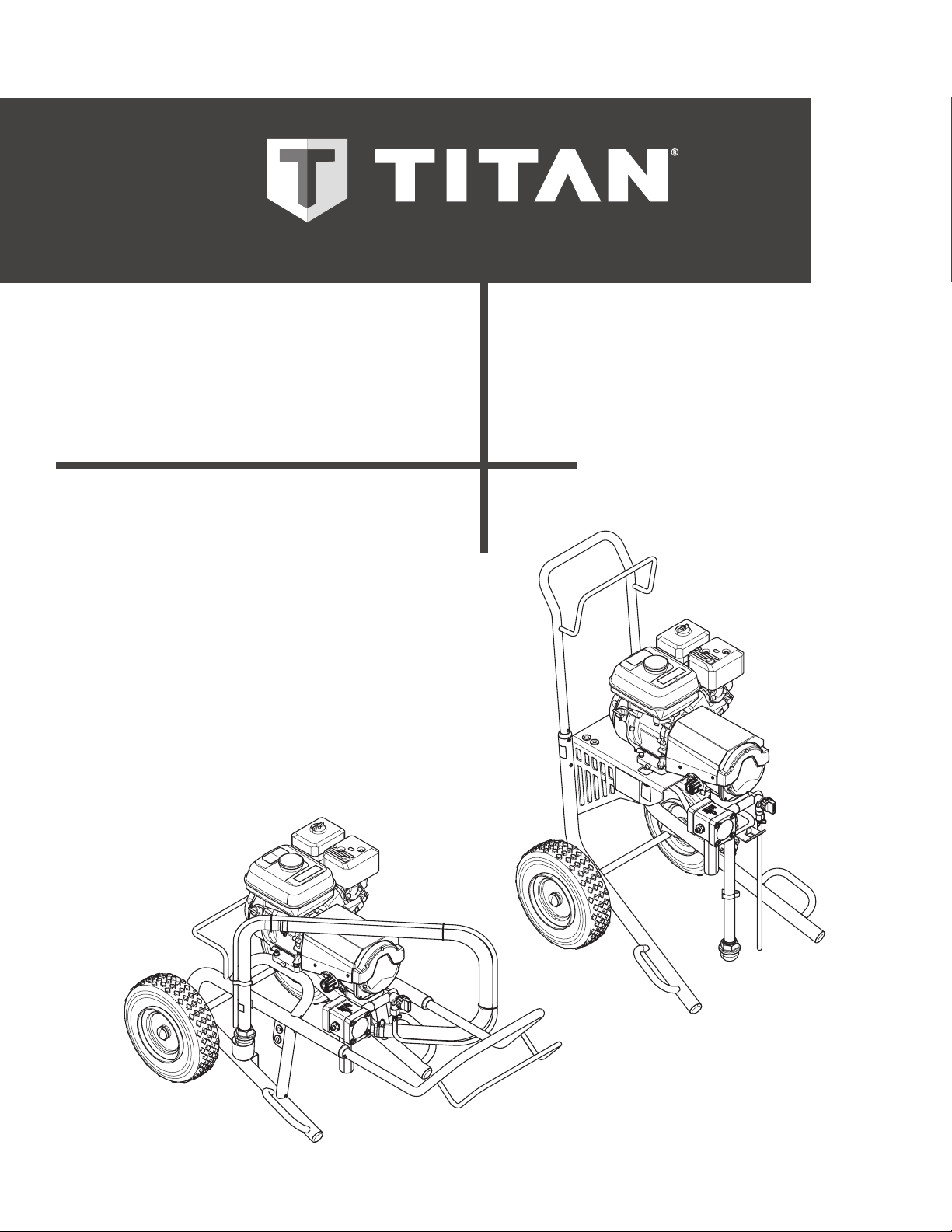

Page 1

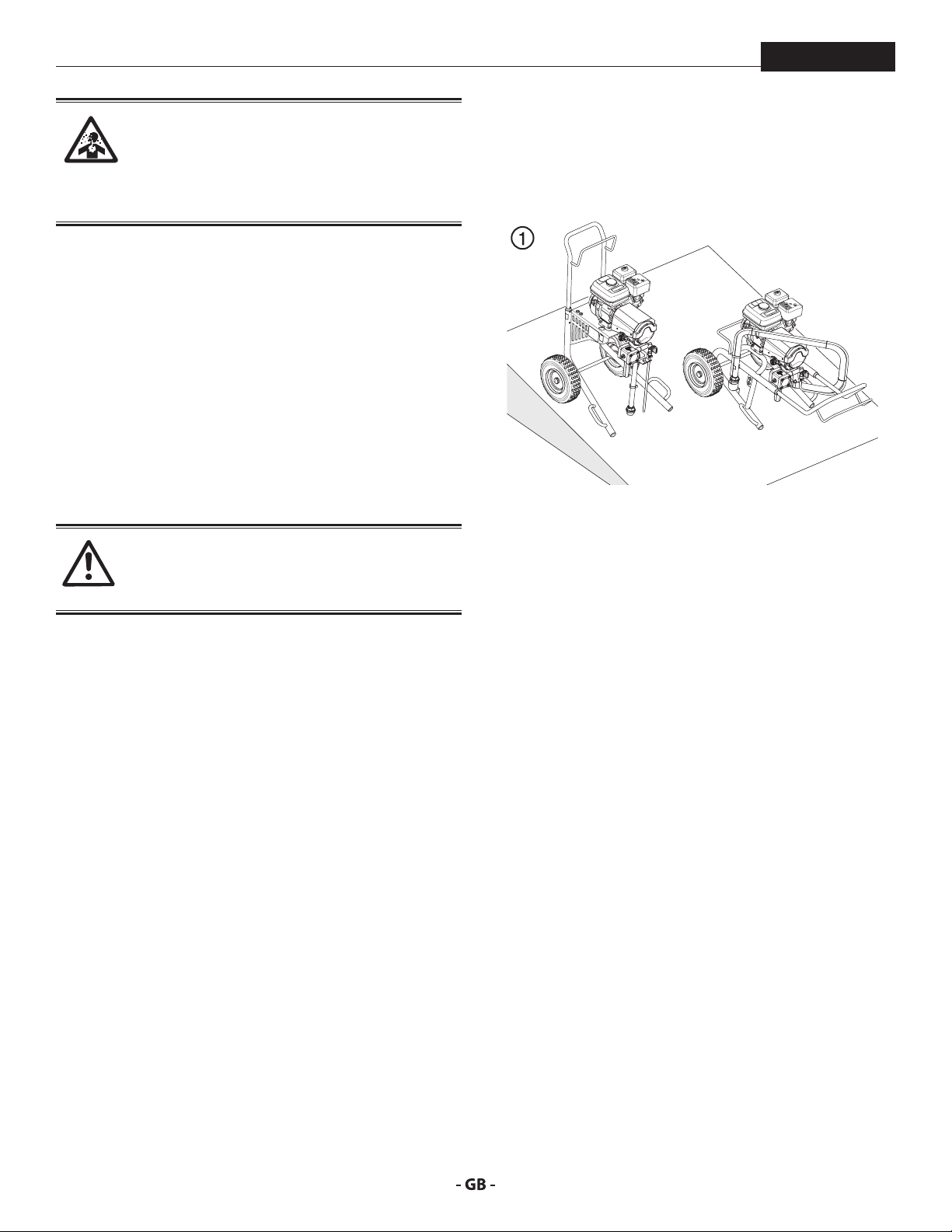

Elite™ 3500

Airless, high-pressure

sprAying unit

Airless hochdruckspritzgerät

operAting MAnuAl

- d - BetrieBsAnleitung 26

- F - Mode d’eMploi 50

MODEL 0537012

groupe de projection à

hAute pression

MODEL 0537013

0317 • Form No. 0537806D

Page 2

original operating manual

Airless units develop extremely high spraying pressures.

1

Elite 3500

Warning!

Attention: Danger of injury by injection!

Never put your ngers, hands or any other parts of the body into

the spray jet!

Never point the spray gun at yourself, other persons or animals.

Never use the spray gun without safety guard.

Do not treat a spraying injury as a harmless cut. In case of injury

to the skin through coating materials or solvents, consult a doctor

immediately for quick and expert treatment. Inform the doctor

about the coating material or solvent used.

2

3

The operating instructions state that the following points must

always be observed before starting up:

1. Faulty units must not be used.

2. Secure Titan spray gun using the trigger lock on the trigger.

3. Ensure that the unit is properly earthed.

4. Check allowable operating pressure of high-pressure hose and spray gun.

5. Check all connections for leaks.

The instructions regarding regular cleaning and maintenance of

the unit must be strictly observed.

Before any work is done on the unit or for every break in work the

following rules must be observed:

1. Release the pressure from spray gun and hose.

2. Secure the Titan spray gun using the trigger lock on the trigger.

3. Switch o unit.

Be safety conscious!

2

Page 3

contents

Elite 3500

1 SAFETY REGULATIONS FOR AIRLESS

SPRAYING ______________________________ 4

1.1 Explanation of symbols used _____________________4

1.2 Safety hazards ________________________________4

1.3 Setup on an uneven surface _____________________6

1.4 Gasoline engine safety__________________________6

1.5 Fueling (gas engine) ___________________________7

2 MAIN AREAS OF APPLICATION ____________ 8

2.1 Application ___________________________________ 8

2.2 Coating materials ______________________________ 8

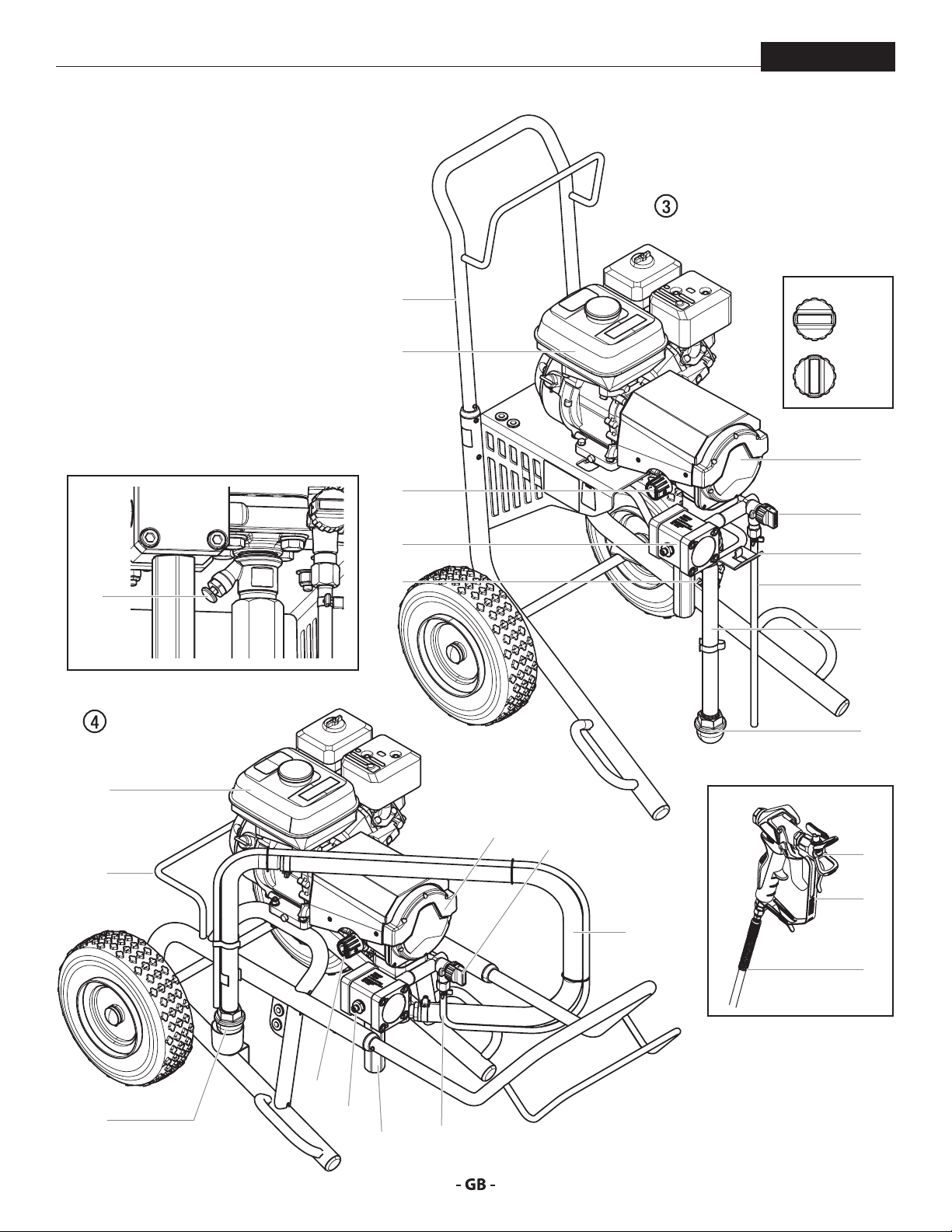

3 DESCRIPTION OF UNIT ___________________ 9

3.1 Airless process ________________________________9

3.2 Functioning of the unit _________________________9

3.3 System diagram ______________________________10

3.4 Technical data _______________________________11

3.5 Transportation _______________________________11

4 OPERATION ____________________________ 12

4.1 High pressure hose and spray gun _______________12

4.2 Starting the engine ___________________________13

4.3 Preparing a new sprayer _______________________13

4.4 Preparing to paint ____________________________14

4.5 Pressure relief procedure _______________________ 14

5 SPRAYING _____________________________15

5.1 Cleaning a clogged tip _________________________ 15

5.2 Interruption of work __________________________16

5.3 Handling the high pressure hose ________________16

7 SERVICING _____________________________ 19

7.1 General servicing _____________________________19

7.2 High pressure hose ___________________________19

7.3 Basic engine maintenance______________________20

7.4 Troubleshooting _____________________________21

8 REPAIRS _______________________________22

8.1 Inlet valve pusher _____________________________ 22

8.2 Inlet valve ___________________________________22

8.3 Outlet valve _________________________________23

8.4 Pressure control valve _________________________23

8.5 Typical wear parts ____________________________23

9 APPENDIX _____________________________24

9.1 Selection of tip _______________________________24

9.2 Servicing and cleaning of Airless hard-metal tips ___24

9.3 Accessories __________________________________ 24

WARRANTY _________________________________ 25

SPARE PARTS LIST ___________________________ 74

Spare parts list for the main assembly _______________ 74/75

Spare parts list for the cart assembly • 0537012 _______ 76/77

Spare parts list for the cart assembly • 0537013 _______ 78/79

Spare parts list for the pump assembly ______________ 80/81

Spare parts list for the high-pressure lter ______________82

Spare parts list for the outlet valve assembly ____________83

Spare parts list for the pusher stem assembly ___________84

Spare parts list for siphon system • 0537013 _____________ 85

6 CLEANUP ______________________________17

6.1 Special cleanup instructions for use with

ammable solvents ___________________________17

6.2 Cleaning the sprayer __________________________17

6.3 Cleaning the unit from outside __________________17

6.4 Suction lter _________________________________ 18

6.5 Cleaning the high-pressure lter ________________18

6.6 Cleaning the airless spray gun __________________19

3

Page 4

safety precautions

At

i

A high pressure stream produced by this

equipment can pierce the skin and underlying

tissues, leading to serious injury and possible

or solvents, consult a doctor immediately for

quick and expert treatment. Inform the doctor

Elite 3500

1 SAFETY REGULATIONS FOR AIRLESS

SPRAYING

1.1

This manual contains information that must be read and

understood before using the equipment. When you come to

an area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

EXPLANATION OF SYMBOLS USED

This symbol indicates a potential hazard

that may cause serious injury or loss of life.

Important safety information will follow.

This symbol indicates a potential hazard

to you or to the equipment. Important

tention

information that tells how to prevent

damage to the equipment or how to avoid

causes of minor injuries will follow.

Danger of skin injection

Danger of re from solvent and paint fumes

Danger of explosion from solvent, paint

fumes and incompatible materials

Danger of injury from inhalation of harmful

vapors

Notes give important information which

should be given special attention.

1.2 SAFETY HAZARDS

HAZARD: INJECTION INJURY

amputation.

Do not treat a spraying injury as a harmless cut. In

case of injury to the skin through coating materials

about the coating material or solvent used.

PREVENTION:

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to touch the uid stream.

DO NOT allow body to touch a leak in the uid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the uid pump o and

release all pressure before servicing, cleaning the tip guard,

changing tips, or leaving unattended. Pressure will not be

released by turning o the engine. The PRIME/SPRAY valve

or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure.

• ALWAYS keep tip guard in place while spraying. The tip

guard provides some protection but is mainly a warning

device.

• ALWAYS remove the spray tip before ushing or cleaning

the system.

• NEVER use a spray gun without a working trigger lock and

trigger guard in place.

• All accessories must be rated at or above the maximum

operating pressure range of the sprayer. This includes

spray tips, guns, extensions, and hose.

4

Page 5

safety precautions

The paint hose can develop leaks from wear,

Flammable vapors, such as solvent and paint

Elite 3500

HAZARD: HIGH PRESSURE HOSE

kinking and abuse. A leak can inject material into

the skin. Inspect the hose before each use.

PREVENTION:

• Avoid sharp bending or kinking of the high-pressure hose.

The smallest bending radius amounts to about 8” (20 cm).

• Do not drive over the high-pressure hose. Protect against

sharp objects and edges.

• Replace any damaged high-pressure hose immediately.

• Never repair damaged high-pressure hoses yourself!

• Electrostatic charging of spray guns and the high-pressure

hose is discharged through the high-pressure hose. For this

reason the electric resistance between the connections of

the high-pressure hose must be equal to or lower than

1M.

• For reasons of function, safety and durability use only

original Titan high-pressure hoses.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a paint hose. Replace it with

another earthed high-pressure hose.

• Make sure power cord, air hose and spray hoses are routed

in such a manner to minimize slip, trip and fall hazard.

HAZARD: EXPLOSION OR FIRE

vapors, in work area can ignite or explode.

PREVENTION:

• Use equipment only in well ventilated area. Keep a good

supply of fresh air moving through the area to keep the air

within the spray area free from accumulation of ammable

vapors. Keep pump assembly in well ventilated area. Do

not spray pump assembly.

• Gas models only - Do not ll fuel tank while engine is

running or hot; shut o engine and allow to cool. Fuel is

ammable and can ignite or explode if spilled on a hot

surface.

• Eliminate all ignition sources, such as pilot lights, cigarettes,

portable electric lamps and plastic drop cloths (potential

static arc).

• Keep work area free of debris, including solvent, rags and

gasoline.

• Do not plug or unplug power cords, or turn power or light

switches on or o when ammable vapors are present.

• Ground equipment and conductive objects in work

area. Make sure the grounding cable (not equipped) is

connected from the grounding lug to a true earth ground.

• Use only grounded hoses.

• Hold spray gun rmly to the side of a grounded pail when

triggering into pail.

• If there is static sparking or if you feel a shock, stop

operation immediately.

• Know the contents of the paint and solvents being sprayed.

Read all Material Safety Data Sheets (MSDS) and container

labels provided with the paints and solvents. Follow the

paint and solvent manufacturer’s safety instructions.

• Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach, mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating supplier

about compatibility of material with aluminum.

• Keep a re extinguisher in work area.

5

Page 6

safety precautions

Paints, solvents, and other materials can be

harmful if inhaled or come in contact with body.

Vapors can cause severe nausea, fainting, or

Elite 3500

HAZARD: HAZARDOUS VAPORS

poisoning.

PREVENTION:

• Wear respiratory protection when spraying. Read all

instructions supplied with the mask to be sure it will

provide the necessary protection.

• All local regulations regarding protection against

hazardous vapors must be observed.

• Wear protective eyewear.

• Protective clothing, gloves and possibly skin protection

cream are necessary for the protection of the skin. Observe

the regulations of the manufacturer concerning coating

materials, solvents and cleaning agents in preparation,

processing and cleaning units.

HAZARD: GENERAL

This product can cause severe injury or property

damage.

PREVENTION:

• Follow all appropriate local, state, and national codes

governing ventilation, re prevention, and operation.

• Pulling the trigger causes a recoil force to the hand that is

holding the spray gun. The recoil force of the spray gun

is particularly powerful when the tip has been removed

and high pressure has been set on the airless pump. When

cleaning without a spray tip, set the pressure control knob

to the lowest pressure.

• Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specications and safety devices of the pump

manufacturer.

• ALWAYS follow the material manufacturer’s instructions

for safe handling of paint and solvents.

• Clean up all material and solvent spills immediately to

prevent slip hazard.

• Wear ear protection. This unit can produce noise levels

above 85 dB(A).

• Never leave this equipment unattended. Keep away from

children or anyone not familiar with the operation of airless

equipment.

• Do not spray on windy days.

• The device and all related liquids (i.e. hydraulic oil) must be

disposed of in an environmentally friendly way.

6

1.3 SETUP ON AN UNEVEN SURFACE

The front end must always point downwards in order to avoid

sliding away.

If possible do not use the unit on an inclined surface since the

unit tends to wander due to the resulting vibrations.

1.4 GASOLINE ENGINE SAFETY

1. Gas engines are designed to give safe and dependable

service if operated according to instructions. Read and

understand the engine manufacturer’s Owner’s Manual

before operating the engine. Failure to do so could result

in personal injury or equipment damage.

2. To prevent re hazards and to provide adequate

ventilation, keep the engine at least 1 meter (3 feet) away

from buildings and other equipment during operation. Do

not place ammable objects close to the engine.

3. People who are not operating the device must stay away

from the area of operation due to a possibility of burns from

hot engine components or injury from any equipment the

engine may be used to operate.

4. Know how to stop the engine quickly, and understand the

operation of all controls. Never permit anyone to operate

the engine without proper instructions.

5. Gasoline is extremely ammable and is explosive under

certain conditions.

6. Refuel in a well-ventilated area with the engine stopped.

Do not smoke or allow ames or sparks in the refueling

area or where gasoline is stored.

7. Do not overll the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

8. Be careful not to spill fuel when refueling. Fuel vapor or

spilled fuel may ignite. If any fuel is spilled, make sure the

area is dry before starting the engine.

9. Never run the engine in an enclosed or conned area.

Exhaust contains poisonous carbon monoxide gas;

exposure may cause loss of consciousness and may lead

to death.

Page 7

safety precautions

At

i

i

Elite 3500

10. The muer becomes very hot during operation and

remains hot for a while after stopping the engine. Be

careful not to touch the muer while it is hot. To avoid

severe burns or re hazards, let the engine cool before

transporting it or storing it indoors.

11. Never ship/transport sprayer with gasoline in the tank.

DO NOT use this equipment to spray water or

acid.

Do not lift by cart handle when loading or

unloading.

tention

Device is very heavy. Three-person lift is required.

1.5 FUELING GAS ENGINE

Gasoline is extremely ammable and is explosive

under certain conditions.

GASOLINES CONTAINING ALCOHOL

If you decide to use a gasoline containing alcohol (gasohol), be

sure its octane rating is at least as high as that recommended

by the engine manufacturer. There are two types of “gasohol”:

one containing ethanol, and the other containing methanol.

Do not use gasohol that contains more than 10% ethanol. Do

not use gasoline containing methanol (methyl or wood alcohol)

that does not also contain co-solvents and corrosion inhibitors

for methanol. Never use gasoline containing more than 5%

methanol, even if it has co-solvents and corrosion inhibitors.

Fuel system damage or engine performance

problems resulting from the use of fuels that

contain alcohol is not covered under the

warranty. The engine manufacturer cannot

endorse the use of fuels containing methanol

since evidence of their suitability is incomplete

at this time.

Before buying gasoline from an unfamiliar

station, try to nd out if the gasoline contains

alcohol. If it does, conrm the type and

percentage of alcohol used. If you notice any

undesirable operating characteristics while using

a gasoline that contains alcohol, or one that you

think contains alcohol, switch to a gasoline that

you know does not contain alcohol.

FUEL SPECIFICATIONS

Use automotive gasoline that has a pump octane number of 86

or higher, or that has a research octane number of 91 or higher.

Use of a lower octane gasoline can cause persistent “pinging” or

heavy “spark knock” (a metallic rapping noise) which, if severe,

can lead to engine damage.

If “spark knock” or “pinging” occurs at a steady

engine speed under normal load, change brands

of gasoline. If spark knock or pinging persists,

consult an authorized dealer of the engine

manufacturer. Failure to do so is considered

misuse, and damage caused by misuse is not

covered by the engine manufacturer’s limited

warranty.

Occasionally you may experience light spark

knock while operating under heavy loads. This

is no cause for concern, it simply means your

engine is operating eciently.

• Unleaded fuel produces fewer engine and spark plug

deposits and extends the life of the exhaust system

components.

• Never use stale or contaminated gasoline or an oil/gasoline

mixture. Avoid getting dirt, dust, or water in the fuel tank.

7

Page 8

main areas of application

i

i

2 MAIN AREAS OF APPLICATION

Elite 3500

2.1

The main area of application are thick layers of highly viscous

coating material for large areas and a high consumption of

material.

Priming and nal coating of large areas, sealing, impregnation,

construction sanitation, façade protection and renovation, rust

protection and building protection, concrete sanitation, as well

as heavy corrosion protection.

EXAMPLES OF OBJECTS TO BE SPRAYED

Large-scale construction sites, cooling towers, bridges, sewage

treatment plants and terraces.

APPLICATION

2.2 COATING MATERIALS

PROCESSIBLE COATING MATERIALS

Diluting lacquers and paints or those containing solvents, twocomponent coating materials, dispersion and latex paints.

No other materials should be used for spraying without Titan‘s

approval.

Pay attention to the Airless quality of the coating

materials to be processed.

The unit is able to process coating materials with up to

20,000 mPas. If highly viscous coating materials cannot be

taken in or the performance of the unit is to low, the paint must

be diluted in accordance with the manufacturer‘s instructions.

Attention: Make sure, when stirring up with

motor-driven agitators that no air bubbles are

stirred in. Air bubbles disturb when spraying and

can, in fact, lead to interruption of operation.

COATING MATERIALS WITH ABRASIVE MATERIALS

These particles have a strong wear and tear eect on valves and

tips, but also on the spray gun. This impairs the durability of

these wearing parts considerably.

FILTERING

Sucient ltering is required for fault-free operation. The unit

is equipped with a suction lter, an insertion lter in the spray

gun and a high pressure lter on the unit. Regular inspection

of these lters for damage or soiling is urgently recommended.

8

Page 9

description of unit

Elite 3500

3 DESCRIPTION OF UNIT

3.1

A diaphragm pump takes in the coating material by suction and

conveys it to the tip. Pressed through the tip at a pressure of

up to a maximum of 3300 PSI (228 bar, 22.8 MPa), the coating

material is atomised. This high pressure has the eect of micro

ne atomization of the coating material.

As no air is used in this process, it is described as an AIRLESS

process.

This method of spraying has the advantages of nest

atomization, cloudless operation and a smooth, bubble-free

surface. As well as these, the advantages of the speed of work

and convenience must be mentioned.

AIRLESS PROCESS

3.2 FUNCTIONING OF THE UNIT

The following section contains a brief description of the

technical construction for better understanding of the function

of the unit:

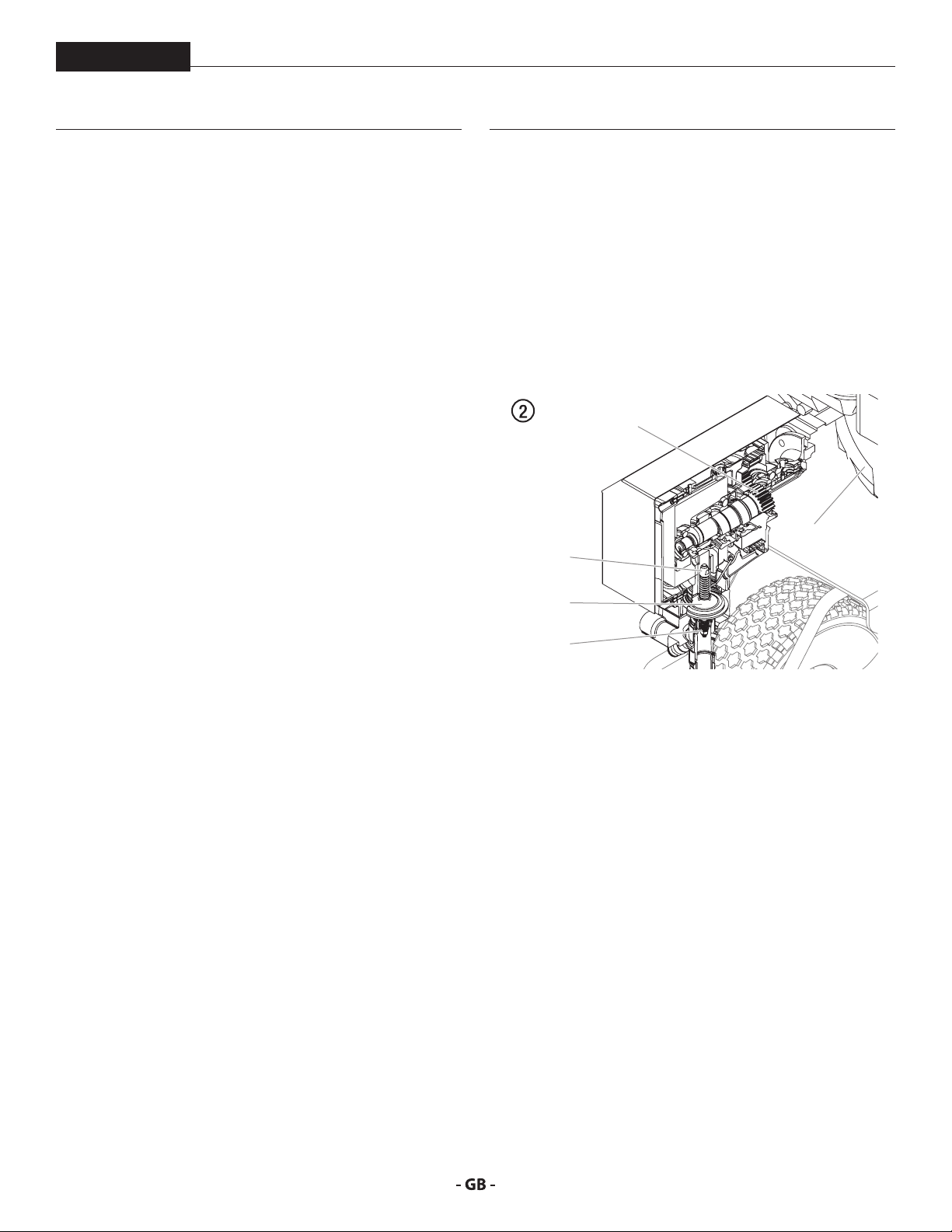

Elite™ 3500 is a gas engine-driven high-pressure paint sprayer.

The gas engine (Fig. 2, 1) drives the hydraulic pump via planetary

gears (2). A piston (3) is moved up and down so that hydraulic

oil is moved under the diaphragm (4) which then moves.

The downwards movement of the machine opens the disk inlet

valve (5) automatically and coating material is sucked in.

2

1

3

4

5

During the upwards movement of the diaphragm, the coating

material is displaced and the outlet valve opens while the inlet

valve is closed.

The coating material ows under high pressure through the

high-pressure hose to the spray gun and is atomized when it

exits from the tip.

The pressure control valve limits the set pressure in the hydraulic

oil circuit and thus also the pressure of the coating material.

A pressure change when the same tip is used also leads to a

change in the amount of paint atomized.

9

Page 10

description of unit

3.3 SYSTEM DIAGRAM

Elite 3500

1. Tip guard with airless tip

2. Spray gun

3. High-pressure hose

4. Cart

5. Gasoline engine

6. Pressure control knob

7. High-pressure hose

connection

8. High pressure lter

9. Pump assembly

10. Relief valve

PRIME = k

SPRAY = p

15

11. Pail hook

12. Bleed hose

13. Suction tube

14. Suction lter

15. Pusher stem

MODEL 0537012

4

10

= k

5

= p

9

6

10

7

8

11

12

MODEL 0537013

5

4

13

14

9

10

1

2

13

3

10

14

6

7

8

12

Page 11

description of unit

Elite 3500

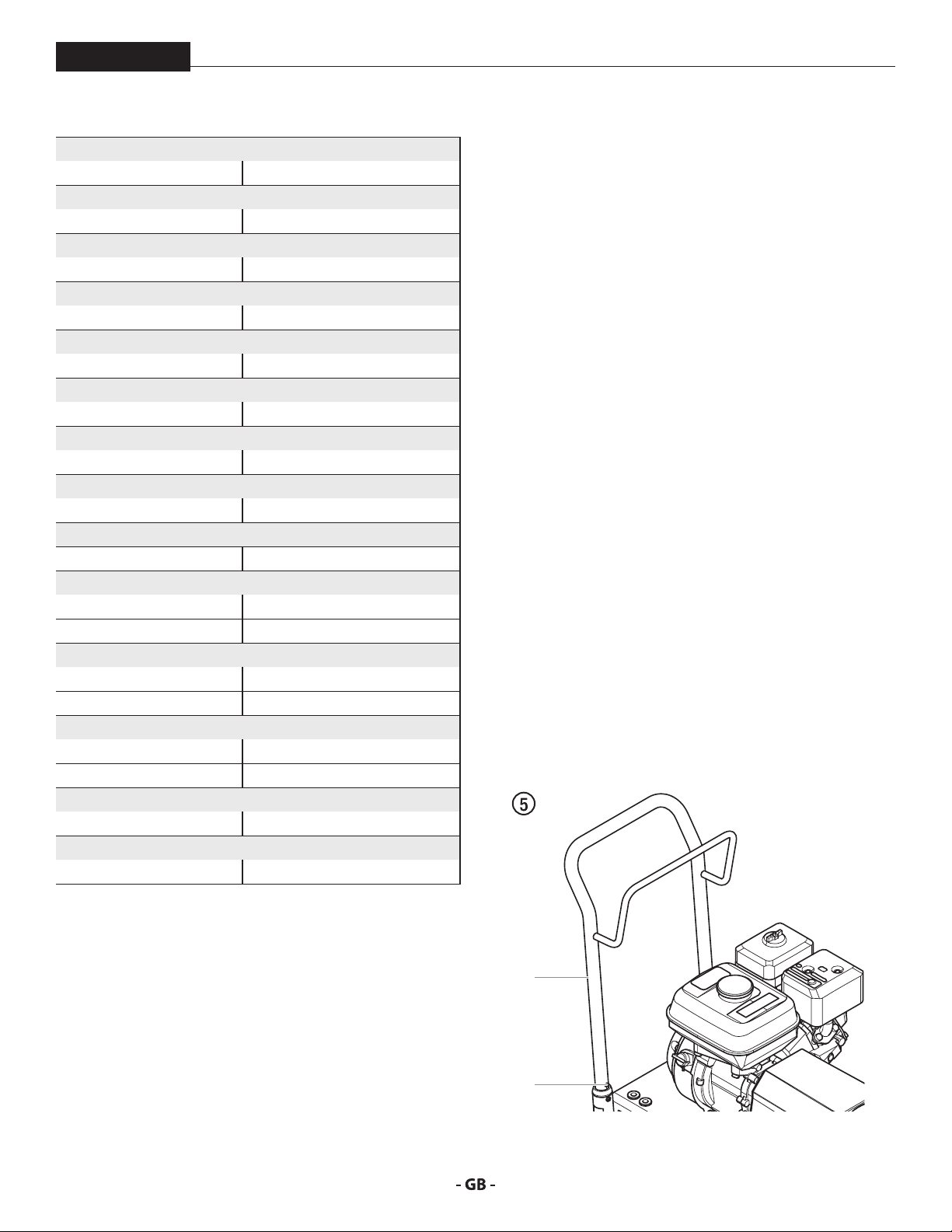

3.4 TECHNICAL DATA

Gasoline engine, power

120cc, 4.0 Hp

Fuel capacity

0.66 US gal (2.5 l)

Max. operating pressure

3300 PSI (22,8 MPa, 228 bar)

Max. volume ow

0.75 gal/min (2.8 l/min)

Volume ow at 0.6 MPa (6 bar) with water

0.61 gal/min (2.3 l/min)

Max. temperature of the coating material

109º F (43 °C)

Material hose connection

1/4”-18 NPSM

Max. viscosity

20,000 mPas

Max. size of tip with a spray gun

0.027” – 0.68 mm

Empty weight

High cart 103 lbs (47 kg)

Low cart 95 lbs (43 kg)

Dimensions

High cart 64 cm x 60 cm x 114 cm

Low cart 200 cm x 64 cm x 70 cm

Hydraulic oil lling quantity

Hydraulics housing 1.15 liter

Gears 0.05 liter

Max. vibration at the spray gun

lower than 2.5 m/s

Max. sound pressure level

74 dB (A)*

OPERATING TEMPERATURE

This equipment will operate correctly in its intended ambient,

at a minimum between +50ºF (10°C) and 104ºF (+40°C).

RELATIVE HUMIDITY

The equipment will operate correctly within an environment

at 50% RH, 104ºF (+40°C). Higher RH may be allowed at lower

temperatures.

Measures shall be taken by the Purchaser to avoid the harmful

eects of occasional condensation.

ALTITUDE

This equipment will operate correctly up to 2100 m above

mean sea level.

TRANSPORTATION AND STORAGE

This equipment will withstand, or has been protected against,

transportation and storage temperatures of -13ºF (-25°C) to

131ºF (+55°C) and for short periods up to 150ºF (+70°C).

It has been packaged to prevent damage from the eects of

normal humidity, vibration and shock.

3.5 TRANSPORTATION

TRANSPORTATION IN VEHICLE

Secure the unit with a suitable fastening.

PUSHING OR PULLING THE UNIT

Pull out the handle (Fig. 5, Item 1) until it will come no further.

Insert the handle – push the buttons (2) on the cart, and then

push in the handle.

* Place of measurement: 1 m distance from unit and

1.60m above oor, 12 MPa (120 bar) operating pressure,

reverberant oor

1

2

11

Page 12

operation

4

4 OPERATION

Elite 3500

This equipment produces a uid stream at

extremely high pressure. Read and understand

the warnings in the Safety Precautions section

at the front of this manual before operating this

equipment.

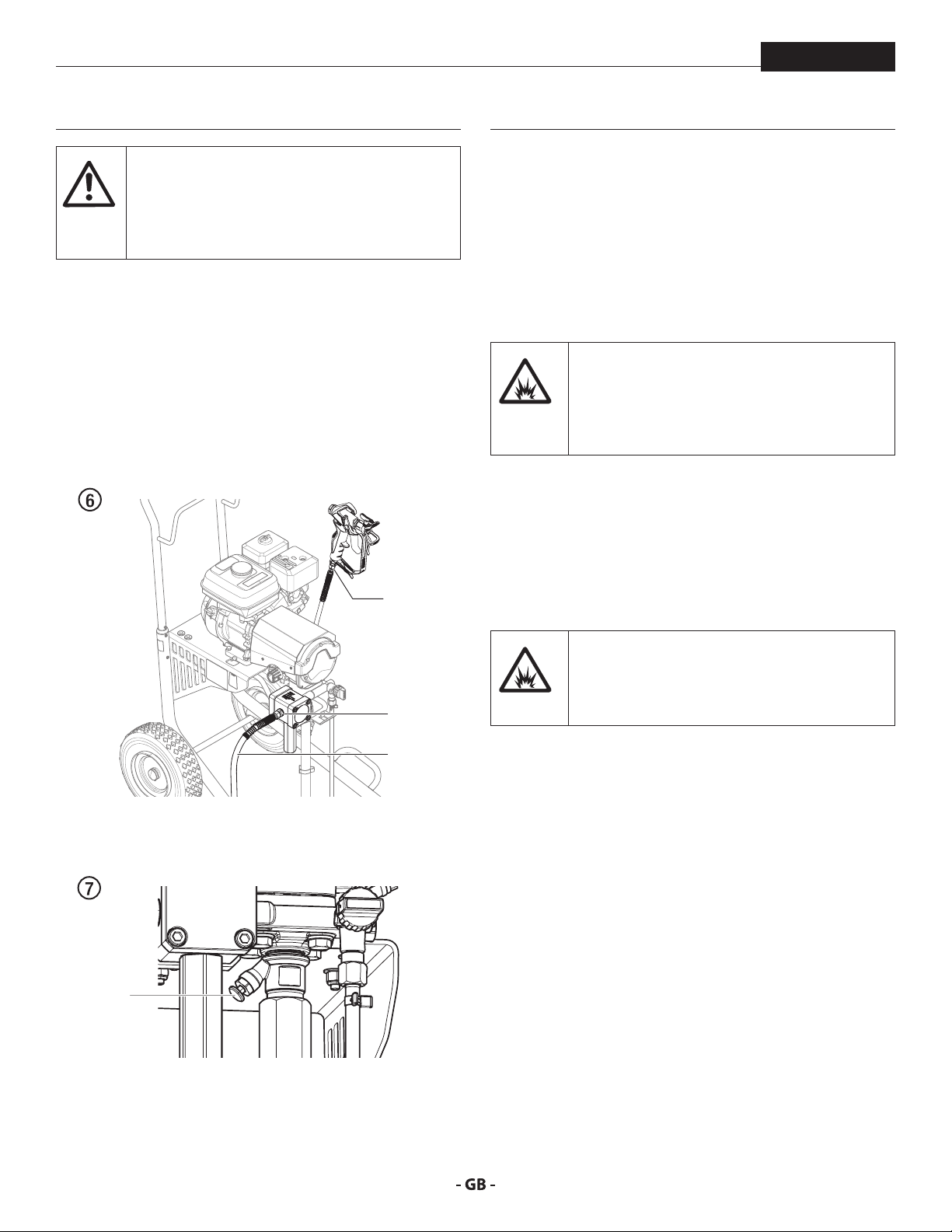

4.1 HIGH PRESSURE HOSE AND SPRAY GUN

1. Screw the high-pressure hose (2) to the coating material

outlet (Fig. 6, Item 1).

2. Screw the spray gun (3) with the selected tip onto the high

pressure hose.

3. Tighten the union nuts at the high-pressure hoses rmly

so that coating material does not leak.

3

5. Check the engine oil level daily before starting the sprayer.

The gasoline engine oil level is determined by the engine

manufacturer. Refer to the engine manufacturer’s service

manual supplied with this sprayer.

6. Make sure the sprayer is grounded/earthed. All sprayers

are equipped with a earthing lug. An earthing cable (not

supplied) should be used to connect the sprayer to a true

earth ground. Check your local electrical regulations for

detailed earthing instructions.

Proper grounding/earthing is important. The

passage of some materials through the nylon

uid hose will build up a static electric charge,

which if discharged, could ignite solvent vapors

present and create an explosion.

7. Strain all paints with a nylon strainer to ensure trouble

free operation and freedom from frequent cleaning of the

suction lter and gun lter.

8. Make sure the spray area is well ventilated to prevent

hazardous operation with volatile solvents or exhaust

fumes.

1

2

4. Fully depress the pusher stem (Fig. 7, item 4) to make sure

the inlet ball is free.

If lacquer or other ammable materials are to be

sprayed, ALWAYS locate the sprayer outside the

immediate spraying area. Failure to do so may

cause an explosion.

9. Locate the sprayer outside the immediate spraying area to

avoid clogged air intake of the engine with overspray.

12

Page 13

description of unit

i

i

i

At

Elite 3500

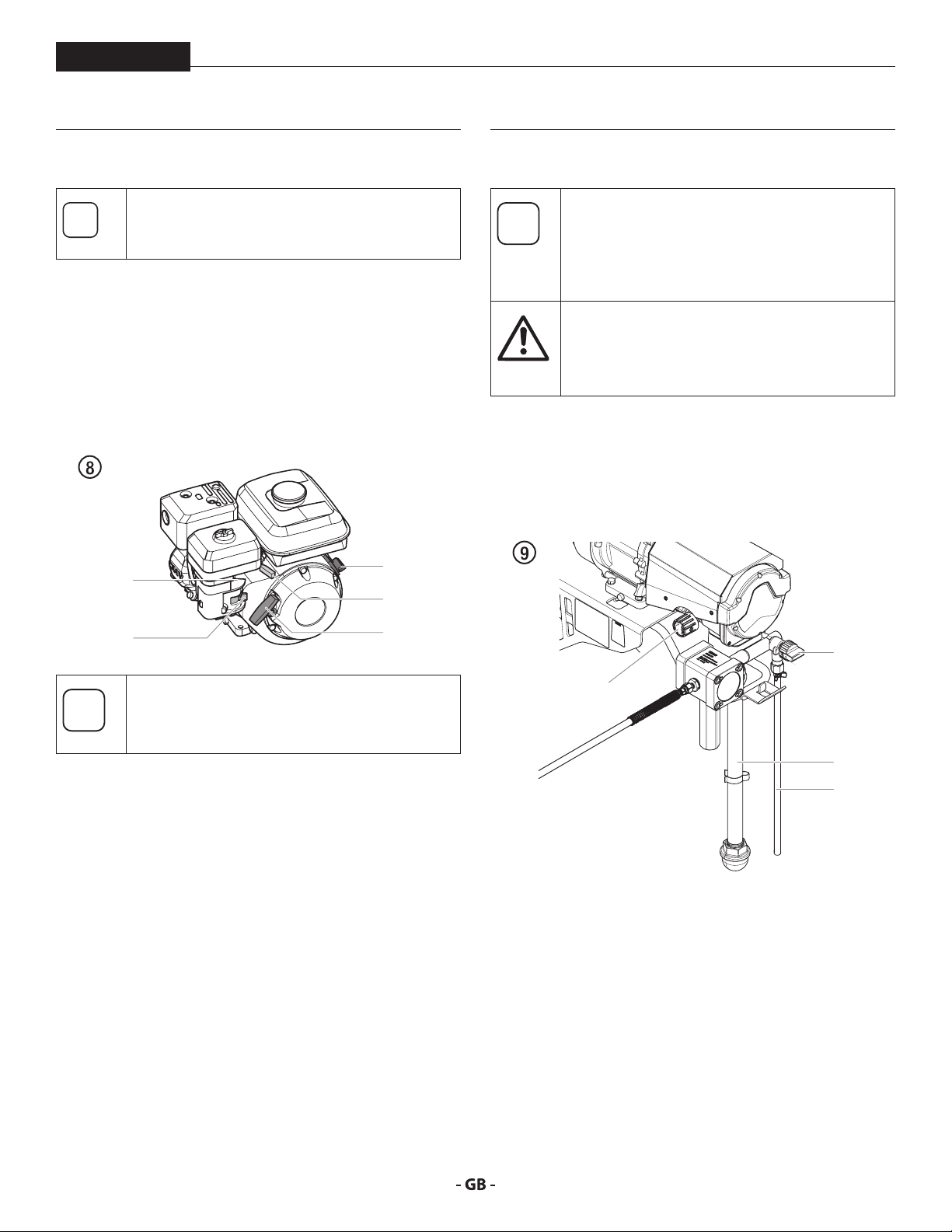

4.2 STARTING THE ENGINE

Follow these instructions whenever prompted in

this manual to start the engine.

1. Move the fuel valve lever (Fig. 8, item 2) to the open

position.

2. Move the throttle lever (3) to its middle point.

3. Move the choke lever (4) to the closed position for a cold

engine or to the open position for a warm engine,

4. Turn the engine switch (1) to the ON position, and

5. Pull the starter rope (5) briskly until the engine starts.

1

4

3

4.3 PREPARING A NEW SPRAYER

If this unit is new, it is shipped with test uid in

the uid section to prevent corrosion during

shipment and storage. This uid must be

thoroughly cleaned out of the system with

mineral spirits before you begin spraying.

Always keep the trigger lock on the spray gun in

the locked position while preparing the system.

tention

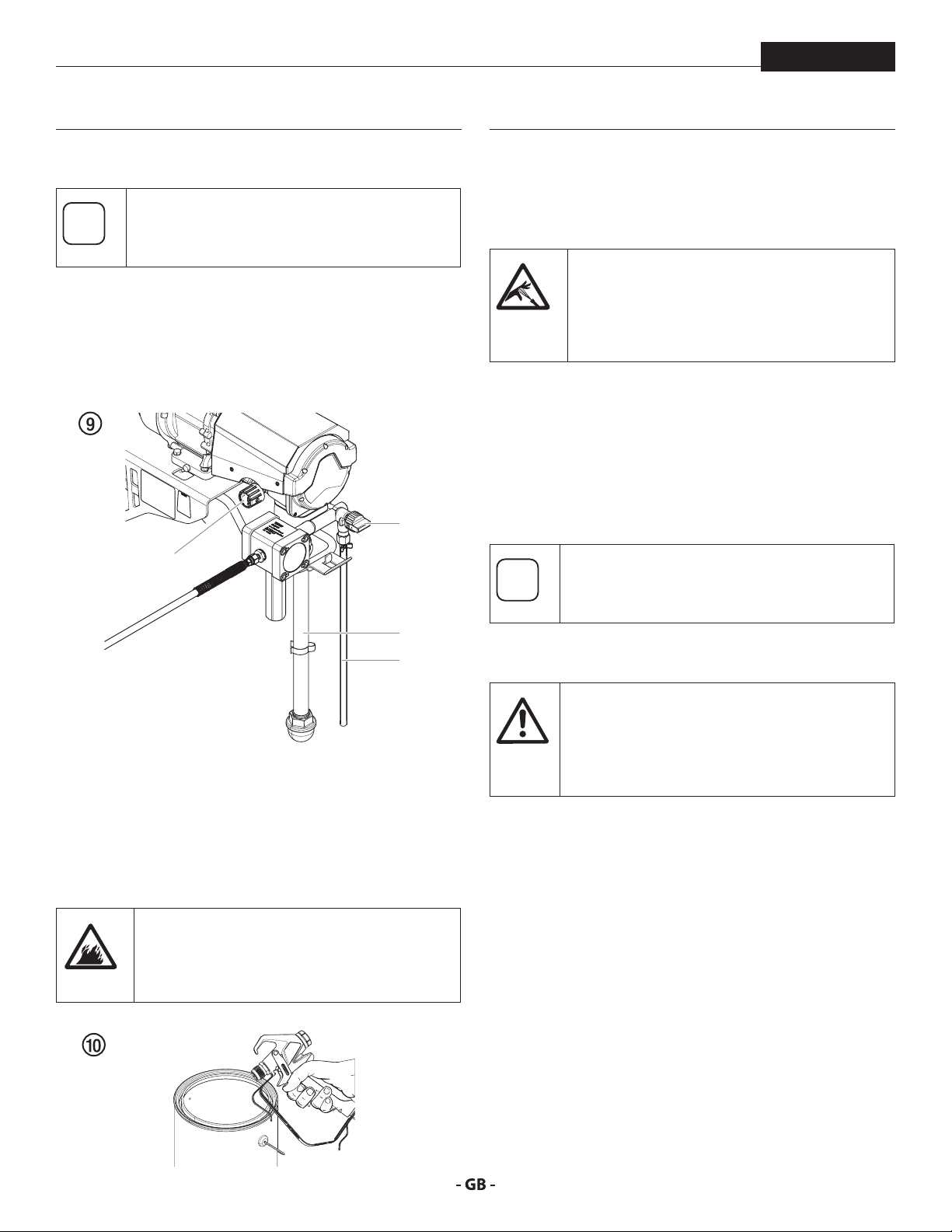

1. Immerse the suction tube (Fig. 9, Item 1) and return hose

2. Turn the pressure control knob counterclockwise (3) to

3. Turn the relief valve (4) to PRIME (k circulation).

Refer to the spray gun instruction manual for

trigger lock instructions.

(2) into a container with a suitable cleaning agent.

minimum pressure.

2

If choke lever (4) was moved to closed position to

start the engine, it must be opened again once

the engine is running.

5

4

3

1

2

4. Start the engine (refer to section 4.2).

5. Wait until the cleaning agent exudes from the return hose.

6. Turn the relief valve (4) to SPRAY (p spray).

7. Unlock the spray gun (refer to spray gun manual). Pull the

trigger of the spray gun.

8. Spray the cleaning agent from the unit into an open

collecting container.

13

Page 14

operation

i

i

Elite 3500

4.4 PREPARING TO PAINT

Make sure that the spray gun does not have a tip

or tip guard installed.

1. Immerse the suction tube (Fig. 9, Item 1) and return hose

(2) into the coating material container.

2. Turn the pressure control knob counterclockwise (3) to

minimum pressure.

3. Turn the relief valve (4) to PRIME (k circulation).

4

3

8. Lock the gun by turning the gun trigger lock to the locked

position (refer to spray gun manual).

9. Attach tip guard and tip to the gun as instructed by the tip

guard or tip manuals.

POSSIBLE INJECTION HAZARD. Do not spray

without the tip guard in place. Never trigger the

gun unless the tip is in either the spray or the

unclog position. Always engage the gun trigger

lock before removing, replacing or cleaning tip.

10. Increase the pressure by slowly turning up the pressure

control knob.

Check the spray pattern and increase the pressure until

the atomization is correct.

Always turn the pressure control knob to the lowest

setting with good atomization.

11. The unit is ready to spray.

Turning the pressure up higher than needed to

atomize the paint will cause premature tip wear

and additional overspray.

1

2

4. Start the engine (refer to section 4.2).

5. Turn the relief valve (4) to SPRAY (p spray).

6. Pull the trigger of the spray gun.

7. Trigger the spray gun several times and spray into a

collecting container until the coating material exits the

spray gun without interruption.

Ground/Earth the gun by holding it against

the edge of the metal container while ushing.

Failure to do so may lead to a static electric

discharge, which may cause a re.

4.5 PRESSURE RELIEF PROCEDURE

Be sure to follow the Pressure Relief Procedure

when shutting the unit down for any purpose,

including servicing or adjusting any part of the

spray system, changing or cleaning spray nozzles,

or preparing for cleanup.

1. Lock the spray gun by turning the gun trigger lock to the

locked position.

2. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

3. Turn the relief valve (4) to PRIME (k circulation).

4. Move the throttle lever to the slow position.

5. Turn the engine switch to the OFF position.

6. Unlock the gun by turning the gun trigger lock to the

unlocked position (refer to spray gun manual).

7. Hold the metal part of the gun rmly to the side of a metal

waste container to ground/earth the gun and avoid a build

up of static electricity.

8. Trigger the gun to remove any pressure that may still be

in the hose.

9. Lock the gun by turning the gun trigger lock to the locked

position (refer to spray gun manual).

14

Page 15

spraying

i

i

Elite 3500

5 SPRAYING

Injection hazard. Do not spray without the tip

guard in place. NEVER trigger the gun unless

the tip is completely turned to either the spray

or the unclog position. ALWAYS engage the

gun trigger lock before removing, replacing or

cleaning tip.

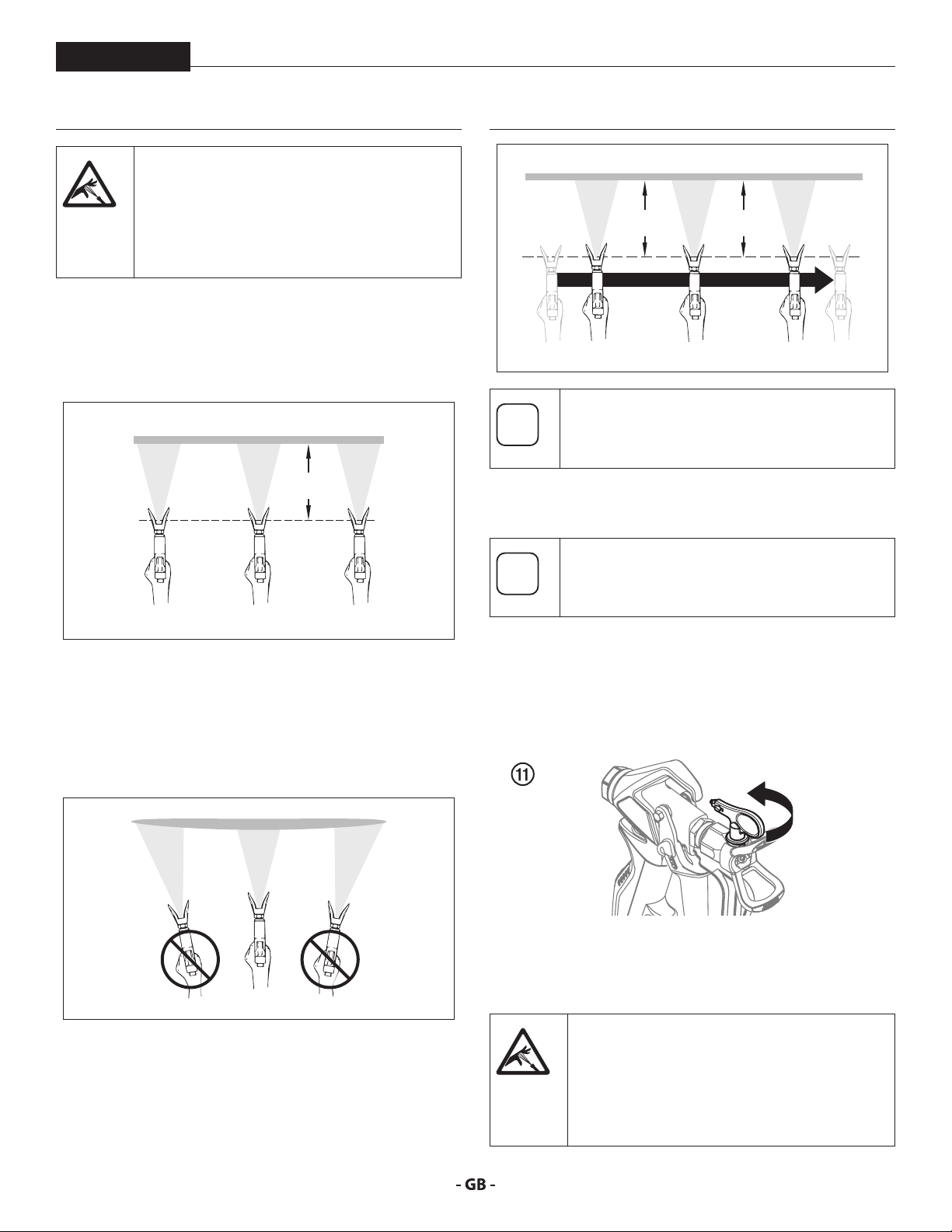

A) The key to a good paint job is an even coating over the

entire surface. Keep your arm moving at a constant speed

and keep the spray gun at a constant distance from the

surface. The best spraying distance is 10-12 inches (25 to

30 cm) between the spray tip and the surface.

A

25 - 30 cm

C

25 - 30 cm25 - 30 cm

If very sharp edges result or if there are streaks in

the spray jet – increase the operating pressure or

dilute the coating material.

5.1 CLEANING A CLOGGED TIP

If the spray pattern becomes distorted or stops

completely while pulling the trigger, perform the

steps below.

B) Keep the spray gun at right angles to the surface. This

means moving your entire arm back and forth rather than

just exing your wrist.

Keep the spray gun perpendicular to the surface,

otherwise one end of the pattern will be thicker than the

other.

B

C) Trigger gun after starting the stroke. Release the trigger

before ending the stroke. The spray gun should be

moving when the trigger is pulled and released. Overlap

each stroke by about 30%. This will ensure an even

coating.

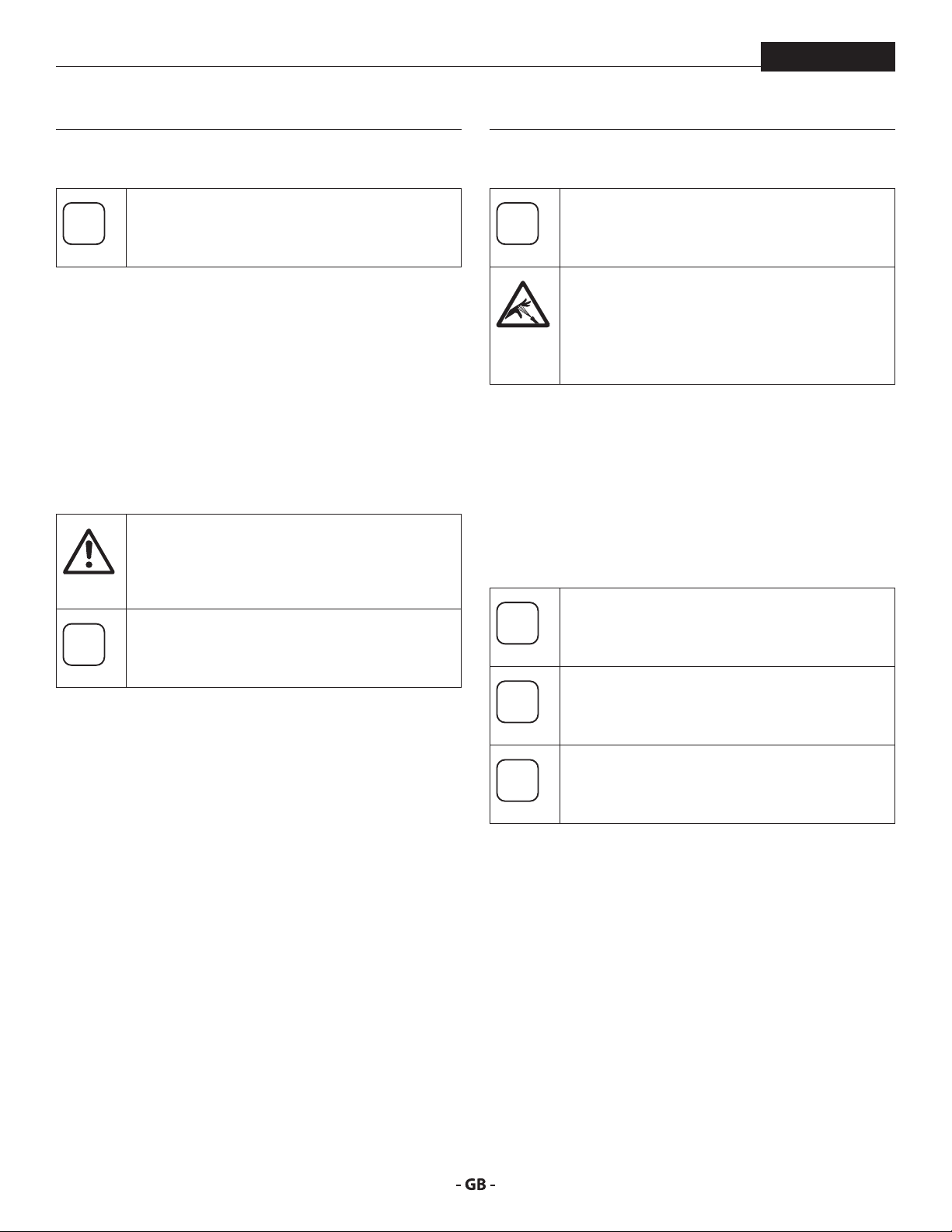

1. Turn the relief valve to PRIME (k circulation).

2. If the tip clogs, rotate the tip handle 180° until the arrow on

the handle is facing the opposite of the spray direction and

the handle clicks in the reverse position (Fig. 11).

3. Turn the relief valve to SPRAY (p spray).

4. Trigger the gun once so that the pressure can blow the

clog out. NEVER use the tip in the reverse position for

more than ONE trigger pull at a time. This procedure can

be repeated until the tip is free of clogging.

The ow from the spray tip is at very high

pressure. Contact with any body part may be

dangerous. Do not place nger on gun outlet.

Do not point the gun at any person. Never

operate the spray gun without the proper tip

guard.

15

Page 16

spraying

i

At

i

i

i

i

i

Elite 3500

5.2 INTERRUPTION OF WORK

Follow these steps if stopping work for up to 20

hours.

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual, section 4.5.

2. If a standard tip is to be cleaned, see Page 24, Section 9.2.

If a non-standard tip is installed, proceed according to the

relevant operating manual.

3. Leave the suction tube and return hose immersed in

the coating material or immerse it into a corresponding

cleaning agent.

4. Cover the coating material with plastic and place unit in a

cool, shaded spot to keep material from drying out.

If fast-drying or two-component coating material

is used, ensure that the unit is rinsed with a

tention

suitable cleaning agent within the processing

time.

When ready to being spraying again, remove the

plastic from the material container and restart

the sprayer by following the steps in section 4.4.

5.3 HANDLING THE HIGHPRESSURE HOSE

The unit is equipped with a high-pressure hose

specially suited for airless pumps.

Danger of injury through leaking high-pressure

hose. Replace any damaged high-pressure hose

immediately.

Never repair defective high-pressure hoses

yourself!

The high-pressure hose is to be handled with care. Avoid sharp

bends and folds: the smallest bending radius is about 8” (20 cm).

Do not drive over the high-pressure hose. Protect against sharp

objects and edges.

Never pull on the high-pressure hose to move the device.

Make sure that the high-pressure hose cannot twist. This can

be avoided by using a Titan spray gun with a swivel joint and a

hose system.

When using the high-pressure hose while

working on scaolding, it is best to always guide

the hose along the outside of the scaolding.

The risk of damage rises with the age of the

high-pressure hose. Titan recommends replacing

high-pressure hoses after 6 years.

Use only Titan original-high-pressure hoses

in order to ensure functionality, safety and

durability.

16

Page 17

cleanup

At

At

i

At

Attention

Elite 3500

6 CLEANUP

9. Switch the unit OFF (turn the engine switch OFF).

tention

The sprayer, hose, and gun should be cleaned

thoroughly after daily use. Failure to do so

permits material to build up, seriously aecting

the performance of the unit.

10. Turn the relief valve to SPRAY (p spray).

11. Start the engine (refer to section 4.2).

Always spray at minimum pressure with the gun

nozzle tip removed when using mineral spirits

or any other solvent to clean the sprayer, hose,

or gun. Static electricity buildup may result in a

re or explosion in the presence of ammable

vapors.

6.1 SPECIAL CLEANUP INSTRUCTIONS FOR USE

WITH FLAMMABLE SOLVENTS

• Always ush spray gun preferably outside and at least one

hose length from spray pump.

• If collecting ushed solvents in a one gallon metal

container, place it into an empty ve gallon container, then

ush solvents.

• Area must be free of ammable vapors.

• Follow all cleanup instructions.

6.2 CLEANING THE SPRAYER

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual, section 4.5.

2. Remove the gun tip and tip guard and clean with a brush

using the appropriate solvent.

3. Place the siphon tube into a container of the appropriate

solvent.

Earth the gun by holding it against the edge

of the metal container while ushing. Failure

to do so may lead to a static electric discharge,

which may cause a re.

12. Trigger the gun into the metal waste container until the

paint is ushed out of the hose and solvent is coming out

of the gun.

13. Continue to trigger the spray gun into the waste container

until the solvent coming out of the gun is clean.

For long-term or cold weather storage, pump

mineral sprits through the entire system.

14. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

15. Store the sprayer in a clean, dry area.

Do not store the sprayer under pressure.

tention

6.3 CLEANING UNIT FROM OUTSIDE

Use only compatible solvents when cleaning

out oil based enamels, lacquers, coal tar, and

tention

4. Place the bleed hose into a metal waste container.

5. Set the pressure to minimum by turning the pressure

6. Turn the relief valve to PRIME (k circulation).

7. Start the engine (refer to section 4.2).

8. Allow the solvent to circulate through the sprayer and

17

epoxies. Check with the uid manufacturer for

the recommended solvent.

control knob fully counterclockwise.

ush the paint out of the bleed hose into the metal waste

container.

Wipe down unit externally with a cloth which has been

immersed in a suitable cleaning agent.

Never spray down the unit with high-pressure

washer or high-pressure steam cleaners.

Do not put the high-pressure hose into solvents.

Use only a wet cloth to wipe down the outside of

the hose.

Page 18

cleanup

i

i

At

Elite 3500

6.4 SUCTION FILTER

A clean suction lter always guarantees maximum

feed quantity, constant spraying pressure and

problem-free functioning of the unit.

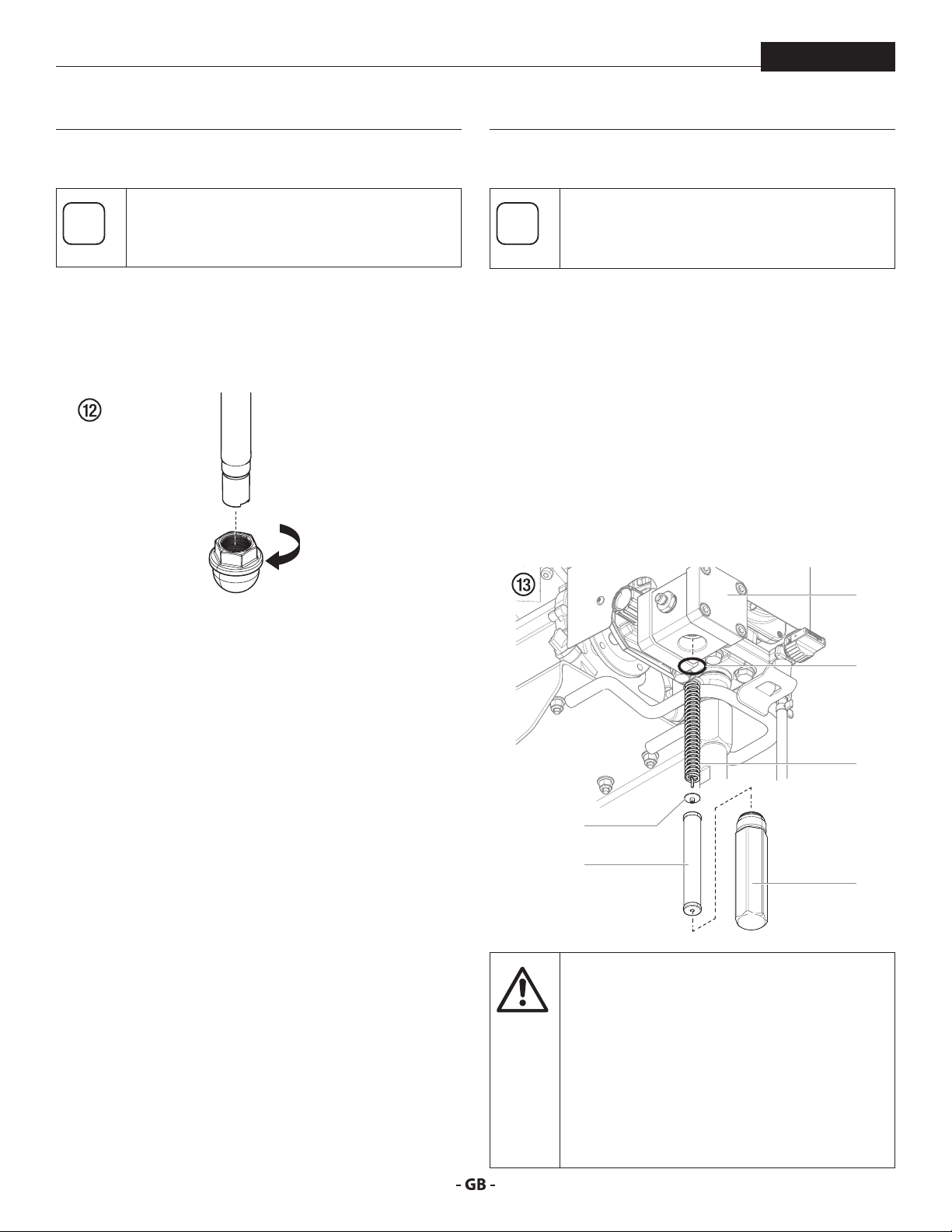

1. Screw o the lter (Fig. 12) from suction tube.

2. Clean or replace the lter.

Carry out cleaning with a hard brush and an appropriate

cleaning agent.

6.5 CLEANING THE HIGHPRESSURE FILTER

Clean the lter cartridge regularly.

A soiled or clogged high-pressure lter can cause

a poor spray pattern or a clogged tip.

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual, section 4.5.

2. Unscrew the lter housing (Fig. 13, Item 1) with a strap

wrench.

3. Pull the lter cartridge (2) from the lter support (3).

4. Clean all the parts with the corresponding cleaning agent.

If necessary, replace the lter cartridge.

5. Check the O-ring (4), replace it if necessary.

6. Place the lter insert (5) against the lter support (3). Slide

the lter cartridge (2) over the bearing spring.

7. Screw in lter housing (1) and tighten it as far as possible

with the strap wrench.

6

tention

4

3

5

2

1

The pulsation dampener (6) carries a lifetime

warranty.

The pulsation dampener contains nitrogen gas

and should never be opened. Tampering with

the pulsation dampener (i.e. removing the four

bolts on the dampener face) will void the lifetime

warranty.

Contact Titan Technical Service at 1-800-5265362 if you believe the pulsation dampener

requires service.

18

Page 19

cleanup / serVicing

i

i

At

i

Elite 3500

7 SERVICING

6.6 CLEANING AIRLESS SPRAY GUN

Clean the spray gun after each use.

1. Rinse airless spray gun with an appropriate cleaning agent.

2. Clean tip thoroughly with appropriate cleaning agent so

that no coating material residue remains.

3. Thoroughly clean the outside of the airless spray gun.

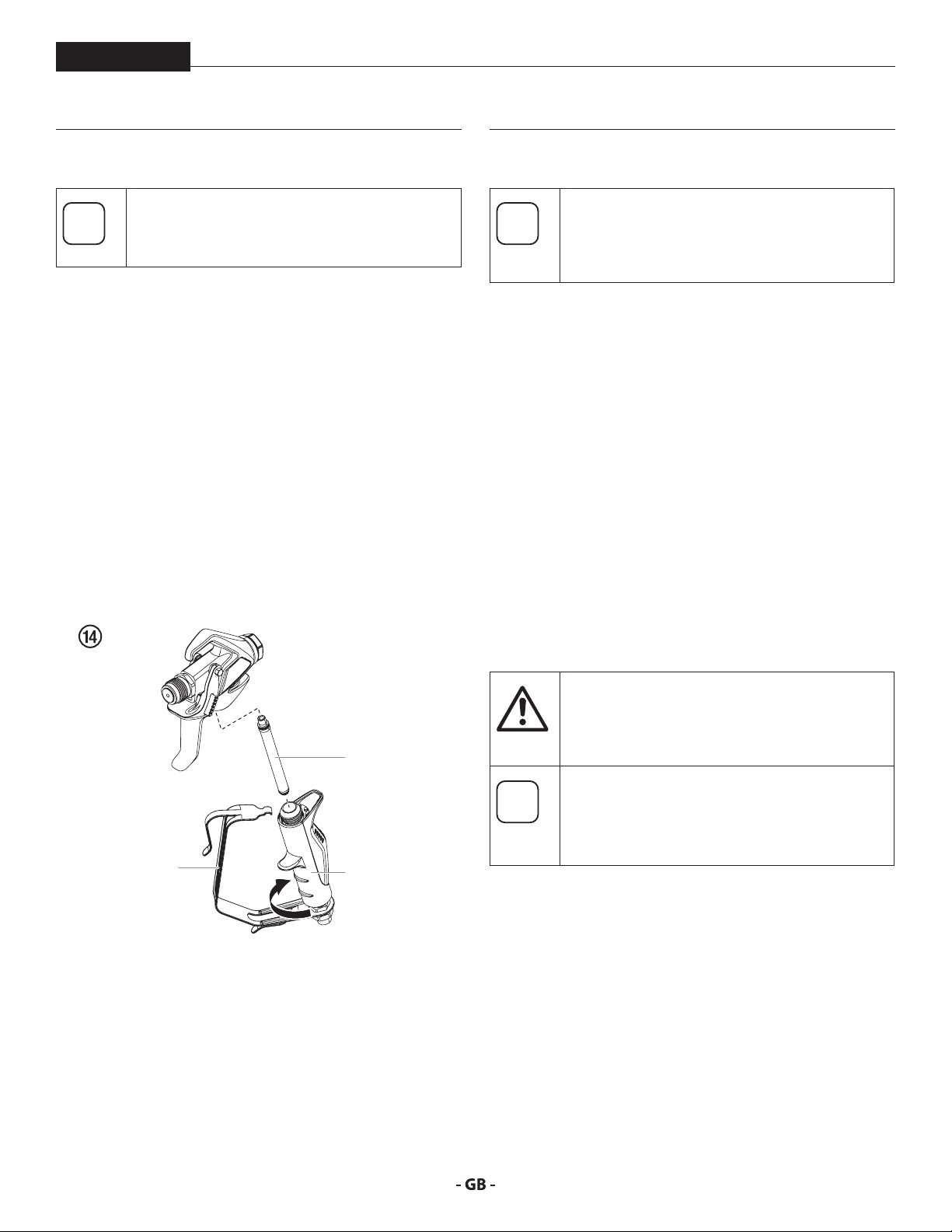

INTAKE FILTER IN AIRLESS SPRAY GUN FIG. 14

1. Unclip the top of the trigger guard (1) from the gun head.

2. Using the bottom of the trigger guard as a wrench, loosen

and remove the handle assembly (2) from the gun head.

3. Pull the old lter (3) out of the gun head. Clean or replace.

4. Slide the new lter, tapered end rst, into the gun head.

5. Thread the handle assembly into the gun head. Tighten

with the trigger wrench.

6. Snap the trigger guard back onto the gun head.

7.1

MINIMUM CHECK BEFORE EVERY STARTUP:

1. Check the high-pressure hose and spray gun connections.

CHECK AT PERIODICAL INTERVALS:

1. Check inlet and outlet valve according wear. Clean it and

2. Check all lter inserts (spray gun, suction system and

GENERAL SERVICING

We strongly recommend having an annual check

carried out by technicians for safety reasons.

Please observe all the applicable national

regulations.

replace worn out parts.

pump lter) clean it and replace if necessary.

7.2 HIGHPRESSURE HOSE

Inspect the high-pressure hose visually for any notches or

bulges, in particular at the transition in the ttings. It must be

possible to turn the union nuts freely. A conductivity of less

than 1 MΩ must exist across the entire length.

Have all the electric tests carried by an Authorized

Titan Service Center.

tention

3

The risk of damage rises with the age of the highpressure hose.

Titan recommends replacing high-pressure

hoses after 6 years.

1

2

19

Page 20

serVicing

7.3 BASIC ENGINE MAINTENANCE GAS ENGINE

Elite 3500

• For detailed engine maintenance and technical

specications refer to the separate gasoline engine manual.

• All service to the engine should be performed by a dealer

authorized by the engine manufacturer.

• Use a premium quality motor oil. 10W30 is recommended

for general all temperature use. Other viscosities may be

required in other climates.

• Use only a (NGK) BR-6HS spark plug. Gap the plug to 0.028

to 0.031 In. (0.7 to 0.8 mm) Always use a spark plug wrench.

DAILY

1. Check engine oil level, and ll as necessary.

2. Check gasoline level, and ll as necessary.

Always follow the fueling procedure outlined

earlier in this manual.

FIRST 20 HOURS

• Change engine oil.

ENGINE OPERATION AND SERVICE

• Clean and oil air lter pad on gasoline engine every 25

hours or once weekly. Do not permit the air intake screen

around the y wheel of the gas engine to load up with paint

or trash. Clean it regularly. The service life and eciency

of the gas engine model depends upon keeping the

gasoline engine running properly. Change the oil in the

engine every 100 hours. Failure to observe this may result

in engine overheating. Consult the engine manufacturer’s

service manual provided.

• To conserve fuel, service life, and eciency of the sprayer,

always operate the gasoline engine at the lowest RPM at

which it runs smoothly without laboring and delivers the

amount required for the particular painting operation.

Higher RPM does not produce higher working pressure.

• The warranty on gasoline engines or electric motors is

limited to the original manufacturer.

EVERY 100 HOURS

• Change engine oil.

• Clean the sediment cup.

• Clean and re-gap the spark plug.

• Clean the spark arrestor.

WEEKLY

• Remove the air lter cover and clean the element. In

very dusty environments, check the lter daily. Replace

the element as needed. Replacement elements can be

purchased from your local engine manufacturer dealer.

20

Page 21

trouBlesHooting

Elite 3500

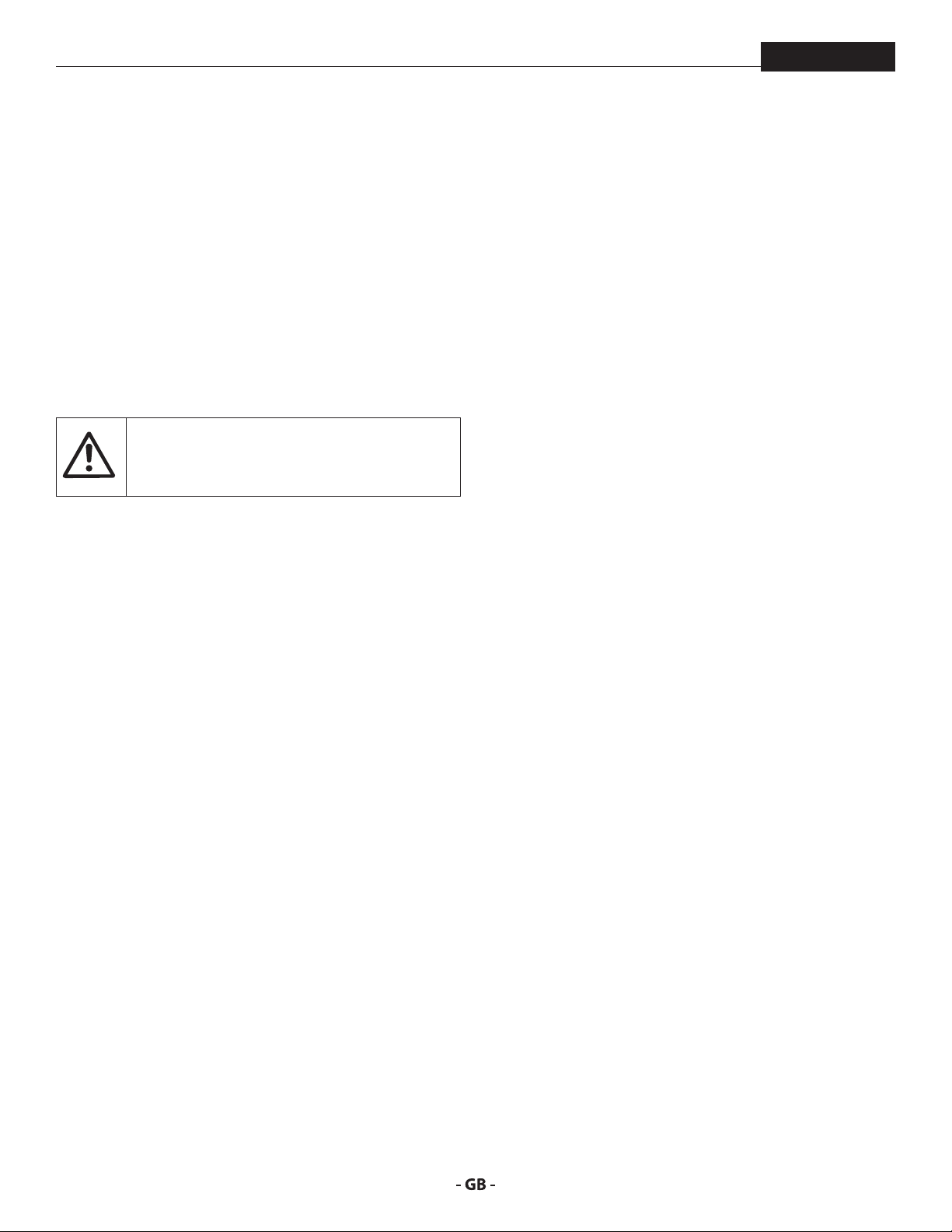

7.4 TROUBLESHOOTING

Type of malfunction What else? Possible cause Measures for eliminating the malfunction

Unit does not start Engine out of gas Fill engine with gas

Unit does not suck in Air bubbles do not exit

at the return hose

Air bubbles exit from

the return hose

Unit does not

generate pressure

Unit has sucked in air Air in the oil circuit Bleed the oil circuit in the unit by turning the

Unit reached pressure,

but the pressure

collapses during

spraying.

Unit reached pressure,

but the pressure

collapses during

spraying.

Inlet valve clogged Press the inlet valve button until the stop is

reached several times by hand

Inlet/outlet valve soiled /

foreign bodies drawn in

/ worn

Pressure control valve

turned down completely

Unit is sucking in outside

air

Suction lter clogged Check the suction lter. If necessary, clean/

Paint cannot be worked

in this state. Due to its

properties the paint clogs

the valves (inlet valve)

and the delivery rate is

too low.

Clogged lter do not let

enough paint pass

Tip clogged Clean the tip (-> refer to Section 5.2)

Remove the valves and clean then (-> refer to

Section 8.2/8.3) / replace worn parts

Turn the pressure control valve to the right

until the stop is reached

Check: Suction system tightened properly?

Cleaning connection (if available) at rigid

suction tube screwed tight and not leaking?

Inlet valve button leaky? -> Replace wiper and

O-ring (-> refer to Section 8.1)

pressure control valve completely to the left

and let it run approx. 2 – 3 min. Then turn the

pressure control valve to the right and set

the spraying pressure (repeat process several

times, if necessary).

replace

Dilute the paint

Check/clean the (high-pressure lter) gun lter

Unit does not generate

the max. pressure

possible. Paint

nevertheless exits at

the return hose.

21

Relief valve defective Please contact Titan Customer Service

Page 22

repairs

8 REPAIRS

Elite 3500

Prior to making any repairs, make sure to perform

the Pressure Relief Procedure, section 4.5.

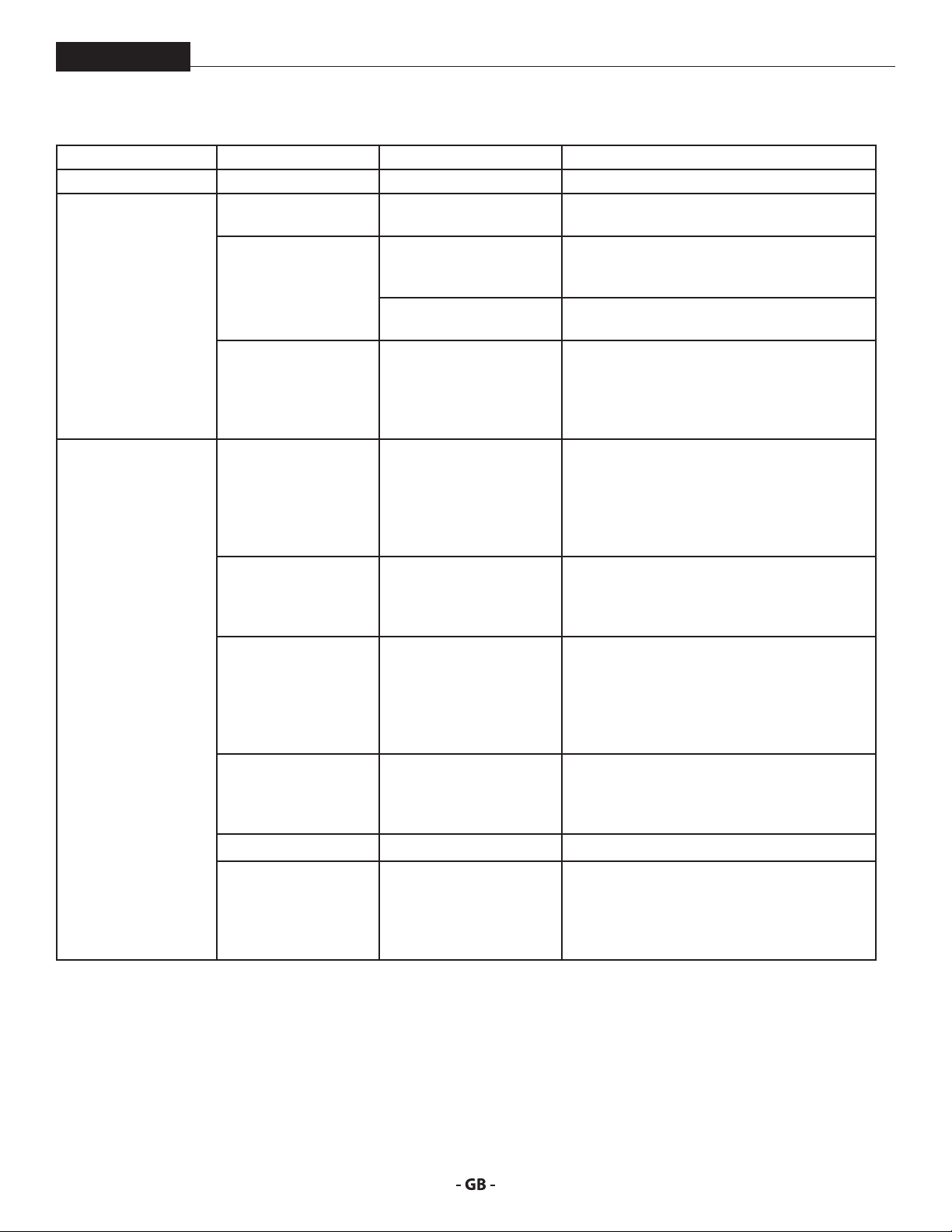

8.1 INLET VALVE PUSHER

1. Use a 17 mm wrench to screw out the inlet valve button

(Fig. 15, item 1).

2. Replace the wiper (2) and O-ring (3).

2

3

1

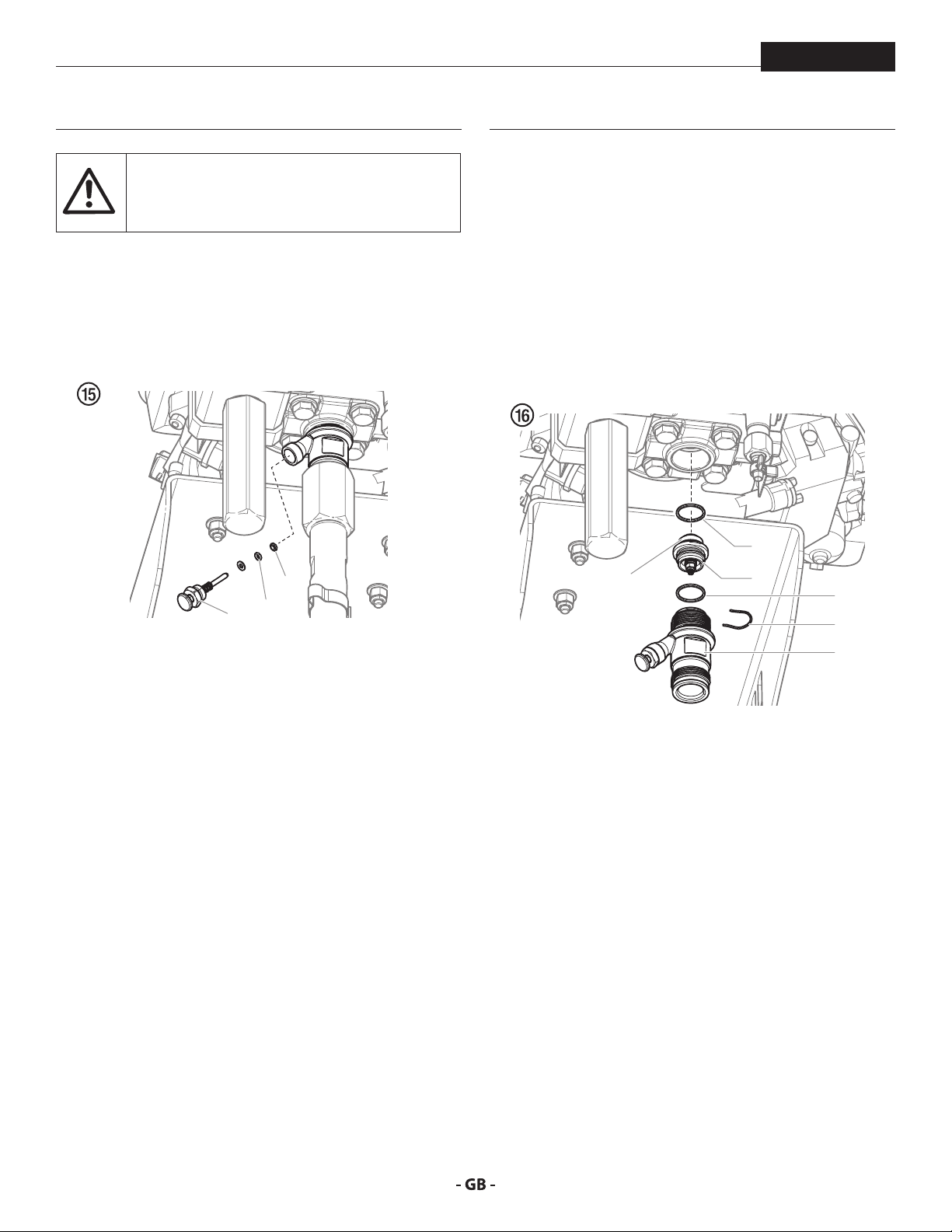

INSTALLATION

1. Insert the inlet valve (2) into the housing (1) and secure with

the clasp (3). Ensure that the (black) seal (5) is mounted in

the trigger housing.

2. Screw the unit from the housing and the inlet valve into the

paint section. The same (black) seal (6) has to be mounted

in the paint section.

3. Tighten the trigger housing with the 30 mm wrench and

tighten with three light blows of the hammer on the end

of the wrench. (Corresponds to approx. 90 Nm tightening

torque).

6

2

4

5

3

8.2 INLET VALVE

1. Place a 30 mm wrench on the housing (Fig. 16, item 1).

2. Loosen the housing (1) with light blows of a hammer on

the end of the wrench.

3. Screw out the housing with the inlet valve (2) from the

paint section.

4. Remove the clasp (3) using a screwdriver.

5. Place the 30 mm wrench on the inlet valve (2). Turn out the

inlet valve carefully.

6. Clean the valve seat (4) with a cleaning agent and brush

(ensure that no brush hairs are left behind).

7. Clean the seals (5, 6) and check for damage. Replace, if

necessary.

8. Check all the valve parts for damage. In case of visible wear

replace the inlet valve.

1

22

Page 23

repairs

Elite 3500

8.3 OUTLET VALVE

1. Use a 22 mm wrench to remove the outlet valve from the

paint section.

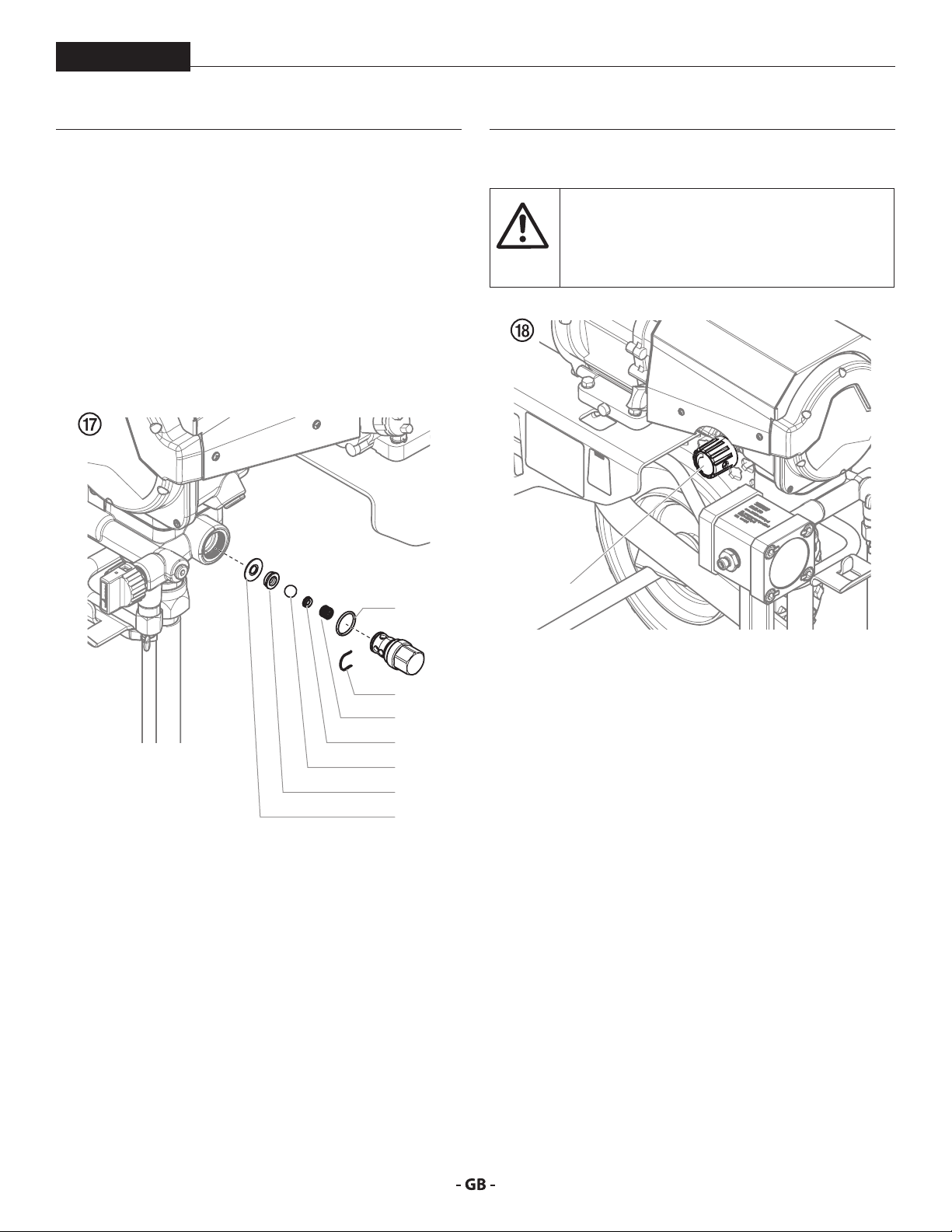

2. Carefully remove the clasp (Fig. 17, pos. 1) using a

screwdriver. The compression spring (2) presses ball (4)

and valve seat (5) out.

3. Clean or replace the components.

4. Check the O-ring (7) for damage.

5. Check the installation position when mounting the spring

support ring (3) (clipped onto spring (2)), outlet valve seat

(5) and seal (6), refer to gure.

7

8.4 PRESSURE CONTROL VALVE

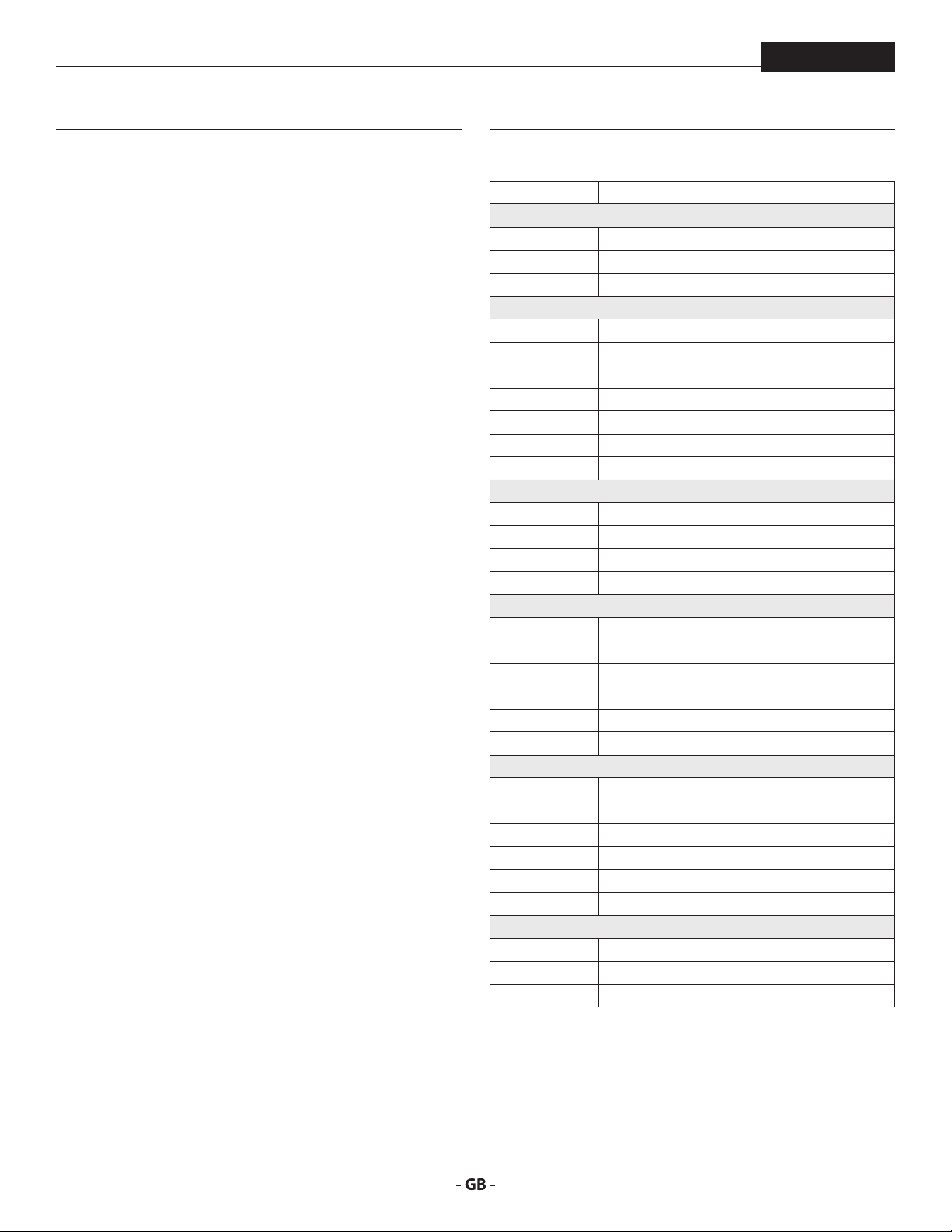

Only have the pressure control valve (1) replaced

by an Authorized Titan Service Center.

The max. operating pressure has to be reset by

an Authorized Titan Service Center.

1

1

2

3

4

5

6

8.5 TYPICAL WEAR PARTS

Despite the use of high-quality materials the highly abrasive

eect of the paints means that wear can occur at the following

parts:

INLET VALVE (spare part Order No.: 0344700)

For replacing refer to Section 8.2

(failure becomes noticeable through performance loss and/or

poor or no suction)

OUTLET VALVE (spare part Order No.: 0341702)

For replacing refer to Section 8.3

23

Page 24

appendix

9 APPENDIX

Elite 3500

9.1

SELECTION OF TIP

To achieve faultless and rational working, the selection of the

tip is of the greatest importance.

In many cases the correct tip can only be determined by means

of a spraying test.

SOME RULES FOR THIS:

The spray jet must be even.

If streaks appear in the spray jet the spraying pressure is either

too low or the viscosity of the coating material to high.

REMEDY: Increase pressure or dilute coating material. Each

pump conveys a certain quantity in proportion to the size of

the tip:

The following principle is valid: large tip = low pressure

small tip = high pressure

There is a large range of tips with various spraying angles.

9.2 SERVICING AND CLEANING OF AIRLESS

HARDMETAL TIPS

STANDARD TIPS

If a dierent tip type has been tted, then clean it according to

manufacturer’s instructions.

The tip has a bore processed with the greatest precision. Careful

handling is necessary to achieve long durability. Do not forget

the fact that the hard-metal insert is brittle! Never throw the tip

or handle with sharp metal objects.

The following points must be observed to keep the tip

clean and ready for use:

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual, section 4.5.

2. Remove the tip from the spray gun.

3. Place tip in an appropriate cleaning agent until all coating

material residue is dissolved.

4. If there is high-pressure air available, blow out tip.

5. Remove any residue by means of a sharp wooden rod

(toothpick).

6. Check the tip with the help of a magnifying glass and, if

necessary, repeat points 3 to 5.

9.3 ACCESSORIES

PART NO. DESCRIPTION

SPRAY GUNS

0538020 RX-Pro with TR-1 Tip

0538005 RX-80 4 nger with TR-1 Tip

0538006 RX-80 2 nger with TR-1 Tip

SPRAY TIPS AND ACCESSORIES

662-XXX SC-6+ Tip*

695-XXX TR-1 Tip*

692-XXX TR-2 Tip*

671-XXX Fine Finish Tip*

0289228 No Build Tip Guard

651-139 Tip Swivel

661-020 Tip seat and seal kit (5 pack)

FILTERS

0089957 Coarse Mesh Filter (Green)

0089958 Medium Mesh Filter (White)

0089959 Fine Mesh Filter (Yellow)

0089960 Extra Fine Mesh Filter (Red)

EXTENSIONS

651-070 6" Tip Extension

651-071 12" Tip Extension

651-072 18" Tip Extension

651-073 24" Tip Extension

310-390 3' Extension Pole

310-391 6' Extension Pole

AIRLESS HOSE AND ACCESSORIES

316-505 1/4" x 50' Airless Hose

316-506 3/16" x 5' Whip Hose

490-012 1/4" x 1/4" hose connector

0508239 High Pressure Fluid Gauge

310-150 9” Pressure Roller Kit

0521012 Non-Spit Valve

LUBRICANTS AND CLEANERS

314-482 Liquid Shield™ 1 Quart

0297055 Pump Shield™, 12 oz.

0508071 Paint Mate 1 Quart

* Go to www.titantool.com for tip sizes

24

Page 25

Warranty

Elite 3500

WARRANTY

Titan Tool, Inc., (“Titan”) warrants that at the time of delivery to the original purchaser for use (“End User”), the equipment covered

by this warranty is free from defects in material and workmanship. With the exception of any special, limited, or extended warranty

published by Titan, Titan’s obligation under this warranty is limited to replacing or repairing without charge those parts which, to

Titan’s reasonable satisfaction, are shown to be defective within twelve (12) months after sale to the End User. This warranty applies

only when the unit is installed and operated in accordance with the recommendations and instructions of Titan.

This warranty does not apply in the case of damage or wear caused by abrasion, corrosion or misuse, negligence, accident, faulty

installation, substitution of non-Titan component parts, or tampering with the unit in a manner to impair normal operation.

Defective parts are to be returned to an authorized Titan sales/service outlet. All transportation charges, including return to the

factory, if necessary, are to be borne and prepaid by the End User. Repaired or replaced equipment will be returned to the End User

transportation prepaid.

THERE IS NO OTHER EXPRESS WARRANTY. TITAN HEREBY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES INCLUDING, BUT NOT

LIMITED TO, THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, TO THE EXTENT PERMITTED BY LAW.

THE DURATION OF ANY IMPLIED WARRANTIES WHICH CANNOT BE DISCLAIMED IS LIMITED TO THE TIME PERIOD SPECIFIED IN

THE EXPRESS WARRANTY. IN NO CASE SHALL TITAN LIABILITY EXCEED THE AMOUNT OF THE PURCHASE PRICE. LIABILITY FOR

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES UNDER ANY AND ALL WARRANTIES IS EXCLUDED TO THE EXTENT PERMITTED

BY LAW.

TITAN MAKES NO WARRANTY AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE WITH RESPECT TO ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY TITAN.

THOSE ITEMS SOLD, BUT NOT MANUFACTURED BY TITAN (SUCH AS GAS ENGINES, SWITCHES, HOSES, ETC.) ARE SUBJECT TO THE

WARRANTY, IF ANY, OF THEIR MANUFACTURER. TITAN WILL PROVIDE THE PURCHASER WITH REASONABLE ASSISTANCE IN MAKING

ANY CLAIM FOR BREACH OF THESE WARRANTIES.

United States Sales & Service

Phone:

1-800-526-5362

Fax:

1-800-528-4826

1770 Fernbrook Lane

Minneapolis, MN 55447

www.titantool.com

25

international@titantool.com

www.titantool-international.com

International

Fax: 1-763-519-3509

1770 Fernbrook Lane

Minneapolis, MN 55447

Page 26

ÜBersetzung der originalBetrieBsanleitung

Warnung!

Achtung: Verletzungsgefahr durch Injektion!

Airless-Geräte entwickeln extrem hohe Spritzdrücke.

Niemals Finger, Hände oder andere Körperteile mit dem Spritzstrahl

in Berührung bringen!

1

Nie die Spritzpistole auf sich, Personen und Tiere richten.

Nie die Spritzpistole ohne Spritzstrahl-Berührungsschutz benutzen.

Behandeln Sie eine Spritzverletzung nicht als harmlose Schnittver-

letzung. Bei einer Hautverletzung durch Beschichtungssto oder

Lösemittel sofort einen Arzt aufsuchen zur schnellen, fachkundigen

Behandlung. Informieren Sie den Arzt über den verwendeten

Beschichtungssto oder das Lösemittel.

Elite 3500

2

3

Vor jeder Inbetriebnahme sind gemäß Betriebsanleitung folgende

Punkte zu beachten:

1. Fehlerhafte Geräte dürfen nicht benutzt werden.

2. Titan-Spritzpistole sichern mit Sicherungshebel am Abzugsbügel.

3. Erdung sicherstellen.

4. Zulässigen Betriebsdruck von Hochdruckschlauch und Spritzpistole

überprüfen.

5. Alle Verbindungsteile auf Dichtheit prüfen.

Anweisungen zur regelmäßigen Reinigung und Wartung des

Gerätes sind streng einzuhalten.

Vor allen Arbeiten am Gerät und bei jeder Arbeitspause folgende

Regeln beachten:

1. Spritzpistole und Hochdruckschlauch druckentlasten.

2. Titan-Spritzpistole sichern mit Sicherungshebel am Abzugsbüge.

3. Gerät ausschalten.

26

Achte auf Sicherheit!

Page 27

inHalt

Elite 3500

1 SICHERHEITSVORSCHRIFTEN FÜR DAS

AIRLESSSPRITZEN _____________________ 28

1.1 Erklärung der verwendeten Symbole _____________28

1.2 Sicherheitsrisiken _____________________________ 28

1.3 Aufstellung in unebenem gelanände _____________30

1.4 Benzinmotoren-Betriebssicherheit _______________30

1.5 Betanken (Benzinmotor) _______________________31

2 ANWENDUNGSÜBERSICHT ______________32

2.1 Einsatzgebiete _______________________________32

2.2 Beschichtungsstoe __________________________32

3 GERÄTEBESCHREIBUNG _________________33

3.1 Airless-Verfahren _____________________________33

3.2 Funktion des Gerätes __________________________ 33

3.3 Erklärungsbild ______________________________34

3.4 Technische Daten ____________________________35

3.5 Transport ___________________________________35

4 BEDIENUNG ____________________________36

4.1 Hochdruckschlauch und Spritzpistole ____________36

4.2 Start des Benzinmotors ________________________37

4.3 Vorbereitung eines neuen Spritzgeräts ___________37

4.4 Vorbereitung der Farbe ________________________38

4.5 Vorgehensweise bei Druckentlastung ____________38

5 SPRITZTECHNIK ________________________39

5.1 Eine verstopfte Düse reinigen ___________________ 39

5.2 Arbeitsunterbrechung _________________________ 40

5.3 Handhabung des Hochdruck-schlauches __________ 40

7 WARTUNG _____________________________43

7.1 Allgemeine Wartung __________________________43

7.2 Hochdruckschlauch ___________________________43

7.3 Einfacher Unterhalt des Motors (Benzinmotor) _____44

7.4 Hilfe bei Störungen ___________________________45

8 REPARATUREN AM GERÄT _______________46

8.1 Einlassventildrücker ___________________________ 46

8.2 Einlassventil _________________________________46

8.3 Auslassventil_________________________________47

8.4 Druckregelventil _____________________________47

8.5 Typische Verschleißteile _______________________47

9 ANHANG ______________________________48

9.1 Düsenauswahl _______________________________48

9.2 Wartung und Reinigung von

Airless-Hartmetall-Düsen _______________________48

9.3 Zubehör ____________________________________48

GARANTIE __________________________________ 49

ERSATZTEILE _______________________________ 74

Ersatzteilliste Hauptbaugruppe ____________________ 74/75

Ersatzteilliste Wagen • 0537012 ____________________ 76/77

Ersatzteilliste Wagen • 0537013 ____________________ 78/79

Ersatzteileliste Pumpenbaugruppe _________________ 80/81

Ersatzteilliste Hochdrucklter ________________________82

Ersatzteileliste Auslassventilbaugruppe ________________83

Ersatzteileliste Kolbenbaugruppe _____________________84

Ersatzteilliste Syphonschlauchbaugruppe ______________85

6 REINIGUNG ____________________________41

6.1 Besondere Reinigungshinweise bei Verwendung

entflammbarer Lösungsmittel __________________41

6.2 Reinigung des Spritzgeräts _____________________41

6.3 Gerätereinigung von außen ____________________41

6.4 Ansauglter _________________________________42

6.5 Hochdrucklter reinigen _______________________42

6.6 Reinigung der Airless-Spritzpistole _______________ 43

27

Page 28

sicHerHeitsVorscHriften

i

Eine unter hohem Druck stehende Flüssigkeit,

Bindegewebe eindringen und so zu schweren

Behandeln Sie eine Spritzverletzung nicht

als harmlose Schnittver-letzung. Bei einer

Hautverletzung durch Beschichtungssto

oder Lösemittel sofort einen Arzt aufsuchen

zur schnellen, fachkundigen Behandlung.

Elite 3500

1 SICHERHEITSVORSCHRIFTEN FÜR

DAS AIRLESSSPRITZEN

1.1

Diese Bedienanleitung enthält Informationen, die der Benutzer

vor Verwendung des Geräts gründlich durcharbeiten muss. In

Bereichen, die mit den folgenden Symbolen gekennzeichnet

sind, besonders vorsichtig arbeiten und alle Sicherheitshinweise

beachten.

ERKLÄRUNG DER VERWENDETEN SYMBOLE

Dieses Symbol verweist auf eine

potenzielle Gefahr, die zum Tode

oder zu schweren Verletzungen

führen kann. Hier nden Sie wichtige

Sicherheitsinformationen.

Dieses Symbol weist auf eine potenzielle

Gefahr für Sie bzw. das Gerät hin. Unter

Achtung

diesem Symbol nden Sie wichtige

Informationen, wie Sie Schäden an dem

Gerät und Verletzungsgefahr vermeiden.

Injektionsgefahr

Brandgefahr durch Lösemittel und

Farbdämpfe

Explosionsgefahr durch Lösemittel,

Farbdämpfe und ungeeignete Materialien

Verletzungsgefahr durch das Einatmen von

schädlichen Dämpfen

Hinweise enthalten wichtige Informationen,

die beachtet werden sollten.

1.2 SICHERHEITSRISIKEN

GEFAHR: VERLETZUNG DURCH

FLÜSSIGKEITEN UNTER DRUCK

wie sie von diesem Gerät erzeugt wird, kann die

Haut durchdringen und in das darunter liegende

Verletzungen und selbst zur Amputation führen.

Informieren Sie den Arzt über den verwendeten

Beschichtungssto oder das Lösemittel.

VORSICHTSMASSNAHMEN:

• NIEMALS die Spritzpistole auf Körperteile halten.

• NIEMALS mit Körperteilen den Flüssigkeitsstrahl berühren.

NIEMALS mit dem Körper eine Leckstelle im Druckschlauch

berühren.

• NIEMALS die Hand vor die Düse der Spritzpistole

halten. Handschuhe stellen keinen sicheren Schutz vor

Verletzungen durch injizierte Flüssigkeiten dar.

• STETS den Auslöser der Spritzpistole verriegeln, die Pumpe

ausschalten und den Druck vollständig entspannen,

bevor Wartungs- und Reinigungsarbeiten, Durchsichten,

Düsenwechsel oder ähnliche Arbeiten durchgeführt

werden oder das Gerät unbeaufsichtigt gelassen wird.

Auch nach dem Ausschalten des Motors steht das Gerät

noch unter Druck. Das Ventil PRIME/SPRAY (Vorfüll-/

Sprühventil) bzw. das Druckentlastungsventil müssen

in ihren Sollpositionen stehen, um den Systemdruck zu

entspannen.

• STETS den Düsenschutz aufsetzen, wenn Spritzarbeiten

durchgeführt werden. Der Düsenschutz stellt einen

gewissen Schutz dar, ist aber vor allem als Warnvorrichtung

gedacht.

• STETS die Spritzdüse entfernen, bevor das System gereinigt

oder gespült wird.

• NIEMALS eine Spritzpistole ohne funktionsfähige

Auslöserverriegelung und ohne Auslöserbügel verwenden.

• Das gesamte Zubehör muss mindestens für den maximalen

Betriebsdruckbereich des Spritzgeräts zugelassen sein.

Dazu gehören Spritzdüsen, Spritzpistolen, Verlängerungen

und Schlauch.

28

Page 29

sicHerHeitsVorscHriften

Durch Verschleiß, Knicken und nicht

zweckentsprechende Verwendung können

sich Leckstellen im Farbschlauch bilden. Durch

eine Leckstelle kann Flüssigkeit in die Haut

injiziert werden. Vor Verwendung den Schlauch

Brennbare Dämpfe, wie z. B. Dämpfe von

Lösungsmitteln und Farben können sich in den

Elite 3500

GEFAHR: HOCHDRUCKSCHLAUCH

gründlich prüfen.

VORSICHTSMASSNAHMEN:

• Scharfes Biegen oder Knicken des Hochdruckschlauches

vermeiden, kleinster Biegeradius etwa 20 cm.

• Hochdruckschlauch nicht überfahren, sowie vor scharfen

Gegenständen und Kanten schützen.

• Beschädigten Hochdruckschlauch sofort ersetzen.

• Niemals defekten Hochdruckschlauch selbst reparieren!

• Elektrostatische Auadung von Spritzpistole und

Hochdruckschlauch wird über den Hochdruckschlauch

abgeleitet. Deshalb muss der elektrische Widerstand

zwischen den Anschlüssen des Hochdruckschlauchs gleich

oder kleiner ein Megaohm betragen.

• Aus Gründen der Funktion, Sicherheit und Lebensdauer,

nur Titan-Original-Ersatzhochdruckschläuche verwenden.

• Vor jedem Einsatz alle Schläuche auf Einschnitte,

Leckstellen, Scheuerstellen oder gewölbte Oberächen

kontrollieren. Die Kupplungen auf Unversehrtheit und

festen Sitz kontrollieren. Schläuche unverzüglich ersetzen,

wenn einer der oben genannten Fehler festgestellt wird.

Einen Farbschlauch niemals reparieren. Einen defekten

Schlauch durch einen geerdeten Hochdruckschlauch

ersetzen.

• Achten Sie darauf, Spritzschläuche so zu verlegen, dass die

Rutsch-, Stolper-, und Umfallgefahr minimiert wird.

29

GEFAHR: EXPLOSIONS UND

BRANDGEFAHR

Arbeitsbereichen entzünden oder explodieren.

VORSICHTSMASSNAHMEN:

• Verwenden Sie das Gerät ausschließlich in gut belüfteten

Bereichen. Achten Sie auf ausreichende Frischluftzufuhr im

gesamten Bereich, damit sich keine brennbaren Dämpfe in

der Luft im Spritzbereich ansammeln können. Bewahren

Sie die Pumpenbaugruppe in einem gut belüfteten Bereich

auf. Besprühen Sie nicht die Pumpenbaugruppe.

• Nur Modelle mit Benzin - Befüllen Sie den Treibstotank

nicht, wenn der Motor läuft oder heiß ist; schalten Sie den

Motor ab und lassen diesen abkühlen. Der Treibsto ist

brennbar und kann sich entzünden bzw. explodieren, wenn

dieser mit einer heißen Oberäche in Berührung kommt.

• Beseitigen Sie alle Zündquellen, wie z. B. Zündammen,

Zigaretten, tragbare elektrische Lampen und

Plastikabdeckplanen (potenzieller elektrostatischer

Lichtbogen).

• Halten Sie die Arbeitsbereiche frei von Verunreinigungen,

einschließlich Lösungsmittel, Lappen und Benzin.

• Schließen Sie die Elektrozuleitungen nicht bzw. bzw.

trennen diese nicht ab bzw. schalten Sie die Netzschalter

bzw. Lichtschalter nicht ein bzw. aus, wenn sich brennbare

Dämpfe entwickelt haben.

• Schutzleiter und leitfähige Gegenstände im Arbeitsbereich.

Achten Sie darauf, dass die Erdleitung (in der Lieferung

nicht enthalten) von der Erdungsklemme mit einem

wirksamen Erdungsanschluss verbunden ist.

• Verwenden Sie ausschließlich geerdete Schläuche.

• Halten Sie die Spritzpistole fest an die Seite eines geerdeten

Eimers, wenn Sie in den Eimer spritzen.

• Kommt es durch statische Auadung zu Funkenbildung

bzw. wenn Sie einen Stromschlag verspüren, brechen Sie

den Vorgang umgehend ab.

• Sie müssen die Zusammensetzung der Farben und

Lösungsmittel, die Sie spritzen möchten, kennen. Lesen

Sie alle Materialsicherheitsdatenblätter (MSDS) und

Behälterbeschriftungen von Farben und Lösungsmitteln

durch. Befolgen Sie die Sicherheitsanweisungen des

Farben- und Lösungsmittelherstellers.

• Verwenden Sie keine Farben bzw. Lösungsmittel, die

Halogenkohlenwasserstoe enthalten, wie z. B. Chlor,

Bleiche, Antischimmelmittel, Methylenchlorid und

Trichlorethan. Sie sind nicht kompatibel mit Aluminium.

Setzen Sie sich mit dem Lieferanten der Beschichtung

hinsichtlich der Kompatibilität des Materials mit Aluminium

in Verbindung.

• Halten Sie im Arbeitsbereich einen Feuerlöscher bereit.

Page 30

sicHerHeitsVorscHriften

Farben, Lösungsmittel und andere Materialien

können beim Einatmen oder beim Kontakt mit

dem Körper gesundheitsschädlich sein. Die

Dämpfe können schwere Übelkeit, Ohnmacht

Kann schwere Personen- oder Sachschäden

GEFAHR: GEFÄHRLICHE DÄMPFE

Elite 3500

• An windigen Tagen nicht im Freien spritzen.

• Das Gerät inklusive aller Flüssigkeiten (z.B. Hydrauliköl)

müssen umweltgerecht entsorgt werden.

1.3 AUFSTELLUNG IN UNEBENEM GELÄNDE

und Vergiftungen verursachen.

VORSICHTSMASSNAHMEN :

• Bei Spritzarbeiten Atemschutz tragen. Alle mit der

Gesichtsmaske mitgelieferten Anleitungen durcharbeiten,

damit die Gesichtsmaske auch den gewünschten Schutz

bietet.

• Dem Benutzer ist eine Atemschutzmaske zur Verfügung

zu stellen (Berufs-Genossenschaftliche Regeln „Regeln für

den Einsatz von Atemschutzgeräten“ (BGR 190).

• Arbeitsschutzbrille tragen.

• Zum Schutz der Haut sind Schutzkleidung, Handschuhe

und eventuell Hautschutzcreme erforderlich (BGR 197

“Benutzung von Hautschutz”). Vorschriften der Hersteller

beachten zu den Beschichtungsstoen, Lösemittel und

Reinigungsmittel bei Aufbereitung, Verarbeitung und

Gerätereinigung.

GEFAHR: ALLGEMEINES

verursachen.

VORSICHTSMASSNAHMEN :

• Alle lokalen sowie im Land bzw. Bundesland geltenden

Vorschriften zum Brandschutz, zur Bedienung und Lüftung

einhalten.

• Bei Betätigung des Auslösers zieht die Spritzpistole zur

Seite. Diese Kraftwirkung der Spritzpistole ist besonders

stark, wenn die Düse entfernt und bei der Pumpe

hoher Druck eingestellt wurde. Bei der Reinigung mit

abgeschraubter Düse daher den Druckreglerknopf auf den

niedrigsten Druck einstellen.

• Nur vom Hersteller zugelassene Teile verwenden. Bei

Verwendung von Teilen, die nicht die technischen

Mindestanforderungen erfüllen, trägt der Benutzer alle

Risiken und die gesamte Haftung. Dies gilt auch für die

Sicherheitsvorrichtungen der Pumpe.

• IMMER die Hinweise des Herstellers zum sicheren Umgang

mit Farben und Lösungsmitteln einhalten.

• Verschüttete Materialien und Lösemitteln sofort

aufwischen, um Rutschgefahr zu vermeiden.

• Gehörschutz tragen. Dieses Gerät kann einen Schalldruck

über 85 dB(A) erzeugen.

• Das Gerät niemals unbeaufsichtigt lassen. Kinder oder

andere Personen, die mit dem Betrieb des druckluftlosen

Spritzgeräts nicht vertraut sind, von dem Gerät fern halten.

30

Die Vorderseite muss nach unten zeigen, um ein Wegrutschen

zu vermeiden.

Auf schrägen Untergründen ist das Gerät nicht zu betreiben, da

es durch Vibrationen zum Wandern neigt.

1.4 BENZINMOTORENBETRIEBSSICHERHEIT

1. Benzinmotoren sind so gebaut, dass sie sicher und

verlässlich funktionieren, wenn sie gemäss der

Instruktionen bedient werden. Vor der Bedienung des

Motos muss das Besitzerhandbuch des Herstellers

gelesen und verstanden werden. Bei Unterlassung kann

Personenverletzung oder Materialschaden entstehen.

2. Um Feuergefahr zu vermeiden und genügend Ventilation

zu erlauben, muss der Motor mindestens 1 Meter von

Gebäuden und anderen Maschinen entfernt sein wenn er

in Betrieb ist. Keine brennbaren Gegenstände in der Nähe

des Motors aufbewahren.

3. Personen, die das Gerät nicht bedienen, dürfen den

Betriebsbereich nicht betreten, da die Möglichkeit

besteht Verbrennungen von heissen Motorenteilen oder

Verletzungen durch Geräte, die zur Bedienung des Motors

benutzt werden, zu erleiden.

4. Seien Sie vertraut damit, wie Sie den Motor schnell

abstellen können und wissen Sie Bescheid über alle

Bedienungselemente und deren Handhabung. Erlauben

Sie niemandem, den Motor ohne sachgerechte Anleitung

zu bedienen.

5. Benzin ist äusserst ammbar und unter bestimmten

Bedingungen explosiv.

6. Tanken Sie Benzin nur in einem gut durchlüfteten Bereich

nach, nachdem der Motor abgestellt wurde. Rauchen

Page 31

sicHerHeitsVorscHriften

Ac

i

i

Elite 3500

Sie nicht und erlauben Sie keine Flammen oder Funken

im Bereich in welchem aufgetankt wird oder Benzin

aufbewahrt wird.

7. Ueberfüllen Sie den Benzintank nicht. Nach dem Auftanken,

vergewissern Sie sich, dass die Tankverschlusskappe

richtig und sicher aufgeschraubt ist.

8. Seien Sie darauf bedacht, beim Auftanken kein Benzin

zu verschütten. Benzindämpfe oder verschüttetes Benzin

könnte sich entammen. Falls Benzin verschüttet wurde,

vergewissern Sie sich, dass der Bereich trocken ist, bevor

Sie den Motor starten.

9. Lassen Sie den Motor nie in einem geschlossenen

oder engen Bereich laufen. Abgase enthalten giftige

Kohlenmonoxidgase; diesen ausgesetzt läuft man Gefahr

das Bewusstsein zu verlieren und es kann soagar zu Tod

führen.

10. Der Auspu wird während des Laufen des Motors sehr

heiss und bleibt nach abstellen des Motors noch für

eine Weile heiss. Seien Sie darauf Bedacht, den Auspu

nicht zu berühren, solange er noch heiss ist. Um schwere

Verbrennungen oder Feuergefahr zu vermeiden, lassen

Sie den Motor abkühlen, bevor Sie ihn transportieren oder

in einem Innenraum aufbewahren.

11. Verschien oder transportieren Sie die Sprühanlage

niemals mit Benzin im Tank.

Benutzen Sie diese Anlage NICHT um Wasser

oder Säuren zu spritzen.

Beim Auf- oder Abladen, nicht an der Deichsel

halten.

htung

Gerät ist sehr schwer. Muss von drei Personen

getragen werden.

Wechseln Sie die Treibstomarke, wenn das

“Klopfen” oder “Motorklopfen” bei einer stetigen

Motorgeschwindigkeit unter normaler Belastung

auftritt. Bleibt das Klopfen bzw. Motorklopfen,

setzen Sie sich mit einem autorisierten Händler

des Motorherstellers in Verbindung. Bei

Nichteinhaltung gilt dies als Fehlgebrauch und

Schäden durch Fehlgebrauch sind nicht durch

die Herstellergarantie gedeckt.

Gelegentlich entsteht ein leichtes Klopfen, wenn

das Gerät stark belastet wird. Das ist kein Grund

zur Beunruhigung. Dies bedeutet nur, dass der

Motor ezient funktioniert.

• Bleifreier Treibsto verursacht weniger Ablagerungen

im Motor und in den Zündkerzen und verlängert die

Lebensdauer der Komponenten des Abgassystems.

• Verwenden Sie niemals abgestandenes oder verschmutztes

Benzin und/oder ein Öl-/Benzingemisch. Vermeiden Sie,

dass Schmutz, Staub oder Wasser in den Treibstotank

gelangen.

KRAFTSTOFF AUS BENZINALKOHOLGEMISCH

Wenn Sie sich für einen Kraftsto aus einem Benzin-AlkoholGemisch (Gasohol) entscheiden, müssen Sie darauf achten,

dass dessen Oktanzahl mindest so hoch ist, wie diese vom

Motorenhersteller empfohlen wird. Es gibt zwei Arten von

Benzin-Alkohol-Gemisch: die eine enthält Ethanol und die

andere Methanol. Verwenden Sie kein Gasohol, das mehr als 10 %

Ethanol enthält. Verwenden Sie kein Benzin-Methanol-Gemisch

(Methyl oder Holzalkohol), das keine Zusatzlösungsmittel und

Korrosionshemmstoe für Methanol enthält. Verwenden Sie

niemals Benzin, das mehr als 5 % Methanol enthält, auch dann

nicht, wenn es Zusatzlösungsmittel und Korrosionshemmstoe

enthält.

1.5 BETANKEN BENZINMOTOR

Benzin ist äußerst entammbar und unter