Page 1

Owner’s Manual

Notice d’utilisation

Manual del Propietario

Do not use this equipment before

reading this manual!

CAPSPRAY

HVLP Power Cart

Model Number: 0524000

NOTE: This manual contains important

warnings and instructions. Please

read and retain for reference.

0611 • © Titan Tool Inc. All Rights Reserved. Form No. 0524872C

Page 2

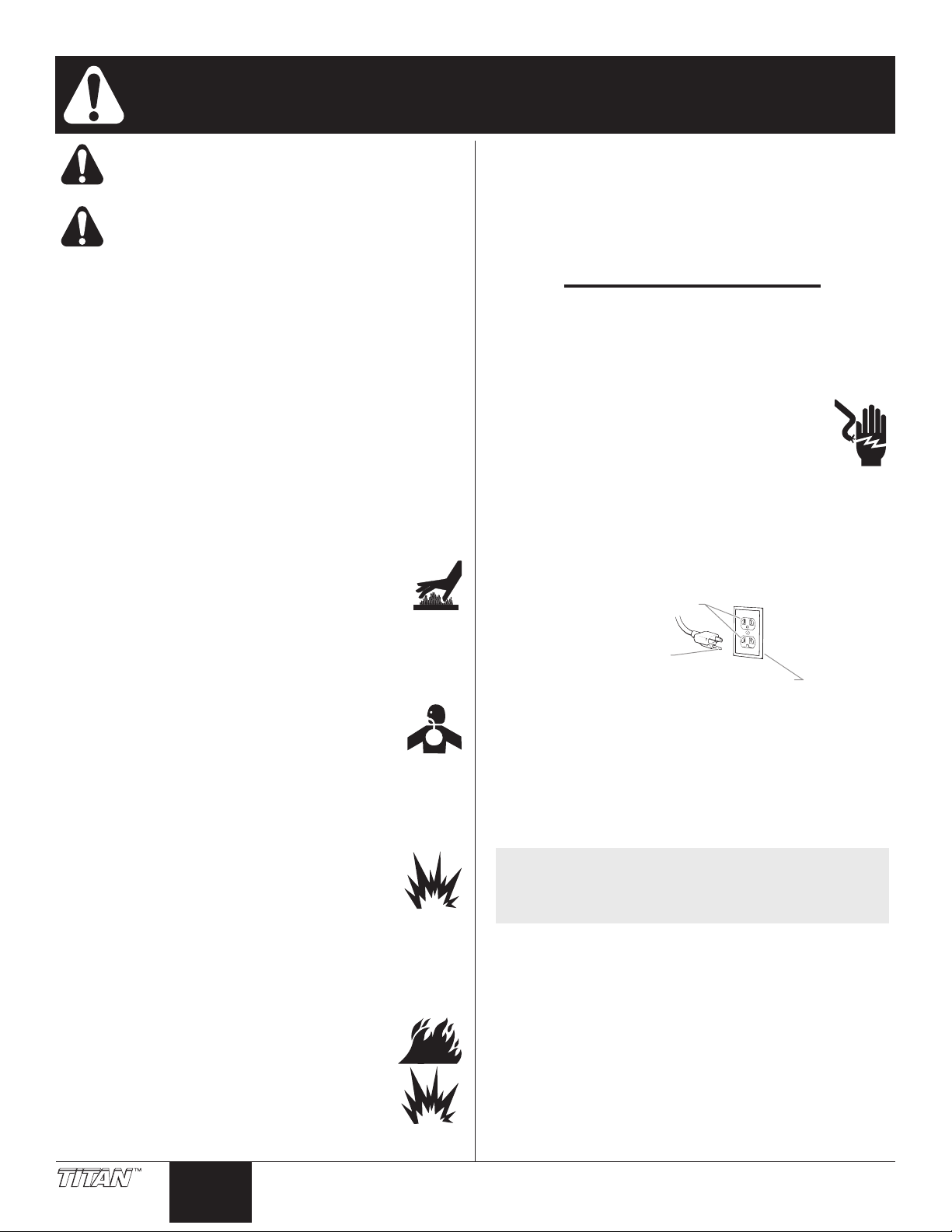

Important Safety Information · Read all safety information before

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

operating the equipment. SAVE THESE INSTRUCTIONS.

This symbol indicates a hazardous situation, which, if not

not avoided could result in death or serious injury.

To reduce the risks of fire or explosion, electrical shock

and the injury to persons, read and understand all

instructions included in this manual. Be familiar with the

controls and proper usage of the equipment.

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before operating any

equipment.

• Comply with all appropriate local, state and national codes

governing ventilation, re prevention, and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act (OSHA).

These standards, particularly Part 1910 of the General Standards

and Part 1926 of the Construction Standard should be consulted.

• This equipment is designed to be used with authorized parts only.

When using this equipment with parts that do not comply with

the minimum specications and safety devices of the equipment

manufacturer, the user assumes all risks and liabilities.

• Check all hoses for cuts, leaks, abrasion or bulging of cover, as

well as damage or movement of couplings before each use. If any

of these conditions exist, replace the hose immediately. Never

repair a paint hose.

• Never aim the spray gun at any part of the body.

HAZARD: SKIN BURN INJURY

Heated parts can cause severe skin burn injury.

PREVENTION:

• Quick-disconnect ttings on the hose and the spray

gun become hot during use. Avoid skin contact with any quickdisconnect ttings when they are hot. Allow the quick disconnect

ttings to cool before disconnecting the spray gun from the hose

• The compressor becomes hot during use. Allow the compressor

to cool before touching it.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials can be

harmful if inhaled or come in contact with the body. Vapors can

cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask whenever there is a chance that vapors

may be inhaled. Read all instructions with the mask to insure that

it will provide the necessary protection against the inhalation of

harmful vapors.

• Avoid all ignition sources such as static electricity sparks, open

ames, pilot lights, hot objects, cigarettes, and sparks caused by

connecting and disconnecting power cords and operating light

switches.

• Keep the motor away from spray area to avoid solvent and paint

fumes. Motor contains arcing parts which emit sparks.

• Fire extinguishing equipment must be present and in working

order.

• The power cord must be connected to a grounded circuit.

• Follow the material and solvent manufacturer’s safety precautions

and warnings.

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape

wire for the electric current. This product is equipped with a cord having

a grounding wire with an appropriate grounding plug. The plug must

be plugged into an outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary,

do not connect the green grounding wire to either at blade

terminal. The wire with insulation having a green outer

surface with or without yellow stripes is the grounding wire and must be

connected to the grounding pin.

Check with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as

to whether the product is properly grounded. Do not modify the plug

provided. If the plug will not t the outlet, have the proper outlet installed

by a qualied electrician.

IMPORTANT: Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the plug on

the product. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough

to carry the current your product will draw. An undersized cord

will cause a drop in line voltage resulting in loss of power and

overheating. A 12 gauge cord is recommended. If an extension

cord is to be used outdoors, it must be marked with the suffix

W-A after the cord type designation. For example, a designation

of SJTW-A would indicate that the cord would be appropriate for

outdoor use.

HAZARD: EXPLOSION

Compressed air has great force and may cause injury.

PREVENTION:

• The pressure pot assembly is protected from overpressurizing by a safety valve. Pull the ring on the safety valve

occasionally to make sure that the valve operates freely. The

valve must be replaced if it does not operate freely or if it does not

release air when the ring is pulled.

• Never modify the pressure pot or the compressor.

• Never connect other air tools to the compressor.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Property

damage and/or severe injury can occur.

PREVENTION:

• Exhaust and fresh air introduction must be provided

to keep the air within the spray area free from the

accumulation of ammable vapors.

• Keep the turbine at the maximum distance possible from the

spray area.

2 © Titan Tool. All rights reserved.

NOTE: More than 100 feet of extension cord is not

recommended. Use more paint hose, not more

extension cord. Shorter extension cords will assure

maximum electrical power for proper operation.

English

Page 3

Table of Contents

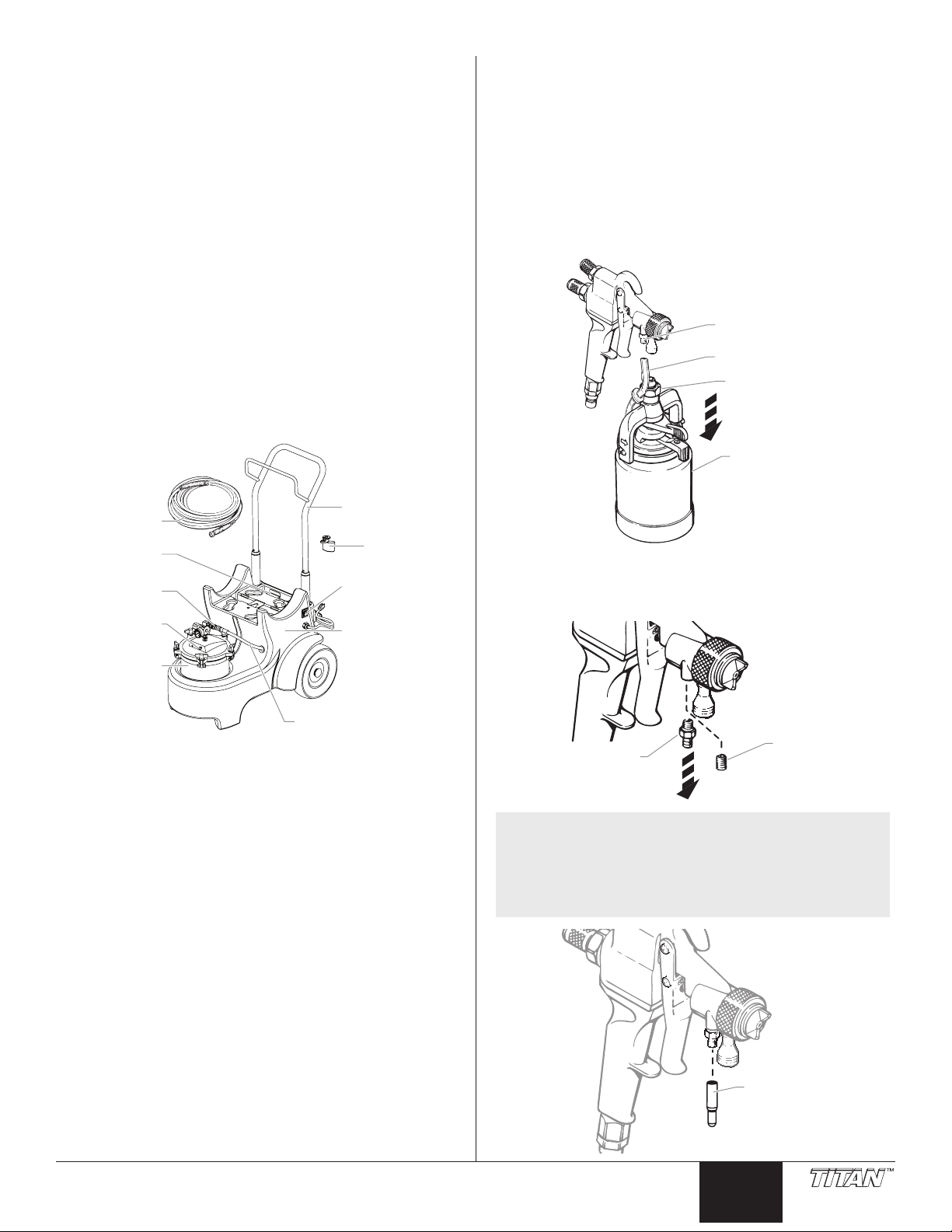

Pressure Pot

Air Inlet

Latch Bracket

3/8” X 30 ft

Fluid hose

Pressure Pot

Fluid Outlet

Pressure Pot

Assembly

Pressure Pot Air Hose

Power Switch

Compressor

Assembly

(inside housing)

Cart

Turbine

Bracket

Air Tube

Retaining Nut

Cup Assembly

Air Tube Fitting

Set Screw

Air Tube Fitting

Air Tube Cap

Safety ......................................................................................... 2

Introduction ............................................................................... 3

Setup ..........................................................................................3

Converting the Gun to Pressure Feed................................. 3

Mounting the Turbine .......................................................... 4

Connecting the Power Cart ................................................. 4

Hose Congurations ............................................................ 4

Preparing to Spray .............................................................. 5

Cleanup .....................................................................................5

Troubleshooting ....................................................................... 6

Parts List ............................................................................20-21

Warranty .................................................................................. 24

Introduction

The HVLP power cart is designed for use with CAPspray spray

systems. The power cart adds tremendous versatility to an

already complete system. Components of the HVLP power

cart include a power switch, a cart, a pressure pot assembly, a

compressor assembly, a pressure pot inlet, a pressure pot hose,

a pressure pot outlet, a uid hose, and a turbine bracket.

Setup

Use the following procedures to set up your spray gun and HVLP

power cart.

Converting the Gun to Pressure Feed

Before using the HVLP power cart, it is necessary to convert your

spray gun from a cup gun to a pressure fed gun.

1. Loosen the retaining nut using a wrench and remove the

one quart cup assembly.

2. Pull the air tube off of the air tube tting on the spray gun.

© Titan Tool. All rights reserved. 3

3. Remove the air tube tting using a 1/4” wrench.

4. Thread the set screw into the air tube tting location and

tighten into place.

Optional (in place of steps 3 and 4): If desired, a

temporary cap (also included) can be used to close off

the air tube tting rather than performing steps 3 and 4

above. This is a convenient method of capping the air

tube tting if the operator will be frequently switching

back and forth between a 1-quart cup and a pressure pot.

English

Page 4

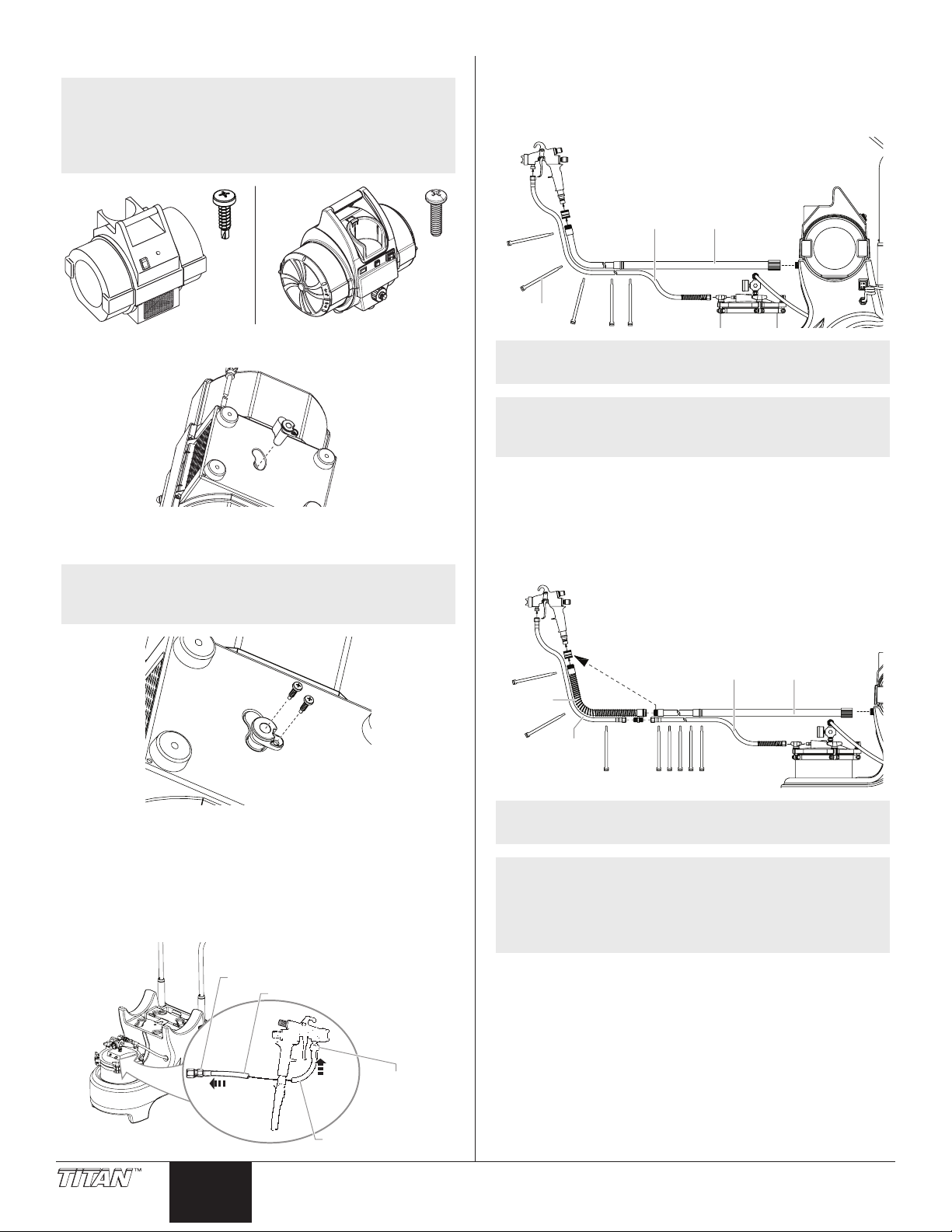

Mounting the Turbine

Pressure Pot Outlet

Fluid Hose

Fluid Hose

Spray Gun

Inlet

Air HoseFluid Hose

Straps

Air HoseFluid Hose

Fluid Whip

Hose

Air Whip

Hose

Straps

Move coupling

NOTE: If you are mounting an older CAPSpray turbine,

use the self-drilling screws shown on the left.

If you are mounting a newer Titan CAPSpray

turbine, use the thread-forming screws shown

on the right.

1. Insert plastic latch bracket into the bottom of the turbine as

shown.

2. Using a cordless drill with a Phillips driver, insert provided

screws into the casing using a low clutch setting. DO NOT

over-torque.

NOTE: If the drill does not have a clutch, drive the

screw with the drill until the threads start to

engage, and then tighten by hand.

Hose Congurations

Spraying without whip hoses

Follow the conguration below if you want to spray without the

uid and air whip accessories.

TIP: When strapping the hoses together, start at the

spray gun and work your way back.

NOTE: 30 ft uid hose - included with Power Cart.

30 ft air hose - included with turbine.

Hose straps - included with Power Cart

Spraying with whip hoses

Follow the conguration below if:

1. You already have the air whip hose and you purchased a

uid whip hose kit.

2. You have purchased both the uid whip hose kit and the

air hose whip kit.

3. Place the turbine onto the power cart. Push the latch

bracket in to secure the turbine.

Connecting the Power Cart

1. Thread the end of the uid hose onto the pressure pot

uid outlet and tighten.

2. Thread the other end of the material hose onto the spray

gun inlet and tighten.

4 © Titan Tool. All rights reserved.

English

TIP: When strapping the hoses together, start at the

spray gun and work your way back.

NOTE: 30 ft uid hose - included with Power Cart.

30 ft air hose - included with turbine.

5 ft air whip hose - included with the CS9900 and

CS9960

5 ft uid whip hose - sold separately.

Page 5

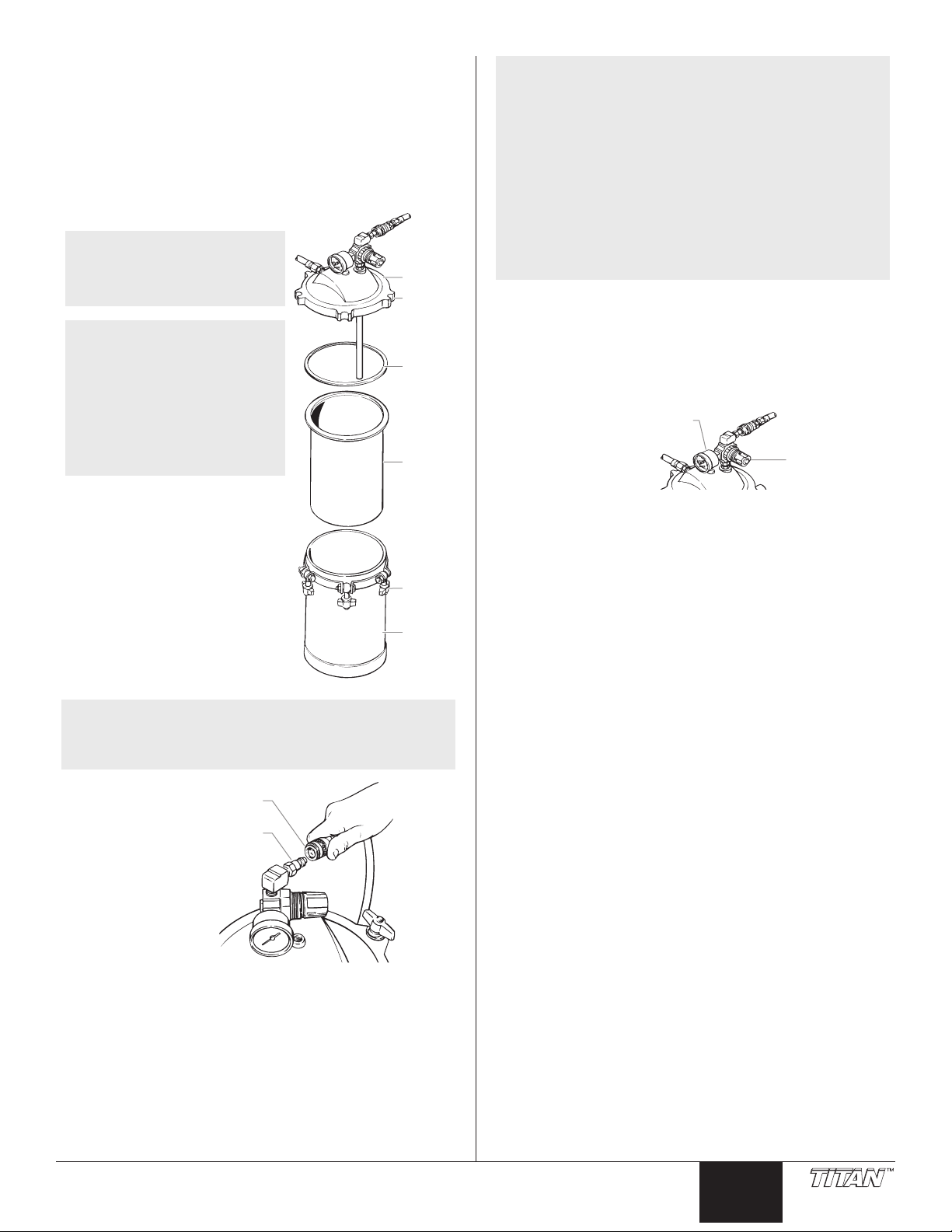

Preparing to Spray

Cover

Groove

Seal

Locking

Clamp

Pressure

Pot

Pot

Liner

Pressure Pot Air Inlet

Pressure Pot Air Hose

Pressure

Control

Knob

Pressure Control Gauge

IMPORTANT: Use a pot liner in the pressure pot when

spraying or cleaning with hot solvents such as lacquerbased paints, lacquer thinner, and M.E.K. The use of hot

solvents in the pressure pot without a pot liner may lift the

paint off the interior of the pressure pot and contaminate the

paint finish. Refer to the parts list in this manual for the pot

liner part number.

1. Fill the pressure pot with spray material.

TIP: On smaller jobs a onegallon container may be

placed inside the pressure pot

to aid in quicker cleanup.

NOTE: For best results,

always strain material prior to

spraying.

NOTE: When using the onegallon container, take care not

to tip the Power Cart back too

far in order to prevent material

from spilling out of the can.

NOTE: The compressor should run continuously (up to

2 minutes) upon initially charging the pressure

pot. As the compressor reaches the desired

pressure (set by the regulator), the compressor

will diminish its cycling rate. If the system

is left idle (i.e. no material being sprayed) for

several minutes, the compressor will cycle

periodically due to normal air losses. When the

system is idle the compressor may cycle up to

4 times per minute. If the compressor cycles

more frequently than this or does not stop, see

Troubleshooting section.

When material is being sprayed, the compressor

should normally cycle every 5-10 seconds.

5. Pull out the pressure control knob and turn it until the

pressure is set properly for the type of material you are

using.

For thin materials, set regulator to 8 PSI.

For thicker materials, set regulator to between 8 and

14 PSI.

2. Fasten the cover securely onto

the pressure pot by placing

the ve locking clamps into

the cover grooves and rotating

each clockwise until hand tight.

Be certain that the seal is in

place.

3. Connect the pressure pot air

hose to the pressure pot air

inlet.

NOTE: The hose features quick-disconnect ttings.

4. Plug in the power cords for both the Power Cart and the

To use, pull back on the spring-loaded collar

of each tting. Slide the hose tting over the

correct connection and release the collar.

turbine. Turn the cart power switch to the ON (I) position

to turn on the compressor.

6. Turn on the turbine.

7. Practice spraying on a piece of scrap wood or cardboard

until you are satised with the pressure, spray pattern, and

spray shape. The spray pattern adjustments and spray

shape selections are described in your gun manual.

Cleanup

1. Turn off the turbine.

2. Turn off the Power Cart.

3. Relieve the pressure from the pressure pot and remove

the pressure pot cover.

4. Remove excess material from the pot, wiping down the

inside of the pot and uid pick-up tube.

5. Place a container of the appropriate cleaning solvent into

the pressure pot to clean out the hose and gun.

6. Replace the cover, making sure the pickup tube is inside

the solvent container, and tighten the pot cover.

7. Turn on the Power Cart and adjust the pressure to 10 psi.

8. With the turbine off, depress the spray gun trigger while

pointing the gun into the material container. This will drain

the material into the container until all material has been

pushed through.

9. Continue running the solvent through the hose and gun

until they are completely clean.

© Titan Tool. All rights reserved. 5

English

Page 6

Troubleshooting

Problem

A. Compressor does not shut off

or runs more than 30% of the

time.

B. Compressor does not start

and there is no pressure in the

tank.

C. No material ow to spray gun.

Cause

1. Pressure pot lid not tight.

2. Lid gasket has material build-up, causing a

leak.

3. The compressor pressure switch is faulty.

4. Air ttings may be leaking.

1. No power to unit.

2. The regulator is set too low.

3. Compressor pressure switch is faulty.

4. Compressor motor is faulty.

5. Pressure gauge is faulty.

6. Regulator is faulty.

1. Regulator is set too low.

2. Hose or gun may be plugged.

Solution

1. Remove cover, reposition pot, replace cover and retighten clamps in a star pattern, increasing tightness

at each nut. Give one nal tightening to ensure

equal torque on each nut.

2. Inspect and clean the lid gasket, or replace with a

new gasket.

3. Replace the compressor pressure switch

(Replacement kit P/N 0524205 available by calling

technical service at 1-800-526-4826).

4. Bubble-check ttings to determine location.

Disassemble applicable joints. Add thread sealant.

Reassemble.

1. Check that the unit is plugged in and the outlet is

powered.

2. Turn clockwise to increase pressure.

3. Replace the compressor pressure switch

(Replacement kit P/N 0524205 available by calling

technical service at 1-800-526-4826).

4. Replace compressor (see parts list).

5. Replace pressure gauge (see parts list).

6. Replace regulator (see parts list).

1. Adjust regulator between 8-14 psi.

2. Inspect and clean.

D. Pressure pot relief valve

releases.

1. Regulator set too high.

2. Regulator is faulty.

3. Relief valve is faulty.

4. Pressure gauge is faulty.

1. Decrease pressure below 35 psi.

2. Replace regulator (see parts list).

3. Replace relief valve (see parts list).

4. Replace pressure gauge (see parts list).

6 © Titan Tool. All rights reserved.

English

Page 7

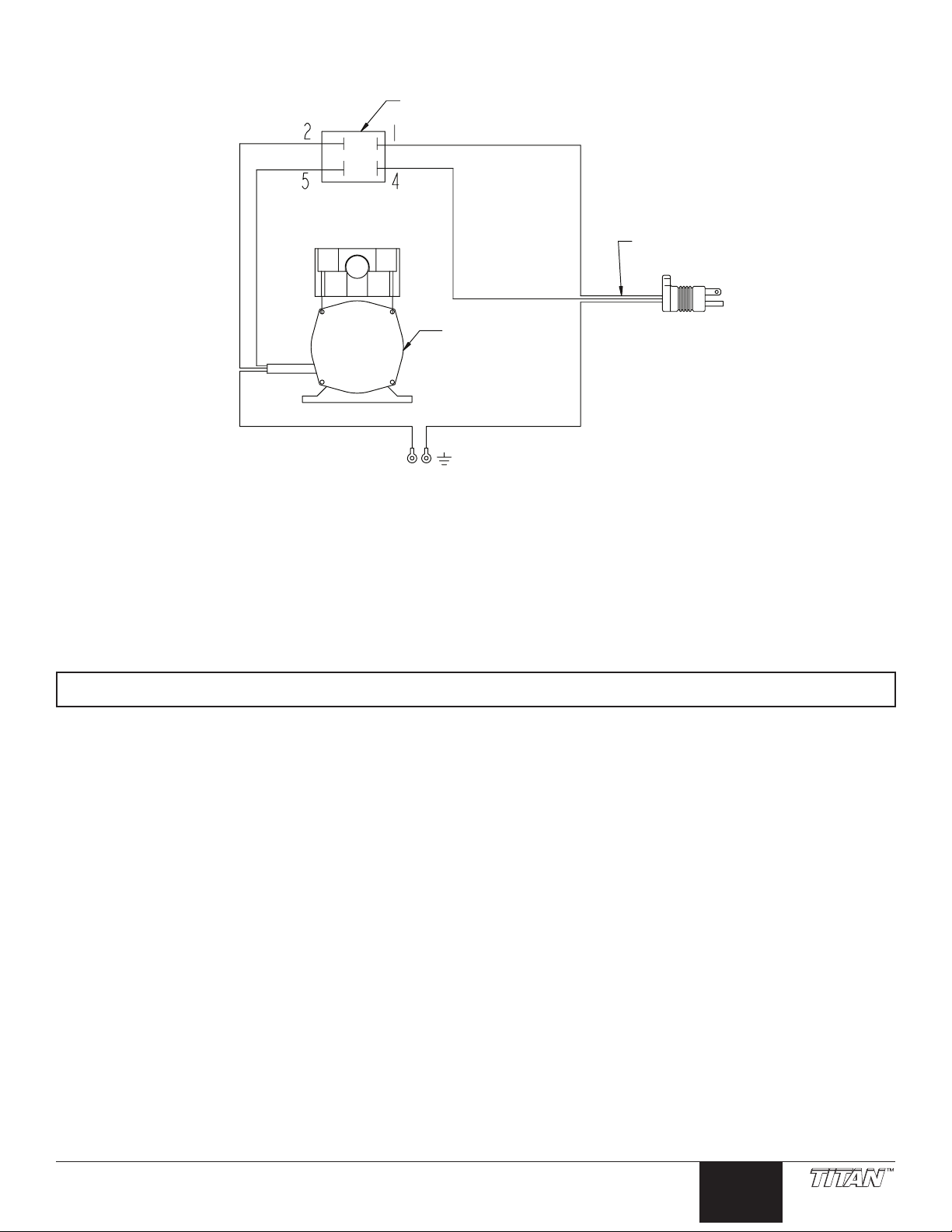

Electrical Schematic

ON/OFF switch

(P/N 9850936)

Compressor

(P/N 0524202)

Power cord

(P/N 0524313)

White

White

Black

Black

GreenGreen

Patents

These products are covered by one or more of the following U.S. patents:

5,550,336 5,556,255 5,639,222 5,702,131

5,772,711 5,655,714 5,558,492

Material Safety Data Sheets (MSDS) are available on Titan’s website or by calling Technical Service.

© Titan Tool. All rights reserved. 7

English

Page 8

Consignes de sécurite important · Lire toutes ces consignes avant

Prise trifilaire

Broche de mise à la terre

Plaque murale de la prise

d’utiliser l’appareil. GARDER CES CONSIGNES.

Indique une situation à risque, laquelle, si elle n’est pas

évitée, peut entraîner des blessures graves, voire la mort.

Pour réduire les risques d’incendie ou d’explosion, de

choc électrique et de blessure, vous devez lire et

comprendre les directives figurant dans ce manuel.

Familiarisez-vous avec les commandes et l’utilisation

adéquate de l’équipement.

DANGER : GÉNÉRAUX

Risques de dommages matériels et de blessures graves.

PRÉVENTION :

• Lire toutes les directives et mises en garde avant de faire

fonctionner l’équipement, quel qu’il soit.

• Se conformer à tous les codes locaux, provinciaux et nationaux

qui régissent la ventilation, la prévention des incendies et le

fonctionnement des dispositifs.

• Les normes de sécurité adoptées par le gouvernement américain

l’ont été en vertu de sa Occupational Safety and Health Act

(OSHA); ces normes, particulièrement les parties 1910 des

normes générales et 1926 des normes de construction, devraient

toujours être consultées.

• Cet équipement est conçu pour fonctionner avec les pièces

autorisées seulement. Si on l’utilise avec des pièces non

conformes aux spécications et exigences en matière de sécurité

du fabricant, on devra accepter les responsabilités et risques

inhérents.

• On doit s’assurer que les tuyaux soient exempts de coupures,

de fuites, d’abrasions ou de renements et que les raccords ne

soient ni endommagés ni mal assujettis avant chaque usage.

Le cas échéant, il faut remplacer le tuyau sur le champ, en ne

tentant jamais de le réparer.

• On ne doit jamais orienter le pistolet vers une partie du corps.

DANGER : DANGER DE BRÛLURE

Les pièces chauffées peuvent causer de graves brûlures

cutanées.

PRÉVENTION :

• Les raccords à dégagement rapide du tuyau exible et du pistolet

peuvent s’échauffer en cours d’utilisation; il faut alors éviter les

contacts cutanés, en attendant que les raccords refroidissent

avant de séparer le pistolet du tuyau.

• Le compresseur devient chaud à l’utilisation. Le laisser refroidir

avant d’y toucher.

DANGER : ÉMANATIONS DANGEREUSES

Les peintures, les solvants, les insecticides et autres

substances peuvent être dangereuses si inhalées, entraînant

de graves nausées, des pertes de connaissance ou une

intoxication.

PRÉVENTION :

• Utiliser un masque ou un respirateur en présence de risques

d’inhalation. Lire toutes les directives relatives au dispositif de

protection an d’en assurer l’efcacité dans l’usage auquel il est

destiné.

DANGER : EXPLOSION

L’air comprimé est très puissant et peut provoquer des

blessures.

PRÉVENTION :

• L’ensemble réservoir est protégé contre la surpression par une

soupape de sécurité. De temps en temps, tirer sur l’anneau de la

soupape de sécurité pour vérier qu’elle fonctionne normalement.

Remplacer la soupape si elle ne fonctionne pas bien ou si elle ne

laisse pas passer l’air quand on tire sur l’anneau.

• Ne jamais modier le réservoir sous pression ni le compresseur.

• Ne connecter aucun autre outil pneumatique au compresseur.

DANGER : D’EXPLOSION OU D’INCENDIE

Les émanations de solvants et de peintures peuvent exploser

ou s’enammer, entraînant des dommages matériels ou des

blessures graves.

PREVENTION :

• On doit assurer la ventilation et l’introduction d’air

neuf dans la zone de pulvérisation an d’éviter les

accumulations de vapeurs inammables.

• Placer la turbine le plus loin possible de la zone de pulvérisation.

• Il faut éviter les sources de combustion comme l’électricité

statique, les ammes nues, les veilleuses de bec de gaz, les

objets chauds, les cigarettes et les étincelles provoquées

par la connexion/déconnexion de cordon d’alimentation et la

commutation d’interrupteurs d’éclairage.

• Placer le moteur le plus loin possible de la zone de pulvérisation

pour l’éloigner des vapeurs de solvant et de peinture. Le moteur

contient des pièces qui peuvent émettre des étincelles.

• On doit avoir à portée de la main de l’équipement d’extinction en

bon état de marche.

• Le cordon d’alimentation doit être raccordé à un circuit mis à la

terre.

• S’assurer de suivre les directives en matière de sécurité et de

lire les mises en garde du fabricant des solvants et des produits

utilisés.

Instructions de mise à la terre

Cet appareil doit être mis à la terre. La mise à la terre réduit les risques

d’électrocution lors d’un court-circuit en permettant au courant de

s’écouler par le l de mise à la terre. Cet appareil est muni d’un cordon

électrique avec l de mise à la terre ainsi que d’une che de terre. La

che doit être branchée sur une prise installée correctement et mise à la

terre conformément à la réglementation et aux codes en vigueur.

MISE EN GARDE - Le fait de ne pas brancher correctement

la fiche trifilaire de l’appareil peut entraîner des risques de

choc électrique.

Si on doit réparer ou remplacer le cordon ou la che, ne pas raccorder

le l de terre à la borne des broches plates (lames) de cette dernière. Ce

l, normalement vert (avec ou sans rayures jaunes), doit être relié à la

broche de terre.

Consulter un technicien ou un électricien qualié à défaut de comprendre

l’ensemble des présentes directives ou en cas d’incertitude quant à la

mise à terre de l’appareil. Ne pas modier la che de l’appareil; si elle ne

s’adapte pas dans la prise voulue, faire remplacer cette dernière par un

électricien qualié.

IMPORTANT : Utiliser uniquement une rallonge à trois fils

munie d’une fiche de terre dans une prise secteur mise à la terre

correspondant au type de fiche de l’appareil. S’assurer que votre

rallonge est en bon état. Lorsque vous utilisez une rallonge,

assurez-vous qu’elle soit d’un calibre suffisant pour supporter

l’intensité du courant requise par l’appareil. Une rallonge trop

mince entraîne une chute de tension, une diminution de l’intensité

et une surchauffe. Une rallonge de calibre 12 est recommandée.

Si vous devez utiliser une rallonge à l’extérieur, celle-ci doit

comprendre la marque W-A après la désignation indiquant le type de

cordon. Par exemple, la désignation SJTW-A indique que le cordon

est conçu pour être utilisé à l’extérieur.

NOTA : On ne recommande pas l’utilisation de rallonges de

plus de 31 m (100 pi); il est préférable de rallonger

le tuyau à peinture que le cordon d’alimentation.

Les rallonges plus courtes assureront la puissance

électrique requise pour un fonctionnement adéquat.

8 © Titan Tool. Tous droits réservés.

Français

Page 9

Table des matières

Entrée d’air du

cylindre à pression

Loquet du support

Tuyau à peinture

de 3/8 po x 30 pi

Sortie de peinture

du cylindre à pression

Assemblage cylindre

à pression

Tuyau à air du

cylindre à pression

Interrupteur

Assemblage

compresseur

(à l’intérieur)

Chariot

Support à

turbine

Tuyau à air

Écrou de retenue

Godet

Raccord pour

tuyau à air

Raccord pour

tuyau à air

Vis de montage

Bouchon du tuyau à air

Sécurité .....................................................................................8

Introduction ............................................................................... 9

Préparation................................................................................ 9

Conversion du pistolet pour l’alimentation à pression ......... 9

Montage de la turbine........................................................ 10

Raccordement du Power Cart ........................................... 10

Congurations du tuyau .................................................... 10

Préparation préalable à la vaporisation ............................. 11

Nettoyage ................................................................................ 11

Dépannage .............................................................................. 12

Liste des pièces ................................................................. 20-21

Garantie ................................................................................... 22

Introduction

Le Power Cart HVLP est conçu pour les systèmes de

vaporisation CAPSpray. Le Power Cart ajoute beaucoup de

polyvalence à un système déjà complet. Le Power Cart HVLP

est équipé des composantes suivantes : interrupteur, chariot,

cylindre à pression, compresseur, entrée du cylindre à pression,

tuyau du cylindre à pression, sortie du cylindre à pression, tuyau

à peinture et support à turbine.

Préparation

Suivez les procédures suivantes pour préparer votre pistolet de

pulvérisation et Power Cart HVLP à l’emploi.

Conversion du pistolet pour l’alimentation à

pression

Avant d’utiliser le Power Cart HVLP, vous devez convertir votre

pistolet à godet en pistolet à alimentation à pression.

1. Desserrez l’écrou de retenue à l’aide d’une clé et retirez le

godet d’une pinte.

2. Détachez le tuyau d’air du raccord situé sur le pistolet.

© Titan Tool. Tous droits réservés. 9

3. Retirez le raccord du tuyau à air au moyen d’une clé de

1/4 po.

4. Vissez la vis de pression à la place du raccord du tuyau à

air et serrez.

FACULTATIF (à la place des étapes 3 et 4) : On peut

utiliser un bouchon temporaire (également compris) pour

boucher le raccord du tuyau à air, au lieu d’effectuer les

étapes 3 et 4 ci dessus, au besoin. Il s’agit d’une manière

pratique de bloquer le raccord du tuyau à air lorsque

l’opérateur alterne fréquemment entre le godet d’une

pinte et le cylindre à pression.

Français

Page 10

Montage de la turbine

Sortie de peinture

du cylindre à pression

Tuyau à peinture

Tuyau à peinture

Entrée du

pistolet de

pulvérisation

Tuyau à air Tuyau à fluid

Attaches

Tuyau à air Tuyau à fluide

Tuyau à

peinture

flexible

Tuyau à air

flexible

Attaches

Déplacer le couplage

NOTA : Si vous montez une vielle turbine de CAPSpray,

utiliser les vis auto-perceuse illustré sur la

gauche.

Si vous montez une nouveau turbine de Titan

CAPSpray, utiliser les vis autotaraudeuses

gurant sur la droite.

Congurations du tuyau

Vaporisation sans tuyaux exibles

Suivez la conguration ci-dessous si vous voulez vaporiser sans

les accessoires exibles à peinture et à air.

1. Insérez le support de blocage en plastique sous la turbine

tel qu’illustré.

2. À l’aide d’un tournevis électrique sans l avec embout

Phillips, insérez les vis fournies dans le boîtier en

choisissant un réglage de couple peu élevé. Ne serrez

PAS trop fort.

REMARQUE : Si le tournevis électrique ne possède pas

de réglages de couple, vissez jusqu’à ce que le let

s’engage, puis serrez à la main.

CONSEIL : Lorsque les tuyau cerclage, le départ à la

pistolets et de travailler en arrière.

REMARQUE :

Tuyau à uide de 30 pi – compris avec le Power Cart.

Tuyau à air de 30 pi – compris avec la turbine.

Attaches de tuyau – comprises avec le Power Cart.

Vaporisation avec tuyaux exibles

Respectez la conguration ci-dessous dans les cas suivants :

1. Vous possédez déjà le tuyau à air exible et vous avez

acheté un ensemble avec tuyau à peinture exible.

2. Vous avez acheté les ensembles avec tuyau à air exible

et tuyau à peinture exible.

3. Placez la turbine sur le chariot. Enfoncez le support de

blocage pour xer la turbine.

Raccordement du Power Cart

CONSEIL : Lorsque les tuyau cerclage, le départ à la

pistolets et de travailler en arrière.

1. Vissez l’une des extrémités du tuyau à peinture à la sortie

de peinture du cylindre à pression et serrez..

2. Vissez l’autre extrémité du tuyau au pistolet de

pulvérisation et serrez.

REMARQUE:

Tuyau à uide de 30 pi – compris avec le Power Cart.

Tuyau à air de 30 pi – compris avec la turbine.

Tuyau à air exible de 5 po - compris avec la modès

de CS9900 and CS9960.

Tuyau à peinture exible de 5 po - Vendu séparément.

10 © Titan Tool. Tous droits réservés.

Français

Page 11

Préparation préalable à la vaporisation

Couvercle

Rainure

Joint

d’étanchéité

Patte de

serrage

Cylindre

à pression

Doublure

du cylindre

Entrée d’air du cylindre

à pression

Tuyau à air du cylindre

à pression

Bouton de commande

de pression

Manomètre

IMPORTANT : Insérez une doublure dans le cylindre à

pression lorsque vous vaporisez ou nettoyez avec des

solvants chauds comme les peintures à base de laque, les

diluants à peinture-lacque et la méthylacétone. Utiliser des

solvants chauds dans le cylindre à pression sans y ajouter

une doublure risque de détacher la peinture qui recouvre

l’intérieur du cylindre et de contaminer le fini de la peinture.

Reportez-vous à la liste des pièces de ce manuel pour

connaître le numéro de la doublure pour cylindre.

1. Remplissez le cylindre à pression avec le matériau à

pulvériser.

CONSEIL : Pour les plus

petites tâches, vous pouvez

introduire un contenant

d’un gallon à l’intérieur du

cylindre à pression pour

faciliter le nettoyage.

REMARQUE : Pour de

meilleurs résultats, ltrez

toujours le matériau avant de

le vaporiser.

REMARQUE : Lorsque vous

vous servez d’un contenant

d’un gallon, assurez-vous de

ne pas trop incliner le chariot

vers l’arrière pour éviter que

le matériau se répande hors

du contenant.

2. Fixez solidement le

couvercle sur le cylindre à

pression en plaçant les cinq

pattes de serrage dans les

rainures du couvercle et

en les faisant tourner dans

le sens horaire jusqu’à ce

qu’elles soient bien serrées.

Assurez-vous que le joint

d’étanchéité est en place.

3. Raccordez le tuyau à air du cylindre à pression à l’entrée

d’air du cylindre à pression.

REMARQUE : Le tuyau est doté de raccords à

dégagement rapide. Pour dégager le tuyau, tirez sur

le collet à ressort de chaque raccord. Faites glisser le

raccord du tuyau sur le bon point de branchement, puis

relâchez le collet.

REMARQUE : Vous devez laisser fonctionner

le compresseur sans arrêt (jusqu’à 2 minutes)

pour permettre le chargement initial du cylindre à

pression. Lorsque le compresseur atteint sa pression

nominale (déterminée par le régulateur), sa cadence

de fonctionnement diminue. Lorsque le système est

laissé au repos (c’est à dire, aucune pulvérisation de

liquide) pendant plusieurs minutes, le compresseur se

met périodiquement en marche en raison des pertes

d’air normales. Il peut se mettre en marche jusqu’à

4 fois par minute lorsque le système est au repos. Si

le compresseur se met en marche plus fréquemment

ou s’il ne s’arrête jamais, voir la section consacrée au

dépannage.

Pendant la pulvérisation de liquide, le compresseur se

met normalement en marche toutes les 5 à 10 secondes.

5. Tirez sur le bouton de commande de pression et tournezle jusqu’à ce que la pression convienne au type de

matériau que vous utilisez.

Pour les matériaux légers, réglez le régulateur à 8 psi.

Pour les matériaux plus épais, réglez le régulateur

entre 8 et 14 psi.

6. Mettez la turbine en marche.

7. Essayez le jet sur un bout de bois ou de carton jusqu’à

ce que la pression, la forme et la largeur du jet soient

satisfaisantes. Consultez le manuel de votre pistolet

pour ajuster la forme du jet et pour connaître les choix

possibles.

Nettoyage

1. Éteignez la turbine.

2. Éteignez aussi le Power Cart.

3. Libérez la pression du cylindre à pression et retirez le

couvercle du cylindre.

4. Enlevez l’excédent de matériau en essuyant l’intérieur du

cylindre et le tuyau à peinture.

5. Placez un contenant renfermant le solvant approprié dans

le cylindre à pression pour nettoyer le tuyau et le pistolet.

6. Replacez le couvercle en vous assurant que le tube à

peinture est introduit dans le contenant de solvant, puis

serrez le couvercle.

7. Mettez le Power Cart sous tension et réglez la pression à

10 psi.

8. En laissant la turbine hors tension, pressez la détente du

pistolet en visant l’intérieur du contenant de matériau. De

cette façon, le matériau s’égouttera dans le contenant

jusqu’à évacuation complète.

9. Continuez à faire circuler le solvant dans le tuyau et le

pistolet jusqu’à ce qu’ils soient bien propres.

4. Branchez le cordon d’alimentation du chariot et de la

turbine sur une prise de courant. Tournez l’interrupteur

à la position ON (I) pour mettre le compresseur sous

tension.

© Titan Tool. Tous droits réservés. 11

Français

Page 12

Dépannage

Problème

A. Le compresseur ne s’arrête

pas ou il fonctionne plus de

30 % du temps.

B. Le compresseur refuse de

se mettre en marche et il n’y

a pas de pression dans le

réservoir.

Cause

1. Le couvercle du cylindre à pression n’est

pas bien fermé.

2. Il y a fuite car le joint d’étanchéité du

couvercle est couvert de peinture.

3. L’interrupteur à pression du compresseur

est défectueux.

4. Les raccords du tuyau à air pourraient

avoir une fuite.

1. Pas d’alimentation électrique.

2. Le réglage du régulateur est trop bas.

3. L’interrupteur à pression du compresseur

est défectueux.

4. Le moteur du compresseur est défectueux.

5. Le manomètre est défectueux.

6. Le régulateur est défectueux.

Solution

1. Retirez le couvercle, corrigez la position du cylindre,

replacez le couvercle et resserrez le collier de

serrage, qui a l’apparence d’une étoile, en serrant

chacun des écrous. Resserrez les une dernière fois

an de vous assurer que chaque écrou a reçu un

effort de serrage égal.

2. Inspectez et nettoyez le joint d’étanchéité du

couvercle.

3. Remplacez l’interrupteur à pression du compresseur

(appelez les services techniques au 1 800 5264826 pour demander la trousse de rechange P/N

0524205).

4. Faites une vérication antibulles an d’en déceler

l’origine. Démontez les joints en question. Ajoutez du

mastic pour tuyaux letés. Remontez les joints.

1. Vériez si l’appareil est branché correctement à

la prise électrique et si la prise est alimentée en

courant.

2. Tournez dans le sens horaire pour augmenter la

pression.

3. Remplacez l’interrupteur à pression du compresseur

(appelez les services techniques au 1 800 5264826 pour demander la trousse de rechange P/N

0524205).

4. Remplacez le compresseur (voir liste des pièces).

5. Remplacez le manomètre (voir liste des pièces).

6. Remplacez le régulateur (voir liste des pièces).

C. Le matériau ne coule pas vers

le pistolet.

D. Le détendeur de pression du

cylindre s’ouvre.

1. Le réglage du régulateur est trop bas.

2. Le tuyau ou le pistolet est peut-être

branché.

1. Le réglage du régulateur est trop élevé.

2. Le régulateur est défectueux.

3. Le détendeur de pression est défectueux.

4. Le manomètre est défectueux.

1. Réglez le régulateur entre 8 et 14 psi.

2. Inspectez et nettoyez.

1. Diminuez la pression sous 35 psi.

2. Remplacez le régulateur (voir liste des pièces).

3. Remplacez le détendeur de pression (voir liste des

pièces).

4. Remplacez le manomètre (voir liste des pièces).

12 © Titan Tool. Tous droits réservés.

Français

Page 13

Diagramme électrique

Commutateur

(Nº de pièce 9850936)

Compresseur

(Nº de pièce

0524202)

Cordon

(Nº de pièce 0524313)

Blanc

Blanc

Noir

Noir

Vert Vert

Brevets

Ces produits sont protégés par un ou plusieurs des brevets (U.S.A.) suivants :

5,550,336 5,556,255 5,639,222 5,702,131

5,772,711 5,655,714 5,558,492

Des ches techniques de sécurité des produits (FTSS) sont disponibles sur le site Internet de Titan ou par téléphone

en vous adressant au Service Client.

© Titan Tool. Tous droits réservés. 13

Français

Page 14

Información de seguridad importante · Lea toda la información de

Receptáculo conectado a tierra

Pata a tierra

Tapa de la caja de receptáculo conectada a tierra

Información de seguridad importante · Lea toda la información de

seguridad antes de operar el equipo. GUARDE ESTAS INSTRUCCIONES.

seguridad antes de operar el equipo. GUARDE ESTAS INSTRUCCIONES.

Indica una situación peligrosa que, de no evitarse, puede

causar la muerte o lesiones graves.

Para reducir los riesgos de incendios, explosiones,

descargas eléctricas o lesiones a las personas, lea y

entienda todas las instrucciones incluidas en este

manual. Familiarícese con los controles y el uso

adecuado del equipo.

PELIGRO: GENERAL

Puede causar daños en la propiedad o lesiones severas.

PREVENCIÓN:

• Lea todas las instrucciones y advertencias de seguridad antes de

hacer funcionar cualquier equipo.

• Cumpla con todos los códigos locales, estatales y nacionales de

ventilación, prevención de incendios y operación que rijan.

• Los Estándares de Seguridad del Gobierno de los Estados

Unidos se han adoptado bajo el Decreto de Seguridad y Salud

Ocupacionales (OSHA por sus siglas en inglés). Deben consultarse

estos estándares, particularmente la parte 1910 de los Estándares

Generales y la parte 1926 de los Estándares de la Construcción.

• Este equipo está diseñado para usarse solamente con piezas

autorizadas por el fabricante. Cuando se use este equipo con

piezas que no cumplan con las especicaciones mínimas ni con

las de los dispositivos de seguridad del fabricante de la bomba, el

usuario asumirá todos los riesgos y responsabilidades legales.

• Cada vez, antes de usarlo, revise todas las mangueras para ver que

no tengan cortadas, fugas, una cubierta desgastada por abrasión

o con abolladuras, así como uniones dañadas o que se hayan

movido. Si existiera cualquiera de estas condiciones, reemplace la

manguera inmediatamente. Nunca repare una manguera de pintura.

• Nunca apunte la pistola hacia alguna parte del cuerpo.

PELIGRO: QUEMADURA DE LA PIEL

Las piezas calientes pueden causar lesiones de quemadura de la

piel severas.

PREVENCIÓN:

• Las conexiones de desconexión rápida de la manguera y

la pistola de atomización se llegan a calentar mientras se

usan. Evite que la piel tenga contacto con las conexiones

de desconexión rápida cuando se calienten. Deje que las

conexiones de desconexión rápida se enfríen antes de

desconectar la pistola de atomización de la manguera.

• El compresor se calienta durante el uso. Permita que el

compresor se enfríe antes de tocarlo.

PELIGRO: VAPORES PELIGROSOS

Las pinturas, solventes, insecticidas y otros materiales

pueden ser peligrosos si se inhalan; pueden causar náuseas,

desmayos o envenenamientos severos.

PREVENCIÓN:

• Use un respirador o una mascarilla siempre que exista el riesgo de

poder inhalar los vapores. Lea las instrucciones de la mascarilla

para asegurarse de que proporcionará la protección necesaria

contra la inhalación de vapores dañinos.

PELIGRO: EXPLOSION

El aire comprimido tiene una gran fuerza y pudiera causar

lesiones.

PREVENCION:

• El ensamble del tanque de presión está protegido con una

válvula de seguridad en caso de una sobre presurización.

Ocasionalmente jale la argolla de la válvula de seguridad para

asegurarse que la válvula opere libremente. En caso de no

operar con libertad o si la válvula no libera aire cuando se jala la

argolla, debe cambiarse.

• Nunca modique el tanque de presión o el compresor.

• Nunca conecte otras herramientas de aire al compresor.

PELIGRO: INCENDIO O EXPLOSIÓN

Los vapores de los solventes y pinturas pueden explotar o

encenderse y causar con esto daños en la propiedad y/o

lesiones severas.

PREVENCIÓN:

• On doit assurer la ventilation et l’introduction d’air

neuf dans la zone de pulvérisation an d’éviter les

accumulations de vapeurs inammables.

• Mantenga la turbina a la máxima distancia posible del área de

pintado.

• Evite que haya cualquier fuente de ignición como la electricidad

estática, llamas abiertas, amas de pilotos, objetos calientes,

cigarros y chispas que provengan de conectar y desconectar cables

de energía e interruptores de luces que estén funcionando.

• Mantenga el motor alejado del área de pintado para evitar vapores

de solvente y pintura. El motor contiene partes que al arquear

producen chispas.

• Debe haber equipo para extinción de incendios que además

funcione bien.

• El cable de energía debe conectarse en un circuito que esté

conectado a tierra.

• Siga las medidas de precaución y advertencias de seguridad del

fabricante del material y del solvente.

Instrucciones para conectar a tierra

Este producto se debe conectar a tierra. En caso de que ocurra un

corto circuito, la conexión a tierra reduce el riesgo de choque eléctrico

al proporcionar un alambre de escape para la corriente eléctrica. Este

producto está equipado con un cable que tiene un alambre de conexión a

tierra con un enchufe de conexión a tierra apropiado. El enchufe se debe

enchufar en una toma de corriente que se haya instalado y conectado a

tierra debidamente, de acuerdo con todos los códigos y estatutos locales.

ADVERTENCIA - La instalación incorrecta del enchufe a

tierra puede ocasionar un riesgo de choque eléctrico.

Si es necesario reparar o cambiar el cable o el enchufe, no

conecte el cable verde a tierra a ninguno de las terminales de espiga

plana. El cable con aislamiento de color verde por fuera con o sin rayas

amarillas es el alambre a tierra y debe conectarse a la espiga a tierra.

Consulte a un electricista o técnico de servicio capacitado si las

instrucciones para la conexión a tierra no se entienden claramente o si

tiene dudas en cuanto a que el producto esté debidamente conectado a

tierra. No modifique el enchufe que se incluye. Si el enchufe no encaja

en el receptáculo, pida a un electricistas capacitado que instale un

receptáculo adecuado.

IMPORTANTE: Use solamente extensiones trifilares que tengan un

enchufe de conexión a tierra de 3 hojas y un receptáculo de triple

ranura que acepte el enchufe del producto. Asegúrese de que su

extensión esté en buenas condiciones. Cuando use una extensión,

asegúrese de usar una que sea lo suficientemente resistente como

para soportar la corriente que descargue su producto. Un cable de

un tamaño menor causará una caída de voltage en la línea que dará

como resultado una pérdida de energía y un sobrecalenta|ôento. Se

recomienda usar un cable de calibre 12. Si se utiliza un cable de

extensión en el exterior, tiene que estar marcado con el sufijo W-A

después de la designación del tipo de cable. Por ejemplo, SJTW-A

para indicar que el cable es apropiado para uso en exteriores.

NOTA: No se recomienda usar una extensión de más de 100

pies. Use una longitud mayor de manguera de pintura,

no una extensión más larga. Una extensión más corta

asegurará que haya la energía eléctrica máxima para

tener un funcionamiento apropiado.

14 © Titan Tool. Todos los derechos reservados.

Español

Page 15

Tabla de Contenido

Entrada de aire del

tanque de presión

Lengüeta soporte

Manguera para

fluidos de 3/8” x

30 pies

Salida de fluido del

tanque de presión

Ensamblaje del

tanque de presión

Manguera de aire

del tanque de presión

Interruptor

de energía

Ensamblaje

de compresor

(dentro de la

caja)

Manija

Soporte

de turbina

Tuyau à air

Écrou de retenue

Godet

Raccord pour

tuyau à air

Adaptador del

tubo de aire

Tornillo de ajuste

Ta pa del tubo de aire

Seguridad ................................................................................ 14

Introducción ............................................................................ 15

Conguración ......................................................................... 15

Cómo Convertir la Pistola a una Alimentada a Presión .... 15

Cómo Montar la Turbina.................................................... 16

Cómo Conectar el Power Cart .......................................... 16

Conguraciones de la Manguera ...................................... 16

Preparación para Rociar ................................................... 17

Limpieza .................................................................................. 17

Solución de Problemas .......................................................... 18

Lista de Piezas ................................................................... 20-21

Garantía ................................................................................... 23

Introducción

El Power Cart HVLP (de Alto Volumen y Baja Presión) está

diseñado para su uso con sistemas de rociadores CAPSpray. El

Power Cart le brinda gran versatilidad a un sistema ya completo.

Los componentes del Power Cart HVLP incluyen un interruptor

de energía, una manija, un ensamblaje de tanque de presión, un

ensamblaje de compresor, una entrada de tanque de presión,

una manguera de tanque de presión, una salida de tanque de

presión, una manguera para uidos y un soporte de turbina.

Conguración

Utilice los siguientes procedimientos para congurar su pistola

rociadora y Power Cart HVLP.

Cómo Convertir la Pistola a una Alimentada a

Presión

Antes de utilizar el Power Cart HVLP, es necesario convertir su

pistola rociadora de una pistola de copa a una pistola alimentada

a presión.

1. Aoje la tuerca de sujeción con una llave y quite el

ensamblaje de compartimiento de un cuarto.

2. Tire del tubo de aire hacia afuera del acoplador del tubo

de aire que se encuentra en la pistola rociadora.

© Titan Tool. Todos los derechos reservados. 15

3. Quite el acoplador de tubo de aire por medio de una llave

de 1/4”.

4. Enrosque el tornillo jado en el lugar del acoplador de

tubo de aire y ajústelo en su lugar.

OPCIONAL (válido para pasos 3 y 4): Si lo desea, se

puede utilizar una tapa temporal (también incluida) para

cerrar el acoplamiento del tubo de aire en vez de llevar

a cabo los pasos 3 y 4 arriba mencionados. Este es un

método conveniente de tapar el acoplamiento del tubo de

aire si el operador alternará de manera frecuente entre

una taza de 1 cuarto y un tanque de presión.

Español

Page 16

Cómo montar la turbina

Salida del tanque de presión

Manguera para fluidos

Manguera para fluidos

Entrada de

la pistola

rociadora

Manguera

para fluidos

Manguera

para aire

Correas

Manguera

flexible

para fluidos

Manguera

flexible

para aire

Mover el acoplamiento

Manguera

para fluidos

Manguera

para aire

Correas

NOTA: Si va a montar una turbina de CAPSpray

mayores, utilice los tornillos autotaladrantes

muestra a la izquierda.

Si va a montar una nueva turbina de Titan

CAPSpray, utilice los tornillos autoroscantes

muestra a la derecha.

Conguraciones de la Manguera

Cómo rociar sin mangueras exibles

Siga la conguración a continuación si desea rociar sin los

accesorios exibles de uidos y aire.

1. Inserte un soporte de seguridad plástico en el fondo de la

turbina como se muestra.

2. Por medio de un taladro inalámbrico con punta de

destornillador Phillips, inserte los tornillos que se incluyen

en la cubierta utilizando un ajuste de embrague bajo. NO

ajuste demasiado.

NOTA: Si el destornillador no posee embrague, atornille

con el taladro hasta que las roscas comiencen a

ajustarse, y luego ajuste a mano.

CONSEJO: Cuando el tirante del mangueras, comenzar

en la pistola y el trabajo atrás.

NOTA: Manguera para uidos de 30 pies - incluida con

el Power Cart.

Manguera para aire de 30 pies - incluida con la

turbina.

Correas para manguera - incluidas con el Power

Cart.

Cómo rociar con mangueras exibles

Siga la conguración a continuación si usted:

1. Ya tiene la manguera exible para aire y adquirió un juego

de manguera exible para uidos.

2. Ya tiene ambos, el juego de manguera exible para

uidos y el juego exible de manguera para aire.

3. Coloque la turbina sobre el power cart. Empuje el soporte

de seguridad hacia adentro para asegurar la turbina.

Cómo Conectar el Power Cart

1. Enrosque el extremo de la manguera para uidos en la

CONSEJO: Cuando el tirante del mangueras, comenzar

en la pistola y el trabajo atrás.

salida de uidos del tanque de presión y ajuste.

2. Enrosque el otro extremo de la manguera para material

en la entrada de la pistola rociadora y ajuste.

NOTA: Manguera para uidos de 30 pies - incluida con

el Power Cart.

Manguera para aire de 30 pies - incluida con la

turbina.

Manguera exible para aire de 5 pies - incluida

con modelos de CS9900 y CS9960,

Manguera exible para uidos de 5 pies - se

16 © Titan Tool. Todos los derechos reservados.

Español

vende por separado

Page 17

Preparación para Rociar

Cubierta

Ranura

Sello

Abrazadera

de seguridad

Ta nque

de presión

Funda para

tanques

Entrada de aire del

tanque de presión

Manguera de aire del

tanque de presión

Perilla de control

de presión

Medidor de control

de presión

IMPORTANTE: Utilice una funda para tanques en el tanque

de presión cuando rocíe o limpie con solventes calientes

tales como pinturas a base de laca, disolvente de laca y

MEK (Metil Etil Cetona). El uso de solventes calientes en

el tanque de presión sin una funda para tanques puede

despegar la pintura del interior del tanque de presión y

contaminar el acabado de pintura. Consulte la lista de

piezas en este manual para el número correspondiente a la

funda para tanques.

1. Llene el tanque de presión con el material a rociar.

CONSEJO: En trabajos más

pequeños, puede colocarse

un contenedor de un galón

dentro del tanque de presión

para ayudar a limpiar más

rápidamente.

NOTA: Para obtener mejores

resultados, cuele siempre el

material antes de rociar.

NOTA: Al utilizar el

contenedor de un galón,

asegúrese de no inclinar

demasiado hacia atrás el

Power Cart para evitar que el

material se derrame.

NOTA: El compresor debe funcionar en forma continua

(hasta 2 minutos) para cargar inicialmente el

tanque de presión. A medida que el compresor

alcance la presión que desee (jada por

el regulador), el compresor disminuirá su

velocidad de ciclo. Si se deja inactivo el sistema

(es decir, no se pulveriza material) durante

varios minutos, el compresor realizará un ciclo

de manera periódica debido a las pérdidas de

aire normales. Cuando el sistema esté inactivo,

el compresor puede realizar un ciclo hasta 4

veces por minuto. Si el compresor realiza un

ciclo de manera más frecuente que ésta o no

se detiene, consulte la sección Solución de

problemas.

Cuando se pulveriza material, normalmente el

compresor debiera realizar un ciclo cada 5 a 10

segundos.

5. Tire hacia afuera la perilla de control de presión y gírela

hasta ajustar la presión en forma adecuada al material

que está utilizando.

Para materiales delgados, ajuste el regulador a 8 PSI.

Para materiales más gruesos, ajuste el regulador

entre 8 y 14 PSI.

2. Ajuste bien la cubierta

al tanque de presión

colocando las cinco

abrazaderas de seguridad

en las ranuras de la

cubierta y rotando cada

una de ellas en el sentido

de las manecillas del reloj

hasta que estén ajustadas.

Asegúrese de que el sello

esté en su lugar.

3. Conecte la manguera de aire del tanque de presión a la

entrada de aire del tanque de presión.

NOTA: La manguera posee acopladores de fácil

4. Enchufe los cables de alimentación del Power Cart y de

la turbina. Lleve el interruptor del cart power a la posición

de ON (I) para encender el compresor.

© Titan Tool. Todos los derechos reservados. 17

conexión. Para utilizarlos, tire hacia atrás

el collar accionado por resortes de cada

acoplador. Deslice el acoplador de manguera

sobre la conexión correcta y suelte el collar.

6. Encienda la turbina.

7. Practique rociando un trozo de madera desechable

o cartón hasta que esté satisfecho con la presión, la

modalidad de rociado y la forma de rociado. Los ajustes

para la modalidad de rociado y las selecciones de forma

de rociado están descriptos en el manual de su pistola.

Limpieza

1. Apague la turbina.

2. Apague el Power Cart.

3. Libere la presión del tanque de presión y quite la cubierta

del tanque de presión.

4. Quite el exceso de material del tanque, limpiando el

interior del tanque y el tubo receptor de uidos.

5. Coloque un contenedor del solvente de limpieza

apropiado dentro del tanque de presión para limpiar la

manguera y la pistola.

6. Reemplace la cubierta, asegúrese de que el tubo receptor

esté dentro del contenedor de solvente, y ajuste la

cubierta del tanque.

7. Encienda el Power Cart y ajuste la presión a 10 psi.

8. Con la turbina apagada, quite presión en el gatillo de la

pistola rociadora mientras apunta dentro del contenedor

del material. Esto permitirá vaciar el material dentro

del contenedor hasta que todo el material haya sido

transferido.

9. Siga haciendo correr el solvente a través de la manguera

y la pistola hasta que éstas estén completamente limpias.

Español

Page 18

Solución de problemas

Problema

A. El compresor no se apaga

o funciona un 30% más de

tiempo.

B. El compresor no arranca y no

hay presión en el tanque.

Causa

1. La tapa del tanque de presión no está

ajustada.

2. La junta de la tapa tiene material

acumulado y, por lo tanto, causa una

ltración.

3. El interruptor de presión del compresor

está defectuoso.

4. Los acopladores de aire pueden tener

fugas.

1. La unidad no recibe suministro eléctrico.

2. El regulador está ajustado demasiado

bajo.

3. El interruptor de presión del compresor

está defectuoso.

4. El motor del compresor está defectuoso.

5. El medidor de presión está defectuoso.

6. El regulador está defectuoso.

Solución

1. Retire la cubierta, vuelva a colocar el tanque,

vuelva a colocar la cubierta y vuelva a apretar las

abrazaderas en estrella, apriete cada vez más cada

tuerca. Apriete una última vez para asegurar una

torsión igual en cada tuerca.

2. Revise y limpie la junta de la tapa.

3. Reemplace el interruptor de presión del compresor

(Juego de repuesto P/N 0524205 disponible

llamando al servicio técnico al 1-800-526-4826).

4. Verique que los acopladores no tengan burbujas de

aire y determine en donde se encuentran si las hay.

Desarme las juntas pertinentes. Añada sellador para

rosca. Vuelva a ensamblar todo.

1. Controle que la unidad esté enchufada y que el

enchufe tenga corriente.

2. Gire en el sentido de las manecillas del reloj para

aumentar la presión.

3. Reemplace el interruptor de presión del compresor

(Juego de repuesto P/N 0524205 disponible

llamando al servicio técnico al 1-800-526-4826).

4. Reemplace el compresor (ver lista de piezas).

5. Reemplace el medidor de presión (ver lista de

piezas).

6. Reemplace el regulador (ver lista de piezas).

C. El material no circula por la

pistola rociadora.

D. La válvula de seguridad del

tanque de presión se suelta.

1. El regulador está ajustado demasiado

bajo.

2. La manguera o la pistola pueden estar

enchufadas.

1. El regulador está ajustado demasiado alto.

2. El regulador está defectuoso.

3. La válvula de seguridad está defectuosa.

4. El medidor de presión está defectuoso.

1. Ajuste el regulador entre 8 y 14 psi.

2. Revise y limpie.

1. Disminuya la presión a menos de 35 psi.

2. Reemplace el regulador (ver lista de piezas).

3. Reemplace la válvula de seguridad (ver lista de

piezas).

4. Reemplace el medidor de presión (ver lista de

piezas).

18 © Titan Tool. Todos los derechos reservados.

Español

Español

Page 19

Diagrama eléctrico

Interruptor

(No. de pieza 9850936)

Compresor

(No. de pieza

0524202)

Cordón

(No. de pieza 0524313)

Blanco

Blanco

Negro

Negro

VerdeVerde

Patentes

Estos productos están protegidos por una de las siguientes patentes (U.S.A.):

5,550,336 5,556,255 5,639,222 5,702,131

5,772,711 5,655,714 5,558,492

Las Hojas de Datos de Seguridad (Material Safety Data Sheets - MSDS) se encuentran disponibles en el sitio web de Titan o

llamando al Servicio al Cliente.

© Titan Tool. Todos los derechos reservados. 19

Español

Page 20

Parts List • Liste de pièces • Lista de piezas

1

24

2

3

4

8

9

10

18

22

23

20

26

27

28

29

30

31

25

32

33

34

35

37

38

39 40

36

21

19

5

6

7

11

12

13

14

16

17

15

20 © Titan Tool. All rights reserved.

English

EspañolFrançais

Page 21

English

Item Part # Description Quantity

1 0275697 Fitting, 90° elbow, brass ..................................... 2

2 0275696 Fitting, 1/4” male, air nipple ................................ 1

3 0275640 Coupler, air ......................................................... 1

4 0524316 Compressor hose ............................................... 1

5 0276538 Gauge, Air........................................................... 1

6 0524442 Regulator ............................................................ 1

7 05045 Fitting, 1/4” x 1/4” ................................................ 1

8 0275717 Relief valve ......................................................... 1

9 0277348 Hose, uid 3/8” x 30 ft ......................................... 1

10 0275698 Fitting, uid ......................................................... 1

11* ------- Pot lid .................................................................. 1

12* 0508943 Gasket, pot ......................................................... 1

13* 0279924 Tube, pick up ...................................................... 1

14* 0275702 Pot liner .............................................................. 1

15 0524322 Screw, Truss #10-32 X 1/2” ................................ 1

16* ------- Pot bottom .......................................................... 1

0279285 Galvanized pot bottom (accessory)

17 0524365 Edge protector .................................................... 1

18 9850936 Power switch assembly ...................................... 1

19 765-063 Strain relief.......................................................... 1

20 0524313 Power cord set .................................................... 1

21 0278373 Wheel.................................................................. 2

22 0294534 Spacer, wheel ..................................................... 4

23 9890104 Cap, hub ............................................................. 2

24 0524309 Handle, cart ........................................................ 1

Français

Article Nº de pièce Description Quantité

1 0275697 Raccord, coude laiton à 90° ............................... 2

2 0275696 Raccord, raccord d’air mâle

de 1/4” pouce ...................................................... 1

3 0275640 Coupleur, d’air .................................................... 1

4 0524316 Tuyau de compresseur ....................................... 1

5 0276538 Manomètre.......................................................... 1

6 0524442 Détendeur ........................................................... 1

7 05045 Raccord, 1/4” x 1/4” ............................................ 1

8 0275717 Soupape de surpression ..................................... 1

9 0277348 Tuyau, uide 3/8” x 30 ft ..................................... 1

10 0275698 Raccord, uide .................................................... 1

11* ------- Couvercle............................................................ 1

12* 0508943 Joint, réservoir .................................................... 1

13* 0279924 Tuyau xateur ..................................................... 1

14* 0275702 Doublure de protection ....................................... 1

15 5024322 Vis, treillis, #10-32 x 1/2” .................................... 1

16* ------- Réservoir, fond ................................................... 1

0279285 Fond de réservoir galvanisé (accessoire)

17 0524365 Coussinet de protection ...................................... 1

18 9850936 Ensemble de interrupteur ................................... 1

19 765-063 Renfort ................................................................ 1

20 0524313 Jeu de câble d’alimentation ................................ 1

21 0278373 Roue ................................................................... 2

22 0294534 Entretoise, roue .................................................. 4

23 9890104 Chapeau du moyeu ............................................ 2

24 0524309 Poignée du chariot .............................................. 1

Item Part # Description Quantity

25 590-508 Roll pin, 5/16” x 1 1/8”......................................... 2

26 9841504 Button, snap........................................................ 2

27 590-504 Sleeve, handle .................................................... 2

28 590-506 Washer, at......................................................... 2

29 0524320 Screw, Pan, #10, self-drilling .............................. 2

30 0524319 Turbine latch plug ............................................... 1

31 856-002 Washer lock #10 ................................................. 4

32 856-921 Screw, pan #10-32 x 1/4”.................................... 4

33 0524308 Bracket, latch ...................................................... 1

34 0524202 Compressor assembly ........................................ 1

35 0524321 Fitting, 90º, 1/8” x 1/4” ........................................ 1

36 0524318 Nut, #10-32 ......................................................... 4

37 9802526 Screw, 1/4”-20 x 1/2” .......................................... 4

38 9802252 Screw, #10-32 x 3/4”........................................... 4

39 9805229 Screw, 1/4-20 x 2”............................................... 4

40 9820206 Washer, at......................................................... 9

Accessories

0508183 Spray hose, 1/4” x 30’

*0275692 Pressure pot assy (includes items 8, 10-13, 16)

0295272 Pot liners, 12 pack

0524206 Fluid whip hose kit, 1/4”

0524205 Pressure Switch Replacement kit

0295727 Hose strap

0524212 Pressure cap (3)

Article Nº de pièce Description Quantité

25 590-508 Goupille rouleau, 5-16” x 1 1/8” .......................... 2

26 9841504 Bouton d’enclenchement .................................... 2

27 590-504 Manche de poignée ............................................ 2

28 590-506 Rondelle plate ..................................................... 2

29 0524320 Vis, pan, #10, L’autonomie de forage ................. 2

30 0524319 Support de la turbine .......................................... 1

31 856-002 Rondelle de sécurité, #10 ................................... 4

32 856-921 Vis, pan #10-32 x 1/4”......................................... 4

33 0524308 Loquet du support ............................................... 1

34 0524202 Ensemble compresseur ...................................... 1

35 0524321 Raccord, coude laiton à 90°, 1/8” x 1/4” ............. 1

36 0524318 écrou, #10-32...................................................... 4

37 9802526 Vis, 1/4”-20 x 1/2” ............................................... 4

38 9802252 Vis, #10-32 x 3/4”................................................ 4

39 9805229 Vis, 1/4-20 x 2”.................................................... 4

40 9820206 Rondelle, Plate ................................................... 9

Accessoires

0508183 Tuyau de pulvériser, 1/4” x 30 po

*0275692 Ensemble de réservoir sous pression

(comprend les éléments 8, 10-13, 16)

0295272 Doublures, paquet de 12

0524206 Ensemble avec tuyau

à peinture exible, 1/4 po

0524205 Trousse de rechange de l’interrupteur à pression

0295727 Attache à tuyau

0524212 Couvercle étanche à la pression (3)

Español

Artículo Pieza # Descripción Cantidad

1 0275697 Conector, 90° Codo, Latón ................................. 2

2 0275696 Conector, 1/4” Macho, Niple de Aire................... 1

3 0275640 Cople .................................................................. 1

4 0524316 Manguera del compresor .................................... 1

5 0276538 Medidor, Aire ...................................................... 1

6 0524442 Regulador ........................................................... 1

7 05045 Conector, 1/4” x 1/4” ........................................... 1

8 0275717 Aliviar la válvula .................................................. 1

9 0277348 Manguera, Fluido 3/8” x 30 ft .............................. 1

10 0275698 Conector, Fluido ................................................. 1

11* ------- Tapa.................................................................... 1

12* 0508943 Empaque, Tanque .............................................. 1

13* 0279924 Tubo, Pick Up ..................................................... 1

14* 0275702 Forro del Tanque ............................................... 1

15 5024322 Tornillo ................................................................ 1

16* ------- Fondo del Tanque............................................... 1

0279285 Fondo galvinizado de tanque (accesorio)

17 0524365 Protector de borde .............................................. 1

18 9850936 Ensamblaje de interruptor................................... 1

19 765-063 Aliviador de Tensión ........................................... 1

20 0508337 Conjunto de cable de energía............................. 1

21 0278373 Rueda ................................................................. 2

22 0294534 Espaciador, Rueda ............................................. 4

23 9890104 Tapa, Eje ............................................................ 2

24 0524309 Mango de Carrito ................................................ 1

© Titan Tool. All rights reserved. 21

Artículo Pieza # Descripción Cantidad

25 590-508 Pasador de rollo, 5-16” x 1 1/8” .......................... 2

26 9841504 Botón, a presion.................................................. 2

27 590-504 Manga de carrito ................................................. 2

28 590-506 Rondana, plana .................................................. 2

29 0524320 Tornillo, pan #10, La libre perforación ................ 2

30 0524319 Turbina de soporte.............................................. 1

31 856-002 Rondana de seguridad, #10 ............................... 4

32 856-921 Tornillo, pan #10-32 x 1/4” .................................. 4

33 0524308 Lengüeta soporte ................................................ 1

34 0524202 Ensamble del Compresor ................................... 1

35 0524321 Conector, 90° Codo, 1/8” x 1/4” .......................... 1

36 0524318 Tuerca,#10-32 .................................................... 4

37 9802526 Tornillo,1/4”-20 x 1/2”.......................................... 4

38 9820252 Tornillo, #10-32 x 3/4” ........................................ 4

39 9805229 Tornillo, 1/4-20 x 2” ............................................. 4

40 9820206 Rondelle, piso ..................................................... 9

Accesorios

0508183 Manguera de rociadora, 1/4” x 30’

*0275692 Ensamblaje del tanque de presión

(incluye artículos del 8, 10-13, 16)

0295272 Fundas para tanques, paquete de 12

0524206 Juego de manguera exible

para uidos de 1/4”

0524205 Juego de Repuesto de Interruptor de Presión

0295727 Correa para manguera

0524212 Tapa de presión (3)

Español Français

English

Page 22

Garantie Limitée

Titan Tools, inc. (« Titan ») garantit qu’au moment de la livraison à l’acheteur original (« Utilisateur »), l’appareil couvert par la

présente garantie sera exempt de défauts de matériaux et de fabrication. Avec l’exception de spécial, limité, ou garantie allongée

publiée par de Titan, les responsabilités de Titan en vertu de cette garantie se limitent au remplacement ou à la réparation sans frais

des pièces dont on aura, à la satisfaction raisonnable de Titan, démontré la défectuosité dans un délai de douze (12) mois après la

date d’achat par l’Utilisateur. Cette garantie ne s’applique que si l’appareil a été installé et utilisé conformément aux recommandations

et directives de Titan.

Cette garantie ne s’applique pas dans les cas d’endommagement ou d’usure engendrés par de l’abrasion, de la corrosion, un mauvais

usage, de la négligence, un accident, une installation incorrecte, un remplacement par des composants non fournis par Titan ou toute

intervention non autorisée apte à nuire au fonctionnement normal de l’appareil.

Les pièces défectueuses doivent être envoyées à un centre de service/vente Titan autorisé; les frais de transport, incluant le retour

à l’usine, le cas échéant, doivent être défrayés à l’avance par l’Utilisateur. Une fois remplacées ou réparées, les pièces seront

renvoyées à ce dernier par transport prépayé.

AUCUNE AUTRE GARANTIE EXPLICITE N’EST DONNÉE. PAR LES PRÉSENTES, TITAN SE DÉGAGE DE TOUTE

AUTRE GARANTIE IMPLICITE, INCLUANT, SANS TOUTEFOIS S’Y LIMITER, LES GARANTIES DE COMMERCIABILITÉ ET

D’ADAPTATION À UN USAGE PARTICULIER, DANS LES LIMITES PERMISES PAR LA LOI. LA DURÉE DES GARANTIES

IMPLICITES NE POUVANT ÊTRE DÉCLINÉES SE LIMITE À LA PÉRIODE INDIQUÉE DANS LA GARANTIE EXPLICITE. LES

RESPONSABILITÉS DE TITAN NE SAURAIENT EN AUCUN CAS SE CHIFFRER À UN MONTANT SUPÉRIEUR À CELUI DU

PRIX D’ACHAT, ET CELLES RELATIVES AUX DOMMAGES CONSÉCUTIFS, ACCESSOIRES OU PARTICULIERS EN VERTU DE

TOUTE GARANTIE SONT ÉGALEMENT DÉCLINÉES, DANS LES LIMITES PERMISES PAR LA LOI.

TITAN NE DONNE AUCUNE AUTRE GARANTIE EXPLICITE ET DÉCLINE TOUTE GARANTIE IMPLICITE DE COMMERCIABILITÉ

ET D’ADAPTATION À UN USAGE PARTICULIER RELATIVEMENT AUX ACCESSOIRES, À L’ÉQUIPEMENT, AUX MATÉRIAUX OU

AUX COMPOSANTS VENDUS MAIS NON FABRIQUÉS PAR ELLE; CES ÉLÉMENTS (MOTEURS À ESSENCE, COMMUTATEURS,

FLEXIBLES, ETC.) SONT PLUTÔT SOUMIS, LE CAS ÉCHÉANT, AUX GARANTIES DE LEUR FABRICANT. TITAN S’ENGAGE

À OFFRIR UN SOUTIEN RAISONNABLE AUX UTILISATEURS QUI FERONT DES RÉCLAMATIONS RELATIVES À

L’INOBSERVATION DE CES GARANTIES.

22 © Titan Tool. Tous droits réservés.

Français

Page 23

Garantía limitada

Titan Tool, Inc., (“Titan”) garantiza que en el momento de la entrega al comprador original para su uso (“Usuario nal”), el equipo

cubierto por esta garantía está exento de defectos en material y fabricación. Con la excepción de cualquier especial, limitada, o

extendido garantía publicado por Titan, la obligación de Titan en virtud de esta garantía se limita a sustituir o reparar sin cargo

las piezas que; a la entera satisfacción de Titan, demuestren estar defectuosas dentro de doce (12) meses después de la venta

al usuario nal. Esta garantía corresponde solamente cuando la unidad se instala y funciona según las recomendaciones e

instrucciones de Titan.

Esta garantía no corresponde en el caso de daños o desgaste causados por abrasión, corrosión o uso indebido, negligencia,