Page 1

Owner’s Manual

Notice d’utilisation

Manual del Propietario

Do not use this equipment before

reading this manual!

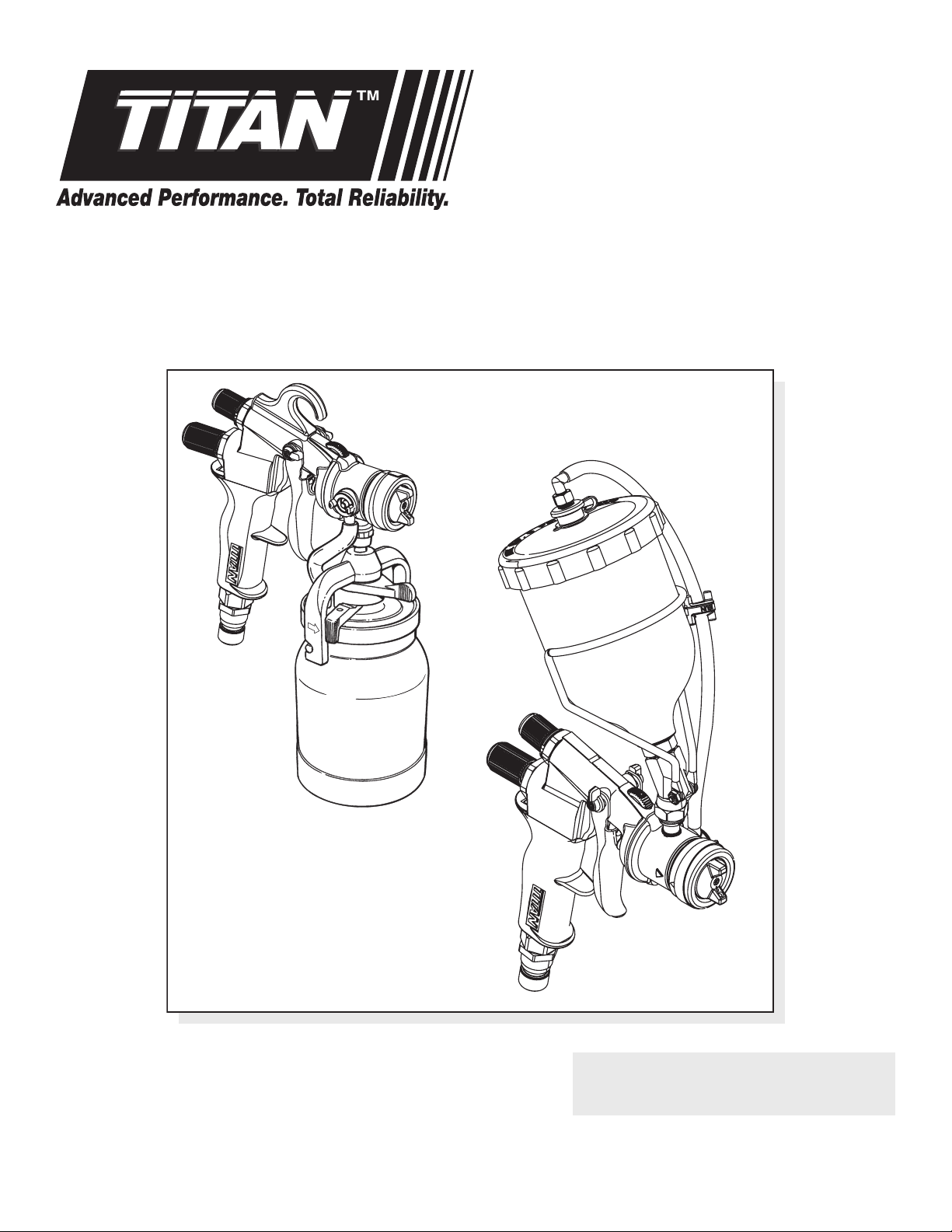

CAPSPRAY Maxum Elite

HVLP Spray Gun

Model 0524027

Model Number: 0524027

0524052

U.S. Patent No. 5,655,714

D616,527

Other patents pending

Model 0524052

NOTE: This manual contains important

warnings and instructions. Please read

and retain for reference.

0515 • © Titan Tool Inc. All Rights Reserved. Form No. 0524838J

Page 2

Important Safety Information

Read all safety information before operating the

equipment. Save these instructions.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

To reduce the risks of re or explosion, electrical shock

and the injury to persons, read and understand all

instructions included in this manual. Be familiar with the

controls and proper usage of the equipment.

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before operating any

equipment.

• Follow all appropriate local, state, and national codes governing

ventilation, re prevention, and operation.

• The United States Government Safety Standards have been adopted

under the Occupational Safety and Health Act (OSHA). These

standards, particularly Part 1910 of the General Standards and Part

1926 of the Construction Standard should be consulted.

• Use only manufacturer authorized parts. User assumes all risks

and liabilities when using parts that do not meet the minimum

specications and safety devices of the manufacturer.

• Before each use, check all hoses for cuts, leaks, abrasion or bulging

of cover. Check for damage or movement of couplings. Immediately

replace the hose if any of these conditions exist. Never repair a hose.

Replace it with an identical replacement hose.

• Do not spray outdoors on windy days.

• Wear clothing to keep paint o skin and hair.

• Never aim the spray gun at any part of the body.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS

Will cause property damage or severe injury.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as bleach,

mildewcide, methylene chloride and 1,1,1 - trichloroethane. They are

not compatible with aluminum.

• Contact your coating supplier about the compatibility of material with

aluminum.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Property

damage and/or severe injury can occur.

PREVENTION:

• Provide extensive exhaust and fresh air introduction to keep the air

within the spray area free from accumulation of ammable vapors.

• Avoid all ignition sources such as static electric sparks, open ames,

pilot lights, and hot objects. Connecting or disconnecting power

cords or working light switches can make sparks.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working order.

• The power cord must be connected to a grounded circuit.

• Follow the material and solvent manufacturer’s safety precautions and

warnings.

• Use extreme caution when using materials with a ashpoint below

100° F (38° C). Flashpoint is the temperature that a uid can produce

enough vapors to ignite.

• Plastic can cause static sparks. Never hang plastic to enclose a spray

area. Do not use plastic drop cloths when spraying ammable

materials.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials can

be harmful if inhaled or come in contact with the body.

Vapors can cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read all instructions

supplied with the mask to be sure it will provide the necessary

protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

HAZARD: SKIN BURN INJURY

Heated parts can cause severe skin burn injury.

PREVENTION:

• Quick disconnect ttings on the hose and spray gun become hot

during use. Avoid skin contact with quick disconnect ttings

when they are hot. Allow quick disconnect ttings to cool before

disconnecting the spray gun from the hose.

Table of Contents

Safety ................................................................................................ 2

Service .............................................................................................. 3

Introduction ..................................................................................... 3

Split Design ........................................................................................................ 3

Using an HVLP Spray Gun ............................................................ 4-5

Preparing to Spray ........................................................................................... 4

Selecting a Spray Pattern .............................................................................. 4

Spray Pattern Size ............................................................................................ 4

Adjusting the Material and Air Flow ......................................................... 4

Spraying .............................................................................................................. 5

Adjusting the Swivel Tube ............................................................................ 5

Cleaning your Spray Gun ................................................................ 5

Maintenance .................................................................................6-7

Adjusting the Packing Nut............................................................................ 6

Replacing the Needle Packing and Air Valve Seals .............................. 6

Replacing the Gun Head Seal and Gun Body O-ring ........................... 7

Replacing the Check Valve Retainer, Valve Seal,

and Air Tube ...................................................................................................... 7

Replacing the Air Flow Valve O-ring ......................................................... 8

Replacing the Cup Gasket ............................................................................. 8

Using a Pressure Feed System ........................................................ 8

Converting the Gun to Pressure Feed ...................................................... 8

Connecting to a 2-Quart Remote Pressure Pot System ..................... 8

Converting to Top Feed .................................................................. 9

Converting the Gun from Non-Bleeder to Bleeder ....................... 9

Choosing a Projector Set ............................................................... 10

Changing a Projector Set ............................................................................10

Optional Accessories ..................................................................... 10

Material reduction/projector set chart ........................................ 11

Troubleshooting ............................................................................ 11

Parts List ....................................................................................32-34

Spray gun assembly ............................................................................... 32-33

Cup assembly ..................................................................................................34

Top feed cup assembly ................................................................................35

Français .......................................................................................... 12

Español ........................................................................................... 22

Warranty ........................................................................................ 36

2 © Titan Tool Inc. All rights reserved.

English

Page 3

Service

Ma

Air ow

t cup

Gun rear

Gun head

Should your HVLP spray gun need service during the warranty period,

return the unit and the proof of purchase to the distributor where it

was purchased. At our option, the unit will be repaired or replaced. In

a continued commitment to improve quality, we reserve the right to

make component or design changes when necessary.

Introduction

These spray guns are designed for use in a High Volume/Low Pressure

(HVLP) painting system.

With an HVLP system, the highest quality professional nish can be

achieved with little preparation or setup time. HVLP systems are

not intended to replace airless systems. Instead, they are meant to

compliment airless by improving the nal nish on the substrate,

minimizing waste, and reducing labor time. In addition to enhancing

protability, HVLP systems are compliant with the most stringent

transfer eciency requirements.

The HVLP spray guns described in this manual include the turbine

cup gun and the turbine top feed gun. Please review all the

information contained in this manual before operating an HVLP

system.

NOTE: The general operation and maintenance of each style

Packing nut

Check valve

of HVLP spray gun are the same. For illustration

purposes, the turbine cup gun is pictured. However,

any information specic to a style of gun is described

where necessary. A parts listing for each style of gun

is included near the back of this manual.

adj. knob

terial ow

adj. knob

Trigger

release

Trigger

Air Inlet

Hook

Lever

Air cap ring

Air cap

Fluid inlet

Cup locking

lever

1-Quar

assembly

Split Design

This HVLP spray gun has a split-gun design that allows for easier

cleaning and disassembly. The two sections are the gun head and

gun rear.

To separate the two halves of the HVLP spray gun, follow the steps

below.

1. Make sure the air hose is removed from the air inlet of the

spray gun.

2. Swivel the trigger releases on

both sides of the spray gun so

they are pointing up.

3. Push the lever toward the rear of

the gun to unlock the two gun

halves.

4. While looking at the rear of the

spray gun, turn the gun rear counterclockwise to remove it

from the gun head.

Needle

NOTE: The needle will remain inside the gun head. Be sure

not to remove unless instructed.

Swivel tube

lever

NOTE: The hook on top of the gun body can be easily

© Titan Tool Inc. All rights reserved. 3

removed or reversed. Slide the hook toward the rear

of the gun to remove it.

To join the two halves of the HVLP spray gun, follow the steps below.

1. Make sure the trigger releases on both sides of the spray gun

are pointing up (toward the gun hook).

2. With the gun rear oriented upside down, bring the two halves

together. While looking at the rear of the spray gun, turn the

trigger section clockwise until it snaps back into place with the

gun head.

3. Swivel the trigger releases on both sides of the spray gun so

that they are pointing toward the gun head.

English

Page 4

Using an HVLP Spray Gun

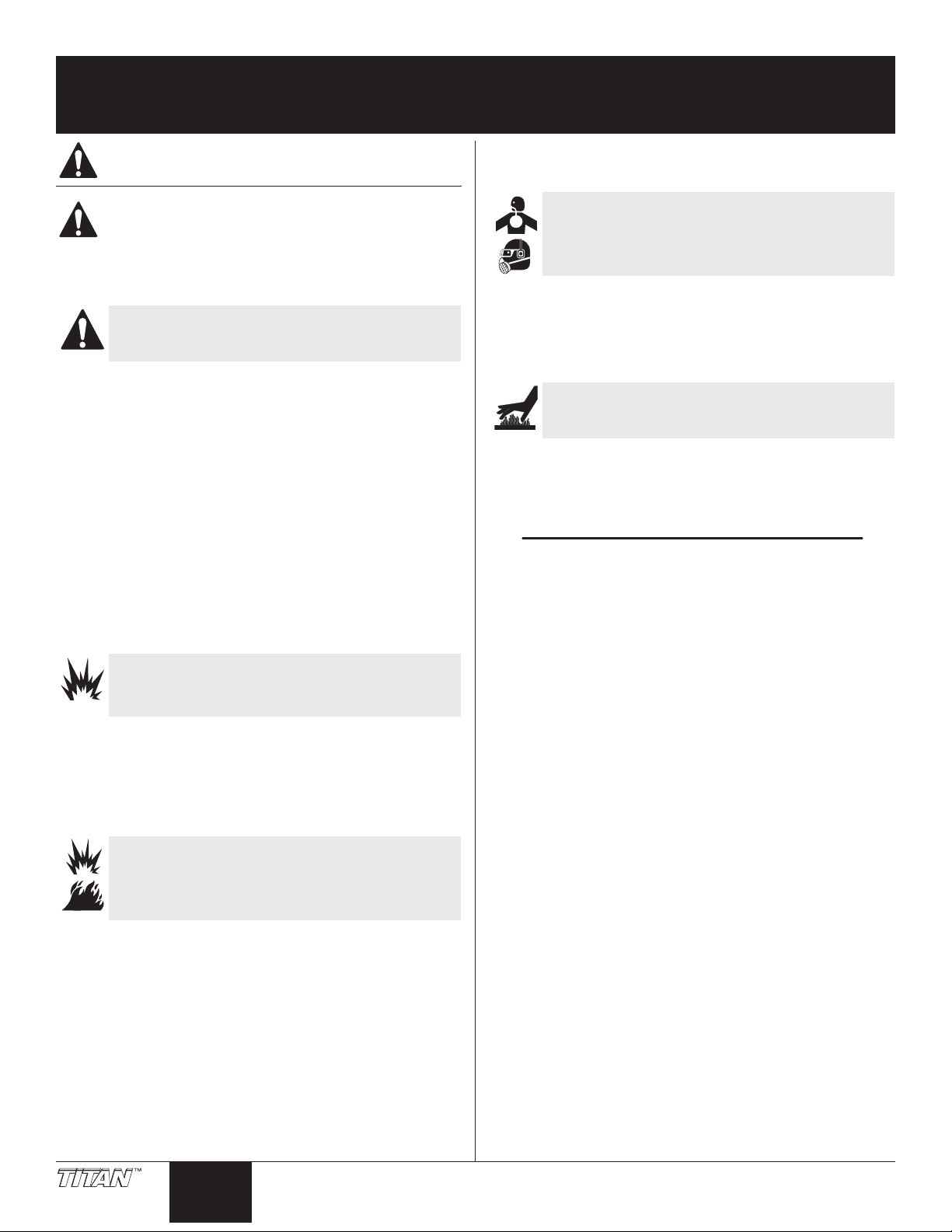

Air cap tabs

pattern

tip position

pattern

tip position

Vertical

pattern

tip position

adjustment knob

Air ow

adjustment knob

Preparing to Spray

1. Release the cup locking lever and remove the cup.

2. Make sure that the cup and the cup gasket is clean and in

position. Fill the cup with the desired painting material.

3. Place the cup on the spray gun and tighten the cup locking

lever.

4. Attach the air supply hose to the air inlet tting at the bottom

of the gun handle.

5. Turn on the air supply.

Selecting a Spray Pattern

The spray pattern is adjusted by turning the air cap into either a

vertical, horizontal, or diagonal position. To turn the air cap, grasp

the two front tabs and twist. Never trigger the gun while adjusting

the spray pattern.

Spray Pattern Size

To change the spray pattern size without changing the spray pattern

shape, turn the air cap ring.

Air Cap Ring

Bigger

Pattern

(b)

(a)

Smaller

Pattern

NOTE: An ideal starting point is when the triangle mark on

Turning the ring clockwise will make the pattern bigger. Turning the

ring counterclockwise will make the pattern smaller. As you reduce

the spray pattern size, you will need to move closer to the surface.

the air cap ring (a) is aligned with the triangle mark

on the gun head (b).

Adjusting the Material and Air Flow

Each individual job and material may require slight adjustments in

the material ow and air ow.

Turn the material ow adjustment knob clockwise for less uid and

counterclockwise for more uid.

Vertical

Diagonal

Horizontal

Horizontal

Round

Material ow

More

uid

Turn the air ow adjustment knob to adjust for more or less air. Set

the mark on the knob to the left for maximum airow. Remember to

test the spray on a piece of scrap wood or cardboard before using.

Maximum Minimum

+

Less

uid

-

4 © Titan Tool Inc. All rights reserved.

English

Page 5

Spraying

Correct

Begin

pass

pass

gun

trigger

stroke

Incorrect

Cup Locking Lever

Hold the spray gun between 1 and 8 inches from the spraying

surface, depending on the size of the spray pattern that you need.

The closer to the surface you hold the gun, the smaller the spray

pattern.

Keep the gun at right angles to the spraying surface in order to apply

an even coat of material. If you keep the spray gun moving at a

smooth and constant speed, the spray material is less likely to run or

sag.

Turn swivel tube lever

fully counterclockwise

when spraying up.

The arrow on the

counterclockwise side

of the bridge corresponds

with the position of the

swivel tube.

Trigger

Always squeeze the trigger of the spray gun after you begin your

spray pass and release it before the pass is done. For best results,

make the spray passes about 20 inches long and overlap each pass

by 4 or 5 inches. Remember to keep the gun at right angles to the

spraying surface.

Even

Release

End

Adjusting the Swivel Tube

The adjustable swivel tube on your spray gun lets you get the most

out of the material in your cup no amatter at what angle you need to

spray.

If you are holding your spray gun angled down, turn the swivel tube

lever fully clockwise.

NOTE: An arrow on each side of the bridge indicates the

direction that the swivel tube is pointing when the

swivel tube lever is in its fully clockwise or fully

counterclockwise position.

NOTE: The swivel tube lever is directly below the cup

locking lever. The cup locking lever secures the cup

to the spray gun.

Swivel Tube Lever

Cleaning the Spray Gun

It is very important to clean your HVLP spray gun thoroughly after

each use.

1. Empty the spray material from the cup.

2. Pour a small amount of the appropriate solvent in the cup and

attach the cup to the spray gun.

3. Shake and spray the gun in a well ventilated area.

NOTE: Do not restrict the nozzle when cleaning. Back

ushing of the system is not necessary.

4. Repeat the steps above until the solvent appears clear.

5. Wipe the interior/exterior of the cup and the spray gun with

the appropriate solvent until it is clean.

6. Separate the gun head from the gun rear (see instructions

on page 3). Remove the needle, uid nozzle, and air cap and

clean them thoroughly. Make sure that the air holes and

material passages are completely clean. Never use metal tools

or picks to clean the air cap or nozzle.

IMPORTANT: Any attempt to remove the fluid inlet fitting will

result in damage to the gun body and void the warranty.

Turn

swivel tube lever

fully clockwise

when spraying

If you are holding the spray gun angled up, turn the swivel tube lever

fully counterclockwise.

© Titan Tool Inc. All rights reserved. 5

down.

NOTE: Remove the needle packing only when replacing

with a new needle packing. Do not remove the

needle packing for cleaning.

7. Disassemble, clean, and dry the check valve and air tube after

each use.

IMPORTANT: DO NOT clean the air tube with hot solvents such as

lacquer thinner. Hot solvents will damage the air tube.

NOTE: Lubricate all of the threaded parts on the spray

gun with petroleum jelly when you put them

back together. This will help keep them working

properly.

IMPORTANT: Do not use any lubricants containing silicone.

Silicone can cause problems when used with some paints.

English

Page 6

Maintenance

Gun head

ing nut

valve nut

t

bushing

SIDE VIEW

Fr

Beveled Side

Perform the following maintenance procedures to keep your HVLP

spray gun working properly. New parts can be obtained by ordering

the HVLP Gun Repair Kit, part number 0279911.

Adjusting the Packing Nut

If material leaks from around or through the packing nut, readjust the

packing nut.

1. Disconnect the air hose from the air inlet and remove the cup

assembly.

2. Pull the trigger all the way back and hold.

3. Tighten the packing nut using a 3/8 inch wrench until the

needle remains retracted inside the nozzle when you release

the trigger.

4. Loosen the packing nut slowly

until the needle moves freely

back into position in the nozzle.

Once you have adjusted the nut,

reconnect the air hose and the cup

assembly. Squeeze the trigger to see if

the leaking has stopped. If it has not,

make sure the packing nut is as tight as

possible, while allowing the needle to

move freely. If adjusting the packing

nut does not stop the leak, replace the

packing.

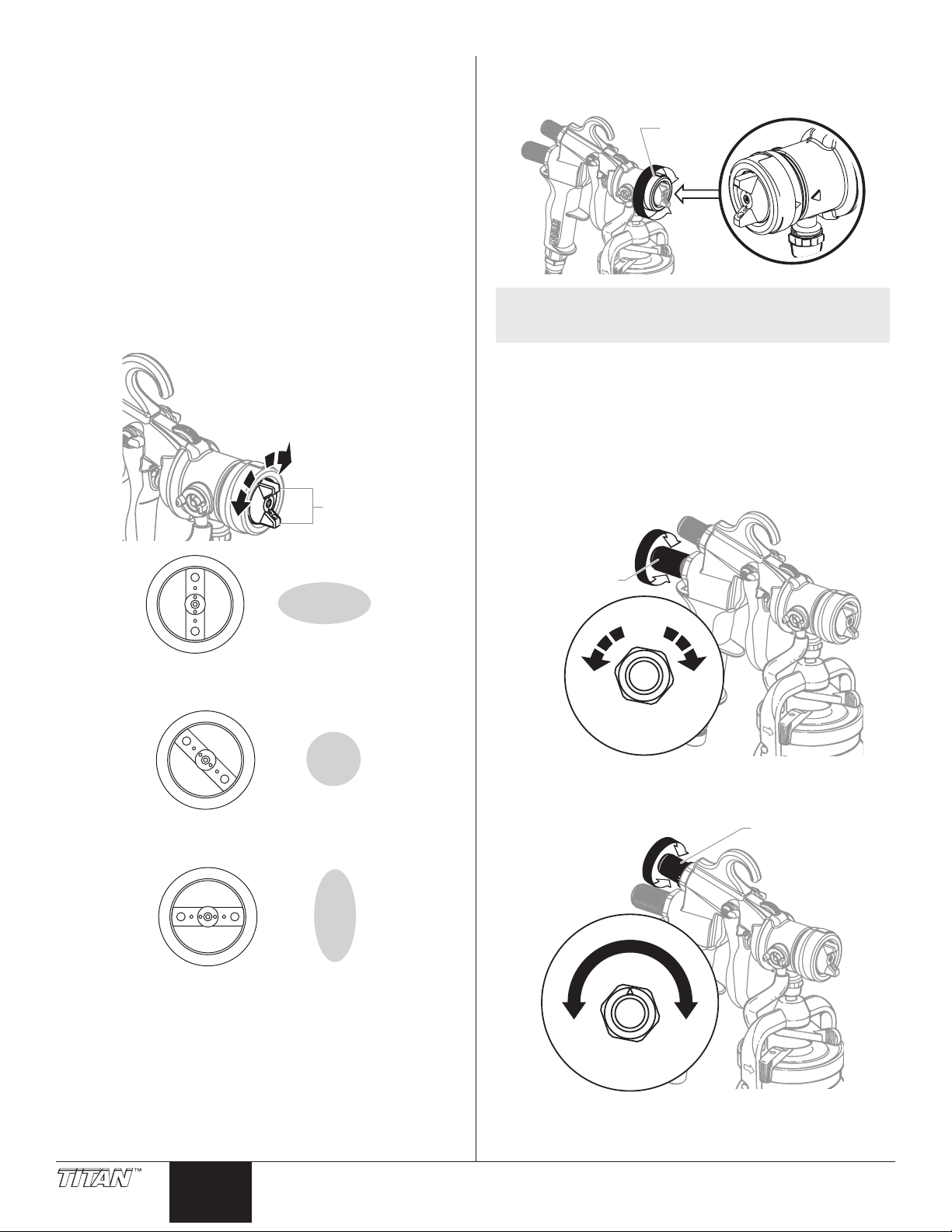

Replacing the Needle Packing

and Air Valve Seals

NOTE: Remove the needle packing only when replacing

with a new needle packing. Do not remove the

needle packing for cleaning.

The needle packing and the air valve seals can be

replaced separately. If you are replacing only one of

them, use the appropriate steps from the following

procedures.

Packing Nut

B) Removing the Needle and Housing

1. Disconnect the air hose from the air inlet.

2. Separate the gun head from the gun rear (see instructions on

page 3). The needle will remain in the gun head.

3. Loosen the air ow valve nut and remove the air ow

adjustment knob and the air ow valve nut to allow access to

the material ow adjustment housing.

4. Loosen and remove the material ow adjustment housing,

seal, and spring using a wrench.

Air ow

Material

Adjustment

Housing

5. Insert an 1/8 inch hex wrench into the back of the needle

guide shaft.

6. Hold the trigger bushing with a small pliers and turn the 1/8

inch hex wrench counterclockwise to remove the retaining

nut.

7. Pull the needle guide shaft out of the gun body. Do not lose

the trigger bushing.

Trigger

Seal and

spring

Needle

guide shaf

A) Removing / Replacing the Packing

1. Separate the gun head from the gun rear (see instructions on

page 3). The needle will remain in the gun head.

2. With the two sections of the gun still separated, remove the

needle.

3. Remove the packing nut using a 3/8 inch wrench.

4. Remove the packing from the packing nut.

Packing

Pack

NOTE: Make sure all of the old packing is removed before

5. Place the new packing into the packing hole.

6. Thread the packing nut one turn into the packing hole. Do

7. Replace needle into packing nut.

8. Tighten the packing nut securely using a 3/8 inch wrench,

9. Reassemble the gun head into the gun body.

10. Pull the trigger to make certain the needle moves freely. If

installing the new packing.

not tighten.

then loosen the packing nut a quarter turn.

the needle sticks, loosen the packing nut. If the packing leaks,

tighten the packing nut.

C) Replacing the Air Valve Seals

1. Remove the old rear air valve seal. It may stay on the end

of the needle guide shaft spring or in the material ow

adjustment housing.

2. Slide the new rear seal into the material adjustment housing.

3. Remove the front seal retaining clip using a snap-ring pliers.

4. Slide the old front air valve seal o of the needle guide shaft.

5. Place the new front air valve seal on the needle guide shaft

with the beveled side facing the gun.

NOTE: Make sure that the new front air valve seal looks like

the one that was just removed.

ont Air Valve Seal

6 © Titan Tool Inc. All rights reserved.

English

Page 7

6. Snap the front seal retaining clip onto the needle guide shaft.

Front seal

adjustment housing

head

body

retainer /

lve stem should

retaining clip

Front air valve seal

Needle guide shaft

Spring

Rear air

valve seal

Material ow

7. Reassemble the parts into the gun rear by reversing the steps

above.

NOTE: When replacing the needle guide shaft and the

trigger guide, secure the trigger guide in an

adjustable wrench. This will hold it in place while

the needle guide shaft is reinstalled.

Replacing the gun head seal and gun body O-ring

1. Remove the spray gun head from the gun body (see

instructions on page 3).

2. Pull the old gun head seal from the gun body. Do not install

the new one yet.

3. Using a 7/64 in hex wrench, remove the two gun body insert

screws. Remove the gun body insert.

4. Remove the gun body O-ring from the gun body. You may

need to use a needle-nose pliers or some other long, thin

object to remove it from the gun body.

Replacing the Check Valve Retainer, Valve Seal and

Air Tube

The check valve is a one-way valve designed to allow air into the

cup, pressurizing the cup’s contents. Because it is a one-way valve, it

prevents paint from seeping up the air tube into the air passages of

the gun. It also eliminates any delay in material ow when the gun is

triggered by maintaining pressure in the cup.

The check valve rotates open easily for cleaning. It contains a valve

seal that can be removed and cleaned with soap and water for

waterborne materials or a compatible solvent for other materials. To

replace the the valve seal and/or the air tube:

1. Unscrew the check valve retainer by turning it

counterclockwise.

2. Pull the valve seal out of the gun head. Clean or replace the

valve seal.

NOTE: The check valve area inside the gun head should

also be cleaned of any accumulated spray material.

DO NOT use anything metal or abrasive to clean the

check valve area as it will scratch the metal surface,

and the valve seal will not seal properly.

3. Reinstall the valve seal. Insert the stem of the valve seal into

the hole of the gun head.

Va

be facing toward

the gun

NOTE: Make sure this area of the gun body is free from all

5. Lubricate the new O-ring with petroleum jelly and install into

6. Replace the gun body insert and secure with the gun body

7. Install the new gun head seal into the gun head body as

8. Reassemble the spray gun head onto the gun body (see page

Gun

spray material residue before reinstalling the new

gun body O-ring.

the gun body.

insert screws.

shown.

3).

Gun body insert

Screws

Gun head

seal

Gun body

O-ring

Gun

Valve seal

Check valve

O-ring

4. Screw the new or cleaned check valve retainer / o-ring back

into the gun head by turning it clockwise.

5. To replace the air tube, pull it from the nipples on both the

gun head and the cup assembly. Replace with a new tube.

Air tube

© Titan Tool Inc. All rights reserved. 7

English

Page 8

Replacing the Air Flow Valve O-ring

Adjustment

Cup Gasket

Swivel Lever

1. Using a wrench, loosen the air ow valve nut and remove the

air ow adjustment knob assembly.

2. Using a screwdriver, remove the adjustment knob screw.

Separate the adjusment knob from the air ow valve nut. Be

careful not to lose the washer.

3. Separate the air ow valve from the air ow valve nut. The air

ow valve O-ring is located on the air ow valve.

4. Remove the air ow valve O-ring from the air ow valve.

5. Lubricate the new O-ring with a small amount of petroleum

jelly, and replace into the gun body.

6. Reassemble the air ow adjustment knob assembly:

a. Insert the air ow valve into the rear of the spray gun.

b. Place the air ow valve nut over the air ow valve and

thread it into the rear of the gun. Tigthen with a wrench.

c. Turn the air ow valve slightly counterclockwise until it

does not turn any further.

d. Install the washer.

e. Place the adjustment knob over the air ow valve. The

mark on the knob should be in the 9:00 o’clock position

(all the way to the left).

f. Secure the adjustment knob with the screw. Tighten

with a screwdriver.

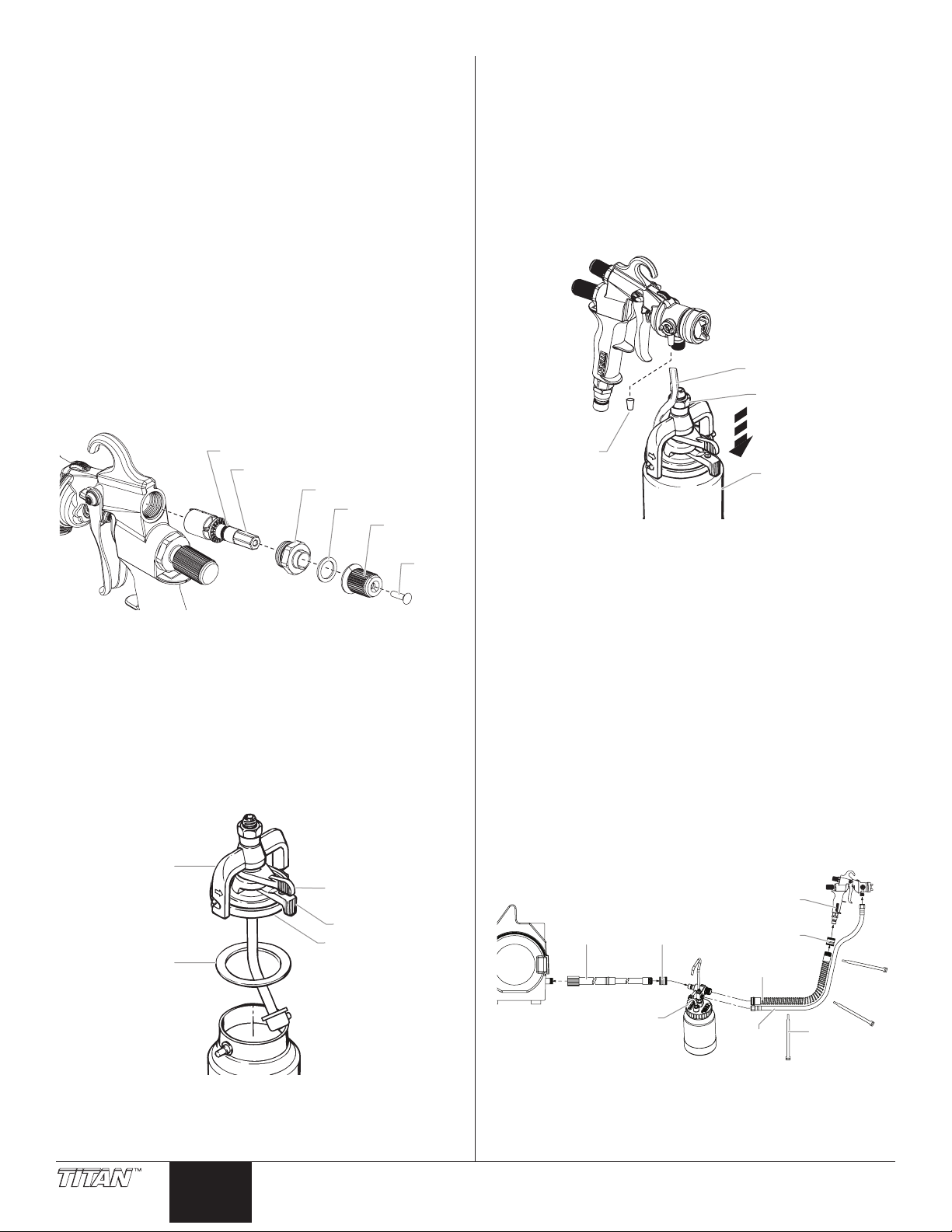

Using a Pressure Feed System

To increase spray time between material rells, your HVLP spray

gun can be connected to a larger material pressure pot and air

compressor.

Converting the Gun to Pressure Feed

Before using a pressure feed system, the spray gun must be

converted to a pressure fed gun.

1. Loosen the retaining nut using a wrench and remove the one

quart cup assembly.

2. Pull the air tube o of the air tube tting on the spray gun.

Air tube

Retaining nut

Air ow valve O-ring

Air ow valve

Air ow valve nut

Washer

knob

Screw

Replacing the Cup Gasket

The cup gasket must be replaced periodically due to normal wear. It is

important to inspect the cup gasket during each cleaning.

1. Release the cup locking lever.

2. Hold the cup and twist the spray gun in the direction

indicated by the arrows on the bridge.

3. Lift the spray gun away from the cup.

4. Pull the worn cup gasket out of the lid.

5. Press a new cup gasket into the lid.

6. Place the spray gun onto the top of the cup.

Bridge

Cup Locking

Lever

Pressure cap

Cup assembly

3. Place the pressure cap over the nipple on the gun head.

Connecting to a 2-Quart Remote Pressure Pot

1. Convert the gun to pressure feed.

2. Connect hoses:

a. Make sure turbine is turned OFF and unplugged.

b. Attach remote pressure pot to the turbine via the hose

conguration shown below.

c. Tighten the air hose connections by hand.

d. Tighten the uid hose connections with an adjustable

wrench.

1) Turbine

2) 7.5m air hose

3) Female quick-disconnect coupling

4) 2-quart pressure tank assembly

5) 1.5m air whip hose

6) 1.5m uid whip hose

7) Hose straps

8) Female quick-disconnect coupling

9) Spray gun

9

Lid

2

3

1

8

5

4

6

7. Turn the spray gun opposite the direction indicated by the

arrows on the bridge until the pegs on the cup are in the

notches of the bridge.

8. Tighten the cup locking lever.

8 © Titan Tool Inc. All rights reserved.

English

7

Page 9

Converting to Top Feed

adjustmen

Air inlet

The cup is designed for a maximum working pressure

of 6 PSI (0.41 bar). Pressures higher than 6 psi can

result in cup leakage, damage to the equipment, and/

or potential injury to the user.

The top feed HVLP spray gun is designed for use in special

applications such as spraying in conned areas. The position of

the cup gives the top feed gun the ability to spray downward and

overhead. When spraying with the top feed gun, remember the

following tips for the best results. Keep the cup pressurized at all

times when spraying. Attempting to gravity feed the material will

slow or stop the ow of material at the nozzle.

NOTE: It is recommended that the gun hook be removed

whenever using the top feed cup assembly.

To set up the spray gun for top feed delivery:

1. Loosen the retaining nut using a wrench and remove the one

quart cup assembly.

2. Pull the air tube o of the air tube tting on the spray gun.

3. Separate the gun head from the gun rear (see instructions

on page 3). Reassemble gun head upside-down so uid inlet

tting on gun head points upward to accept the top feed cup

assembly.

4. Remove the gun hook and thread the retaining nut of the topfeed cup assembly onto the uid inlet of the gun head. Rotate

the stand away from the cup and set the gun assembly on a

level surface.

5. Using an adjustable wrench, secure the retaining nut, making

sure the gun/cup assembly stays in a level position. The cup

should end up in a vertical position when supported by the

stand.

6. Connect the air tube to the air tube tting on the spray gun.

IMPORTANT: The gun, when converted to top-feed, will not

stand on its own. Make sure to use the stand when filling. Do not

lay the gun on its side when it is filled with material. Do not hang

the gun by its hook when lled with material.

Converting the gun from Non-Bleeder to

Bleeder

Your HVLP spray gun can be converted from a non-bleeder to a

bleeder setup. Bleeder setup provides more atomizing power for

higher viscosity materials, such as latex and enamels. Bleeder setup

can make it easier to spray in conned spaces, such as inside cabinets,

because the air hose is moved to the back of the gun.

To convert a spray gun to bleeder setup:

1. Remove the air ow adjustment knob from the rear of the gun

using a wrench.

2. Remove the air inlet tting from the bottom of the gun handle

using a wrench.

3. Thread the air inlet tting into the air ow adjustment knob

location at the rear of the gun. Secure the tting in place.

Air ow

t

knob

Air inlet

tting

4. Thread the air inlet plug (shipped loose with the gun literature

pack) into the air inlet at the bottom of the gun handle.

Secure the plug in place.

Air tube

Air tube tting

Fluid inlet

© Titan Tool Inc. All rights reserved. 9

plug

5. Attach the air hose to the relocated air inlet tting.

NOTE: In bleeder setup, the removal of the air ow

adjustment knob causes the air supply to be on at all

times when the air hose is attached to the gun.

English

Page 10

Choosing a Projector Set

Fluid nozzle

Air cap

Your HVLP spray gun should be tted with the proper projector set

for the type of work you will be performing. A projector set consists

of a needle assembly, a uid nozzle, and an air cap.

Needle assembly

You should choose a projector set based on two things: the type of

material to be sprayed and the nish desired.

The chart on the following page should help you to make the right

choice.

Changing a Projector Set

1. Remove the air cap ring, air cap, and spring plate.

Air cap ring

Air cap

Spring plate

2. Remove the uid nozzle.

Optional Accessories

Part Number Description

0524293 Projector set, #2 complete

0524294 Projector set, #3 complete

0524295 Projector set, #4 complete

0524296 Projector set, #5 complete

0524297 Projector set, #6 complete

0524298 Projector set, #7 complete

0276449 Air cap, #2

0276452 Air cap, #3

0276455 Air cap, #4

0276458 Air cap, #5

0276417 Air cap, #6

0524401 Air cap, #7

0276446 Nozzle, #2

0276451 Nozzle, #3

0276454 Nozzle, #4

0276457 Nozzle, #5

0276418 Nozzle, #6

0524363 Nozzle, #7

0524282A Needle assembly, #2

0524283A Needle assembly, #3

0524284A Needle assembly, #4

0524285A Needle assembly, #5

0524286A Needle assembly, #6

0524287A Needle assembly, #7

0508124 Cover, clip-on, 1 quart

0524188 Tip accessory kit

0524189 Deluxe tip accessory kit

0524271A Cup assembly

0524045 Top feed cup assembly

Repair Kits

Part Number Description

0276257 Check valve membrane kit

(includes 10 membranes)

0297052 Gasket, cup, white (includes 6 gaskets)

0524507 Nozzle key

0279911 HVLP gun repair kit*

*Includes:

• air valve seal (0277486)

• rear air valve seal (0275501)

• needle packing (0275579)

• check valve retainer assembly (0529220)

• gun body o-ring (0524618)

• air ow valve o-ring (0508403)

• check valve seal (0276415)

• cup gasket (0277495)

• gun head seal (0524503)

* See parts lists on page 32-35 for part locations.

3. Separate the gun head from the gun rear (see instructions on

page 3).

4. Remove the needle.

IMPORTANT: If the needle does not slide out easily, loosen

the packing nut to prevent the needle or packing from being

damaged.

5. Install the new projector set in reverse order.

10 © Titan Tool Inc. All rights reserved.

English

United States Sales & Service

Phone:

1-800-526-5362

Fax:

1-800-528-4826

1770 Fernbrook Lane

Minneapolis, MN 55447

www.titantool.com

Page 11

Material Reduction/Projector Set Chart

Before spraying, the material being used must be thinned with an appropriate solvent and the proper projector set must be installed. It is

always best to follow the material manufacturers recommendations and thinning procedures.

There are two simple methods of measuring the proper thickness of a material:

1. Dip a paint stick into the material and remove it, watching carefully as the material runs o. When the material begins to form drops, the

drops should fall about 1 second apart.

2. Use a viscosity cup (P/N 0153165). Dip the cup into the material and remove it. Use a watch or clock to time how long the material drains

from the cup in a continuous stream. Once the continuous stream breaks, stop timing and refer to the table below. Add the appropriate

solvent and continue testing until the proper thickness is reached for the type of material you are using.

Material % of reduction Time Solvent Projector Set

Latex .......................................... 20-25% ............................................... 30-35 sec. ...................Water ..............................................................5

Oil ............................................... 10-20% ............................................... 20-30 sec. ................... Mineral Spirits .............................................4

Epoxy.........................................1-10% ................................................. 30-35 sec. ...................Mfg. Recommendations ..........................5

Clear wood nish .................. Full strength .............................................................................Mfg. Recommendations ..........................4

Varnish ...................................... Mfg. Recommendations ...................................................... Naphtha.........................................................3

Polyurethane .......................... 10% ..................................................... 18-22 sec. ................... M.E.K. ..............................................................3

Sealer.........................................Full strength .............................................................................Mineral spirits ..............................................3

Oil-based primer ................... 15-20% ............................................... 30-35 ........................... Mineral spirits ..............................................4

Fast-dry enamel ....................25% ..................................................... 20-25 ........................... Mineral spirits ..............................................4

Stain ........................................... Full strength ............................................................................. Mfg. Recommendations ..........................3

Metal primer ........................... 15% ..................................................... 25-30 sec. ................... Mineral spirits .............................................. 4

Industrial enamel .................. 15% ..................................................... 30-35 sec. ................... Mineral spirits ..............................................4

Aluminum paint .................... Full strength .............................................................................Mineral spirits ..............................................4

Lacquer sealer ........................ Mfg. Recommendations .............. 18-22 sec. ................... Lacquer thinner .......................................... 3

Lacquer .....................................50% ..................................................... 18-22 sec. ................... Lacquer thinner .......................................... 3

Troubleshooting

Problem

A. Little or no paint ow

B. Paint leaking

C. Paint is backing up past the

check valve

D. Poor spray pattern

E. Pulsating spray

F. Pattern is heavy in the middle

G. Gun spitting paint

H. Paint build up on the air cap

I. Too much overspray

Cause

1. Dried paint blocking uid nozzle

2. No air pressure in paint cup or pot

3. Check valve in air tube plugged

4. No uid pressure

5. Blockage in material hose

1. Improper size needle or nozzle

2. Damaged needle or nozzle

3. Loose nozzle

4. Loose packing nut

5. Needle not closing properly

1. Gun is being tilted too much when it is not

spraying

2. Check valve leaks

1. Air holes in air cap ears are clogged

2. Nozzle is clogged

3. Damaged nozzle or needle

1. Loose or damaged packing

1. Too much uid pressure

1. Valve in air tube is not operating properly

2. Material too thick

3. Projector set is too small.

1. Improper adjustment of cap

1. Air pressure too high

2. Material too thin

3. Spray gun too far from surface

Solution

1. Disassemble and clean

2. Inspect air tube, cup or pot gasket, clean or replace.

3. Clean or replace the check valve assembly

4. Check material supply

5. Clean by ushing with solvent

1. Replace

2. Replace

3. Tighten

4. Tighten

5. a) Loosen packing nut

b) Replace needle spring

c) Remove dried paint from needle

1. Tilt the gun only when spraying

2. Clean or replace the check valve

1. Remove and clean air holes

2. Clean with appropriate solvent

3. Remove and replace

1. Tighten or replace

1. Reduce pressure

1. Replace valve assembly

2. Thin material

3. Install the proper projector set.

1. Adjust the air cap properly so that paint ows freely

through the cap

1. Reduce air pressure

2. Add unthinned paint

3. Move closer

© Titan Tool Inc. All rights reserved. 11

English

Page 12

Consignes de sécurite important

Lire toutes ces consignes avant d’utiliser l’appareil.

Garder ces consignes.

Indique une situation à risque, laquelle, si elle n’est pas évitée,

peut entraîner des blessures graves, voire la mort.

Pour réduire les risques d’incendie ou d’explosion, de choc

électrique et de blessure, vous devez lire et comprendre les

directives gurant dans ce manuel. Familiarisez-vous avec les

commandes et l’utilisation adéquate de l’équipement.

DANGER : GÉNÉRAUX

Risques de dommages matériels et de blessures graves.

PRÉVENTION :

• Lire toutes les directives et mises en garde avant de faire fonctionner

l’équipement, quel qu’il soit.

• Se conformer à la législation locale, provinciale ou fédérale pour

tout ce qui concerne la ventilation, la prévention des incendies et les

conditions générales d’utilisation.

• Les normes de sécurité adoptées par le gouvernement américain l’ont

été en vertu de sa Occupational Safety and Health Act (OSHA); ces

normes, particulièrement les parties 1910 des normes générales et

1926 des normes de construction, devraient toujours être consultées.

• N’utiliser que les pièces autorisées par le fabricant. L’utilisateur

assume tous les risques et responsabilités lorsqu’il utilise des pièces

qui ne sont pas conformes aux caractéristiques techniques minimales

ainsi qu’aux dispositifs de sécurité du fabricant.

• Vérier, avant toute utilisation, que les exibles ne présentent pas

d’entaille ou de fuite, que le couvercle ne soit pas goné et que les

raccords ne soient pas endommagés. Si le exible a subi l’un des

dommages précités, remplacez-le immédiatement. Ne jamais réparer

un exible d’alimentation. Le remplacer avec un exible identique de

remplacement.

• Ne jamais pulvériser lorsqu’il vente.

• Porter des vêtements pour protéger la peau et les cheveux contre

tout contact avec la peinture.

• On ne doit jamais orienter le pistolet vers une partie du corps.

DANGER : RISQUES D’EXPLOSION PAR INCOMPATIBILITÉ

Peuvent être à l’origine de corporels sérieux ou dommages matériels.

PRÉVENTION :

• Ne pas utiliser de matériaux contenant des agents de blanchiment ou

du chlore.

• Ne pas utiliser des solvants à base d’hydrocarbure halogéné tels que

l’agent anticryptogamique, le chlorure de méthylène et le trichloroéthane-1,1,1. Ces produits ne sont pas compatibles avec l’aluminium.

• Communiquer avec votre fournisseur de revêtement pour connaître la

compatibilité du matériau avec l’aluminium.

DANGER : RISQUES D’EXPLOSION OU D’INCENDIE

Les vapeurs dégagées par le solvant ou la peinture sont

explosives et inammables et peuvent causer des corporels

sérieux ou dommages matériels.

PRÉVENTION :

• Veiller à éviter toute accumulation de vapeurs inammables en vous

assurant que la zone où la pulvérisation a lieu est susamment

ventilée.

• Veiller à éviter la présence de toute source incandescente telle

qu’étincelle électrostatique, amme nue, amme-pilote, objet

brûlant, cigarette et étincelle provenant du branchement ou du

débranchement d’un cordon d’alimentation électrique ou d’un

commutateur.

• Ne pas fumer dans la zone d’épandage.

• Toujours avoir un extincteur en état de fonctionner à portée de la main.

• Le cordon d’alimentation doit être raccordé à un circuit mis à la terre.

• S’assurer de suivre les directives en matière de sécurité et de lire les

mises en garde du fabricant des solvants et des produits utilisés.

12 © Titan Tool Inc. Tous droits réservés.

DES MATÉRIAUX

Français

• S’entourer de toutes les précautions possibles lorsqu’on utilise des

produits ayant un point d’éclair inférieur à 38 °C (100 °F). Le point

d’éclair d’un uide est la température à laquelle les vapeurs émanant du

uide peuvent s’enammer au contact d’une amme ou d’une étincelle.

• Le plastique peut être une source d’étincelles provoquées par

l’électricité statique. Ne jamais utiliser une couverture en plastique

pour fermer une zone d’épandage ni utiliser des toiles de protection en

plastique lors de la pulvérisation de matières inammables.

DANGER : VAPEURS NOCIVES

La peinture, les solvants, les insecticides et autres matériaux

peuvent être nocifs lorsqu’ils sont inhalés ou en contact avec le

corps. Les vapeurs peuvent causer une nausée importante, des

évanouissements ou un empoisonnement.

PRÉVENTION :

• Utiliser un respirateur ou un masque chaque fois qu’il y a des risques

d’inhalation de vapeurs. Lire attentivement toutes les instructions

se rapportant au masque pour vérier que celui-ci vous assure une

protection susante contre les vapeurs toxiques.

• Porter des lunettes de protection.

• Porter des vêtements de protection, conformément aux directives du

fabricant de revêtement.

DANGER : DANGER DE BRÛLURE

Les pièces chauées peuvent causer de graves brûlures cutanées.

PRÉVENTION :

• Les raccords à dégagement rapide du tuyau exible et du pistolet

peuvent s’échauer en cours d’utilisation; il faut alors éviter les

contacts cutanés, en attendant que les raccords refroidissent avant de

séparer le pistolet du tuyau.

Table des matières

Sécurité.........................................................................................................12

Entretien et réparations ..............................................................................13

Introduction .................................................................................................13

Conception divisée ........................................................................................................13

Utilisation d’un pistolet de vaporisation HVLP................................... 14-15

Préparation à la vaporisation .....................................................................................14

Sélection d’une forme de pulvérisation .................................................................14

Aire de pulvérisation .....................................................................................................14

Réglage du débit d’air et de produit .......................................................................14

Pulvérisation ....................................................................................................................15

Réglage du tube orientable .......................................................................................15

Nettoyage du pistolet .................................................................................15

Maintenance .......................................................................................... 16-17

Réglage de l’écrou presse-garniture .......................................................................16

Remplacement de la garniture de pointeau et

des joints de soupape de régulation d’air.............................................................16

Remplacement du joint de la tête du pistolet et

du joint torique de la tête du pistolet.....................................................................17

Remplacement la retenue de clapet anti-retour, du joint de

clapet et de tube d’air ..................................................................................................17

Remplacement du joint torique de la soupape de régulation d’air ............18

Remplacement du joint d’étanchéité du godet .................................................18

Utilisation d’un système d’alimentation sous pression ................................ 18

Modication du pistolet pour alimentation sous pression.............................18

Raccordement récipient système sous pression du deux pintes .................18

Convertissement à l’alimentation par le haut...........................................19

Modication du pistolet non-purgeur en pistolet purgeur .........................19

Choix d’un projecteur .................................................................................20

Échange du projecteur.................................................................................................20

Accessoires optionnels................................................................................20

Réduction du produit/tableau des projecteurs ........................................21

Diagnostic des anomalies ...........................................................................21

Liste de pièces ........................................................................................ 32-34

Ensemble de pistolet ............................................................................................. 32-33

Ensemble godet .............................................................................................................34

Ensemble godet à alimentation par le haut .........................................................35

Garantie limitée ...........................................................................................36

Page 13

Entretien et réparations

Bouton de

Déclenchemen

xation du

godet de 1

Crochet

Arrière du

pistolet

Si le pistolet requiert de l’entretien ou des réparations pendant la

période de la garantie, on doit le retourner, accompagné d’une

preuve d’achat, au distributeur chez qui on l’a acheté. Il sera alors,

selon le choix du fabricant, réparé ou remplacé. Dans le cadre de son

engagement perpétuel envers l’amélioration de la qualité, Titan se

réserve le droit de modier les composants ou la conception de ses

produits si elle le juge nécessaire.

Introduction

Ces pistolets de vaporisation sont conçus pour une utilisation dans

les systèmes de peinture “High Volume/Low Pressure” (HVLP) (grand

volume/basse pression).

Avec un système HVLP, il est possible d’obtenir une nition de très

haute qualité professionnelle avec peu de préparation et de temps

de réglage. Les systèmes HVLP ne sont pas destinés à remplacer

les systèmes sans air. Au contraire ils sont conçus pour compléter

les systèmes sans air en améliorant la nition sur les substrats, en

minimisant les pertes et en réduisant le temps de travail. En plus

d’améliorer la rentabilité, les systèmes HVLP sont compatibles avec

les exigences de rendement de transfert les plus sévères.

Les pistolets de vaporisation HVLP décrits dans ce manuel

comprennent le pistolet à godet et turbine, et le pistolet à turbine

à alimentation supérieure. SVP, consultez toutes les informations

contenues dans ce manuel avant d’utiliser un système HVLP.

NOTA : Le fonctionnement général et la maintenance de chaque

type de pistolet de vaporisation HVLP sont les mêmes.

Pour les besoins des illustrations, seul le pistolet à

godet et turbine est représenté. Cependant, toutes

les informations spéciques à un type particulier de

pistolet sont données où cela est nécessaire. Les listes

de pièces pour chaque type de pistolet sont incluses à la

n de ce manuel.

Conception divisée

Ce pistolet de vaporisation HVLP (grand volume/basse pression) est

d’une conception divisée qui facilite le nettoyage et le démontage.

Les deux sections sont la tête du pistolet et l’arrière du pistolet.

Tête du

pistolet

Pour séparer les deux moitiés du pistolet de vaporisation HVLP, suivre

les étapes suivantes.

1. S’assurer que le boyau d’air est retiré de l’entrée d’air du

pistolet de vaporisation.

2. Orienter les déclenchements

de la détente des deux côtés du

pistolet de vaporisation de façon

à ce qu’ils pointent vers le haut.

3. Pousser le levier vers l’arrière du

pistolet pour déverrouiller les

deux moitiés du pistolet.

4. Tout en regardant à l’arrière du pistolet de vaporisation,

tourner l’arrière du pistolet dans le sens contraire des aiguilles

d’une montre an de le retirer de la tête du pistolet.

NOTA : Le crochet sur le haut du corps de pistolet peut être

réglage du

débit d'air

Bouton de

réglage du

débit de

produit

de la détente

Écrou presse-

anti-retour

Entrée d'air

t

garniture

Détente

Clapet

facilement retiré ou renversé. Glisser le crochet vers

l’arrière du pistolet an de le retirer.

Levier

Bague de

bouchon

d'air

Bouchon

d'air

Entrée du

uide

Levier de

blocage

du godet

Ensemble

litre

Levier

de tube

orientable

NOTA : Le pointeau demeurera à l’intérieur de la tête du

pistolet. S’assurer de ne pas le retirer, à moins que ce

soit indiqué.

Pour joindre les deux moitiés du pistolet de vaporisation HVLP, suivre

les étapes suivantes.

1. S’assurer que les déclenchements de la détente des deux

côtés du pistolet de vaporisation sont orientés vers le haut

(vers l’agrafe du pistolet).

2. Avec l’arrière du pistolet orienté à

l’envers, joindre les deux moitiés.

Tout en regardant à l’arrière du

pistolet de vaporisation, tourner

la section de la détente dans le

sens des aiguilles d’une montre

jusqu’à ce qu’elle soit en place

avec la tête du pistolet.

3. Orienter les déclenchements

de la détente des deux côtés du

pistolet de vaporisation de façon

à ce qu’ils pointent vers la tête du pistolet.

Pointeau

© Titan Tool Inc. Tous droits réservés. 13

Français

Page 14

Utilisation d’un pistolet de vaporisation HVLP

bouchon d'air

horizontale

verticale

circulaire

diagonale

verticale

horizontale

Bague de xation du

du débit de produit

Bouton de réglage

Préparation à la vaporisation

1. Libérer le levier de blocage du godet et démonter le godet.

2. S’assurer que le godet et le joint d’étanchéité du godet soit

propre et à la bonne position. Remplir le godet avec le produit

de peinture désiré.

3. Placer le godet sur le pistolet et serrer le levier de blocage du

godet.

4. Fixer le boyau d’alimentation en air sur le raccord d’entrée

d’air à la partie inférieure de la poignée de pistolet.

5. Activer l’alimentation d’air.

Sélection d’une forme de pulvérisation

On peut modier la forme de pulvérisation en faisant tourner le

bouchon d’air en position verticale, horizontale ou diagonale. Pour

ce faire, saisir les deux pattes avant et tourner. Il ne faut jamais

appuyer sur la détente du pistolet lors de ce réglage.

Pattes du

Aire de pulvérisation

On peut changer l’aire de pulvérisation sans en modier la forme, en

faisant tourner la bague de xation du bouchon d’air.

bouchon d'air

Grande

(b)

(a)

Petite

NOTA : Un point de départ idéal est lorsque le triangle sur la

bague de réglage (a) est aligné avec le triangle sur la

tête du pistolet (b).

En tournant la bague vers la droite, on agrandit l’aire; en la tournant

vers la gauche, on la réduit. À mesure que l’aire rapetisse, on doit

s’approcher de la surface à pulvériser.

Réglage du débit d’air et de produit

Chaque projet peut requérir un léger réglage du débit d’air ou de

produit. Pour ce qui est de ce dernier, le débit diminue lorsqu’on

tourne le bouton de réglage vers la droite et augmente lorsqu’on le

tourne vers la gauche.

Position

Position

Position

Forme

Forme

Forme

Bouton de réglage

Plus de

uide

L’autre bouton sert à augmenter ou à réduire le débit d’air. Si

l’encoche est en position vers la gauche, le débit est maximal. Rappel

: il faut toujours eectuer des essais sur des retailles de bois ou de

carton avant de procéder à la pulvérisation.

Moins

de uide

du débit d'air

14 © Titan Tool Inc. Tous droits réservés.

Français

Maximal Minimal

+

-

Page 15

Pulvérisation

Bonne position

mouvement

mouvement

détente

détente

Mauvaise position

de la vaporisation vers le bas.

Tenir le pistolet à une distance de 2,5 cm (1 po) à 20,3 cm (8 po) de

la surface à pulvériser, selon l’aire de pulvérisation choisie; plus le

pistolet est près de la surface, moins l’aire est grande. Le pistolet

doit être tenu à angle droit par rapport à la surface à pulvériser de

manière à assurer une application uniforme du produit. Si le pistolet

se déplace à vitesse continue et constante, le produit risque moins de

former des gouttes ou des coulures.

Tourner le levier orientable

entièrement dans le sens

anti-horaire lors de la

vaporisation vers le haut.

La èche sur le côté antihoraire de la couronne

correspond à la position

du levier d'orientation.

Début du

Il faut toujours appuyer sur la détente après avoir commencé son

mouvement et la relâcher avant que celui-ci ne se termine. Pour

obtenir de meilleurs résultats, les mouvements de pulvérisation

devraient être longs d’environ 50 cm (20 po) en se chevauchant les

uns les autres de 10 ou 12 cm (4 ou 5 po). Rappel : le pistolet doit être

perpendiculaire à la surface à pulvériser.

Appui

de la

Mouvement

uniforme

Relâche-

ment de la

Fin du

Réglage du tube orientable

Le tube orientable du pistolet permet d’éviter le plus de gaspillage de

produit possible, quel que soit l’angle de pulvérisation.

Si le pistolet est orienté vers le bas, il faut pousser le levier

d’orientation à l’extrême droite.

NOTA : De chaque côté de la couronne, une èche indique

la direction dans laquelle le tube orientable pointe

lorsque le levier du tube orientable est dans la

position extrême de rotation en sens horaire ou

extrême de rotation dans le sens anti-horaire.

NOTA : Le levier orientable est placé directement sous le

levier de blocage du godet. Celui-ci assure la xation

du godet avec le pistolet.

Levier de blocage du godet

Levier d'orientation

Nettoyage du pistolet

Il est important de nettoyer entièrement le pistolet après chaque

utilisation.

1. Vider le godet du produit résiduel.

2. Verser une petite quantité de solvant approprié dans le godet

et xer celui-ci au pistolet.

3. Remuer et vaporiser dans un endroit bien ventilé.

NOTA : Ne pas obturer la buse lors du nettoyage. Un

refoulement dans le système n’est pas nécessaire.

4. Répéter les opérations ci-dessus jusqu’à ce que le solvant reste

clair.

5. Nettoyer l’extérieur/interieur du godet et du pistolet avec un

solvant approprié jusqu’à ce qu’ils soient propres.

6. Séparer la tête du pistolet de l’arrière du pistolet (consulter

les consignes à la page 13). Démonter le pointeau, la buse à

uide et le bouchon d’air et les nettoyer entièrement. S’assurer

que les trous de passage de l’air et les passages de produit

soient bien propres. Ne jamais utiliser de pointes ou d’outils

métalliques pour nettoyer le bouchon d’air et la buse.

IMPORTANT : Toute tentative de démontage du raccord d’entrée

de fluide entraîne des dommages au corps du pistolet et annule

la garantie.

Si le pistolet est orienté vers le haut, il faut pousser le levier

d’orientation à l’extrême gauche.

© Titan Tool Inc. Tous droits réservés. 15

Tourner le levier

orientable entièrement

dans le sens horaire lors

NOTA : Démonter la garniture de pointeau uniquement lors

de son remplacement. Ne pas démonter la garniture

de pointeau pour la nettoyer.

7. Démonter, nettoyer et sécher le clapet anti-retour et le tube

d’air après chaque utilisation.

IMPORTANT : NE PAS nettoyer le tube d’air avec un solvant

chaud tel qu’un diluant à peinture-laque. Les solvants chauds

endommagent le tube d’air.

NOTA : Lors du remontage, lubrier toutes les parties

letées du pistolet avec du pétrolatum. Cette

lubrication facilite leur bon fonctionnement.

IMPORTANT : Ne pas utiliser de lubrifiants à base de silicone;

cette substance peut engendrer des problèmes si elle est

combinée à certaines peintures.

Français

Page 16

Maintenance

pistolet

e

régulation d'air

Guide de

VUE LATÉRALE

Joint avant de soupape

Face conique

Suivre les procédures de maintenance suivantes de manière à

faciliter le bon fonctionnement du pistolet HVLP. On peut obtenir de

nouvelles pièces en commandant le lot de réparation du pistolet à

débit élevé et à basse pression, le numéro de pièce est 0279911.

Réglage de l’écrou presse-garniture

S’il y a une fuite de produit autour de l’écrou presse-garniture, régler

de nouveau celui-ci.

1. Déconnecter le boyau d’air de l’entrée d’air et démonter

l’ensemble godet.

2. Tirer la détente complètement vers l’arrière et la maintenir

dans cette position.

3. Serrer l’écrou presse-garniture au moyen d’une clé de 3/8

de pouce jusqu’à ce que le pointeau demeure rétracté à

l’intérieur de la buse lorsque la détente est relâchée.

4. Desserrer légèrement

l’écrou jusqu’à ce que le

pointeau recule librement

vers sa position à l’intérieur

de la buse.

Après avoir réglé l’écrou,

connecter de nouveau le boyau

et remonter l’ensemble godet.

Serrer la détente pour vérier s’il y

a encore une fuite. S’il y a encore

une fuite, s’assurer que l’écrou

presse-garniture soit aussi serré

que possible, tout en permettant

au pointeau de se déplacer

librement. Si le réglage de l’écrou

presse-garniture ne permet pas d’arrêter la fuite, changer la garniture.

Remplacement de la garniture de pointeau et des

joints de soupape de régulation d’air

NOTA : Démonter la garniture de pointeau uniquement lors

de son remplacement. Ne pas démonter la garniture

de pointeau pour la nettoyer.

La garniture de pointeau et les joints de soupape de

régulation d’air peuvent être remplacés séparément.

En cas de remplacement d’un seul de ces éléments,

eectuer les opérations selon la procédure suivante.

Écrou presse-garniture

8. Serrer fermement l’écrou presse-garniture au moyen d’une clé

de 3/8 de pouce puis desserrer l’écrou presse-garniture d’un

quart de tour.

9. Remonter la tête du pistolet dans le arrière du pistolet.

10. Appuyer sur la détente pour s’assurer que le pointeau se

déplace librement. Si le pointeau coince, desserrer l’écrou

presse-garniture. Si la garniture fuit, serrer l’écrou presse-

garniture.

B) Démontage du pointeau et du bouchon

1. Déconnecter le boyau d’air de l’entrée d’air.

2. Séparer la tête du pistolet de l’arrière du pistolet (consulter les

consignes à la page 13). Le pointeau demeurera dans la tête

du pistolet.

3. Desserrer l’écrou de la soupape de régulation d’air et retirer le

bouton de réglage du débit d’air et l’écrou de la soupape de

régulation d’air pour permettre l’accès au bouchon de réglage

du débit de produit.

4. Desserrer et retirer le bouchon de réglage du débit de produit,

le joint et le ressort à l’aide d’une clé.

Écrou de

soupape de

Bouchon de

réglage du débit

de produit

5. Insérer une clé six-pans de 1/8 de pouce à l’arrière de la tige de

guidage du pointeau.

6. Maintenir le guide de détente au moyen d’une pinces et

tourner la clé six-pans de 1/8 de pouce dans le sens antihoraire pour démonter l’écrou de retenue.

7. Retirer la tige de guidage du pointeau hors du corps de

pistolet. Ne pas perdre le guide de détente.

Joint et

ressort

Tige de guidage

du pointeau

A) Démontage / Remontage de la garniture

1. Séparer la tête du pistolet de l’arrière du pistolet (consulter les

consignes à la page 13). Le pointeau demeurera dans la tête

du pistolet.

2. Avec les deux sections du pistolet toujours séparées, retirer le

pointeau.

3. Retirer l’écrou presse-garniture à l’aide d’une clé de 3/8 pouce.

4. Retirer la garniture de l’écrou presse-garniture.

Tête du

NOTA : S’assurer que la garniture usée soit retirée avant de

5. Placer une nouvelle garniture dans le trou de garniture.

6. Faire tourner la garniture d’un tour à l’intérieur du trou. Ne pas

7. Remettre le pointeau dans l’écrou presse-garniture.

16 © Titan Tool Inc. Tous droits réservés.

monter une nouvelle garniture.

serrer.

Français

Garniture

Ecrou

presse-garnitur

détente

C) Remplacement des joints de soupape de régulation d’air

1. Retirer le joint arrière de soupape de régulation d’air usé.

Il pourrait rester sur l’extrémité de la tige de guidage du

pointeau ou dans le bouchon de réglage de débit de produit.

2. Insérer un nouveau joint dans le bouchon de réglage de débit

de produit.

3. Retirer le circlips de joint avant au moyen d’une clé à circlips.

4. Faire glisser le joint avant usé en dehors de la tige de guidage

de pointeau.

5. Placer un nouveau joint avant sur la tige de guidage de

pointeau avec la face conique faisant face au pistolet.

NOTA : S’assurer que le nouveau joint avant soit bien

similaire à celui qui vient d’être démonté.

de régulation d'air

6. Monter le circlips de joint avant sur la tige de guidage du

pointeau.

Page 17

régulation d'air

Circlip de

joint avant

de débit de produit

Tête du

pistolet

doit être orientée

clapet anti-retour

Bouchon de réglage

7. Remonter les pièces dans l’arrière du pistolet en inversant les

étapes ci-dessus.

NOTA : Lors du remplacement de la tige de guidage du

pointeau et du guide de détente, xer le guide de

détente dans une clé ajustable. Celui-ci le gardera en

place pendant la réinstallation de la tige de guidage

du pointeau.

Joint avant de soupape

de régulation d'air

Tige de guidage

du pointeau

Ressort

Joint arrière de

soupape de

Remplacement du joint de la tête du pistolet et du

joint torique de la tête du pistolet

1. Retirer la tête du pistolet de pulvérisation du corps du pistolet

(voir les directives à la page 13).

2. Tirer l’ancien joint de la tête de pistolet du corps du pistolet.

Ne pas installer le nouveau joint immédiatement.

3. À l’aide d’une clé à tête hexagonale de 7/64 po, retirer les deux

vis de l’insert du corps du pistolet. Retirer l’insert du corps du

pistolet.

4. Retirer le joint torique du corps du pistolet. Il peut être

nécessaire d’utiliser une pince à becs pointus ou un autre

objet mince et long pour le retirer du corps du pistolet.

NOTA : S’assurer que cette zone du corps du pistolet est

5. Lubrier le nouveau joint torique avec du pétrolatum et

6. Replacer l’insert du corps du pistolet et le xer à l’aide des vis

7. Installer le nouveau joint dans la tête du pistolet tel qu’illustré.

8. Remonter la tête du pistolet sur le corps du pistolet (voir la

exempte de résidus du produit pulvérisé avant de

réinstaller le joint torique du corps du pistolet.

l’installer dans le corps du pistolet.

de l’insert du corps du pistolet.

page 13).

Corps du

pistolet

Remplacement la retenue de clapet anti-retour, du

joint de clapet et des tube d’air

Le clapet anti-retour est un clapet unidirectionnel conçu pour

admettre l’air dans le godet et mettre le contenu de celui-ci sous

pression. Comme c’est un clapet unidirectionnel, il empêche la

peinture de s’inltrer dans le tube d’air et de pénétrer dans les

passages d’air du pistolet. En maintenant la pression dans le godet, il

élimine également tout retard de débit de produit lorsque le pistolet

est activé.

Le clapet s’ouvre facilement pour le nettoyage. Il comporte un joint

de clapet qui peut être retiré et nettoyé avec du savon et de l’eau

pour les produits aqueux ou avec un solvant compatible pour les

autres produits. Pour remplacer le joint de clapet et/ou les tubes d’air,

suivre les opérations suivantes :

1. Dévisser la retenue de clapet anti-retour en la tournant dans le

sens contraire des aiguilles d’une montre.

2. Retirer le joint de clapet de l’arrière du pistolet. Nettoyer ou

remplacer le joint de clapet.

NOTA: Le produit à pulvériser accumulé dans le clapet

3. Réinstaller le joint de clapet. Insérer la tige du joint de clapet

Joint d’étanchéité

4. Visser la nouvelle retenue de clapet anti-retour/nouveau joint

5. Pour remplacer le tube d’air, le retirer des raccords sur la tête

antiretour à l’intérieur de la tête du pistolet devrait

également être nettoyé. NE PAS utiliser de produits

en métal ou abrasifs pour nettoyer le clapet

antiretour, étant donné qu’ils égratigneront la

surface en métal et le joint d’étanchéité ne scellera

pas correctement.

dans le trou de l’arrière du pistolet.

La tige de la joint

vers l’arrière du

pistolet.

Joint de clapet

Retenue de

/

torique ou la pièce nettoyée dans la tête du pistolet en la

tournant dans le sens des aiguilles d’une montre.

du pistolet et l’ensemble godet. Le remplacer par un nouveau

tube.

Tube d'air

© Titan Tool Inc. Tous droits réservés. 17

Joint torique

du corps du pistolet

Écrou du corps du pistolet

Vis

Joint de la

tête du pistolet

Français

Page 18

Remplacement du joint torique de la soupape de

Bouton de

Joint d'étanchéité

Levier de blocage

soupape de

Ensemble godet

régulation d’air

1. À l’aide d’une clé, desserrer l’écrou de la soupape de

régulation d’air et retirer l’ensemble du bouton de réglage du

débit d’air.

2. À l’aide d’un tournevis, retirer la vis du bouton de réglage.

Séparer le bouton de réglage de l’écrou de la soupape de

régulation d’air. Éviter de desserrer la rondelle.

3. Séparer la soupape de régulation d’air de l’écrou de la soupape

de régulation d’air. Le joint torique de la soupape de régulation

d’air se trouve sur la soupape de régulation d’air.

4. Retirer le joint torique de la soupape de régulation d’air de la

soupape de régulation d’air.

5. Lubrier le nouveau joint torique avec une petite quantité de

pétrolatum et le placer dans le corps du pistolet.

6. Remonter l’ensemble du bouton de réglage du débit d’air :

a. Insérer la soupape de régulation d’air à l’arrière du

pistolet pulvérisateur.

b. Placer l’écrou de la soupape de régulation d’air par-dessus la

soupape de régulation d’air et le visser à l’arrière du pistolet

pulvérisateur. Serrer à l’aide d’une clé.

c. Tourner légèrement la soupape de régulation d’air dans

le sens contraire des aiguilles d’une montre jusqu’à ce

qu’elle ne tourne plus.

d. Installer la rondelle.

e. Placer le bouton de réglage par-dessus la soupape de

régulation d’air. La marque sur le bouton devrait se

trouver à la position 9 h (tout à fait à la gauche).

f. Fixer le bouton de réglage à l’aide de la vis. Serrer à l’aide

d’un tournevis.

Joint torique de la

soupape de régulation d’air

Soupape de régulation d’air

Écrou de la soupape

de régulation d’air

Rondelle

réglage

Vis

Remplacement du joint d’étanchéité du godet

L’usure normale du joint d’étanchéité du godet requiert son

remplacement périodique. Il est important de vérier son état lors de

chaque nettoyage.

1. Libérer le levier de blocage du godet.

2. Maintenir le godet et tourner le pistolet dans le sens indiqué

par les èches de la couronne.

3. Retirer le pistolet du godet.

4. Retirer le joint usé du couvercle.

5. Insérer un nouveau joint dans le couvercle.

6. Remettre le pistolet sur le godet.

7. Tourner le pistolet dans la direction opposée à celle indiquée

par les èches de la couronne jusqu’à ce que les tenons du

godet soient dans les encoches de la couronne.

8. Serrer le levier de blocage du godet.

Utilisation d’un système d’alimentation sous

pression

De manière à augmenter le temps de vaporisation entre les

remplissages de produit, le pistolet HVLP peut être connecté à un

récipient de produit sous pression et un compresseur d’air plus

grands.

Modication du pistolet pour alimentation sous

pression

Avant d’utiliser un système d’alimentation sous pression, le pistolet

doit être modié pour recevoir cette alimentation sous pression.

1. Desserrer l’écrou de retenue au moyen d’une clé et retirer

l’ensemble godet d’une pinte.

2. Retirer le tube d’air de son raccord sur le pistolet.

Tube d'air

Écrou de retenue

Bouchon à

pression

3. Placer le bouchon à soupape de pression sur le raccord de la

tête du pistolet.

Raccordement récipient sous pression de deux pintes

1. Convertir le pistolet à l’alimentation sous pression.

2. Raccorder les tuyaux :

a. S’assurer que la turbine est À L’ARRÊT et débranchée;

b. Fixer le réservoir sous pression à la turbine selon la

conguration de tuyau illustrée ci dessous;

c. Serrer manuellement les raccords de tuyau d’air;

d. Serrer les raccords de tuyau de uide à l’aide d’une clé à

molette.

1) Turbine

2) Tuyau d’air de 9 m

3) Raccord rapide femelle

4) Ensemble de réservoir sous pression de 2 pintes

5) Tuyau d’arrivée d’air de 1,5 m

6) Tuyau d’arrivée de uide de 1,5 m

7) Attaches de tuyau

8) Raccord rapide femelle

9) Pistolet de pulvérisation

18 © Titan Tool Inc. Tous droits réservés.

Couronne

de godet

Français

du godet

Levier

d'orientation

Couvercle

9

2

3

1

8

5

4

6

7

Page 19

Convertissement à l’alimentation par le haut

Raccord de tube d’air

d'air

d'entrée d'air

Le godet est conçu pour une pression d’utilisation

maximale de 6 lb/po2 (0,41 bar). Les pressions

supérieures à 6 lb/po2 pt peuvent entraîner la fuite

du godet, des dommages à l’équipement et/ou des

blessures à l’utilisateur.

Le pistolet à alimentation supérieure HVLP est conçu pour les

applications spéciales telles que la vaporisation dans les endroits

étroits. La position du godet permet au pistolet à alimentation

supérieure de vaporiser vers le bas et vers le haut. Lors de la

vaporisation avec le pistolet à alimentation supérieure, observer les

conseils qui suivent pour obtenir les meilleurs résultats. Maintenir

le godet sous pression en tout temps lors de la vaporisation.

L’alimentation par gravité du produit ralentit ou arrête le débit de

produit vers la buse.

NOTA : Il est recommandé de retirer le crochet pendant

l’utilisation de l’ensemble godet à alimentation par

le haut.

Modication du pistolet non-purgeur en

pistolet purgeur

Le pistolet HVLP peut être modié en pistolet purgeur. Le montage

en pistolet purgeur procure un pouvoir atomisant supérieur pour les

produits à viscosité plus importante tels que le latex et les émaux. Le

montage avec purgeur peut faciliter la vaporisation dans les endroits

connés tels que les intérieurs des armoires car le boyau d’air est

déplacé à l’arrière du pistolet.

Pour modier un pistolet en pistolet purgeur, suivre les

opérations suivantes:

1. Démonter le bouton de réglage de débit d’air de l’arrière du