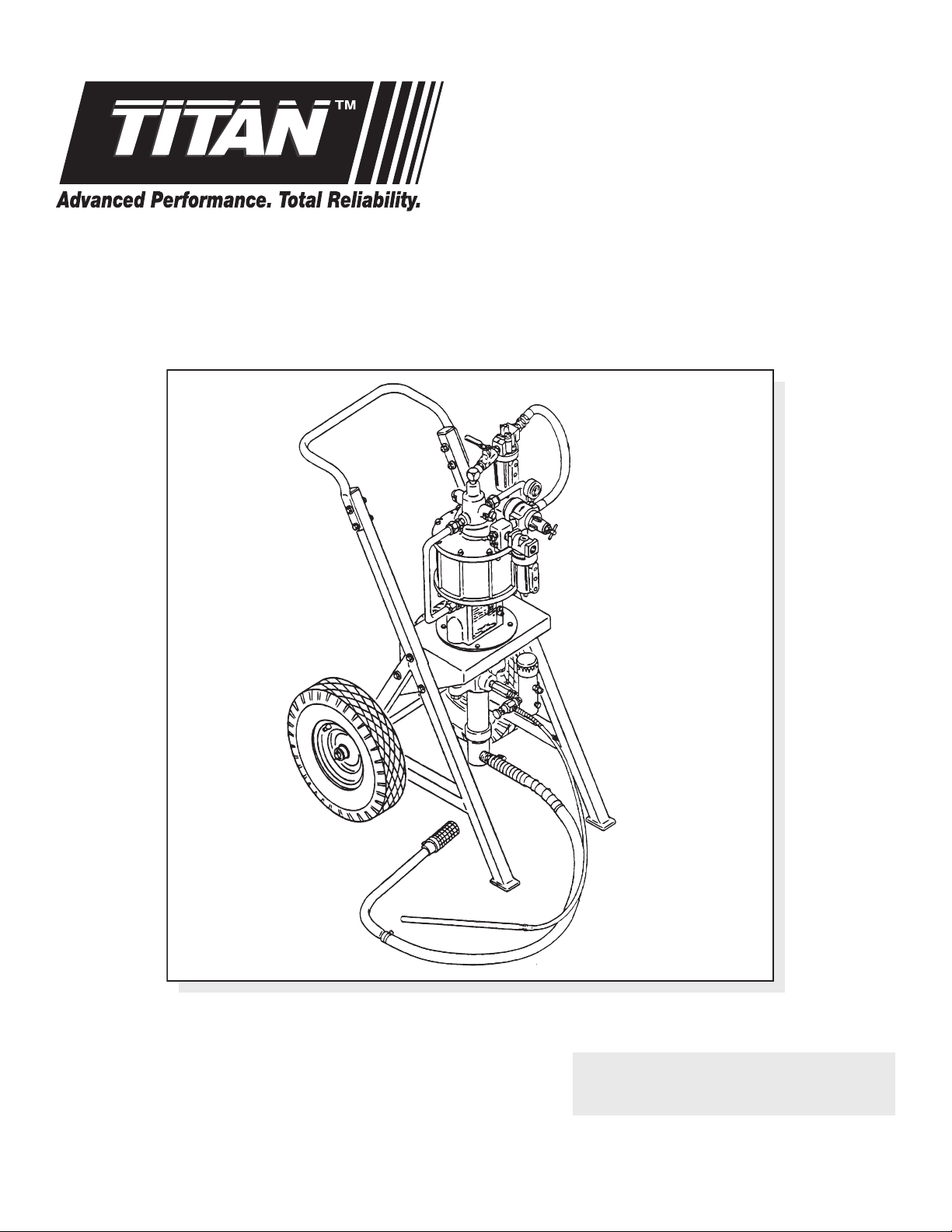

Page 1

Owner’s Manual

For professional use only

Do not use this equipment

before reading this manual!

SPEEFLO Commander

Air Powered Airless Sprayer

Model Numbers:

741-440

761-301

761-411

741-331

Printed in the U.S.A.

NOTE: This manual contains important

warnings and instructions. Please

read and retain for reference.

1014 • © Titan Tool Inc. All Rights Reserved. Form No. 0528924D

Page 2

Important Safety Information · Read all safety information before

operating the equipment. SAVE THESE INSTRUCTIONS.

This symbol indicates a hazardous situation,

which, if not not avoided could result in death or

serious injury.

To reduce the risks of fire or explosion, electrical

shock and the injury to persons, read and

understand all instructions included in this manual.

Be familiar with the controls and proper usage of

the equipment.

HAZARD: INJECTION INJURY

A high pressure paint stream produced by this

equipment can pierce the skin and underlying

tissues, leading to serious injury and possible

amputation. See a physician immediately.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE

CUT! Injection can lead to amputation. See a physician

immediately.

PREVENTION:

• NEVER aim the gun at any part of the body.

• Do not aim the gun at, or spray any person or animal.

• NEVER allow any part of the body to touch the uid stream.

DO NOT allow body to touch a leak in the uid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the pump off, and

release all pressure before servicing, cleaning the tip or

guard, changing tip, or leaving unattended. Pressure will

not be released by turning off the motor. The PRIME/

SPRAY valve or pressure bleed valve must be turned to

their appropriate positions to relieve system pressure.

Refer to the PRESSURE RELIEF PROCEDURE

described in this manual.

• ALWAYS keep the tip guard in place while spraying. The

tip guard provides some protection but is mainly a warning

device.

• ALWAYS remove the spray tip before ushing or cleaning

the system.

• Paint hose can develop leaks from wear, kinking and

abuse. A leak can inject material into the skin. Inspect

the hose before each use. Do not use hose to lift or pull

equipment.

• NEVER use a spray gun without a working trigger lock and

trigger guard in place.

• All accessories must be rated at or above the maximum

spraying pressure of the unit. This includes spray tips,

guns, extensions, and hose.

• Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn off the unit and

relieve the pressure in accordance with the PRESSURE

RELIEF PROCEDURE described in this manual.

• Verify that all connections are secure before operating the

unit. Unsecured parts may eject at great force or leak a

high pressure uid stream causing severe injury.

• Always engage the trigger lock when not spraying. Verify

the trigger lock is functioning properly.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is

important to treat the injury as soon as possible. DO

NOT delay treatment to research toxicity. Toxicity is a

concern with some coatings injected directly into the

blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials

can be harmful if inhaled or come in contact with the

body. Vapors can cause severe nausea, fainting, or

poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be

inhaled. Read all instructions supplied

with the mask to be sure it will provide the

necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite.

Property damage and/or severe injury can occur.

PREVENTION:

• Provide extensive exhaust and fresh air

introduction to keep the air within the spray area free from

accumulation of ammable vapors. Solvent and paint

fumes can explode or ignite.

• Do not spray in a conned area.

• Avoid all ignition sources such as static electric sparks,

open ames, pilot lights, electrical appliances, and hot

objects. Connecting or disconnecting power cords or

working light switches can make sparks. Paint or solvent

owing through the equipment is able to result in static

electricity.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

order.

• Place pump at least 25 feet (7.62 meters) from the

spray object in a well ventilated area (add more hose if

necessary). Flammable vapors are often heavier than air.

Floor area must be extremely well ventilated. The pump

contains arcing parts that emit sparks and can ignite vapors.

• The equipment and objects in and around the spray area

must be properly grounded to prevent static sparks.

• Keep area clean and free of paint or solvent containers,

rags and other ammable materials.

• Use only conductive or grounded high pressure uid hose.

Gun must be grounded through hose connections.

• For electric units — power cord must be connected to a

grounded circuit.

• Always ush unit into a separate metal container, at low

pump pressure, with spray tip removed. Hold gun rmly

against side of container to ground container and prevent

static sparks.

• Follow the material and solvent manufacturer’s warnings

and instructions. Know the contents of the paints and

solvents being sprayed. Read all Material Safety Data

Sheets (MSDS) and container labels provided with

the paints and solvents. Follow the paint and solvent

manufacturer’s safety instructions.

• Use extreme caution when using materials with a

ashpoint below 100ºF (38ºC). Flashpoint is the

temperature that a uid can produce enough vapors to

ignite.

• Plastic can cause static sparks. Never hang plastic to

enclose a spray area. Do not use plastic drop cloths when

spraying ammable materials.

• Use lowest possible pressure to ush equipment.

• Do not spray onto pump assembly.

2 © Titan Tool Inc. All rights reserved.

English

Page 3

Important Safety Information · Read all safety information before

operating the equipment. SAVE THESE INSTRUCTIONS.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS

Will cause property damage or severe injury.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such

as bleach, mildewcide, methylene chloride and 1,1,1 trichloroethane. They are not compatible with aluminum.

• Contact your coating supplier about the compatibility of

material with aluminum.

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before

operating equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, re prevention, and operation.

• The United States Government Safety Standards have

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards should be consulted.

• Use only manufacturer authorized parts. User assumes

all risks and liabilities when using parts that do not meet

the minimum specications and safety requirements of the

pump manufacturer.

• All hoses, ttings, and lter parts must be secured before

operating spray pump. Unsecured parts can eject at great

force or leak a high pressure uid stream causing severe

injury.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a paint hose. Replace it with

another grounded high-pressure hose.

• Do not kink or over-bend the hose. Airless hose can

develop leaks from wear, kinking and abuse. A leak can

inject material into the skin.

• Do not expose the hose to temperatures or pressures in

excess of those specied by manufacturer.

• Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

• Do not operate or spray near children. Keep children

away from the equipment at all times.

• Do not overreach or stand on an unstable support. Keep

effective footing and balance at all times.

• Use lowest possible pressure to ush equipment.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the

inuence of drugs or alcohol.

• For electric units — Always unplug cord from outlet before

working on equipment.

• Do not use the hose as a strength member to pull or lift the

equipment.

• Do not lift by cart handle when loading or unloading.

Grounding Instructions

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product is

equipped with a cord having a grounding wire with an appropriate

grounding plug. The plug must be plugged into an outlet that

is properly installed and grounded in accordance with all local

codes and ordinances.

WARNING - Improper installation of the grounding plug can

result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green grounding wire to either at blade terminal.

The wire with insulation having a green outer surface with

or without yellow stripes is the grounding wire and must be

connected to the grounding pin.

Check with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt

as to whether the product is properly grounded. Do not modify

the plug provided. If the plug will not t the outlet, have the

proper outlet installed by a qualied electrician.

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

IMPORTANT: Use only a 3-wire extension cord that has

a 3-blade grounding plug and a 3-slot receptacle that will

accept the plug on the product. Make sure your extension

cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and overheating. A 12

gauge cord is recommended. If an extension cord is to be

used outdoors, it must be marked with the suffix W-A after

the cord type designation. For example, a designation of

SJTW-A would indicate that the cord would be appropriate

for outdoor use.

© Titan Tool Inc. All rights reserved. 3

Page 4

Table of Contents

Safety Precautions ................................................................... 2

Grounding Instructions ........................................................ 3

Specications ........................................................................... 4

Introduction ............................................................................... 5

Setup .......................................................................................... 6

Startup ................................................................................. 7

Operation ................................................................................... 8

Pressure Relief Procedure .................................................. 7

Cleaning a Clogged Tip ....................................................... 8

Color Change / Clean Out ................................................... 8

Air Motor Maintenance ........................................................ 9

Fluid Pump Maintenance..................................................... 9

Troubleshooting ..................................................................... 10

Airless Spraying ................................................................ 10

Spray Patterns................................................................... 10

Air Motor ............................................................................ 11

Fluid Sections .................................................................... 11

Parts Lists and Service Instructions .................................... 12

Commander™ Series Portable Models ............................. 12

Commander™ Series Wall Mount and

Drum Mount Models .......................................................... 14

Air Motors .......................................................................... 16

Fluid Pump, 140-556 ......................................................... 18

Fluid Pump, 155-559 ......................................................... 20

Fluid Pump, 181-556 ......................................................... 22

Fluid Pump, 185-551 ......................................................... 24

Fluid Pump, 245-555 ......................................................... 26

Air Assembly ..................................................................... 28

Heavy Duty Cart ................................................................ 29

Pump Mount Drum Cover.................................................. 30

Pump Mounts .................................................................... 31

920 Outlet Manifold Filter Assembly.................................. 32

Fluid Accessories .............................................................. 34

Outlet Accessories ............................................................ 37

Accessories and Service Kits ............................................... 38

Warranty .................................................................................. 40

Specications

20:1

Gallons per minute (GPM) ............. 6.0

Liters per minute (LPM) ................. 22.7

Cycle rate per gallon...................... 13

Cycle rate per liter ......................... 3.4

Maximum tip size @2000 psi ........ 0.65”

Pressure ratio ................................ 20:1

Maximum pressure ........................ 2000 psi (20.7 MPa, 138 bar)

Fluid inlet ....................................... 1 1/4” NPT(F)

Fluid outlet ..................................... 3/4” NPT(F)

Hose connection ............................ 1/2” NPT(F)

Approximate air requirement

per gallon of output @ 100 psi

air pressure.................................... 17 SCFM (0.48m3/min)

Air inlet ......................................... 1/2” NPT (F)

30:1

Gallons per minute (GPM) ............. 4.0

Liters per minute (LPM) ................. 15.1

Cycle rate per gallon...................... 20

Cycle rate per liter ......................... 5.3

Maximum tip size @2000 psi ........ 0.55”

Pressure ratio ................................ 30:1

Maximum pressure ........................ 3000 psi (20.7 MPa, 207 bar)

Fluid inlet ....................................... 1” NPT(F)

Fluid outlet ..................................... 3/4” NPT(F)

Hose connection ............................ 1/4” NPSM (M)

Approximate air requirement

per gallon of output @ 100 psi

air pressure.................................... 28 SCFM (0.79m

Air inlet ......................................... 1/2” NPT (F)

3

/min)

45:1

Gallons per minute (GPM) ............. 2.6

Liters per minute (LPM) ................. 9.8

Cycle rate per gallon...................... 30

Cycle rate per liter ......................... 7.9

Maximum tip size @2000 psi ........ 0.47”

Pressure ratio ................................ 45:1

Maximum pressure ........................ 4500 psi (27.6 MPa, 276 bar)

Fluid inlet ....................................... 1” NPT(F)

Fluid outlet ..................................... 1/2” NPT(F)

Hose connection ............................ 1/4” NPSM (M)

Approximate air requirement

per gallon of output @ 100 psi

air pressure.................................... 40 SCFM (1.13m3/min)

Air inlet ......................................... 1/2” NPT (F)

60:1

Gallons per minute (GPM) ............. 2.0

Liters per minute (LPM) ................. 7.6

Cycle rate per gallon...................... 40

Cycle rate per liter ......................... 10.6

Maximum tip size @2000 psi ........ 0.43”

Pressure ratio ................................ 60:1

Maximum pressure ........................ 6000 psi (41.4 MPa, 414 bar)

Fluid inlet ....................................... 3/4” NPT(F)

Fluid outlet ..................................... 1/2” NPT(F)

Hose connection ............................ 1/4” NPSM (M)

Approximate air requirement

per gallon of output @ 100 psi

air pressure.................................... 52 SCFM (1.47m3/min)

Air inlet ......................................... 1/2” NPT (F)

4 © Titan Tool Inc. All rights reserved.

Page 5

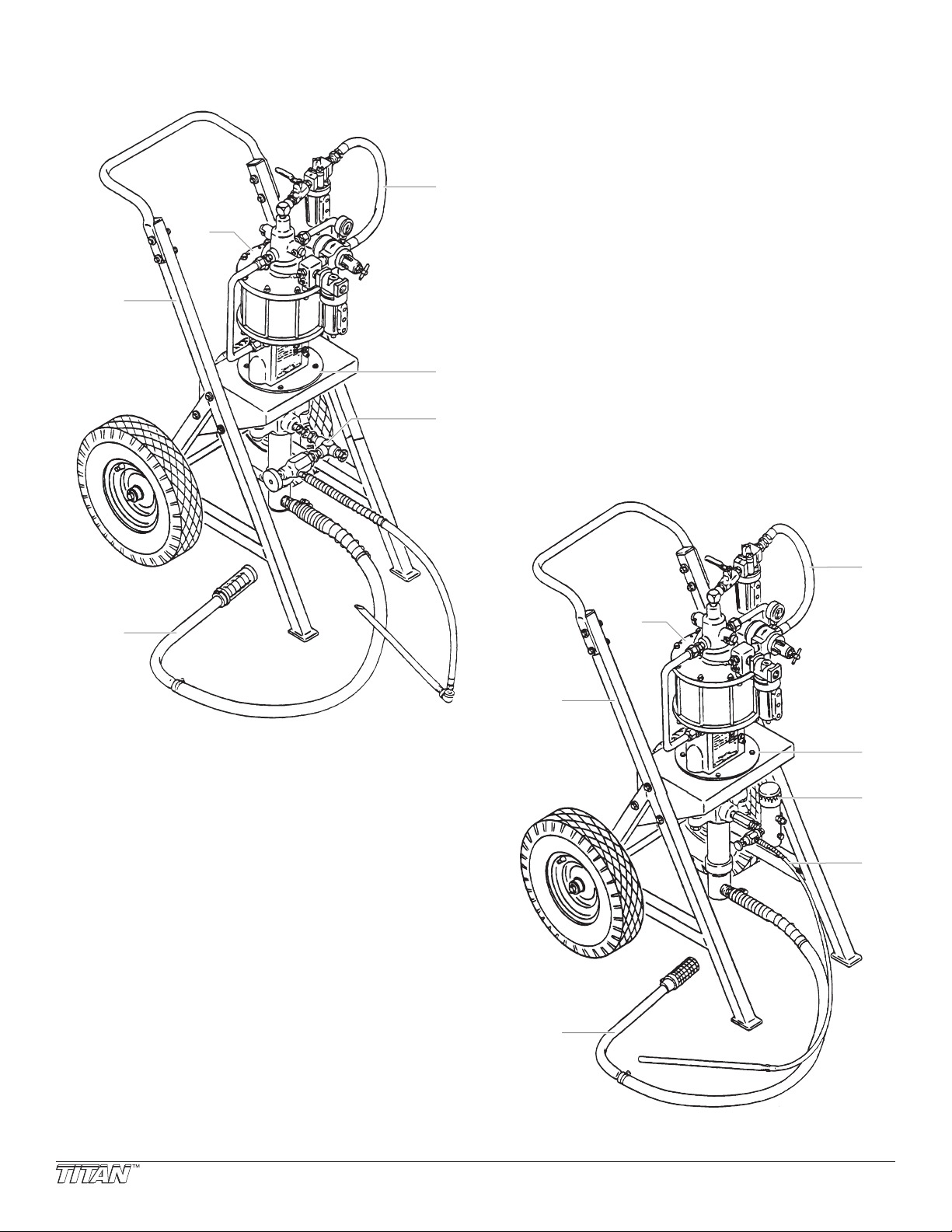

Introduction

Congratulations on having selected the nest airless sprayer

available in the world. This Commander™ represents the latest

in airless technology. Its ability to efciently apply a wide range

of coatings makes it an excellent buy. We thank you for your

purchase and welcome you to our large and growing family of

Titan Speeo users.

Titan pumps are proven performers for all types of jobs. There

are models for virtually any application, including architectural,

nishing, industrial maintenance, corrosion control, cold applied

roong, waterproong and marine protective coatings. More than

75,000 Titan pumps are in operation around the world, providing

their owners with dependable, efcient operation.

Pumps are specically designed for easy application of today’s

low VOC, high solids and abrasive coatings.

Standard features assure superior reliability. Famous Titan

Severe Service™ paint pumps and high efciency air motors are

standard on all models.

Severe Service paint pumps mean twice the life, half the

maintenance.

• Hard-chrome precision polished rods and cylinders give

maximum abrasion and corrosion resistance with minimum

friction. Result: long life.

• Tungsten carbide valve seats with hardened stainless

steel check balls prevent uid cutting and resist plugging.

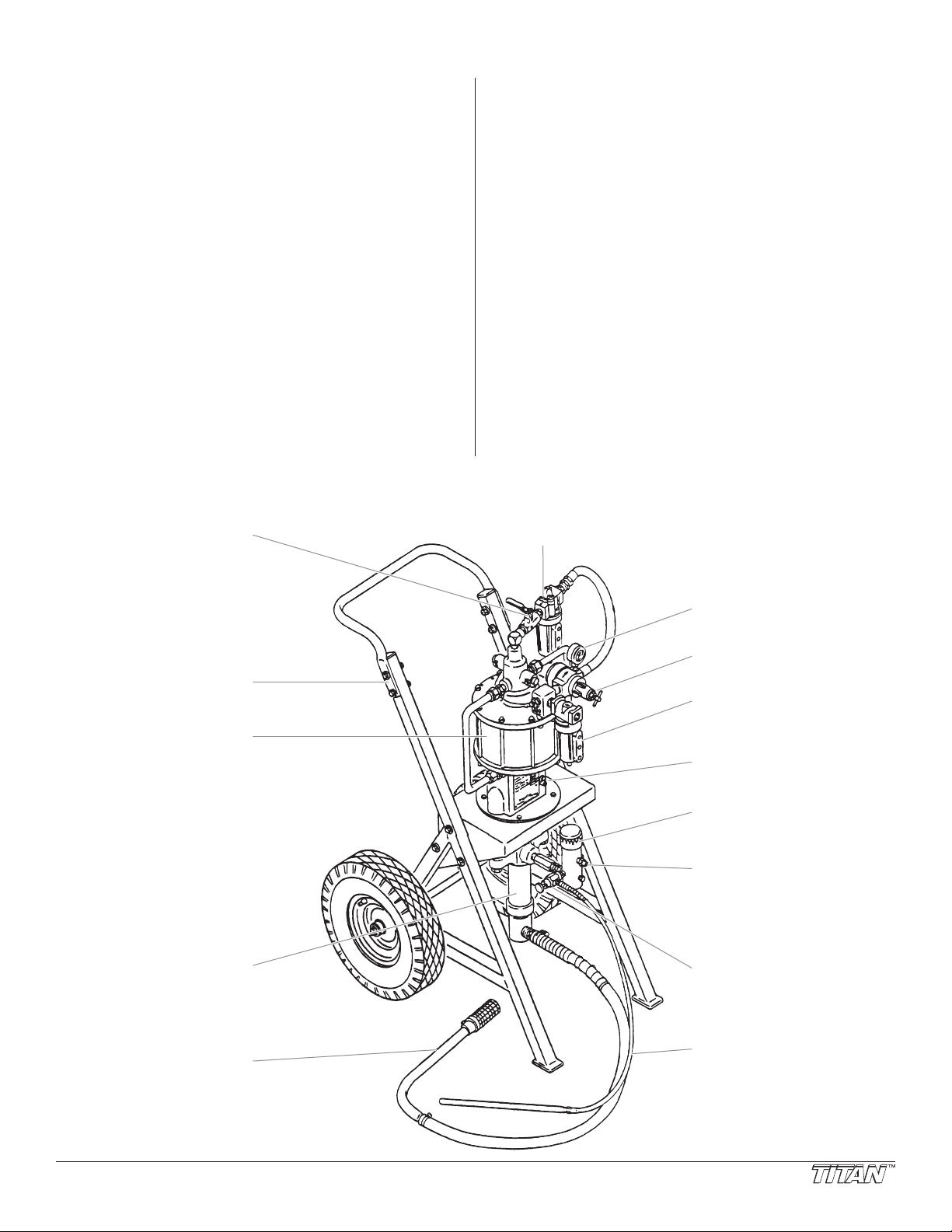

Commander™ Series

Vented shutoff valve

Long-Life Packings are also standard.

• Self adjusting, pressure compensated spring loaded

packings ensure proper seal and long life.

• Standard packing sets of leather and UHMWPE (ultra

high molecular weight polyethylene) provide the industry’s

longest packing life.

• Wiper seal on lower packings keeps abrasive materials

from hardening on cylinder wall.

• Alternate packing materials are available fro specialized

applications.

Standard air motor features include:

High-efciency -

• Maximum output per cubic foot of air input.

• More work with less air than competitive air motors.

No motor icing -

• Continuous operation without icing even at high cycle

rates.

• Oversized valving and exhaust porting.

You have made an excellent choice. We know you will be

pleased with your new Commander™. Thanks again for

selecting Titan. We appreciate your business.

Automatic

lubricator

Cart assembly

Air motor

Fluid pump

Siphon hose

Air pressure gauge

Air regulator

Air filter /

moisture separator

Grounding lug

Paint filter

Gun hose connection

Pressure bleed

valve

Bleed line

© Titan Tool Inc. All rights reserved. 5

Page 6

Setup

The flow from the spray tip is at very high pressure.

Contact with any body part may be dangerous. Do

not place finger on gun outlet. Do not point the

gun at any person.

Read, understand, and follow all warnings before

starting or operating this sprayer.

Required tools: Crescent wrench and screwdriver

1. Compressor Requirements:

Consult the Technical Specications on each model for

the approximate air requirements.

NOTE: The requirements will vary on each model.

Proper grounding in important. This applies to

gas, electric and air powered models. The passage

of some materials through the nylon hose will build

up a static electric charge, which if discharged,

could ignite solvent vapors present and create an

explosion.

2. Grounding the pump:

Be sure the Commander™ system is grounded. All Titan

units are equipped with a grounding lug. A Grounding

Clamp, Part No. 101-208 and Ground Wire, Part No.

101-212 should be used to connect the unit to a true earth

ground. These accessories can be ordered from your

local distributor.

a. Loosen the Grounding Screw.

b. Insert one end of the Grounding Wire into the slot in the

Grounding Lug. Tighten the screw.

c. Connect the other end of the Grounding Wire to a true

earth ground. Check local electrical regulations for

detailed grounding instructions.

5. Connecting the paint hoses:

The siphon hose and the bleed line hose have factory

installed PTFE tape on the male end of the hoses.

Tigthen the siphon hose and bleed line wrench tight.

6. One Gun Operation:

Attach the gun and hose. Always use a spray hose at

least 50 feet long. Do not use PTFE or thread sealant on

this assembly. Do not install the spray tip.

7. Multiple Gun Operation:

For models equipped with a second gun outlet, remove

the plug from the outlet and connect a second hose and

gun to the outlet.

Multigun manifolds with shut-off valves can be used when

more than two guns are needed. Never use this second

gun outlet for a one-gun operation.

For guns without a second gun outlet, connect a multi-

gun manifold at the single gun outlet. These manifolds

are either 2, 3, or 4 gun manifolds with shut-off valves.

Connect a hose and gun to each outlet.

3. Ventilation:

Areas must be well ventilated to prevent hazardous

operation with volatile solvents or exhaust fumes.

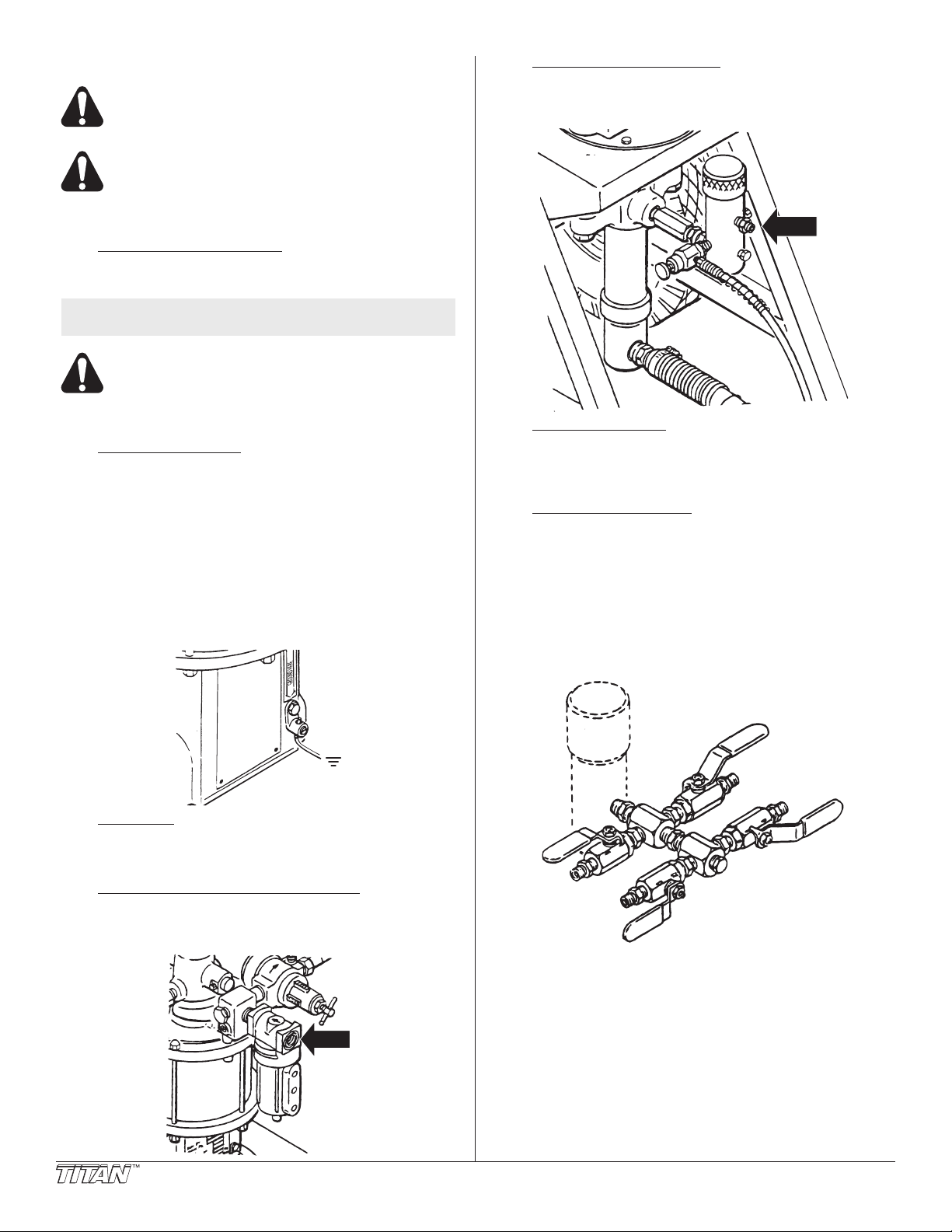

4. Connecting compressor to the sprayer:

Tighten the air hose wrench tight. The air hose has

factory installed PTFE ape on the male end of the hose.

See gure below.

8. Fill the Wet-Cup 1/2 full with Titan’s Lubrisolv, supplied

by the factory. This extends packing life.

9. Strain all paints with Titan’s 5 gallon Nylon strainer, Part

No. 160-500 or 1 gallon Nylon strainer, Part No. 160100 to assure trouble-free operation and freedom from

frequent cleaning of inlet screen and gun strainer.

6 © Titan Tool Inc. All rights reserved.

Page 7

Startup

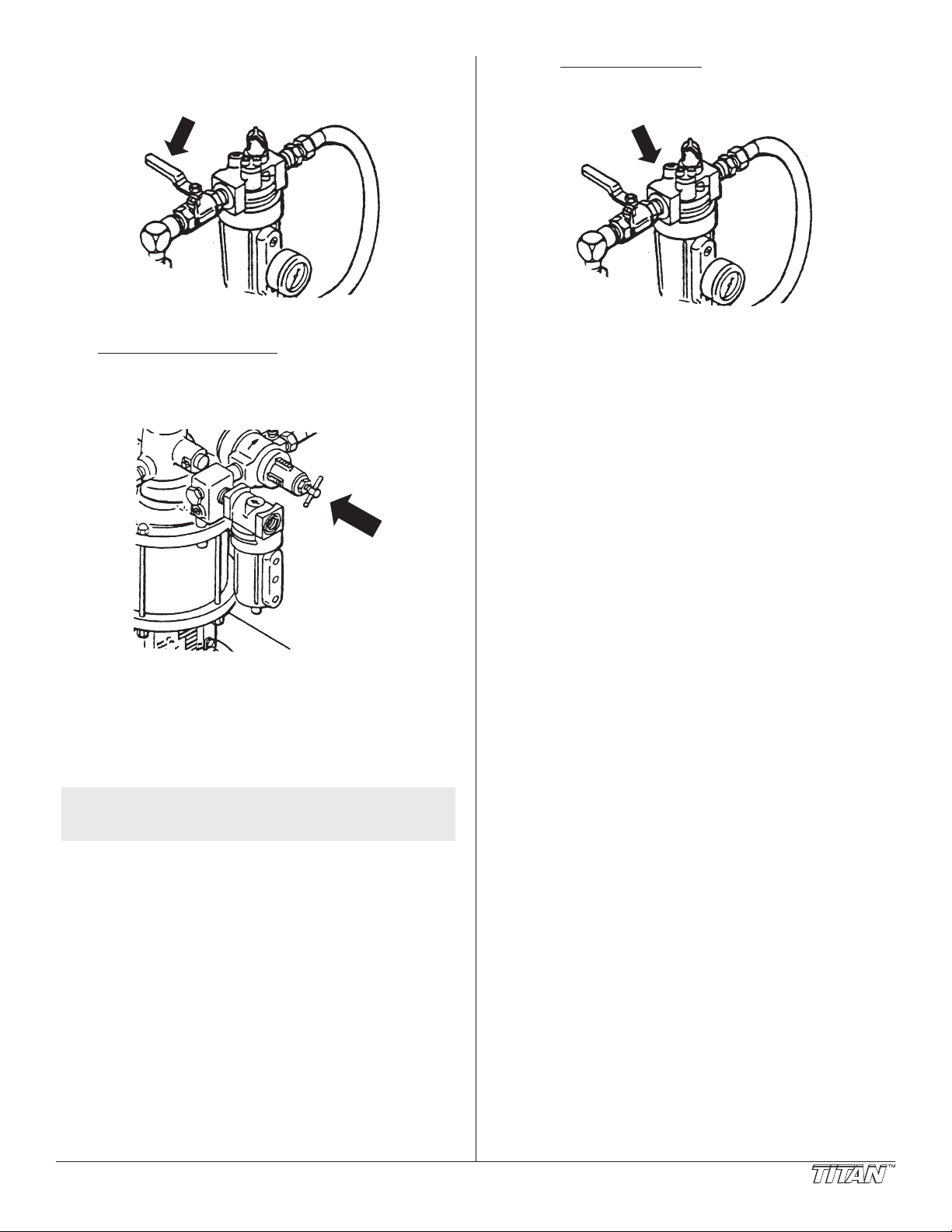

1. Close the self relieving shutoff valve. The gure below

shows the handle in the closed position.

9. The Automatic Lubricator was set at the factory for the

correct injection rate. Do not adjust the lubricator until it is

necessary to rell the reservoir. The lubricator is lled with

AirCare™ lubricant. See gure below.

2. Start the compressor.

3. Drain the Petcock by pushing it off center.

4. Adjusting the air regulator:

The air motor is designed for a maximum air input of 120

psi. Turn the T-Handle clockwise to increase pressure

and counter-clockwise to decrease pressure. Verify the

amount of air pressure by reading the air gauge.

Paint pressure is directly proportional to the amount of air

pressure.

Example: Commander 30:1

100 psi reading at air gauge = 3000 psi at pump outlet.

Consult the materials manufacturer for guidelines in establishing

the correct air pressure.

10. After relling the reservoir, the automatic lubricator will

need adjusting. Turn the adjusting screw clockwise

to increase the AirCare™ injection rate and counterclockwise to decrease it.

Check the injection rate by observing the ow through the

sight dome. The proper ow rate is 1 drop of AirCare™

per minute or every 90-125 cycles. In cold weather when

icing may occur, increase to one drop every 50-60 cycles.

Operation at very high cycle rates (i.e. greater than 60) will

require a higher AirCare™ injection rate.

IMPORTANT: Use only Titan AirCare™ Part No. 311-011

lubricant. Use of any detergent-type lubricants will cause a

serious problem with the pump and void the warranty.

11. Close the pressure bleed valve. The system is now under

pressure.

NOTE: Using a higher pressure than required will only

Once the correct air pressure has been established, lock the air

regulator by tightening the lock nut.

5. Place the siphon hose in the compatible ushing uid.

A water soluble oil was used to test your new sprayer at

• If you are spraying a water-based latex, ush with warm

• If you are using any other coating, ush with warm

6. Place waste container below bleed line.

7. Open pressure bleed valve.

8. Open self-relieving vented shutoff valve. The handle

© Titan Tool Inc. All rights reserved. 7

wear out tips. Use the guidelines in establishing

the lowest pressures for proper atomization.

the factory. You must clean the system before spraying to

avoid contamination of the sprayed material.

soapy water followed by a clean water rinse.

soapy water followed by a solvent. Check with the

material manufacturer for a compatible solvent.

should now be in line with the valve.

Page 8

Operation

1. Repeat above Startup procedure with paint material. Lock

gun trigger and attach spray tip. See the Technical Data

Sheet on the gun provided for installation and selection of

the proper tip size.

2. Test spray pattern. Operate the pump at the lowest air

gauge reading which provides good atomization.

See the Troubleshooting guide if you are not getting the

proper pattern.

3. When restarting the unit, reduce the pressure at the air

regulator and open the pressure bleed valve.

Pressure Relief Procedure

Always reduce fluid pressure when you are

cleaning a clogged tip, changing a tip, servicing

any part of the system, or shutting down. Follow

the steps below.

1. Engage the gun trigger lock.

2. Close the self-relieving vented shutoff valve.

3. Open the pressure bleed valve by turning it counterclockwise three full turns.

4. Disengage the gun trigger lock and hold trigger open until

owof material stops.

Cleaning a Clogged Tip

The flow from the spray tip is at very high pressure.

Contact with any body part may be dangerous. Do

not place finger on gun outlet. Do not point the

gun at any person. Never operate the spray gun

without the proper tip guard.

1. Follow the Pressure Relief Procedure outlined above.

2. Lock the gun trigger.

3. Unscrew the nozzle cap and remove the spray tip. Wash

the tip in solvent and use a tip probe to remove any

clogged material.

4. If the gun is equipped with a Titan TAC 5™ Assembly, see

Technical Data Manual 150:99 for instructions.

5. Release the gun trigger lock and spray briey into a waste

container to ush out any clogged particles.

6. Reset the trigger lock in the “Trigger Locked” position.

Release the trigger lock and resume spraying.

Color Change / Clean Out

IMPORTANT: Use only compatible solvents when cleaning

out oil based enamels, lacquers, coal tar, and epoxies.

Check with the fluid manufacturer for a recommended

solvent.

1. Reduce pressure by following the Pressure Relief

Procedure.

The pressure bleed valve should be turned counter-

clockwise three full turns.

2. Pull the siphon tube out of the material container.

3. Remove the spray tip from the gun. Hold the gun trigger

open until material ow stops.

4. Put siphon tube into wash solvent or water as applicable,

and operate pump slowly at low pressure until solvent

ows freely from pressure bleed valve line.

5. Close pressure bleed valve and hold gun trigger open

until solvent ows freely from gun. If solvent is not too

dirty, recirculate it by owing gun stream back into solvent

container. Use additional clean solvent and repeat

procedure if necessary.

6. If your model is equipped with a gun strainer screen and

pump outlet lter, check them daily. Use 50 mesh screens

with spray tip size .018 and larger. Use 100 or 200 mesh

screens with spray tip sizes .015 and smaller. Always

check the materials manufacturer’s recommendations for

proper ltration requirements.

7. On models with a outlet paint lter, replace paint lter cap

by turning clockwise. The lter cover should be hand

removable after the rst or second use with a new PTFE

O-ring.

IMPORTANT: O-ring must have PTFE backup washer to seal

properly.

8. If unit has been spraying a water soluble material, ush

with water and then repeat procedure with mineral spirits

or similar solvent.

9. Wash spray tip and preorice in solvent. Blow tip clean

with air pressure directed through the tip in the reverse

direction. Store preorice and tips in clean place.

8 © Titan Tool Inc. All rights reserved.

Page 9

Air Motor Maintenance

Air motors require a normal maintenance and service inspection

at 1500 hours service. Service procedure includes replacement

of motor service kit, minor. It is suggested that one motor

service kit, major (which includes the minor kit) be kept on hand

for normal maintenance and emergency repairs. Check the

individual model’s specications for correct part numbers.

Air motors should be served with moisure free air and for this, an

airline lter / moisture separator, such as Titan Part No. 141-057

is recommended. Very cold and humid air conditions combined

with high speed and high operating pressure may require a

moisture separator and an automatic lubricator to avoid icing.

NOTE: Anairlinelter/moistureseparatorarestandard

on many models.

Best lubrication will be obtained with an automatic lubricator such

as Titan Part No. 151-055.

Fluid Pump Maintenance

If the uid pump is going to be out of service for an extended

period of time, it is recommended that following cleanup, a

kerosene and oil mixture be introduced as a preservative.

Packings may tend to dry out from lack of use. The is particularly

true of the upper packing set for which upper packing lubricant,

Lubrisolv, Titan Part No. 310-200, is recommended in normal

usage. A sample of Lubrisolv accompanies each new unit. Do

not substitute water or paint solvent for Lubrisolv. Ordinary oil

may contaminate the paint material and is not recommended.

If the uid pump has been out of service for an extended period

of time, it may be necessary to prime the suction by pouring

some of the paint solvent into the inlet siphon tube to restart.

IMPORTANT: It is very important that the threads on the

inlet siphon hose coupling are properly sealed. Any air

leakage will produce erratic operation of pump and may

damage the system.

The up and down strokes should be approximately equal in

time. That is, one should not be faster than the other. A fast up

or down stroke may indicate air in the system or malfunctioning

valve seats. See Troubleshooting guide.

Hydraulic Motor and Paint Pump Service

See the individual Technical Data Manual Sheets for

maintenance and service instructions on the reciprocating

hydraulic motor and for mechanical service and maintenance on

the uid pump.

© Titan Tool Inc. All rights reserved. 9

Page 10

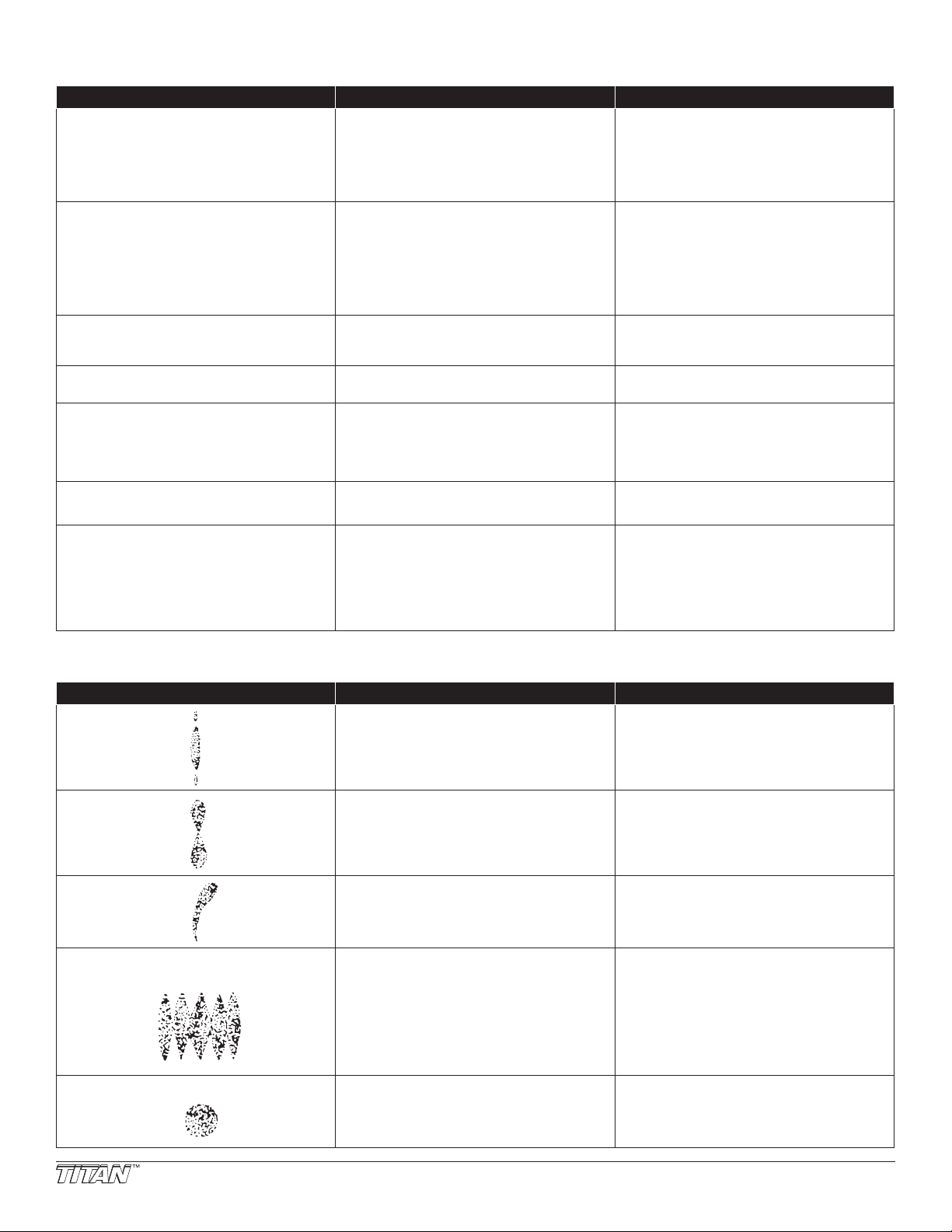

Troubleshooting - Airless Spraying

Condition Possible Cause Correction

A. Poor spray pattern and / or tails at

top and bottom of the spray pattern.

B. The gun drips or throws a drop at

the beginning or end of the spray

pattern.

C. Spray tip stops up frequently. Particles too large for spray tip are passing

D. Spray pattern changes with pump

cycle.

E. Irregular ow of material. One

stroke faster than the other.

F. Spitting. Air in system.

G. Gun does not spray any uid. Suction hose leak.

Worn or incorrect tip and/or insufcient

atomization.

Hose size or length is too small or too

long.

Dirty lter.

Needle may not be seating correctly.

Increase spring tension.

lter and/or gun screen.

Restrictions in the uid system. Check gun and pump lter screens.

Packings are worn or valve balls are not

seating.

Restriction in the siphon system.

Dirty gun.

No paint.

Plugged foot valve.

Plugged lters or tip.

Ball check valve stuck open.

Be sure the tip is not worn. Increase

pressure. Lower viscosity. Reduce

surface tension by increasing hose size to

minimize pressure drop through hose and/

or reduce hose lengths. Use preorice

disc (H disc).

Needle-orice combination should be

factory relapped. Needle packing may

be too tight. Loosen as much as possible

without leakage.

Turn adjusting screw on back of gun

clockwise to increase tension or use the

green HP spring Part # 701-098.

Use 100 mesh gun screen instead of 50

mesh for small spray tips. Use 100 mesh

screen in pump lter. Strain paint.

Always clean screens before they load up.

Check siphon hose assembly to be sure no

air is entering, then recheck all threaded

ttings for leakage. See Troubleshooting

- Fluid Section for additional service

information.

Inspect for siphon hose leak.

Disassemble and clean gun.

Inspect for siphon hose leak.

Check uid supply.

Remove, clean, inspect foot valve.

Clean lters or tip.

Clean and inspect pump ball check valve.

Troubleshooting - Spray Patterns

Condition Possible Cause Correction

A. Tails Inadequate uid delivery.

Fluid not atomizing correctly.

B. Hour glass Inadequate uid delivery. Same as above.

C. Distorted Plugged or worn nozzle tip. Clean or replace nozzle tip.

D. Pattern expanding and contracting

(surge)

E. Round pattern. Worn tip.

Suction leak.

Pulsating uid delivery.

Fluid too heavy for tip.

Increase uid pressure. Change to small

tip orice size. Reduce uid viscosity.

Reduce hose length.

Clean gun and lter(s). Reduce number of

guns using pump.

Inspect for siphon hose leak.

Change to a smaller tip orice size.

Install pulsation dampener in system or

drain existing one. Reduce number of

guns using pump.

Remove restrictions in system, clean tip

screen if lter is used.

Replace tip.

Increase pressure. Thin material. Change

nozzle tip.

10 © Titan Tool Inc. All rights reserved.

Page 11

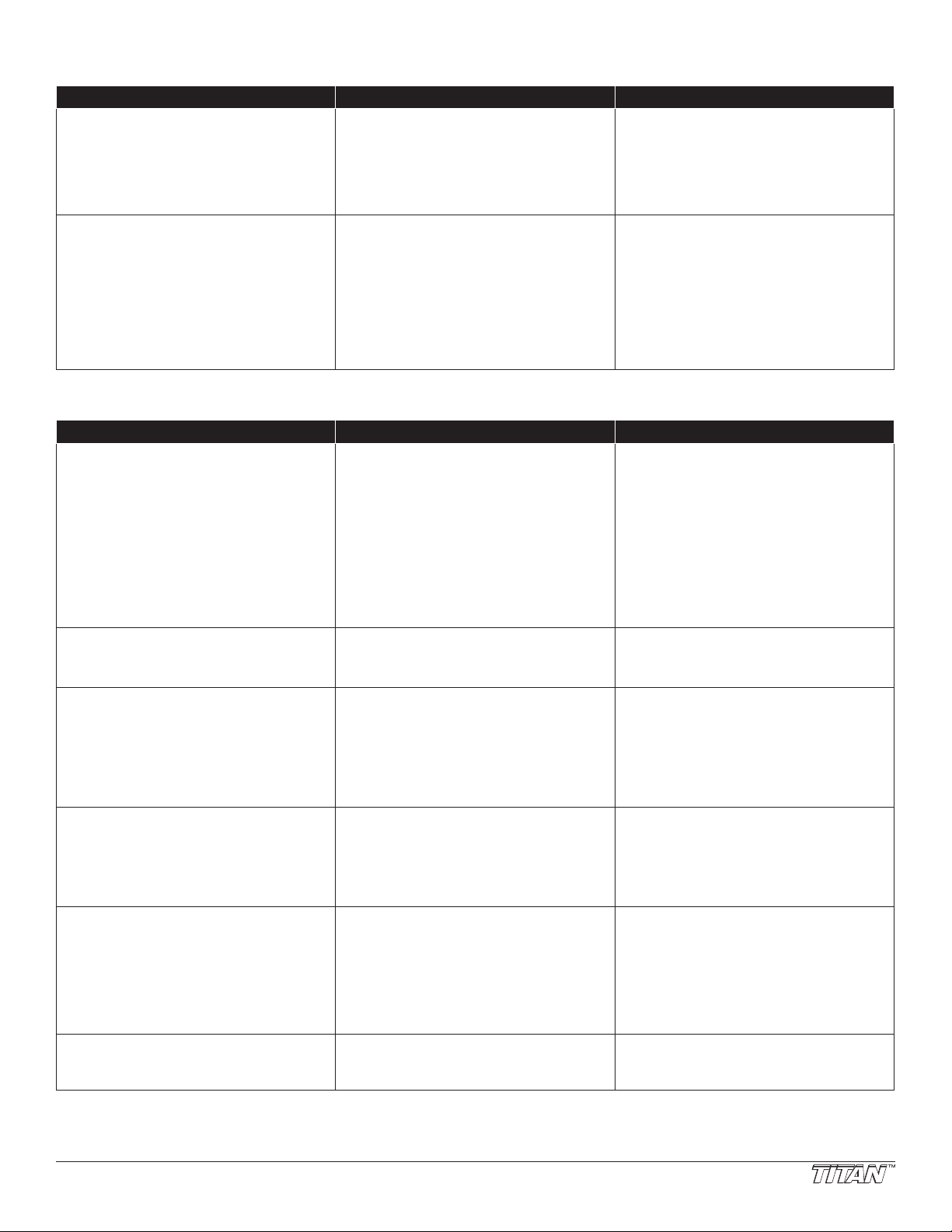

Troubleshooting - Air Motor

Condition Possible Cause Correction

A. Motor stops at top or bottom of

stroke - air does not exhaust when

gun is open.

B. Motor stops, blows air from exhaust

when gun is open.

Piston rod is loose where it connects to the

uid section.

Trip springs or valve spring broken.

Motor is frozen due to icing or lack of

lubrication.

See above.

Air valve is in dead stall position.

O-rings were worn or damaged.

Tighten connection.

Inspect and replace where neessary.

Add 30 weight nondetergent oil to manual

oiler. If condition persists, install moisture

separator and automatic lubricator.

See above.

Remove one trip spring retainer, trip spring

and ball. Push spool valve up or down,

lubricate, reassemble and restart.

Install minor service kit and follow

instructions in General Maintenance and

Service section of manual.

If dust or dirt is found inside motor, check

air supply for contamination.

Troubleshooting - Fluid Sections

Condition Possible Cause Correction

A. Pump delivers on upstroke only

or goes up slowly and down fast

(commonly called downstroke dive).

B. Pump delivers on down stroke only

or goes up fast and down slowly.

C. Pump moves up and down fast, not

delivering material.

D. Pump moves up and down slowly

when spray gun is shut off.

E. Not enough uid pressure at gun. Spray tip is worn.

F. Pump chatters on up or down stroke Solvent has caused upper packing to

Lower foot valve ball is not seating due to

trash or wear.

Material to viscous to siphon.

Air leaking in on siphon side or damaged

siphon hose. Siphon may be too small for

heavy material.

Upper packing nut (if applicable) is loose

or upper packings are worn.

Upper ball is not seating due to trash or

wear.

Lower packing set is worn.

Material container is empty or material is

too thick to ow through the siphon hose.

Bottom ball stuck to foot valve seat.

Siphon hose is kinked or loose.

Loose connections. Bleed valve is open

partially or bleed valve is worn. Lower

packing set is worn.

Upper and/or lower ball not seating.

Compressor (air operated units only) too

small. Outlet lter or gun lter is clogged.

Low voltage and/or inadequate amperage.

Hose size or length is too small or too

long.

swell, or packing is too tight.

Remove foot valve assembly. Clean and

inspect. Test foot valve by lling with

water. If ball fails to seal the seat, replace

ball.

Thin material - contact manufacturer for

proper thinning procedures.

Tighten all connections between pump

and paint container. If damaged, replace.

Switch to bigger siphon set.

If tightening upper packing nut does not

correct, change upper packings.

Check upper seat and ball with water. If

ball fails to seal seat, replace.

Replace packing set is worn.

Rell with new material. If too thick,

remove siphon hose and immerse pump or

add thinner to material. Change to bigger

siphon set. Open bleed valve to remove air

and restart pump.

Remove foot valve. Clean ball and seat.

Straighten.

Check all connections between pump and

gun. Tighten as necessary. If material is

owing from bleed hose, close bleed valve

or replace if necessary. Should none of

above be evident, replace lower packing.

Reset balls by cleaning.

Replace.

Clean or replace lter. Recommend proper

hose size and/or air compressor size.

Check electrical service. Correct as required.

Increase hose size to minimize pressure

drop through hose and/or reduce hose

lengths.

Back off upper packing nut 1/4 turn (if

applicable) and restart pump. Repeat if

necessary.

© Titan Tool Inc. All rights reserved. 11

Page 12

Commander™ Series Portable Models

1

3

2

8

4

2

7

3

1

8

5

6

7

12 © Titan Tool Inc. All rights reserved.

Page 13

Commander™ Series Portable Models

ALL MODELS WITH HEAVY DUTY CART 20:1 30:1 40:1 60:1

ITEM NO. PART NO. DESCRIPTION 721-443 731-441 741-440 761-411 761-461

1 742-245

742-555

142-104

245-555

1a 742-183

742-557

142-100

185-551

1b 742-559

742-557

140-100

140-556

1c 742-140

742-557

140-100

140-556

2 928-513 Air assembly, 3/4” 1 1 1 1 1

3 590-301 Cart assembly, heavy duty 1 1 1 1 1

4 840-208 Outlet assembly, 3/4” 1

4a 840-205 Outlet assembly, 1/2” 1

5 920-554 Filter assembly, outlet (5000 psi) 1 1

5a 920-605 Filter assembly, outlet manifold, 6000 psi 1

6 840-209 Bleed line assembly w/valve 1 1 1

7 103-800 Siphon hose assembly, 3/4” w/rock catcher 1 1

7a 103-807 Siphon hose assembly, 1” w/rock catcher 1 1

7b 103-812 Siphon hose assembly, 1 1/4” w/rock catcher 1

8 219-100 Mounting kit 1 1 1

8a 219-200 Mounting kit 1 1 1 1 1

Motor pump assembly

Air motor

Assembly set

Fluid pump assembly

Motor pump assembly

Air motor

Assembly set

Fluid pump assembly

Motor pump assembly

Air motor

Assembly set

Fluid pump assembly

Motor pump assembly

Air motor

Assembly set

Fluid pump assembly

1

1

1

1 1

© Titan Tool Inc. All rights reserved. 13

Page 14

Commander™ Series Wall Mount and Drum Mount Models

2

1

4

9

5

6

8

1

3

2

6

14 © Titan Tool Inc. All rights reserved.

Page 15

Commander™ Series Wall Mount and Drum Mount Models

20:1 30:1 45:1 60:1

Drum

Mount

ITEM NO. PART NO. DESCRIPTION 721-532 721-354 731-331 731-431 731-183 741-331 761-301

1 742-246

742-555

142-103

245-555

1a 742-245

742-555

142-104

245-555

1b 742-186

742-557

142-100

185-551

1c 742-183

742-557

142-100

185-551

1d 742-185

742-557

183-101

185-551

1e 742-559

742-557

142-102

155-559

1f 742-140

742-557

140-100

140-556

2 928-513 Air assembly, 3/4” 1 1 1 1 1 1 1

3 219-600 Drum cover assembly, 55 Gal. 1 1

4 590-300 Bracket assembly, wall mount 1 1 1 1

4a 590-303 Bracket assembly, wall mount 1

5 219-504 Plate, adapter 1 1

6 840-208 Outlet assembly, 3/4” 1

6a 840-210 Outlet assembly, 3/4” 1

7 920-554 Filter assembly, outlet (5000 psi) 1

7a 920-556 Filter assembly, outlet (5000 psi) 1 1 1

7b 920-610 Filter assembly, outlet (6000 psi) 1

8 840-209 Bleed line assembly w/valve 1 1 1 1 1

9 103-806 Siphon hose assembly, 3/4” w/rock

9a 103-808 Siphon hose assembly, 1” w/rock

9b 103-812 Siphon hose assembly, 1 1/4” w/

Motor pump assembly, drum mount

Air motor

Assembly set

Fluid pump assembly

Motor pump assembly

Air motor

Assembly set

Fluid pump assembly

Motor pump assembly

Air motor

Assembly set

Fluid pump assembly

Motor pump assembly

Air motor

Assembly set

Fluid pump assembly

Motor pump assembly, drum mount

Air motor

Assembly set

Fluid pump assembly

Motor pump assembly

Air motor

Assembly set

Fluid pump assembly

Motor pump assembly

Air motor

Assembly set

Fluid pump assembly

catcher

catcher

rock catcher

1

Wall

Mount

1

1

Wall

Mount

1

1 1 1

Wall

Mount

1

Drum

Mount

1

Wall

Mount

1

1

Mount

Wall

1

© Titan Tool Inc. All rights reserved. 15

Page 16

Commander™ 742-555 and 742-557 Air Motor

17

10

11

12

31

32

18

19

20

21

22

23

24

25

26

27

28

29

30

33

34

33

35

36

37

38

39

40

41

1

2

3

4

5

9

6

78

14

13

16

15

ITEM

NO.

1 818-003 Elbow 1 1

2 738-026 Bolt 6 6

3 742-007 Adapter 2 2

4 742-943 Air line 1 1

5 742-997 Head, cylinder 1 1

6 928-103 Adapter 2 2

7 850-967 Plate, exhaust 2 2

8 862-701 Nut 2 2

9 138-340 Ball 2 2

10 738-213 Spring, trip 2 2

11 742-001 O-ring 2 2

12 742-905 Retainer, trip spring 2 2

13 742-913 Sleeve, valve 1 1

14 742-223 O-ring 4 4

15 858-611 Nut 2 2

16 858-660 Screw 2 2

17 858-812 Nut, stop 1 1

18 738-218 Keeper, upper valve 1 1

19 740-925 Valve 1 1

20 738-224 O-ring 2 2

21 740-985 Keeper, lower valve 1 1

PART

NO.

DESCRIPTION

742-557 742-555

QTY. QTY.

ITEM

NO.

22 742-011 Bushing 1 1

23 742-223 O-ring 1 1

24 890-114 O-ring 1 1

25 742-016 Clip, retainer 1 1

26 738-985 Nut, piston 1 1

27 742-005 Washer, piston 1 1

28 743-011 Valve rod assembly 1 1

29 850-917 PIston 1 1

30 850-016 O-ring 1 1

31 743-227 Collar, valve trip 1 1

32 738-937 Rod, piston 1 1

33 850-004 Gasket 2 2

34 850-952 Cylinder 1 1

35 738-021 O-ring 1 1

36 742-224 Ring, wear 1 1

37 742-947 Base, motor 1 1

38 101-205 Lug, ground 1 1

39 858-624 Screw 1 1

40 862-701 Nut 6 6

41 138-007 Nut, coupling 1

41a 138-017 Nut, coupling 1

PART

NO.

DESCRIPTION

742-557 742-555

QTY. QTY.

16 © Titan Tool Inc. All rights reserved.

Page 17

Air Motor Service Procedure

This Air Motor requires a normal mantenance inspection at 1500

hours of service on the non-circulating models and 800 hours of

service on the circulating models. Service procedure includes

replacement of the Motor Service Kit, Minor Part # 742-051 listed

below. It is suggested that one Motor Service Kit, Major Part

# 742-501 (which includes the minor kit) be kept on hand for

normal maintenance and emergency repairs.

Maintenance

The 742 Series Air Motor should be served with moisture-free

air. A water trap, Titan Part #141-057, is recommended. For use

under very cold and humid conditions a moisture separator and

an automatic oiler may be necessary to avoid icing.

Disassembly Procedure

1. Disconnect air hose from elbow (1).

2. Remove locking bolts and nuts (15, 16), trip spring

retainers (12), O-rings (11), trip springs (10), and balls (9)

from both sides of the cylinder head (5).

3. Disconnect air line (4) from adaptors (3) top and bottom.

4. Remove six nuts (40) and six bolts (2).

5. With piston (29) in down position, place wrench on ats

of piston rod (32) and disconnect piston rod from pump

connecting rod.

6. With piston (29) at top of stroke, raise cylinder head (5)

and remove retainer (25). Lift off cylinder head (5). Valve

sleeve (13) may pull out of cylinder head. If so, lift valve

sleeve off separately.

7. Remove stop nut (17) and then unthread upper valve

keeper (18).

8. Remove air valve (19) followed by lower valve keeper (21)

and bushing (22).

9. If valve sleeve (13) is still in cylinder head, leave it there

unless it is necessary to change O-rings. To remove, use

Sleeve Removal Tool Part # 900-021 to remove sleeve

(13).

10. Remove cylinder (34).

11. Remove piston rod (32) and piston (29) from motor base

(37).

12. Secure piston (29) in vise and remove piston nut (26) and

piston washer (27).

IMPORTANT: Do not clamp on O.D. of the piston.

13. Remove valve rod assembly (28) and valve trip collar (31).

14. Unscrew piston rod (32) from piston (29).

15. Remove O-ring (30) from piston (29).

16. Remove O-rings (23, 24) from bushing (22), O-ring (35)

and wear ring (36) from motor base (37).

Reassembly Procedure

Wash all replaceable parts thoroughly with kerosene and

lubricate with Lubri-Plate or similar non-water soluble grease.

For routine servicing, use new parts from the Air Motor Service

Kit Part # 742-051. Inspect all other parts for abnormal wear or

damage and replace if necessary.

1. Install new O-ring (35) and new wear ring (36) into motor

base (37) and new O-rings (23, 24) into bushing (22). Use

care to avoid damaging O-rings and make sure they are

properly seated in the O-ring grooves.

2. Place valve trip collar (31) into piston rod (32) followed by

valve rod assembly (28).

3. Screw piston rod (32) into piston (29). Replace piston nut

and washer (26, 27).

4. Install new piston O-ring (30) into piston (29).

5. Place new gasket (33) into position in motor base (37).

6. Place piston assembly (29, 32) into motor base (37). Do

not damage O-ring.

7. Place new O-rings (20) on air valve (19).

8. Mount air valve assembly onto valve rod (29) by placing

bushing (22) over valve rod (28), followed by keeper (21),

air valve (19) and upper valve keeper (18). Thread upper

valve keeper (18) down on air valve hand tight. Then

loosen approximately 1/4 turn. Place wrench on ats of

valve rod (28) and hold to prevent valve rod (28) from

turning. Thread stop nut (17) down on valve rod (28) to

lock upper valve keeper (18) in position. Be sure upper

valve keeper (18) does not change position.

9. Grease inside of cylinder (34) and work cylinder down

over piston gently in order to avoid damage to piston

O-ring (30).

10. Install new O-rings (14) on valve sleeve (13). Grease

valve sleeve and install into cylinder head (5) so large

holes in sleeve line up with trip retainer holes in cylinder

head (5). Put one trip retainer (12) with new O-ring (11)

into cylinder head without ball (9) or spring (10) and hold

in position temporarily with locking bolt (16) and nut (15).

11. Place new gasket (33) into position in cylinder head (5)

and hold with gasket cement or grease.

12. Carefully position air valve assembly up into cylinder head

(5).

13. Push bushing (22) up into bottom of cylinder head (5) to

sufciently permit installation of retainer (25).

14. To install trip spring retainer be sure one of the detents

of valve (19) is properly lined up with hole in the cylinder

head (5). Place new trip spring retainer O-ring (11) onto

remaining trip spring retainer (12). Install new ball (9)

followed by trip spring (10) and trip spring retainer (12) into

hole of cylinder head (5). Lock into position with bolt (16)

and nut (15).

15. For opposite trip spring retainer (12) replacement, repeat

step #14.

16. Connect air line (4) to adapters (3) top and bottom.

17. Replace bolts (2) and nuts (40). Always tighten nuts

180 degrees apart in order to obtain proper and even

compression.

18. Place wrench on the ats of piston rod (32) and connect

pump connecting rod.

19. Reconnect air hose to elbow (1).

Service Kits

Part No. Description

743-012 Valve rod and spring assembly

Includes items 17, 28 and 31

742-051 Motor service kit, minor

Includes items 9-11, 14, 17, 20, 23-24. 30, 33, 35-

36.

742-501 Motor service kit, major

Includes minor service kit 850-050, and items 13,

18-19, 21, 28 and 31.

742-942 Air line assembly

Includes item 4, and compression nut, part #

742-009 and ferrule, part # 742-010 (each is a

component of item 3, adapter part # 742-007).

© Titan Tool Inc. All rights reserved. 17

Page 18

Commander™ 140-556 Fluid Pump Assembly

20

22

21

24

23

20

19

2

1

3

ITEM

NO.

1 142-917 Block, pump 1

2 228-002 Adapter 1

3 138-053 Upper leather packing

4 142-004 Spring, packing 1

5 138-029 Gasket 1

6 140-922 Cylinder 1

7 140-009 O-ring 1

8 138-917 Rod, displacement 1

9 138-001 Retainer, spring 1

10 142-003 Spring, packing 1

11 138-154 Lower leather packing

12 138-225 Ball 1

13 143-945 Piston seat assembly 1

14 138-031 Gasket 2

15 138-032 Ball stop 1

16 138-340 Ball 1

17 140-991 Valve, foot 1

18 818-010 Elbow 1

PART

NO.

DESCRIPTION QTY.

1

set

1

set

8

4

5

9

10

6

11

7

12

13

14

15

14

16

17

18

142-100 Assembly Set

ITEM

NO.

19 870-401 Nut 2

20 870-004 Washer 6

21 140-016 Stanchion 2

22 441-955 Rod, connecting 1

23 866-601 Nut, jam 1

24 138-007 Nut, coupling *

PART

NO.

DESCRIPTION QTY.

18 © Titan Tool Inc. All rights reserved.

Page 19

140-556 Fluid Pump Service Information

IMPORTANT: Use of non-Titan manufactured service parts

may void warranty.

The 140 Series Pump should receive a routine servicing after

approximately 1200 hours of use. A 140-052 Minor Pump Kit

should be installed at this time. It is recommended that the

piston ball (12) and foot valve ball (16) be replaced with each

replacement of the packings. The optional PTFE packings could

shorten the overall life of the displacement rod (8) and/or cylinder

(6).

Disassembly Procedure

1. Remove siphon hose assembly.

2. Hold piston rod of air motor with wrench and unthread

coupling nut (26).

3. Remove stanchion nuts. Remove pump assembly from air

motor. Take care not to lose nuts.

4. Secure pump block (1) in vise and remove cylinder (6)

with foot valve (17) intact.

5. Remove cylinder gasket (5), packing spring (4) and

packing set (3).

6. Secure piston set (13) in vise and unthread displacement

rod (8). Remove piston ball (12), packing set (11), lower

packing spring (10) and spring retainer (9).

7. Secure foot valve (17) in vise and unthread cylinder (6).

8. Remove ball stop (15), both cylinder gaskets (14) and foot

valve ball (16). Remove cylinder O-ring (7) from cylinder

(6).

Service Kits

140-052 Pump service kit, minor

ITEM

NO.

11 138-154 Packing set, lower 1

12 138-225 Ball 1

14 138-031 Gasket 2

16 138-340 Ball 1

ITEM

NO.

PART

NO.

3 138-053 Packing set, upper 1

5 138-028 Gasket 1

7 140-009 O-ring 1

PART

NO.

140-052 Service kit, minor 1

6 140-922 Cylinder 1

8 138-917 Rod, displacement 1

DESCRIPTION QTY.

140-501 Pump service kit, major

DESCRIPTION QTY.

Reassembly Procedure

1. Install new cylinder O-ring (7) into O-ring groove of

cylinder (6).

2. Place new foot valve ball (16) in foot valve (17) and install

ball stop (15) between the two new cylinder gaskets (14).

3. Connect foot valve (17) to cylinder (6).

4. Place new packing set (11) over piston seat (13).

IMPORTANT: Peak of “V” packings must point down

towards foot valve (17).

5. Insert new packing set (3) into pump block (1).

IMPORTANT: Peak of “V” packings must point up towards

the air motor.

6. Insert displacement rod (8) through pump block (1) holding

packings (3) in place with ngers.

7. Place packing spring (4) and new cylinder gaskt (5) over

displacement rod (8) and up into the lower cavity of pump

block (1).

8. Place spring retainer (9) over lower end of displacement

rod (8) and packing spring (10) over spring retainer (9).

Place new piston ball (12) onto piston seat (13) and

connect piston seat (13) to displacement rod (8).

9. Insert cylinder (6) over packings and connect to pump

block (1).

IMPORTANT: Cylinder gasket (5) and packing spring (4)

must be in plae before connecting cylinder to pump block.

10. Attach pump assembly to stanchion (21 or 25), inserting

stanchion washers on both sides of pump block (1).

Attach and tigthen stanchion nuts (19 or 24) with wrench.

11. Connect coupling nut (26) to piston rod of air motor or

hydraulic motor.

12. Attach siphon assembly.

© Titan Tool Inc. All rights reserved. 19

Page 20

Commander™ 155-559 Fluid Pump Assembly

18

21

22

ITEM

4

NO.

1 431-007 Nut, coupling *

PART

NO.

DESCRIPTION QTY.

2 155-907 Block, pump 1

19

5

11

3 138-053 Packing set, Poly/Lthr. 2

4 155-906 Upper packing spring 1

1

6

12

5 155-010 Washer 1

6 155-982 Rod, displacement 1

7 155-009 Washer, piston 1

1A

8 155-001 Lower packing spring 1

9 155-225 Ball, S.S. 1

20

2

7

11

8

10 155-921 Piston seat assembly 1

11 891-373 O-ring 2

12 155-932 Cylinder 1

13 174-113 Stop, ball 1

14 174-102 Cage, ball 1

13

3

15 178-700 Ball, S.S. 1

16 155-991 Valve, foot 1

14

142-100 Assembly Set

9

15

3

10

16

ITEM

NO.

18 140-016 Stanchion 2

19 441-956 Rod, connecting 1

20 868-101 Nut 1

21 870-004 Washer 6

22 870-401 Nut 2

PART

NO.

DESCRIPTION QTY.

Displacement

Rod Area

2

IN

CM

Stroke Length Displacement Volume /

Stroke

2

IN CM IN

3

CM3LITER IN

Displacement Volume / 40 Cycles

/ 80 Strokes

3

GAL. CM3LITER

Motor

Selection

Motor Pump

ratio

742 Series 45:1.976 6.3 4 10.2 3.9 63.9 .0639 312 1.35 5113 5.113

20 © Titan Tool Inc. All rights reserved.

Page 21

155-559 Fluid Pump Service Information

IMPORTANT: Use of non-Titan manufactured service parts

may void warranty.

The 155 Series Pump should receive a routine servicing after

approximately 1000 hours of use or earlier if there is excessive

leakage from the top packing, or if pump strokes become faster

on one stroke or another. The use of Titan Lubrisolv Part #

310-200 is recommended as an upper packing lubricant. DO

NOT SUBSTITUTE oil, water or solvent for an upper packing

lubricant.

Disassembly Procedure

1. Remove siphon hose assembly.

2. If the pump is connected to an air motor, hold motor piston

rod at wrench ats and unthread coupling nut (1a) to

separate pump from motor.

If the pump is connected to a hydraulic motor, hold motor

piston rod at wrench ats (after removing locking pin with

an allen key) and unthread coupling nut (1) to separate

pump from hydraulic motor.

3. Unthread and remove foot valve (16) and pump cylinder

(12) to separate from pump block (2) and remove ball stop

(13), ball cage (14), ball (15) and O-ring (11).

4. Secure piston seat assembly (10) in a vise and unthread

displacement rod (6) to remove packing set (3), spring (8)

and washer (7).

5. Inspect and clean all parts. Reject cylinder (12) and/or

displacement rod (6) if hard chrome is grooved or worn

through to gray metal.

Service Kits

Pump Service Kits, minor

ITEM

NO.

3a 155-053 Packing set, leather/poly. 2

11 891-373 O-ring 2 2

15 178-700 Ball, S.S. 1 1

ITEM

NO.

12 155-932 Cylinder 1 1

PART

NO.

3 155-052 Packing set, leather 2

9 155-225 Ball, S.S. 1 1

426-051 Loctite sealant 1 1

PART

NO.

155-051 Minor service kit 1

155-505 Minor service kit 1

6 155-981 Rod, displacement 1 1

DESCRIPTION

Pump Service Kits, major

DESCRIPTION

155-

051

155-

500

155-

055

155-

505

Reassembly Procedure

NOTE: If cylinder (12) and displacement rod (6) are

1. Place new packing set (3) over piston seat (10) with “V”

2. Insert new upper packing set (3) into pump block (2).

IMPORTANT: Peak of “V” packings must point upwards on

reassembly.

Install upper packing spring (4) and spring retainer (5).

3. Insert displacement rod assembly (6) through pump block

4. Lubricate the threaded ends of cylinder (12) including the

5. Thread cylinder (12) into pump block (2). Do not

6. Place new ball (15), ball cage (14), and ball stop (13) into

NOTE: It is not necessary to overtighten foot valve and

reusable then only a minor kit # 155-051 or 155055 may be required for reassembly.

packings pointing downward and reassemble with new ball

(9), spring (8), washer (7) and displacement rod (6) in that

order. Tighten and use Loctite on clean threads.

(2) holding upper packing set (3) in place with ngers.

new O-rings (11) to protect them on reassembly.

overtighten.

foot valve (16) and thread onto cylinder (12). The O-ring

(11) should be lubricated to protect it on replacement of

foot valve. It is not necessary to overtighten as seal is

obtained when parts are fully threaded together.

cylinder into pump block. O-ring seals perform

sealing function without excessive tightening.

Fullthreadengagementissufcient.Thefoot

valve (16) may be rotated back up to 1/2 turn from

full engagement for convenient hose position.

For siphon hose attachment, it is critically important that

the thread of the siphon hose t snugly into the foot valve

with the hose assembly couplings PTFE-taped and sealed

to prevent air inlet leakage.

© Titan Tool Inc. All rights reserved. 21

Page 22

Commander™ 181-556 Fluid Pump Assembly

23

22

21

20

25

24

ITEM

NO.

PART

NO.

DESCRIPTION QTY.

1 185-981 Pin, roll 1

2 185-984 Rod, displacement 1

3 181-906 Block, pump 1

4 175-001 Upper packing set, Lthr. 1

5 182-906 Spring, packing 1

6 228-002 Nipple, hex 1

1

2

8 185-011 Retainer, spring 1

9 185-010 Spring, packing 1

7 182-007

O-ring, PTFE

1

10 180-002 Lower packing set, Lthr. 1

3

4

5

11 182-921 Seat, piston 1

12 182-932 Cylinder 1

13 174-113 Stop, ball 1

14 174-102 Cage, ball 1

15 178-700 Ball, S.S. 1

16 155-981 Valve, foot 1

6

7

18 174-001

19 920-103 Ball 1

17 742-223

O-ring

O-ring, PTFE

1

1

Displacement

Rod Area

2

IN

CM

19

18

17

16

Stroke Length Displacement Volume /

Stroke

2

IN CM IN

3

CM3LITER IN

8

9

10

11

12

13

14

15

Displacement Volume / 40 Cycles

3

ITEM

NO.

PART

NO.

DESCRIPTION QTY.

20 868-101 Nut 2

21 870-004 Washer 2

22 870-005 Washer, spacer 4

23 140-016 Stanchion 2

24 441-956 Rod, connecting 1

25 138-007 Nut, coupling *

* Not included in this assembly

/ 80 Strokes

GAL. CM3LITER

142-101 Assembly Set

Motor

Selection

742 Series 30:11.38 8.90 4 10.2 5.55 90.9 0.091 444 1.92 7272 7.27

Motor Pump

ratio

22 © Titan Tool Inc. All rights reserved.

Page 23

181-556 Fluid Pump Service Information

IMPORTANT: Use of non-Titan manufactured service parts

may void warranty.

The 181 Series Pump should receive a routine servicing after

approximately 1000 hours of use or earlier if there is excessive

leakage from the top packing, or if pump strokes become faster

on one stroke or another. The use of Titan Lubrisolv Part #

310-200 is recommended as an upper packing lubricant. DO

NOT SUBSTITUTE oil, water or solvent for an upper packing

lubricant.

Disassembly Procedure

1. Test pump before disassembly. Follow test procedure in

Troubleshooting Guide - Fluid Section.

2. Remove siphon hose assembly.

3. Remove stanchion nuts (20) and washers (21).

4. If the uid section is connected to an air motor, hold the air

motor piston rod at the wrench ats and unthread coupling

nut (25) to separate pump from motor.

If the motor is connected to a hydraulic motor, remove

allen set screw between the two ats on hydraulic motor

rod. Hold the hydraulic motor rod at the wrench ats

and unthread coupling nut (25) to separate pump from

hydraulic motor.

IMPORTANT: Never use a pipe wrench, pliers, etc. on the

chrome part of hydraulic, air or fluid section rod.

5. Remove roll pin (1) on connecting rod (24). Remove

connecting rod from displacement rod (2).

6. Unthread and remove foot valve (16).

7. Remove PTFE O-ring (18), O-ring (17), ball stop ring (13),

ball cage (14) and ball (15).

8. Remove cylinder (12).

9. Remove displacement rod (2).

10. Place piston seat (11) in a vise and use a wrench on the

ats to remove the displacement rod (2) from the piston

seat (11).

11. Remove lower packing set (10), spring (9), spring retainer

(8) and ball (19).

12. Remove upper packing spring (5), O-ring (7) and packing

set (4) from pump block (3).

13. Clean and inspect all parts. Inspect rod or pump tube’s

hard chrome for grooves, dents or worn areas. Replace if

hard chrome is damaged. Inspect valve seats and replace

if cracked or worn.

8. Insert ball (15), ball cage (14), ball stop retainer ring (13),

O-ring (17) and PTFE O-ring (18) into foot valve.

IMPORTANT: Lubricate all O-rings.

9. Thread foot valve (16) back into cylinder (12).

NOTE: It is not necessary to overtighten foot valve and

10. Insert coupling nut (25) back onto connecting rod (24) and

cylinder into pump block. O-ring seals perform

sealing function without excessive tightening.

Fullthreadengagementissufcient.Thefoot

valve (16) may be rotated back up to 3/4 turn from

full engagement for convenient hose position.

thread connecting rod (24) back onto displacement rod

(2).

Service Kits

Pump service kit, minor (Part # 182-050)

ITEM

NO.

10 180-002 Packing set, leather 1

15 178-700 Ball 1

17 742-223 O-ring 1

18 174-001

19 920-103 Ball 1

ITEM

NO.

11 182-921 Seat, piston 1

12 182-932 Cylinder 1

PART

NO.

4 175-001 Packing set, leather 1

7 182-007

Pump service kit, major (Part # 182-520)

PART

NO.

182-050 Pump service kit, minor 1

2 185-984 Rod, displacement 1

DESCRIPTION QTY.

O-ring, PTFE

O-ring, PTFE

DESCRIPTION QTY.

1

1

Reassembly Procedure

1. Insert upper packing set (4) into pump block (7)

IMPORTANT: Peak of “V” packings must point upwards on

reassembly.

2. Insert upper spring (5); small end of spring must go toward

the packing set.

3. Place packing set (10) over piston seat (11).

IMPORTANT: Peak of “V” packings must point downward

on reassembly.

4. Replace spring (9), spring retainer (8) and ball on piston

seat (11).

5. Thread seat back onto displacement rod (2).

IMPORTANT: Use Loctite on clean threads.

6. Insert displacement rod (2) assembly through upper

packing set (4) in pump block (3).

7. Place O-ring (7) on end of cylinder (12) and thread back

into pump block (3).

IMPORTANT: Lubricate all O-rings before assembly.

© Titan Tool Inc. All rights reserved. 23

Page 24

Commander™ 185-551 Fluid Pump Assembly

21

20

23

22

ITEM

NO.

PART

NO.

DESCRIPTION QTY.

1 185-981 Pin, roll 1

2 185-984 Rod, displacement 1

3 181-906 Block, pump 1

1

2

3

4 178-001 Packing set, upper 1

5 228-002 Nipple, hex 1

6 182-906 Spring, packing 1

7 182-007

O-ring, PTFE

1

8 183-930 Cylinder 1

4

5

6

9 185-011 Retainer, spring 1

10 185-010 Spring, packing 1

11 180-001 Packing set, lower 1

12 920-103 Ball 1

13 182-921 Seat, piston 1

14 183-230

15 182-007

O-ring

O-ring, PTFE

1

1

16 183-992 Valve, foot 1

7

8

9

10

11

12

13

17 314-180 Ball 1

18 240-022 Cage, ball 1

18a 241-109 Pin 1

142-100 Assembly Set

ITEM

NO.

19 870-401 Nut 2

20 870-004 Washer 6

PART

NO.

DESCRIPTION QTY.

21 140-016 Stanchion 2

22 442-956 Rod, connecting 1

14

868-101 Nut (not shown) 1

183-101 Assembly Set** (for 55 gallon drum

15

16

17

cover)

ITEM

NO.

19a 870-401 Nut 2

20 870-004 Washer 6

21a 314-024 Stanchion 2

22 442-956 Rod, connecting 1

22a 180-979 Extension, connecting

23 868-101 Nut 1

24 840-214 Riser pipe assembly 1

PART

NO.

DESCRIPTION QTY.

rod

1

** Not shown

Displacement

Rod Area

2

IN

CM

Stroke Length Displacement Volume /

Stroke

2

IN CM IN

3

CM3LITER IN

Displacement Volume / 40 Cycles

/ 80 Strokes

3

GAL. CM3LITER

Motor

Selection

Motor Pump

ratio

742 Series 30:11.38 8.90 4 10.2 5.55 90.9 0.091 444 1.92 7272 7.27

24 © Titan Tool Inc. All rights reserved.

Page 25

185-551 Fluid Pump Service Information

IMPORTANT: Use of non-Titan manufactured service parts

may void warranty.

The 185 Series Pump should receive a routine servicing after

approximately 1000 hours of use or earlier if there is excessive

leakage from the top packing, or if pump strokes become faster

on one stroke or another. The use of Titan Lubrisolv Part #

310-200 is recommended as an upper packing lubricant. DO

NOT SUBSTITUTE oil, water or solvent for an upper packing

lubricant.

Disassembly Procedure

1. Test pump before disassembly. Follow test procedure in

Troubleshooting Guide - Fluid Section.

2. Remove siphon hose assembly.

3. Remove stanchion nuts (19) and washers (20).

4. Hold the air motor piston rod at the wrench ats and

unthread coupling nut to separate pump from motor.

IMPORTANT: Never use a pipe wrench, pliers, etc. on the

chrome part of hydraulic, air or fluid section rod.

5. Remove roll pin (1) or jam nut on connecting rod (22).

Remove connecting rod (22) from displacement rod (2).

6. Unthread and remove foot valve (16).

7. Remove PTFE O-ring (15), O-ring (14), ball cage

assembly (18) and ball (17).

8. Remove cylinder (8).

9. Remove displacement rod (2).

10. Place piston seat (13) in a vise and use a wrench on the

ats to remove the displacement rod (2) from the piston

seat (13).

11. Remove lower packing set (11), spring (10), spring

retainer (9) and ball (12).

12. Remove upper packing spring (6), packing set (4) and

O-ring (7).

13. Clean and inspect all parts. Inspect displacement rod’s

(2) and cylinder’s (8) chrome for grooves, dents or worn

areas. Replace if hard chrome is damaged. Inspect valve

seats and replace if cracked or worn.

Reassembly Procedure

1. Insert upper packing set (4) into pump block (3)

IMPORTANT: Peak of “V” packings must point upwards on

reassembly.

2. Insert upper spring (6); small end of spring must go toward

the packing set.

3. Insert spring retainer (9).

4. Place new lower packing set (11) over piston seat (13).

IMPORTANT: Peak of “V” must point downward on

reassembly.

5. Replace spring (10), spring retainer (9) and new ball (12)

on piston seat (13).

6. Thread piston seat (13) back onto displacement rod (2).

IMPORTANT: Use Loctite on clean threads.

7. Insert displacement rod (2) assembly through upper

packing set (4) in pump block (3).

8. Place new O-ring (7) on end of cylinder (8) and thread

back into pump block (3).

IMPORTANT: Lubricate all O-rings before assembly.

9. Insert new ball (17), ball cage (18), and new O-ring (14)

into foot valve.

NOTE: Ball cage pin (18a) to be in lower position unless

10. Place new PTFE O-ring (15) on cylinder (8) and then

NOTE: It is not necessary to overtighten foot valve and

11. Insert connecting rod (22) through coupling nut and thread

12. Insert roll pin (1) into connecting rod (22).

For siphon hose attachment, it is critically important that

pumpistobeusedforheavyblocklleror

roongmaterials.

install foot valve assembly (16)

cylinder into pump block. O-ring seals perform

sealing function without excessive tightening.

Fullthreadengagementissufcient.Thefoot

valve (16) may be rotated back up to 3/4 turn from

full engagement for convenient hose position.

connecting rod (22) into displacement rod (2).

the thread of the siphon hose t snugly into the foot valve

with the hose assembly couplings PTFE-taped and sealed

to prevent air inlet leakage.

Service Kits

NOTE: Minor service kit # 185-050 has polyethylene/

Minor service kit # 180-051 has leather packings.

Minor service kit # 185-052 has PTFE packings.

ITEM

NO.

11 180-002 Packing set, lower 1

11 180-322 Packing set, lower 1

11 183-001 Packing set, lower 1

12 920-103 Ball 1 1 1

14 183-230 O-ring 1 1 1

15 182-007

17 314-180 Ball 1 1 1

ITEM

NO.

leather packings.

Pump service kit, minor CTR IND

PART

NO.

4 175-001 Packing set, upper 1

4 178-001 Packing set, upper 1

4 178-320 Packing set, upper 1

7 182-007

426-051 Loctite Sealant 1 1 1

Pump service kit, major CTR IND

PART

NO.

185-050 Minor kit 1

185-051 Minor kit 1

185-052 Minor kit 1

2 182-984 Displacement rod 1 1 1

6 182-906 Spring, packing 1 1 1

8 183-930 Cylinder 1 1 1

DESCRIPTION

O-ring, PTFE

O-ring, PTFE

DESCRIPTION

185-

050

185-

500

185-

1 1 1

1 1 1

185-

051

501

PTFE

185-

052

PTFE

185-

502

© Titan Tool Inc. All rights reserved. 25

Page 26

Commander™ 245-555 Fluid Pump Assembly

20

19

10

11

ITEM

24

23

22

121

2

3

NO.

1 245-907 Block, pump 1

2 240-001 Packing set, Poly/Lthr. 1

3 245-005 Packing spring, upper 1

4 245-013 Retainer, spring 1

5 892-323 O-ring, Telfon 1

PART

NO.

DESCRIPTION QTY.

6 245-012 Cylinder 1

7 920-103 Ball, S.S. 1

8 245-020 Retainer, spring 1

4

5

9 245-014 Spring, packing 1

10 240-001 Packing set, Poly/Lthr 1

11 241-007 Seat, piston 1

6

7

8

9

18

24

23

27

25

(For 55

Gallon)

12 240-022 Cage, ball 1

12a 241-109 Pin, ball stop 1

13 891-403

14 892-281

O-ring, PTFE

O-ring

15 245-018 Valve, foot 1

16 314-180 Ball, S.S. 1

17 245-021 Retainer, cage 1

18 245-009 Rod, displacement 1

1

1

Displacement

Rod Area

2

IN

CM

12

12a

13

14

17

16

15

Stroke Length Displacement Volume /

Stroke

2

IN CM IN

3

CM3LITER IN

27

26

18

ITEM

NO.

19 870-401 Nut 2 2

20 870-004 Washer 6 6

PART

NO.

DESCRIPTION

21 140-016 Stanchion 2

21a 314-024 Stanchion, 55 Gal 2

22 245-109 Roll pin 1

23 442-959 Connecting rod 1

23a 441-959 Connecting rod 1

24 138-007 Nut, coupling * *