Titus Electric Heat User Manual

Installation Manual

EHeat-IOM-1.0 6-1-01

Electric Coil Installation, Operation, and Maintenance Man ual

(For use with Titus Electric Coils manufactured after June 2 001)

General Information

All fan terminals with electric coils are ETL listed.

All single duct electric coils are ETL listed.

All electric coil control enclosures meet NEMA 1.

Single point power connection.

Installation

All terminal units with electric coils are designed to be

mounted in a horizontal plane with regard to the UP arrow

marked on the product label.

Always inspect electric coils for damage prior to applying

power.

Use copper conductors only.

All field wiring must conform to NEC and local building

codes.

Phase rotation of the incoming power is recommended

when connecting three phase electric coils to balance

building loads.

Always allow a minimum clearance of 36” in front of all

electric coil enclosures.

All terminal units must be properly grounded per NEC 42414 and 250.

Always check product label for voltage and current data to

determine proper wire size and current protection.

These recommendations are not meant to preclude NEC

requirements or local building codes that may be

applicable, which are the responsibility of the installing

contractor.

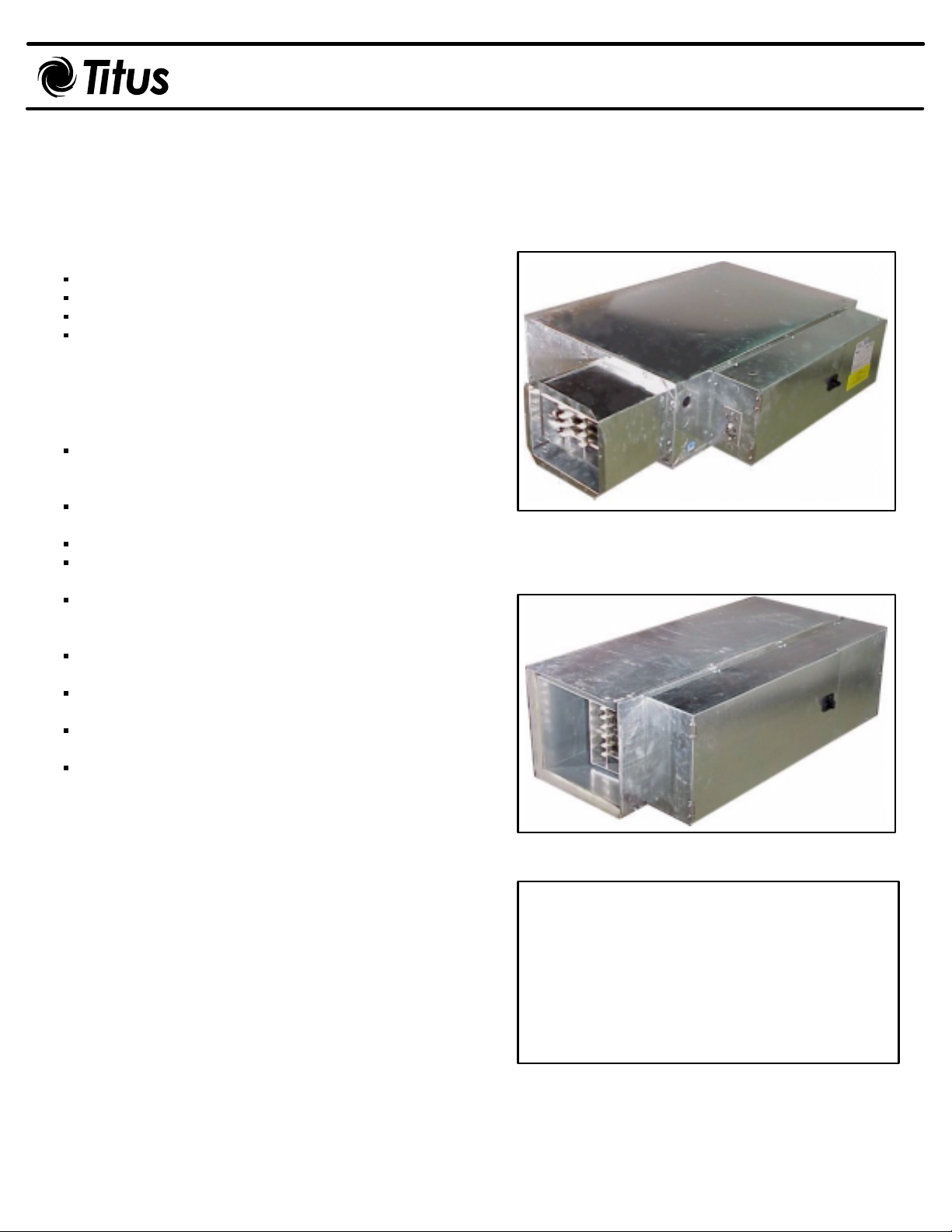

Fan Terminal Unit with Heater

Single Duct Terminal Unit with Heater

CAUTION

ELECTRIC SHOCK MAY RESULT

1. DISCONNECT POWER BEFORE

SERVICING UNIT.

2. DO NOT OPERATE UNIT WITHOUT

CONTROL COVER INSTALLED.

EHeat-IOM-2.0 6-1-01

Data Label

All electric coils are provided with a product label affixed to the control enclosure cover. This label contains all

necessary information regarding electrical power and circuit protection requirements, as specified by UL. See Figure 1.

Figure 1.

FAN UNIT

MODEL NO DTQ S CODE 99-361901-B 6 REV:

MOTOR VOLT 277 PHASE 1 HZ 60

HP 1/6 FLA(EA) 1.40

HEAT VOLT 277 PHAS E 1 HZ 60

KW 6.0 AMPS 21.66

MOTOR(S) ARE THERMALLY PROTECTED MAXIMUM OVERCURRENT

N. SUPPLY CIRCUIT AMPS 1.38 AMP PROTECTION = 15 AMP

MI

XXXXXXXXXXXXXXXXXXXXXXXXXXX

MAX. OUTLET AIR TEMPERATURE 200

UNIT DESIGNED TO OPERATE AT NO LESS THAN 0.2 IWG STATIC PRESSURE

ZERO CLEARANCE FROM UNIT, CONNECTED DUCT AND/OR PLENUM

TO COMBUSTIBLE MATERIAL.

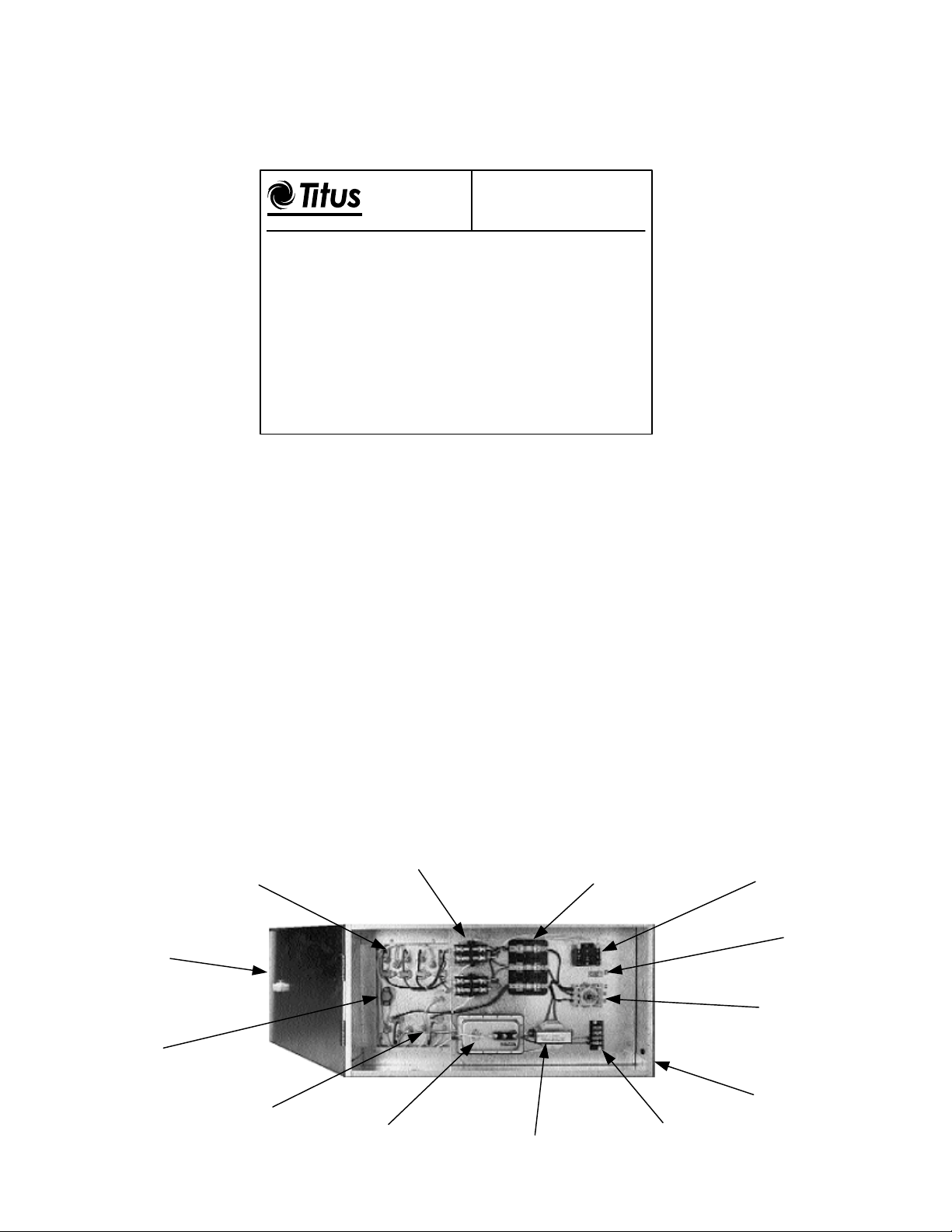

Heater Control Enclosure

O

F

Figure 2 shows the interior of a typical electric coil control enclosure. Various components contained within this

enclosure are necessary for the safe operation of the product. An interlocking safety door disconnect switch is

recommended, but not required. It prevents access to the enclosure until all ungrounded conductors are disconnected

from the electric coil circuit. If an optional disconnect switch is not ordered, a terminal block will be provided for single

point electrical hook-up. A ground lug is provided to insure proper grounding of the terminal unit housing and

enclosure. Optional line fuses and fan motor fuses provide overcurrent protection, if permitted by local building

codes. An air flow switch is always provided to lock-out the coil when there is no air flow across the elements. An

automatic reset thermal cut-out is required to de-energize elements whenever discharge temperature is excessive.

The coil will resume operation when discharge temperatures decrease. An optional manual reset thermal cut-out will

protect the elements in the event of a thermal cut-out failure and prevent the coil from operating until qualified service

personnel can make repairs. Fuse links are required on all single duct electric coils to provide safety in event of a

thermal cut-out failure. Fuse links must be replaced as they cannot be reset. A control transformer is provided

whenever a 24 V circuit is required. PE switches may be load bearing on small pneumatically-controlled electric coil s,

or pilot duty when current loads require magnetic contactors. Optional mercury contactors are available for extra

long service life and / or silent operation. In addition to these components, fan powered terminals may include an SCR

motor speed control and a fan relay.

Heating Element Terminal Box

Recessed into Air Stream for

Accurate Temperature Sensing by

Thermal Cutouts

Hinged Access Door

Latched by Optional

Interlock Disconnect Switch

Automatic Reset

Thermal Cutout

Magnetic Contactors

for Primary Control

Line Fuse Block and

Fuses (3 Phase

Shown)

Fan Interlock Relay

Ground Lug

Door Interlock

Disconnect Switch

(Optional)

Figure 2.

Heating Elements

Staggered for Uniform

Heat Transfer

Differential Pressure

Air Flow Switch

Control Transformer

NEMA 1 Casing, Heavy

Gauge Corrosion

Resistant Steel

Control Circuit

Terminal Block

Wiring Diagrams

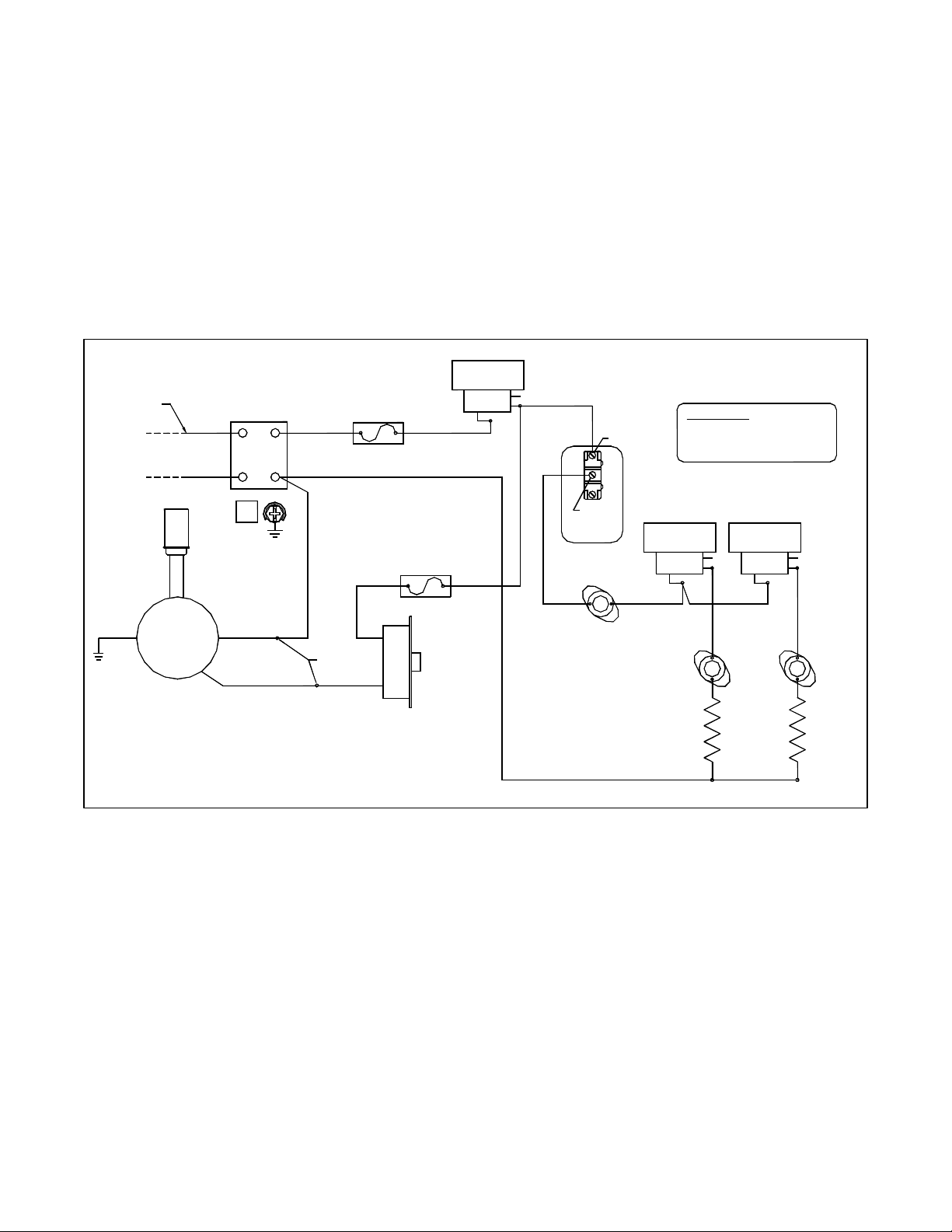

Figure 3 - Typical pneumatic parallel fan powered terminal with load bearing PE switches.

Figure 4 - Typical pneumatic parallel fan powered terminal with contactors.

Figure 5 - Typical pneumatic series fan powered terminal with load bearing PE switches.

Figure 6 - Typical fan powered terminal with factory wired controls.

Figure 7 - Typical electronic fan powered terminal with field mounted controls.

Figure 8 - Typical electronic single duct terminal with field mounted controls.

Figure 9 - Typical pneumatic single duct terminal with contactor.

Figure 3.

Pneumatic Parallel (Variable Volume) Fan Powered Terminal

Electric Reheat, 277V, 1φ, 2 Stage, 2 Element

P.E. SWITCH

FAN

USE COPPER

CONDUCTORS ONLY

L1

N

BLACK

WHITE

TERM BLOCK

OR OPTIONAL

DISC SWITCH

BROWN

WHITE

OPTIONAL

LINE FUSE

BLACK

COM

NC

ORANGE

NO

COM

BLACK

EHeat-IOM-3.0 6-1-01

CAUTION:

ELECTRIC SHOCK MAY RESULT

DISCONNECT POWER SUPPLY

PRIOR TO SERVICING UNIT.

GREEN

MOTOR

ORANGE

N.O.

AFS

OPTIONAL

MANUAL RESET

ORANGE

SEE NOTE #1

P.E. SWITCH

STEP 1

COM

WHITE

SEE NOTE #1

P.E. SWITCH

STEP 2

NC

NO

ORANGE

BROWN

COM

NC

NO

RED

THERMAL

HI LIMIT

(TYP)

CAP

BROWN

BROWN

3

G

WHITE

1

BLACK

NOTES:

1. FACTORY WIRED P.E. SWITCH. DIRECT ACTING WIRED N.C.,

REVERSE ACTING WIRED N.O. AND PIPED TO THERMOSTAT LINE.

WHITE

OPTIONAL

CRIMP CAP

RED

MOTOR FUSE

RED

RED

SCR

BLACK

Loading...

Loading...