Page 1

Owner’s Manual

Do not use this equipment

before reading this manual!

ADVANTAGE 1100

Electric Piston Pump

Model

0552068

Register your product online at:

www.titantool.com

Model

0552069

NOTE: This manual contains important

warnings and instructions. Please read

and retain for reference.

Serial Number* _ _ _ _ _ _ _ _ _ _

* See page 3 for location

0914 • © Titan Tool Inc. All Rights Reserved. Form No. 0552846F

Page 2

Important Safety Information

Grounded Outlet

Grounding Pin

Read all safety information before operating the

equipment. Save these instructions.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

To reduce the risks of re or explosion, electrical shock

and the injury to persons, read and understand all

instructions included in this manual. Be familiar with the

controls and proper usage of the equipment.

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape wire

for the electric current. This product is equipped with a cord having a

grounding wire with an appropriate grounding plug. The plug must

be plugged into an outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect

the green grounding wire to either at blade terminal. The wire with

insulation having a green outer surface with or without yellow stripes is

the grounding wire and must be connected to the grounding pin.

Check with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as

to whether the product is properly grounded. Do not modify the plug

provided. If the plug will not t the outlet, have the proper outlet

installed by a qualied electrician.

This product is for use on a nominal 120 volt circuit and has a grounding

plug that looks like the plug illustrated below. Make sure that the product

is connected to an outlet having the same conguration as the plug. No

adapter should be used with this product.

conductive or grounded high-pressure airless paint sprayer hoses

specied by the manufacturer.

• Verify that all containers and collection systems are grounded to

prevent static discharge.

• Connect to a grounded outlet and use grounded extension cords

(electric models only). Do not use a 3 to 2 adapter.

• Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach mildewcide, methylene

chloride and trichloroethane. They are not compatible with

aluminum. Contact the coating supplier about compatibility of

material with aluminum.

• Keep spray area well ventilated. Keep a good supply of fresh air

moving through the area to keep the air within the spray area free

from accumulation of ammable vapors. Keep pump assembly in

well ventilated area. Do not spray pump assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark producing

products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and

other ammable materials.

• Know the contents of the paint and solvents being sprayed.

Read all Material Safety Data Sheets (MSDS) and container labels

provided with the paints and solvents. Follow the paint and

solvent manufacture’s safety instructions.

• Place pump at least 25 feet (7.62 meters) from the spray object in

a well ventilated area (add more hose if necessary). Flammable

vapors are often heavier than air. Floor area must be extremely

well ventilated. The pump contains arcing parts that emit sparks

and can ignite vapors.

• Plastic can cause static sparks. Never hang plastic to enclose spray

area. Do not use plastic drop cloths when spraying ammable

material.

• Fire extinguisher equipment shall be present and working.

IMPORTANT: When the sprayer is used with a generator

or uncontrolled line voltage, the use of Titan’s “Line Surge

Protector” (P/N 800-935) is recommended.

PREVENTION:

• Do not spray ammable or combustible materials near an open

• Use extreme caution when using materials with a ashpoint

• Paint or solvent owing through the equipment is able to result

2 © Titan Tool Inc. All rights reserved.

Cover for grounded outlet box

WARNING: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Property

damage and/or severe injury can occur.

ame, pilot lights or sources of ignition such as hot objects,

cigarettes, motors, electrical equipment and electrical appliances.

Avoid creating sparks from connecting and disconnecting power

cords.

below 100ºF (38ºC). Flashpoint is the temperature that a uid can

produce enough vapors to ignite.

in static electricity. Static electricity creates a risk of re or

explosion in the presence of paint or solvent fumes. All parts

of the spray system, including the pump, hose assembly, spray

gun and objects in and around the spray area shall be properly

grounded to protect against static discharge and sparks. Use only

WARNING: INJECTION INJURY

A high pressure paint stream produced by this equipment

can pierce the skin and underlying tissues, leading to

serious injury and possible amputation. See a physician

immediately.

PREVENTION:

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For

example, do not try to stop leaks with any part of the body.

• NEVER put your hand in front of the gun. Gloves will not provide

protection against an injection injury.

• ALWAYS keep the tip guard in place while spraying. The tip guard

provides some protection but is mainly a warning device.

• Only use a nozzle tip specied by the manufacturer.

• Use caution when cleaning and changing nozzle tips. In the

case where the nozzle tip clogs while spraying, ALWAYS lock

gun trigger, shut pump o, and release all pressure before

servicing, cleaning tip or guard, or changing tip. Pressure will

not be released by turning o the motor. The PRIME/SPRAY

valve or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure. Refer to PRESSURE RELIEF

PROCEDURE described in the pump manual.

• Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn o the unit and

relieve the pressure in accordance with the manufacturer’s

instructions.

• High-pressure spray is able to inject toxins into the body and

cause serious bodily injury. In the event that injection occurs,

seek medical attention immediately.

• Check hoses and parts for signs of damage, a leak can inject

material into the skin. Inspect hose before each use. Replace any

damaged hoses or parts. Only use TITAN original-high-pressure

hoses in order to ensure functionality, safety and durability.

Page 3

Important Safety Information

• This system is capable of producing 3100 PSI / 214 Bar. Only

use replacement parts or accessories that are specied by the

manufacturer and that are rated a minimum of 3100 PSI. This

includes spray tips, nozzle guards, guns, extensions, ttings, and

hose.

• Always engage the trigger lock when not spraying. Verify the

trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be

thoroughly familiar with the controls. Pressure will not be

released by turning o the motor. The PRIME/SPRAY valve

or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure. Refer to PRESSURE RELIEF

PROCEDURE described in the pump manual.

• Always remove the spray tip before ushing or cleaning the

system.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury which can lead to

possible amputation. It is important to treat the injury as soon as

possible. DO NOT delay treatment to research toxicity. Toxicity

is a concern with some coatings injected directly into the blood

stream. Consultation with a plastic surgeon or reconstructive hand

surgeon may be advisable.

WARNING: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials can

be harmful if inhaled or come in contact with the body.

Vapors can cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read all

instructions supplied with the mask to be sure it will provide the

necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

WARNING: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Always wear appropriate gloves, eye protection, clothing and a

respirator or mask when painting.

• Do not operate or spray near children. Keep children away from

equipment at all times.

• Do not overreach or stand on an unstable support. Keep eective

footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the inuence of

drugs or alcohol.

• Do not kink or over-bend the hose. Airless hose can develop leaks

from wear, kinking and abuse. A leak can inject material into the

skin.

• Do not expose the hose to temperatures or pressures in excess of

those specied by manufacturer.

• Do not use the hose as a strength member to pull or lift the

equipment.

• Use lowest possible pressure to ush equipment.

• Follow all appropriate local, state and national codes governing

ventilation, re prevention and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act (OSHA).

These standards, particularly part 1910 of the General Standards

and part 1926 of the Construction Standards should be consulted.

© Titan Tool Inc. All rights reserved. 3

• Before each use, check all hoses for cuts, leaks, abrasion or

bulging of cover. Check for damage or movement of couplings.

Immediately replace hose if any of those conditions exist. Never

repair a paint hose. Replace with a conductive high-pressure

hose.

• Do not spray outdoors on windy days.

• Always unplug cord from outlet before working on equipment

(electric models only).

Specications

Gallons per minute (GPM) ................1.15 (4.35 LPM)

Maximum tip sizes ..............................One gun - 0.033”

Two guns - 0.021”

Maximum pressure .............................3100 PSI (21.4 MPa)

Power .......................................................2.2 HP PMDC brushless motor,

120VAC

Weight .....................................................105 lbs. (47.6 kg)

Maximum hose length ......................300’ (91.4 m)

Table of Contents

Safety Precautions ........................................................................... 2

Specications ................................................................................... 3

Product Registration ....................................................................... 3

Serial Number Location .............................................................................. 3

General Description ........................................................................ 4

Operation ......................................................................................... 4

Setup ................................................................................................................. 4

Preparing to Paint.........................................................................................4

Painting ............................................................................................................ 5

Pressure Relief Procedure .......................................................................... 6

Spraying ........................................................................................... 6

Spraying Technique ..................................................................................... 6

Practice ............................................................................................................. 6

Unclogging the Spray Tip .......................................................................... 7

Cleanup ............................................................................................ 7

Cleaning the Spray Tip ................................................................................7

Maintenance .................................................................................... 7

General Repair and Service Notes .......................................................... 7

Replacing the PRIME/SPRAY Valve ......................................................... 8

Replacing the Filters .................................................................................... 8

Replacing the Motor Assembly (with Electronic Control) ..............9

Replacing the Gears ..................................................................................... 9

Replacing the Transducer ........................................................................10

Servicing the Fluid Section ......................................................................10

Troubleshooting ............................................................................ 12

Parts List ......................................................................................... 18

Main Assembly ............................................................................................18

Drive Assembly ............................................................................................19

Fluid Section Assembly ............................................................................20

Upright Cart Assembly ..............................................................................21

Filter Assembly ............................................................................................21

Suction Set Assembly (low boy) ............................................................22

Low Boy Cart Assembly ............................................................................22

Labels ..............................................................................................................22

Electrical Schematic ...................................................................................23

Accessories ....................................................................................................23

Limited Warranty ........................................................................... 24

Product Registration

Register your product online at www.titantool.com.

Serial Number Location

The serial number for your sprayer is shown on a label that is

adhered to the underside of the main gearbox housing.

Page 4

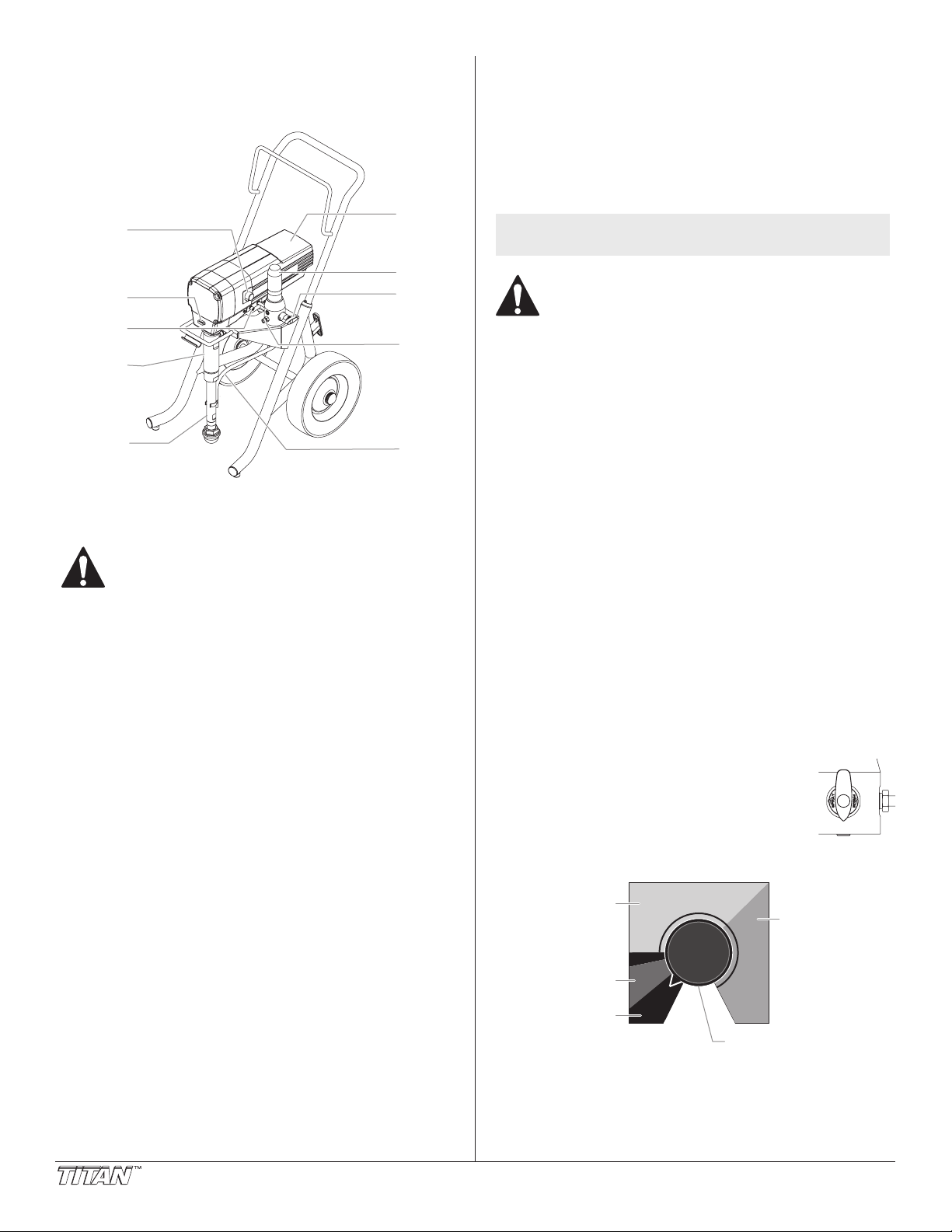

General Description

Pr

n

Tu

1800 – 3300 PSI

Pressure Control Knob

This airless sprayer is a precision power tool used for spraying many

types of materials. Read and follow this Owner’s Manual carefully for

proper operating instructions, maintenance, and safety information.

Motor

essure

Control

Knob

Filter

Oil Cup

Fuse

PRIME/

SPRAY

Valve

Outlet

Fluid

Fitting

Section

Siphon

Tube

Retur

Hose

Operation

This equipment produces a fluid stream at extremely

high pressure. Read and understand the warnings

in the Safety Precautions section at the front of this

manual before operating this equipment.

Setup

Perform the following procedure before plugging in the power cord

of an electric unit.

1. Ensure that the siphon tube/suction set and the return hose

are attached and secure.

2. Using a wrench, attach a minimum of 50’ of 1/4” airless spray

hose to the outlet tting on the sprayer. Tighten securely.

3. Attach an airless spray gun to the spray hose. Using two

wrenches (one on the gun and one on the hose), tighten

securely.

NOTE: Do not attach the tip to the spray gun yet. Remove

the tip if it is already attached.

Make sure all airless hoses and spray guns are

electrically grounded and rated at or above the

maximum operating pressure range of the airless

sprayer.

4. Make sure the pressure control knob is in the OFF position in

the black zone.

5. Fill the oil cup with approximately one tablespoon of

separating oil (P/N 314-481).

IMPORTANT: Never operate unit for more than ten seconds

without fluid. Operating this unit without fluid will cause

unnecessary wear to the packings.

6. Make sure the electrical service is 120V, 15 amp minimum.

7. Plug the power cord into a properly grounded outlet at least

25’ from the spray area.

IMPORTANT: Always use a minimum 12 gauge, three-wire

extension cord with a grounded plug. Never remove the third

prong or use an adapter.

Preparing a New Sprayer

If this sprayer is new, it is shipped with test uid in the uid section

to prevent corrosion during shipment and storage. This uid must

be cleaned out of the system thoroughly with mineral spirits before

spraying paint.

IMPORTANT: Always keep the trigger lock on the spray gun in

the locked position while preparing the system.

1. Place the siphon tube into a container of mineral spirits that

has a ash point of 140ºF (60ºC) or above.

2. Place the return hose into a metal waste

container.

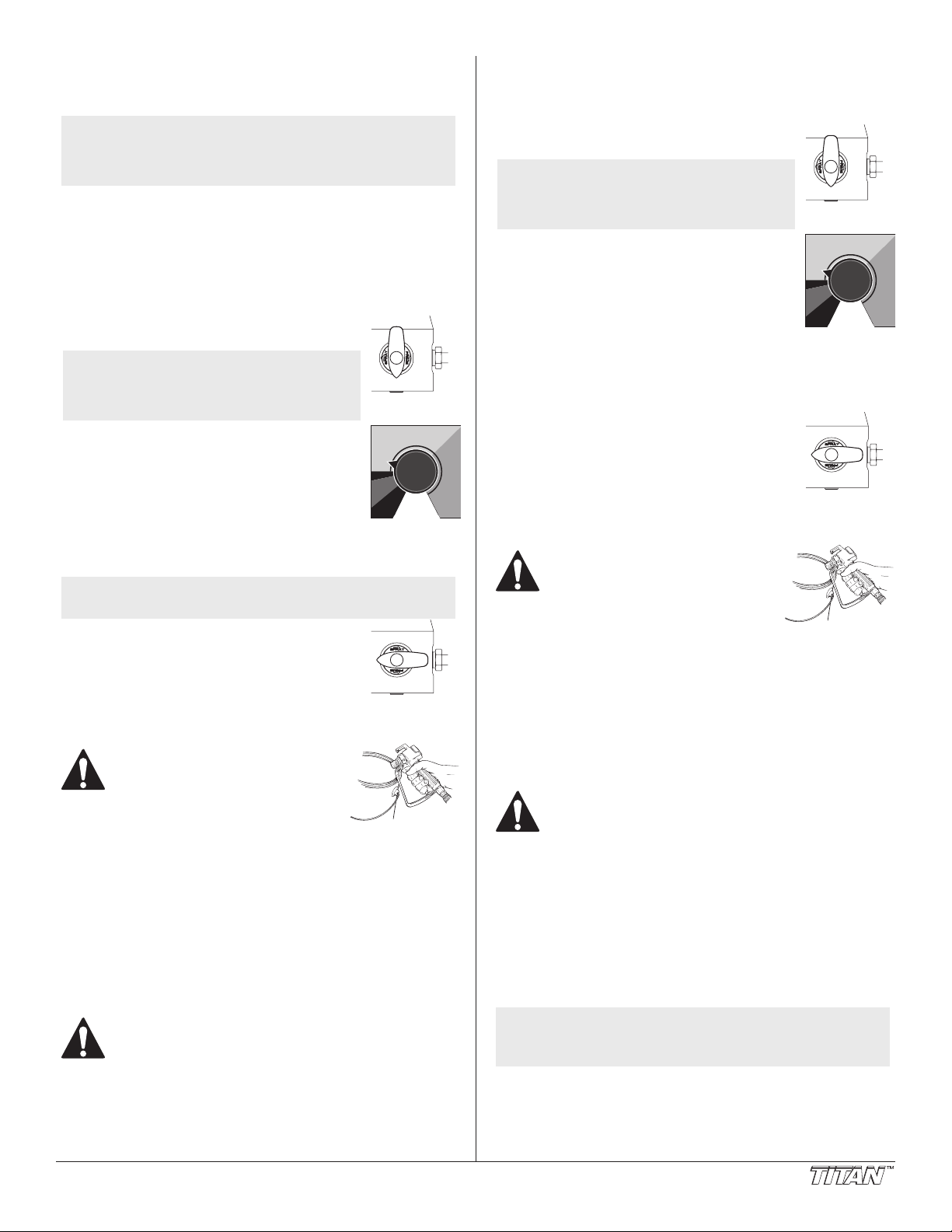

3. Move the PRIME/SPRAY valve down to the

PRIME position.

4. Turn the unit on and set the pressure to

minimum by turning the pressure control

knob to the “MIN PSI” setting in the yellow

zone.

E

&

n

s

r

a

m

e

u

e

q

l

c

s

Min. – 1800 PSI

(yellow zone)

rbo PulseClean

(red zone)

OFF

Min.

PSI

(Bar)

Clean

On/O

a

L

,

s

r

a

e

l

C

y

a

r

p

S

H

e

a

v

t

i

n

g

s

Max. PSI

(Bar)

S

p

r

a

y

L

i

e

a

r

t

e

C

x

o

P

a

a

i

n

t

s

&

(green zone)

(black zone)

5. Allow the sprayer to run for 15–30 seconds to ush the

test uid out through the return hose and into the waste

container.

6. Turn o the sprayer by moving the pressure control knob to

the OFF position in the black zone.

4 © Titan Tool Inc. All rights reserved.

Page 5

Preparing to Paint

Before painting, it is important to make sure that the uid in the

system is compatible with the paint that is going to be used.

NOTE: Incompatible uids and paint may cause the valves

IMPORTANT: Always keep the trigger lock on the spray gun in

the locked position while preparing the system.

1. Place the siphon tube into a container of the appropriate

2. Place the return hose into a metal waste container.

3. Move the PRIME/SPRAY valve down to the

NOTE: Hold the return hose in the waste

4. Set the pressure to minimum by turning

5. Allow the sprayer to run for 15–30 seconds

6. Turn o the sprayer by moving the pressure control knob to

NOTE: Make sure that the spray gun does not have a tip or

7. Move the PRIME/SPRAY valve up to the

8. Set the pressure to minimum by turning

9. Unlock the gun by turning the gun trigger lock to the

10. Trigger the gun into the metal waste container until the old

11. Lock the gun by turning the gun trigger lock to the locked

12. Set down the gun and increase the pressure by turning the

13. Check the entire system for leaks. If leaks occur, turn o the

14. Follow the “Pressure Relief Procedure” in this manual before

to become stuck closed, which would require

disassembly and cleaning of the sprayer’s uid

section.

solvent for the material being sprayed (refer to

recommendations of the material manufacturer). An example

of an appropriate solvent is water for latex paint.

PRIME position.

container when moving the PRIME/

SPRAY valve to PRIME in case the

sprayer is pressurized.

E

&

n

s

r

a

e

m

u

e

q

l

c

s

a

L

,

s

r

a

e

l

C

y

a

r

p

the pressure control knob to the “MIN PSI”

setting in the yellow zone.

to ush the old solvent out through the

return hose and into the metal waste

S

Min.

PSI

(Bar)

Clean

On/O

container.

the OFF position in the black zone.

tip guard installed.

SPRAY position.

the pressure control knob to the “MIN PSI”

setting in the yellow zone.

unlocked position.

Ground the gun by holding it against

the edge of the metal container

while flushing. Failure to do so may

lead to a static electric discharge,

which may cause a fire.

solvent is gone and fresh solvent is coming out of the gun.

position.

pressure control knob slowly clockwise into the green zone.

sprayer and follow the “Pressure Relief Procedure” in this

manual before tightening any ttings or hoses.

changing from solvent to paint.

Max. PSI

Painting

1. Place the siphon tube into a container of paint.

2. Place the return hose into a metal waste container.

3. Move the PRIME/SPRAY valve down to the

PRIME position.

NOTE: Hold the return hose in the waste

4. Turn the unit on and set the pressure to

5. Allow the sprayer to run until paint is

6. Turn the unit o by moving the pressure control knob to the

7. Remove the return hose from the waste container and place it

8. Move the PRIME/SPRAY valve up to the

S

p

H

g

s

(Bar)

9. Turn the unit on and set the pressure to

r

e

a

a

y

v

L

i

e

a

r

t

e

C

x

o

P

a

a

t

i

i

n

n

t

s

&

10. Unlock the gun by turning the gun trigger lock to the

11. Trigger the gun into the metal waste container until all air and

12. Lock the gun by turning the gun trigger lock to the locked

13. Turn the unit o by moving the pressure control knob to the

14. Attach tip guard and tip to the gun as instructed by the tip

15. Turn the unit on and set the pressure to minimum by turning

16. Increase the pressure by turning the pressure control knob

container when moving the PRIME/

SPRAY valve to PRIME in case the

sprayer is pressurized.

E

&

n

s

r

a

e

m

u

e

q

l

c

s

a

L

,

s

r

a

e

l

C

y

a

r

p

minimum by turning the pressure control

knob to the “MIN PSI” setting in the

yellow zone.

coming through the return hose into the

S

Min.

PSI

(Bar)

Clean

On/O

metal waste container.

OFF position in the black zone.

in its operating position above the container of paint.

SPRAY position.

minimum by turning the pressure control

knob to the “MIN PSI” setting in the yellow

zone.

unlocked position.

Ground the gun by holding it against

the edge of the metal container

while flushing. Failure to do so may

lead to a static electric discharge,

which may cause a fire.

solvent is ushed from the spray hose and paint is owing

freely from the gun.

position.

OFF position in the black zone.

guard or tip manuals.

POSSIBLE INJECTION HAZARD. Do not spray without

the tip guard in place. Never trigger the gun unless

the tip is in either the spray or the unclog position.

Always engage the gun trigger lock before removing,

replacing or cleaning tip.

the pressure control knob to the “Min PSI” setting in the

yellow zone.

slowly clockwise and test the spray pattern on a piece of

cardboard. Adjust the pressure control knob until the

spray from the gun is completely atomized. Try to keep the

pressure control knob at the lowest setting that maintains

good atomization.

Max. PSI

S

p

H

r

e

a

a

y

v

L

i

e

a

r

t

e

C

x

o

P

a

a

t

i

i

n

n

g

t

s

s

&

(Bar)

Be sure to follow the pressure relief procedure when

shutting down the sprayer for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for

cleanup.

© Titan Tool Inc. All rights reserved. 5

NOTE: Turning the pressure up higher than needed to

atomize the paint will cause premature tip wear and

additional overspray.

Page 6

Pressure Relief Procedure

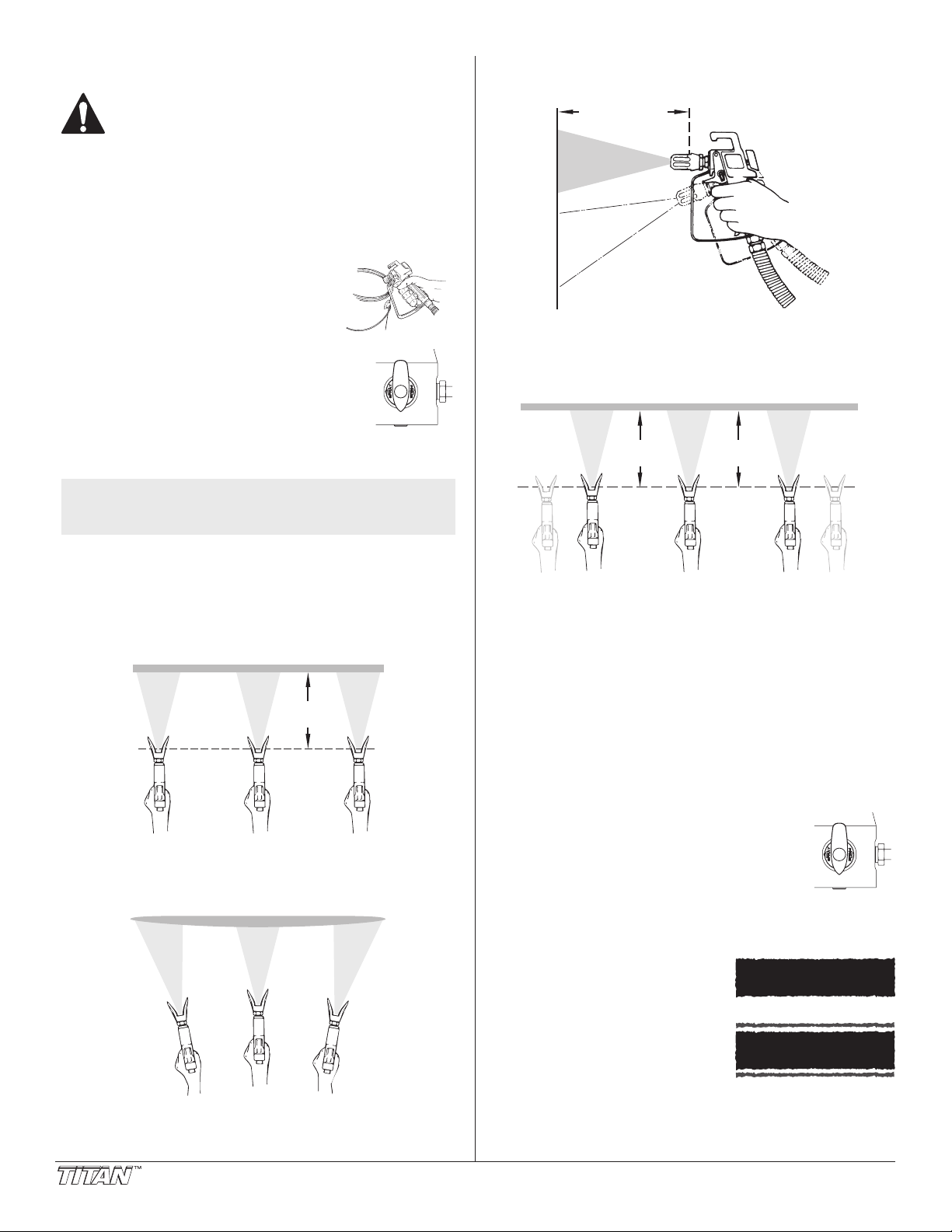

Keep stroke smooth and at an even speed.

Even coat throughout

Heavy Coat

Do not ex wrist while spraying.

Light Coat Light Coat

Approximately

Proper way to trigger the spray gun

Start stroke End strokePull trigger Release triggerKeep steady

Be sure to follow the Pressure Relief Procedure when

shutting down the sprayer for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for

cleanup.

1. Lock the gun by turning the gun trigger lock to the locked

position.

2. Turn o the sprayer by moving the pressure control knob to

the OFF position in the black zone.

3. Unlock the gun by turning the gun trigger lock to the

unlocked position.

4. Hold the metal part of the gun rmly to

the side of a metal container to ground

the gun and avoid a build up of static

electricity.

5. Trigger the gun to remove any pressure

that may still be in the hose.

6. Lock the gun by turning the gun trigger lock

to the locked position.

7. Move the PRIME/SPRAY valve down to the

PRIME position.

Keep the spray gun perpendicular to the surface, otherwise one end

of the pattern will be thicker than the other.

10 to 12 inches

Right way

Wrong way

The spray gun should be triggered by turning it on and o with each

stroke. This will save paint and avoid paint buildup at the end of the

stroke. Do not trigger the gun during the middle of a stroke. This will

result in an uneven spray and splotchy coverage.

Spraying

NOTE: When spraying block ller, mastics or high solid

Spraying Technique

The key to a good paint job is an even coating over the entire surface.

This is done by using even strokes. Keep your arm moving at a

constant speed and keep the spray gun at a constant distance from

the surface. The best spraying distance is 10 to 12 inches between

the spray tip and the surface.

Keep the spray gun at right angles to the surface. This means moving

your entire arm back and forth rather than just exing your wrist.

coating, remove the gun lter and high pressure

lter screens.

Approximately

10 to 12 inches

Keep stroke

even

Approximately

10 to 12 inches

Overlap each stroke by about 30%. This will ensure an even coating.

When you stop painting, lock the gun trigger lock, turn the pressure

control knob counterclockwise to its lowest setting and set the

PRIME/SPRAY valve to PRIME. Turn the ON/OFF switch to the OFF

position and unplug the sprayer.

Practice

1. Be sure that the paint hose is free of kinks and clear of objects

with sharp cutting edges.

2. Turn the unit on and set the pressure to minimum by turning

the pressure control knob to the “MIN PSI” setting in the

yellow zone.

3. Move the PRIME/SPRAY valve up to the SPRAY

position.

4. Turn the pressure control knob clockwise to its

highest setting. The paint hose should stien

as paint begins to ow through it.

5. Unlock the gun trigger lock.

6. Trigger the spray gun to bleed air out of the hose.

7. When paint reaches the spray tip, spray a test area to check

the spray pattern.

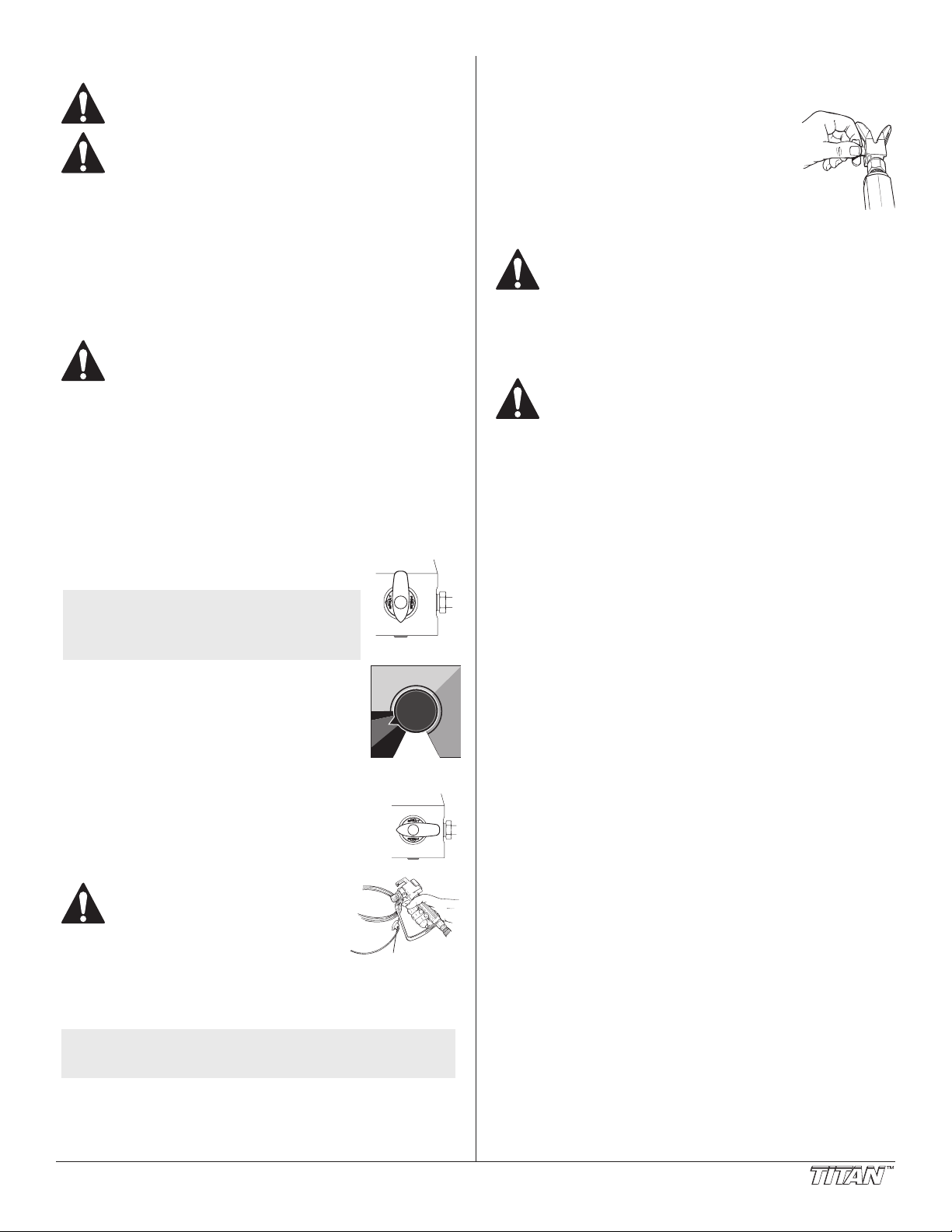

8. Use the lowest pressure setting

necessary to get a good spray

pattern. If the pressure is set

too high, the spray pattern will

Good spray pattern

be too light. If the pressure is

set too low, tailing will appear

or the paint will spatter out in

gobs rather than in a ne spray.

Paint tailing pattern

6 © Titan Tool Inc. All rights reserved.

Page 7

Cleanup

Do not use gasoline to clean the sprayer.

Special cleanup instructions for use with flammable

solvents:

• Always ush spray gun preferably outside and at least one

hose length from spray pump.

• If collecting ushed solvents in a one gallon metal container,

place it into an empty ve gallon container, then ush solvents.

• Area must be free of ammable vapors.

• Follow all cleanup instructions.

IMPORTANT: The sprayer, hose, and gun should be cleaned

thoroughly after daily use. Failure to do so permits material to

build up, seriously affecting the performance of the unit.

Cleaning the Spray Tip

1. Flush the gun with solvent immediately after the work is

completed.

2. Oil the sliding pins to prevent them

from seizing up.

Should the spray tip become clogged, reverse

the spray tip with the lever and pull the trigger.

Once the obstruction comes out of the spray

tip, release the trigger, reverse the spray tip

back to the spray pattern setting, and resume

spraying.

Do not attempt to clean the tip with your finger.

Do not use a needle or other sharp pointed instrument

to clean the tip. The hard tungsten carbide is brittle

and can be chipped.

Always spray at minimum pressure with the gun

nozzle tip removed when using mineral spirits or any

other solvent to clean the sprayer, hose, or gun. Static

electricity buildup may result in a fire or explosion in

the presence of flammable vapors.

1. Follow the “Pressure Relief Procedure” found in the Operation

section of this manual.

2. Remove the gun tip and tip guard and clean with a brush

using the appropriate solvent.

3. Place the siphon tube into a container of the appropriate

solvent (refer to recommendations of the material

manufacturer). An example of the appropriate solvent is

water for latex paint.

4. Place the return hose into a metal waste container.

5. Move the PRIME/SPRAY valve down to the

PRIME position.

NOTE: Hold the return hose in the waste

container when moving the PRIME/

SPRAY valve to PRIME in case the

sprayer is pressurized.

E

&

n

s

r

a

e

m

u

e

q

l

c

s

a

L

,

6. Turn the unit on and set the pressure to Turbo

PulseClean by turning the pressure control

knob to its CLEAN position in the red zone.

7. Allow the solvent to circulate through the unit

and ush the paint out of the return hose into

the metal waste container.

s

r

a

e

l

C

y

a

r

p

S

Min.

PSI

(Bar)

Clean

On/O

Max. PSI

H

e

a

v

i

e

r

C

o

a

t

i

n

g

s

(Bar)

8. Turn the unit o by moving the pressure

control knob to the OFF position in the black zone.

9. Move the PRIME/SPRAY valve up to its SPRAY

position.

10. Turn the unit on and set the pressure to Turbo

PulseClean by turning the pressure control knob

to its CLEAN position in the red zone.

Ground the gun by holding it against

the edge of the metal container

while flushing. Failure to do so may

lead to a static electric discharge,

which may cause a fire.

11. Trigger the gun into the metal waste container until the paint

is ushed out of the hose and solvent is coming out of the gun.

12. Continue to trigger the spray gun into the waste container

until the solvent coming out of the gun is clean.

Maintenance

Before proceeding, follow the “Pressure Relief

Procedure” outlined previously in this manual.

Additionally, follow all other warnings to reduce the

risk of an injection injury, injury from moving parts

or electric shock. Always unplug the sprayer before

servicing!

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

Phillips Screwdriver 3/8” Hex Wrench

Needle Nose Pliers 5/16” Hex Wrench

Adjustable Wrench 1/4” Hex Wrench

Rubber Mallet 3/16” Hex Wrench

Flat-blade Screwdriver 5/32” Hex Wrench

1. Before repairing any part of the sprayer, read the instructions

carefully, including all warnings.

IMPORTANT: Never pull on a wire to disconnect it. Pulling on a

wire could loosen the connector from the wire.

S

p

r

a

y

L

2. Test your repair before regular operation of the sprayer to be

a

t

e

x

P

a

i

n

t

s

&

sure that the problem is corrected. If the sprayer does not

operate properly, review the repair procedure to determine if

everything was done correctly. Refer to the Troubleshooting

section to help identify other possible problems.

3. Make sure that the service area is well ventilated in case

solvents are used during cleaning. Always wear protective

eyewear while servicing. Additional protective equipment

may be required depending on the type of cleaning solvent.

Always contact the supplier of solvents for recommendations.

4. If you have any further questions concerning your TITAN

Airless Sprayer, call TITAN:

Technical Service (U.S.) ...................................... 1-800-526-5362

Fax ................................................................. 1-800-528-4826

NOTE: For long-term or cold weather storage, pump

mineral sprits through the entire system.

13. Follow the “Pressure Relief Procedure” found in the Operation

section of this manual.

14. Unplug the sprayer and store in a clean, dry area.

IMPORTANT: Do not store the unit under pressure.

© Titan Tool Inc. All rights reserved. 7

Page 8

Replacing the PRIME/SPRAY Valve

Housing

Valve Handle

n

Handle

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 0507690.

1. Drive the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly.

4. Make sure the gasket is in place and thread the new valve

housing assembly into the lter block. Tighten securely with a

wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam with

the lter block using the dowel pin.

6. Line up the hole on the valve stem with the hole in the valve

handle.

7. Insert the groove pin into the valve handle and through the

valve stem to secure the valve handle in position.

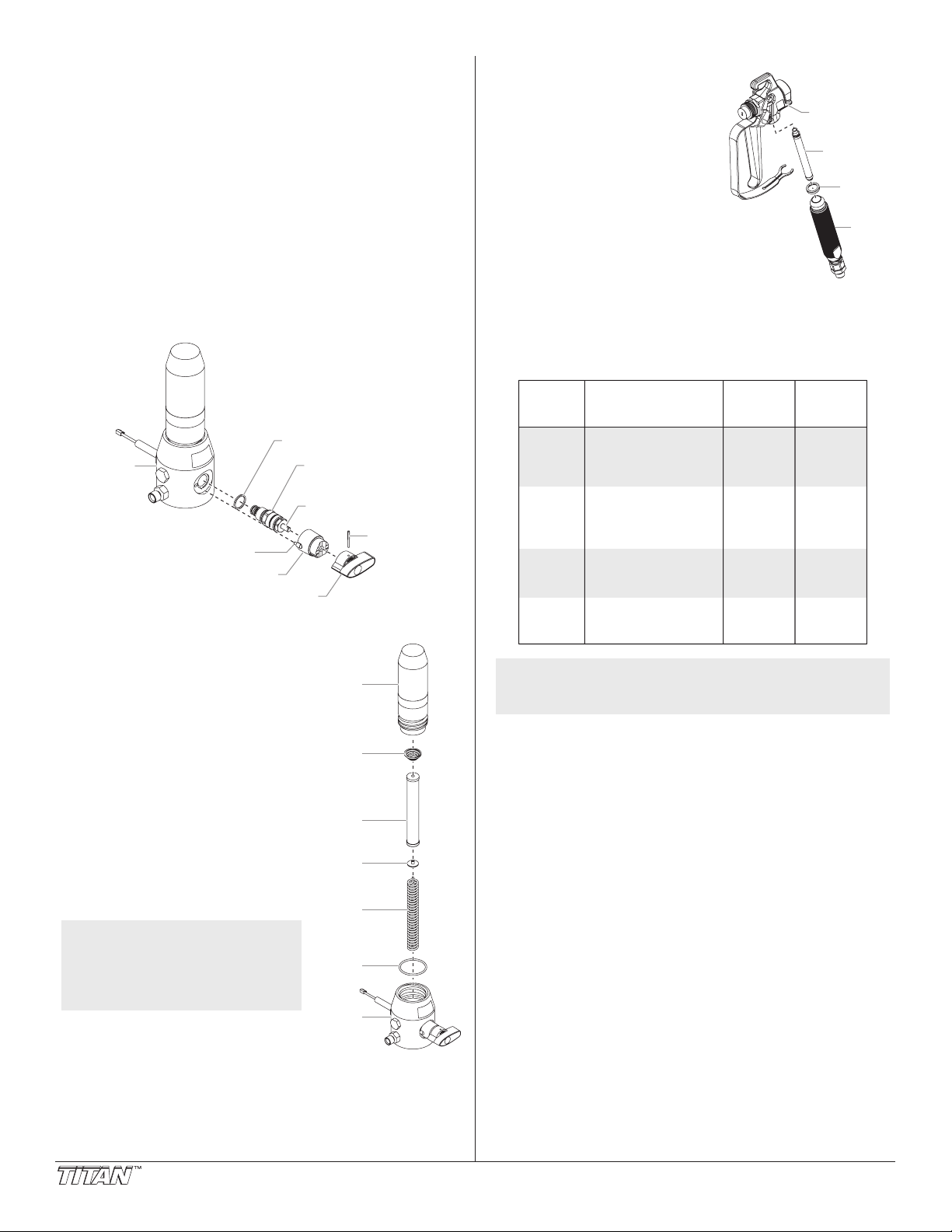

Gun Filter

1. Pull the bottom of the trigger

guard forward so that it comes

loose from the handle assembly.

2. Loosen and remove the handle

assembly from the gun head.

Gun

Housing

Filter

3. Pull the old lter out of the gun

head.

4. Slide the new lter, tapered end

rst, into the gun head.

Handle

Seal

5. Make sure the handle seal is in

position and thread the handle

assembly into the gun head until

secure.

6. Snap the trigger guard back onto the handle assembly.

Choosing the Correct Spray Gun Filter

Use the proper gun lter based on the type of material being applied

as shown below.

Gasket

Filter

Dowel Pin

Cam Base

Replacing the Filters

Pump Filter

1. Loosen and remove the lter body

by hand.

2. Slip the lter o of the core spring.

3. Inspect the lter. Based on

inspection, clean or replace the

lter.

4. Inspect the o-ring. Based on

inspection, clean or replace the

o-ring.

5. Slide the new or cleaned lter over

the core spring with the lter spring

adapter in place. Push the lter

into the center of the lter housing.

6. Slide the lter body over the lter

and thread it into the lter housing

until secure.

NOTE: The lter housing should be

hand-tightened, but make

sure the lter housing is

seated fully into the pump

manifold.

Valve Housing

Assembly

Valve Stem

Groove Pi

Filter

Body

Filter

Spring

Filter

Adapter

Core

Spring

O-ring

Filter

Housing

Part

Number

0089960 Synthetic resin,

0089959 Base coat enamels,

0089958 Emulsions,

0089957 Heavy bodied latex,

Application Filter

enamels, clean

varnishes, stains

azures

primer enamels,

llers, marking paints,

textured enamels

latex paints,

acrylic paints

blockllers,

elastometrics

Type

Extrane red

Fine yellow

Medium white

Coarse green

Color of

Filter

Body

NOTE: For more detail, part number information, and an

assembly drawing, please see the G-10 Airless Spray

Gun Owner’s Manual (P/N 0286928).

8 © Titan Tool Inc. All rights reserved.

Page 9

Replacing the Motor Assembly (with Electronic

Motor Shroud Screws

Housing Gasket

Elec

Front End Bell

Fr

Control)

Electrostatic discharge (ESD) potential could cause

damage to electronic control. Use ESD wrist strap

when working on electronic control with electronic

cover removed.

1. Perform the Pressure Relief Procedure and unplug the sprayer.

2. Turn the pressure control knob to the “MIN PSI” position to

make sure the power supply has discharged.

3. Loosen and remove the four motor shroud screws. Remove

the motor shroud.

4. Release the tie wrap on the top of the bae assembly and slip

the bae assembly down o of the motor.

5. Loosen and remove the three electronic cover screws. Lift the

electronic cover o of the electronic control assembly on the

motor.

6. At the electronic control assembly:

a. Disconnect the white wire coming from the power cord and

the white wire coming from the relay.

b. Disconnect the three wires coming from the potentiometer.

7. Loosen and remove the three motor mounting screws.

8. Pull the motor out of the gearbox housing.

9. With the motor removed, inspect the gears in the gearbox

housing for damage or excessive wear. Replace the gears, if

necessary.

10. Install the new motor into the gearbox housing. Make sure

the housing gasket is positioned properly.

11. Secure the motor with the three motor mounting screws.

12. Reconnect the wires to the electronic control assembly (refer

to the electrical schematic in the Parts List section of this

manual).

13. Position the electronic cover over the electronic control

assembly. Secure the electronic cover with the three

electronic cover screws.

IMPORTANT: Use only Titan electronic cover screws to secure the

electronic cover (see Drive Assembly parts list). Use of any other

screws may damage the electronic control assembly.

14. Slip the bae assembly up and around the motor. Secure the

bae assembly with the tie wrap.

15. Slide the motor shroud over the motor.

16. Secure the motor shroud with the four motor shroud screws.

Replacing the Gears

1. Perform the Pressure Relief Procedure and unplug the unit.

2. Turn the pressure control knob to the “MIN PSI” position to

make sure the power supply has discharged.

3. Loosen and remove the four motor shroud screws. Remove

the motor shroud.

4. Release the tie wrap on the top of the bae assembly and slip

the bae assembly down o of the motor.

5. Loosen and remove the three electronic cover screws. Lift the

electronic cover o of the electronic control assembly on the

motor.

6. At the electronic control assembly:

a. Disconnect the white wire coming from the power cord and

the white wire coming from the relay.

b. Disconnect the three wires coming from the potentiometer.

7. Loosen and remove the three motor mounting screws.

8. Pull the motor out of the gearbox housing.

9. Inspect the armature gear on the end of the motor for

damage or excessive wear. If this gear is completely worn out,

replace the motor.

10. Remove and inspect the 1st stage gear and 2nd stage

gear assemblies for damage or excessive wear. Replace, if

necessary.

11. Remove and inspect the front gear box assembly for damage

or excessive wear. If damaged or worn, replace the front gear

box assembly.

NOTE: Clean and rell the gear box cavity up to the rear face

of each gear with grease (P/N 9870304).

12. Install the motor into the gearbox housing. Make sure the

housing gasket is positioned properly.

13. Secure the motor with the three motor mounting screws.

14. Reconnect the wires to the electronic control assembly (refer

to the electrical schematic in the Parts List section of this

manual).

15. Position the electronic cover over the electronic control

assembly. Secure the electronic cover with the three

electronic cover screws.

16. Slip the bae assembly up and around the motor. Secure the

bae assembly with the tie wrap.

17. Slide the motor shroud over the motor.

18. Secure the motor shroud with the four motor shroud screws.

Motor Shroud

Electronic Cover

tronic Cover

Screw

Gearbox

Housing

© Titan Tool Inc. All rights reserved. 9

Motor Mounting

Screw

Electronic Control

Assembly

Motor

Bae Assembly

Assembly

Armature Gear

1st Stage Gear

2nd Stage Gear

ont Gear Box

Assembly

Housing

Gasket

Page 10

Replacing the Transducer

Motor Shroud Screws

ilter

e

e

e

e

Cylinder

1. Perform the Pressure Relief Procedure and unplug the unit.

2. Turn the pressure control knob to the “MIN PSI” position to

make sure the power supply has discharged.

3. Loosen and remove the four motor shroud screws. Remove

the motor shroud.

4. At the electronic control assembly, disconnect the black wire

coming from the transducer.

5. Pull the grommet out of the mounting plate and slide it up

the shaft of the transducer until it is clear of the mounting

plate.

6. Using a wrench, loosen and remove the transducer from

the lter housing. Carefully thread the transducer wire out

through the mounting plate.

7. Slide the grommet o of the old transducer and onto the new

transducer.

8. Thread the new transducer wire through the mounting plate

and up to the electronic control assembly.

9. Thread the new transducer into the lter housing and tighten

securely with a wrench.

NOTE: Make sure the transducer cap and inner seal on

the transducer are in place before threading the

transducer into the lter housing.

10. Push the grommet into the mounting plate.

11. Connect the transducer wire to the electronic control

assembly (refer to the electrical schematic in the Parts List

section of this manual).

12. Slide the motor shroud over the motor.

13. Secure the motor shroud with the four motor shroud screws.

Electronic

Control

Assembly

Servicing the Fluid Section

Use the following procedures to service the valves and repack the

uid section.

1. Loosen and remove the four front cover screws. Remove the

front cover.

2. Position the crankshaft/slider assembly at the bottom, deadcenter of its stroke so that the connecting pin and retaining

ring are visible below the slider assembly. This is done

by turning the sprayer on and o in short bursts until the

connecting pin is visible below the slider housing.

3. Turn o and unplug the unit.

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce the

risk of an injection injury, injury from moving parts

or electric shock. Always unplug the sprayer before

servicing!

4. Remove the return hose from the clamp on the siphon tube.

5. Unscrew the siphon tube/suction set from the inlet valve.

6. Loosen and remove the high-pressure hose from the nipple

on the back of the cylinder of the uid section.

7. Slide the retaining ring up on

the slider assembly to expose

the connecting pin.

8. Push the connecting pin

forward through the slider

assembly and piston. The

connecting pin will fall into

a recessed area of the gear

box housing where it can be

retrieved.

9. Using a wrench, turn the jam

nut counterclockwise to loosen

it from the gear box housing.

10. Turn the uid section

counterclockwise to remove it

from the gear box housing.

11. Place the uid section cylinder

upright in a vise by clamping

on the wrench ats.

Crankshaft

Slider

Assembly

Connecting

Pin

Retaining

Ring

Jam Nut

Cylinder

Mounting Plate

Grommet

Transducer

To F

Motor Shroud

NOTE: Do not over-tighten the vise. Damage to the

12. Loosen and remove the

13. Remove the inlet valve cage,

14. Clean out any debris in the

15. Using a wrench, remove the

16. Slide the piston rod out

17. Inspect the piston rod for wear

18. Remove the upper packing assembly from the top of the

19. Remove the adapter and lower packing assembly from the

NOTE: Be careful not to scratch, score, or otherwise

cylinder may occur.

inlet valve housing from the

cylinder.

inlet valve ball, inlet valve seat,

and o-ring from the inlet valve.

inlet valve housing and

examine the housing and the

inlet valve seat. If the seat is

damaged, reverse or replace

the seat.

upper seal retainer.

through the bottom of the

cylinder.

and replace if necessary.

cylinder.

bottom of the cylinder.

damage the cylinder during removal of the

packings.

Inlet Valv

Cage

Inlet Valv

Ball

Inlet Valv

Seat

O-ring

Viton

O-Ring

PTFE

Back-Up

Ring

Inlet Valv

Housing

10 © Titan Tool Inc. All rights reserved.

Page 11

Upper

e

e

e

e

e

Retainer

20. Remove the cylinder from the vise.

21. Insert the connection pin through

the hole at the top of the piston

rod and clamp each end of the

connecting pin in the vise. This will

hold the piston rod in position for

disassembly.

Seal

Retainer

Upper

Support

Ring

Upper

Packing

NOTE: Do not clamp the piston

Assembly

rod directly in the vise.

Damage to the piston rod

will occur.

22. Using a 3/8” hex wrench, loosen

Cylinder

and remove the outlet valve

retainer from the piston rod.

23. Remove the outlet valve seat,

outlet valve ball, nylon washer,

outlet valve cage, and outlet valve

seal from the piston rod.

24. Clean out any debris and examine

the retainer and outlet valve seat.

If the seat is damaged, reverse or

Lower

Packing

Assembly

Adapter

replace the seat.

25. Clean and inspect the outlet valve

cage and outlet valve ball. Replace

if they are worn or damaged.

26. Reassemble the outlet valve

Piston Rod

assembly into the piston rod in

the reverse order of how it was

disassembled. Torque the outlet

valve retainer to 12 ft. lbs.

27. Remove the piston rod from the

vise.

28. Clean the cylinder. Inspect the

cylinder for damage and replace if

necessary.

29. Place the cylinder upright in a vise

by clamping on the wrench ats.

30. Locate the new upper and lower

packings and remove the pre-form

tools. Save the upper packing

Outlet Valv

Seal

Outlet Valv

Cage

Nylon

Washer

Outlet Valv

Ball

Outlet Valv

Seat

Outlet Valv

pre-form tool for use as the piston

insertion tool later in this procedure.

NOTE: Do not remove the pre-form tools from the upper

and lower packings until immediately before they

are installed into the cylinder.

31. Pack the areas between the packing

lips with grease. Lubricate the

o-rings on the exterior of the

Install upper packing

with raised lip

facing down.

packings with grease.

32. Insert the upper packing into the

top of the cylinder with the raised

lip on the packing facing down

toward the cylinder.

Raised Lip

33. Insert the upper support ring on top of the upper packing.

34. Thread the upper seal retainer into

Large Beveled Edge

the cylinder and torque to 25-30 ft.

lbs.

35. Rotate the cylinder in the vise so that

the bottom end is facing up.

36. Insert the lower packing partially into

the bottom of the cylinder with the

large beveled edge facing toward the

cylinder (beveled edge will be facing

Install lower packing so

large beveled edge will

be facing up when the

cylinder is upright.

up when the cylinder is upright).

37. Push the lower packing assembly

into position using the lower packing insertion tool (see Fluid

Section Assembly parts list for lower packing insertion tool

P/N).

© Titan Tool Inc. All rights reserved. 11

NOTE: Coat the piston insertion tool (i.e. upper packing

pre-form tool) and the piston rod with grease

before inserting them into the cylinder.

38. Place the piston insertion tool over the top of the piston rod.

39. Insert the piston rod into the bottom of the cylinder, through

the lower packing assembly, through the upper packing

assembly, and out through the upper seal retainer.

NOTE: Make sure the raised lip on the bottom of the lower

packing is fully outside the packing around the

piston rod after insertion of the piston rod.

40. Remove the piston insertion tool from the top of the piston

rod.

41. Turn the jam nut counterclockwise until it is ush against the

top of the cylinder.

42. Lubricate the threads on the cylinder with anti-seize

compound. Remove the cylinder from the vise.

43. Thread the cylinder into the gear box housing, turning

clockwise. When the connecting pin hole on the piston

rod lines up with the hole in the slider assembly, insert the

connecting pin.

44. Slide the retaining ring down over the connecting pin.

45. Continue to turn the cylinder clockwise until the jam nut is

ush against the gear box housing.

NOTE: If the nipple on the cylinder does not face the back

of the unit, turn the cylinder counterclockwise until

the nipple faces the back of the unit. Do not turn

the cylinder more than one full turn.

46. Once the nipple is positioned, turn the jam nut clockwise until

it contacts the gear box housing.

47. Tighten the jam nut with a wrench to tighten it against the

gear box housing.

48. Attach the high-pressure hose to the nipple on the back of the

cylinder and tighten with a wrench. Do not kink the hose.

NOTE: For low rider units, make sure the hose does not

touch the cart frame. If it does, reposition the

nipple by turning the cylinder until the hose is clear

of the frame and the nipple is within 45º of the back

of the unit.

49. Insert the adapter into the bottom of the cylinder.

50. Making sure that the Viton o-ring and PTFE back-up ring are

lubricated and in place, reassemble the inlet valve assembly

and and thread it into the cylinder. Tighten the inlet valve

housing until the o-ring engages, then continue to tighten

until snug. Once snug, tighten an additional 1/8–1/4 turn.

51. Thread the siphon tube/suction set into the inlet valve

housing and tighten securely. Make sure to wrap the threads

on the down tube/siphon hose adapter with PTFE tape before

assembly.

52. Replace the return hose into the clamp on the siphon tube.

53. Place the front cover on the gearbox housing and secure in

position using the four front cover screws.

54. Turn on the sprayer by following the procedure in the

“Operation” section of this manual and check for leaks.

NOTE: Repacking kit P/N 0551687 is available. For best

results use all parts supplied in this kit.

Page 12

Troubleshooting

Problem

A. The unit will not run.

B. The unit will not prime.

C. The unit will not build or

maintain pressure.

D. Fluid leakage at the upper end

of the uid section.

E. Excessive surge at the spray

gun.

F. Poor spray pattern.

G. The unit lacks power.

Cause

1. The unit is not plugged in.

2. Tripped breaker.

3. The pressure is set too low (pressure control

knob set at minimum setting does not supply

power to unit).

4. Faulty or loose wiring.

5. Excessive motor temperature.

1. The PRIME/SPRAY valve is in the SPRAY

position.

2. Air leak in the siphon tube/suction set.

3. The pump lter and/or inlet screen is clogged.

4. The siphon tube/suction set is clogged.

1. The spray tip is worn.

2. The spray tip is too large.

3. The pressure control knob is not set properly.

4. The pump lter, gun lter, or inlet screen is

clogged.

5. Material ows from the return hose when the

PRIME/SPRAY valve is in the SPRAY position.

6. Air leak in the siphon tube/suction set.

7. There is external uid leak.

8. There is an internal uid section leak

(packings are worn and/or dirty, valve balls

are worn).

9. Worn valve seats

10. Motor powers but fails to rotate

1. The upper packings are worn.

2. The piston rod is worn.

1. Wrong type of airless spray hose.

2. The spray tip worn or too large.

3. Excessive pressure.

1. The spray tip is too large for the material

being used.

2. Incorrect pressure setting.

3. Insucient uid delivery.

4. The material being sprayed is too viscous.

1. The pressure adjustment is too low.

2. Improper voltage supply.

Solution

1. Plug the unit in.

2. Reset the breaker.

3. Turn the pressure control knob clockwise to supply

power to the unit and increase the pressure setting.

4. Inspect or take to a Titan authorized service center.

5. Allow motor to cool.

1. Rotate the PRIME/SPRAY valve clockwise to the PRIME

position.

2. Check the siphon tube/suction set connection and

tighten or re-tape the connection with PTFE tape.

3. Remove the pump lter element and clean. Remove the

inlet screen and clean.

4. Remove the siphon tube/suction set and clean.

1. Replace the spray tip following the instructions that

came with the spray gun.

2. Replace the spray tip with a tip that has a smaller orice

following the instructions that came with the spray gun.

3. Turn the pressure control knob clockwise to increase the

pressure setting.

4. Remove the pump lter element and clean. Remove the

gun lter and clean. Remove the inlet screen and clean.

5. Clean or replace the PRIME/SPRAY valve.

6. Check the siphon tube/suction set connection and

tighten or re-tape the connection with PTFE tape.

7. Check for external leaks at all connections. Tighten

connections, if necessary.

8. Clean the valves and service the uid section following

the “Servicing the Fluid Section” procedure in the

Maintenance section of this manual.

9. Reverse or replace the valve seats following the

“Servicing the Fluid Section” procedure in the

Maintenance section of this manual.

10. Take unit to a Titan authorized service center.

1. Repack the pump following the “Servicing the Fluid

Section” procedure in the Maintenance section of this

manual.

2. Replace the piston rod following the “Servicing the Fluid

Section” procedure in the Maintenance section of this

manual.

1. Replace hose with a minimum of 50’ of 1/4” grounded

textile braid airless paint spray hose.

2. Replace the spray tip following the instructions that

came with the spray gun.

3. Rotate the pressure control knob counterclockwise to

decrease spray pressure.

1. Replace the spray tip with a new or smaller spray tip

following the instructions that came with the spray gun.

2. Rotate the pressure control knob to adjust the pressure

for a proper spray pattern.

3. Clean all screens and lters.

4. Add solvent to the material according to the

manufacturer’s recommendations.

1. Rotate the pressure control knob clockwise to increase

the pressure setting.

2. Reconnect the input voltage for 120V AC.

12 © Titan Tool Inc. All rights reserved.

Page 13

Notes

© Titan Tool Inc. All rights reserved. 13

Page 14

Consignes de sécurite important

Lire toutes ces consignes avant d’utiliser l’appareil.

Garder ces consignes.

Indique une situation à risque, laquelle, si elle n’est pas

évitée, peut entraîner des blessures graves, voire la mort.

Pour réduire les risques d’incendie ou d’explosion,

de choc électrique et de blessure, vous devez lire et

comprendre les directives gurant dans ce manuel.

Familiarisez-vous avec les commandes et l’utilisation

adéquate de l’équipement.

Directives de mise à la terre

Cet appareil doit être mis à la terre. En cas de court-circuit, cette précaution

réduit les risques de choc en procurant un parcours au courant électrique. Le

cordon de l’appareil est doté d’un l de terre relié à la troisième broche de sa

che. Cette dernière doit être branchée dans une prise correctement câblée et

mise à la terre conformément aux codes et règlements locaux.

MISE EN GARDE - Le fait de ne pas brancher correctement la

che trilaire de l’appareil peut entraîner des risques de choc

électrique.

Si on doit réparer ou remplacer le cordon ou la che, ne pas raccorder le

l de terre à la borne des broches plates (lames) de cette dernière. Ce l,

normalement vert (avec ou sans rayures jaunes), doit être relié à la broche de

terre.

Consulter un technicien ou un électricien qualié à défaut de comprendre

l’ensemble des présentes directives ou en cas d’incertitude quant à la mise à

terre de l’appareil. Ne pas modier la che de l’appareil; si elle ne s’adapte pas

dans la prise voulue, la faire remplacer par un électricien qualié.

Conçu pour les circuits de 120 V, cet appareil est doté d’une che ressemblant

à celle illustrée ci-dessous. S’assurer que le produit est connecté à une prise

électrique ayant la même conguration que la che mâle. Ne pas utiliser

d’adaptateur avec ce produit.

Prise trilaire

Broche de mise à la terre

Plaque murale de la prise

IMPORTANT: Quand le pulvérisateur est utilisé avec un générateur de

tension de la ligne ou non, l’utilisation de Titan “Line Surge Protector” (P

/ N 800-935) est recommandé.

MISE EN GARDE : EXPLOSION OU INCENDIE

Les émanations de certains produits peuvent exploser

ou s’enammer, et risquent d’entraîner des dommages

matériels ou de graves blessures.

MESURES PRÉVENTIVES :

• Ne pulvérisez pas de matières inammables ou combustibles près

d’une amme nue, de voyants lumineux ou de sources d’ignition

telles que des objets chauds, cigarettes, moteurs, matériel et appareils

électriques. Évitez de produire des étincelles en connectant et en

déconnectant les cordons électriques.

• S’entourer de toutes les précautions possibles lorsqu’on utilise

des produits ayant un point d’éclair inférieur à 38°C (100°F). Le

point d’éclair est la température à laquelle le liquide peut créer

susamment de vapeurs et s’enammer.

• L’écoulement de peinture ou de solvant dans l’équipement peut

produire de l’électricité statique. L’électricité statique crée un risque

d’incendie ou d’explosion en présence de fumées de peinture ou de

solvant. Toutes les pièces du système du pulvérisateur, y compris la

pompe, l’ensemble du tuyau, le pistolet de pulvérisation et les objets

dans et autour de la zone de pulvérisation doivent être correctement

reliés à la terre pour protéger contre les décharges d’électricité

statique et les étincelles. N’utilisez que des tuyaux conducteurs ou

reliés à la terre pour pulvérisateurs de peinture sous vide à haute

pression, spéciés par le fabricant.

• Vériez que tous les conteneurs ou systèmes de stockage sont reliés à

la terre pour éviter les décharges d’électricité statique.

• Connectez à une prise électrique avec prise de terre et utilisez des

rallonges électriques reliées à la terre. N’utilisez pas d’adaptateur 3 à 2.

• N’utilisez pas de peinture ou de solvant contenant du halon,

par exemple, le chlore, les agents antimoisissure à l’eau de

Javel, le chlorure de méthylène et le trichloroéthane. Ils ne sont

pas compatibles avec l’aluminium. Contactez le fournisseur de

revêtements pour connaître la compatibilité du matériau avec

l’aluminium.

• La zone de pulvérisation doit toujours être bien aérée. Une

bonne quantité d’air frais doit constamment traverser la zone de

pulvérisation pour éviter les accumulations de vapeurs inammables.

Le système de pompage doit être placé dans une zone bien aérée. Ne

pulvérisez pas le système de pompage.

• Ne fumez pas dans la zone de pulvérisation.

• N’actionnez pas d’interrupteurs électriques, de moteurs ou autres

dispositifs produisant des étincelles dans la zone de pulvérisation.

• Maintenez la propreté de la zone et veillez à ce qu’elle ne contienne

pas de conteneurs de peinture ou de solvant, de chions et autres

matières inammables.

• Sachez ce que contiennent la peinture et les solvants pulvérisés. Lisez

les ches de sécurité du matériel (MSDS) et les étiquettes apposées sur

les conteneurs de peintures et de solvants. Respectez les consignes de

sécurité du fabricant de peinture et de solvant.

• Placez la pompe à une distance minimum de 7,62 mètres (25 pieds) de

l’objet à pulvériser, dans une zone bien aérée (ajoutez de la longueur

de tuyau si besoin est). Les vapeurs inammables sont souvent plus

lourdes que l’air. La zone près du sol doit être très bien aérée. La

pompe contient des pièces qui produisent des arcs et émettent des

étincelles pouvant enammer les vapeurs.

• Le plastique peut causer des étincelles d’électricité statique.

N’accrochez aucun plastique dans une zone de pulvérisation fermée.

N’utilisez pas de toiles de protection en plastique quand vous

pulvérisez une matière inammable.

• Ayez un extincteur en bon état de fonctionnement à portée de main.

14 © Titan Tool Inc. Tous droits réservés.

Français

Page 15

Consignes de sécurite important

MISE EN GARDE : INJECTION CUTANÉE

Le jet de haute pression produit par cet appareil peut

transpercer la peau et les tissus sous-jacents, causant des

blessures graves pouvant entraîner l’amputation.

MESURES PRÉVENTIVES :

• Ne dirigez pas le pistolet sur et ne pulvérisez pas les personnes ou les

animaux.

• N’approchez pas les mains ni d’autres parties du corps de la sortie du

produit. Par exemple, ne tentez pas d’arrêter une fuite avec une partie

du corps.

• NE JAMAIS mettre la main, même gantée, devant le pistolet (les gants

n’orent aucune protection contre les blessures par injection).

• TOUJOURS s’assurer que le protège-embout est en place avant

de pulvériser. Il est cependant à noter que, s’il assure une certaine

protection, ce dispositif joue surtout un rôle préventif.

• Utilisez exclusivement un embout de buse spécié par le fabricant.

• Prenez garde quand vous nettoyez ou que vous changez les embouts

de buse. Si l’embout se bouche pendant que vous pulvérisez,

verrouillez TOUJOURS la détente du pistolet, arrêtez la pompe et

libérez toute la pression avant de réparer ou de nettoyer l’embout

ou le protecteur ou avant de changer d’embout. La pression n’est

pas libérée par l’arrêt du moteur. La poignée du robinet-valve PRIME/

SPRAY doit être placée sur PRIME pour libérer la pression. Consultez

la PROCÉDURE DE DÉCOMPRESSION décrite dans le manuel de la

pompe.

• Ne laissez pas l’appareil sous tension ou sous pression quand vous

vous en éloignez. Quand vous n’utilisez pas l’appareil, éteignez-le et

libérez la pression conformément aux instructions du fabricant.

• La pulvérisation à haute pression peut injecter des toxines dans le

corps et causer de graves blessures corporelles. Si une telle injection se

produisait, consultez immédiatement un médecin.

• Vériez les tuyaux et les pièces pour détecter des signes

d’endommagement : une fuite peut injecter le produit dans la peau.

Inspectez le tuyau avant chaque emploi. Changez tous les tuyaux

ou pièces endommagés. Pour des raisons de fonctionnement, de

sécurité et de durée de vie, utiliser exclusivement des tuyaux exibles

à haute pression d‘origine de TITAN.

• Ce système peut produire une pression de 3 100 PSI / 214 Bar.

N’utilisez que les pièces de rechange ou les accessoires spéciés par le

fabricant et ayant une pression nominale minimum de 3 100 PSI. Ceci

est valable pour les embouts de pulvérisation, les protecteurs de buse,

les pistolets, les rallonges, les raccords et le tuyau.

• Verrouillez toujours la détente quand vous ne pulvérisez pas. Vériez

que le verrou de la détente fonctionne correctement.

• Vériez que toutes les connexions sont bien serrées avant d’utiliser

l’appareil.

• Sachez comment arrêter l’appareil et le dépressuriser rapidement.

Soyez bien familiarisé avec les commandes. La pression n’est pas

libérée lorsque le moteur est arrêté. La poignée du robinet-valve

PRIME/SPRAY doit être placée sur PRIME pour libérer la pression.

Consultez la PROCÉDURE DE DÉCOMPRESSION décrite dans le

manuel de la pompe.

• Retirez toujours l’embout de pulvérisation avant de rincer ou de

nettoyer le système.

REMARQUE À L’INTENTION DES MÉDECINS : Les injections cutanées

sont des lésions traumatiques; il importe donc de les traiter sans délai.

On NE DOIT PAS retarder ce traitement sous prétexte de vérier la

toxicité du produit en cause, celle-ci n’étant conséquente que dans le

cas d’injection directe de certains produits dans le système sanguin.

Il pourrait s’avérer nécessaire de consulter un plasticien ou un

spécialiste en chirurgie reconstructive de la main.

MISE EN GARDE : ÉMANATIONS DANGEREUSES

Certains produits (peintures, solvants, insecticides ou

autres) peuvent être nocifs s’ils sont inhalés ou entrent en

contact avec l’organisme. Les émanations de ces produits

peuvent provoquer de graves nausées, évanouissements

ou empoisonnements.

MESURES PRÉVENTIVES :

• Se servir d’un masque ou d’un respirateur s’il y a risque d’inhalation

(lire toutes les directives concernant ces dispositifs an de s’assurer

qu’ils orent la protection requise).

• Porter des lunettes de protection.

• Porter les vêtements de protection prescrits par le fabricant du produit

utilisé.

MISE EN GARDE : GÉNÉRALITÉS

D’autres dangers peuvent entraîner des dommages

matériels ou des blessures graves.

MESURES PRÉVENTIVES :

• Portez toujours les gants, la protection oculaire, les vêtements et un

respirateur ou masque appropriés quand vous peignez.

• Ne travaillez pas et ne pulvérisez pas près d’enfants. Éloignez toujours

les enfants de l’équipement.

• Ne travaillez pas avec les bras au-dessus de la tête ni sur un support

instable. Appuyez-vous bien sur les deux pieds pour toujours

conserver l’équilibre.

• Soyez attentif et regardez ce que vous faites.

• N’utilisez pas l’appareil quand vous êtes fatigué ou sous l’inuence de

drogues ou d’alcool.

• Ne faites pas de nœuds avec le tuyau et ne le tordez pas trop. Le

tuyau à vide peut présenter des fuites suite à l’usure, les nœuds ou

les mauvais traitements. Une fuite risque d’injecter du produit dans la

peau.

• N’exposez pas le tuyau à des températures ou des pressions

supérieures à celles spéciées par le fabricant.

• N’utilisez pas le tuyau pour tirer ou soulever l’équipement.

• Utilisez la plus basse pression possible pour rincer l’équipement.

• Respectez tous les codes locaux, étatiques et nationaux qui régulent la

ventilation, la prévention d’incendies et le fonctionnement.

• Les normes de sécurité du gouvernement des États-Unis ont été

adoptées dans la loi Occupational safety and Health Act (OSHA). Ces

normes, en particulier la partie 1910 des Normes générales et la partie

1926 des Normes de construction, doivent être consultées.

• Avant chaque emploi, vériez tous les tuyaux pour détecter

d’éventuelles coupures, fuites, abrasion ou couvercle bombé. Vériez

l’état ou le mouvement des accouplements. Changez immédiatement

le tuyau si l’une de ces conditions est vériée. Ne réparez jamais un

tuyau de peinture. Remplacez-le par un tuyau conducteur à haute

pression.

• Ne pulvérisez pas à l’extérieur par temps venteux.

• Débranchez toujours le cordon électrique de la prise avant de

travailler sur l’équipement.

© Titan Tool Inc. Tous droits réservés. 15

Français

Page 16

Información de seguridad importante

Receptáculo conectado a tierra

Lea toda la información de seguridad antes de

operar el equipo. Guarde estas insturcciones.

Indica una situación peligrosa que, de no evitarse,

puede causar la muerte o lesiones graves.

Para reducir los riesgos de incendios, explosiones,

descargas eléctricas o lesiones a las personas, lea y

entienda todas las instrucciones incluidas en este

manual. Familiarícese con los controles y el uso

adecuado del equipo.

Instrucciones para la conexión a tierra

Este producto debe conectarse a tierra. En caso de un cortocircuito eléctrico,

la conexión a tierra reduce el riesgo de choque eléctrico al aportar un alambre

de escape para la corriente eléctrica. Este producto está equipado con un

cable que tiene alambre a tierra con un enchufe a tierra adecuado. Debe

usarse el enchufe para conectar a un receptáculo que esté debidamente

instalado y conectado a tierra en conformidad con los códigos y las

ordenanzas locales.

ADVERTENCIA - La instalación incorrecta del enchufe a tierra

puede ocasionar un riesgo de choque eléctrico.

Si es necesario reparar o cambiar el cable o el enchufe, no conecte el cable

verde a tierra a ninguno de las terminales de espiga plana. El cable con

aislamiento de color verde por fuera con o sin rayas amarillas es el alambre a

tierra y debe conectarse a la espiga a tierra.

Consulte a un electricista o técnico de servicio capacitado si las instrucciones

para la conexión a tierra no se entienden claramente o si tiene dudas en

cuanto a que el producto esté debidamente conectado a tierra. No modique

el enchufe que se incluye. Si el enchufe no encaja en el receptáculo, pida a un

electricistas capacitado que instale un receptáculo adecuado.

Este producto es para utilizarse en un circuito de 120 voltios nominales y

tiene un enchufe a tierra que tiene un aspecto similar al ilustrado más abajo.

Asegúrese que el producto esté conectado a un tomacorriente que tenga la

misma conguración que el enchufe. No deben utilizarse adaptadores para

este producto.

Pata a tierra

Tapa de la caja de receptáculo conectada a tierra

IMPORTANTE: Cuando se usa el rociador con un generador o línea o sin

control, uncontrolled line voltage, se recomienda que Titan’s “Line Surge

Protector” (P/N 800-935) se utiliza.

ADVERTENCIA: EXPLOSIÓN O INCENDIO

Los vapores de solventes y pinturas pueden explotar o

inamarse. Pueden producirse daños materiales, lesiones

graves o ambos.

PREVENCIÓN:

• No pulverice materiales inamables ni combustibles cerca de llamas

desnudas, pilotos o fuentes de ignición como objetos calientes,

cigarrillos, motores, equipos eléctricos o electrodomésticos. Evite

producir chispas al conectar y desconectar los cables de alimentación.

• Tenga muchísmo cuidado al usar materiales cuyo punto de ignición

sea inferior a 38 ºC (100 °F). El punto de inamación es la temperatura

a la que un uido puede producir vapor suciente como para

incendiarse.

• La pintura o disolvente que pase por el equipo puede producir

electricidad estática. La electricidad estática supone un riesgo de

incendio o explosión en presencia de emanaciones de pintura o

disolvente. Todas las piezas del sistema pulverizador, incluyendo

la bomba, el conjunto de mangueras, la pistola pulverizadora y los

objetos dentro y alrededor de la zona de pulverización se conectarán

a tierra para protegerlos frente a descargas estáticas y chispas. Utilice

solamente mangueras para pulverizadores de pintura airless (sin aire)

de alta presión conductoras o con toma a tierra especicadas por el

fabricante.

• Compruebe que todos los recipientes y sistemas de recogida están

conectados a tierra para evitar descargas eléctricas.

• Conecte a una salida con toma a tierra y utilice cables alargadores

puestos a tierra. No utilice un adaptador de 3 a 2.

• No utilice pintura o disolvente que contenga hidrocarburos

halogenados, como cloro, fungicida blanqueador, cloruro de

metileno y tricloroetano. No son compatibles con el aluminio.