Titus HAB User Manual

Installation Manual

IOM-HAB-00 06-30-04

HAB Horizontal Air Handler Belt Drive

Installation, Operation, and Maintenance Manual

Contents Page

General ....................................................................1

Introduction.............................................................1

Safety .......................................................................1

Inspection................................................................1

Product Description ...............................................1

Model Number Specification .............................................1

Unit Cabinet Dimensions...................................................2

Coil Specifications.............................................................2

Standard Installation ..............................................3

Ductwork ...........................................................................3

Duct Insulation and Vapor Proofing................................... 4

Condensate Drain .............................................................4

Water Piping...................................................................... 5

Sound Attenuation............................................................. 5

Motors and Drives ............................................................. 5

Electrical Connections....................................................... 5

Installation of Options............................................5

Grille Plenum..................................................................... 5

Mixing Box Installation.......................................................6

Electric Heat......................................................................7

Face and Bypass Damper Add-on Filter Sectio

n ..............8

Startup .....................................................................8

Operation and Maintenance ..................................9

Return Air Filters ...............................................................9

Coil ....................................................................................9

Belt and Pulley ..................................................................9

Motor .................................................................................9

Blower ...............................................................................9

Abbreviations..........................................................9

General

This document provides installation, operation, and

maintenance information for the Titus Horizontal Air

Handler Belt Drive (HAB) models.

Additional information may be found at the Titus website,

its address is www.titus-hvac.com.

Introduction

The following information is to be used by the installer as a

guide. Since each installation is unique unto itself, only

general

topics are covered. Installation may not occur in

the same order as topics are presented.

This guide does NOT supersede or circumvent any

applicable national, state, or local codes.

The installation is to be performed only by individuals

whose experience meets or exceeds the requirements of

the work involved.

The installer MUST read the entire contents of this guide

and develop a thorough understanding before beginning

installation.

Due to a continuing program of product research, Titus

reserves the right to discontinue or change without notice,

any or all specifications or designs without incurring

obligations.

Safety

The installation and/or servicing of comfort conditioning

equipment can be hazardous due to system pressures

and electrical devices.

Caution: Only trained and qualified personnel

should perform service and/or installation.

Observe all precautions and warnings in product

data or attached to the unit.

Follow all safety codes. Wear eye protection and gloves.

Have a fire extinguisher readily available.

Caution: Disconnect all power supplies before

accessing equipment.

Disconnecting more than one power supply may

be required to de-energize some equipment.

DANGER

ELECTRIC SHOCK CAN CAUSE DEATH.

Inspection

Thoroughly inspect all packages upon receipt. Ensure

carton(s) have not been dropped, crushed or punctured.

Inspect all contents for damage. If damage is found,

immediately file a claim with the delivering carrier.

Product Description

This section provides model number nomenclature,

various unit dimensions, and coil specification.

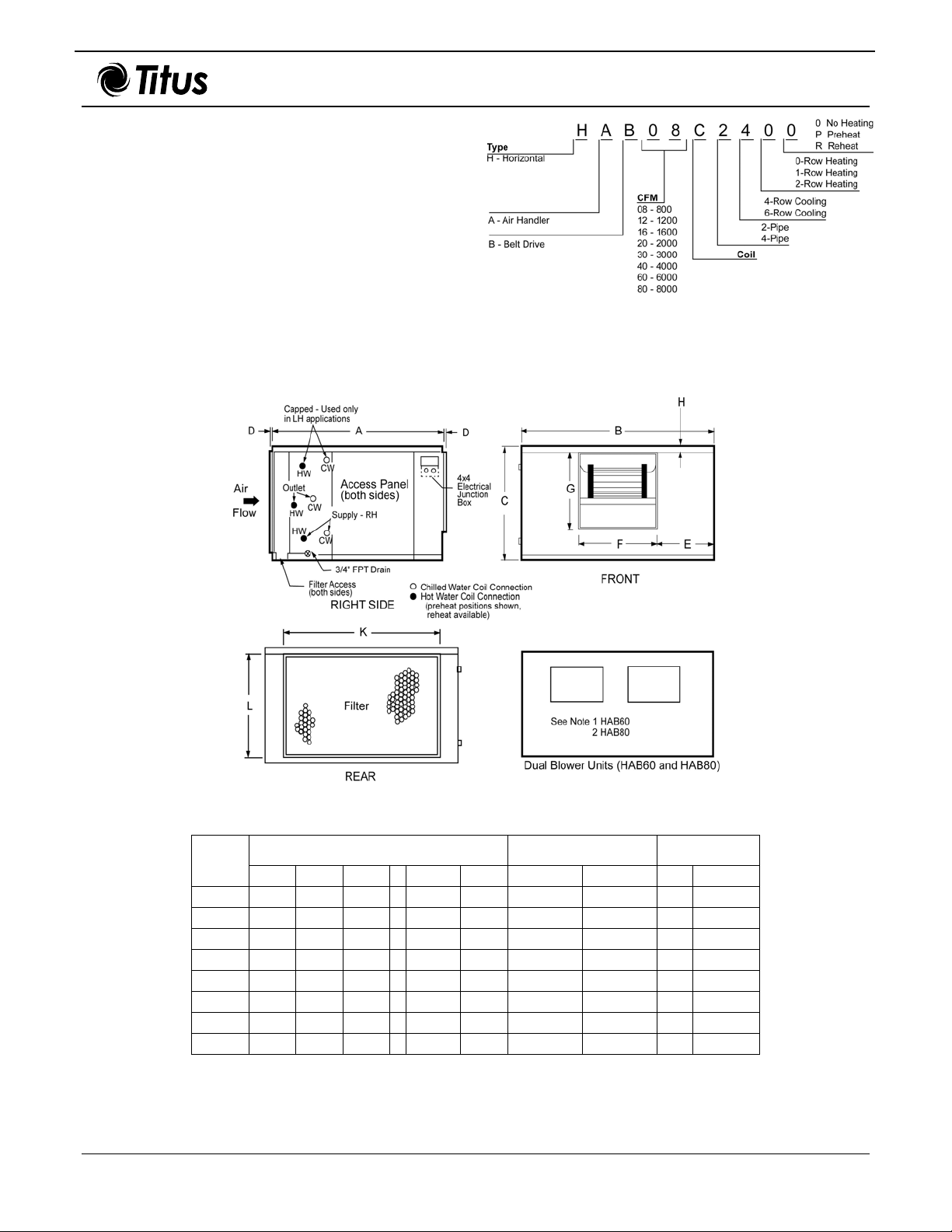

Model Number Specification

Figure 1 defines model number nomenclature specifics.

605 Shiloh Road • Plano, Texas 75074 • 972- 212- 4800

All rights reserved. No part of this work may be reproduced or transmitted in any form or any means, electronic or mechanical, including photocopying and recording, or by any information storage retrieval system without permission in writing from Air Distribution Technologies.

HAB Installation Manual

Unit Cabinet Dimensions

Figure 2 shows dimensional callouts for all sides of an

HAB unit. Table 1 provides the cabinet dimensions for

each HAB model along with the blower-opening outlet.

Coil Specifications

Table 2 provides HAB model specifics for the chilled

and hot water coil outside diameter and shipping weight

based on the number of coils (weight for 4-row chilled

water coil includes weight for entire unit).

IOM-HAB-00 06-30-04

Figure 1. Air Handler Model Number

Nomenclature

Figure 2. HAB Dimensional Views

Table 1. Cabinet Dimensions (in inches)

Model

A B C D E H F G K L

HAB08 37.00 27.00 18.00 1 9.13 1.00 8.75 10.00 18.00 16.00

HAB12 37.00 36.50 18.00 1 12.09 1.00 12.31 10.88 27.50 16.00

HAB16 42.00 38.00 22.00 1 14.25 1.00 9.50 14.00 29.00 20.00

HAB20 42.00 45.00 22.00 1 16.00 1.00 13.00 14.00 36.00 20.00

HAB30 52.50 54.00 27.00 1 20.38 1.00 13.25 16.75 45.00 25.00

HAB40 52.50 57.00 34.00 1 21.88 8.50 13.25 16.75 48.00 32.00

HAB60 57.50 67.13 42.00 1 Note 1 7.00 (2) 16.07 (2) 15.88 57.75 40.25

HAB80 57.50 72.00 47.0 1 Note 2 11.88 (2) 16.07 (2) 15.88 66.00 45.00

Note 1: Blower opening 7 inches down from top of unit. Looking at discharge 14-3/8 inches left side

and 8-3/8 inches right side.

Note 2: Blower opening 11-7/8 inches down from top of unit. Looking at discharge 14-3/16 inches left,

11-3/8 inches center and 3-15/16 inches right side.

Unit Blower Opening Outlet

2 of 9

Return Duct

Connection

HAB Installation Manual

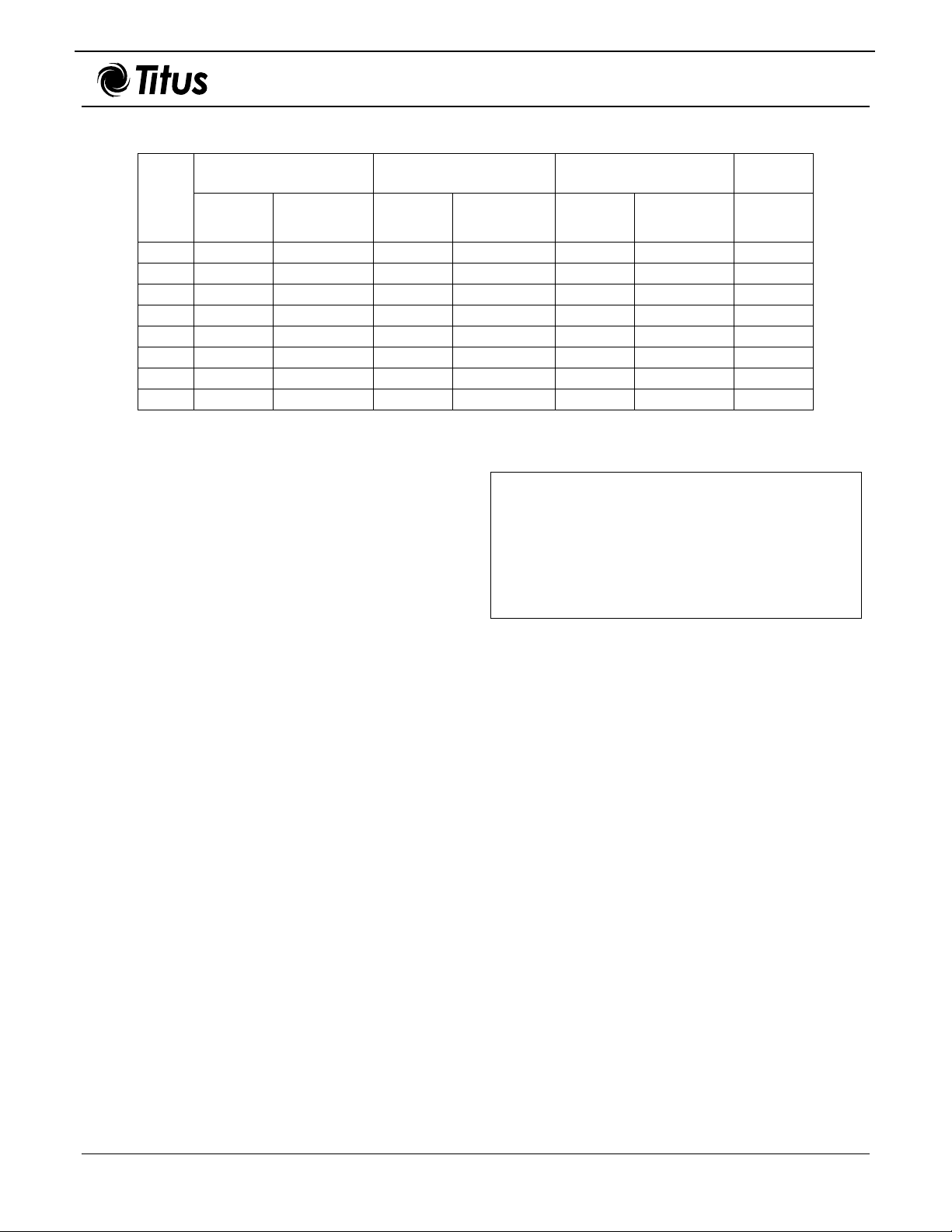

Table 2. HAB Installation Data

4-Row Unit 6-Row Unit 2-Row Coil

Model

HAB08

HAB12

HAB16

HAB20

HAB30

HAB40

HAB60

HAB80

Connection

Size OD

SWT

3/4" 145 3/4" 156 5/8" 13 5/8"

3/4" 171 7/8" 190 7/8" 18 5/8"

7/8" 200 1-1/8" 222 7/8" 25 7/8"

1-1/8" 244 1-1/8" 263 1-1/8" 30 7/8"

1-1/8" 457 1-3/8" 475 1-1/8" 41 N/A

1-3/8" 512 1-5/8" 547 1-1/8" 53 N/A

1-3/8" 700 1-5/8" 787 1-3/8" 86 N/A

(2) 1-5/8" 775 (2) 1-5/8" 855 (2) 1-1/8" 106 N/A

Ship Weight

(lbs)

Connection

Size OD

SWT

Ship Weight

(lbs)

Note: Shipping weight of a one-row coil is same as two-row coils.

Connection

Size OD

SWT

IOM-HAB-00 06-30-04

1-Row Coil

(Note)

Ship Weight

(lbs)

Connection

Size OD

SWT

Standard Installation

Basic installation procedure covers verifying and/or

installing the following items.

• Ductwork.

• Duct insulation and vapor proofing.

• Unit placement.

• Sound attenuation.

• Condensate drain.

• Water piping.

• Motors and drives.

• Electrical connections.

Note: If mixing boxes form part of the unit, install the

mixing boxes prior to installing unit. See Mixing Box

Installation topic within this document.

Ductwork

Use accepted industry practices and design guidelines of

the ASHRAE Fundamentals H

comply with all building codes and the National Fire

Protection Association’s pamphlet 90A and 90B.

Carefully inspect any previously installed ductwork to

determine suitability.

Note: Ductwork should be of a size meeting

requirements of the installation. Ductwork should

transition gradually from a smaller size blower

outlet to required duct run size to avoid excessive

loss of air velocity.

andbook. Ductwork must

DANGER

BEFORE INSTALLING UNIT, DETERMINE WHETHER

THE UNIT WEIGHT CAN BE SUPPORTED SAFELY.

POSSIBLE INJURY AND DAMAGE MAY RESULT DUE

TO JOIST/TRUSS OVERLOADING.

When return air duct connection is smaller than return

inlet opening, construct the transition piece so the vertical

and horizontal dimensions of transition do not increase

more than one inch for every seven inches of length.

Allow a minimum of three feet of straight ductwork

following an equipment outlet.

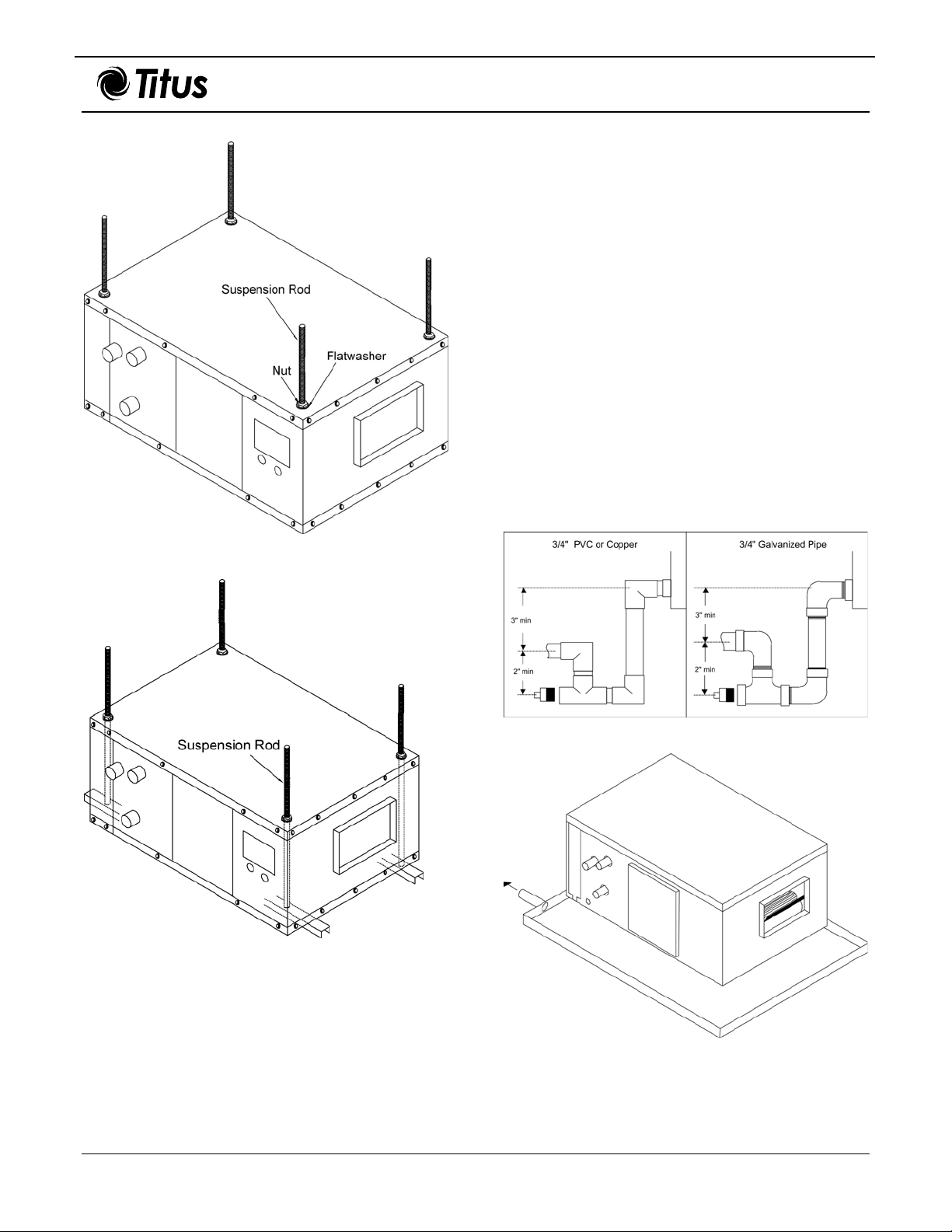

Suspend unit or support unit from floor. Models HAB08

through 20 have 3/8-inch weld nuts provided in each

corner of the top for suspending the unit with threaded

rod. See Figure 3. Models HAB30 through 80 have 7/8inch knockouts in each corner of top and bottom panels

for suspension rods to pass through, located 3-1/2 inches

in from corners on centerline. It is recommended that

angle iron or unistrut be used under the unit for support

(these support pieces should extend approximately one

inch beyond each end of the unit, see Figure 4.

Ensure the suspension rods are located so the rods do

not block ac

mechanical or drain functions of the unit.

Install unit with 1/8-inch pitch toward condensate drain

opening.

cess panels or interfere with electrical,

3 of 9

HAB Installation Manual

Externally insulated ductwork must have adequate vapor

seal for summer operation, especially where duct is

exposed to high humidity conditions.

Condensate Drain

Condensate drain must consist of a minimum of ¾-inch

copper tubing, ¾-inch galvanized pipe, or ¾-inch PVC

pipe. Figure 5 shows condensate drain setup. The drain

trap must be properly configured to ensure the removal of

all condensate runoff. Ensure drain pitches downward at a

slope of one inch every 10 feet.

Note 1: Incorrect trapping can hold water in pan,

causing overflow.

Note 2: Consult local codes for additional precautions

before instal

Caution: If unit location is above an occupied

space or where damage may result from

condensate overflow, install a watertight pan of

corrosion-resistant metal beneath unit to catch

overflow. If this condition exists, a separate

¾-inch condensate drain must be provided for

this added pan. See Figure 6.

IOM-HAB-00 06-30-04

ling condensate pan.

Figure 3. HAB08 through 20 Suspension

Figure 4. HAB30 through 80 Suspension

Duct Insulation and Vapor Proofing

Previously installed heating supply ductwork may already

have adequate insulation against excessive heat loss.

This insulation may be satisfactory for protection against

heat gain from summer cooling. Depending upon

application, additional insulation may be required.

Figure 5. Condensate Drain

Figure 6. Occupied Space Condensate Pan

(Field Supplied) Installation

4 of 9

Loading...

Loading...