Page 1

Instruction manual

HKE-L

223 000200

Combined strapping tool for

steel strap

Important!

Do not dispose of this manual. It is the

customers responsibility to ensure that all

operators and servicemen read and understand

this manual.

Page 2

HKE-L

H 223 EU 03/11

2.

General information

Many thanks for your confidence in the technology of

TITAN Umreifungstechnik GmbH & Co. KG

These operating instructions are intended to simplify familiarisation with the HKE-L and the

possibilities of application for the intended purpose. The operating instructions contain

important information concerning the safe, proper and efficient use of the strapping

tool. Following the instructions helps avoid risks, reduces repairs and downtimes and

increases reliability and life of the unit.

The operating instructions must always be available at the place of operation of the strapping

tool. They must be read and observed by persons concerned with work on the strapping tool.

This work specifically includes operation, refilling of operating material, fault elimination and

maintenance.

In addition to the operating instructions and the regulations for accident prevention effective

in the country of use and place of application, the recognized technical regulations for safety

and proper working must also be observed.

Explanatory notes on the warning and instruction symbols:

Caution!

Used where there is danger to life and health.

Attention!

Used for danger which cause material damage.

Note!

Used for general information and information which if not followed can cause

faults in the operating sequences.

The manufacturer reserves the right to make changes to the scope of delivery

at any time for the purpose of improving the product.

Copyright © TITAN Umreifungstechnik GmbH & Co.KG 2011 All rights reserved.

The contents of this document must not be duplicated, handed to third parties, published or saved in any form,

neither fully nor partly, without prior written permission by TITAN Umreifungstechnik GmbH & Co.KG.

is a registered trademark of TITAN Umreifungstechnik GmbH & Co.KG.

Page 3

HKE-L

H 223 EU 22/11

2.1.

Intended use

This tool is made for strapping packages, pallet loads etc. The tool is designed

and manufactured for safe handling during the strapping operation.

This tool is intended for strapping with steel strap material.

Unintended use!

Strapping material must not be used for the hoisting of loads; this strapping

tool may only be used as intended and specified above.

The use of plastic straps is not allowed with this device.

The strapping tool HKE-L complies with the German and European safety

standards and is in accordance with EU Guidelines: see Declaration of

conformity of the machinery.

Standards applied and technical specifications:

See Declaration of conformity of the machinery.

2.2.

Warranty & liability

TITAN Umreifungstechnik GmbH & Co. KG guarantees all strapping tools

sold by the company for a period of 6 months. The warranty covers all

defects that can be demonstrated to result from faulty craftsmanship or

defective materials.

Wear parts are excluded from the warranty.

Warranty and liability claims shall be excluded if they are due to one or more of

the following causes:

Misuse of the tool.

Incorrect assembly, commissioning, operation and maintenance of the tool.

Operation of the tool with improper safety and protective devices.

Failure to comply with the information in the operating manual.

Unauthorized structural modifications to the tool.

Insufficient monitoring of tool parts that are subject to wear.

Improper repairs.

2.3.

Information on environmental protection

This tool is manufactured without any physical or chemical

substances which could be dangerous to health. For disposal of

all the parts, the governmental instructions must be observed.

Page 4

HKE-L

H 223 EU 33/10

3.

Safety instructions

Failure to comply with the following safety instructions, in addition to errors in

handling the device, can result in serious injuries.

Be informed!

Caution: Danger of crushing!

Read the operating manual

Do not insert fingers into the

carefully before using the

pulley area.

device.

Protect yourself!

Caution:

Always wear eye, face and hand

Strap only objects to be

protection (cut-resistance

packed!

gloves) when working.

Make sure that no hands or

other body parts are between

the strap and the goods to be

packaged.

Attention: Strap can break!

Attention: Strap flies outward!

The strap can break during

When cutting the strap, hold the

tightening! Do not stand in the

top part firmly and stand to the

path of the strap. Make sure that

side.

no one else is in the working

Attention: The lower part of the

area.

strap will fly outward.

Use only original TITAN

replacement parts!

The use of other than original

TITAN replacement parts will

void the warranty and all liability.

The use of straps other than

This tool may be operated only

recommended can result in

by personnel who have been

broken straps during the

trained accordingly. Please

tightening process and

consult your TITAN packaging

insufficient strapping. Use only

consultant if you have any

corresponding quality

questions about this.

products from TITAN!

Workplace!

Always maintain an orderly

workplace. A disorderly

workplace can cause accidents.

When operating the crimper,

make sure that you‟re in a wellbraced position in order to

maintain optimum balance and

prevent the risk of falling. Never

operate the tool in an awkward

working position!

Maintenance!

In order to operate safely, the

tool must be properly

maintained. Check the condition

of your tool regularly for defects

or worn parts. Never use a tool

that has defects or worn parts.

Modifications to the tool are

strictly prohibited. Failure to

comply with this regulation can

result in serious injury.

Page 5

HKE-L

H 223 EU 22/11

4.

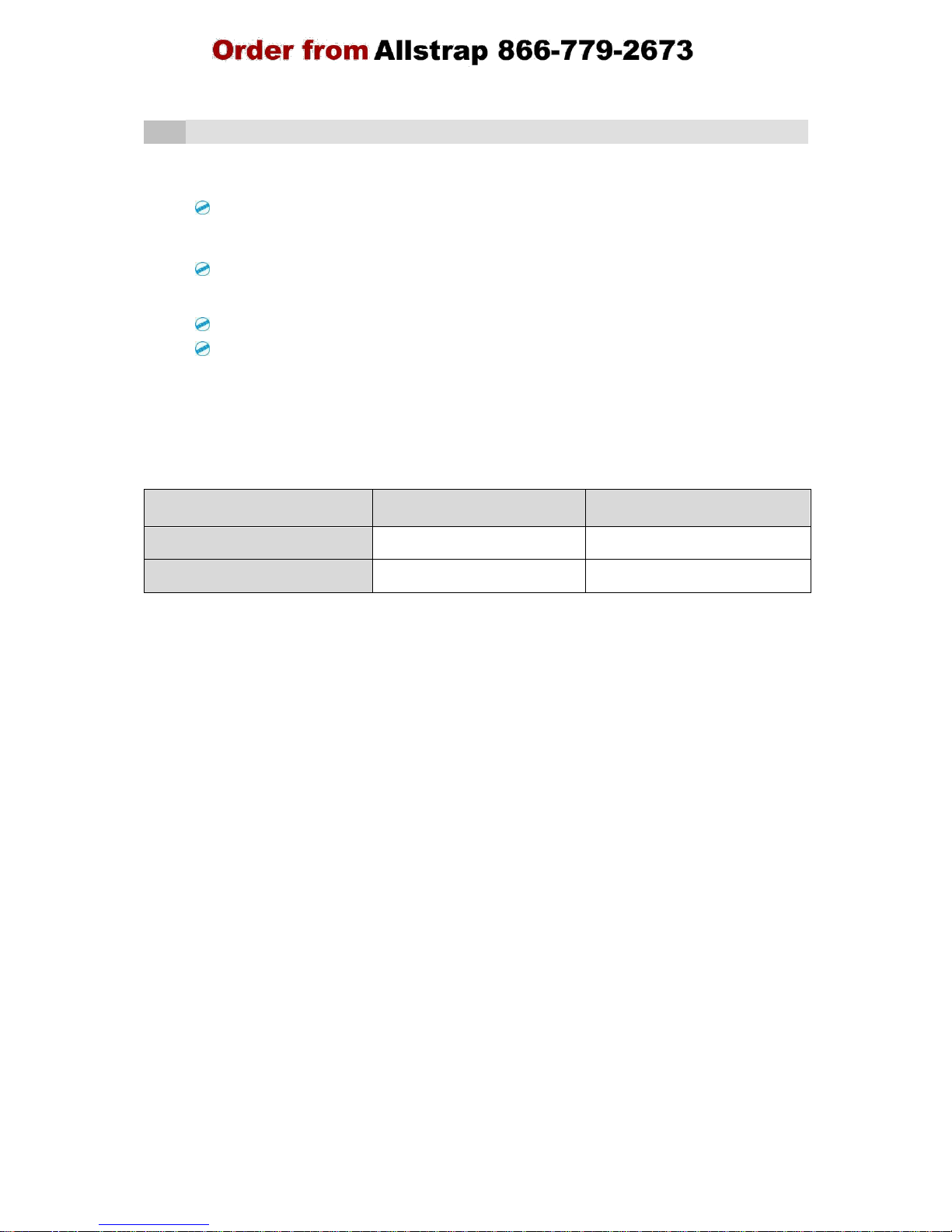

Technical data

Joint: No seal joint

Tension force: up to approx. 6.000 N

Weight: 3.2 kg

Dimension: L = 475 mm

B = 115 mm

H = 190 mm

Steel strap for

strap width 13, 16, 19 mm

Standard quality

(Automatenband)

High quality

(Megaband)

Strap thickness

0.4 – 0.6 mm

0.4 – 0.63 mm

Tensile strength

up to approx. 900 N/mm²

up to approx. 1.100 N/mm²

Page 6

HKE-L

H 223 EU 21/06

5.

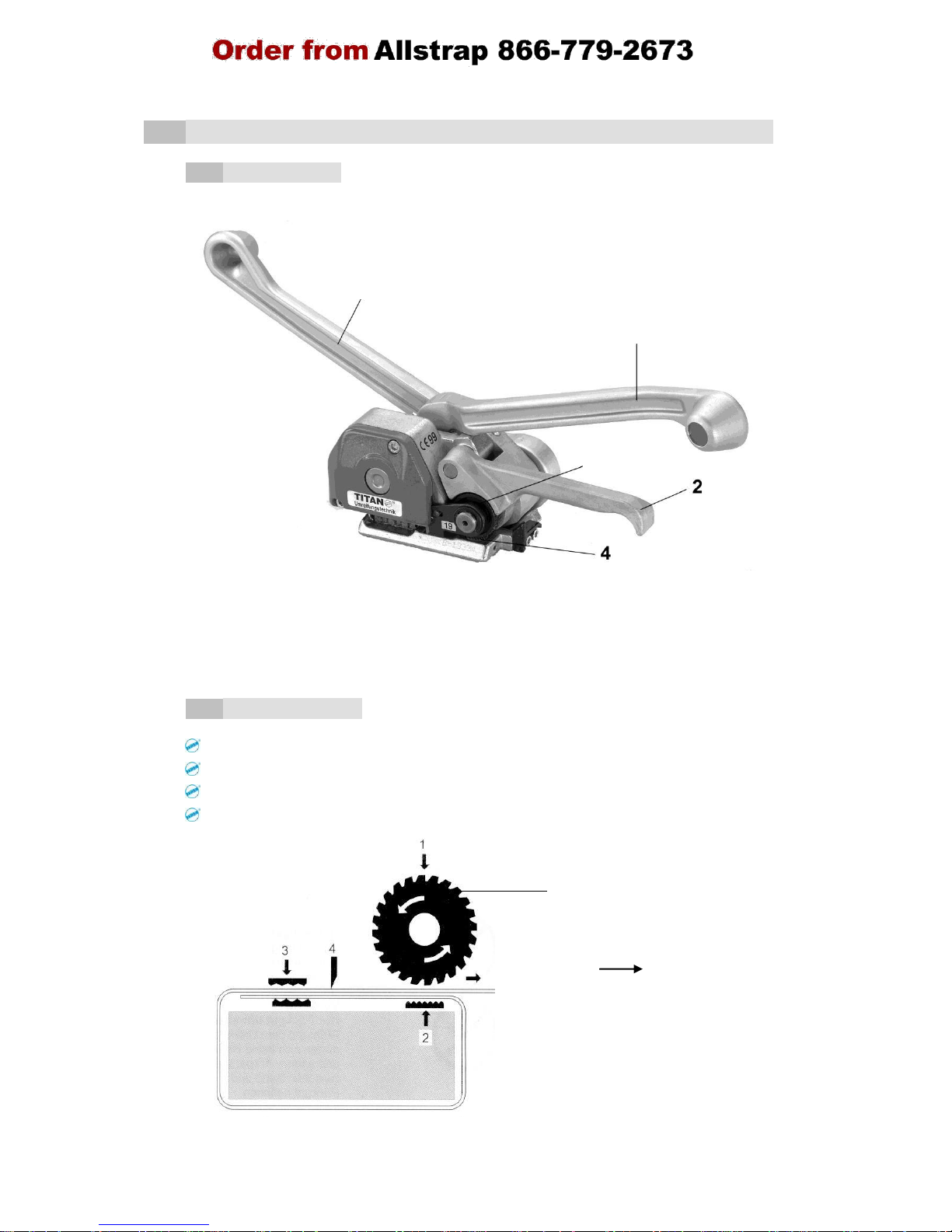

Description

5.1.

Design

29 = Tension wheel 503 = Gripper plate

35 = Cutting lever 508 = Tension lever complete

509 = Rocker complete

5.2.

Function

Strap clamped by pressure on gripper plate1/2

Tensioning by turning feed wheel 1

Sealing by punching the strap 3

Cutting the strap with cutter 4

Attention!

When changing the feed wheel

strictly observe the moving

direction!

Arrow

508

35

29

509

503

Page 7

HKE-L

H 223 EU 21/06

6.

Operating instructions

1.

TITAN steel strap around package

from top. Pull end of strap until it is

positioned in the middle of the

package below the upper strap.

2.

Pull through the strap end until it is in

the centre of the package beneath

the upper run of strap and juts out

approx. 15 cm.

3.

With the left hand hold the upper and

lower run of the strap together. Both

straps must be placed exactly on top

of one another. Grip and press rocker

509 together with the cutting lever 35

with the right hand. Insert the steel

strap laterally until it strikes against

the case wall, ensuring that the lower

run of strap projects slightly out of the

tool at the front. The right hand now

releases the levers which have been

pressed together.

If the straps are not inserted correctly in the tool, it is not possible to

perform the tensioning operation.

Page 8

HKE-L

H 223 EU 21/06

4.

If necessary, tighten the great

strap loop. The left hand pulls the

strap loop, the right hand grasps

the lifting Rocker 509.

5.

The right hand grasps the tension

lever 508 and moves it back and

forth to obtain the desired strap

tension. At the same time the left

hand holds the cutting lever 35.

6.

After having reached the desired

strap tension bring tension lever

508 back into its initial position.

The right hand remains there and

provides support for the joining

process. The TITAN “No-seal” joint

is formed by pushing the cutting

lever 35 forwards rapidly with the

left hand until it strikes against the

case; the steel strap is

simultaneously cut off directly

behind the joint.

7.

Bring tension lever 508 back into

its initial position. Grasp and press

together rocker 509 with cutting

lever 35. Withdraw the tool from

the package by a rotary movement

to the right side.

Page 9

HKE-L

H 223 EU 05/10

The following picture shows a correctly carved seal.

Check the seals regular:

for even carved cuttings,

for neat cutting edges,

for that the lower run of strap is soaked in the cuttings,

for correct adjustment of the cutter,

for a sufficient overlap of the lower run of strap and

for that the seal is placed in the centre of the strap.

Page 10

HKE-L

H 223 EU 21/06

7.

Adjustments

7.1.

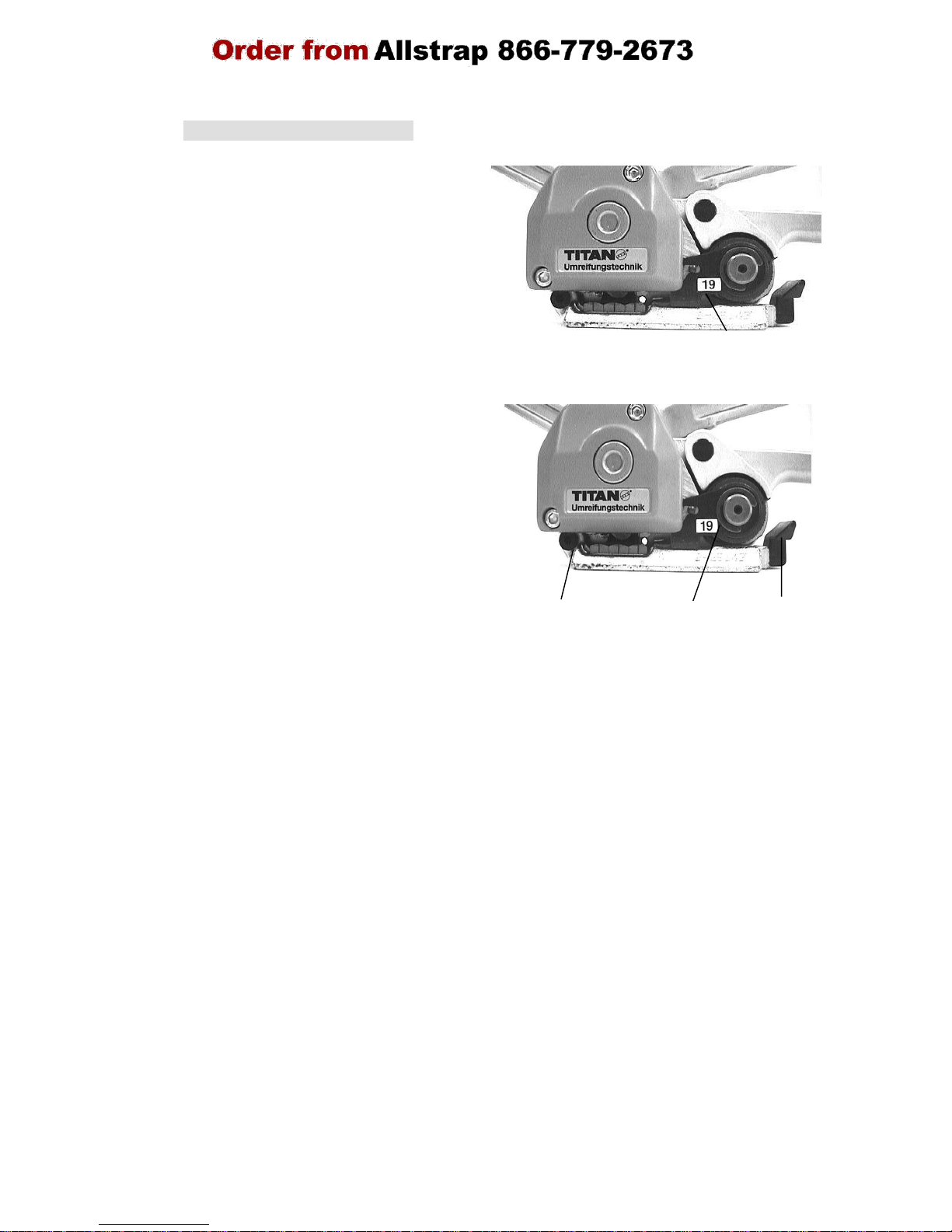

Cutter adjustment

The cutter has been adjusted for the

respective thickness in the case of

varying strap thicknesses.

Release hexagon nut 72, turn set screw

49 (thread pin with flat point) by means

of a screwdriver,

clockwise = less cutting

depth

counter clockwise = greater cutting

depth

Fasten hexagon nut 72 after adjustment has been completed.

Note! After adjustment there should not be any, or very

few, signs of cutting on the lower strap.

7.2.

Distance between the feed wheel and the gripper plate

The distance between the feed wheel 29

and the gripper plate 503 is adjusted to

0.2 mm. The adjusting screw 84 is

located behind the plastic cover of the

housing. Unscrew the hexagon nut 8

using the 10 mm open-jawed spanner

and adjust a 0.2 mm gap at the

adjusting screw 84.

Note!

The feed wheel and the gripper plate may not come

into contact with each other. Otherwise both parts

will be subject to premature wear.

72

49

84

8

Page 11

HKE-L

H 223 EU 21/06

The strap guide 500 located next to the

feed wheel is replaced when the strap

width is modified. In order to do so the

safety ring has to be removed by means

of a screwdriver and the lifting rocker

509 and the cutting lever 35 pressed

together. The strap guide may now be

pulled off towards the front and be

replaced with the strap guide for other

strap widths. Replace safety ring

afterwards.

Since the strap is guided at three points

in the tool the rear strap guide 42 and

the strap guide front 76 also have to be

set in such a way that the punching is

placed at the centre of the strap.

In order to do this, loosen the two

fastening screws for the rear strap guide

42 and adjust the strap guide to the

respective strap width.

Left = 13mm

Middle = 16mm

Right = 19mm

Fasten screws afterwards.

Also loosen the cap screw at the front strap guide 76 and place the corresponding

number of washers DIN 125-6.4 under the strap guide:

13 mm band width = 2 washers

16 mm band width = 1 washer

19 mm band width = no washer

Fasten cap screw again after adjustment.

7.3. Adjusting strap width

500

76

500

42

Page 12

HKE-L

H 223 EU 05/10

8.

Maintenance

8.1.

Cleaning the tool

Soil and debris hamper the proper functioning of the tool. For this

reason the following areas should be cleaned once a week.

Insertion slot

Cavities between the upper and lower jaws

Tensioning wheel

Gripper plate

Blow off using compressed air if possible (wear protection goggles).

Lubricate with fine conventional spray oil afterwards.

8.2.

Tool inspection

Perform a daily visual inspection of the outside of the unit. The early detection of

damaged parts extends the life of the unit. Replace all damaged parts immediately

with Original TITAN spare parts.

For health reasons please do not use any cleaning

agents which contain solvents.

Page 13

9. Declaration of conformity of the machinery

Loading...

Loading...