Page 1

HORIZONTAL HIGH OUTPUT HH-IOM-00 01-19-09

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

HHC, HHE, HHP

INSTALLER MUST BE A TRAINED, EXPERIENCED SERVICE

TECHNICIAN

1. PRESSURE CHECK

The complete unit including coil, valve package and associated piping is shipped

pressurized. Use the air valve to release the pressure. Should there be no pressure,

inspect the unit for possible shipping damage. The unit must be pressure tested again

prior to installation.

2.

Each unit has four (4) mounting holes. Rubber grommets are supplied with each unit.

Level the unit to ensure proper condensate drainage.

3.

3.1 All piping leading to the unit must be adequately supported to prevent excessive stress

3.2 Do NOT over-tighten threaded connections.

3.3 Do NOT overheat sweat connection. Use solder (95/5) with a melting temperature

3.4 When the valve package is supplied separately for field installation, carefully follow

MOUNTING

Due to the various installation conditions, the mounting bolts/rods, steel washers and

nuts are field supplied.

PIPING

on the unit’s piping. However, sufficient free movement is required for thermal

expansion/contraction.

o

below 600

the schematic piping diagram and installation instructions provided with the package.

F.

3.5 All pipes and fittings that extend beyond the drain pan MUST be insulated.

6 fo 1 egaP

Page 2

HORIZONTAL HIGH OUTPUT HH-IOM-00 01-19-09

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

4. ELECTRICAL

4.1 All electrical connections are to be made in accordance with the National Electric

Code, state and local codes, bylaws, ordinances or the authority having jurisdiction.

Make all electrical connections inside the internal electric junction box by carefully

following the wiring diagram.

4.2 Electrical wiring diagram is located inside the unit’s enclosure. Adhere strictly to it in

order to avoid damage and/or personal injury.

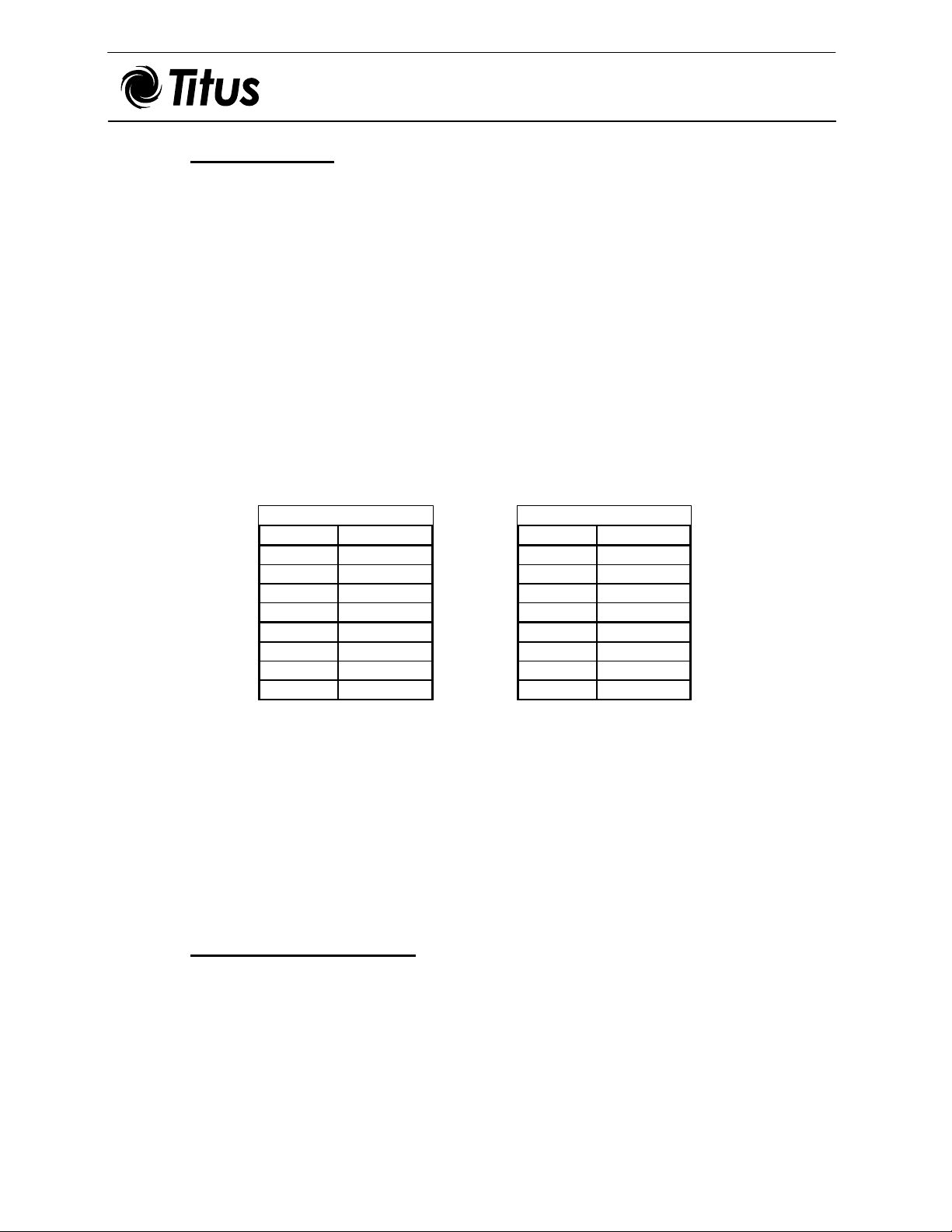

4.3 When the thermostat and fan switch are field supplied, the following are the minimum

electrical ratings:

- Thermostat (valve load) = 0.1A @ 115V

(0.05A @ 230V)

- Fan Motor(s) @ full load amps, FLA (@115V):

HHC & HHE

SIZE FLA (Amps)

06 3.6

08 4.3

10 4.3

12 5.1

14* 4.2

16* 4.4

18* 4.6

20* 4.5

*Note: Units are equipped with two (2) motors; full load amperage listed is per motor.

SIZE FLA (Amps)

HHP

06 3.5

08 3.9

10 4.1

12 4.9

14* 4.1

16* 4.2

18* 4.3

20* 4.5

4.4 Where electric heating is provided with the unit (optional), an external HEAT/COOL

changeover switch has to be installed – normally wall mounted together with the fan

speed selector switch. At minimum, this switch should be rated: 10A @ 115V (5A @

230V).

Follow the wiring diagram for correct installation.

5.

FILTER (HHE & HHP)

The filter is secured to the access panel with a filter-retaining clip. To install filter, slip

filter into the filter rack and fasten it with the filter retainer clip.

6 fo 2 egaP

Page 3

HORIZONTAL HIGH OUTPUT HH-IOM-00 01-19-09

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

6. GENERAL PRECAUTIONS

After completing the installation, recheck the following:

6.1 The drain pans, fans and motors are clean of all foreign material.

6.2 All electric wiring is properly routed, secure and capped.

6.3 The filter, where provided, is clean and secured in its position.

7.

7.1 Chilled/Hot Water Unit

7.1.1 Ensure that the main distribution system is operable (i.e. both supply and return piping

7.1.2 Open the unit’s isolating ball valves (optional) and observe that no leaks are evident.

7.1.3 Open the 2-Way or 3-Way Valve (optional) manually by turning the manual override

7.1.4 Remove the cap of the air-vent valve and depress the needle to release the trapped air.

8.

8.1 The unit is wired to operate with a four-position fan selector switch:

OFF

HI High fan speed

MED Medium fan speed

LO Low fan speed

INITIAL START-UP

are under full operating pressure).

to the open position on the valve actuator thus pressurizing the unit’s coil.

Continue until only liquid is coming through and then re-cap and secure tightly.

OPERATION AND CONTROL

8.2 An external thermostat (normally wall mounted) is used to select the desired room

temperature.

8.3 Where the unit is provided with electric heating (optional), the external HEAT/COOL

changeover switch has to be set in the HEAT position to enable the thermostat to

switch the heater ON when the room temperature drops below the set point.

6 fo 3 egaP

Page 4

HORIZONTAL HIGH OUTPUT HH-IOM-00 01-19-09

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

9. MAINTENANCE

***CAUTION: All maintenance must be performed by a trained, experienced

service technician. To prevent electrical shock, disconnect electric power to system

at main fuse or circuit breaker box until maintenance is complete.

While the HHC model is fully accessible, maintenance on the HHP & HHE models is

done by removing the access panel. The unit must be isolated from the power

supply.

9.1 Filter (HHP & HHE)

The useful life of the throwaway filter depends on the environment in which the unit is

operating. However, it is recommended to change the filter at least every three (3)

months.

9.1.1 To replace the filter on the HHE, remove the access panel, unfasten the Velcro-backed

filter-retaining channels, remove channel to replace the filter. For the HHP, unfasten

the filter retaining clips and slide the filter out.

9.2 Drain Pans

Periodic cleaning of the drain pans is essential, especially in high humidity areas.

Remove all foreign material to ensure the free flow of condensation.

9.3 Coils

Clogged coils are a major cause of unit failure. Periodic inspection should take place

at least once a year.

9.3.1 Dirty coils should be cleaned with the appropriate brush and vacuum cleaner or

compressed air.

9.4 Electric Motor(s)

A yearly motor inspection should take place and the following is recommended:

9.4.1 Clean all dirt and lint with a brush and/or vacuum cleaner.

6 fo 4 egaP

Page 5

HORIZONTAL HIGH OUTPUT HH-IOM-00 01-19-09

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

9.5 Strainer (Optional)

The frequency that the strainer has to be cleaned depends on the overall conditions of

the distribution piping system. However, frequent cleaning is recommended during the

installation and start-up stages and thereafter at every season change

(Summer/Winter).

9.5.1 Open the clean-out cap on the strainer to release the dirt. Close it once clear liquid is

observed.

9.6 Pete’s Plug (Optional)

The plug is installed as an aid in measuring pressure and temperature.

9.7 Electric Heater(s) (Optional)

The heater is fastened to the fan deck at the blower outlet with sheet metal screws.

In case of heater failure, follow the procedure described below:

9.7.1 Disconnect all power sources before attempting to open the unit. Check all electrical

wiring to ensure the unit is fully isolated.

9.7.2 Unscrew the fan deck and expose the heater(s).

9.7.3 If the thermal cut-out switch is defective, disconnect the electrical wires and unscrew

it from the heater assembly. Obtain a replacement from TITUS and reinstall.

6 fo 5 egaP

Page 6

HORIZONTAL HIGH OUTPUT HH-IOM-00 01-19-09

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

9.7.4 If the heating element (the spiral resistance wire) is burned out, unscrew the heater

assembly from the fan deck, disconnect the terminals and replace with a new heater

obtained from TITUS.

***When contacting TITUS for replacement parts, always

refer to the complete Model, Order and Line numbers on the Serial

Plate located on the blower housing.

605 Shiloh Road

Plano, Texas 75074

972-212- 4800

6 fo 6 egaP

Loading...

Loading...