

4) Check that discharge temperature setpoint is not below the airflow temperature.

5) Check Relay wiring. Solid state relays are polarity sensitive. The wire from “+” on the EHM control board should be

terminated on “+3” VDC terminal of the relay. The wire from “-“ on the EHM control board should be terminated on

“4-“ VDC terminal of the relay. If there are two relays used in the heater, the relays are daisy chained from “4-“ to

“+3” together (See page 7 for one example).

Problem: Discharge Temperature not at Temperature Setting.

1) Check that wires from sensor are stripped and terminated in EHM control terminals.

2) Check that wires from controls are terminated at the correct point on EHM board. Inrease or stage 1 signal should be

terminated at “Inc”. Decrease or stage 2 signal should be terminated at “Dec”.

3) Check volt setting. Use chart and procedure on page 3.

4) Check sensor placement. Make sure that sensor is well placed vertically in ductwork and at least 36” from discharge.

Sensor tip should not touch inside of ductwork.

5) Try staging or ramping of output on oversized heaters. When controls call for full heat from cooling mode, if heaters

are too large and heating times are small, the heater output may be over setpoint. Staging or ramping of output over a

60 second interval will provide smooth transition. If only one output of heat is available from controls, application

LX5 will proportionally ramp heat output from 0 to 100% over a 2 minute 15 second span.

4

Page 5

ENCLOSURE

VOLTAGE

HEATER

APPLICATION

LX3

(0-20mA)

0-10 Vdc

TO HI

ENCLOSURE

VOLTAGE

TO HI

APPLICATION

LX1

HEATER

ON/OFF

SEQUENCE

BLACK #18

DESIGNATED

FOR CONTROL

YEL #18

BLUE #18

RED #18

ON PINS

JUMPERS

24Vac

Neutral

Relay +

Relay -

Xfmr

Neutral24Vac

Neutral24Vac

+

+

Relay

Relay

SSRs

-

-

On/Off

Float

Incr

0-10V

2Stg

2-10V

Bin

Select Sequence>

Com

Tcal

32°C

90°F

120°F

49°C

20°C

68°F

High

Limit

EVO/EHM-

Earth

PLACE

SENSOR

Neutral 24Vac

Signal

Com

Dec

iCom

Inc

DISCHARGE

TEMP

Aux

10Vmax

(24Vac)

(24Vac)

OPTIONAL

24VacNeutral

Neutral

iCOM

Signal

INC

Red

Black

Sensor Com

Dec

iCom

Inc

24Vac

BLUE #18

BLACK #18

RED #18

ANALOG OUT POS

ANALOG OUT NEG

CONTROLLER

24VAC INPUT

YELLOW #18

SEQUENCE

BLACK #18

DESIGNATED

FOR CONTROL

ON PINS

YEL #18

BLUE #18

RED #18

JUMPERS

24Vac

Neutral

Relay +

Relay -

Xfmr

Neutral24Vac

Neutral24Vac

+

+

Relay

Relay

SSRs

-

-

On/Off

Float

Incr

0-10V

2Stg

2-10V

Bin

Select Sequence>

Com

Tcal

32°C

90°F

120°F

49°C

20°C

68°F

High

Limit

EVO/EHM-

Earth

PLACE

Aux

Neutral 24Vac

Signal

10Vmax

Com

Dec

(24Vac)

iCom

(24Vac)

Inc

OUTPUT

24Vac

24VacNeutral

Neutral

Signal

Sensor Com

Dec

iCOM

iCom

INC

Inc

HEATER

CONTROLS

YELLOW #18

BLUE #18

Black

POWER

CONTROLS

TO

BLACK #18

RED #18

COMMON

CONTROLS

Red

DISCHARGE

OPTIONAL

SENSOR

TEMP

ENCLOSURE

VOLTAGE

HEATER

APPLICATION

TO HI

LX4

(4-20mA)

2-10 Vdc

YEL #18

BLUE #18

RED #18

BLACK #18

24Vac

Neutral

Relay +

Relay -

Xfmr

Neutral24Vac

Neutral24Vac

+

+

Relay

Relay

SSRs

-

-

On/Off

Float

Incr

0-10V

2Stg

2-10V

Bin

Select Sequence>

Com

Tcal

32°C

90°F

120°F

49°C

20°C

68°F

High

Limit

EVO/EHM-

Earth

24Vac

24VacNeutral

Aux

Neutral

Neutral 24Vac

iCOM

Signal

Signal

INC

10Vmax

Com

Red

Black

Sensor Com

Dec

Dec

(24Vac)

iCom

iCom

(24Vac)

Inc

Inc

BLACK #18

RED #18

ANALOG OUT POS

ANALOG OUT NEG

YELLOW #18

BLUE #18

24VAC INPUT

ENCLOSURE

VOLTAGE

TO HI

APPLICATION

LX2

HEATER

2 STAGE

YEL #18

BLUE #18

RED #18

BLACK #18

24Vac

Neutral

Relay +

Relay -

Xfmr

Neutral24Vac

Neutral24Vac

+

+

Relay

Relay

SSRs

-

-

On/Off

Float

Incr

0-10V

2Stg

2-10V

Bin

Select Sequence>

Com

Tcal

32°C

90°F

120°F

49°C

20°C

68°F

High

Limit

EVO/EHM-

Earth

24Vac

24VacNeutral

Aux

Neutral

Neutral 24Vac

Signal

Signal

10Vmax

Com

Red

Black

Sensor Com

Dec

Dec

Dec

iCOM

(24Vac)

iCom

iCom

(24Vac)

INC

Inc

Inc

WHITE #18

BLACK #18

RED #18

POWER

YELLOW #18

BLUE #18

CONTROLS

TO

SEQUENCE

DESIGNATED

FOR CONTROL

PLACE

ON PINS

JUMPERS

DISCHARGE

OPTIONAL

SENSOR

TEMP

CONTROLLER

SEQUENCE

FOR CONTROL

ON PINS

JUMPERS

COMMON

2ND STAGE

1ST STAGE

DISCHARGE

OPTIONAL

SENSOR

TEMP

PLACE

DESIGNATED

CONTROLLER

5

Page 6

ENCLOSURE

VOLTAGE

LX7

FLOATING

HEATER

(Float)

APPLICATION

THREE POINT

TO HI

ENCLOSURE

VOLTAGE

(Incr)

INCREMENTAL

LX5

HEATER

APPLICATION

TO HI

SEQUENCE

BLACK #18

DESIGNATED

FOR CONTROL

YEL #18

BLUE #18

RED #18

ON PINS

JUMPERS

24Vac

Neutral

Relay +

Relay -

Xfmr

Neutral24Vac

Neutral24Vac

+

+

Relay

Relay

SSRs

-

-

On/Off

Float

Incr

0-10V

2Stg

2-10V

Bin

Select Sequence>

Com

Tcal

32°C

90°F

120°F

49°C

20°C

68°F

High

Limit

EVO/EHM-

Earth

PLACE

24Vac

24VacNeutral

Aux

Neutral

Neutral 24Vac

Signal

Signal

10Vmax

Com

Red

Black

Dec

Dec

Dec Sensor Com

iCOM

(24Vac)

iCom

(24Vac)

Inc

iComInc

INCREASE

INC

HEATER

BLACK #18

RED #18

DECREASE

COMMON

BLUE #18

POWER

WHITE #18

CONTROLS

HEATER

DISCHARGE

SENSOR

TEMP

TO

OPTIONAL

YELLOW #18

SEQUENCE

BLACK #18

DESIGNATED

FOR CONTROL

YEL #18

BLUE #18

RED #18

ON PINS

JUMPERS

24Vac

Neutral

Relay +

Relay -

Xfmr

Neutral24Vac

Neutral24Vac

+

+

Relay

Relay

SSRs

-

-

On/Off

Float

Incr

0-10V

2Stg

2-10V

Bin

Select Sequence>

Com

Tcal

32°C

90°F

120°F

49°C

20°C

68°F

High

Limit

EVO/EHM-

Earth

PLACE

24Vac

24VacNeutral

Aux

Neutral

Neutral 24Vac

Signal

Signal

10Vmax

Com

Sensor Com

Dec

Dec

iCOM

(24Vac)

iCom

iCom

(24Vac)

INC

Inc

Inc

HEATER

OUTPUT

Black

BLACK #18

RED #18

CONTROLS

COMMON

Red

CONTROLS

SENSOR

BLUE #18

POWER

CONTROLS

DISCHARGE

TEMP

YELLOW #18

TO

OPTIONAL

CONTROLLER

ENCLOSURE

VOLTAGE

HEATER

APPLICATION

TO HI

LX6

BINARY 3 STAGE

(Bin)

YEL #18

BLUE #18

RED #18

BLACK #18

24Vac

Neutral

Relay +

Relay -

Xfmr

Neutral24Vac

Neutral24Vac

+

+

Relay

Relay

SSRs

-

-

On/Off

Float

Incr

0-10V

2Stg

2-10V

Bin

Select Sequence>

Com

Tcal

32°C

90°F

120°F

49°C

20°C

68°F

High

Limit

EVO/EHM-

Earth

24Vac

24VacNeutral

Aux

Neutral

Neutral 24Vac

Signal

Signal

10Vmax

Com

Red

Black

Sensor Com

Dec

Dec

Dec

iCOM

(24Vac)

iCom

iCom

(24Vac)

INC

Inc

Inc

WHITE #18

BLACK #18

RED #18

POWER

YELLOW #18

BLUE #18

CONTROLS

TO

PLACE

DESIGNATED

FOR CONTROL

ON PINS

SEQUENCE

JUMPERS

COMMON

2ND STAGE

1ST STAGE

DISCHARGE

OPTIONAL

SENSOR

TEMP

CONTROLLER

6

Page 7

SAMPLE LINEAHEAT SCHEMATIC

MOVE JUMPER ON LINEAHEAT FROM

"NEUTRAL", TO "24VAC".

24Vac

Xfmr

Neutral

Neutral24Vac

+

+

Relay

Relay

INTERNALLY SWITCH "24VAC COM",

TO THE OUTPUTS. FOR CONTROLS THAT

CONTROLS WITH NO COMMON OUTPUT

THAT INTERNALLY SWITCHES "24VAC+"

DRAWING SHOWS WIRING FOR

SSRs

-

-

On/Off

Float

Incr

2Stg

Bin

Select Sequence>

CONTROLLER

Com

24VacNeutral

24Vac

Aux

Neutral

Tcal

Signal

Signal

10Vmax

32°C

90°F

2-10V

0-10V

UNIT

Com

Sensor Com

120°F

49°C

20°C

68°F

High

Limit

Dec

EVO/EHM-

Earth

TER M IN A L

Dec

(24Vac)

iCom

iCom

(24Vac)

Inc

Inc

7

Loading...

Loading...