Page 1

Owner’s Manual

For professional use only

Do not use this equipment before reading this manual!

ProFinish C-100

Model Number 773-950

Printed in the U. S. A.

NOTE: This manual contains important warnings

and instructions. Please read and retain for

reference.

0900 © 2000 Titan Tool Inc. All rights reserved. Form No. 313-1511, REV B

Page 2

Table of Contents

WARNING

CAUTION

WARNING

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Español. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connecting the Spray System . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Spray Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–10

Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cart Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety

This manual contains information that must be read and

understood before using the equipment. When you come to

an area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information will

follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information that should

be given special attention.

HAZARD: EXPLOSION OR FIRE - Solvent and paint fumes

can explode or ignite. Severe injury and/or

property damage can occur.

PREVENTION:

• Provide extensive exhaust and fresh air introduction to

keep the air within the spray area free from accumulation

of flammable vapors.

• Avoid all ignition sources such as static electric sparks,

open flames, pilot lights, and hot objects. Connecting or

disconnecting power cords or working light switches can

make sparks.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

order.

• Place spray system at a minimum of 3 feet (preferably

more) into a separate, well ventilated room from the spray

object or at least 20 feet from the spray object in a well

ventilated area. Flammable vapors are often heavier than

air. Floor area must be extremely well ventilated. The

spray system contains arcing parts that emit spark and

can ignite vapors.

• Follow the material and solvent manufacturer's warnings

and instructions.

• Use extreme caution when using materials with a

flashpoint below 70° F (21° C). Flashpoint is the

temperature that a fluid can produce enough vapors to

ignite.

• Plastic can cause static sparks. Never hang plastic to

enclose a spray area. Do not use plastic drop cloths

when spraying flammable materials.

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

MATERIALS - Will cause severe injury or

property damage.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as

mildewcide, methylene chloride and 1,1,1 trichloroethane. They are not compatible with aluminum.

• Contact your coating supplier about the compatibility of

material with aluminum.

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

insecticides, and other materials can be harmful if

inhaled or come in contact with the body. Vapors

can cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read

all instructions supplied with the mask to be sure it will

provide the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

HAZARD: SKIN BURN INJURY— Heated parts can cause

severe skin burn injury.

PREVENTION:

• Quick-disconnect fittings on the hose and the spray gun

become hot during use. Avoid skin contact with any

quick-disconnect fittings when they are hot. Allow the

quick disconnect fittings to cool before disconnecting the

spray gun from the hose

• The compressor becomes hot during use. Allow the

compressor to cool before touching it.

HAZARD: GENERAL - This product can cause severe

injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before

operating equipment.

• Always disconnect the motor from the power supply

before working on the equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards should be consulted.

• Use only manufacturer authorized parts. User assumes

all risks and liabilities when using parts that do not meet

the minimum specifications and safety devices of the

manufacturer.

• Power cord must be connected to a grounded circuit.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a hose. Replace it with an

identical replacement hose.

• Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

• Never aim spray gun at any part of the body.

HAZARD: EXPLOSION — Compressed air has great force

and may cause injury.

PREVENTION:

• The maximum operating range of the unit is 125 PSI air

pressure.

• The pressure pot assembly is protected from overpressurizing by a safety valve. Pull the ring on the safety

valve occasionally to make sure that the valve operates

freely. The valve must be replaced if it does not operate

freely or if it does not release air when the ring is pulled.

• Never modify the pressure pot or the compressor.

• All accessories must be rated at or above 125 PSI. This

includes spray tips, guns, extensions, hoses, and other tools.

2 © Titan Tool Inc. All rights reserved.

Page 3

Grounding Instructions

Grounded Outlet

Grounding Pin

Tab for

Grounding Screw

Adapter

Metal Screw

Cover for grounded outlet box

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER — Improper installation of the grounding plug can

result in a risk of electric shock. If repair or replacement of the

cord or plug is necessary, do not connect the green grounding

wire to either flat blade terminal. The wire with insulation

having a green outer surface with or without yellow stripes is

the grounding wire and must be connected to the grounding

pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. A

temporary adapter which looks like the adapter illustrated in

the figure below may be used to connect this plug to a 2 pole

receptacle as shown if a properly grounded outlet is not

available.

The temporary adapter should be used only until a properly

grounded outlet as shown below can be installed by a qualified

electrician. The green colored rigid ear, lug, or the grounding

wire extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box

cover. Whenever the adapter is used, it must be held in place

by a metal screw.

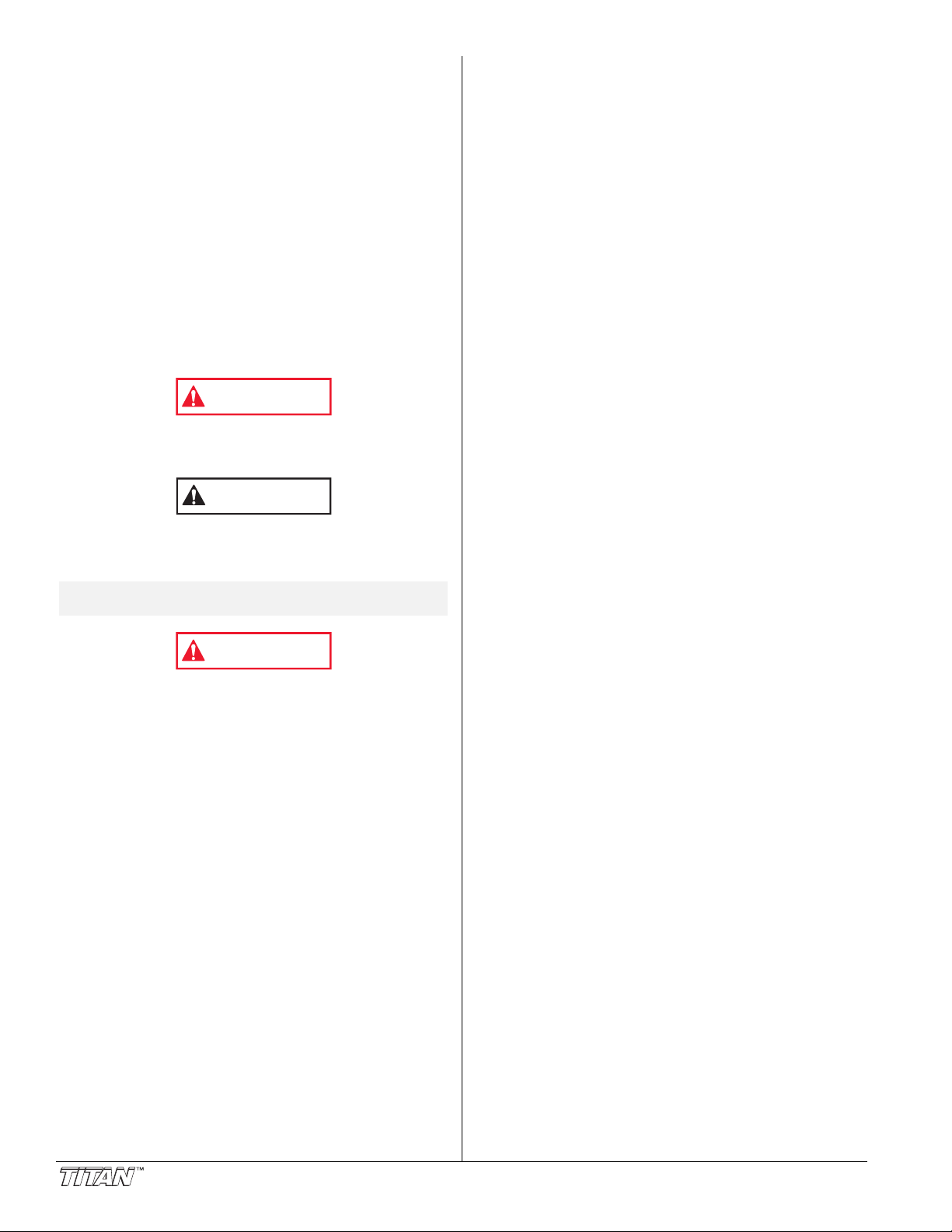

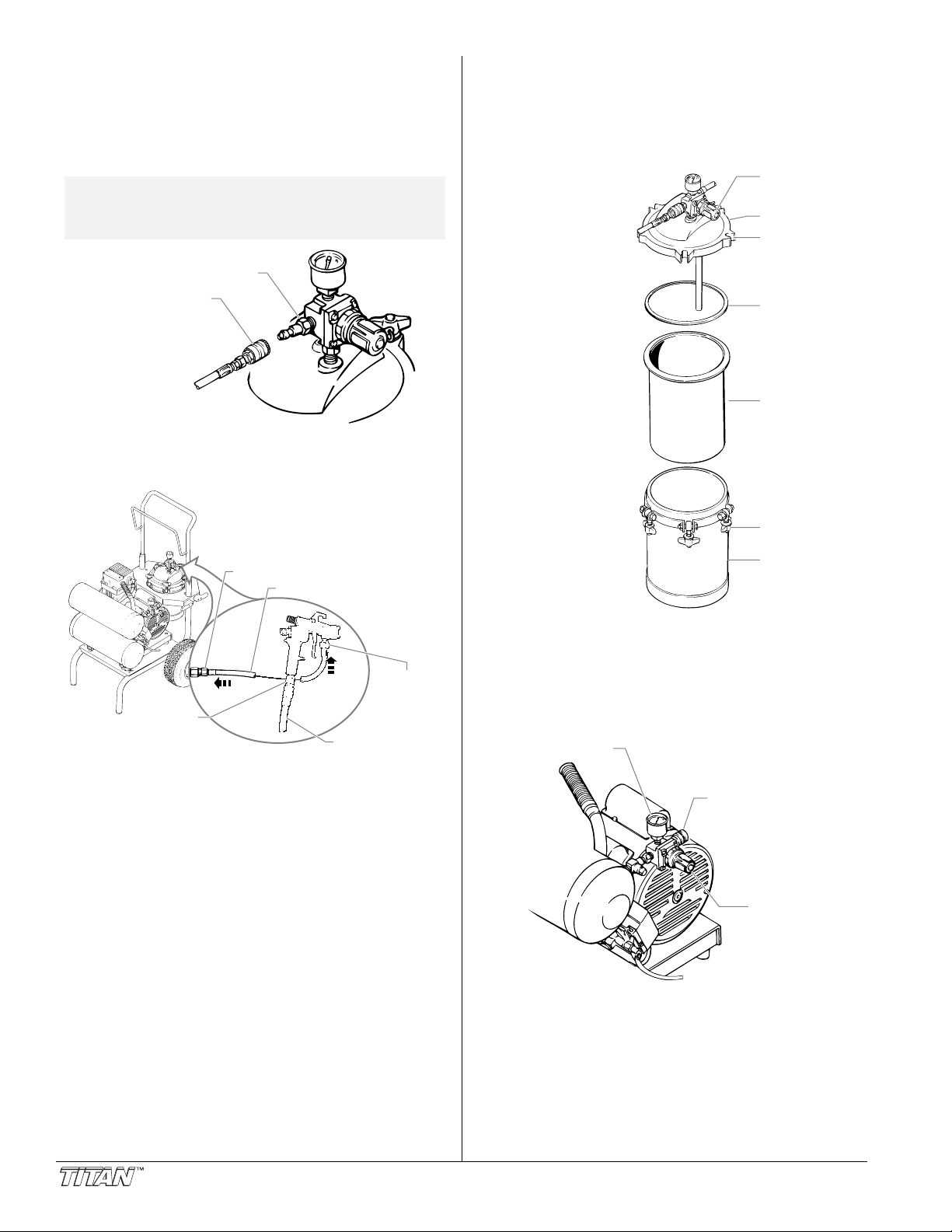

Introduction

The ProFinish C-100 HVLP spray system is designed for use

as a large capacity, fine finish spray painting tool.

Components of the spray system include a compressor, a cart,

a compressor air outlet, a pressure switch, a pressure pot, a

pressure pot air inlet, and a pressure pot material outlet.

Pressure Pot

Air Inlet

Pressure Pot

Compressor

Storage

Tanks

Cart

NOTE: The compressor can be used to supply air for

other air-powered tools. A tee fitting on the

compressor air outlet allows the installation of

an additional regulator.

Pressure Pot

Material Outlet

(behind regulator)

Compressor

Air Outlet

Pressure Switch

CAUTION

Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the

plug on the product. Make sure your extension cord is in

good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your

product will draw. For lengths less than 25 feet, No. 16

AWG extension cords should be used. Between 25 feet

and 50 feet, the minimum gauge is 12 AWG. An

undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. If an extension cord is

to be used outdoors, it must be marked with the suffix WA after the cord type designation. For example, a

designation of SJTW-A would indicate that the cord would

be appropriate for outdoor use.

© Titan Tool Inc. All rights reserved. 3

Page 4

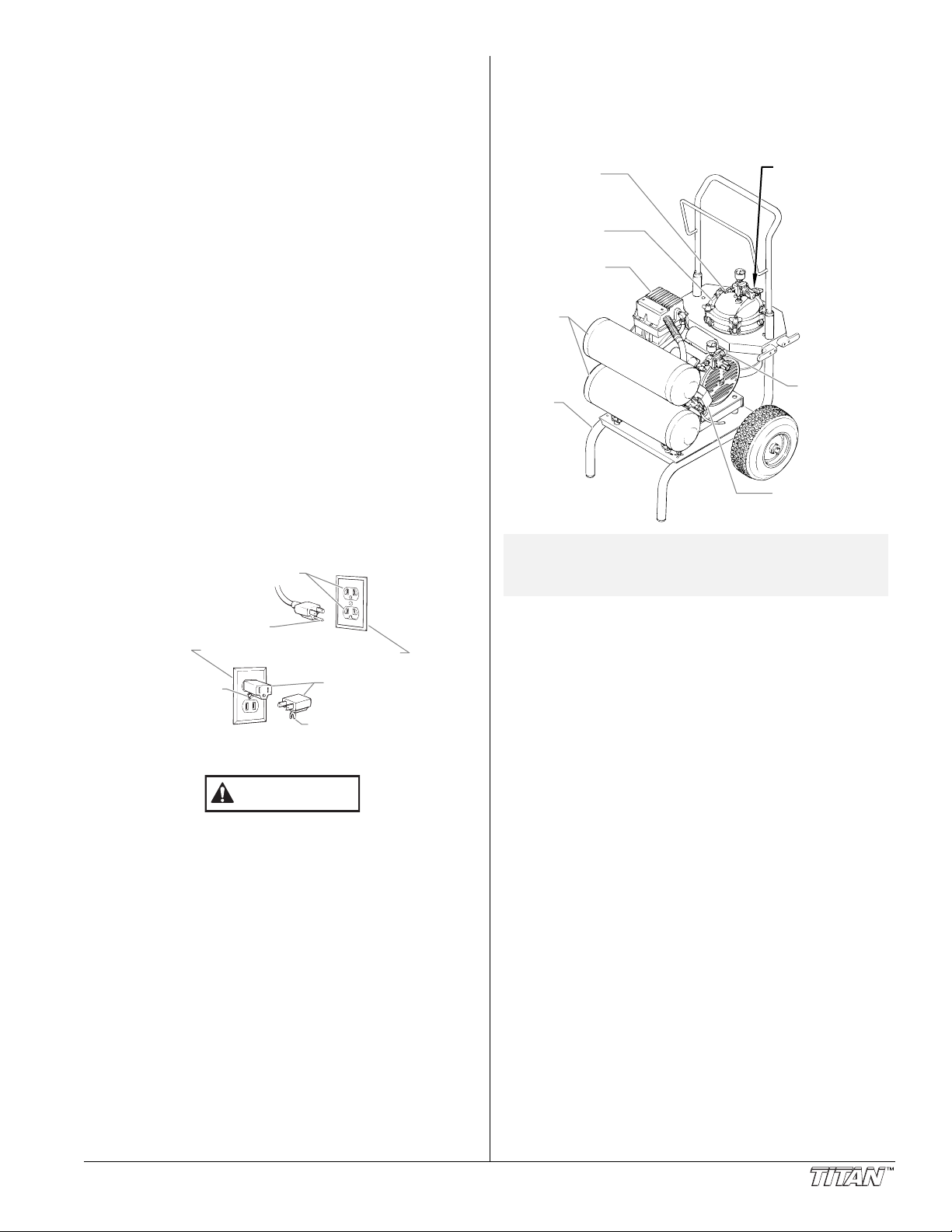

Setup

Pressure Pot Outlet

Material Hose

Air Hose

Spray Gun

Material

Inlet

Spray Gun

Air Inlet

Compressor

Air Outlet

Pressure

Control Knob

Pressure Gauge

Cover

Groove

Seal

Locking Clamp

Pressure Pot

Pressure

Control Knob

Pot Liner

(optional)

Operation

Connecting the Spray System

1. Make sure the ON/OFF lever on the pressure switch is on

the OFF position.

2. Connect the compressor hose from the lower storage tank

to the pressure pot air inlet.

NOTE: The hose features quick-disconnect fittings.

To use, pull back on the spring-loaded collar

of each fitting. Slide the hose fitting over the

correct connection and release the collar.

Pressure Pot Air Inlet

Compressor Hose

3. Thread the end of the material hose onto the pressure pot

material outlet and tighten.

4. Thread the other end of the material hose onto the spray

gun material inlet and tighten.

Startup

1. Place the unit in a clean, dry and well-ventilated area.

The compressor should be located at least 12” from walls

or other obstructions that could interfere with the flow of

air.

2. Fill the pressure pot

with spray material.

3. Fasten the cover

securely onto the

pressure pot by

placing the five

locking clamps into

the cover grooves

and rotating each

clockwise until hand

tight. Be certain that

the seal is in place.

4. Plug in the power

cord for the

compressor.

5. Move the ON/OFF

lever on the pressure

switch to the ON

position to start the

compressor. Allow

the tank pressure to

build. When the

motor stops, the

compressor has

reached cut-out

pressure, and the

system is ready for

use.

6. Pull out the pressure

control knob on the

pressure pot and

turn it until the pressure pot pressure is set properly for

the type of material you are using.

• For thin materials, set to 8 PSI.

• For thicker materials, set to between 8 and 14 PSI.

7. Pull out the pressure control knob on the compressor air

outlet and turn it until the gun pressure is set properly for

the type of material you are using (see spray chart for

reference).

5. Connect the air hose to compressor air outlet.

6. Thread the other end of the air hose onto the spray gun

air inlet and tighten.

8. Practice spraying on a piece of scrap wood or cardboard

until you are satisfied with the pot pressure, gun air

pressure, spray pattern, and spray shape. The spray

pattern adjustments and spray shape selections are

described in your gun manual.

Shutdown

1. Move the ON/OFF lever on the pressure switch to the

OFF position.

2. Allow the compressor to cool.

3. Drain the storage tanks (refer to compressor manual for

procedure).

4 © Titan Tool Inc. All rights reserved.

Page 5

Spray Charts

Spraying Pressure Air Consumption

Pressure

Inside Cap

Compressor Pressure*

Air CFM

6 PSI 6.5 9

15

18

20

24

7.5

7.8

8

8.5

8 PSI

10 PSI

12 PSI

14 PSI

*The pressure at the compressor air outlet

when spraying gun.

Français

Sécurité

AVERTISSEMENT

© Titan Tool Inc. All rights reserved. 5

DANGER: RISQUES D'EXPLOSION OU D'INCENDIE - Les

vapeurs dégagées par le solvant ou la peinture

sont explosives et inflammables et peuvent

causer des corporels sérieux ou dommages

matériels.

MESURES PRÉVENTIVES:

• Veiller à éviter toute accumulation de vapeurs

inflammables en vous assurant que la zone où la

pulvérisation a lieu est suffisamment ventilée.

• Veiller à éviter la présence de toute source incandescente

telle qu'étincelle électrostatique, flamme nue, flammepilote, objet brûlant, cigarette et étincelle provenant du

branchement ou du débranchement d'un cordon

d'alimentation électrique ou d'un commutateur.

• Ne pas fumer dans la zone d’épandage.

• Toujours avoir un extincteur en état de fonctionner à

portée de la main.

• Placer la pompe à peinture à une distance d’au moins un

mètre (3 pi) (on recommande d’ailleurs une plus grande

distance) de l’objet qui doit être vaporisé dans une pièce

séparée bien aérée, ou à une distance d’au moins six

mètres (20 pi) de celui-ci dans une zone bien aérée. Les

vapeurs inflammables sont souvent plus lourdes que l’air.

Le plancher doit être extrêmement bien aéré. La pompe à

peinture contient des pièces pouvant créer des étincelles

et enflammer les vapeurs présentes dans l’air.

• Se conformer aux consignes et recommandations de

sécurité du fabricant du solvant ou du produit.

• S’entourer de toutes les précautions possibles lorsqu’on

utilise des produits ayant un point d’éclair inférieur à 21

°C (70 °F). Le point d’éclair d’un fluide est la température

à laquelle les vapeurs émanant du fluide peuvent

s’enflammer au contact d’une flamme ou d’une étincelle.

• Le plastique peut être une source d’étincelles provoquées

par l’électricité statique. Ne jamais utiliser une couverture

en plastique pour fermer une zone d’épandage ni utiliser

des toiles de protection en plastique lors de la

pulvérisation de matières inflammables.

DANGER: RISQUES D'EXPLOSION PAR

INCOMPATIBILITÉ DES MATÉRIAUX - Peuvent

être à l'origine de corporels sérieux ou

dommages matériels.

MESURES PRÉVENTIVES:

• Ne pas utiliser de matériaux contenant des agents de

blanchiment ou du chlore.

• Ne pas utiliser des solvants à base d’hydrocarbure

halogéné tels que l’agent anticryptogamique, le chlorure

de méthylène et le trichloro-éthane-1,1,1. Ces produits ne

sont pas compatibles avec l’aluminium

• Communiquer avec votre fournisseur de revêtement pour

connaître la compatibilité du matériau avec l’aluminium.

DANGER: VAPEURS NOCIVES – la peinture, les solvants,

les insecticides et autres matériaux peuvent

être nocifs lorsqu’ils sont inhalés ou en

contact avec le corps. Les vapeurs peuvent

causer une nausée importante, des

évanouissements ou un empoisonnement.

MESURES PRÉVENTIVES:

• Utiliser un respirateur ou un masque chaque fois qu'il y a

des risques d'inhalation de vapeurs. Lire attentivement

toutes les instructions se rapportant au masque pour

vérifier que celui-ci vous assure une protection suffisante

contre les vapeurs toxiques.

• Porter des lunettes de protection.

• Porter des vêtements de protection, conformément aux

directives du fabricant de revêtement.

Page 6

DANGER: DANGER DE BRÛLURE — Les pièces

Prise de terre

Goupille de mise la terre

Patte pour

vis de mise

la terre

Adapteur

Vis m tallique

Couvercle du bo tier de prise de terre

chauffées peuvent causer de graves brûlures

cutanées.

PRÉVENTION:

• Les raccords à dégagement rapide du tuyau flexible et du

pistolet peuvent s'échauffer en cours d'utilisation; il faut

alors éviter les contacts cutanés, en attendant que les

raccords refroidissent avant de séparer le pistolet du

tuyau.

• Le compresseur devient chaud à l'utilisation. Le laisser

refroidir avant d'y toucher.

DANGER: GÉNÉRALITÉS - Peut causer des dommages

matériels ou corporels sérieux.

MESURES PRÉVENTIVES:

• Avant d'utiliser tout équipement, lire attentivement toutes

les instructions et les consignes de sécurité

• Toujours débrancher le moteur de l’alimentation électrique

avant d’effectuer des travaux sur l’appareil.

• Se conformer à la législation locale, provinciale ou fédérale

pour tout ce qui concerne la ventilation, la prévention des

incendies et les conditions générales d'utilisation.

• Les normes de sécurité du Gouvernement américain sont

régies par le Occupational Safety and Health Act (OSHA).

Il est important de consulter ces normes, en particulier la

section 1910 sur le normes générales et la section 1926

sur les des normes de la construction.

• N’utiliser que les pièces autorisées par le fabricant.

L’utilisateur assume tous les risques et responsabilités

lorsqu’il utilise des pièces qui ne sont pas conformes aux

caractéristiques techniques minimales ainsi qu’aux

dispositifs de sécurité du fabricant.

• Le cordon d’alimentation doit être raccordé à un circuit

mis à la terre.

• Vérifier, avant toute utilisation, que les flexibles ne

présentent pas d'entaille ou de fuite, que le couvercle ne

soit pas gonflé et que les raccords ne soient pas

endommagés. Si le flexible a subi l'un des dommages

précités, remplacez-le immédiatement. Ne jamais réparer

un flexible d'alimentation. Le remplacer avec un flexible

identique de remplacement.

• Ne jamais pulvériser lorsqu'il vente.

• Porter des vêtements pour protéger la peau et les

cheveux contre tout contact avec la peinture.

• NE JAMAIS diriger le pistolet vers une quelconque partie

du corps.

DANGER: EXPLOSION — L'air comprimé est très

puissant et peut provoquer des blessures.

PREVENTION:

• L'ensemble réservoir est protégé contre la surpression par

une soupape de sécurité. De temps en temps, tirer sur

l'anneau de la soupape de sécurité pour vérifier qu'elle

fonctionne normalement. Remplacer la soupape si elle ne

fonctionne pas bien ou si elle ne laisse pas passer l'air

quand on tire sur l'anneau.

• Ne jamais modifier le réservoir sous pression ni le

compresseur.

• Ne connecter aucun autre outil pneumatique au

compresseur.

Instructions de mise à la terre

Cet appareil doit être mis à la terre. La mise à la terre réduit

les risques d'électrocution lors d'un court-circuit en permettant

au courant de s'écouler par le fil de mise à la terre. Cet

appareil est muni d'un cordon électrique avec fil de mise à la

terre ainsi que d'une fiche de terre. La fiche doit être branchée

sur une prise installée correctement et mise à la terre

conformément à la réglementation et aux codes en vigueur.

DANGER — Une prise de terre mal branchée peut être à

l'origine d'électrocutions. S'il s'avère nécessaire de réparer ou

de remplacer le cordon électrique ou la fiche, ne pas brancher le

fil vert de mise à la terre sur l'une ou l'autre des bornes à broche

plate. Le fil recouvert d'un isolant vert avec ou sans rayures

jaunes est le fil de mise à la terre et doit être branché sur la

broche de mise à la terre.

Si vous ne comprenez pas les instructions de mise à la terre

ou si vous n'êtes pas sûr que l'appareil est correctement mis à

la terre, contactez un électricien agréé. Ne pas modifier la

fiche d'origine. Si la prise ne convient pas à la fiche, faites

installer la prise adéquate par un électricien agréé.

Cet appareil est conçu pour un tension normale de 120 V et

est muni d'une fiche de mise à la terre semblable à celle de

l'illustration ci-dessous. Un adaptateur temporaire semblable à

celui illustré à la figure ci-dessous, peut être utilisé pour

raccorder cette fiche dans une prise bipolaire, tel qu’illustré,

lorsqu’une prise de courant avec contact de mise à la terre

n’est pas disponible.

L’adaptateur temporaire doit être utilisé seulement jusqu’à ce

qu’une prise de courant avec contact de mise à la terre, tel

qu’illustré ci-dessous, puisse être installée par un électricien

qualifié. L’oreillette de fixation rigide de couleur verte ou le fil

de mise à la terre raccordé à l’adaptateur doit être mis à la

terre en permanence, par l’entremise d’un composant

quelconque, tel qu’une boîte de sortie. Lorsque l’adaptateur

est utilisé, il doit être tenu en place au moyen d’une vis

métallique.

ATTENTION

Utiliser uniquement une rallonge à trois fils munie d'une

fiche de terre dans une prise secteur mise à la terre

correspondant au type de fiche de l'appareil. S'assurer

que votre rallonge est en bon état. Lorsque vous utilisez

une rallonge, assurez-vous qu'elle soit d'un calibre

suffisant pour supporter l'intensité du courant requise par

l'appareil. Pour des longueurs moins que 25 pieds, No.

16 AWG rallonge devraient être employées. Entre 25 et 50

pieds, de calibre minimum est 12 AWG. Une rallonge trop

mince entraîne une chute de tension, une diminution de

l'intensité et une surchauffe. Si vous devez utiliser une

rallonge à l’extérieur, celle-ci doit comprendre la marque

W-A après la désignation indiquant le type de cordon. Par

exemple, la désignation SJTW-A indique que le cordon est

conçu pour être utilisé à l’extérieur.

6 © Titan Tool Inc. All rights reserved.

Page 7

Español

Seguridad

ADVERTENCIA

PELIGRO: EXPLOSIÓN O INCENDIO - Los vapores de

solventes y pintura pueden explotar o

incendiarse, causando con esto lesiones

severas y/o daños en la propiedad.

PARA PREVENIR:

• Debe proveerse un escape y aire fresco para hacer que el

aire que está dentro del área de atomización se mantenga

libre de acumulaciones de vapores inflamables.

• Evite todas las fuentes de ignición como son las chispas

electrostáticas, llamas abiertas, flamas de piloto, objetos

calientes, cigarros, y chispas que se generan al conectar

y desconectar las extensiones o de apagadores de luz

que estén funcionando.

• No fume en la zona de trabajo.

• Debe haber un equipo para extinguir incendios

permanentemente y en buenas condiciones.

• Coloque la bomba para pintar a un mínimo de 1 m (de

preferencia más) en una habitación aparte, bien ventilada,

alejada del objeto que va a pintar o a por lo menos 6 m

de dicho objeto, en una zona bien ventilada (utilice una

manguera más larga, si es necesario). Los gases

inflamables a menudo son más pesados que el aire. La

zona del piso debe tener la debida ventilación. La bomba

para pintar contiene piezas que forman arcos que emiten

chispas y pueden encender los gases.

• Siga las advertencias y avisos de seguridad del fabricante

de los materiales y solventes.

• Tenga muchísimo cuidado al usar materiales cuyo punto

de ignición sea inferior a 70° F (21° C). El punto de

ignición es la temperatura a la cual pueden encenderse

los vapores emanados por un fluido al exponerlos a

llamas o chispas.

• El plástico puede causar chispas estáticas. Nunca

cuelgue plástico en las ventanas ni en las puertas del

área donde va a pintar. No utilice plástico para proteger

el piso cuando pinte materiales inflamables.

PELIGRO: PELIGRO DE EXPLOSIÓN DEBIDO A

MATERIALES INCOMPATIBLES - Podría

causar lesiones severas o daños en la

propiedad.

PARA PREVENIR:

• No utilice materiales que contengan blanqueador o cloro.

• No use solventes con hidrocarburos halogenados, tales

como productos para eliminar el moho, cloruro de

metileno y 1,1,1 - tricloroetano. Estos no son compatibles

con el aluminio.

• Comuníquese con el proveedor del producto para obtener

información de compatibilidad con materiales de aluminio.

PELIGRO: GASES PELIGROSOS - Las pinturas, solventes,

insecticidas y otros materiales pueden ser

perjudiciales si se inhalan o entran en contacto

con el cuerpo. Los gases pueden causar

náusea, desmayos o envenenamiento graves.

PARA PREVENIR:

• Use una mascarilla respiratoria o careta siempre que

exista la posibilidad de que se puedan inhalar vapores.

Lea todas las intrucciones que vengan con la careta para

estar seguro de que se tendrá la protección necesaria

contra la inhalación de vapores dañinos.

• Use gafas protectoras.

• Use ropa de protección, según lo requiera el fabricante

del producto.

PELIGRO: QUEMADURA DE LA PIEL — Las piezas

calientes pueden causar lesiones de

quemadura de la piel severas.

PREVENCIÓN:

• Las conexiones de desconexión rápida de la manguera y

la pistola de atomización se llegan a calentar mientras se

usan. Evite que la piel tenga contacto con las conexiones

de desconexión rápida cuando se calienten. Deje que las

conexiones de desconexión rápida se enfríen antes de

desconectar la pistola de atomización de la manguera.

• El compresor se calienta durante el uso. Permita que el

compresor se enfríe antes de tocarlo.

PELIGRO: GENERAL - Puede causar daños en la

propiedad o lesiones severas.

PARA PREVENIR:

• Lea todas las instrucciones y advertencias de seguridad

antes de hacer funcionar cualquier equipo.

• Desconecte siempre el motor del suministro eléctrico

antes de dar servicio al equipo.

• Observe todos los códigos locales, estatales y nacionales

apropiados que rigen las medidas de ventilación,

prevención de incendios y operación.

• Los Estándares de Seguridad del Gobierno de los

Estados Unidos se han adoptado bajo el Acta de

Seguridad y Salud Ocupacionales (OSHA por sus siglas

en inglés). Deben consultarse estos estándares,

particularmente la parte 1910 de los Estándares

Generales y la parte 1926 de los Estándares de la

Construcción.

• Utilice únicamente piezas autorizadas por el fabricante.

El usuario asume todos los riesgos y responsabilidades si

usa piezas que no cumplen con las especificaciones

mínimas y dispositivos de seguridad del fabricante.

• El cable de alimentación debe enchufarse a un circuito

aterrado.

• Antes de usarla cada vez, revise todas las mangueras para

ver que no tengan cortadas, fugas, una cubierta desgastada

por abrasión o con abolladuras, así como uniones dañadas

o que se hayan movido. Si existiera cualquiera de estas

condiciones, reemplace la manguera inmediatamente. No

repare nunca una manguera. Reemplazar lo con una

manguera idéntica de reemplazo.

• No atomice en días con viento.

• Use ropa que evite el contacto de la pintura con la piel y

el cabello.

• NO dirija NUNCA la punta de la pistola hacia alguna parte

del cuerpo.

PELIGRO: EXPLOSION — El aire comprimido tiene una

gran fuerza y pudiera causar lesiones.

PREVENCION:

• El ensamble del tanque de presión está protegido con una

válvula de seguridad en caso de una sobre presurización.

Ocasionalmente jale la argolla de la válvula de seguridad

para asegurarse que la válvula opere libremente. En caso

de no operar con libertad o si la válvula no libera aire

cuando se jala la argolla, debe cambiarse.

• Nunca modifique el tanque de presión o el compresor.

• Nunca conecte otras herramientas de aire al compresor.

© Titan Tool Inc. All rights reserved. 7

Page 8

Instrucciones para conectar a tierra

PRECAUCION

Este producto se debe conectar a tierra. En caso de que

ocurra un corto circuito, la conexión a tierra reduce el riesgo

de choque eléctrico al proporcionar un alambre de escape

para la corriente eléctrica. Este producto está equipado con

un cable que tiene un alambre de conexión a tierra con un

enchufe de conexión a tierra apropiado. El enchufe se debe

enchufar en una toma de corriente que se haya instalado y

conectado a tierra debidamente, de acuerdo con todos los

códigos y estatutos locales.

PELIGRO — Una instalación inapropiada del enchufe de

conexión a tierra puede dar como resultado el que exista un

riesgo de choque eléctrico. Si es necesario reparar o

reemplazar el cable o el enchufe, no conecte el alambre de

conexión a tierra a ninguno de los terminales de hoja planos.

El alambre con aislamiento que tiene la superficie exterior de

color verde con franjas amarillas o sin ellas es el alambre de

conexión a tierra que debe conectarse al conector de conexión

a tierra.

Verifique con un electricista o técnico de servicio calificado si

las instrucciones para conectar a tierra no le han quedado

completamente claras, o si duda que el producto haya

quedado conectado a tierra de manera apropiada. No

modifique el enchufe que se proporciona. Si el enchufe no

entra en la toma de corriente, pídale a un electricista calificado

que instale la toma apropiada.

Este producto está diseñado para usarse en un circuito de 120

voltios nominales y el enchufe de conexión a tierra que tiene

se parece al enchufe que se ilustra a continuación. Si no

dispone de una toma de corriente con conexión a tierra, puede

usar un adaptador temporal que se asemeja al adaptador

ilustrado en la figura a continuación, para conectar este

enchufe en un receptáculo de 2 polos como se muestra.

El adaptador temporal solamente se debe utilizar hasta que un

electricista calificado instale debidamente una toma de

corriente con conexión a tierra. La patilla verde o alambre de

conexión a tierra que se extiende desde el adaptador se debe

conectar a tierra permanente, tal como la tapa de una caja de

distribución conectada a tierra. Cuando use el adaptador, debe

mantenerlo en su lugar con un tornillo metálico.

Tomacorriente aterrado

Terminal de tierra

Tapa de la caja del tomacorriente aterrado

Tornillo met lico

Use solamente extensiones trifilares que tengan un

enchufe de conexión a tierra de 3 hojas y un receptáculo

de triple ranura que acepte el enchufe del producto.

Asegúrese de que su extensión esté en buenas

condiciones. Cuando use una extensión, asegúrese de

usar una que sea lo suficientemente resistente como para

soportar la corriente que descargue su producto. Para

longitudes menos de 25 los pies, usan únicos un No. 16

AWG cable de extensión. Entre 25 y 50 pies, el calibre

mínimo es 12 AWG. Un cable de un tamaño menor

causará una caída de voltage en la línea que dará como

resultado una pérdida de energía y un sobrecalenta|ôento.

Si se utiliza un cable de extensión en el exterior, tiene que

estar marcado con el sufijo W-A después de la

designación del tipo de cable. Por ejemplo, SJTW-A para

indicar que el cable es apropiado para uso en exteriores.

Adaptador

Lengueta

del tornillo

de conexi n a tierra

8 © Titan Tool Inc. All rights reserved.

Page 9

3

1

2

11

4

7

5

6

8

2

9

10

11

12

13

14

15

16

18

17

19

20

21

To gun

Parts List

Main Assembly

Item Part # Description Quantity

1 773-914 Air hose.................................................1

2 770-543 Fitting, air, 1/4" male, quick connect.....2

3 773-927 Compressor ..........................................1

4 773-910 Cart .......................................................1

5 858-001 Washer..................................................4

6 763-551 Lock washer..........................................4

7 858-625 Screw....................................................4

8 0275640 Coupling, quick connect .......................1

9 770-544 Pressure gauge, 60 psi.........................1

10 227-027 Plug, 1/4” ..............................................1

11 773-937 Regulator ..............................................2

Item

12 770-541 Fitting, 1/4” x 1/8”..................................1

13 0277348 Hose, material (connects to gun) .........1

14 770-576 Valve, relief ...........................................1

15 770-575 Fitting, fluid ...........................................1

16 770-564 Lid .........................................................1

17 770-563 Tube, pick up ........................................1

18 773-760 Pot gasket.............................................1

19 770-535 Pot liner (optional) ................................1

20 773-938 Pot bottom ............................................1

21 773-913 Pressure pot assembly

Part # Description Quantity

(Includes Items 15, 16,17, 18, and 20)...1

© Titan Tool Inc. All rights reserved. 9

Page 10

2

1

3

4

5

6

7

8

10

12

13

14

15

16

17

18

4

5

19

20

21

22

23

24

11

9

Cart Assembly (P/N 773-910)

Item

1 770-708 Hole trim ...............................................1

2 773-902 Platform ................................................1

3 773-917 Screw....................................................4

4 860-004 Washer..................................................6

5 763-549 Nut ........................................................6

6 773-912 Leg, left.................................................1

7 335-018 Plug.......................................................2

8 0508144 Handle ..................................................1

9 590-508 Roll pin..................................................2

10 590-507 Snap button ..........................................2

11 773-918 Screw....................................................2

12 590-504 Sleeve...................................................2

Part #

Description Quantity

Item

13 590-506 Washer..................................................2

14 773-908 Pressure pot holder ..............................1

15 0279437 Cord wrap.............................................2

16 773-921 Screw....................................................4

17 856-921 Screw....................................................4

18 856-002 Washer..................................................4

19 590-203 Axle.......................................................1

20 570-010 Cotter pin ..............................................2

21 773-743 Spacer ..................................................2

22 773-952 Wheel....................................................2

23 870-004 Washer..................................................2

24 773-911 Leg, right...............................................1

Part # Description Quantity

10 © Titan Tool Inc. All rights reserved.

Page 11

Notes

© Titan Tool Inc. All rights reserved. 11

Page 12

Limited Warranty - High Volume, Low Pressure Spray Equipment

What Is Covered By This Warranty:

This product, manufactured by Titan Tool Inc., is warranted against defects in material and workmanship for one (1) year following

date of purchase if operated in accordance with Titan's printed recommendations and instructions.

Within the applicable warranty period, Titan tool Inc. will repair or replace, at our option, defective parts without charge if such

parts are returned with transportation charges prepaid to the nearest Authorized Service Center or to Titan Tool Inc.. If Titan Tool

Inc. is unable to repair this product as to conform to this Limited Warranty after a reasonable number of attempts, Titan Tool Inc.

will provide, at our option, either a replacement for this product or a full refund of the purchase price of this product. These

remedies are the sole and exclusive remedies available for breach of express and implied warranties.

What is Not Covered By This Warranty:

1. This Warranty does not cover any defects or damages caused by either:

a) the use or installation of repair or replacement parts or accessories not manufactured by Titan Tool Inc., or

b) repair performed by anyone other than a Titan Tool Inc. Authorized Service Center.

2. The Warranty does not cover equipment and accessories supplied to Titan Tool Inc. from an original equipment

manufacturer, including but not limited to: hoses, tips, or accessories. Titan Tool Inc. will provide the purchaser with copies of

the original equipment manufacturer’s express warranties provided to Titan Tool Inc. along with the name and address of the

appropriate manufacturer. In the case of the compressor, the manufacturer has extended the warranty — first year for parts

and service, second year on parts only.

3. This Warranty does not cover damage or defects caused by or related to abrasion, corrosion, abuse, misuse, negligence,

accident, normal wear, faulty installation or tampering in a manner which impairs normal operation.

Limitation of Remedies:

IN NO CASE SHALL TITAN TOOL INC. BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES OR

LOSS, INCLUDING TRANSPORTATION COSTS, WHETHER SUCH DAMAGES ARE BASED UPON A BREACH OF EXPRESS

OR IMPLIED WARRANTIES, BREACH OF CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER LEGAL THEORY.

Disclaimer Of Implied Warranties:

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABlLlTY AND FITNESS FOR A PARTICULAR PURPOSE.

No Ability To Transfer:

This warranty is extended to the original purchaser only and is not transferable.

Your Rights Under State Law:

Some states do not allow limitations on how long an implied warranty lasts or the exclusion of incidental or consequential

damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

National Sales & Service

1-800-526-5362

Fax 1-800-528-4826

556 Commerce Street

Franklin Lakes, NJ 07417

www.titantool.com

Canadian Branch

1-800-565-8665

Fax 1-905-856-8496

200 Trowers Road, Unit 7B

Woodbridge, L4L 5Z8

12 © Titan Tool Inc. All rights reserved.

International

1-201-405-7520

Fax 1-201-405-7449

556 Commerce Street

Franklin Lakes, NJ 07417 USA

www.titan-tools.com

Loading...

Loading...