Page 1

Installation, Operation and

TU-LSC-IOM-1.0

Maintenance

Low Profile, Series Fan Powered Terminal Unit with

Sensible Cooling Coil

(400 to 1800 cfm)

11-16-12

Model: LSC RevA

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating,

and air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or

altered equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all

precautions in the literature and on the tags, stickers, and labels that are attached to the equipm

This IOM is meant to demonstrate general dimensions and information of this product. The drawings are not meant to detail every aspect of the product. Drawings are not to scale.

®

605 Shiloh Road • Plano, Texas 75074• 972-212-4800

All rights reserved. No part of this work may be reproduced or transmitted in any form or any means, electronic or mechanical, including photocopying and recording, or by any information storage retrieval system without permission in writing from Air Distribution Technologies

Titus reserves the right to make changes without written notice.

ent.

Page 2

TU-LSC-IOM

Warnings, Cautions and Notices. Note that warnings,

cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provide to alert

installing contractors to potential hazards that could result in

death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in

personal injury, while notices indicate a situation that could

result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions. Read this manual thoroughly before operating

or servicing this unit.

ATTENTION: Warnings, Cautions and Notices appear at

appropriate sections throughout this literature. Read these

carefully:

WARNING Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION Indicates a potentially hazardous situation which,

if not avoided, could result in minor or moderate injury. It

could also be used to alert against unsafe practices.

NOTICE: Indicates a situation that could result in

equipment or property-damage only

WARNING

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements

for field wiring installation and grounding as described

in NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

WARNING

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure

to electrical, mechanical and chemical hazards.

Before installing/servicing this unit, technicians

MUST put on all Personal Protective Equipment

(PPE) recommended for the work being

undertaken. ALWAYS refer to appropriate MSDS

sheets and OSHA guidelines for proper PPE.

When working with or around hazardous

chemicals, ALWAYS refer to the appropriate MSDS

sheets and OSHA guidelines for information on

allowable personal exposure levels, proper

respiratory protection and handling

recommendations.

If there is a risk of arc or flash, technicians MUST

put on all Personal Protective Equipment (PPE) in

accordance with NFPA 70E or other countryspecific requirements for arc flash protection,

PRIOR to servicing the unit.

Failure to follow recommendations could result in

death or serious injury.

2

Page 3

Warnings, Cautions and Notices 2

Model Number Descriptions 4

General Information 6

Pre-Installation

Receiving and Handling 7

Shipping Package 7

Receiving Check List 7

Jobsite Storage 7

Installation Preparation 7

Service Access 8

Pre-Installation Check List 8

Components Data 9

Unit Dimensions 10

Coil Flange Connections 11

Weights 12

Water Coil Pipe Connections 13

Installation Mechanical

Duct Connections 14

Duct Work Recommendations 14

Hydronic Piping Consideration 14

Condensate Drain Connection 14

External Insulation Requirements 15

TU-LSC-IOM

Installation General - Hanging the Unit 16

Installation Check List 17

Installation Electric

Unit Wiring Diagrams 18

Supply Power Supply 18

Electric Heater Min-Max KW – Unit size 3 19

Electric Heater Min-Max KW – Unit size 4 20

ECM Motor Overview and Setup

Overview 21

General Information 21

ECM Motor Fan Flow Adjustment 21

Manual PWM Signal Interface Board 22

Operation 22

Remote PWM Signal Interface Board 22

Jumper Setup 23

Input / Output Control Signals 23

Remote Control Air Balance 23

Manual Air Balance 23

Pre-Startup Checklist 24

Maintenance

Maintenance Procedures 25

Air Filter 25

Inspecting and Cleaning Condensate Pans 25

Coil Maintenance 25

Inspecting and Cleaning Coils 25

Hydronic Coil Cleaning Procedures 26

Winterizing the Coil 26

Replacing Motors 26

Periodic Maintenance Check List 26

3

Page 4

TU-LSC-IOM

LSC – Low Profile Series Fan Powered Terminal Unit

with Cooling Coil

Following is a complete description of the LSC model

number. Each digit in the model has a corresponding

code that identifies specific unit options.

Digit 1, 2, 3, 4 – Unit Type

LSC = Basic Unit

LSCX = Special Unit

Digit 5, 6 – Cabinet Size

03 = Unit size 3

04 = Unit size 4

XX = Special

Digit 7 – Cabinet Configuration

R = Right Hand Control Enclosure

L = Left Hand Control Enclosure

X = Special

Digit 8, 9 – Cabinet Material

2G = 20Ga Galvanized Steel Cabinet

XX = Special

Digit 10 – Cabinet Liner

J = EcoShield Matte faced ½”

L = EcoShield Foil Faced ½”

0 = Fiberglass Dual Density ½”

3 = fiberglass Foil Faced ½”

9 = FiberFree ½”

X = Special

Digit 11 – ECM Motor Power Supply

1 = ECM motor 120V/1Ph/60Hz

2 = ECM Motor 208V/1Ph/60Hz

3 = ECM Motor 277V/1Ph/60Hz

X = Special

Digit 26 – Airflow Measuring Sensor

0= None

3= Aerocross

X = Special

Digit 27,28,29 – Cooling and Heating coils

200 = 2 Rows Cooling only coil

201 = 2 Rows Cool + 1 Row Heating coil

400 = 4 Rows Cooling only coil

401 = 4 Rows Cool + 1 Row Heating coil

XXX = Special

Digit 30, 31 – Filter (Optional Accessories)

00 = None

F1 = 1 x 1" Filter – NOT Ducted

F2 = 1 x 1" Filter + Spare Filter - NOT Ducted

F3 = 1 x 2" Filter – NOT Ducted

F4 = 1 x 2" Filter + Spare Filter - NOT Ducted

F5 = 1 x 1" Filter – Ducted

F6 = 1 x 1" Filter + Spare Filter - Ducted

F7 = 1 x 2" Filter – Ducted

F8 = 1 x 2" Filter + Spare Filter – Ducted

XX = Special

Digit 32,33 – Motor Fuses ( Optional Accessories)

00 = None

MF = Motor Fuses

XX = Special

Digit 34,35 –Unit Accessories

(Optional Accessories)

0= None

B = Hanger Brackets

Y = Slip & Drive Adaptor (Fan Discharge)

X = Special

Digit 36,37,38,39 – Controller

(Optional Accessories)

0000 = None

XXXX = Special

Digit 12 – Motor Control

M = Manual Control Board

R = Remote PWM Control

X = Special

Digit 13 – Primary Inlet Size

4 = 4" Diameter

6 = 6" Diameter

8 = 8" Diameter

22 = 16" x 8" Rectangular

XX = Special

Digit 14,15,16,17 – Minimum Primary Airflow (cfm)

Digit 18,19,20,21 – Maximum Primary Airflow (cfm)

Digit 22,23,24,25 – Fan Airflow (cfm)

Digit 40,41,42,43 – Damper Actuator (

Optional Accessories)

0000 = None

DT01 = Electronic Damper Actuator – Titus

XXXX = Special

Digit 44,45,46,47 – Controls Optional Accessories

0= None

D = Disconnect Switch (Non Fused)

E = Control Enclosure

G = Dust Tight Control Enclosure

T = Dust Tight Disconnect Switch

X = Special

4

Page 5

TU-LSC-IOM

Digit 48,49,50 – Electric Heaters Type

0= None

E21 = 208V/1Ph 1Stage

E22 = 208V/1Ph 2 Stages

E23 = 208V/1Ph 3 Stages

E31 = 240V/1Ph 1Stage

E32 = 240V/1Ph 2 Stages

E33 = 240V/1Ph 3 Stages

E41 = 277V/1Ph 1Stage

E42 = 277V/1Ph 2 Stages

E43 = 277V/1Ph 3 Stages

E61 = 208V/3Ph 1Stage

E62 = 208V/3Ph 2 Stages

E63 = 208V/3Ph 3 Stages

E91 = 480V/3Ph 1Stage

E92 = 480V/3Ph 2 Stages

E93 = 480V/3Ph 3 Stages

E21 = 208V/1Ph 1Stage

E22 = 208V/1Ph 2 Stages

E23 = 208V/1Ph 3 Stages

L21 = 208V/1Ph Lynergy PWM

L22 = 208V/1Ph Lynergy 2 Stage

L23 = 208V/1Ph Lynergy 0-10V or 0-20mA

L24 = 208V/1Ph Lynergy 2-10V or 4-20mA

L25 = 208V/1Ph Lynergy Incremental T-stat

L26 = 208V/1Ph Lynergy Binary

L27 = 208V/1Ph Lynergy 3 Point Floating

L31 = 240V/1Ph Lynergy PWM

L32 = 240V/1Ph Lynergy 2 Stage

L33 = 240V/1Ph Lynergy 0-10V or 0-20mA

L34 = 240V/1Ph Lynergy 2-10V or 4-20mA

L35 = 240V/1Ph Lynergy Incremental T-stat

L36 = 240V/1Ph Lynergy Binary

L37 = 240V/1Ph Lynergy 3 Point Floating

L41 = 277V/1Ph Lynergy PWM

L42 = 277V/1Ph Lynergy 2 Stage

L43 = 277V/1Ph Lynergy 0-10V or 0-20mA

L44 = 277V/1Ph Lynergy 2-10V or 4-20mA

L45 = 277V/1Ph Lynergy Incremental T-stat

L46 = 277V/1Ph Lynergy Binary

L47 = 277V/1Ph Lynergy 3 Point Floating

L61 = 208V/3Ph Lynergy PWM

L62 = 208V/3Ph Lynergy 2 Stage

L63 = 208V/3Ph Lynergy 0-10V or 0-20mA

L64 = 208V/3Ph Lynergy 2-10V or 4-20mA

L65 = 208V/3Ph Lynergy Incremental T-stat

L66 = 208V/3Ph Lynergy Binary

L67 = 208V/3Ph Lynergy 3 Point Floating

L91 = 480V/3Ph Lynergy PWM

L92 = 480V/3Ph Lynergy 2 Stage

L93 = 480V/3Ph Lynergy 0-10V or 0-20mA

L94 = 480V/3Ph Lynergy 2-10V or 4-20mA

L95 = 480V/3Ph Lynergy Incremental T-stat

L96 = 480V/3Ph Lynergy Binary

L97 = 480V/3Ph Lynergy 3 Point Floating

Digit 51,52,53 – Electric Heaters KW rating

1.0 = 1.0 KW

1.5 = 1.5 KW

(Refer to 19 & 20 for available KW rating for alternative

power supply voltages)

Digit 54 – Mercury Contactor

0= None

B = Mercury Contactor

X = Special

Digit 55 – Electric Heater Disconnect Switch and Fuses

0= None

C= Fuses

D = Disconnect Switch Door Interlock Fused

E = Disconnect Switch Door Interlock

X = Special

Digit 56, 57, 58 – Electric Heater Accessories

0= None

F = Secondary Manual Reset Cutout

G = Dust Tight Enclosure

T = Lynergy Discharge Limit Temp Sensor

X = Special

5

Page 6

TU-LSC-IOM

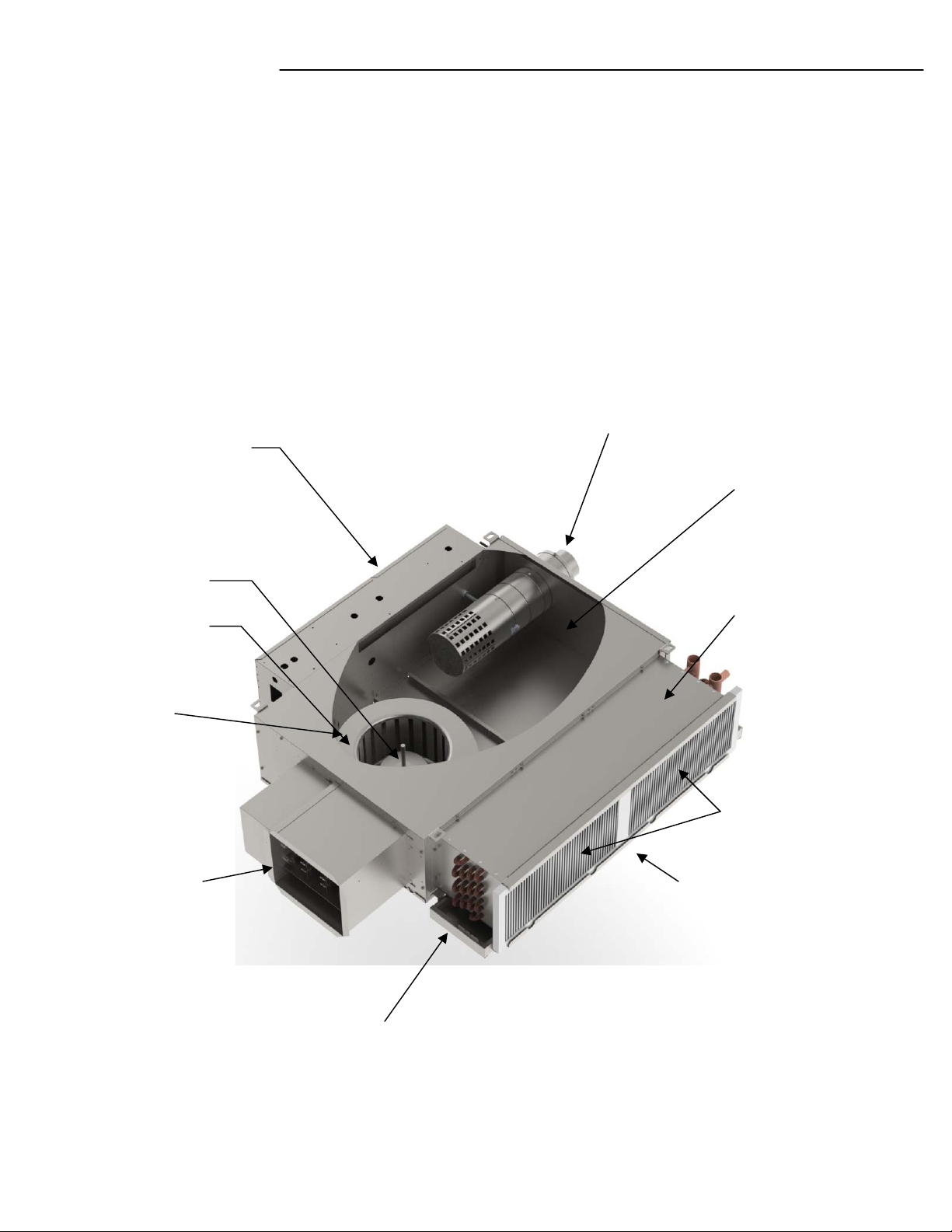

General Information

The LSC units are intended for single or multi zone applications with an airflow range of 400 to 1850 CFM. The LSC units

incorporate as standard a Primary Air damper which receives air from a Dedicated Outside Air system (DOAS), high

efficiency ECM motor(s) and are available as two-pipe systems with or without electric heat (one hydronic circuit), four-pipe

system (two hydronic circuits) or four-pipe with standby electric heating. The unit mounted low voltage 24 VAC, 50VA

Class II transformer provides low voltage to the ECM motor controls and connections field mounted controller/damper

actuator. See Figure 1 for unit components.

FIGURE 1: LSC Unit Major Components (Unit Size 3 shown)

Primary Air Inlet c/w:

Aerocross – Airflow measuring device

Damper Blade

Control Enclosure

EcoShield Liner

ECM Motor

DWDI Centrifugal

Blower

Electric Heater

(Optional)

Sensible Cooling Coil

and

Hot Water Coil

Filter MERV8 (Optional)

Return Air:

Non Ducted (STD)

Ducted Flange (Optional)

Condensate Pan

6

Page 7

Pre - Installation

TU-LSC-IOM

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote disconnects

and discharge all motor start/run capacitors before

servicing. Follow proper lockout/ tagout procedures to

ensure the power cannot be inadvertently energized. For

variable frequency drives or other energy storing

components provided by Titus or others, refer to the

appropriate manufacturer’s literature for allowable waiting

periods for discharge of capacitors. Verify with an

appropriate voltmeter that all capacitors have discharged.

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious injury.

Receiving and Handling

Upon delivery, inspect all components for possible

shipping damage. See “Receiving Checklist” (below) for

detailed instructions. Titus recommends leaving units and

accessories in their shipping packages/skids for protection

and ease of handling until installation.

Shipping Package

The LSC units are multi packed and ship in pallets for

handling and storage ease. Each Unit has tagging

information such as the model number, sales order

number, serial number, unit size, piping connections, and

unit style to help properly locate the unit in the floor plan. If

specified, the unit will ship with tagging designated by the

customer.

Do not continue unpacking the shipment if it appears

damaged. Retain all internal packing, cartons, and crate.

Take photos of damaged material.

Notify the carrier’s terminal of the damage immediately

by phone and mail. Request an immediate joint inspection

of the damage by the carrier and consignee.

Notify your Titus representative of the damage and

arrange for repair. Have the carrier inspect the damage

before making any repairs to the unit.

Compare the electrical data on the unit nameplate with

the ordering and shipping information to verify the correct

unit is received.

Jobsite Storage

This unit is intended for indoor use only. Store the unit

indoors to protect the unit from damage due to the

elements. If indoor storage is not possible, make the

following provisions for outdoor storage:

1. Place the unit(s) on a dry surface or raised off the

ground to assure adequate air circulation beneath unit and

to assure that no portion of the unit contacts standing water

at any time.

2.Cover the entire unit with a canvas tarp only. Do not use

clear, black or plastic tarps as they may cause excessive

moisture condensation and equipment damage.

Receiving Checklist

Complete the following checklist immediately after

receiving unit shipment to detect possible shipping

damage.

Inspect individual pallets before accepting. Check for

rattles, bent corners, or other visible indications of

shipping damage.

If a unit appears damaged, inspect it immediately before

accepting the shipment. Manually rotate the fan wheel to

ensure it turns freely. Make specific notations concerning

the damage on the freight bill. Do not refuse delivery.

Inspect the unit for concealed damage before it is stored

and as soon as possible after delivery. Report concealed

damage to the freight line within the allotted time after

delivery. Check with the carrier for their allotted time to

submit a claim.

Do not move damaged material from the receiving

location. It is the receiver’s responsibility to provide

reasonable evidence that concealed damage did not occur

after delivery.

Installation Preparation

Before installing the unit, consider the following unit

location recommendations to ensure proper unit operation.

1. Clearances: Allow adequate service and code

clearances as recommended in “Service Access” (the next

section). Position the unit and skid assembly in its final

location.

2.Structural support: Ensure the structural support is strong

enough to adequately support the unit. The installer is

responsible for supply support rods for installation of ceiling

units.

3.Level: To ensure proper unit operation, install the unit

level (zero tolerance) in both horizontal axes. Failure to

level the unit properly can result in condensate

management problems, such as standing water inside the

unit.

4.Condensate line & piping: Consider coil piping and

condensate drain requirements. Verify condensate line is

continuously pitched 1 inch per 10 feet of condensate line

run to adequately drain condensate.

7

Page 8

TU-LSC-IOM

Pre – Installation (Cont.)

5. Wall & ceiling openings: concealed units require wall/

ceiling openings. Refer to submittal for specific dimensions

before attempting to install. Concealed units must meet the

requirements of the National Fire Protection Association

(NFPA) Standard 90A or 90B concerning the use of

concealed ceiling spaces as return air plenums. Refer to

the submittal for specific dimensions of ceiling openings.

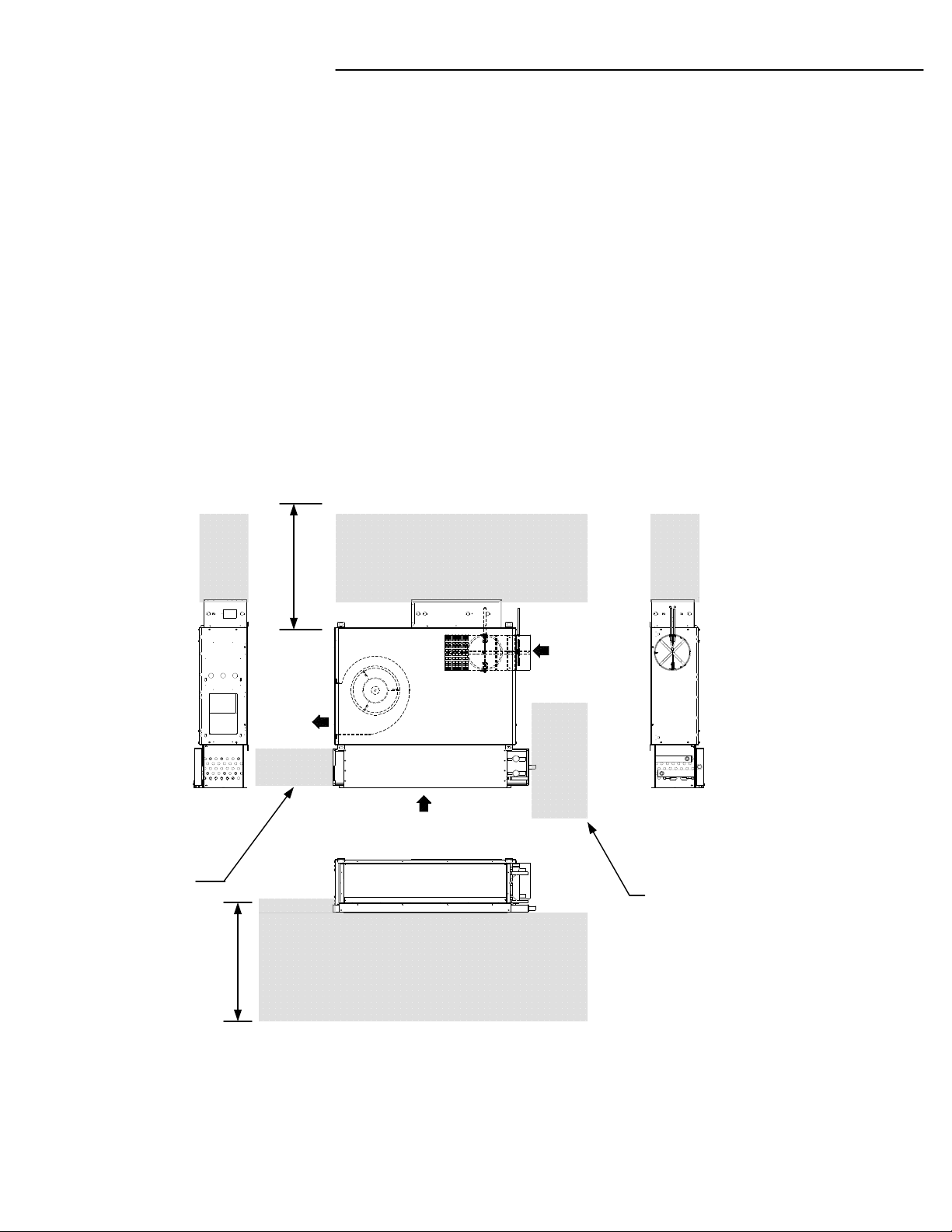

Service Access

Service access is available from the bottom and sides of

the units. Units have removable bottom and side panels to

allow access into the unit. See Figure 2 for recommended

service and operating clearances. Units have front or back

piping connections. Reference piping locations by facing

the front of the unit (airflow discharges from the front). The

control panel is always on the opposite the piping.

Figure 2.

Control Enclosure Access

Min 3'

Pre-Installation Checklist

Complete the following checklist before beginning unit

installation.

Verify the unit size and tagging with the unit nameplate.

Make certain the ceiling is solid, and sufficient to support

the unit and accessory weights. See “Dimensions and

Weights” section.

Allow minimum recommended clearances for routine

maintenance and service. Refer to unit submittals for

dimensions.

Allow 4' of straight duct before the first takeoff or before

the discharge ductwork makes any turns.

FRONT

Air

Discharge

Return Air

Alternative

Condensate Pan

Removal

Bottom Access Area for

Min 3'

Notes:

1. Right Hand unit shown. Control enclosure dictates the

handing of the unit.

2. Condensate Pan may be removed from the front or rear

of the unit.

3.All LSC units are installed with removable bottom access

panels.

Service & Maintenance

Air

Primary

REAR

Coil Connections Access +

Condensate Pan removal

8

Page 9

Components Data

Unit Size 03 04

Cooling Coil Data

TU-LSC-IOM

Heating Coil Data

Fan / Motor Data

Face Area (ft2)

L x D x H (in)

2 Row

4 Row

Volume (US Gal)

2 Row

4 Row

Fin per Inch

Face Area – ft2

1 Row

Volume – US Gal

1 Row

Fan Quantity

2.1875 2.1875

36 x 9 5/8 x 8 3/4 36 x 9 5/8 x 8 3/4

36 x 9 5/8 x 8 3/4 36 x 9 5/8 x 8 3/4

1.75 1.75

3.5 3.5

10 FPI 10 FPI

2.1875 2.1875

36 x 9 5/8 x 8 3/4 36 x 9 5/8 x 8 3/4

0.875 0.875

1 2

Size – Dia(in) x Width (in)

Motor Quantity

Motor Power (HP)

Filter Data

Quantity

Size L x H (Nominal in)

Type

Filtration Efficiency

Notes:

1. Filter dimensions are nominal dimensions

10 5/8 x 8 7/8 10 5/8 x 8 7/8

1 2

1 x 1/3 HP 2 x 1/3 HP

2 2

20 x 10 (each) 20 x 10 (each)

Pleated Pleated

MERV 8 MERV 8

9

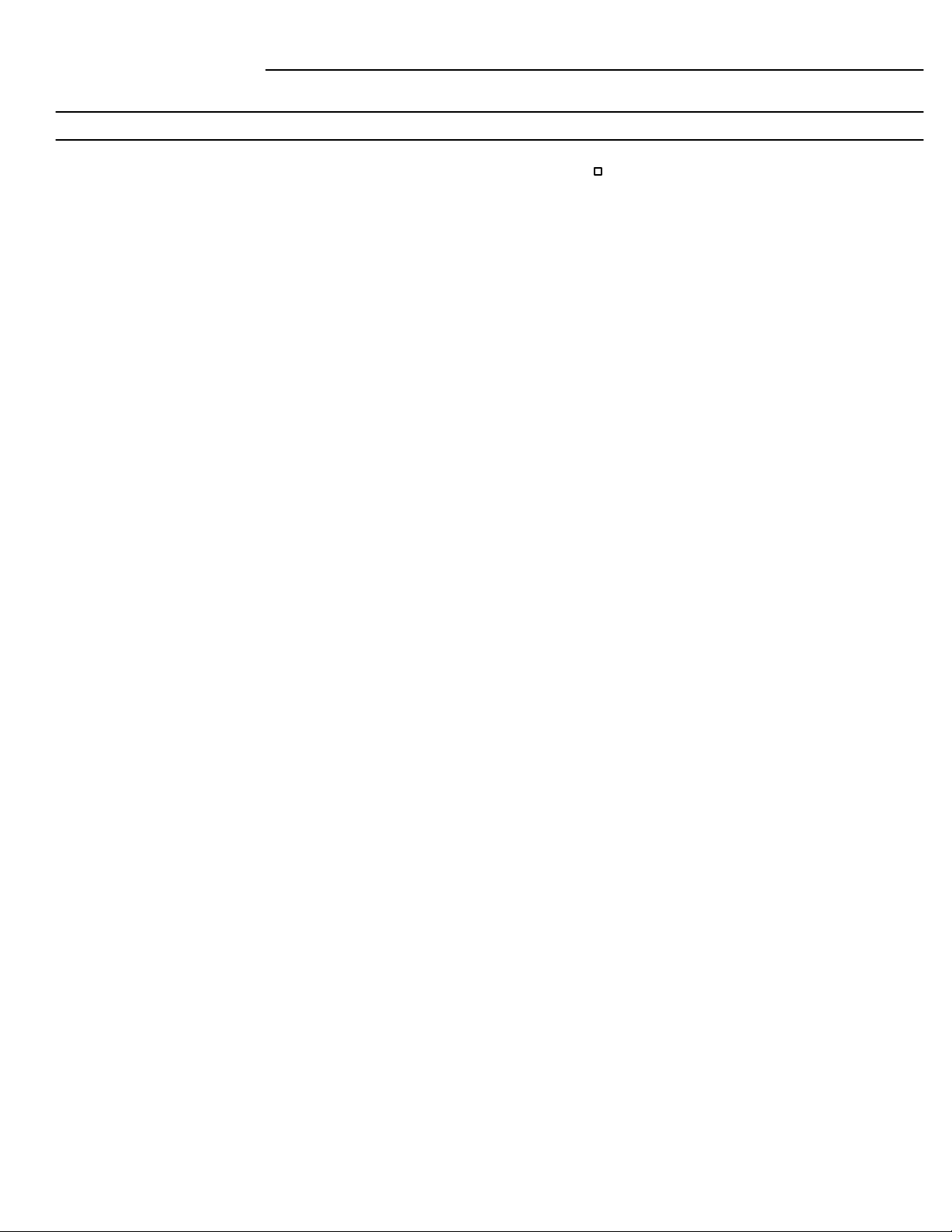

Page 10

TU-LSC-IOM

Dimensions

Unit Size 3

Control Enclosure

ECM Motor

Controller

Supply Air

Water Coil

Unit Size 4 (With Round Primary Air Inlet)

Damper Shaft

Motor/Blower

Assy

Return

Induced Air

Damper Shaft

Primary Air

Supply

Condensate Pan

Condensate Pan Connection - ¾” Dia

Right Hand unit shown. All dimensions are in inches.

Primary Air

Damper

AeroCross

Velocity Sensor

Drawing No: LSC002

Drawing No: LSC001

Water Coil

Control Enclosure

ECM Motor

Controller

Supply Air

Motor/Blower

Assy(s)

Induced Air

Supply

Primary Air

Supply

Condensate Pan

Condensate Pan Connection - ¾” Dia

Primary Air

Damper

AeroCross

Velocity Sensor

10

Right Hand unit shown. All dimensions are in inches.

Page 11

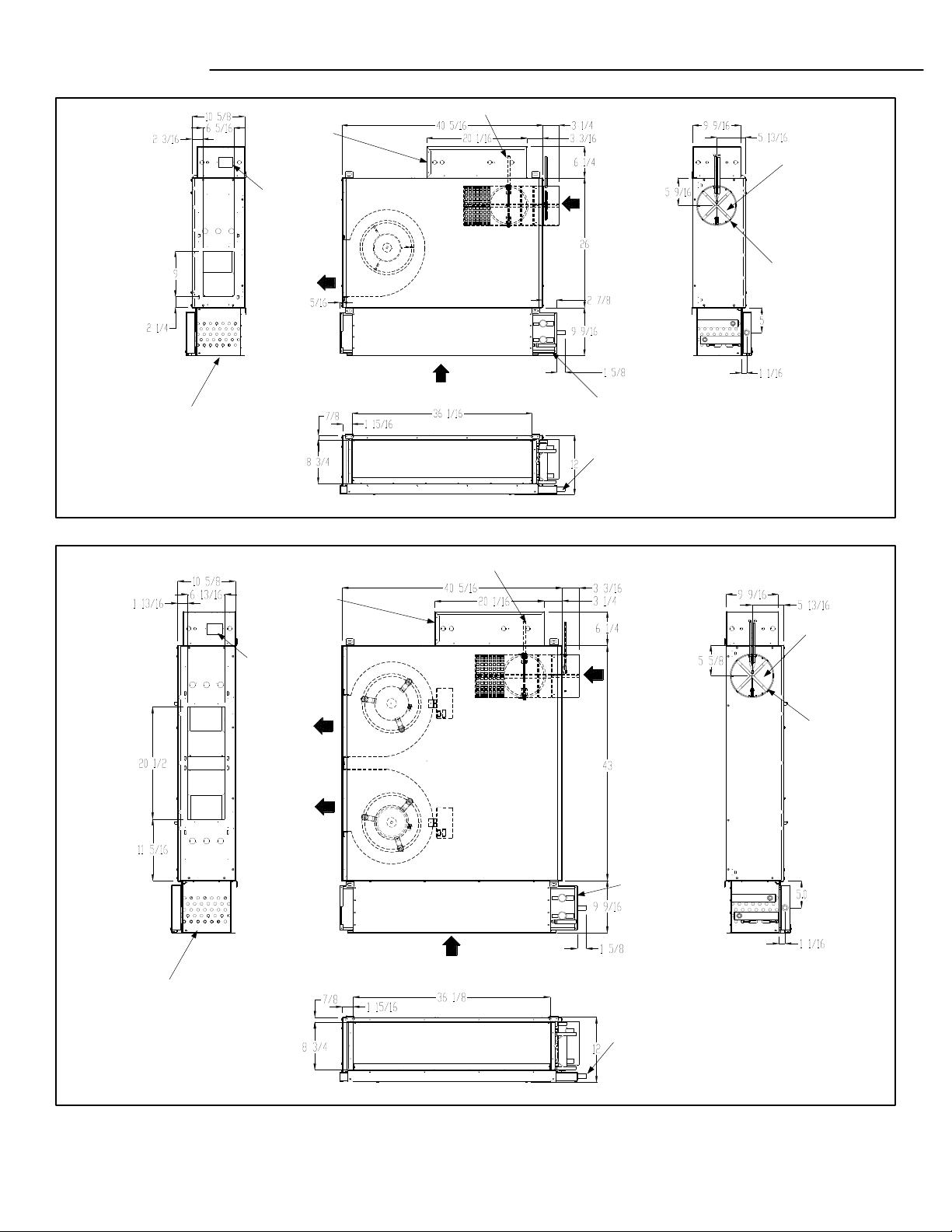

Dimensions (Cont)

TU-LSC-IOM

Unit Size 4 (With Rectangular Primary Air Inlet)

Control Enclosure

ECM Motor

Controller

Supply Air

Water Coil

Damper Shaft

Motor/Blower

Assy(s)

Induced Air

Supply

Primary Air

Supply

Condensate Pan

Drawing No: LSC003

Primary Air

Damper

AeroCross

Velocity Sensor

Unit Size 3 – Electric Heater Option

Drawing No: LSC013

Condensate Pan Connection - ¾” Dia

Right Hand unit shown. All dimensions are in inches.

Unit Size 4 – Electric Heater Option

Drawing No LSC014

11

Page 12

TU-LSC-IOM

Return Air - Cooling/Heating Coils Flange Connection (No Filter)

Drawing No: LSC004

Coil Conections

Primary Air

Supply

Condensate

Right Hand unit shown. All

dimensions are in inches.

Pan

Weights

Return Air - Cooling/Heating Coils Flange Connection (No Filter)

Drawing No: LSC015

Right Hand unit shown. All

dimensions are in inches.

U)sbL( sthgieW gnippihs tinU nit Installed Weights (Lbs)

WEIGHTS (Lbs)

UNIT

SIZE

Basic Unit

3 110

4 160

Cooling + Heating Coils

2R 2+1R 4R 4+1R

14 17 25.5

22.5

14 17 22.5 25.5

Unit Labels

Each unit will have two main labels attached to the casing.

The FAN UNIT label lists:

Model Number

Model Number Description

Unit Power Supply requirements

Motor Horsepower

Full Load Amps

Electric Heater Power Supply requirements

Power – KW

Amperage consumption

Minimum Circuit Amps

Max Recommended Fuse

Heater

Electric

23

23

WEIGHTS (Lbs)

UNIT

SIZE

Basic Unit

3 110

4 160

Notes:

Includes the weight of water in the coils.

Unit Labels

Read all labels on a typical unit, before beginning

installation.

Cooling + Heating Coils

2R 2+1R 4R 4+1R

16.5 21 32.25

28

16.5 21 32.2528

NOTICE

LSC

Heater

Electric

23

23

The AIR FLOW label lists:

Model Number

Unit Size

Factory Order Number

TAG / Location - indicates the engineer's planned

location for the unit to be installed.

There may be other labels attached to the unit, as options or

codes may require.

If you have any questions, please contact the local TITUS

Representative for clarification. Have the key points from the

Flow label available for reference before calling.

Air

LSC

12

Page 13

Water Coil(s) Connections

TU-LSC-IOM

Units with Right Hand Control Panel

Check if provided.

Drawing No: LSC005

2R Cool 4R Cool

2R Cool

1R Heat

4R Cool

1R Heat

Units with Left Hand Control Panel

2R Cool

2R Cool

1R Heat

Drawing No: LSC006

4R Cool

4R Cool

1R Heat

13

Page 14

TU-LSC-IOM

Installation - Mechanical

Duct Connections

Install all air ducts according to National Fire Protection

Association standards for the Installation of Air

Conditioning and Ventilating Systems (NFPA 90A and

90B). Install all air ducts according to the National Fire

Protection Association standards for the “Installation of Air

Conditioning and Ventilation Systems other than

Residence Type (NFPA 90A) and Residence Type Warm

Air Heating and Air Conditioning Systems (NFPA 90B).

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote disconnects

and discharge all motor start/run capacitors before

servicing. Follow proper lockout/ tagout procedures to

ensure the power cannot be inadvertently energized. For

variable frequency drives or other energy storing

components provided by Titus or others, refer to the

appropriate manufacturer’s literature for allowable waiting

periods for discharge of capacitors. Verify with an

appropriate voltmeter that all capacitors have discharged.

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious injury.

Piping Considerations Hydronic Coil Piping

Before installing field piping to the coil, consider the

following:

• Coil connections can be 5/8-inch O.D. (or 1/2-inch

nominal) or 7/8-inch O.D. (or ¾-inch nominal) sweat

copper connections.

• The supply and return piping should not interfere with

the auxiliary drain pan or condensate line connection.

• Supply connection should always be at the bottom of

the coil and return at the top.

• An Air Vent valve must be installed at the highest point

of the water coil to allow removal of “air pockets” inside

the coil.

•The installer must provide adequate piping system

filtration and water treatment.

• Solder the joints using bridgit lead-free solder (ASTM

B32-89) to provide a watertight connection. Avoid

overheating factory soldered joints when soldering field

connections to the coil to prevent leakage from occurring.

The unit’s duct connections varies dependent on options

ordered. Titus recommends using galvanized sheet metal

ductwork with the LSC units. All duct connections should

be sealed and fasten with sheetmetal screws.

Note: Do not run screws through the removable front

panels.

Ductwork Recommendations

Follow the general recommendations listed below when

installing ductwork for the unit.

1. Discharge ductwork should run in a straight line,

unchanged in size or direction, for a minimum of 4'.

2.When making duct turns, placing takeoffs and

transitions avoid sharp turns and use proportional

splits, turning vanes, and air scoops when necessary.

3.When possible, construct, and orient supply ductwork

turns in the same direction as the fan rotation.

• Insulate all piping to coil connections as necessary after

connections and pressure test are complete.

Note: When installing a field piping package in a LSC

unit, allow sufficient room to remove the auxiliary drain

pan.

Condensate Drain Connection (If installed)

1. De-burr the pipe end before making the connection to

the drain pan.

2. Connect a 7/8-inch O.D. copper pipe or tube, with a

0.20 inch wall thickness, to the auxiliary drain pan. This

should be a mechanical connection that allows easy

removal of the auxiliary drain pan when servicing the

piping end pocket.

3 .Slide the copper pipe over the drain pan nipple and

tighten the collar on the pipe with a hose clamp (installer

supplied).

Maintain a continuous drain line pitch of one inch per ten

feet of drain line run to provide adequate condensate

drainage. Extend the drain line straight from the drain pan

a minimum distance of six inches before making any

turns. The installer must provide proper support for the

drain line to prevent undue stress on the auxiliary drain

pan.

Note: The installer is responsible for adequately

insulating field piping. See the “External Insulating

Requirements section for more information.

14

Page 15

Installation – Mechanical (Cont)

External Insulating Requirements

Insulate and vapor seal surfaces colder than surrounding

air dew-point to prevent unplanned condensation. Titus

recommends field-insulation of the following areas to

prevent potential condensate problems:

1. Supply and return water piping connections

2. Condensate drain lines and connections

3. Fresh air intake duct connections

4. Discharge duct connections

TU-LSC-IOM

15

Page 16

TU-LSC-IOM

Installation – General

Installing the Unit

Follow the procedures below to install the unit properly.

Refer to “Dimensions and Weights,” Section for specific

unit dimensions and mounting hole locations.

panel against the unit,

NOTICE

Electrical Wiring!

Do not allow electrical wire to fall between the unit and

installation surface. Failure to comply may result in

electrical shorts or difficulty accessing wires.

NOTICE

Motor Overload!

All unit panels and filters must be in place prior to unit

startup. Failure to have panels and filters in place may cause

motor overload.

Install horizontal units suspended from the ceiling using metal

straps or the optional Hanging Brackets located on the top of the

unit. The hanger holes allow a maximum shank size of 1/2-inch

diameter threaded rods or lag screws (installer provided).

Note: Follow the requirements of National Fire Protection

Association (NFPA) Standard 90A or 90B, concerning the use of

concealed ceiling spaces as return air plenums.

Hanger Brackets – Size 3 Unit

Drawing No: LSC009

Top View

Side View

Drawing No: LSC010

Hanger Brackets – Size 4 Unit

Top View

Follow the installation procedure below.

1. Prepare the ceiling opening for recessed units. Reference

the unit submittals for dimensions.

2. Position and install the suspension rods or a suspension

device (supplied by installer) according to the unit model and

size in “Dimensions and Weights,”

4. Level the unit by referencing the chassis end panels.

Adjust the suspension device.

5. Complete piping and wiring connections, in addition to any

necessary ductwork as instructed in the following sections.

6. Install the bottom panel before starting the unit.

7. If installed ensure condensate drain line is pitched one inch

per ten feet of pipe away from the LSC unit.

Side View

16

Page 17

Installation Checklist

TU-LSC-IOM

WARNING

Hazardous Voltage w/Capacitors!

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by Trane

or others, refer to the appropriate manufacturer’s

literature for allowable waiting periods for discharge of

capacitors. Verify with an appropriate voltmeter that all

capacitors have discharged. Failure to disconnect

power and discharge capacitors before servicing

could result in death or serious injury

NOTICE

Unit Leveling!

The unit must be installed level (zero tolerance) in both

horizontal axis for proper operation.

The following checklist is only an abbreviated guide to the

detailed installation procedures given in this manual. Use this

list to ensure all necessary procedures are complete. For more

detailed information, refer to the appropriate sections in this

manual.

10. Complete all necessary duct connections.

11. Install the filed supplied controls.

12. Complete all interconnection wiring.

13. Connect electrical supply power according to the

NEC and unit wiring diagrams.

14. Remove any miscellaneous debris, such as

sheetrock dust, that may have infiltrated the unit during

construction.

15. Replace the air filter (if installed) as required.

1. Inspect the unit for shipping damage.

2. Level installation location to support the unit weight

adequately. Make all necessary ceiling openings to allow

adequate air flow and service clearances.

3. Ensure the unit chassis is installed level.

4. Verify that wall and ceiling openings are properly cut per

the unit submittals.

5. Verify that installation of units meets the national Fire

Protection Association (N.F.P.A.) Standard 90A or 90B

concerning the use of concealed ceiling spaces as return air

plenums. Verify correct ceiling opening dimensions on unit

submittals. Secure the unit and any accessory items properly

to the ceiling support rods.

6. Complete all piping connections correctly.

7. Check field sweat connections for leaks and tighten the

valve stem packing, and piping package unions if necessary.

8. Install condensate drain line connections if required.

9. Pitch condensate drain line away from LSC unit one-inch

drop per ten feet of pipe.

17

Page 18

TU-LSC-IOM

Installation - Electrical

Unit Wiring Diagrams

Specific unit wiring diagrams, based on unit options

ordered, are provided inside each unit and can be easily

removed for reference. Use these diagrams for

connections or trouble analysis. Wiring diagrams are

attached on the inside of the Control enclosure

Supply Power Wiring

Refer to the unit nameplate to obtain the minimum circuit

ampacity (MCA) and maximum fuse size (MFS) or

maximum circuit breaker (MCB) to properly size field

supply wiring and fuses or circuit breakers.

Refer to the unit operating voltage listed on the unit wiring

schematic, submittal, or nameplate. Reference the wiring

schematic for specific wiring connections.

Note: All field wiring should conform to NEC and all

applicable state and local code requirements. The control

enclosure is always on the end opposite the piping

connections. Access the control box by removing the two

screws that secure the front cover. This will allow the panel

to be removed, to provide access to the electrical

components.

Recommendation: Do not bundle or run interconnection

wiring in parallel with or in the same conduit with any highvoltage wires (110 V or greater). Exposure of

interconnection wiring to high voltage wiring, inductive

loads, or RF transmitters may cause radio frequency

interference (RFI). In addition, improper separation may

cause electrical noise problems. Therefore, use shielded

wire (Belden 83559/83562 or equivalent) in applications

that require a high degree of noise immunity. Connect the

shield to the chassis ground and tape at the other end.

Note: Do not connect any sensor or input circuit to an

external ground connection.

Table 4. Electrically commutated motors Full Load

Amps

Unit

Size

Motor hp277/1/60

3

4

1

/

3

2 x 1/3

FLA

2.3

4.6

208/1/60

FLA

2.7

5.1

120/1/60

FLA

4.1

8.6

All fan motors are single phase, same voltage as electric

coil (when supplied), with exception that 277 V motors are

used with 480V, 3 phase coils (4 wire wye).

NOTICE

Use Copper Conductors Only!

Unit terminals are not designed to accept other types of

conductors. Failure to use copper conductors may result in

equipment damage.

If the unit does not have a disconnect switch, the power

leads and ground terminal are situated inside the high

voltage compartment in the control enclosure. If the unit

has a disconnect switch, power connections are done

directly to the disconnect switch located in the control

enclosure.

NOTICE

Equipment Damage!

Unit transformer provides power to the LSC unit only. Field

connections directly to the transformer may create

immediate or premature unit component failure.

FLA = Full Load Amperage, as tested in accordance with

UL 1995

Minimum Circuit Ampacity (MCA) and Maximum Fuse

Size (MFS) Calculations for Fan-Coils with Single

Phase Electric Heat

Heater amps = (heater kW x 1000)/heater voltage

MCA = 1.25 x (heater amps + all motor FLAs)

MFS type circuit breaker = (2.25 x largest motor FLA) +

second motor FLA + heater amps (if applicable)

Select a standard fuse size or circuit breaker equal to the

MCA. Use the next larger standard size if the MCA does

not equal a standard size.

Standard fuse sizes are: 15, 20, 25, 30, 35, 40, 45, 50, 60

amps.

LSC Unit electric heat MBh = (heater kW)*(3.413)

18

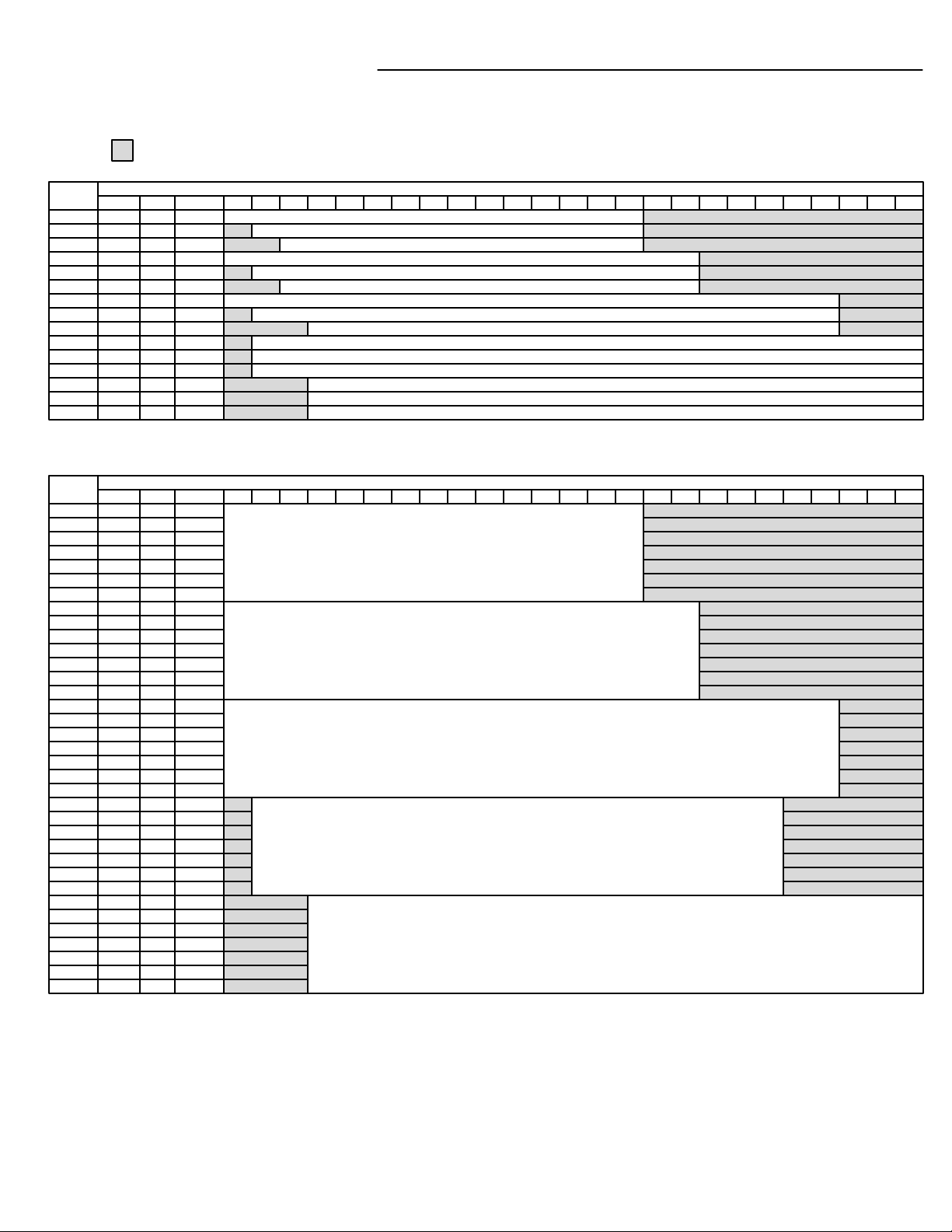

Page 19

Installation – Electrical (Cont)

Electric Heater MIN - MAX KW – LSC Size 3

= Electric Heater NOT available

TU-LSC-IOM

Code

E21

E22

E23

E31

E32

E33

E41

E42

E43

E61

E62

E63

E91

E92

E93

Code

L21

L22

L23

L24

L25

L26

L27

L31

L32

L33

L34

L35

L36

L37

L41

L42

L43

L44

L45

L46

L47

L61

L62

L63

L64

L65

L66

L67

L91

L92

L93

L94

L95

L96

L97

208V

208V

208V

240V

240V

240V

277V

277V

277V

208V

208V

208V

480V

480V

480V

208V

208V

208V

208V

208V

208V

208V

240V

240V

240V

240V

240V

240V

240V

277V

277V

277V

277V

277V

277V

277V

208V

208V

208V

208V

208V

208V

208V

480V

480V

480V

480V

480V

480V

480V

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

3PH

3PH

3PH

3PH

3PH

3PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

1 Step

2 Step

3 Step

1 Step

2 Step

3 Step

1 Step

2 Step

3 Step

1 Step

2 Step

3 Step

1 Step

2 Step

3 Step

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0Voltage PH Type

STAGED - Electric Heater MIN – MAX KW

LYNERGY - Electric Heater MIN – MAX KW

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0Voltage PH Type

NOTES:

1 - All KW’s must remain within Minimum and Maximum range shown for each unit size and step.

2 – Electric Coils are attached to the unit discharge and wired to a control panel for “ Single Point” electric connections.

3 – Electric Coils only include:

Automatic reset thermal cutout (one per step)

Positive Pressure airflow switch

Magnetic Contactor per step for Analog and Digital controls and PE switch for each step for pneumatic units.

19

Page 20

TU-LSC-IOM

Installation – Electrical (Cont)

Electric Heater MIN - MAX KW – LSC Size 4

= Electric Heater NOT available

Code

L21

L22

L23

L31

L32

L33

L41

L42

L43

L61

L62

L63

L91

L92

L93

Code

L21

L22

L23

L24

L25

L26

L27

L31

L32

L33

L34

L35

L36

L37

L41

L42

L43

L44

L45

L46

L47

L61

L62

L63

L64

L65

L66

L67

L91

L92

L93

L94

L95

L96

L97

208V

208V

208V

240V

240V

240V

277V

277V

277V

208V

208V

208V

480V

480V

480V

208V

208V

208V

208V

208V

208V

208V

240V

240V

240V

240V

240V

240V

240V

277V

277V

277V

277V

277V

277V

277V

208V

208V

208V

208V

208V

208V

208V

480V

480V

480V

480V

480V

480V

480V

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

3PH

3PH

3PH

3PH

3PH

3PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

1PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

3PH

PWM

2 STG

0-10V

0-20mA

PWM

2 STG

0-10V

0-20mA

PWM

2 STG

0-10V

0-20mA

PWM

2 STG

0-10V

0-20mA

PWM

2 STG

0-10V

0-20mA

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

PWM

2 STG

0-10V

0-20mA

2-10V

4-20mA

Incremental

T-Stat

Binary

3 Point

Floating

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 13.0 14.0Voltage PH Type

STAGED - Electric Heater MIN – MAX KW

LYNERGY - Electric Heater MIN – MAX KW

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 13.0 14.0Voltage PH Type

`

NOTES:

1 - All KW’s must remain within Minimum and Maximum range shown for each unit size and step.

2 – Electric Coils are attached to the unit discharge and wired to a control panel for “ Single Point” electric connections.

3 – Electric Coils only include:

Automatic reset thermal cutout (one per step)

Positive Pressure airflow switch

Magnetic Contactor per step for Analog and Digital controls and PE switch for each step for pneumatic units.

20

Page 21

ECM Overview and Setup

TU-LSC-IOM

Overview

This section addresses the Titus ECM motor which is

standard on all LSC units. The ECM motor provides

outstanding comfort, safety, and performance with greatly

reduced energy consumption compared to traditional units

with permanent split capacitance AC motors and with

proper installation and operation the units will provide a

long service life . The ECM motor provides a high degree

of flexibility and configurability, with the simplicity of

customized factory configurations appropriate to most

installations. Very little intervention is needed by service

and installation personnel in most applications; however,

installers must read through this entire section before

beginning installation of the new equipment. This literature

focuses on unit motors and associated controls.

General Information

There are four primary components that enable the ECM

technology on the LSC units:

1. Titus ECM Motor

2. ECM Engine Board

3. PWM Controllers

4. Inductors

The motors and modules are combined as a system, and

cannot work without each other.

ECM Engine Board

3. The LSC unit is equipped with either a manual control or

a remote control PWM fan speed controller, mounted on

the side of the line voltage control enclosure.

A - Remote Signal PWM Controller

ECM motors shipped with remote PWM controller require a

signal from the DDC controller to control fan speed.

B- Manual/Unit PWM Controller

ECM Motor

ECM Motor Fan Flow Adjustment

NOTICE

Before starting the fan motor, follow steps 1 and 2

1. Discharge ductwork should be connected. The

minimum

recommended discharge static pressure is 0.2" wg. Be

sure that any fan packing is removed from units prior!

ECM motors with manual PWM controllers are shipped

from the factory at design CFM when provided. Otherwise

motors are shipped at motor full speed setting.

4. Allow motor to run-in at least 15 minutes before

adjusting speed. During initial run-in, check ductwork

connections for leaks and repair if necessary. (Do not

adjust fan speed down if ductwork is not connected).

5. Set the unit to full heating (maximum induction). Adjust

and set remote balancing dampers, if present. Adjust the

speed control to deliver the required CFM by measuring air

quantity at the room outlets.

6. Proceed to primary air adjustment procedure, detailed in

control installation information. Fan should be re-adjusted

with primary air and ventilation air at maximum setpoint,

to insure that no supply air is discharged at the induction

port.

2. All foreign materials should be removed from duct

system. Filters should be installed where required.

21

Page 22

TU-LSC-IOM

ECM Overview and Setup

Manual / Unit PWM Signal Interface Board

Signal

RPM/CFM

Adjustment

RPM/CFM Indicator

24VAC

Power Supply

Communication

connector to

ECM Motor

The Manual PWM interface board allows accurate manual

adjustment and monitor of fan with the GE Electric ECM

Motor.

The Manual interface board features a 4 digit LED

numerical display to allow easy reading in dark spaces.

Watch the display and set the flow index with a screwdriver

adjust. Twenty seconds later, the display shows the

motor RPM. Then, the display periodically alternates

between the flow index and motor RPM.

Operation

GE ECM™ motors configured for Vspd operation are

factory configured for external torque or airflow

adjustment. A numerical flow index accurately adjusts the

fan to the desired torque or airflow. The flow index is a

number from 0-100 having a linear relationship to the

minimum to maximum torque or airflow range specified by

Titus. Refer to the fan specifications, data and charts to

convert the flow index to torque or mass airflow.

The Manual PWM interface board allows local on/off and

fan airflow adjustment. Rotating a single screwdriver

adjuster changes the variable output signal to the motor

from off to full output. While rotating the adjuster, a

numerical flow index is locked on the illuminated

numerical display. After adjustment, the display

shows fan RPM.

Remote PWM Signal Interface Board Details

Jumper Link

Control Signal Type

Manual Adjust

Signal

Communication

connector to

ECM Motor

Control Signall

RPM Out

24VAC Aux Power

24VAC Power Supply

The remote interface allows industry standard 0-10Vdc

automation signals to adjust and monitor General Electric’s

ECM Motor.

The interface board provides remote adjustment of the

ECM output from 0% to 100% of the programmed control

range. A signal lamp on the control continuously flashes

out the flow index

the flow index. A 0-10Vdc signal connects RPM to the

automation control. Jumpers allow the Interface to be

configured for 0-10Vdc automation signal, 2-10Vdc

automation signal, and manual/override control. The

interface can also be used for stand-alone manual control.

The green lamp continuously indicates the flow index. After

a pause, the lamp flashes out the tens digit, then the units

digit of a number between 1 and 99. Long flashes

represent the tens digit, and short flashes represent the

units digit. For example, a flow index of 23 flashes two

longs, then three shorts.

Two extra long flashes indicate a flow index of 0. An extra

long flash and ten short flashes indicates a flow index of

100. The lamp flashes the signal that was present when

the flash sequence started.

Turning Adjust controls the ECM motor to the manually

adjusted setting. The manual setting has authority for 15

minutes.Set the unit to full heating (maximum induction).

Adjust and set remote balancing dampers, if present.

Adjust the speed control to deliver the required CFM by

measuring air quantity at the room outlets.

2. Instruments are not required to read

22

Page 23

ECM Overview and Setup

TU-LSC-IOM

Remote PWM Signal Interface Board Details

Jumpers

P - Jumper provides ON/OFF control by

switching the motor's "GO" control line

when the input signal drops below the

2 volt (4 mA) operating point. without the

jumper, turn power to the interface board

+ On/Off to control motor On/Off.

Rotating Adjust changes the Flow Index

from 0 to 100.

The “P” jumper also allows manual on/off control.

Signal with

“P” Jumper Out

Input / Output Control Signals

"Opt" Configuration - 0-10 Vdc = 1% to 100%

"P" Configuration - 2-10Vdc = 0-100%

- 4-20mA = 0-100%

- ON/OFF Control Between1 & 2

Vdc (2 & 4 mA)

RPM Signal - 0-10 Vdc, 5 mA max. = 0 to 2,000

RPM in 10 RPM steps

Outputs Go & VSpd - 22Vdc @ 5mA

DDC Control - Air Balance

If the DDC Controller signal is already installed, air

balance can be achieved using the DDC Controller

software tools. Please notice that a control signal less than

0.2Vdc may put the interface board into manual override.

Avoid setting the DDC signal to less than 0.2Vdc.

WARNING

Turning Adjust potentiometer locks out the BAS

signal for 15 minutes

Signal with

“P” Jumper In

M - Jumper enables manual override. Manual override is

overridden when the 0-10V automation signal exceeds

0.2Vdc.

Manual override controls the motor before Building

Automation System (BAS) is installed, or when BAS fails.

Without the “M” jumper, manual override is enabled

whenever Adjust is turned. It is disabled by causing the

Interface board to turn the motor off/on 5 times while signal

is greater than 0.1Vdc.

R - Jumper reverses Adjust rotation so adjustment is

correct from the component side of the board.

Opt - The Opt. space has no function. The space

may be used to store an unused jumper.

Cycle power ON/OFF for faster lockout removal.

Manual Air Balance

The interface board can be manually adjusted before the

DDC Controller signal is available. The balancer’s manual

adjustment has authority until automation is connected.

Air Balancer

1. Use Adjust to set the air flow. This adjustment will have

authority for at least 15 minutes.

2. Read the flashing green light and record the flow index

on the air balance report.

DDC Integrator

1. Set the Signal to 0Vdc to invoke manual override.

2. Record the RPM on the air balance report.

3. Enter the flow index the air balancer entered on the air

balance report.

4. Observe the RPM is at or near the RPM observed in

step 2.

5. Cycle the motor on/off 5 times. This clears the manual

override function unless the “M” jumper is in

place.

23

Page 24

TU-LSC-IOM

Pre Start-Up

Pre-Startup Checklist

Complete this checklist after installing the unit to verify all

recommended installation procedures are complete before

unit startup. This does not replace the detailed instructions

in the appropriate sections of this manual. Disconnect

electrical power before performing this checklist. Always

read the entire section carefully to become familiar with the

procedures.

WARNING

Hazardous Voltage w/Capacitors! Disconnect all

electric power, including remote disconnects and discharge

all motor start/run capacitors before servicing. Follow proper

lockout/ tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives or

other energy storing compo nents provided by Trane or

others, refer to the appropriate manufacturer’s literature for

allowable waiting periods for discharge of capacitors. Verify

with an appropriate voltmeter that all capacitors have

discharged. Failure to disconnect power and discharge

capacitors before servicing could result in death or serious

injury.

Receiving

Inspect unit and components for shipping damage. File

damage claims immediately with the delivering carrier.

Check unit for missing material. Look for ship-with

options and sensors that may be packaged separately

from the main unit.

Unit Piping

1. Properly vent the hydronic coil to allow water flow

through the unit.

2. Tighten all pipe connections adequately.

3. Set water flow to the unit properly if unit piping has the

circuit setter valve (installed by others).

4. Check strainers (if installed by others) for debris after

apply system water.

5. Verify the condensate drain piping is complete for the

unit drain pan.

7. Ensure the drain pan and condensate line are not

obstructed. Remove any foreign matter that may have

fallen into the drain pan during installation.

Electrical

Check all electrical connections for tightness.

Electrical Note: Some circumstances may require the unit

to run before building construction is complete. These

operating conditions may be beyond the design

parameters of the unit and may adversely affect the unit.

Check nameplate unit data so that it matches the sales

order requirements.

Unit Location

1. Ensure the unit location is adequate for unit dimensions,

ductwork, piping, and electrical connections.

2. Ensure access and maintenance clearances around the

unit are adequate.

Unit Mounting

1. Ensure unit is installed level.

Component Overview

1. Ensure the fan rotates freely in the correct direction.

2.Ensure all unit access panels are in place.

3.Verify that a clean air filter is in place.

24

Page 25

Maintenance

Maintenance Procedures

Perform the following maintenance procedures to

ensure proper unit operation.

WARNING

Live Electrical Components! During installation,

testing, servicing and troubleshooting of this product, it may

be necessary to work with live electrical components. Have a

qualified licensed electrician or other individual who has

been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety

precautions when exposed to live electrical components

could result in death or serious injury.

WARNING

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by Trane

or others, refer to the appropriate manufacturer’s

literature for allowable waiting periods for discharge of

capacitors. Verify with an appropriate voltmeter that all

capacitors have discharged. Failure to disconnect

power and discharge capacitors before servicing

could result in death or serious injury.

Air Filters

TU-LSC-IOM

Inspecting and Cleaning Drain Pans

Clean the unit drain pan to ensure that any potential

condensate drains. Check the condensate drain pan and

drain line to assure the condensate drains properly at least

every six months or as dictated by operating experience. If

evidence of standing water or condensate overflow exists,

immediately identify and remedy the cause. Clean the

drain pans of any moisture or debris.

Coil Maintenance

Keep coils clean to maintain maximum performance. For

operation at its highest efficiency, clean the coil often

during periods of high demand or when dirty conditions

prevail. Clean the coil a minimum of once a year to prevent

dirt buildup in the coil fins, where it may not be visible.

Remove large debris from the coils and straighten fins

before cleaning. Remove filters before cleaning. Clean the

coil fins using steam with detergent, hot water spray and

detergent, or a commercially available chemical coil

cleaner. Be sure to rinse coils thoroughly after cleaning.

WARNING

Hazardous Chemicals! Coil cleaning agents can be

either acidic or highly alkaline. Handle chemical carefully.

Proper handling should include goggles or face shield,

chemical resistant gloves, boots, apron or suit as required.

For personal safety refer to the cleaning agent

manufacturer’s Materials Safety Data Sheet and follow all

recommended safe handling practices. Failure to follow all

safety instructions could result in death or serious injury.

Change or clean air filters at least twice a year. Filters

require more frequent care under high load or dirty air

conditions since a clogged filter reduces airflow. Pleated

media filters are available for all units.

Depending on the Filter Removal Option installed in the

unit, filters can be removed from the unit in two ways:

1 - Side removal – from the either side of the coil

2 - Bottom removal – from the bottom of the coil side

NOTICE

Replace All Panels and Filters Properly! All unit

panels and filters must be in place prior to unit startup.

Failure to have panels and filters in place could result in

equipment damage.

Inspecting and Cleaning Coils

Coils become externally fouled as a result of normal

operation. Dirt on the coil surface reduces it’s ability to

transfer heat that can result in comfort problems, increased

airflow resistance and thus increased operating energy

costs. If the coil surface dirt becomes wet, which

commonly occurs with cooling coils, microbial growth

(mold) may result, causing unpleasant odors and serious

health-related indoor air quality problems. Inspect coils at

least every six months or more frequently as dictated by

operating experience. Cleaning frequently is dependent

upon system operating hours, filter maintenance, and

efficiency and dirt load. Follow the suggested methods in

the following paragraphs.

25

Page 26

TU-LSC-IOM

Maintenance (Cont)

Hydronic Coil Cleaning Procedure

1. Disconnect all electrical power to the unit.

2. Don the appropriate personal protective equipment

(PPE).

3. Access both sides of the coil.

4. Use a soft brush to remove loose debris from both sides

of the coil.

5. Use a steam cleaning machine, starting from the top of

the coil and working downward. Clean the leaving air side

of the coil first, then the entering air side. Use a block-off to

prevent steam from blowing through the coil and into a dry

section of the unit.

6. Repeat step five as necessary. Confirm that the drain

line is open following completion of the cleaning process.

7. Allow the unit to dry thoroughly before putting the system

back into service.

8. Straighten any coil fins that may be damaged with a fin

rake.

9. Replace all panels and parts and restore electrical power

to the unit.

Winterizing the Coil

Make provisions to drain coils that are not in use, especially

when subjected to freezing temperatures. To drain the coil,

blow the coil out with compressed air. Next, fill and drain

the tubes with full-strength ethylene glycol several times.

Drain the coil as completely as possible.

Work Instruction Steps

In general, replacement of a motor needs to be carried out

as follows:

1. Remove front panels of unit.

2.Free the motor and crossover harnesses from the fan

board, by unplugging the two electric multi plugs from the

motor.

Depress Locking

tabs

3.Remove the fan housing with the motor and loosen fan

Allen screw on the shaft.

4.Unscrew the motor from the fan housing and remove.

5.Insert the replacement motor.

Periodic Maintenance Checklists

NOTICE

Coil Freeze-up Damage!

Failure to properly drain and vent coils when not in

use during freezing temperatures may result in coil

freeze-up damage.

Replacing Motors

Motors are attached to the fan Blower with screws at the

rear of the motors. Fan wheels are attached with Allen

screws on the fan hubs. In most applications, it is

necessary to remove the fan blower to change out the

motor. The fan blower is easily removable, with screws on

the top and bottom edges of fan blower.

NOTICE

Heavy Object!

Support the Fan Blower when removing it from the unit.

Failure to properly support Fan Blowerd may result in minor

to moderate personal injury.

The following check list provides the recommended

maintenance schedule to keep the unit running efficiently.

Monthly Maintenance

1. Inspect unit air filters. Clean or replace if airflow is blocked

or if filters are dirty.

2.Check the drain pans s to be sure the pans are clean and

do not impede the potential condensate flow through the drain

line.

Annual Maintenance

Check and tighten all set screws, bolts, locking collars and

sheaves.

1. Inspect the unit liner clean or repair to provide unit

protection.

2.Inspect the fan wheel and housing for damage. Rotate the

fan wheel manually to be sure movement is not blocked by

obstructions.

3.Inspect the coil fins for excessive dirt or damage. Remove

dirt and straighten fins.

4.Clean and tighten all electrical connections.

5.Inspect the primary air damper and ensure that it rotates

freely from o to 100% open.

26

Page 27

Loading...

Loading...