Page 1

Owner’s Manual

For professional use only

ProFinish Gun

Model Number 773-300

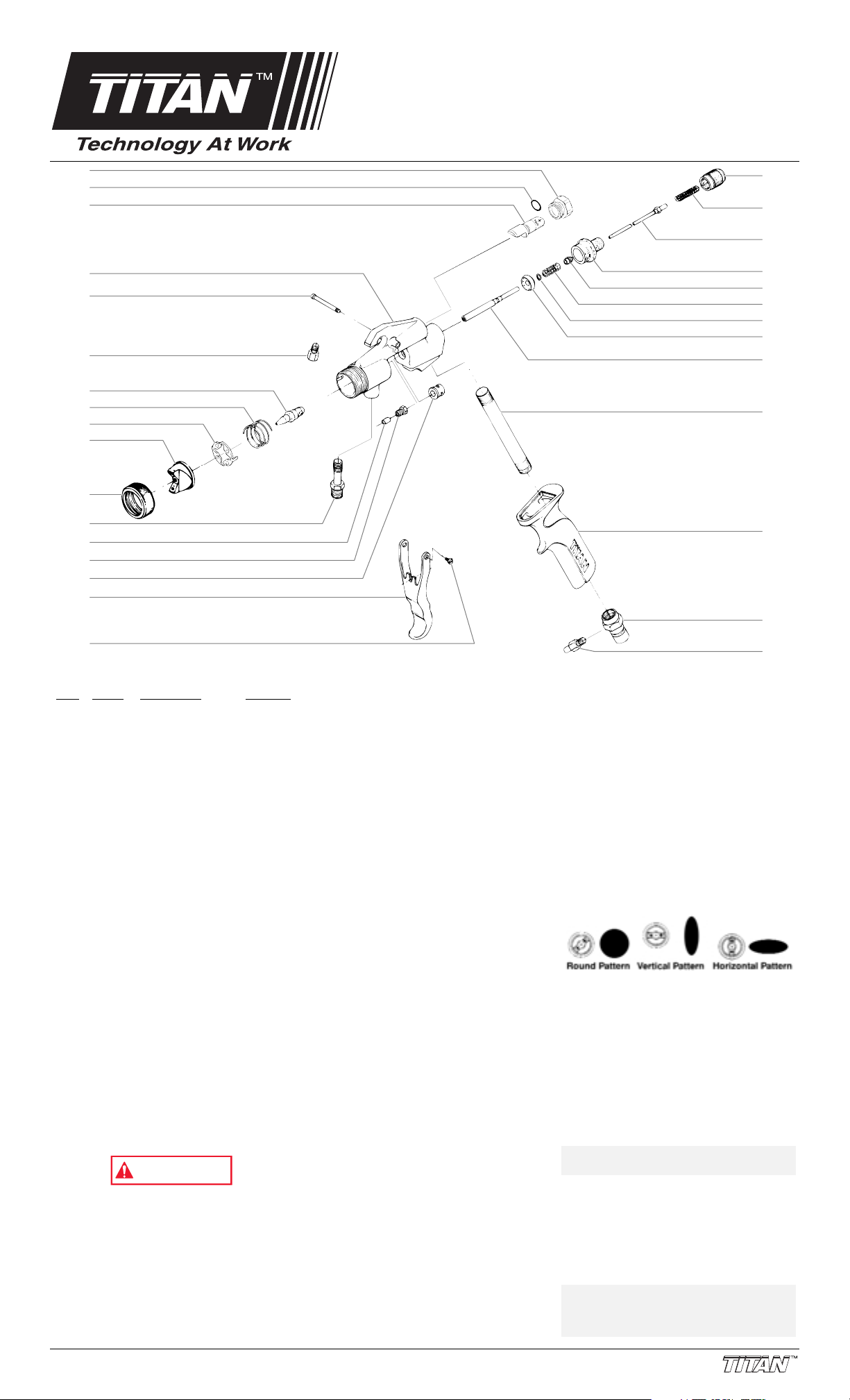

10

11

12

13

14

15

16

1

18

2

3

19

20

4

5

21

22

23

24

25

6

26

7

8

27

9

28

29

17

Parts List

Item Part # Description Quantity

1 773-068 Air valve housing...................1

2 761-722 O-ring ....................................1

3 773-067 Air valve ................................1

4 773-170 Head......................................1

5 580-018 Pivot pin ................................1

6 770-179 Plug .......................................1

7 773-128 Fluid nozzle “.051”.................1

8 773-168 Air cup spring ........................1

9 773-132 Spring plate ...........................1

10 773-156 Air cap “O”.............................1

11 773-003 Retaining ring ........................1

12 490-112 Fluid fitting.............................1

13 773-005 Packing..................................1

14 773-095 Retainer.................................1

15 773-031 Stem gland ............................1

16 773-033 Trigger...................................1

17 580-019 Pivot screw............................1

18 773-017 Adjustment knob ...................1

19 773-019 Needle spring ........................1

20 773-148 Needle assembly...................1

21 773-016 Fluid housing.........................1

22 773-020 Spring bushing ......................1

23 773-021 Trigger spring ........................1

24 773-028 Retaining clip.........................1

25 773-029 Trigger valve .........................1

26 773-027 Trigger stem ..........................1

27 773-023 Air supply tube ......................1

28 773-167 Handle...................................1

29 773-026 Pipe adapter..........................1

30 770-178 Fitting.....................................1

31 773-153 Needle/nozzle set

(includes items 7 and 20)......1

32 773-134 HVLP tool (not shown) ..........1

33 773-135 Brush (not shown).................1

34 313-1078 Label, fan adjustment

(not shown) ...........................1

Safety Precautions

WARNING

Do not use equipment before reading this

section

Never operate this unit unless it is properly

grounded. A fire or explosion hazard is

present when spraying flammable materials.

Please read and understand the following

steps to assure safe operation of your

sprayer.

1. Always keep spray area well ventilated.

Always keep the turbine a minimum of 20

feet from spray activity.

Form No. 313-1079, REV B © 2000 Titan Tool Inc. All rights reserved. 1

2. Always follow the coating or solvent

manufacturer’s safety precautions and

warnings.

3. Never spray flammable materials near

open flames, pilot lights or any other

source of ignition.

4. Always wear spray masks and protective

eye wear while spraying.

5. Never alter or modify any part of this

equipment; doing so could cause it to

malfunction.

6. Never attempt to service or disassemble

the turbine while it is plugged in.

7. Never attempt to clean the exterior of the

turbine while plugged in. CAUTION: TO

REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT EXPOSE TO RAIN –

STORE INDOORS

8. Never point the spray gun at anyone or

any part of the body.

9. Never leave equipment unattended. Keep

away from children or anyone not familiar

with the operation of spray equipment.

10. Never remove lid of pressure pot without

relieving pressure first.

11. Never exceed 50 psi in pressure pot.

12. Do not use halogenated hydrocarbons in

Titan equipment.

Startup Procedures

Prepare the Paint

1. Prepare the material to be sprayed

according to paint manufacturers

recommendations.

2. Strain the paint before each use (cone

strainer P/N 770-119 provided).

3. Thin the material to be sprayed with the

recommended solvent. Most materials

need to be thinned to obtain spraying

consistency. To achieve the proper

viscosity for spraying, either a viscosity

cup can be used or trial and error.

4. If a viscosity cup is not available, thin the

materials to a point where you will achieve

a one second interval between drops after

a paint stick has been inserted and

removed from paint.

Gun and Turbine Set-Up

1. With the turbine switch in the off position,

plug into a grounded outlet at least 20 feet

from spray activity.

2. Attach air atomizing hose to turbine.

30

3. Attach the quart cup to the gun and attach

the tube from the gun to the cup. Attach

the air hose to the bottom of the gun.

Make sure that everything is secure before

spraying.

Spray Gun Adjustments

The “ProFinish” gun comes equipped with a

.051 fluid nozzle and needle and our “#0”

medium air cap. Always test your spray pattern

on a test surface before you begin to work.

1. Fan size adjustment is controlled by

turning the air cap retainer ring. Clockwise

will increase fan width, counterclockwise

will decrease fan width.

2. The top knob controls the air volume.

Clockwise will decrease air flow.

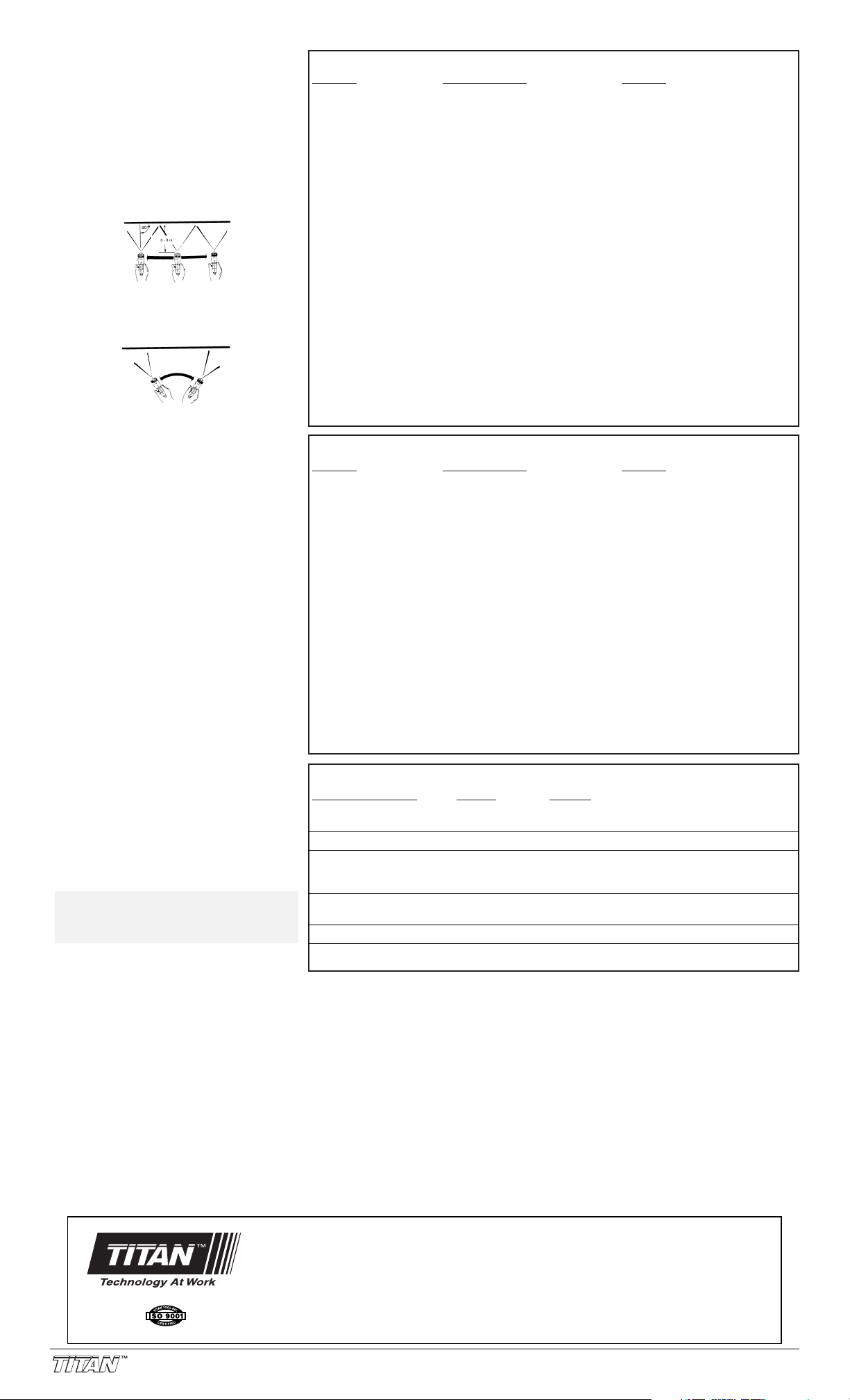

3. A round, horizontal or vertical fan pattern

can be achieved by rotating the air cap as

shown by the diagrams below.

4. A round pattern will require less material

flow than a wide pattern. Turning the lower

knob clockwise will decrease fluid flow;

counter-clockwise will increase fluid flow.

Fluid Nozzle / Needle / Air Cap

Selection

If after all of the appropriate adjustments are

made poor results are obtained, it may be

necessary to change to a different fluid nozzle /

needle or air cap. Refer to our selection chart to

match the appropriate components to the

material being sprayed.

NOTE: The smaller the nozzle size the

greater atomization.

1. To change fluid nozzle and tip remove air

cap (10) and retaining ring (11).

2. Squeeze trigger and with a wrench remove

fluid nozzle (7, use HVLP tool P/N 773134, supplied).

3. Remove adjustment knob (18). Remove

needle spring (19) and needle (20).

Reassemble in reverse order 1 – 3.

NOTE: Never use lubricants containing

silicones. Silicones will adversely

affect spray finishes and is difficult

to remove once on equipment.

Page 2

Application Techniques

The following techniques are recommended to

assure professional painting results. Hold the gun

perpendicular to the surface and always at an

equal distance of approximately 6”-8”.

Move the gun either across or up and down the

surface at a steady rate. Moving the gun at a

consistent speed provides even coverage. The

correct spraying speed allows for a full wet coat

of material without runs or sags. Do not angle the

gun as this will cause uneven paint build-up, runs

or sags. Begin movement of the gun before the

trigger is pulled.

RIGHT

Proper lapping (overlap of spray pattern) is

essential to an even finish. Overlap your strokes

about 50%.

WRONG

Problem Probable Cause

Orange Peel Material is too viscous Thin Material

Runs and Sags Too much solvent Add material

Blushing Fast drying thinner Add retarder

Pin Holing and

Solvent Pops Trapped solvents Reduce fluid flow and apply

Blistering Surface not primed properly Use appropriate primer

Coarse Finish Improper cleaning of surface Clean immediately before

Troubleshooting — Finish Problems

Cleaning Procedures

The Titan ProFinish system has been constructed

with the finest materials to assure trouble free

operation and durability. However, like any paint

tool, proper cleaning is essential for optimum

performance to be maintained. Always clean

thoroughly after each use.

1. Pour remaining material in the quart cup

back into the original container. For single

component materials ONLY. For catalyzed

material, consult coating manufacturer's

recommendation.

2. Pour a small amount of the appropriate

solvent for the type of material you are

spraying into the cup. Swirl the solvent

around in the cup and empty.

3. Thoroughly clean the interior of the cup and

wipe dry.

4. Pour a small amount of solvent into the cup

and spray through the gun to clean fluid

nozzle and needle.

5. After extended use, it might be necessary to

remove the fluid nozzle, needle, and air cap

to clean by hand, with a soft brush. (P/N

770-118, provided). Do not use a wire brush

or hard tools that could damage the

components. Also clean the inside of the

gun with solvent and a soft brush.

Reassemble gun and test with mineral

spirits.

6. Clean the exterior of the gun using solvent.

NEVER soak the gun in solvent. Some

solvents can damage the internal seals.

7. Check filter on turbine, clean or replace.

(Never use solvent to clean turbine filter,

blow clean with compressed air or replace.)

NOTE: If service is required on the turbine,

refer to the service center listing

enclosed or call 1-800-526-5362 for

assistance.

Please dispose of cleaning solvent and unused

coatings in an environmentally safe fashion.

Consult with material manufacturer on proper

procedure.

Problem Probable Cause Solution

Paint will not Flow 1) Blockage in fluid nozzle 1) Clean or replace

Inconsistent Spray 1) Running out of paint 1) Fill cup or pot

Pattern (Spits and 2) Loose fluid tube 2) Tighten

Sputters) 3) Loss of fluid pressure 3) Search for air leaks or

Leakage at 1) Damaged fluid needle 1) Replace

Front of Gun 2) Wrong size fluid needle 2) Replace

Distorted Spray 1) Dirty air cap 1) Clean or replace

Pattern 2) Damaged fluid nozzle or 2) Replace

Fluid Needle/Nozzle Air Cap Material

Size Part No. Size Part No. Consult paint manufacturers for proper thinning

.029 773-151 #3 773-159 Acrylic lacquers, stains, dyes

.043 773-152 #2 773-158 Waterborn clears, epoxy, polyurethanes,

.051 773-153 #0 773-156 Full bodied stains, alkyd enamels, water born

.073 773-154 #1 773-157 Finish grade latexes, alkyd wall paints

.118 773-155 #4 773-160 Heavy-bodied multi-color or textured coatings

Warranty

Titan Tool, Inc., (“Titan”) warrants that at the time of delivery to the original

purchaser for use (“End User”), the equipment covered by this warranty is free

from defects in material and workmanship. Titan’s obligation under this warranty is

limited to replacing or repairing without charge those parts which, to Titan’s

reasonable satisfaction, are shown to be defective within twelve (12) months after

sale to the End User. This warranty applies only when the unit is installed and

operated in accordance with the recommendations and instructions of Titan.

This warranty does not apply in the case of damage or wear caused by abrasion,

corrosion or misuse, negligence, accident, faulty installation, substitution of nonTitan component parts, or tampering with the unit in a manner to impair normal

operation.

Defective parts are to be returned to an authorized Titan sales/service outlet. All

transportation charges, including return to the factory, if necessary, are to be borne

and prepaid by the End User. Repaired or replaced equipment will be returned to

the End User transportation prepaid.

Solution

Consult coating

manufacturer

Improper solvent Use recommended solvent

Insufficient atomizing air Change to a smaller air cap

Gun too close to surface Reduce flow by turning yellow

Wrong fluid nozzle & needle Replace. See chart below

Insufficient atomization Thin material or use a smaller

Surface moisture Dry

recommendations

Consult coating

manufacturer

recommendations

See chart below

regulator knob counterclockwise. Move further from the

surface.

lighter coats. Use faster

solvent

air cap

See chart below

spraying

Troubleshooting — Gun

2) Loss of air pressure in 2) Search for air leaks in air hose

cup and sealing gasket

3) Dirty or stuck one way valve 3) Clean or replace

4) Loose fluid nozzle 4) Tighten

5) Paint tubes loose or 5) Tighten or replace

damaged

6) Coating is too thick 6) Thin the coating

blockages

3) Dirty fluid nozzle 3) Clean

4) Loose fluid nozzle 4) Tighten

needle

3) Fluid nozzle partially 3) Clean

clogged

Selection Chart

recommendations.

automotive, base coat, acrylic urethanes and

enamels

enamels

THERE IS NO OTHER EXPRESS WARRANTY. TITAN HEREBY DISCLAIMS

ANY AND ALL IMPLIED WARRANTIES INCLUDING, BUT NOT LIMITED TO,

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, TO THE EXTENT PERMITTED BY LAW. THE DURATION OF ANY

IMPLIED WARRANTIES WHICH CANNOT BE DISCLAIMED IS LIMITED TO THE

TIME PERIOD SPECIFIED IN THE EXPRESS WARRANTY. IN NO CASE SHALL

TITAN LIABILITY EXCEED THE AMOUNT OF THE PURCHASE PRICE.

LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES

UNDER ANY AND ALL WARRANTIES IS EXCLUDED TO THE EXTENT

PERMITTED BY LAW.

TITAN MAKES NO WARRANTY AND DISCLAIMS ALL IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH

RESPECT TO ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS

SOLD BUT NOT MANUFACTURED BY TITAN. THOSE ITEMS SOLD, BUT NOT

MANUFACTURED BY TITAN (SUCH AS GAS ENGINES, SWITCHES, HOSES,

ETC.) ARE SUBJECT TO THE WARRANTY, IF ANY, OF THEIR

MANUFACTURER. TITAN WILL PROVIDE THE PURCHASER WITH

REASONABLE ASSISTANCE IN MAKING ANY CLAIM FOR BREACH OF THESE

WARRANTIES.

National Sales & Service

1-800-526-5362

Fax 1-800-528-4826

556 Commerce Street

Franklin Lakes, NJ 07417

www.titantool.com

Canadian Branch

1-800-565-8665

Fax 1-905-856-8496

200 Trowers Road, Unit 7B

Woodbridge, L4L 5Z8

International

1-201-405-7520

Fax 1-201-405-7449

556 Commerce Street

Franklin Lakes, NJ 07417 USA

www.titan-tools.com

2 Form No. 313-1079, REV B © 2000 Titan Tool Inc. All rights reserved.

Loading...

Loading...