Page 1

Flowbar

INSTALLATION MANUAL

FlowBar Architectural Linear Diusers

FL-10

FL-15

FL-20

FL-25

FL-30

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 2

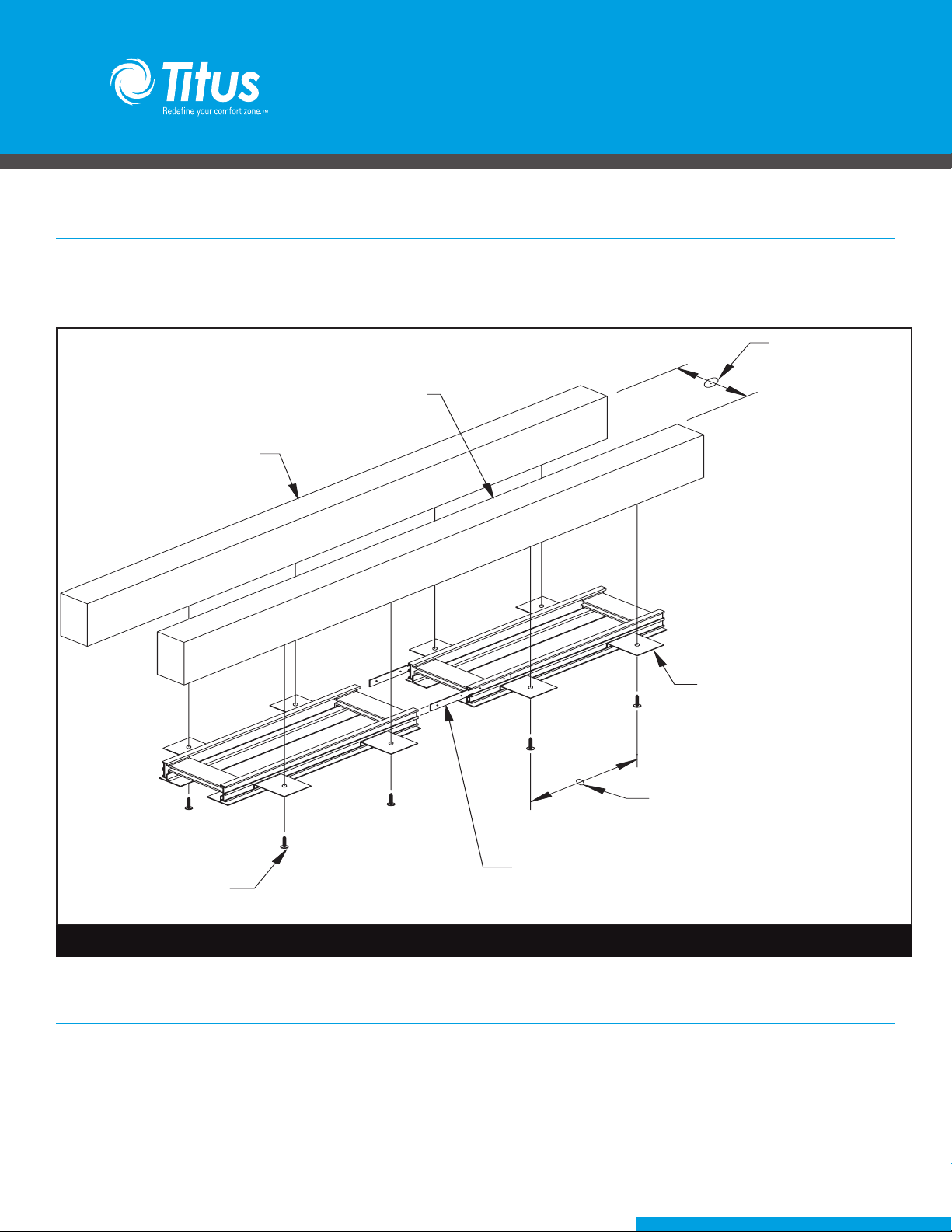

FlowBar Installed During Hard Ceiling Installation

FRAME

MOUNTING

SCREWS

HARD CEILING CLIP

CENTERS

SPLINE SUPPORT CLIP

SS1

10" MAXIMUM

HI, H2, H3 or H4

FRAME

FRAME OPENING

IN TABLE 1

WIDTH (W) SHOWN

FlowBar IOM

Titus FlowBar Linear Diffusers are designed to integrate with the ceiling

system. The integration process takes place by installing the diffuser

concurrently with the ceiling. Figure 1 below summarizes the steps re-

FRAME

FRAME

quired to install a FlowBar Diffuser System as part of the hard ceiling

installation.

FRAME OPENING WIDTH

(W) SHOWN

IN TABLE 1

HARD CEILING CLIP

H1, H2, H3, or H4

MOUNTING

SCREWS

Figure 1. Installation of FlowBar with a Hard Ceiling

Summary of Steps to Install FlowBar with a Hard Ceiling

STEP 1. Identify the Diffuser Border Type

STEP 2. Construct Ceiling Frame Work

STEP 3. Attach Mounting Clips to Diffuser

STEP 4. Attach Diffuser to Ceiling Frame Work

STEP 5. Attach Plenum to Diffuser

2

Installation Manual - FlowBar

SPLINE SUPPORT CLIP

10” MAXIMUM

CENTERS

SS1

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 3

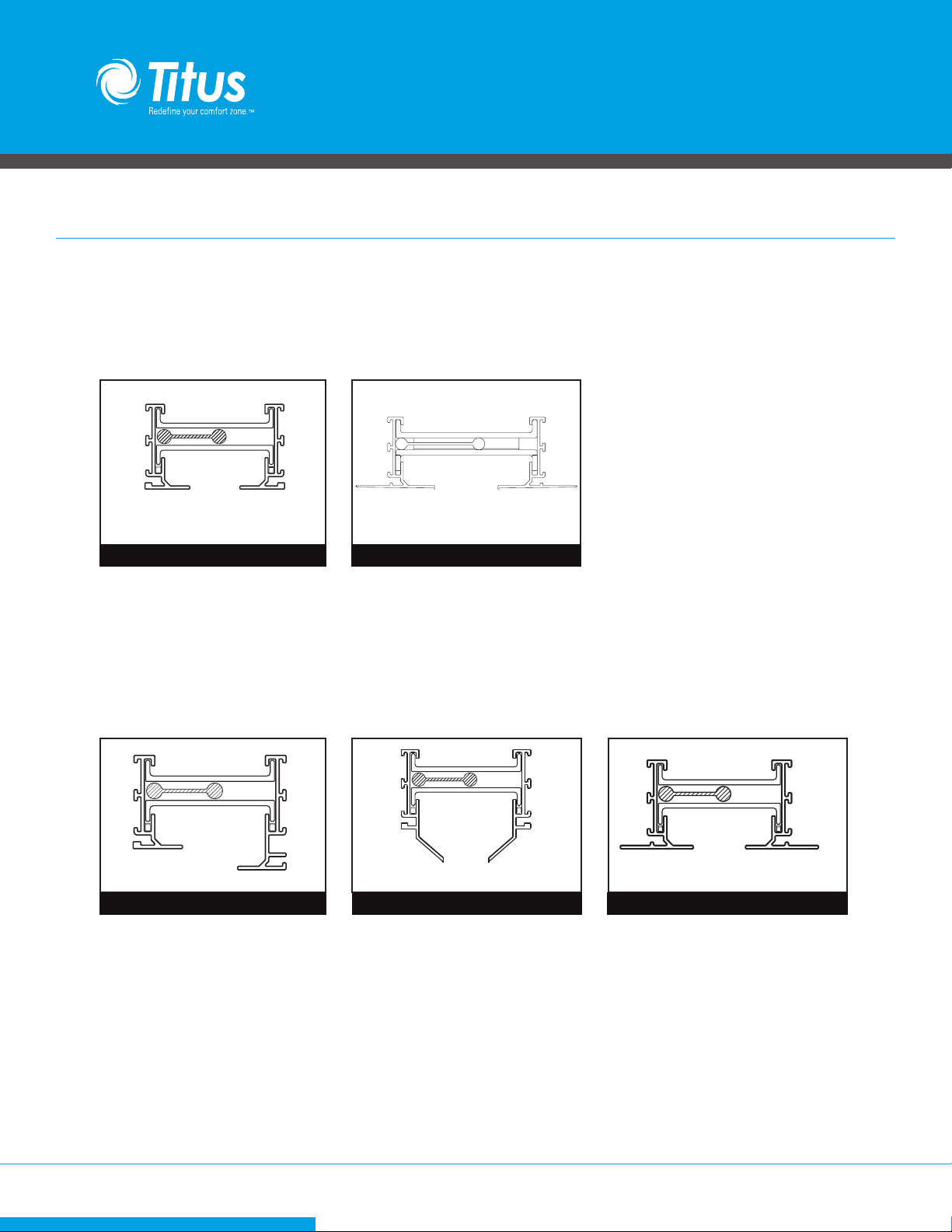

FlowBar Installed During Hard Ceiling Installation

FL-15

HIGH THROW

BORDER 22

FRAME 3. The outer edge of the face

flange is extended 3/16” out to provide a

surface for sheetrock or acoustic ceiling

tile to lay on. Frame 3 is used with border

types 13 or 33.

(Border Type 33 shown)

STEP 1. Identify the Diffuser Border Type

FlowBar IOM

There are five different extrusion styles (identified as “Frame Types” in

this manual) which are combined to form eight different Border Types.

(Border Type 11 shown)

FRAME 1. The outer edge of the face

flange is even with the stack head for

flush mounting. Frame 1 is used with

border types 11, 13, 14 or 16.

FRAME 2. is designed for use with hard

ceiling applications where the finishing

flange is taped and spackled into the

ceiling to leave only the air slot exposed

(Border Type 22 shown)

to the room. Frame 2 is used with order

type 22.

Border Types are identified by combining the two frame styles used i.e.

Border Type 16 has one frame #1 and one frame #6.

(Border Type 14 shown)

FRAME 4. has an extended height for

use with uneven ceiling heights or

where the ceiling meets the wall. Frame

4 is used with frame 1 to form border

type 14.

Redefine your comfort zone. ™ | www.titus-hvac.com

(Border Type 55 shown)

FRAME 5. Like frame 2, is designed for

use with hard ceiling applications where

the finishing flange is taped and spackled into the ceiling. The sheetrock or

wood for frame 5 is cut at an angle to

match the frame. Frame 5 is used with

border ype 55.

(Border Type 66 shown)

FRAME 6. The outer edge of the face

flange is extended 1/2” out to provide an

extended surface for sheetrock or acoustic

ceiling tile to lay on. Frame 6 is used with

border types 16, 66 & 77.

Border Type 77 utilizes the QuickClip®

Mounting System allowing FlowBar to be

installed after the ceiling is in place.

Installation Manual - FlowBar

3

Page 4

FlowBar IOM

PATTERN CONTROLLER

SPREADER

BORDER

SPREADER

BORDER

BORDER

SPREADER

CENTER-TEE SUPPORT

BRACKET

BORDER

PATTERN CONTROLLER

CENTER-TEE

FlowBar Installed During Hard Ceiling Installation

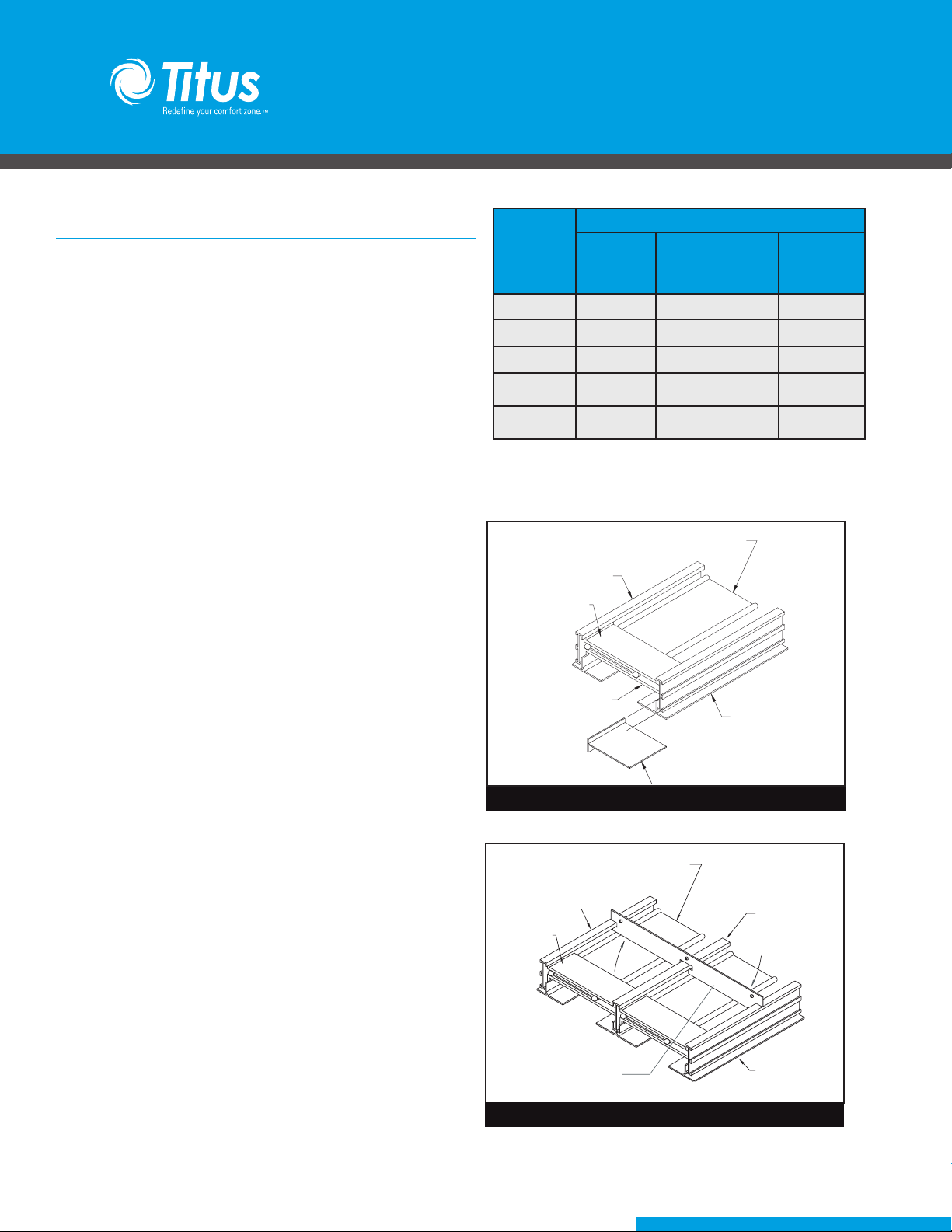

STEP 2. Construct Ceiling Framework

Before installing drywall, a framed opening must be constructed to

support the FlowBar Diffuser.

It is recommended that the framework be continuous to

accommodate the Hard Ceiling Clip spacing requirements.

The framing material must be suitable to hold the Diffuser in place

when attached with screws through the FlowBar Mounting Clips.

The width of the framed opening required depends on the model of

FlowBar being installed. The frame opening width dimension, ‘W’,

is listed in Table 1.

NOTE: If it appears that it will be difficult to install plenums after

the opening is framed and FlowBar installed, then use wires to

support the Plenums above the framework first.

Frame Opening Width (W)

FlowBar

Model

1-SLOT

FL-10 3¼ 5

FL-15 4¼ 7

FL-20 5¼ 9

FL-25 6¼ 11

FL-30 7¼ 13

Table 1. Frame Opening Dimensions

PATTERN CONTROLLER

BORDER

SPREADER

2-SLOT

2CRA & 2CRB

11

⁄16 69⁄16

11

⁄16 89⁄16

11

⁄16 109⁄16

11

⁄16 129⁄16

11

⁄16 149⁄16

2-SLOT

2CRN

STEP 3. Attach Mounting Clips

Hard Ceiling Clips are shipped loose for field attachment to the

FlowBar Diffuser.

Slide the Hard Ceiling Clips into the lower bosses of each frame rail

as shown in Figure 2.

Position the clips at a maximum of 10” intervals along the Diffuser

frame.

The Hard Ceiling Clips must be secured to a framing member.

These Mounting Clips should be attached to the ceiling framework

at a maximum of 10” intervals.

For Diffusers with two slots, a CenterTee Support Bracket is shipped

loose for installation. The Center-Tee Support Bracket is installed

over the center rail of the FlowBar and then rotated to interlock with

the outer FlowBar borders as shown in Figure 3.

SPREADER

BORDER

HARD CEILING CLIP

Figure 2. Installation of Hard Ceiling Clips

PATTERN CONTROLLER

BORDER

CENTER-TEE

SPREADER

CENTER-TEE

SUPPORT BRACKET

Figure 3. Installation of Center-Tee Support Bracket

BORDER

4

Installation Manual - FlowBar

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 5

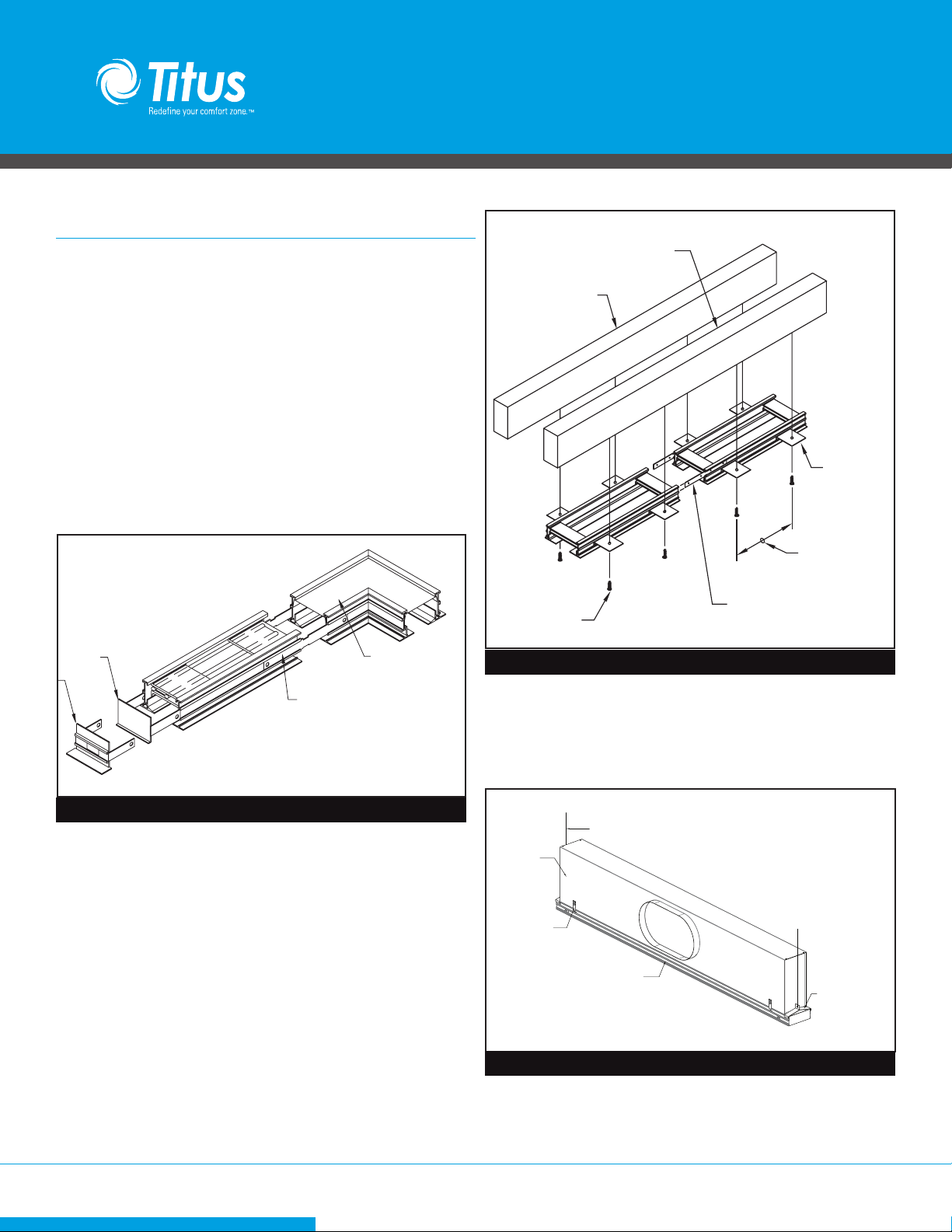

FlowBar Installed During Hard Ceiling Installation

STEP 4. Attach Diffuser to Ceiling Frame

Lift the FlowBar Diffuser into the framed opening and secure the

Mounting Clips to the frame with flat head screws as shown in

Figure 4.

FlowBar IOM

FRAME

If multiple sections of FlowBar are required, repeat previous step by

lifting additional sections into the framed opening. Be sure to insert

Spline Support Clips-SS1 into the FlowBar ends to insure a tight and

aligned connection as shown in Figure 4.

Install and secure end caps and mitered corners if required as

shown in Figure 5.

END CAPS

MITERED CORNER

SPLINE SUPPORT CLIP

Figure 5. Installation of End Caps & Mitered Corner

FRAME

MOUNTING

SCREWS

Figure 4. Installation of Diffuser in Ceiling

HANGAR WIRE

HARD CEILING

CLIP

10” MAXIMUM

CENTERS

SPLINE SUPPORT CLIP

SS1

STEP 5. Attach Plenum to Diffuser

If Plenums were mounted earlier, attach the Plenum by

snapping it to the Diffuser using the clips on the Plenum as

shown in Figure 6.

If Plenums were not mounted earlier, lift the Plenums into place

and attach them to the FlowBar at this time.

Plenums may need support with ceiling wire to the building

structure per code requirements.

Redefine your comfort zone. ™ | www.titus-hvac.com

PLENUM

PLENUM CLIPS

FLOWTEE DIFFUSER

Figure 6. Attachment of Plenum to Diffuser

UPPER HANGER

CLIP

Installation Manual - FlowBar

5

Page 6

FlowBar Installed During Hard Ceiling Installation

STEP 6. Attach Inlet Damper (if required)

Attach optional Inlet Damper assembly (if supplied) to the Inlet

Collar. Position the lever inside the Plenum on the bottom of the

Inlet Collar.

Install the Inlet Duct on the Plenum Inlet Collar using the methods

prescribed by the sheet metal specification.

STEP 7. Install Drywall

FlowBar IOM

Figure 7. View of Inlet Damper

Slide the Drywall tightly between the mounting clips and the

FlowBar Flange as shown in Figure 8. For ease of installation, insert

the tapered edge of the Drywall into this opening. For the best fit,

slide the edge of the Drywall all the way to the vertical leg of the

frame.

Every 12” and between the Hard Ceiling Clips, attach screws

just beside the Diffuser Flange, through the Drywall and into the

Framing Member.

For Border 55 only, before installing the sheetrock or wood ceiling,

the leading edge must be trimmed at a 45° angle to match the

Diffuser as shown in Figure 9.

FRAMING MEMBER

HARD CEILING CLIP

DRYWALL

Figure 8. Drywall Installation

FRAMING MEMBER

DIFFUSER FLANGE

HARD CEILING CLIP

6

Installation Manual - FlowBar

DRYWALL

Figure 9. Drywall Preparation - (Border 55 Only)

Drywall cut at 45° angle to match diffuser flange

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 7

Framing Member

Finishing Flange

Joint Compound

4" wide mesh tape

Bonding Agent

Screw through drywall into

ceiling frame every 12"

Hard Ceiling Clips to be located every 10"

Screw Hard Ceiling Clips to ceiling frame

Ceiling frame opening width (W) shown in Table 1

Drywall

FlowBar Installed During Hard Ceiling Installation

STEP 8. Review Installation - (Borders 22 & 55 Only)

FlowBar IOM

Before continuing it is recommended that the installer confirm that:

The FlowBar Diffuser is secure and straight.

For units longer than twelve feet, a 1/8” gap between sections is

recommended to allow for thermal expansion.

STEP 9. Finish the Surface - (Borders 22 & 55 Only)

Sand the finishing surface with medium grit sandpaper in order to

rough up the surface for good joint compound adhesion.

Remove dust from finishing surface following sanding with a tacky

cloth. Or clean with a mild cleaner/degreaser.

Do not run the HVAC system during the finishing procedures. This

could cause premature drying of the compounds, making them

more prone to cracking.

Apply first coat of joint compound onto the diffuser’s finishing flange

and onto the sheetrock three inches. Use a durabond setting-type

compound.

Embed a 4” wide mesh or paper tape into the first coat of joint

compound. Smooth to remove air pockets. The tape should cover the

aluminum rail, but not extend over the raised lip on the rail. Apply

second coat of finishing compound over the tape and smooth.

After compound has dried, apply two coats of standard finishing

compound and let dry. Sand smooth, prime, and paint as scheduled.

Ceiling Frame opening

Width (W) shown in Table 1

FRAMING MEMBER

FINISHING FLANGE

Figure 10. Summary of Border Type 22 Installation

Redefine your comfort zone. ™ | www.titus-hvac.com

SAND THIS SURFACE

Hard Ceiling Clips to be located every 10”

Screw Hard Ceiling Clips to ceiling frame

Screw through drywall into ceiling frame every12”

JOINT COMPOUND

DRYWALL

Installation Manual - FlowBar

7

Page 8

FlowBar IOM

FlowBar Installed After Hard Ceiling Installation

STEP 1. Install Plenums

Install Titus model FBP or FBPI Plenum and secure to the building

structure using hanger wire.

If Plenum is furnished by others, a hemmed edge inside the bottom

of the Plenum sides is required to capture the hanger bracket

assemblies.

The Plenum should be hung so that the Plenum straddles the ceiling

opening and the bottom edge of the Plenum rests on the backside

of the ceiling as shown in Figure 11.

STEP 2. Make Inlet Duct Connections

Attach the Inlet Duct to the inlet collar using the method prescribed

by the job specification.

NOTE: If the Plenum Inlet is accessible after the ceiling is installed,

this step can be completed later.

Ceiling

Opening

Figure 11. Concealed Fastening Plenum Installation

Ceiling Opening Width

FlowBar

Model

1-SLOT

2-SLOT

2CRA & 2CRB

FL-10 3 5½ 6

FL-15 4 7½ 8

FL-20 5 9½ 10

FL-25 6 11½ 12

Attach hanger

wire

to plenum clips

Hemmed Edge

of Plenum

Ceiling

2-SLOT

2CRN

3

⁄8

3

⁄8

3

⁄8

3

⁄8

STEP 3. Install Drywall Ceiling

The ceiling contractor can now frame in the ceiling around the

Plenum and install the drywall. Complete the ceiling surfacing.

NOTE: The finished opening must be smaller than the overall

FlowBar face dimensions. Refer to Table 2 for the ceiling opening

width required. The Two-Slot Diffusers are available with the three

different types of center extrusions as shown in Figure 12. The type

of center extrusion determines the ceiling opening.

FL-30 7 13½ 14

Table 2. Ceiling Opening Dimensions for Border Type 77

CRA

CRB

CRN

Figure 12. Center Extrusion Configurations

3

⁄8

8

Installation Manual - FlowBar

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 9

FlowBar Installed After Hard Ceiling Installation

STEP 4. Install Concealed Fasteners

Install the QuickClip® Mounting Bracket to the FlowBar Spacer at the

desired interval by pushing the #10 x 2-1/2” long screw through the

hole in the spacer from the face of the Diffuser. Start the threaded

end of the screw into the bracket as shown in Figure 13.

The recommended spacing is 48” maximum between hangers.

FlowBar IOM

Mounting

Bracket

STEP 5. Install Diffuser in Ceiling

If continuous FlowBar is being installed using multiple sections,

assemble the sections together using Spline Support Clips (SS1).

Attach end caps or end borders as required. See Hard Ceiling

Installation, Step 4.

Lift the Diffuser into the Plenum until the Mounting Brackets spring

into the hemmed edge. Using a slotted screw driver, tighten the

screw until the Diffuser is snug against the ceiling as shown in

Figure 14. Before securing the Diffuser, make sure that the Diffuser

Flange overlaps the ceiling opening.

Make sure that at least two QuickClip® Mounting Assemblies line

up with each Plenum.

Where Mounting Brackets do not line up with a Plenum, the Drywall

can be used to support the FlowBar Diffuser. Use a slotted screw

driver to tighten the screws until the Diffuser is snug against the

ceiling as shown in Figure 15.

#10 x 2 1/2” screw

Figure 13. Bracket / Diffuser Assembly

Figure 14. Diffuser Installation with Plenum

FlowBar Spacer

Plenum

Mounting bracket

catches in hemmed

edge of plenum

Diffuser flange overlaps ceiling opening

Mounting Bracket

Ceiling

Redefine your comfort zone. ™ | www.titus-hvac.com

Figure 15. Diffuser Installation without Plenum

Diffuser Flange

Installation Manual - FlowBar

9

Page 10

Field Cutting Linear FlowBar

STEP 1. Prepare Diffuser for Cutting

Working from a table covered with indoor/outdoor carpet, measure

the length of Diffuser to be cut.

Slide the top Spacer sufficiently to allow for removal of the Pattern

Controller(s) as shown in Figure 16.

FlowBar IOM

Remove the Pattern Controller(s) as shown in Figure 17.

Slide both top and bottom Spacers back into the FlowBar frame as

shown in Figure 18, beyond the cut mark to clear the saw blade.

STEP 2. Cut Diffuser to Length

Secure FlowBar to table. Cut through both FlowBar rails with the

finished flanges facing up as shown in Figure 19.

A 10” miter saw with an aluminum cutting blade is recommended.

Caution: Use/Wear proper safety equipment.

Cut the pattern controller so it will fit between the spacers.

STEP 3. Reassemble Diffuser

Figure 16. Diffuser Spacer Removal

Figure 17. Removal of Pattern Controller

Move both Spacers to the end of FlowBar.

Slide the top Spacer sufficiently to allow for replacement of the

Cattern Controller(s).

Reinstall the Pattern Controller(s) and slide the top Spacer back over

the Pattern Controller(s).

Lubricate the portion of the Pattern Controller that fits between the

top and bottom spreader with WD-40 or other lubricants of your

choice.

All FlowBar components may be reused after cutting, however,

additional Spacer Kits are an available option.

10

Installation Manual - FlowBar

Figure 18. Replacement of Diffuser Spreader

Flanges facing up

Figure 19. Field Cutting Diffuser

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 11

FlowBar Installed In Acoustical Ceiling

(by others)

Tee

Spline

Clip

Clip

Spline

Spacer

Unit

Hanger Clip

Upper

Diffuser

FlowBar

Controller

Pattern

Wire

Hanger

STEP 1. Install Hanger Clips to Diffuser

FlowBar IOM

FlowBar Diffusers with one-slot are supported by sliding Upper

Hanger Clips through the top bosses in the FlowBar rails as shown

in Figure 20.

FlowBar Diffusers with two-slots are supported by sliding Upper

Support Hangers through the top bosses in the FlowBar rails as

shown in Figure 21.

The clips are secured to the building structure with hanger wire.

STEP 2. Install Diffuser in Ceiling

If continuous FlowBar is being installed in multiple sections,

assemble the sections together using Spline Support Clips (SS1).

Attach end caps or end borders as required. (Refer to Step 4, Page

5.) (SS1 clips may be secured using #8 - 18 x 1/2” crimptite head

screw).

Where ceiling tees (By Others) intersect the FlowBar, bend the

connecting Spline Support Clip-SS1 90°, slide into the lower FlowBar

rail bosses, and secure to the ceiling tee as shown in Figure 22.

Upper

Hanger

Clip

Figure 20. Attachment of UHC to One-Slot Diffuser

Upper

Support

Hanger

Figure 21. Attachment of UHC to Two-Slot Diffuser

STEP 4. Attached Plenums to Diffusers

After installing the FlowBar into the ceiling suspension system,

install the air distribution plenums and connect to ductwork.

STEP 3. Attached Plenums to Diffusers

After installing the FlowBar into the ceiling suspension system, install

the air distribution plenums and connect to ductwork.

Upper Hanger Clip

(UHC)

Spacer

Tee

(by others)

Figure 22. Installation of FlowBar in Acoustical Ceiling

Redefine your comfort zone. ™ | www.titus-hvac.com

Spline Support Clip

STEP 5. Install Ceiling Tiles

Trim and install the acoustic ceiling tiles.

FlowBar Diffuser

Pattern Controller

Hanger Wire

Spline Support Clip

Installation Manual - FlowBar

11

Page 12

FlowTee Installation

STEP 1. Install Hanger Clips to Diffuser

Slide Upper Hanger Clips into Single Slot Diffuser rails or Upper

Support Hangers into the top bosses at each end of the Diffuser as

described in Acoustical Ceiling Installation, Step 1.

STEP 2. Install Diffuser in Ceiling

Install the Diffuser on top of the ceiling grid as shown in Figure 23.

The Diffuser can be positioned adjacent to a ceiling T-Bar or inside

the module.

STEP 3. Secure Diffuser to Building

Structure

PLENUM

PLENUM CLIPS

DIFFUSER

Figure 23. Installation of FlowTee Diffuser

FlowBar IOM

HOLES FOR WIRE

ATTA CHMENT

(EACH END)

Secure the Diffuser to the building structure by attaching the

Hanger Brackets to the building structure with Hanger Wire.

Secure the Plenums to the building structure by attaching the

Plenum tabs to the building structure with Hanger Wire.

ModuFlow Installation

STEP 1. Install Center Tile in Diffuser

Unlatch spring clips holding the back pan onto the frame and

pattern controller assembly.

Cut ceiling tile to 17-15/16” x 17-15/16”.

Insert the cut ceiling tile into the frame and pattern controller

assembly.

Attach back pan assembly to frame making sure that the clips are

secure.

STEP 4. Make Inlet Duct Connections

Connect the Inlet Duct to the Inlet Collar using the prescribed

methods.

STEP 5. Install Ceiling Tiles

Trim and install acoustic ceiling tiles.

Back pan

Clips to secure

back pan

to diffuser

Ceiling Tile

ModuFlow

Diffuser

12

Installation Manual - FlowBar

Figure 24. Center Tile Installation

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 13

ModuFlow Installation

STEP 2. Install Hanger Clips

Install the Upper Support Hanger (USH) Clips at the clip access

area into the upper boss of the Diffuser extrusion and move a clip

towards each corner as shown in Figure 25.

FlowBar IOM

Additionally for 9/16” bolt slot grids, install the SC1 Clips into the

lower extrusion boss at the access area and move a clip towards

each corner.

STEP 3. Install Diffuser in Ceiling

Install ModuFlow unit into ceiling grid. Moduflow Diffusers lay into

the Acoustical Ceiling Suspension System.

Support Diffuser by attaching Hanger Wire from the clips to the

ceiling structure.

Attach Inlet Duct to the Inlet Collar on the back pan using prescribed

methods.

Hanger Wire

USH Clip

Clip Access Area

Figure 25. Installation of USH clips

USH Clip SC1 Clip

Figure 26. View of USH and SCI Clips

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - FlowBar

13

Page 14

FlowBar Parts List

FlowBar IOM

Model: UHC-10, -15 or -20

Application: Use with One-Slot models FL-10, -15 or -20 any border type, except Border Type 77. Clip inserts into

extrusion boss and hanger wire threads through hole in clip to support FlowBar Diffuser.

Quantity per Bag: 5 pieces

Model: USH

Application: Use with any One-Slot or Two-Slot Diffuser with any border type, except Border Type 77. Insert a clip

into the extrusion boss on each side of the diffuser. Thread hanger wire through hole to support FlowBar Diffuser.

Quantity per Bag: 15 pieces

Model: H1

Application: Use with Frame 3 or Frame 6 in hard ceiling installation. Insert a clip into the extrusion boss on the

outside of the Diffuser frame. Attach clip to Framing Member with flat head screw. Clips should be spaced at 10”

intervals.

Quantity per Bag: 48 pieces

Model: H2 Description: Hard Ceiling Clip

Application: Use with Frame 1 in hard ceiling installation. Insert a clip into the extrusion boss on the outside

of the Diffuser frame. Attach the clip to Framing Member with flat head screw. Clips should be spaced at 10”

intervals.

Quantity per Bag: 48 pieces

Model: H3 Description: Hard Ceiling Clip

Application: Use with Frame 2, Frame 4 or Frame 5 in hard ceiling installation. Insert a clip into the extrusion boss

on the outside of the Diffuser frame. Attach clip to Framing Member with flat head screw. Clips should be spaced

at 10” intervals.

Quantity per Bag: 48 pieces

Description: Upper Hanger Clip

Description: Upper Support Hanger

Description: Hard Ceiling Clip

14

Installation Manual - FlowBar

Model: H4 Description: Hard Ceiling Clip

Application: Use with Frame 4 in hard ceiling installation. Insert a clip into the extrusion boss on the outside

of the Diffuser frame. Attach clip to Framing Member with flat head screw. Clips should be spaced at 10”

intervals.

Quantity per Bag: 48 pieces

Model: WC1 Description: Wall Clip

Application: Use with Frame 3 to install Diffuser flush against side wall. Insert a clip into the extrusion boss on

the outside of the Diffuser frame. Attach clip to Framing Member with flat head screw. Clips should be spaced at

10” intervals.

Quantity per Bag: 28 pieces

Model: WC2 Description: Wall Clip

Application: Use with Frame 1, Frame 3 or Frame 6 to install Diffuser with reveal against side wall. Insert a clip

into the extrusion boss on the outside of the Diffuser frame. Attach clip to Framing Member with flat head screw.

Clips should be spaced at 10” intervals.

Quantity per Bag: 28 pieces

Redefine your comfort zone. ™ | www.titus-hvac.com

Page 15

FlowBar Parts List

FlowBar IOM

Model: WC3

Application: Use with Frame 1 install Diffuser flush against side wall. Insert a clip into the extrusion boss on the

outside of the Diffuser frame. Attach clip to Framing Member with flat head screw. Clips should be spaced at 10”

intervals.

Quantity per Bag: 28 pieces

Model: WC4

Application: Use with Frame 6 or 7 install Diffuser flush against side wall. Insert a clip into the extrusion boss on

the outside of the Diffuser frame. Attach clip to Framing Member with flat head screw. Clips should be spaced at

10” intervals.

Quantity per Bag: 28 pieces

Model: SS1

Application: Used to connect multiple sections of FlowBar Diffusers. Insert clip half way into the extrusion boss on

the outside of the Diffuser frame, then slide exposed end of Spline Support Clip into connecting piece of FlowBar.

Quantity per Bag: 28 pieces

Model: SS1

Application: Spline Support Clip can also be used to connect FlowBar Diffuser to Accoustical Ceiling T-bar. Bend

straight clip 90°. Insert clip half way into the extrusion boss on the outside of the Diffuser frame, then slide exposed end of Spline Support Clip into T-bar.

Quantity per Bag: 28 pieces

Model: SC1

Application: Use with ModuFlow Border Type 13 to install in Bolt-Slot Ceiling System. Insert a clip into the extru-

sion boss on the outside of the Diffuser Frame 1. Thread Hanger Wire through hole in clip. Bottom of support clip

rests on bolt slot ceiling bar.

Quantity per Bag: 28 pieces

Description: Wall Clip

Description: Wall Clip

Description: Spline Support Clip

Description: Spline Support Clip

Description: ModuFlow Support Clip

Model: CFB-10, -15, -20, -25, -30 Description: Concealed Fastener Bracket Kit

Application: Use with FlowBar Border Type 77 to install FlowBar Diffuser after hard ceiling installation. Place

Mounting Bracket above Diffuser. Drill hole into existing FlowBar Spacer(s). Thread #10 x 2 1/2 flat head screw

through each Spacer and into Mounting Bracket. Tighten screw(s) until Diffuser Flanges draw tight against ceiling.

Note: One-Slot models use one screw. Two-Slot models use two screws.

Quantity per Bag: 4 pieces (includes four #10 x 2 1/2 screws for One-Slot models)

4 pieces (includes eight #10 x 2 1/2 screws for One-Slot models)

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation Manual - FlowBar

15

Page 16

Titus FlowBar architectural linear diffuser system maximizes engineering performance without sacrificing aesthetic considerations for the designer. FlowBar’s outstanding performance allows higher airflows than conventional linear diffusers, with

lower noise levels, making it ideal for high profile designs.

FlowBar

The FlowBar was the first supply diffuser in the industry designed specifically for the architect. The wide array of slot

widths allow for more CFM per linear foot while minimizing

noise and pressure loss.

605 Shiloh Rd

Plano TX 75074

ofc: 972.212.4800

fax: 972.212.4884

Loading...

Loading...