Page 1

TU-FB-IOM 08-26-13

Fan Powered Terminals VAV Terminals

Receiving Inspection

After unpacking the terminal, check it for

shipping damage. If any shipping

damage is found, report it immediately

to the delivering carrier. Store units in a

clean dry location and do not stack more

than four high.

Caution: Do not use the inlet collar,

damper shaft, flow sensor or air

tubing as a handle to lift or move

assembly. Damage to the unit or

controls may result.

Before installation, remove fan packing

and all foreign material from the unit.

Check the blower wheel

for free rotation.

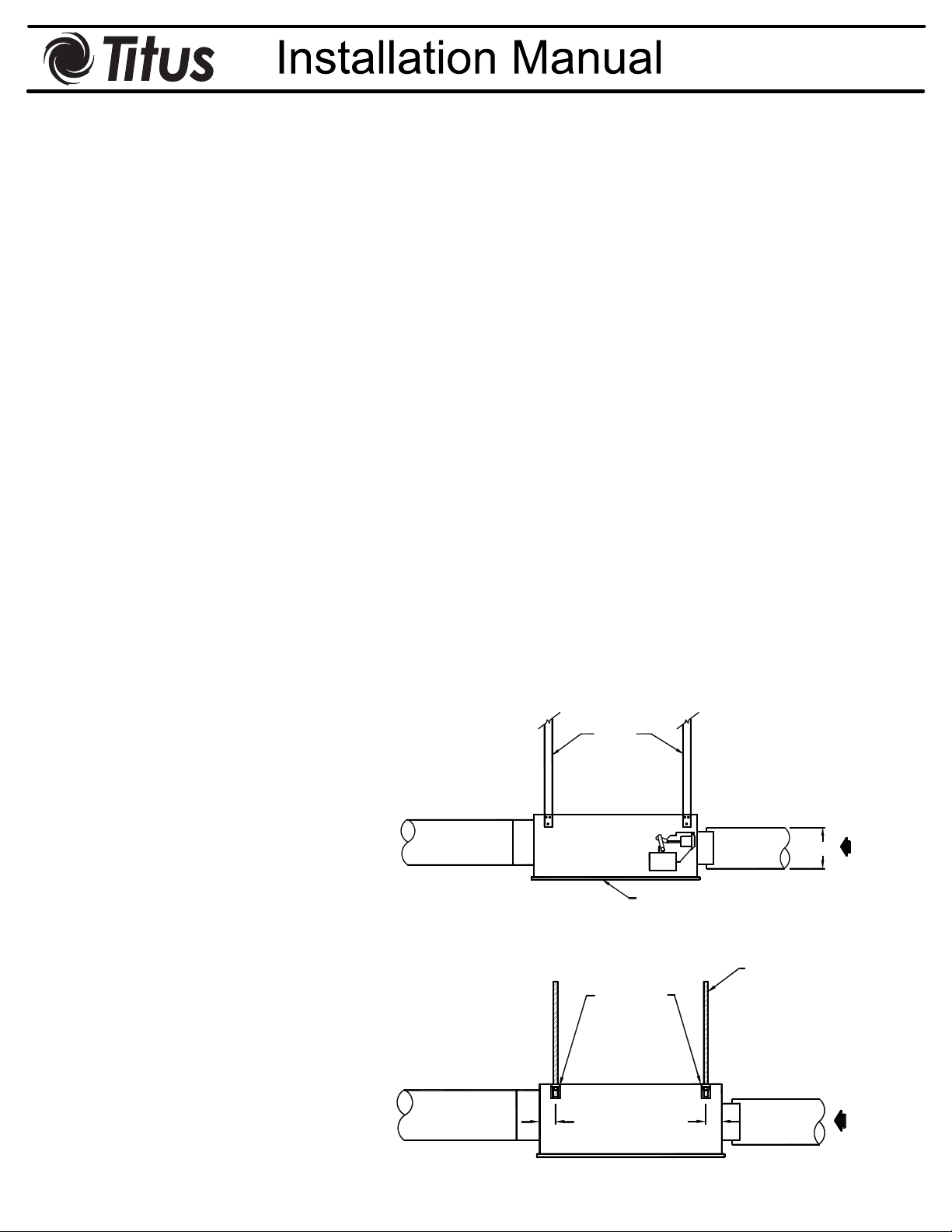

Supporting the Assembly

Suspend the unit from the building

structure in a horizontal plane with the

access panels facing downward.

Do not obstruct the access panels

with support channels or straps.

One inch long sheet metal screws can

be used to penetrate the casing (see

Figure 1). Use the support method

prescribed for the rectangular duct on

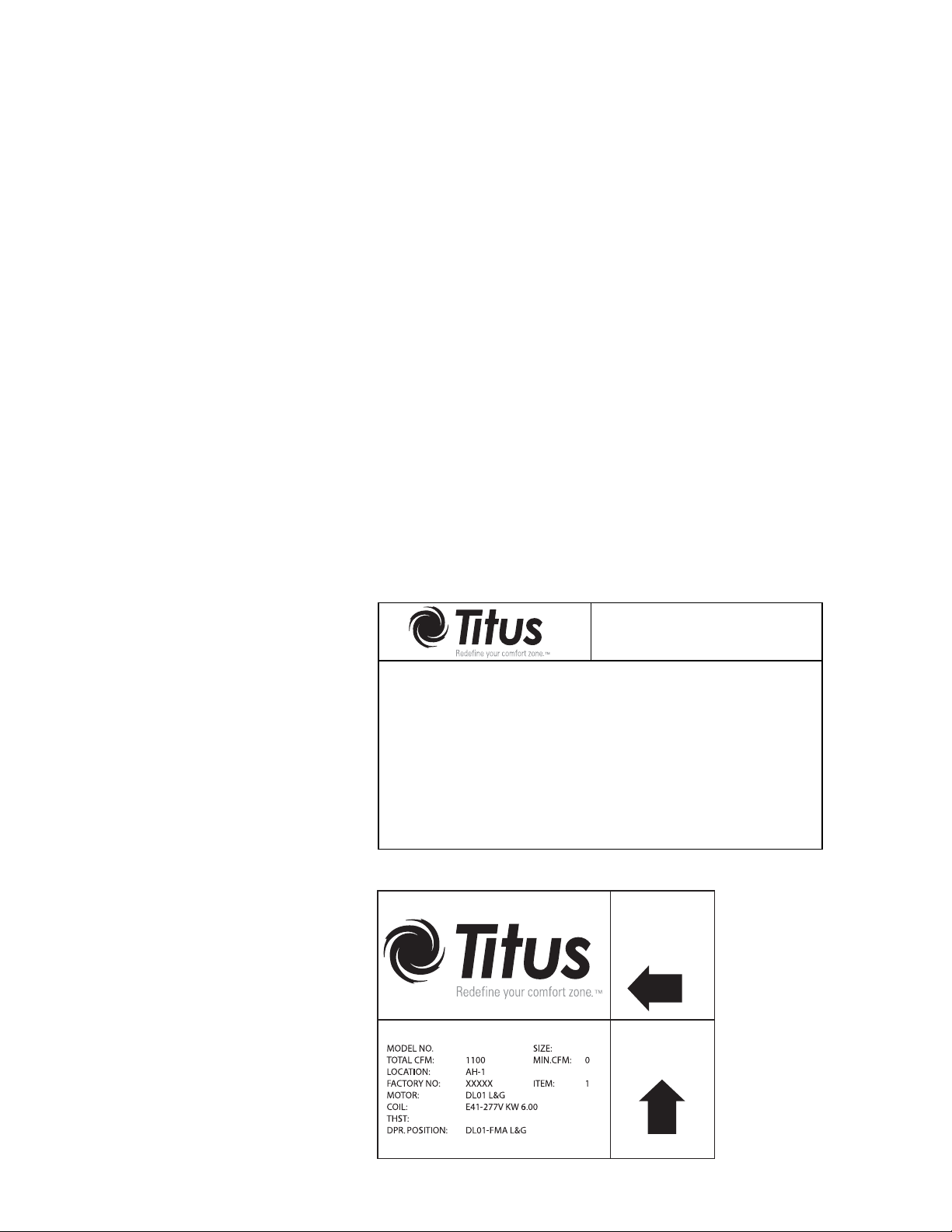

the job specifications. Unit may be

equipped with optional hanging brackets

(see Figure 2). Hanger rod up to 7/16"

diameter may be used.

The diameter of the inlet duct “D” in

inches must

be equal to the listed size of

the terminal; e.g. a duct that actually

measures 8 inches must be fitted to a

size 8 terminal. The inlet collar of the

terminal is made 1/8" smaller than listed

size in order to fit inside the duct (see

Figure 1).

Important: Do not insert duct work

inside the inlet collar of the

assembly.

Inlet duct should be installed in

accordance with SMACNA guidelines.

Rectangular discharge opening is

designed for flanged duct connections.

Fasten and seal

by method prescribed

in the job specification.

If single-point electronic velocity sensor

is used, 3 to 5 inlet duct diameters of

straight duct should be provided at the

terminal inlet.

Minimum Access

Fan Powered terminals require sufficient

clearance to service the fan blower

assembly and internal actuator (if so

equipped) from the bottom of the unit,

Straps

low voltage controls from the side of the

unit, and line voltage motor controls or

electric heat section (if so equipped)

from the rear or discharge of the unit.

For bottom access panel removal, 3"

minimum vertical clearance below the

unit is required, plus sufficient horizontal

clearance to slide the access panel clear

of the bottom of the unit. Horizontal

clearance is dependent on access panel

dimensions as indicated on product

submittals.

For low voltage control enclosure

access, a minimum of 18" is

recommended. Specific control

enclosure location is indicated on

product submittals. Panel for low voltage

enclosures are removable (not hinged).

For line voltage motor controls or electric

heat control access, a minimum

of 36"

should be provided to allow full opening

of hinged access doors. Specific location

is indicated on product submittals.

Important: These recommendations

do not preclude NEC or local codes

that may be applicable, which are

the responsibility of the installing

contractor.

Note: If equipped with pneumatic

control

s, or unit is parallel fan type

(Model TQP or FLP), the terminal must

Discharge

D

be mounted right side up. It must be

level within ±10 degrees of horizontal,

both parallel to the air flow and at the

right angle of air flow. The control side of

the terminal is labeled with an arrow

Figure 1.

Access Panel

(Entire Bottom is

Removeable)

indicating UP.

Hanger Rod

Duct Connections

Slip each inlet duct over the inlet collar

Optional

Hanger

Bracket

of the terminal. Fasten and seal the

connection by the method prescribed by

the job specification.

Discharge

1 1/2"

1 1/2"

Figure 2.

This IOM is meant to demonstrate general product details. The drawings are not meant to detail every aspect of the product. Drawings are not to scale. Titus reserves the right to

All rights reserved. No part of this work may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage retrieval s ystem without permission in writing from Air Distribution Technologies.

make changes without written notice.

Air

Flow

Air

Flow

1 of 9

Page 2

TU-FB-IOM 08-26-13

Field Wiring

All field wiring must comply with the

local codes and with the National

Electrical Code (ANSI/NFPA 70-1996).

Disconnect switches are optional

equipment. Electrical, control, and piping

diagrams are shown on the exterior

labeling or on a diagram on the inside of

the control and high voltage enclosure

covers. Unless specified otherwise in

the order write-up, all units are wired for

a single point electrical connection to the

fan and optional electrical heater. All

electric heaters if provided by TITUS are

balanced by kW per stage. The installing

electrician should rotate incoming

electric service by phase in order to help

balance the building electric load.

Caution—Electrical Requirement:

1. Provide a safety disconnect per

NEC 424-19, 20 & 21.

2. Disconnect all incoming power

before wiring or servicing unit. All

disconnect switches on the terminal

(if so equipped) should be in OFF

position while making power

connections.

3. All field wiring must be in

accordance with NEC and local

code requirements. All units with

electric heat should have copper

wires for 125% of Nameplate

Amperage.

4. Observe wiring diagram and

instructions mounted on the unit.

480 V/3 phase units require a 4th

(neutral) wire in addition to the full

sized ground wire. All units must be

grounded as required by NEC 42414 and 250.

Unit Labeling

Each unit will have two main labels

attached to the casing. The FAN UNIT

label (Figure 3) lists the Model Number,

Supply Voltage requirements, Motor

Horsepower, and Overcurrent Protection

requirements. The AIR FLOW label

(Figure 4) lists the Model Number, Unit

Size, Factory Order Number, and

Location. The Location (or "Tag")

indicates the engineer's planned

location for the unit to be installed.

There may be other labels attached to

the unit, as options or codes may

require.

Control Start-up, Operation

Detailed information regarding power,

accessory and communications

connections, start-up and operating

procedures for the TITUS TD-1

controller (digital) or pneumatic and

analog controls are available from your

local TITUS representative. For specific

information on controls by other

manufacturers contact that

manufacturer’s local branch or dealer.

Note: Controllers may incorporate

specific communication addresses

based on Building Management

Systems Architecture, and original

engineering drawings. Installing the

terminal in a different location than

noted on unit label may result in

excessive start-up labor.

Primary Air Damper

TFS, TQS and TQP Models:

To replace

a. Disconnect power before servicing.

the damper blade and/or

shaft assemblies:

Remove control enclosure cover to

access actuator.

MODEL NO.: DTFS CODE: 88-XXXXX-A 2 REV: 02

MOTOR VOLT: 277 PHASE: 1 HZ 60

HP: 1/4 FLA(EA) 1.4

HEAT VOLT 277 PHASE 1 HZ 60

KW 6.0 AMPS 21.66

MOTOR (S) ARE THERMALLY PROTECTED

MIN. SUPPLY CIRCUIT AMPS: 24 AMP

MAX. FUSE OR OVERCURRENT PROTECTION: 30 AMP

MAX. OUTLET AIR TEMPERATURE: 200F

UNIT DESIGNED TO OPERATE AT NO LESS THAN 0.2 IWG STATIC PRESSURE

ZERO CLEARANCE FROM UNIT, CONNECTED DUCT AND/OR PLENUM

TO COMBUSTIBLE MATERIAL

Figure 3. FAN UNIT Label

DTFS

b. Note position of damper shaft, using

indicating arrow. Loosen linkage or

actuator collar to allow damper to

rotate freely.

c. Remove bottom access door to

expose damper assembly. Rotate

damper to fully closed position,

exposing rivets holding damper

blade to shafts.

d. Drill out rivets using 1/2” drill, rotate

damper to fully open position, and

slide damper and/or shaft

assemblies out of the duct.

e. Fit new damper and/or shaft

assemblies in place, using 1/4-20

screws with lock nuts to replace

rivets.

everse procedure in steps c, b,

f. R

and a, for assembly. When locking

down actuator linkage or collar,

position indicating arrow on damper

in the same location as before the

repair.

FLS and FLP Models:

These units use an opposed blade

damper assembly that is not repairable.

The entire assembly must be replaced.

FAN UNIT

AIR

FLOW

C12

UP

Please read all labels on a typical

unit, before beginning installation. If

you have any questions, please contact

the local TITUS Representative for

clarification. Have the key points from

the Air Flow label available for reference

before calling.

303155001015

Figure 4. AIR FLOW Label

2 of 9

Page 3

TU-FB-IOM 08-26-13

Standard PSC Motor Fan Flow

Adjustment

Note: Before starting fan motor, follow

steps 1 and 2.

1. Discharge ductwork should be

connected. The minimum

recommended discharge static

pressure is 0.2" wg. Be sure fan

packing is removed from units with

fan packing!

2. All foreign materials should be

removed from duct system. Filters

should be installed where required.

3. Standard PSC motors are shipped

from factory at full speed setting.

Allow motor to run-in at least 15

minutes before adjusting speed.

During initial run-in, check ductwork

connections for leaks and repair if

necessary. (Do not adjust fan speed

down if ductwork is not connected).

4. Unit is equipped with manual fan

speed control, mounted on the

bottom of the line voltage motor

enclosure or electric heat

enclosure. Turning the control

counterclockwise will reduce the fan

speed; clockwise will increase

speed.

5. Set the unit to full heating

(maximum induction). Adjust and

set remote balancing dampers, if

present. Adjust the speed control to

deliver the required CFM by

measuring air quantity at the room

outlets.

6. Proceed to primary air adjustment

procedure, detailed in control

installation information. Fan should

be re-adjusted with primary air and

ventilation air at maximum setpoint,

to insure that no supply air is

discharged at the induction port.

Maintenance Procedures:

Fan and Motor

Motor is equipped with permanently

lubricated bearings. Inspect fan and

motor assembly for accumulation of dust

and dirt as required by operating

environment. Clean as necessary.

If fan motor does not run:

a. Free rotation of blower wheel fan

packing removed. Freight or

installation damage.

b. Check for proper unit power

Disconnects should be ON .Check

optional fusing.

c. Check for proper control signal, P/E

switch setting, proper air control 24

Vac at fan contactor, coil energized.

If fan motor runs, excessive noise:

a. Clearance problems on blower. All

components securely attached.

b. Verify integrity of ductwork. Leaks

or loose connections. Rattling

diffusers or balancing dampers.

c. Maximum CFM too high, or

discharge static pressure too low

If fan motor runs, insufficient air flow:

a. Check for ductwork restrictions.

Dirty air filters. Clogged water coils.

b. Re-adjust fan spee d control.

c. Discharge static pressure too high.

If repair or replacement is required:

Motor and fan should be removed as an

assembly. Disconnect all power

before servicing. Remove the hex

nuts from the mounting lugs holding

the fan assembly to the discharge

panel, and lower the assembly. For

model TFS, lift the motor / blower

assembly to release the tabs from

the discharge panel, then lower the

assembly. Do not allow assembly to

hang from wiring.

Optional Water Coil Cleaning

In most cases, the supply side of the

water coil (optional) can be cleaned by

removing the bottom access door and

cleaning the coil face through the open

space between the motor / blower

assembly and the unit casing.

If more space is desired to clean the

water coil, the motor / blower assembly

may be removed and reinstalled as

described above.

If removing motor from blower, first

loosen the set screw holding the

blower wheel to the motor shaft.

Remove the three screws holding

motor to the fan housing, and slide

motor and fan housing apart.

Reverse the procedure for assembly.

Note: Over tightening motor mounting

screws may crush isolation bushings,

causing excessive fan noise.

3 of 9

Page 4

ECM Overview and Setup

TU-FB-IOM 08-26-13

Overview

This section addresses the Titus ECM motor which is

optional on all Fan Powered Terminal units. The ECM

motor provides outstanding comfort, safety, and

performance with greatly reduced energy consumption

compared to traditional units with permanent split

capacitance AC motors and with proper installation and

operation the units will provide a long service life . The

ECM motor provides a high degree of flexibility and

configurability, with the simplicity of customized factory

configurations appropriate to most installations. Very little

intervention is needed by service and installation personnel

in most applications; however, installers must read through

this entire section before beginning installation of the new

equipment. This literature focuses on unit motors and

associated controls.

General Information

There are four primary components that enable the ECM

technology on Fan Powered Terminal units:

1. Titus ECM Motor

2. ECM Engine Board

3. PWM Controllers

4. Inductors

The motors and modules are combined as a system, and

cannot work without each other.

ECM Engine Board

3. The Fan Powered Terminal unit can be equipped with

either a manual control or a remote control PWM fan

speed controller, mounted on the side of the line voltage

control enclosure.

A - Remote Signal PWM Controller

ECM motors shipped with remote PWM controller require a

signal from the DDC controller to control fan speed.

B- Manual/Unit PWM Controller

ECM Motor

ECM Motor Fan Flow Adjustment

NOTICE

Before starting the fan motor, follow steps 1 and 2

1. Discharge ductwork should be connected. The

minimum

recommended discharge static pressure is 0.2" wg. Be

sure that any fan packing is removed from units prior!

ECM motors with manual PWM controllers are shipped

from the factory at design CFM when provided. Otherwise

motors are shipped at motor full speed setting.

4. Allow motor to run-in at least 15 minutes before

adjusting speed. During initial run-in, check ductwork

connections for leaks and repair if necessary. (Do not

adjust fan speed down if ductwork is not connected).

5. Set the unit to full heating (maximum induction). Adjust

and set remote balancing dampers, if present. Adjust the

speed control to deliver the required CFM by measuring air

quantity at the room outlets.

6. Proceed to primary air adjustment procedure, detailed in

control installation information. Fan should be re-adjusted

with primary air and ventilation air at maximum setpoint,

to insure that no supply air is discharged at the induction

port.

2. All foreign materials should be removed from duct

system. Filters should be installed where required.

4 of 9

Page 5

TU-LSC-IOM

ECM Overview and Setup (Cont.)

TU-FB-IOM 08-26-13

Manual / Unit PWM Signal Interface Board

Signal

RPM/CFM

Adjustment

RPM/CFM Indicator

24VAC

Power Supply

Communication

connector to

ECM Motor

The Manual PWM interface board allows accurate manual

adjustment and monitor of fan with the ECM Motor.

The Manual interface board features a 4 digit LED

numerical display to allow easy reading in dark spaces.

Watch the display and set the flow index with a screwdriver

adjust. Twenty seconds later, the display shows the

motor RPM. Then, the display periodically alternates

between the flow index and motor RPM.

Operation

ECM motors configured for Vspd operation are

factory configured for external torque or airflow

adjustment. A numerical flow index accurately adjusts the

fan to the desired torque or airflow. The flow index is a

number from 0-100 having a linear relationship to the

minimum to maximum torque or airflow range specified by

Titus. Refer to the fan specifications, data and charts to

convert the flow index to torque or mass airflow.

The Manual PWM interface board allows local on/off and

fan airflow adjustment. Rotating a single screwdriver

adjuster changes the variable output signal to the motor

from off to full output. While rotating the adjuster, a

numerical flow index is locked on the illuminated

numerical display. After adjustment, the display

shows fan RPM.

Remote PWM Signal Interface Board Details

Jumper Link

Control Signal Type

Manual Adjust

Signal

Communication

connector to

ECM Motor

Control Signall

RPM Out

24VAC Aux Power

24VAC Power Supply

The remote interface allows industry standard 0-10Vdc

automation signals to adjust and monitor ECM Motor.

The interface board provides remote adjustment of the

ECM output from 0% to 100% of the programmed control

range. A signal lamp on the control continuously flashes

out the flow index

the flow index. A 0-10Vdc signal connects RPM to the

automation control. Jumpers allow the Interface to be

configured for 0-10Vdc automation signal, 2-10Vdc

automation signal, and manual/override control. The

interface can also be used for stand-alone manual control.

The green lamp continuously indicates the flow index. After

a pause, the lamp flashes out the tens digit, then the units

digit of a number between 1 and 99. Long flashes

represent the tens digit, and short flashes represent the

units digit. For example, a flow index of 23 flashes two

longs, then three shorts.

Two extra long flashes indicate a flow index of 0. An extra

long flash and ten short flashes indicates a flow index of

100. The lamp flashes the signal that was present when

the flash sequence started.

Turning Adjust controls the ECM motor to the manually

adjusted setting. The manual setting has authority for 15

minutes.Set the unit to full heating (maximum induction).

Adjust and set remote balancing dampers, if present.

Adjust the speed control to deliver the required CFM by

measuring air quantity at the room outlets.

2. Instruments are not required to read

5 of 9

Page 6

ECM Overview and Setup (Cont.)

TU-FB-IOM 08-26-13

Remote PWM Signal Interface Board Details

Jumpers

P - Jumper provides ON/OFF control by

switching the motor's "GO" control line

when the input signal drops below the

2 volt (4 mA) operating point. without the

jumper, turn power to the interface board

+ On/Off to control motor On/Off.

Rotating Adjust changes the Flow Index

from 0 to 100.

The “P” jumper also allows manual on/off control.

Signal with

“P” Jumper Out

Input / Output Control Signals

"Opt" Configuration - 0-10 Vdc = 1% to 100%

"P" Configuration - 2-10Vdc = 0-100%

- 4-20mA = 0-100%

- ON/OFF Control Between1 & 2

Vdc (2 & 4 mA)

RPM Signal - 0-10 Vdc, 5 mA max. = 0 to 2,000

RPM in 10 RPM steps

Outputs Go & VSpd - 22Vdc @ 5mA

DDC Control - Air Balance

If the DDC Controller signal is already installed, air

balance can be achieved using the DDC Controller

software tools. Please notice that a control signal less than

0.2Vdc may put the interface board into manual override.

Avoid setting the DDC signal to less than 0.2Vdc.

WARNING

Turning Adjust potentiometer locks out the BAS

signal for 15 minutes

Signal with

“P” Jumper In

M - Jumper enables manual override. Manual override is

overridden when the 0-10V automation signal exceeds

0.2Vdc.

Manual override controls the motor before Building

Automation System (BAS) is installed, or when BAS fails.

Without the “M” jumper, manual override is enabled

whenever Adjust is turned. It is disabled by causing the

Interface board to turn the motor off/on 5 times while signal

is greater than 0.1Vdc.

R - Jumper reverses Adjust rotation so adjustment is

correct from the component side of the board.

Opt - The Opt. space has no function. The space

may be used to store an unused jumper.

Cycle power ON/OFF for faster lockout removal.

Manual Air Balance

The interface board can be manually adjusted before the

DDC Controller signal is available. The balancer’s manual

adjustment has authority until automation is connected.

Air Balancer

1. Use Adjust to set the air flow. This adjustment will have

authority for at least 15 minutes.

2. Read the flashing green light and record the flow index

on the air balance report.

DDC Integrator

1. Set the Signal to 0Vdc to invoke manual override.

2. Record the RPM on the air balance report.

3. Enter the flow index the air balancer entered on the air

balance report.

4. Observe the RPM is at or near the RPM observed in

step 2.

5. Cycle the motor on/off 5 times. This clears the manual

override function unless the “M” jumper is in

place.

6 of 9

Page 7

Replacement Parts List

TU-FB-IOM 08-26-13

Description Part Number

Multipoint Velocity Sensors

Size 6" 3151520002

Size 8" 3151520004

Size 10" 3151520006

Size 12" 3151520007

Size 14" 3151520008

Size 16" 3151520009

Damper Shaft Extension

Short Stub All Sizes 7 0300301

Long Ext. Sz 6,14,16 70300302

Long Ext. Sz 8,10,12 70300303

Shaft Bearing – All 70324901

Primary Damper Assembly (TFS,TQS,TQP)

Size 6 31171301

Size 8 31171303

Size 10 31171305

Size 12 31171306

Size 14 31171307

Size 16 31171308

Primary Damper Assembly (FLS, FLP)

Sizes 2, 3 31171303

Size 4 FLS 31462102

Size 4 FLP 31462101

Induced Air Filters

Model TFS

B,C 16x14 1026491614

D,E 14x18 1026491418

Model TFS-F Fantom IQ

TM

B,C 11x14 1026491114

D,E 18x17 1026491817

Model TQS, TQP

2,3,4 19x17 1026491917

5,6,7 27x20 1026492720

Model FLS

2,3,4 10x15 1026491015

Model FLP

2,4 18x10 1026491810

Filter Bracket Universal 71124401

Filter Clip, Wire 1026 2701

Control Tube

Red Stripe .25" O.D. 61510035

Green Stripe .25" O.D. 61510034

Red Stripe .38" O.D. 61510279

Green Stripe .38" O.D. 61510280

Tees for Sensor Taps

Plastic .25" 42150011

Plastic .38" 42150020

Description Part Number

Plugs for Tees

.25" (1/4" ) 42160081

.38" (3/8") 10015601

Fan Motor Fuse (SC-CL-G 300V)

1 Amp 10048301

3 Amp 10048501

4 Amp 10048601

6 Amp 10048801

8 Amp 10049001

10 Amp 10049101

12 Amp 10049201

15 Amp 10049301

20 Amp 10105201

Disconnects

Fan Toggle 10027801

Door Interlock 3P/30A 10329101

Door Interlock 3P/60A 10329201

Door Handle 10329301

Adapter Kits

Door Interlock 3P/30A

31489601

Door Interlock 3P/60A

31489602

Fan Relays

1 Pole, 24V Coil 10156901

2 Pole, 24V Coil 10161801

Contactors, Magnetic

2P/20A, 24V coil 10054401

2P/20A, 120V coil 10054402

2P/20A, 208/240V coil 10054404

2P/20A, 277V coil 10054403

Safety Devices

Auto Reset Thermal Cutout for

Elec. Coils 10052101

Air Flow Switch (AFS) 10269501

AFS Sensor 4" length 10057201

AFS Sensor 6" length 10057202

P.E. Switch, 1 step 10000901

P.E. Switch, 2 step 10199801

P.E. Switch, 3 step 10199802

Control Transformers

120/24V, 50 VA 10029301

208/240/24V, 50 VA 10057501

277/24V, 50 VA 10006601

Hanger Brackets

TFS 7247020103

TQS, TQP, FLS, FLP 7073 8001

Description Part Number

Fan Speed Controllers (SCR)

120V 10055301

208/240V 10057601

277V 10053301

Fan Motor Capacitors

(120V, 208/240V, 277V)

1/10 Hp Motor 4 MFD 10053001

1/6 Hp Motor 4MFD 10053001

1/4 Hp Motor 5 MFD 10053002

1/3 Hp Motor 10 MFD 10053003

1/2 Hp Motor 10 MFD 10053003

3/4 Hp Motor 20 MFD 10055701

1 Hp Motor 25 MFD 10053004

Mounting Bracket (all) 10054501

ECM Motor Components

ECM Motor Mounting Assembly

Includes: 31372602

Motor Belly Band

Grommet Set (3)

Nut, ¼ - 20 x 1½

Hex Bolt ¼ x ¾

¼ x ¾ Screw (3)

Washers (4)

PWM (Manual Operation) 10352601

PWM (Remote Operation) 10352602

277V Power Cable, 8 ft. 10320501

277V Power Cable, 5 ft. 10320520

24V Comm. Cable, 8 ft. 10334901

24V Comm. Cable, 5 ft. 10334902

Power Filter (1 hp) 10335001

Power Filter (½, 1/3 hp) 10335001

This IOM is meant to demonstrate general product details. The drawings are not meant to detail every aspect of the product. Drawings are not to scale. Titus reserves the right to

All rights reserved. No part of this work may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage retrieval system without permission in writing from Air Distribution Technologies.

make changes without written notice.

7 of 9

Page 8

Replacement Parts List (cont.)

PSC Motors & Blowers

TU-FB-IOM 08-26-13

Model

TFS, TFS-F

Left Hand

Unit

TFS, TFS-F

Right Hand

Unit

TQS

TQP

Unit Size

A

B

C

D

E

B

C

D

E

2

3

4

5

6

7

2

3

4

5

6

HP

1/10

1/6

1/4

1/3

3/4

1/6

1/4

1/3

3/4

1/6

1/4

1/3

1/3

3/4

1

1/6

1/4

1/3

1/3

3/4

120V/1

10051101

10095302

10051204

10151205

10317204

10095301

10051201

10151201

10317201

10095301

10051201

10151201

10151201

10051401

N/A

10095301

10051201

10151201

10151201

10051401

208/240V/1

10056901

10150102

10150104

10151206

10317205

10150101

10150103

10151203

10317202

10150101

10056902

10151203

10151203

10057003

31423101

10150101

10056902

10151203

10151203

10057003

277V/1

10051102

10096702

10051203

10151204

10317206

10096701

10051202

10151202

10317203

10096701

10051202

10151202

10151202

10051402

31423102

10096701

10051202

10151202

10151202

10051402

Blower

Assembly

10192501

10192402

10045002

10358002

10051006

10192401

10045001

10358001

10051005

10051001

10044601

10051003

10051003

10051005

10311701

10051001

10044601

10044601

10051003

10051005

FLS

FLP

2

3

4

2

4

1/6

1/4

1/6 (2)

1/6

1/4

10095301

10095303

10095301

10095301

10095303

10150101

10150103

10150101

10150101

10150103

10096701

10096703

10096701

10096701

10096703

10045501

10045001

10045002

10045001

10045001

8 of 9

Page 9

Replacement Parts List (cont.)

ECM Motors & Blowers

PRODUCT OPTION CODES SIZE V OLT AGE

FLP LH 2 277 321014-101 CCW 1/3 150237-A0S301

FLP LH 4 277 321014-102 CCW 1/3 150237-A0S301

FLP RH 2 277 32101 4- 14 6 CW 1/3 150237-A0S301

FLP RH 4 277 32101 4- 14 7 CW 1/3 150237-A0S301

FLP LH 2 120/208/240 321014-183 CCW 1/3 150237-A0S302

FLP LH 4 120/208/240 321014-185 CCW 1/3 150237-A0S302

FLP RH 2 120/208/ 240 321014-184 CW 1/3 150237-A0S302

FLP RH 4 120/208/ 240 321014-186 CW 1/3 150237-A0S302

FLS LH 3 277 321014-013 CCW 1/3 10335101 150237-A0S301

FLS RH 4 277 32101 4- 01 4 CW 1/3 10335101 150237-A0S301

FLS LH 4 277 321014-015 CCW 1/3 10335101 150237-A0S301

FLS LH 3 120 321014-028 CCW 1/3 10322601 150237-A0S302

FLS RH 4 120 32101 4- 02 9 CW 1/3 10322601 150237-A0S302

FLS LH 4 120 321014-030 CCW 1/3 10322601 150237-A0S302

FLS LH 3 208 321014-133 CCW 1/3 150237-A0S302

FLS RH 4 208 321014-134 CW 1/3 150237-A0S302

FLS LH 4 208 321014-135 CCW 1/3 150237-A0S302

FLS L H 3 240/50HZ 321014 -176 CCW 1/3 150237-A0S302

FLS RH 4 240/50HZ 321014-177 CW 1/3 150237-A0S302

FLS LH 4 240/50HZ 321014-178 CCW 1/3 150237-A0S302

LHK 3 277 321014- 00 9 CCW 1/3 10335101 150237-A0S301

LHK 4 277 321014- 01 0 CCW 1/3 10335101 150237-A0S301

LHK 3 120 321014- 02 4 CCW 1/3 10322601 150237-A0S302

LHK 4 120 321014- 02 5 CCW 1/3 10322601 150237-A0S302

LHK 3 208 321014-129 CCW 1/3 150237-A0S302

LHK 4 208 321014-130 CCW 1/3 150237-A0S302

LHK 3 220 50HZ 321014-144 CCW 1/3 150237-A0S302

LHK 4 220 50HZ 321014-145 CCW 1/3 150237-A0S302

LSC LH 3 120 321014-187 CCW 1/3 10322601 150237-A0S302

LSC RH 4 120 321014-188 CW 1/3 10322601 150237-A0S302

LSC LH 4 120 321014-189 CCW 1/3 10322601 150237-A0S302

LSC LH 3 208 321014-190 CCW 1/3 150237-A0S 302

LSC RH 4 208 321014-191 CW 1/3 150237-A0S302

LSC LH 4 208 321014-192 CCW 1/3 150237-A0S302

LSC LH 3 240/50HZ 321014-1 93 CCW 1/3 150237-A0S302

LSC RH 4 240/ 5 0HZ 321014-194 CW 1/3 150237-A0S302

LSC LH 4 240/50HZ 321014-195 CCW 1/3 150237- A0S302

LSC LH 3 277 321014-196 CCW 1/3 10335101 150237-A0S301

LSC RH 4 277 321014-197 CW 1/3 10335101 150237-A0S301

LSC LH 4 277 321014-198 CCW 1/3 10335101 150237-A0S301

PFC 14 277 321014-011 CCW 1/2 10322601 150237-B0S301

PFC 16 277 321014-012 CCW 1 10348001 150237-D0S301

PFC 14 120 321014-026 CCW 1/2 10348001 150237-B0S301

PFC 16 120 321014-027 CCW 1 10322501 150237-D0S301

PFC 10 277 321014-033 CCW 1/3 10335101 150237-A0S301

PFC 10 120 321014-034 CCW 1/3 10322601 150237-A0S302

PFC 14 208 321014-131 CCW 1/2 150237-B0S 301

PFC 16 208 321014-132 CCW # 15 023 7-D0S301

PFC 10 208 321014-138 CCW 1/3 150237-A0S 302

PFC 10 220 50HZ 321014-141 CCW 1/3 150237-A0S302

PFC 14 220 50HZ 321014-142 CCW 1/2 150237-B0S301

PFC 16 220 50HZ 321014-143 CCW # 150237-D0S301

TFP LH B 120 32101 4- 07 9 CW 1/3 150237-A0S302

TFP LH C 120 321014-080 CW 1/3 150237-A0S302

TFP LH D 120 321014-081 CW 1/2 150237-B0S301

TFP LH E 120 32101 4- 08 2 CW 3/4 150237-C0S301

TFP LH B 277 32101 4- 08 3 CW 1/3 150237-A0S301

TFP LH C 277 321014-084 CW 1/3 150237-A0S301

TFP LH D 277 321014-085 CW 1/2 150237-B0S301

TFP LH E 277 32101 4- 08 6 CW 3/4 150237-C0S301

TFP RH B 120 321014- 08 7 CCW 1/3 150237-A0S302

TFP RH C 120 321014-088 CCW 1/3 150237-A0S302

TFP RH D 120 321014-089 CCW 1/2 150237-B0S301

TFP RH E 120 321014- 09 0 CCW 3/4 150237-C0S301

TFP RH B 277 321014- 09 1 CCW 1/3 150237-A0S301

TFP RH C 277 321014-092 CCW 1/3 150237-A0S301

TFP RH D 277 321014-093 CCW 1/2 150237-B0S301

TFP RH E 277 321014- 09 4 CCW 3/4 150237-C0S301

TFS RH B 277 321014- 03 9 CCW 1/3 10335101 150237-A0S301

TFS RH C 277 321014-040 CCW 1/3 10335101 150237-A0S301

TFS RH D 277 321014-041 CCW 1/2 10322601 150237-B0S301

TFS RH B 120 321014- 04 7 CCW 1/3 10322601 150237-A0S302

TFS RH C 120 321014-048 CCW 1/3 10322601 150237-A0S302

TFS RH D 120 321014-049 CCW 1/2 10348001 150237-B0S301

TFS LH B 277 32101 4- 05 5 CW 1/3 10335101 150237-A0S301

TFS LH C 277 321014-056 CW 1/3 10335101 150237-A0S301

TFS LH D 277 321014-057 CW 1/2 10322601 150237-B0S301

TFS LH B 120 32101 4- 06 3 CW 1/3 10322601 150237-A0S302

TFS LH C 120 321014-064 CW 1/3 10322601 150237-A0S302

TFS LH D 120 321014-065 CW 1/2 10348001 150237-B0S301

Motor/Blower

Assy

Motor

Rotation

Inductor MTR PART#

HP

TU-FB-IOM 08-26-13

PRODUCT OPTIO N CO DES SIZE VOL T AG E

TFS RH E 120 321014-071 CCW 3/4 10348001 150237-C0S301

TFS RH E 277 321014-072 CCW 3/4 10348001 150237-C0S301

TFS LH E 120 321014-075 CW 3/4 10348001 150237-C0S301

TFS LH E 277 321014-076 CW 3/4 10348001 150237-C0S301

TFS RH B 208 321014-103 CCW 1/3 150237-A0S302

TFS RH C 208 321014-104 CCW 1/ 3 150237-A0S302

TFS RH D 208 321014-105 CCW 1/ 2 150237-B0S301

TFS RH E 208 321014-106 CCW 3/4 150237-C0S301

TFS LH B 208 321014-111 CW 1/ 3 150237-A0S302

TFS LH C 208 321014-112 CW 1/3 150237-A0S302

TFS LH D 208 321014-113 CW 1/2 150237-B0S301

TFS LH E 208 321014-114 CW 3/4 150237-C0S301

TFS RH B 240/50HZ 321014-150 CCW 1/3 150237-A0S302

TFS RH C 240/ 50HZ 321014-151 CCW 1/3 150237-A0S302

TFS RH D 240/ 50HZ 321014-152 CCW 1/2 150237-B0S301

TFS RH E 240 /50HZ 321014-153 CCW 3/4 150237-C0S301

TFS LH B 240/50HZ 321014-158 CW 1/3 150237-A0S302

TFS LH C 240/50HZ 321014-159 CW 1/3 150237-A0S302

TFS LH D 240/50HZ 321014-160 CW 1/2 150237-B0S301

TFS LH E 240/50HZ 321014-161 CW 3/4 150237-C0S301

TFS-A STD A 120 321014-095 CCW 1/3 150237-A0S302

TFS-A STD A 277 321014-096 CCW 1/3 150237-A0S301

TFS-A STD A 208 321014-119 CCW 1/3 150237-A0S302

TFS-A STD A 240/50HZ 321014-166 CCW 1/3 150237-A0S302

TFS-F RH B 277 321014-043 CCW 1/3 10335101 150237-A0S301

TFS-F RH C 277 321014-044 CCW 1/3 10335101 150237-A0S301

TFS-F RH D 277 321014-045 CCW 1/2 10322601 150237-B0S301

TFS-F RH B 120 321014-051 CCW 1/3 10322601 150237-A0S302

TFS-F RH C 120 321014-052 CCW 1/3 10322601 150237-A0S302

TFS-F RH D 120 321014-053 CCW 1/2 10348001 150237-B0S301

TFS-F LH B 277 321014-059 CW 1/3 10335101 150237-A0S301

TFS-F LH C 277 321014-060 CW 1/3 10335101 150237-A0S301

TFS-F LH D 277 321014-061 CW 1/2 10322601 150237-B0S301

TFS-F LH B 120 321014-067 CW 1/3 10322601 150237-A0S302

TFS-F LH C 120 321014-068 CW 1/3 10322601 150237-A0S302

TFS-F LH D 120 321014-069 CW 1/2 10348001 150237-B0S301

TFS-F RH E 120 321014-073 CCW 3/4 10348001 150237-C0S301

TFS-F RH E 277 321014-074 CCW 3/4 10348001 150237-C0S301

TFS-F LH E 120 321014-077 CW 3/4 10348001 150237-C0S301

TFS-F RH E 277 321014-078 CW 3/4 10348001 150237-C0S301

TFS-F RH B 208 321014-107 CCW 1/3 150237-A0S302

TFS-F RH C 208 321014-108 CCW 1/3 150237-A0S 302

TFS-F RH D 208 321014-109 CCW 1/2 150237-B0S 301

TFS-F RH E 208 321014-110 CCW 3/4 150237-C0S301

TFS-F LH B 208 321014-115 CW 1/3 150237-A0S 302

TFS-F LH C 208 321014-116 CW 1/3 150237-A0S302

TFS-F LH D 208 321014-117 CW 1/2 150237-B0S301

TFS-F LH E 208 321014-118 CW 3/4 150237-C0S301

TFS-F RH B 240/ 50HZ 321014-154 CCW 1/3 150237-A0S302

TFS-F RH C 240/50HZ 321014-155 CCW 1/3 150237-A0S302

TFS-F RH D 240/50HZ 321014-156 CCW 1/2 150237-B0S301

TFS-F RH E 240/50HZ 321014-157 CCW 3/4 150237-C0S301

TFS-F LH B 240/50HZ 321014-162 CW 1/3 150237-A0S 302

TFS-F LH C 240/50HZ 321014-163 CW 1/3 150237-A0S302

TFS-F LH D 240/50HZ 321014-164 CW 1/2 150237-B0S301

TFS-F LH E 240/50HZ 321014-165 CW 3/4 150237-C0S301

TFS-G G 120/240 321014-099 CCW 1 150237-D0S301

TFS-G G 277 321014-100 CCW 1 150237-D0S301

TQP 4 277 321014-035 CCW 1/2 10322601 150237-B0S301

TQP 4 120 321014-036 CCW 1/2 10348001 150237-B0S301

TQP 6 277 321014-037 CCW 1 10348001 150237-D0S301

TQP 6 120 321014-038 CCW 1 10322501 150237-D0S301

TQP 4 208 321014-139 CCW 1/2 150237-B0S301

TQP 6 208 321014-140 CCW # 150237-D0S301

TQP 4 240/50HZ 321014-181 CCW 1/2 150237-B0S301

TQP 6 240/50HZ 321014-182 CCW # 150237-D0S301

TQS 4 277 321014-001 CCW 1/2 10322601 150237-B0S301

TQS 6 277 321014-002 CCW 1 10348001 150237-D0S301

TQS 4 120 321014-016 CCW 1/2 10348001 150237-B0S301

TQS 6 120 321014-017 CCW 1 10322501 150237-D0S301

TQS 4 208 321014-121 CCW 1/2 150237-B0S301

TQS 6 208 321014-122 CCW # 150237-D0S301

TQS 4 240/50HZ 321014-168 CCW 1/2 150237-B0S301

TQS 6 240/50HZ 321014-169 CCW # 150237-D0S301

TQS DUAL WALL UltraLoc 4 277 321014-003 CCW 1/2 10322601 150237-B0S301

TQS DUAL WALL UltraLoc 6 277 321014-004 CCW 1 10348001 150237-D0S301

TQS DUAL WALL UltraLoc 4 120 321014-018 CCW 1/2 10348001 150237-B0S301

TQS DUAL WALL UltraLoc 6 120 321014-019 CCW 1 10322501 150237-D0S301

UAL W A LL FRESUltaLoc UNIT ACCY 4,5,6 4 277 321014-007 CCW 1/2 10322601 150237-B0S 301

UAL W A LL FRESUltraLoc, UNIT ACCY 7,8 6 277 321014-008 CCW 1 10348001 150237-D0S301

TQS FRESH AIR UNIT ACCY 4,5,6 4 277 321014-005 CCW 1/ 2 10322601 150237-B0S301

TQS FRESH AIR UNIT ACCY 7,8 6 277 321014-006 CCW 1 10348001 150237-D0S301

Motor/Blower

Assy

Motor

Rotation

Ind u c tor MTR PART#

HP

9 of 9

Loading...

Loading...