Page 1

INSTALLATION & OPERATION MANUAL

Fan Filter Unit

FFD, FFDR, & FFDRA Models

Page 2

INSTALLATION & OPERATION MANUAL

Table of Contents

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

Critical Operations of the Fan Filter Unit .......................................................................... 3

Warnings ................................................................................................................................. 3

Installation.............................................................................................................................4

ON/OFF Switch - Speed/Airflow Adjustment ....................................................................5

Troubleshooting.................................................................................................................6

Pre-filter Cleaning (foam) ..................................................................................................7

Service: Removal and Replacement of FFD Filters.............................................................8

Service: Removal and Replacement of Roomside Replaceable Filters ............................9

Service: FFD and FFDR Motor Removal and Installation .................................................10

Service: FFDRA Motor Removal and Installation .............................................................11

Unit Wiring Diagrams .......................................................................................................12

Unit Replacement Parts List ..............................................................................................13

Drawing - FFD Filter ..........................................................................................................14

Drawing - FFDR & FFDRAFilter .........................................................................................15

Testing...............................................................................................................................16

Installation & Operation

Page 3

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Critical Operation Conditions of FFD, FFDR, & FFDRA models

1. Touching of the HEPA filter will damage it, voiding the warranty on the filter. The screen is only to protect against an

accidental ‘touch’ of the filter. Never place a hand or tool on the filter. Never lie filter face flat down on a surface always

have filter on its side to protect from damage.

2. Prior to powering the unit, verify voltage on label and that the unit has been wired into the correct voltage. The serial

number label on the top of the unit has the required voltage.

3. To insure you order the proper replacement parts or complete unit, record the part number and serial number. This

information is located on the serial number label, located adjacent to the electrical box. If you can’t locate the Sales Order

Number, please contact Titus for this information. Once obtained, record the information for reference.

Warning

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and

standards, including fire-rated construction.

B. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

C. If this unit is to be installed over an area using liquid, such as water or chemical cleaning solutions, it must be marked as

appropriate for the application.

D. Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the manufacturer.

E. Before servicing or cleaning the unit, switch power off at unit service panel and lock service panel to prevent power from

being switched on accidentally.

Installation & Operation

3

Page 4

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Installation

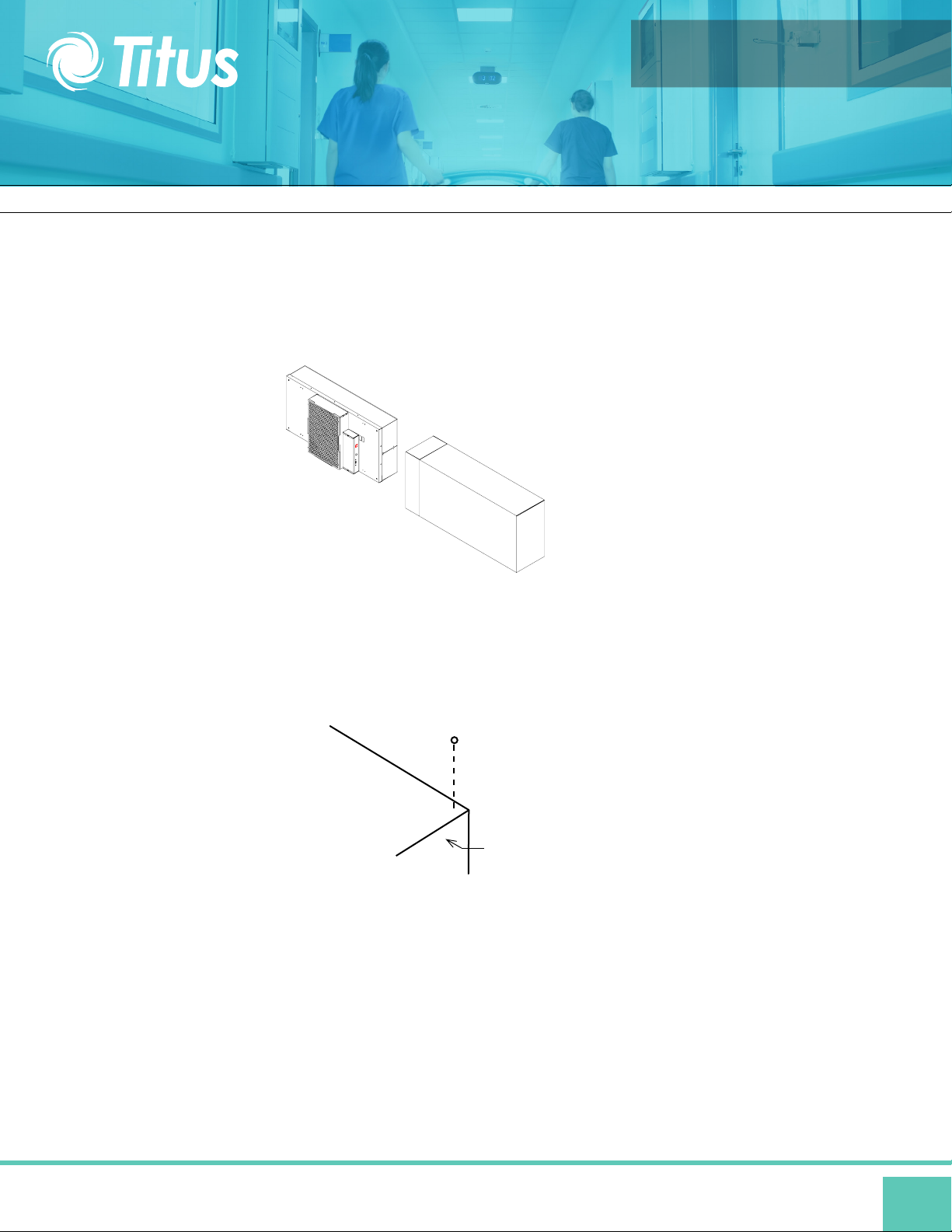

Note: Titus fan filter units are completely assembled at the factory with the exception of the optional ¼”-20 eyebolts

that are used when hanging the unit from an engineered design support system and installation of the HEPA/ULPA filters

(eyebolts not included and can be ordered separately, p/n 222449-001).

Step 1. Carefully remove the unit from the shipping carton and inspect for any damage that may have occurred during

transportation (See Figure 1).

Note: When ordering FFDR and

FFDRA units, the HEPA filters may

be shipped separately to be installed

into units after the fan box has been

installed.

Figure 1: Unboxing

If using rigidly supported grid (usually 2” (50 mm) or wider), raise unit through ceiling and lower onto the gasketed grid.

Step 2.

If using a flexible grid (typically supported with wires), the unit must be secured to an engineered design support system

with s-hooks and chain. Screw the four eyebolts into the nutserts on the lid assembly before lifting into an overhead position

(see Figure 2) Note: Confirm fan dimensions to match T-grid dimensions.

EYEBOLT

FAN FILTER

UNIT

Figure 2: Hanger Supports

Step 3. Raise the unit and secure it into place using the chosen support system method suspended from a structural support

bracing.

Step 4. Have an electrician wire the unit to the appropriate voltage, according to the wiring diagram (page 17), and all national

and local electrical codes. All units are equipped with a three position terminal block for field onnection. Verify correct singlephase

power, before energizing units.

Step 5. Turn on the power using the two position rocker switch (ON/OFF) located on the electrical box. For FFDR and

FFDRA units, let the unit run for a few hours to purge off particulate (if filters are shipped loose) that may be adhered to

the inside of the unit before installing the filters. Do not run fan at full speed as this may cause overload condition.

Note: Your fan filter may have been shipped separate. Controls have been shipped separately.

Installation & Operation

4

Page 5

INSTALLATION & OPERATION MANUAL

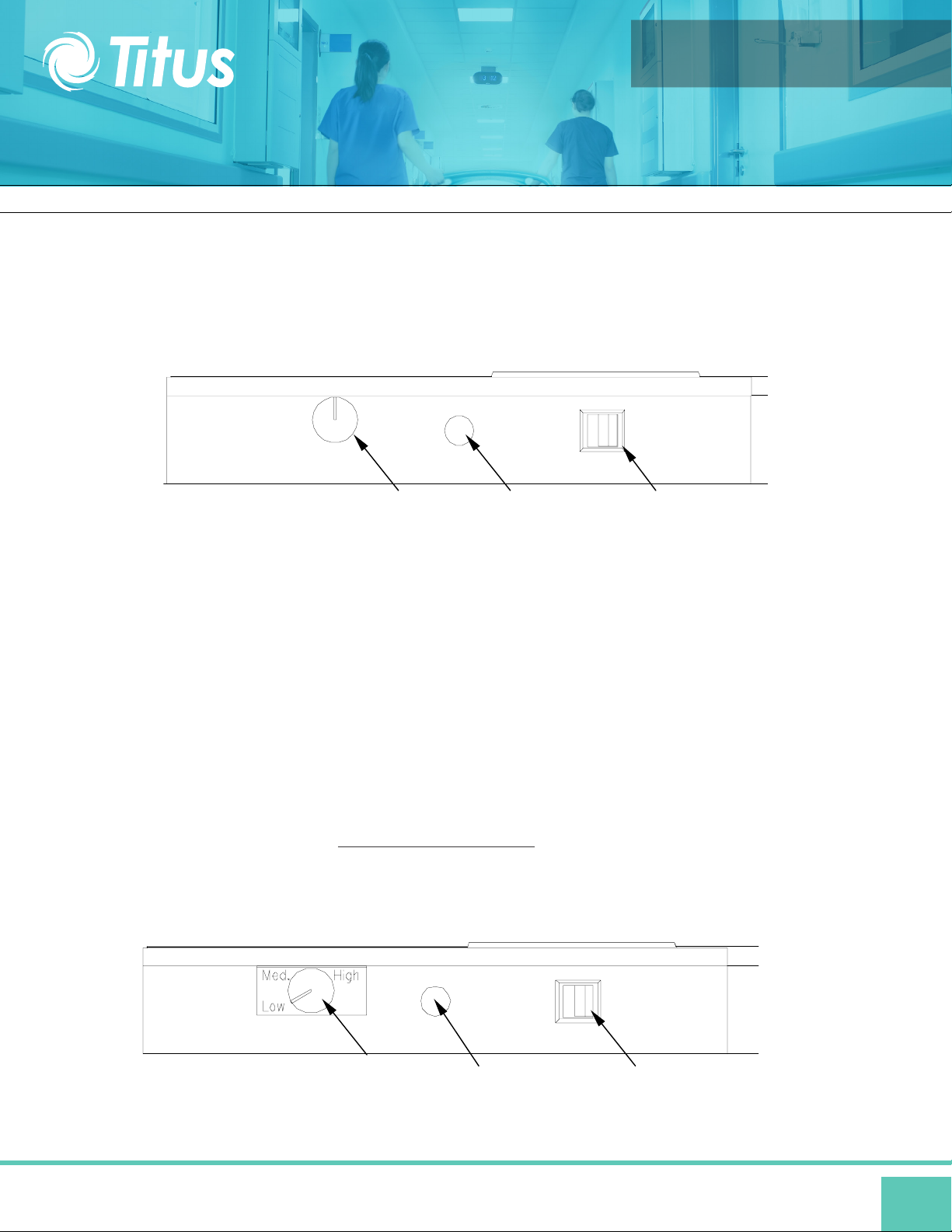

ON/OFF Switch - Speed/Airflow Adjustment

All units are equipped with a speed control enabling adjustment of airflow at any setting

within the recommended performance range. The speed control knob is located on the

side of the electrical box, adjacent to the on/off switch.

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

ON/OFF SwitchElectrical EntranceSpeed Control

Speed Control Adjustment

Airflow/speed is adjusted by rotating the knob (See figure above):

Clockwise Lowers the speed

Counter-Clockwise Increases the speed

Fully rotating the speed control knob to the left or counter-clockwise will turn the unit off.

Note : When turning the unit “ON” from the “OFF” position of the speed control, the fan

is at the highest speed. Turning the speed control knob clockwise will lower the airflow.

Optional Speed Control

For units equipped with a three-position rotary switch, it is located on the side of the

electrical box. (See figure below)

Recommended fan speed during initial start-up and operation is the “LOW” speed. As

airflow eventually decreases due to filter loading, fan speed may be increased by

moving the rocker switch to the top or “MEDIUM” position, and finally to the “HIGH”

position. Periodic airflow velocity readings (per IEST Reccommended Practices)

should be conducted to determine the filter condition and appropriate fan speed

setting.

ON/OFF SwitchElectrical Entrance3-Speed Switch

Installation & Operation

5

Page 6

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Troubleshooting

Low Air Velocity:

Step 1. Adjust variable speed control for higher blower output. For units eqquped with 3-speed, adjust switch setting from

“LOW” to “MEDIUM” to “HIGH”.

Step 2. Check prefilter media; replace or clean as necessary.

Step 3. Check incoming power supply for proper voltage (120,208-240,277/24).

Step 4. Examine the HEPA/ULPA filter.

High Air Velocity:

Step 1. Adjust variable speed control for lower blower output. For units eqquped with 3-speed, adjust switch setting from

“HIGH” to “MEDIUM” to “LOW”.

Filter Issues:

Non-Laminar Flow and/or Excessive Contamination:

Step 1. Insure that no large obstructions are upstream of airflow pattern.

Step 2. Determine that no other air-moving devices are operating in or around clean room which disrupt room’s

airflow pattern.

Step 3. Check air velocity and if low, conduct the “Low Air Velocity” procedure outlined above.

Step 4. Conduct smoke and photometer test on HEPA/ULPA filter. Seal or replace HEPA filter as necessary.

Installation & Operation

6

Page 7

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Cleaning the Pre-filter (foam)

Tools Required: None.

Note: To keep the filter in top operating condition, washing

the foam prefilter is recommended every three to six months.

Step 1. To gain access to the prefilter, remove the ceiling

panel next to the unit, if applicable.

Step 2. Switch the ON-OFF switch to the off position.

Step 3. Remove the 16”x23” prefilter from the snap-in frame. (See figure below)

Step 4. Clean the prefilter by hand washing in water with a mild detergent or by using a vacuum cleaner . Allow prefilter to

dry completely before replacing.

Step 5. Reassemble by reversing the above steps.

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

WARNING

ANY SERVICE

ON/OFF SWITCH

PREFILTER SURFACE ON TOP SIDE

SUPPORT SCREEN ON BOTTOM SIDE

Installation & Operation

7

Page 8

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Service: Removal and Replacement of FFD HEPA/ULPA Filters

WARNING

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE

Note: All filters should be visually inspected for freight damage before installation. It is necessary to use two workers when

removing the filter and for installation to avoid twisting or separation of the media seals. Handle the filter only by the frame

and never place anything on the upstream filter side of the filter. Additionally, it is important to keep the filter level to prevent

any shearing force on the media itself.

For Standard Filters:

Tools Required: Phillips Head Driver, Battery Operated Drill with 5/32 drill bit, Rivet Hand Tool, Ø5/32 aluminum rivet grip

range.126-.187

Step 1. Remove unit from ceiling.

Step 2. Remove the 10 screws holding the HEPA/ULPA filter to the lid assembly.

Step 3. Lift the lid assembly off the HEPA/ULPA filter (see figure). Remove filter deflectors using 5/32 drill bit. Keep filter

deflectors to install in new filter. Discard the used filter as per requirements of the applicable regulations. Carefully install the

filter deflectors into the new filter using the 5/32 rivets. Do not touch or place the filter deflectors on the HEPA/ULPA media

pack. This could cause tears in the filter pack.

Step 4. Before replacing with the new filter, carefully inspect the new filter for any visible damage. Also inspect the gasket

and the T-Bar to insure a tight seal. Replace if necessary.

Step 5. To replace a filter, raise the filter and rotate into position in the ceiling grid (with power off), then lower the plenum

housing into place. Reconnect wiring and hardware from previous steps that have been removed.

Step 6. Restore power and verify proper operation of FFU.

THE STANDARD FILTER IS PROTECTED WITH AN

EXTENDED METAL FACE SCEEN. THIS IS NEVER TO

BE USED TO HANDLE THE FILTER. IT IS ONLY FOR

PROTECTION AGAINST AN ACCIDENTAL TOUCH

OF THE FILTER. ONLY HANDLE THE FILTER BY THE

FRAME

Electrical Knock Out

Filter Deflector

HEPA/ULPA Filter

Standard Filter Change

On/Off Switch

Lid Assembly

#8 Screws (10x)

Ø5/32 Rivet (6x)

Installation & Operation

8

Page 9

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Service: Removal and Replacement of FFDR & FFDRA Filters

WARNING

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE

Note: All filters should be visually inspected for freight damage before installation. It is necessary to use two workers when

removing the filter and for installation to avoid twisting or separation of the media seals. Handle the filter only by the frame

and never place anything on the upstream filter side of the filter. Additionally, it is important to keep the filter level to prevent

any shearing force on the media itself.

For FFDR & FFDRA Filters:

Tools Required: Phillips Head Driver, Battery Operated Drill, 3/16” hex head ball driver (2ea)

Step 1. With the power off, remove the diffuser screen by removing the 6 each 10-32x1/2 screws, then carefully place in a

safe location.

Step 2. Loosen the six 1/4x12 socket head screws far enough to rotate the eight filter clips 90°. The filter may be loose

enough to drop during this operation. If not, slowly pull the filter away from the knife-edge seal, taking care not to touch the

filter face during this operation. It is important to pull the filter slowly away from the seal, so that the gel remains in the filter

gel track.

Step 3. Carefully clean plenum assembly knife edge surface of residual gel material.

Step 4. Inspect filter for visible damage, if damaged set aside for replacement or repair.

Step 5. Inspect the gel seal, if reinstalling the removed filter. Determine if the gel has lost its ability to seal (i.e. the gel should

reform to cover the track without voids or openings), if so repair the gel material or consider replacement of filter.

Step 6. Place the filter evenly against the filter-sealing surface of the unit. Reposition filter clips and screws. The clips

should be rotated and angled into place. It is recommended that four workers work on each corner of the filter

simultaneously, holding the filter seated into the track. Hand tighten clips from opposite corners evenly until all clamps are

tightened.

Step 7. Reinstall diffuser screen by hand-tightening the screws.

Step 8. Determine if recertification or testing of replacement is required.

Step 9: Restore power to FFU and verify proper operation of FFU.

Fan Filter Unit

THE STANDARD FILTER IS PROTECTED WITH AN

EXTENDED METAL FACE SCEEN. THIS IS NEVER TO

BE USED TO HANDLE THE FILTER. IT IS ONLY FOR

PROTECTION AGAINST AN ACCIDENTAL TOUCH

OF THE FILTER. ONLY HANDLE THE FILTER BY THE

FRAME

Filter

2-Piece Welded

Plenum Housing

Filter

Knife- Edge

Seal

Gel Track

Filter Clip and

Screw (typ 6)

Diffuser Screen

Screws (typ 6)

FFDR & FFDRA Filter Change FFDR & FFDRA Filter Replacement

¼ -20

Cap

Screw

10-32

PHP

Screws

Filter Clip

Installation & Operation

Diffuser

Screen

9

Page 10

INSTALLATION & OPERATION MANUAL

Service: FFD and FFDR Motor Removal and Installation

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ELECTRICAL SERVICE SHOULD ONLY BE PERFORMED

BY A LICENSED OR QUALIFIED ELECTRICIAN

WARNING

ANY SERVICE

Tools Required: Phillips Head Driver, Battery Operated Drill, (2) 8” adjustable wrenches, 10 mm hex head wrench,

#2 screwdriver, and slip joint pliers.

Step 1. To gain access to the motor, remove the ceiling panel next to the unit, if applicable.

Step 2. Switch the ON-OFF switch to the off position.

Step 3. Loosen the electrical box cover screws (2), and slide/lift off cover.

Step 4. Make note of all wire routing and locations for later reinstallation.

Step 5. Disconnect the two brown wires from the capacitor, using a pair of pliers. Disconnect the motor wiring from the rotary switch and rocker

switch or speed control and rocker switch and remove the grommet from the motor leads. Save this grommet for reinstallation.

Step 6. Remove the eight mounting screws to free the motor/blower assembly from the lid assembly. If using power drivers,

set the unit to a low torque setting to avoid stripping the sheet metal screws. Carefully remove housing assembly, paying

attention to wire routing.

Step 7. Using an adjustable wrench loosen the two set screws that attach the blower wheel to the motor shaft.

Step 8. Mark the location of the motor support bracket (belly band), then loosen the bolt just enough to allow the motor

support bracket to slid off the motor.

Step 9. Using the removed motor, mark the new motor with the location of the motor support bracket.

Step 10. Replace with the new motor and reassemble by reversing the above steps 1-8. Set the spacing at 0.25” (6.35 mm)

clearance between the blower and the upper motor plate/prefilter frame. This will give a 0.11” overlap between the venturi

ring and the blower.

Prefilter

Power Entrance

Motor/Electrical Removal

Motor

Venturi Ring

Blower Wheel

ON/OFF Switch

Installation & Operation

10

Page 11

INSTALLATION & OPERATION MANUAL

Service: FFDRA Motor Removal and Installation

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ELECTRICAL SERVICE SHOULD ONLY BE PERFORMED

BY A LICENSED OR QUALIFIED ELECTRICIAN

WARNING

ANY SERVICE

Note: Minimum 2 person project.

Tools Required: 3/16 Ball Driver, Phillips screw bit, Head Driver, Battery Operated Drill, (2) 8” adjustable wrenches, 10 mm

hex head wrench, #2 standard screwdriver, and slip joint pliers.

Step 1. To gain access to the motor, remove the gel seal filter.

Step 2. Prior to removing motor/blower assembly, remove blower wheel to expose motor connectors on motor. Using an

adjustable wrench loosen the two set screws that attach the blower wheel to the motor shaft. Disconnect the two brown wires from

the capacitor, using a pair of pliers. Disconnect the motor wiring from the rotary switch and rocker switch or speed control and rocker

switch and remove the grommet from the motor leads. Save this grommet for reinstallation.

Step 3. While supporting the motor blower assembly from below, remove the six screws on the underside of the venturi ring

and lower the assembly. (See Figure 7). Note the baffle does not have to be removed to remove the motor/blower assembly.

Step 4. Before removal of the motor mount bracket, measure the precise location of the bracket on the motor. Remove the

bracket.

Step 5. Replace with the new motor and reassemble by reversing the above steps. Set the location of the motor mount

bracket as measured (see above Step 6). Set the spacing at 0.25” (6.35 mm) clearance between the blower and the upper

motor plate/prefilter frame creating a 0. 1” (2.80 mm) overlap between the wheel and the venturi ring. When reinstalling the

assembly, align the plate to insure that the leads will reach the electrical box.

Electrical connectors

located in inner

prefilter wall

Grommet

Plenum

Motor/Blower

Assy

Baffle Assembly

Gel Seal Filter

Screen

Motor/Electrical Removal

Motor Assembly

Machine Screw

Motor

Wellnut

and washer

Venturi

Ring

Blower

Wheel

Installation & Operation

11

Page 12

Wiring Diagrams

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Three Speed Wiring Diagram

Speed Control Wiring Diagram

Pressure Monitor Switch)

Network Control Card Wiring Diagram

Installation & Operation

12

Page 13

Replacement Parts List

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Model

FFD FFDR

FFDRA

FFD FFDR PSC Motor/Blower Assembly (FFD & FFDR)

Size/Voltage

N/A Disconnect Switch 63739-002

N/A Pre-filter (foam) 62981-001

N/A Deflector - Filter 38532-001

N/A Gasket, Neop .125x.5 62968

N/A Grommet 5/8 Id 1 1/8 Od 63388

120V

208V-240V

277V

120V

208V-240V

277V

230V Speed Controller (CE Marked) 63742

N/A

N/A

120V 64083-001

208V-240V 64083-002

277V 64083-003

120V 24332-001

208V-240V 24332-002

277V 24332-003

120V 24332-015

208V-240V 24332-016

277V 24332-017

Network Control Card (FFD, FFDR, & FFDRA)

PSC Motor/Blower Assembly (FFDRA)FFDRA

Description Part Number

Transformer 24V

Speed Controller

Blower Wheel

Ventiri Ring

63677

63666

63665

63011

63015

63016

63270

62964

Installation & Operation

13

Page 14

FFD Filter Drawing

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Installation & Operation

14

Page 15

FFDR and FFDRA Filter Drawing

Fan Filter Unit IOM

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Installation & Operation

15

Page 16

Fan Filter Unit IOM

Recommended Testing – 8 readings with a Velgrid

FFD, FFDR, FFDRA Models

INSTALLATION & OPERATION MANUAL

Testing

Each fan filter unit is thoroughly tested at the factory before shipment. However, because of the “rigors” of

shipping, Titus encourages units are re-tested after installation.

Titus recommends that the customer contact an independent organization, with technicians trained

and experienced in performance evaluation and maintenance of clean air equipment.

HEPA filters (Type J) are tested to IEST-RP-00034. ULPA filters are tested to (Type F) IEST-RP-00034. All filters

are UL 900 recognized. Your filters may have special requirements, please see original engineering specifications

for you specific project.

All units that are airflow tested at Titus are tested using a Shortridge Airdata Multimeter 870 with a Velgrid head.

The recommended method of reading is to place one corner of the Velgrid head 1-1/4” from the corner of the

filter face and then take four reading evenly spaced along the four foot side, then repeat these reads three

additional times. This gives a total of 8 reading to test the unit. All advertised data is based on using the Velgrid

with 8 readings (128 velocity points). Titus recognized the using 8 reading during a cleanroom start-up may be

time consuming and recommends using 4 Velgrid readings taken on each 2x2 filter section will approximate the

same as 8 readings.

Recommended Testing – 8 readings with a Velgrid

Additional independent testing on the Titus fan filter units show that using one-2x4 or two-2x2 hoods

simultaneously give airflow data (cfm) with 5 percent of a duct traverse using 10 diameters of straight duct

upstream of the fan intake.

Installation & Operation

16

Loading...

Loading...