Page 1

Owner’s Manual

Notice d’utilisation

Manual del Propietario

Do not use this equipment before

reading this manual!

AirCoat

Air-Assisted Airless Spray System

Model 0508074A

Register your product online at:

www.titantool.com

Serial Number _ _ _ _ _ _ _ _ _ _

NOTE: This manual contains important

warnings and instructions. Please read

and retain for reference.

0614 • © Titan Tool Inc. All Rights Reserved. Form No. 0524369F

Page 2

Important Safety Information

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Read all safety information before operating the

equipment. Save these instructions.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

To reduce the risks of re or explosion, electrical shock

and the injury to persons, read and understand all

instructions included in this manual. Be familiar with the

controls and proper usage of the equipment.

Grounding Instructions

This product must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with a

cord having a grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green grounding wire to either at blade terminal. The

wire with insulation having a green outer surface with or without

yellow stripes is the grounding wire and must be connected to the

grounding pin.

Check with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as

to whether the product is properly grounded. Do not modify the plug

provided. If the plug will not t the outlet, have the proper outlet

installed by a qualied electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. Make

sure that the product is connected to an outlet having the same

conguration as the plug. No adapter should be used with this

product.

• Paint or solvent owing through the equipment is able to

result in static electricity. Static electricity creates a risk of re

or explosion in the presence of paint or solvent fumes. All

parts of the spray system, including the pump, hose assembly,

spray gun and objects in and around the spray area shall be

properly grounded to protect against static discharge and

sparks. Use only conductive or grounded high-pressure airless

paint sprayer hoses specied by the manufacturer.

• Verify that all containers and collection systems are grounded

to prevent static discharge.

• Connect to a grounded outlet and use grounded extension

cords (electric models only). Do not use a 3 to 2 adapter.

• Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating supplier

about compatibility of material with aluminum.

• Keep spray area well ventilated. Keep a good supply of fresh

air moving through the area to keep the air within the spray

area free from accumulation of ammable vapors. Keep

pump assembly in well ventilated area. Do not spray pump

assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark

producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags,

and other ammable materials.

• Know the contents of the paint and solvents being sprayed.

Read all Material Safety Data Sheets (MSDS) and container

labels provided with the paints and solvents. Follow the paint

and solvent manufacture’s safety instructions.

• Place pump at least 25 feet (7.62 meters) from the spray

object in a well ventilated area (add more hose if necessary).

Flammable vapors are often heavier than air. Floor area must

be extremely well ventilated. The pump contains arcing parts

that emit sparks and can ignite vapors.

• Plastic can cause static sparks. Never hang plastic to enclose

spray area. Do not use plastic drop cloths when spraying

ammable material.

• Fire extinguisher equipment shall be present and working.

NOTE: More than 100 feet of extension cord is not

WARNING: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Property

damage and/or severe injury can occur.

PREVENTION:

• Do not spray ammable or combustible materials near an

open ame, pilot lights or sources of ignition such as hot

objects, cigarettes, motors, electrical equipment and electrical

appliances. Avoid creating sparks from connecting and

disconnecting power cords.

• Use extreme caution when using materials with a ashpoint

below 100ºF (38ºC). Flashpoint is the temperature that a uid

can produce enough vapors to ignite.

2 © Titan Tool. All rights reserved.

recommended. Use more paint hose, not more

extension cord. Shorter extension cords will assure

maximum electrical power for proper operation.

English

WARNING: INJECTION INJURY

A high pressure paint stream produced by this equipment

can pierce the skin and underlying tissues, leading to

serious injury and possible amputation. See a physician

immediately.

PREVENTION:

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge.

For example, do not try to stop leaks with any part of the

body.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS keep the tip guard in place while spraying. The tip

guard provides some protection but is mainly a warning

device.

• Only use a nozzle tip specied by the manufacturer.

• Use caution when cleaning and changing nozzle tips. In the

case where the nozzle tip clogs while spraying, ALWAYS lock

gun trigger, shut pump o, and release all pressure before

servicing, cleaning tip or guard, or changing tip. Pressure

will not be released by turning o the motor. The PRIME/

SPRAY valve or pressure bleed valve must be turned to their

Page 3

Important Safety Information

appropriate positions to relieve system pressure. Refer to

PRESSURE RELIEF PROCEDURE described in the pump manual.

• Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn o the unit and

relieve the pressure in accordance with the manufacturer’s

instructions.

• High-pressure spray is able to inject toxins into the body and

cause serious bodily injury. In the event that injection occurs,

seek medical attention immediately.

• Check hoses and parts for signs of damage, a leak can inject

material into the skin. Inspect hose before each use. Replace

any damaged hoses or parts. Only use TITAN original-high-

pressure hoses in order to ensure functionality, safety and

durability.

• This system is capable of producing 2800 PSI / 193 Bar. Only

use replacement parts or accessories that are specied by the

manufacturer and that are rated a minimum of 2800 PSI. This

includes spray tips, nozzle guards, guns, extensions, ttings,

and hose.

• Always engage the trigger lock when not spraying. Verify the

trigger lock is functioning properly.

• Verify that all connections are secure before operating the

unit.

• Know how to stop the unit and bleed pressure quickly. Be

thoroughly familiar with the controls. Pressure will not be

released by turning o the motor. The PRIME/SPRAY valve

or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure. Refer to PRESSURE

RELIEF PROCEDURE described in the pump manual.

• Always remove the spray tip before ushing or cleaning the

system.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury which can lead

to possible amputation. It is important to treat the injury as

soon as possible. DO NOT delay treatment to research toxicity.

Toxicity is a concern with some coatings injected directly

into the blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the inuence

of drugs or alcohol.

• Do not kink or over-bend the hose. Airless hose can develop

leaks from wear, kinking and abuse. A leak can inject material

into the skin.

• Do not expose the hose to temperatures or pressures in excess

of those specied by manufacturer.

• Do not use the hose as a strength member to pull or lift the

equipment.

• Use lowest possible pressure to ush equipment.

• Follow all appropriate local, state and national codes

governing ventilation, re prevention and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act

(OSHA). These standards, particularly part 1910 of the General

Standards and part 1926 of the Construction Standards should

be consulted.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement

of couplings. Immediately replace hose if any of those

conditions exist. Never repair a paint hose. Replace with a

conductive high-pressure hose.

• Do not spray outdoors on windy days.

• Always unplug cord from outlet before working on equipment

(electric models only).

IMPORTANT: The diaphragm pump is provided with a thermally

protected automatic reset. If an overload occurs the thermally

protected automatic reset disconnects the motor from the power

supply.

• The motor will restart without warning when the protector

automatically resets.

• Always disconnect the motor from the power supply before

working on the equipment.

• When the thermally protected automatic reset disconnects

the motor from the power supply, relieve pressure by turning

the PRIME/SPRAY valve to PRIME.

• Turn the pump ON/OFF switch to OFF.

WARNING: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials can

be harmful if inhaled or come in contact with the body.

Vapors can cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read all

instructions supplied with the mask to be sure it will provide

the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

WARNING: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Always wear appropriate gloves, eye protection, clothing and

a respirator or mask when painting.

• Do not operate or spray near children. Keep children away

from equipment at all times.

• Do not overreach or stand on an unstable support. Keep

eective footing and balance at all times.

© Titan Tool. All rights reserved. 3

NOTE: The cause of the overload should be corrected

before restarting. Refer to the Troubleshooting

section.

English

Page 4

Table of Contents

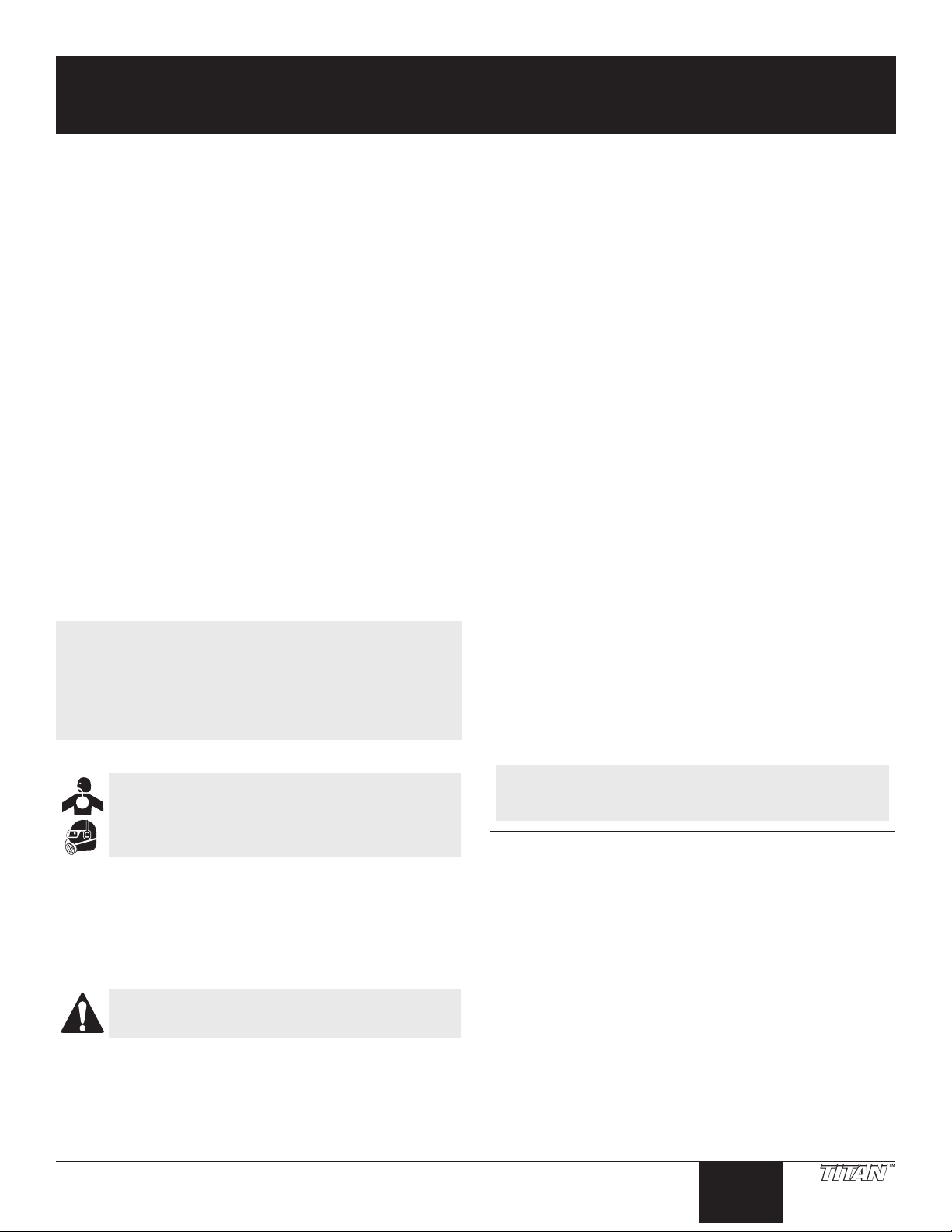

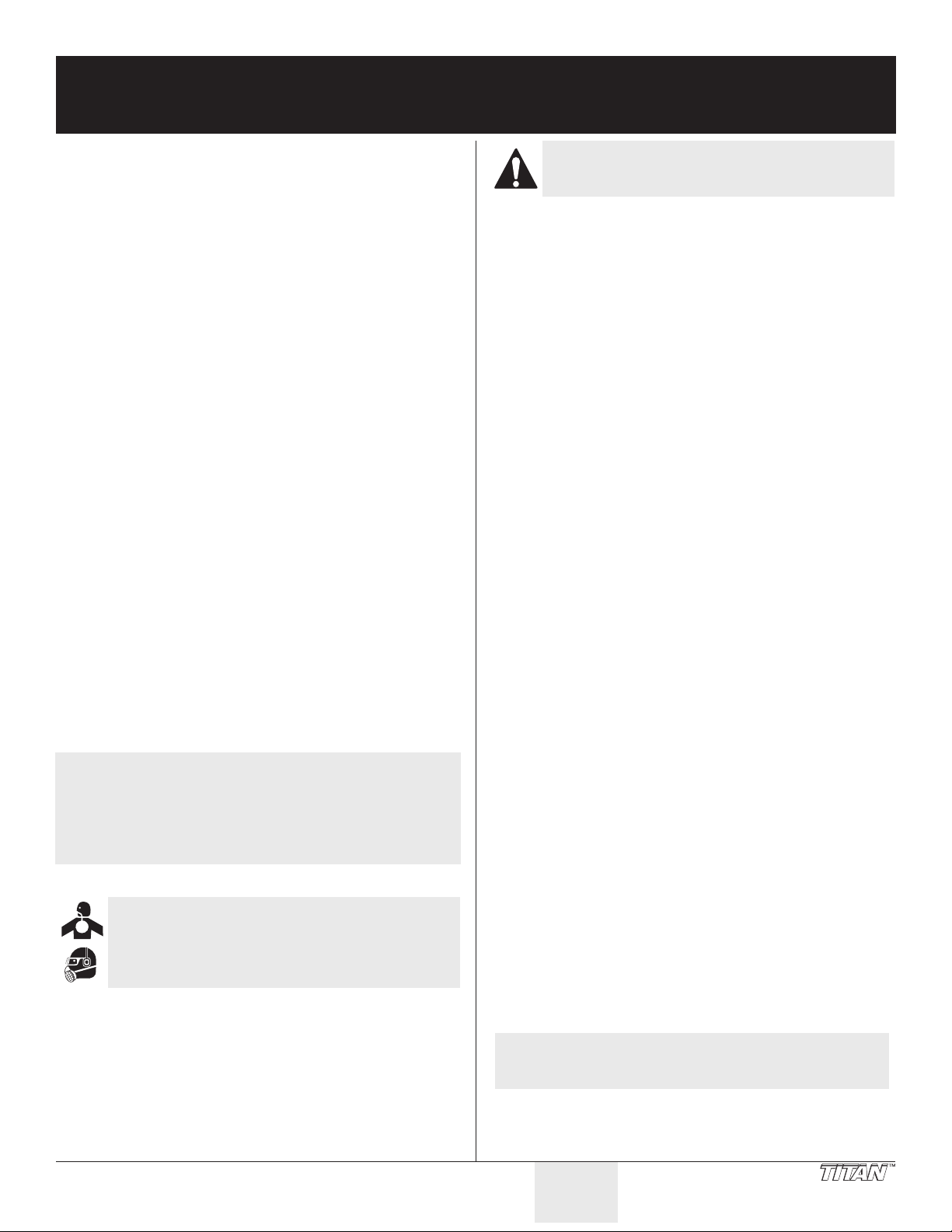

Ma

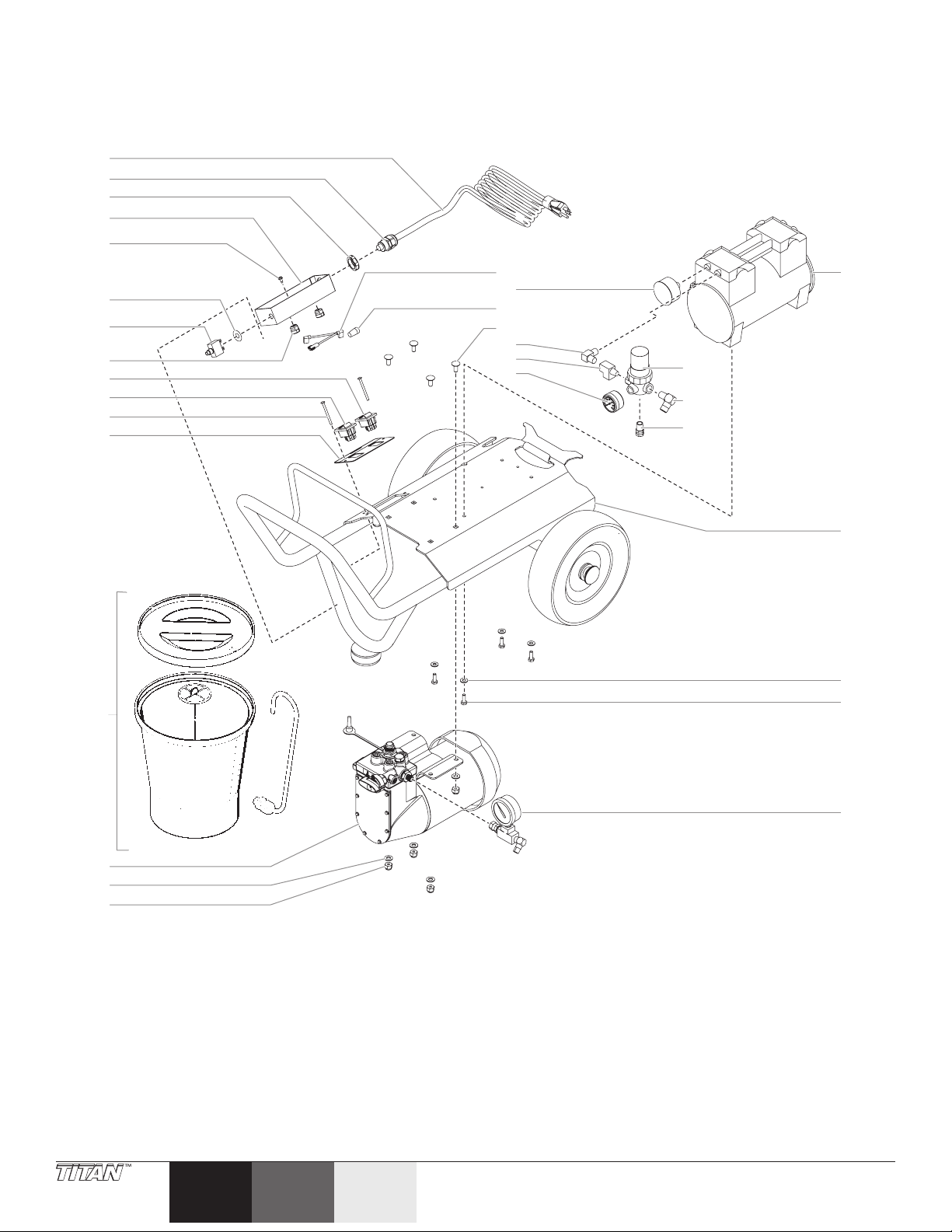

Diaphragm Pump

e

Air Pressure

C

Pressure Control Knob

Pump ON/OFF

terial

Hose

Standard Hose

terial

Safety Precautions ........................................................................2-3

Grounding Instructions .............................................................................. 3

General Description ........................................................................ 4

Setup ................................................................................................ 4

Operation ......................................................................................... 5

Priming the Pump ........................................................................................ 5

Painting ............................................................................................................ 5

Pressure Relief Procedure .......................................................................... 7

Spraying Technique ........................................................................ 7

Cleanup ............................................................................................ 8

Overnight Storage ........................................................................................ 8

Long Term Storage ..................................................................................8-9

Maintenance .................................................................................. 10

Removing and Cleaning the Inlet Valve .............................................10

Removing and Cleaning the Outlet Valve .........................................10

Troubleshooting ............................................................................ 11

Parts List ......................................................................................... 32

Warranty ........................................................................................ 39

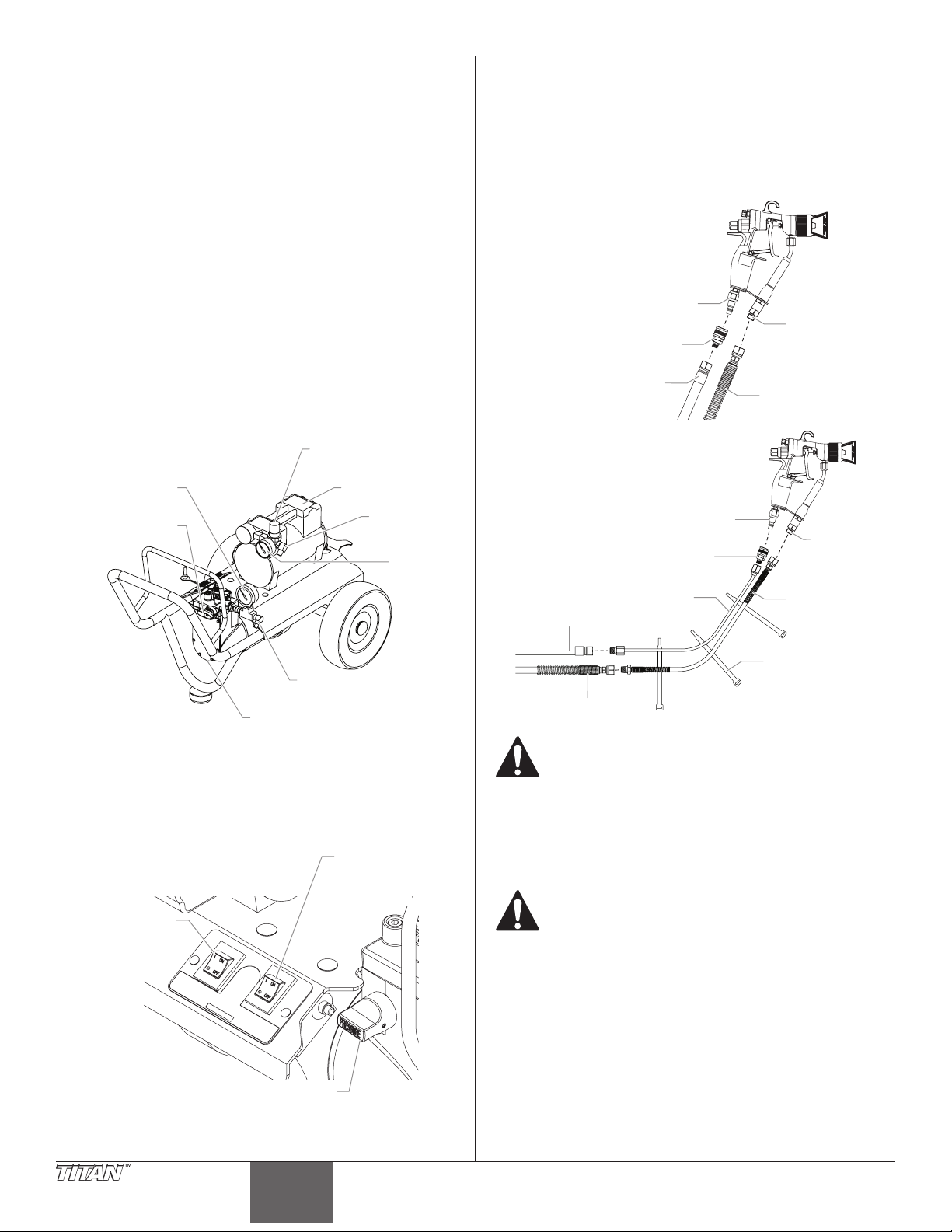

4. Using a wrench, attach a minimum of 50’ of 1/4” nylon airless

spray hose to the material outlet tting on the pump. Tighten

securely.

5. Attach the spray hose to the material inlet tting on the spray

gun. Using two wrenches (one on the gun and one on the

hose), tighten securely.

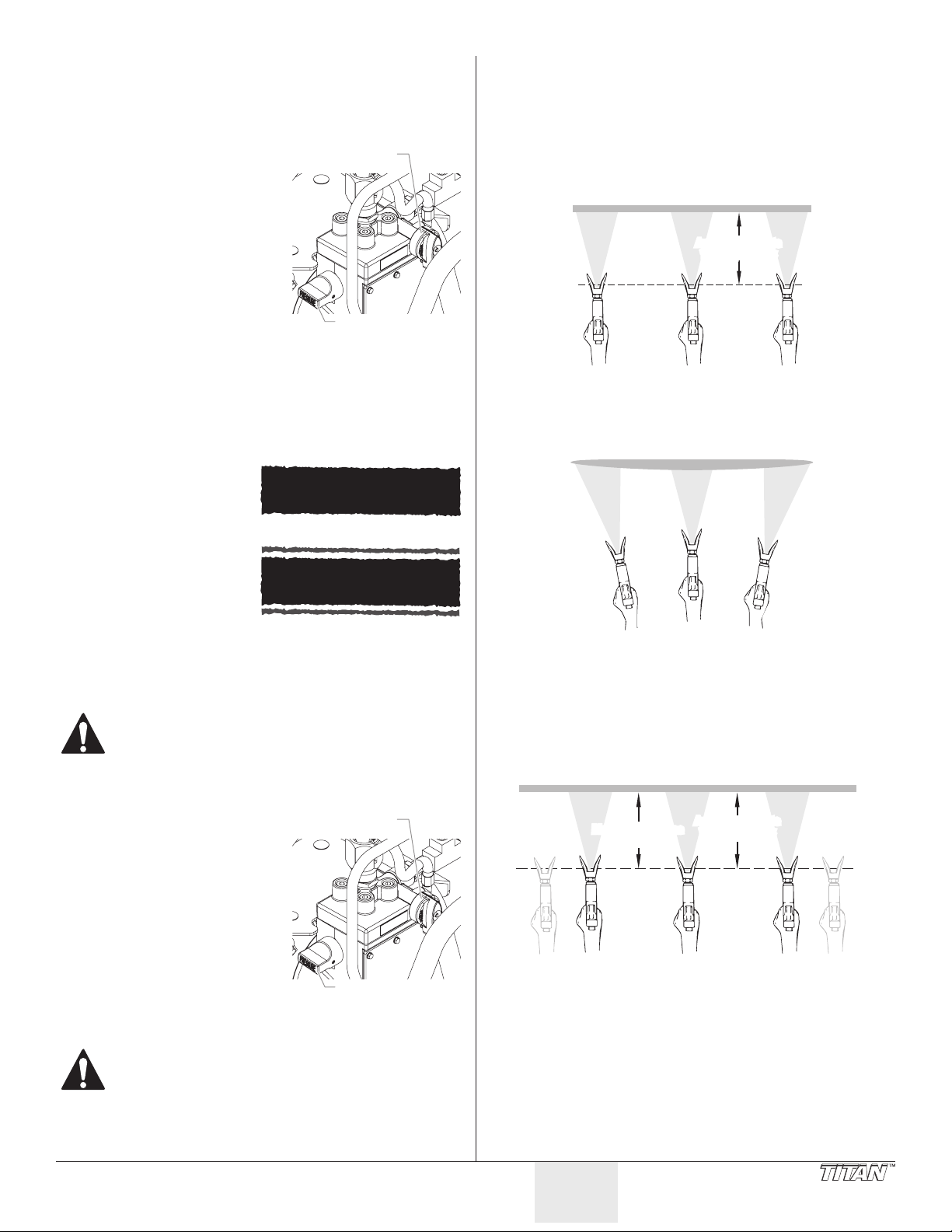

Conguration:

Air Inlet

Fitting

Coupling

Ma

Inlet

Fitting

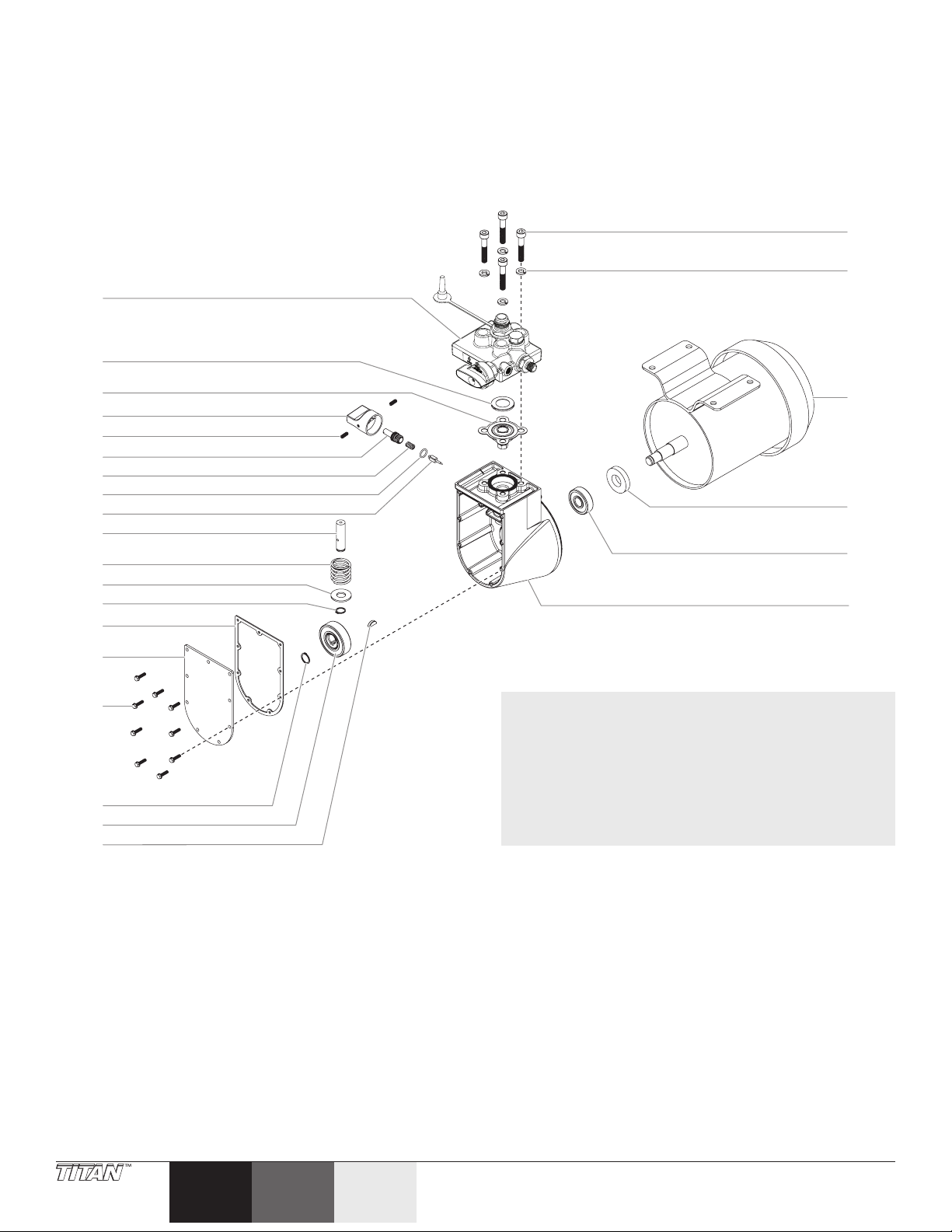

General Description

This ne nish spray system is versatile enough to use for low

pressure ne nish work as well as high pressure airless spraying. The

system includes a diaphragm paint pump and an air compressor that

work together to provide this versatility.

Regulator

terial Pressure

Gauge

PRIME/SPRAY

Valve

Material

Outlet Fitting

Air Compressor

Air Outlet

Fitting

Air

Pressur

Gauge

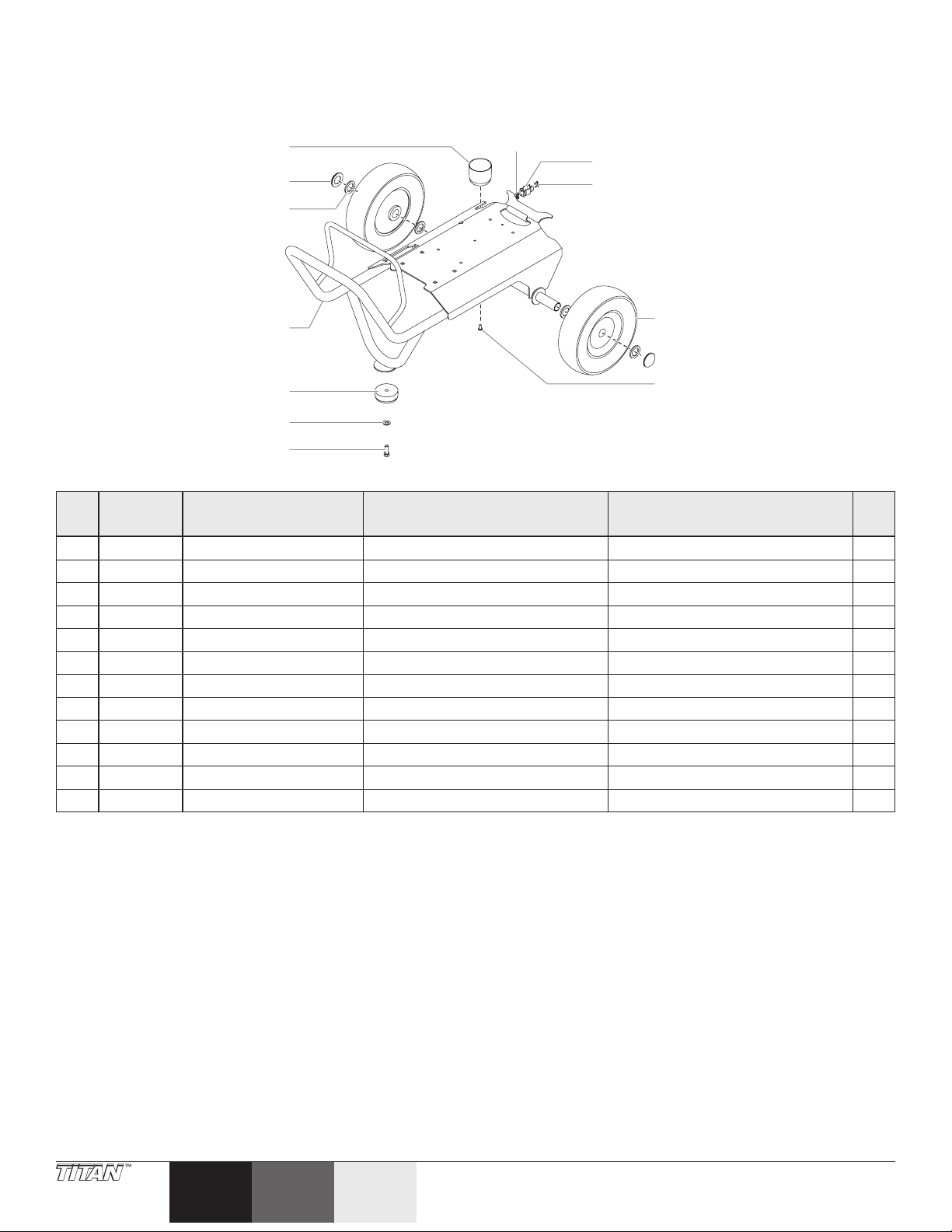

Setup

Use this procedure to set up the spray system.

1. Make sure the pump ON/OFF switch and the compressor ON/

OFF switch are in the OFF position.

Air Hose

Material

With Optional

Whip Hoses:

Air Inlet

Fitting

Coupling

Air Whip

Air Hose

Material Hose

Make sure all airless hoses and spray guns are

electrically grounded and rated for at least 2800 PSI

(19 MPa) fluid pressure.

6. Attach the air hose to the air outlet tting on the compressor.

Tighten securely.

7. Attach the air hose coupling to the air inlet tting on the spray

gun. Attach the air hose to the coupling. Tighten securely.

Hose

Straps

Ma

Inlet

Fitting

Material

Whip Hose

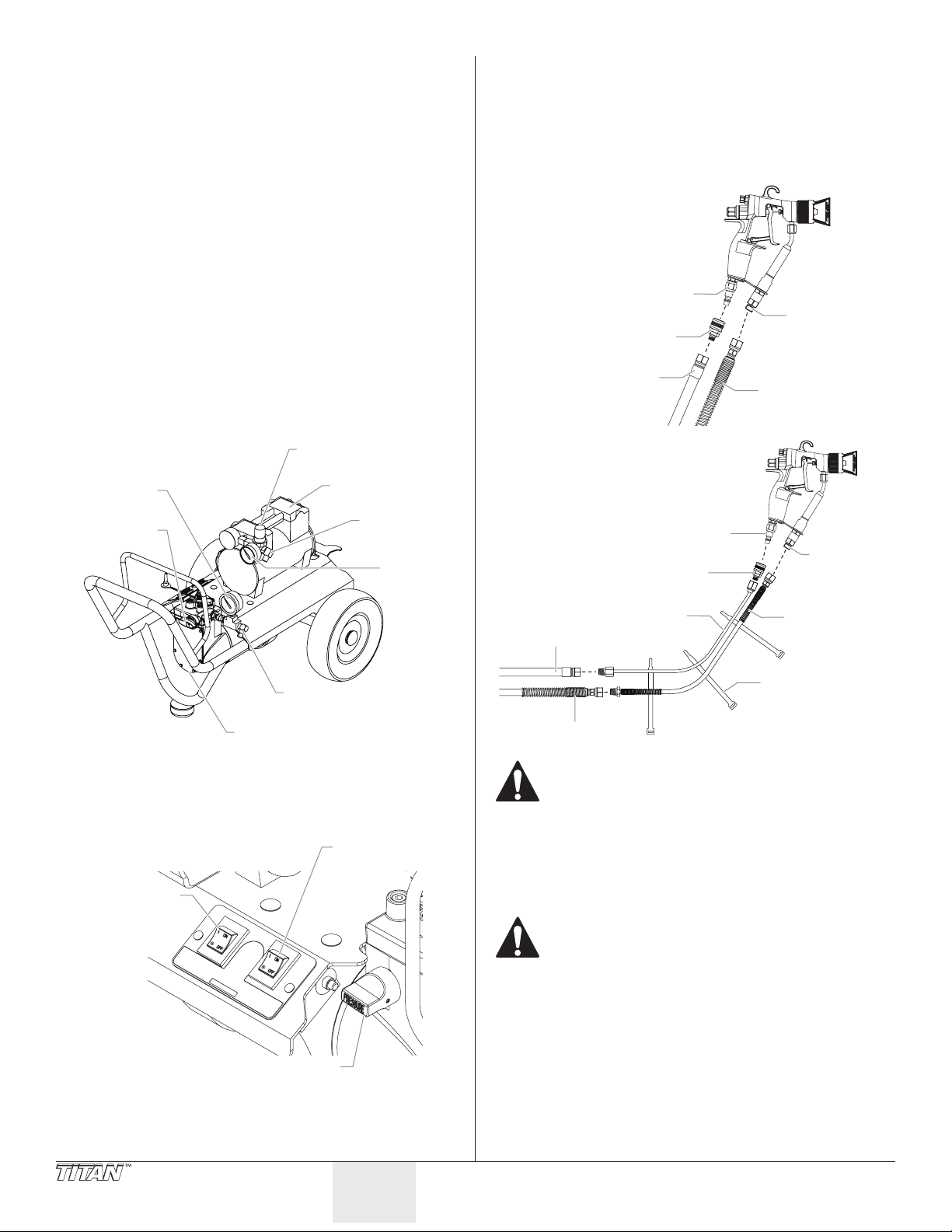

2. Make sure the pressure control knob is turned fully

3. Lock the gun by ipping the trigger lock into lock position

4 © Titan Tool. All rights reserved.

Switch

ompressor

ON/OFF

Switch

counterclockwise to its lowest pressure setting.

(see spray gun manual).

English

Reversing the hose connections could result in serious

injury. Make sure the airless spray hose is connected

from the diaphragm pump to the material inlet fitting

on the gun and the air hose is connected from the

compressor to the air inlet fitting on the gun.

8. Make sure the electrical service is 120V, 15 amp minimum.

9. Plug the power cord into a properly grounded outlet at least

25’ from the spray area.

IMPORTANT: Always use a minimum 12 gauge, three-wire

extension cord with a grounded plug. Never remove the third

prong or use an adapter.

Page 5

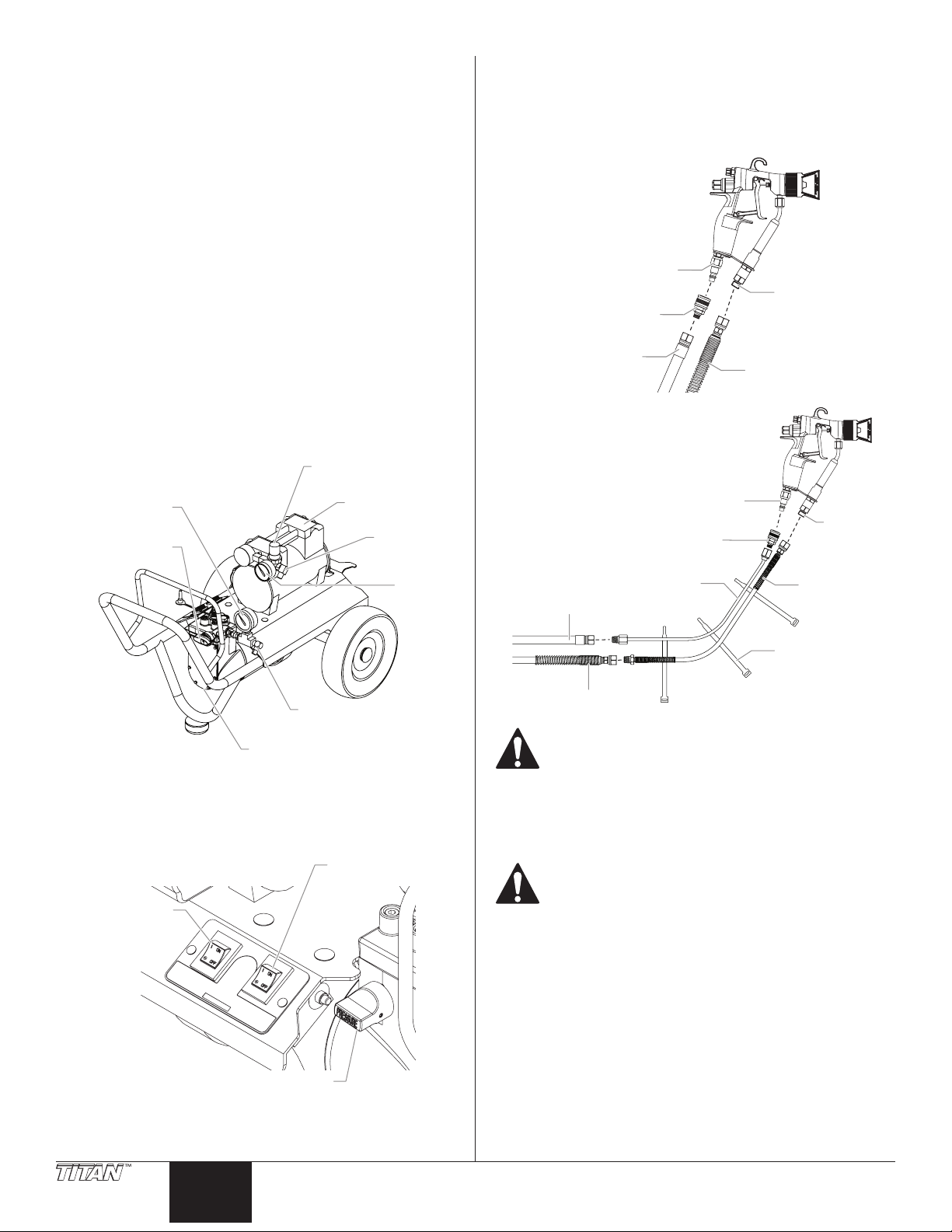

Operation

Valve

Return Tube Fitting

Inlet

Return

Tube

Inlet

Return Tube Fitting

Use the following procedures to operate the spray system.

Priming the Pump

Preparing to Prime

1. Fill the inlet valve with water or with a light household oil.

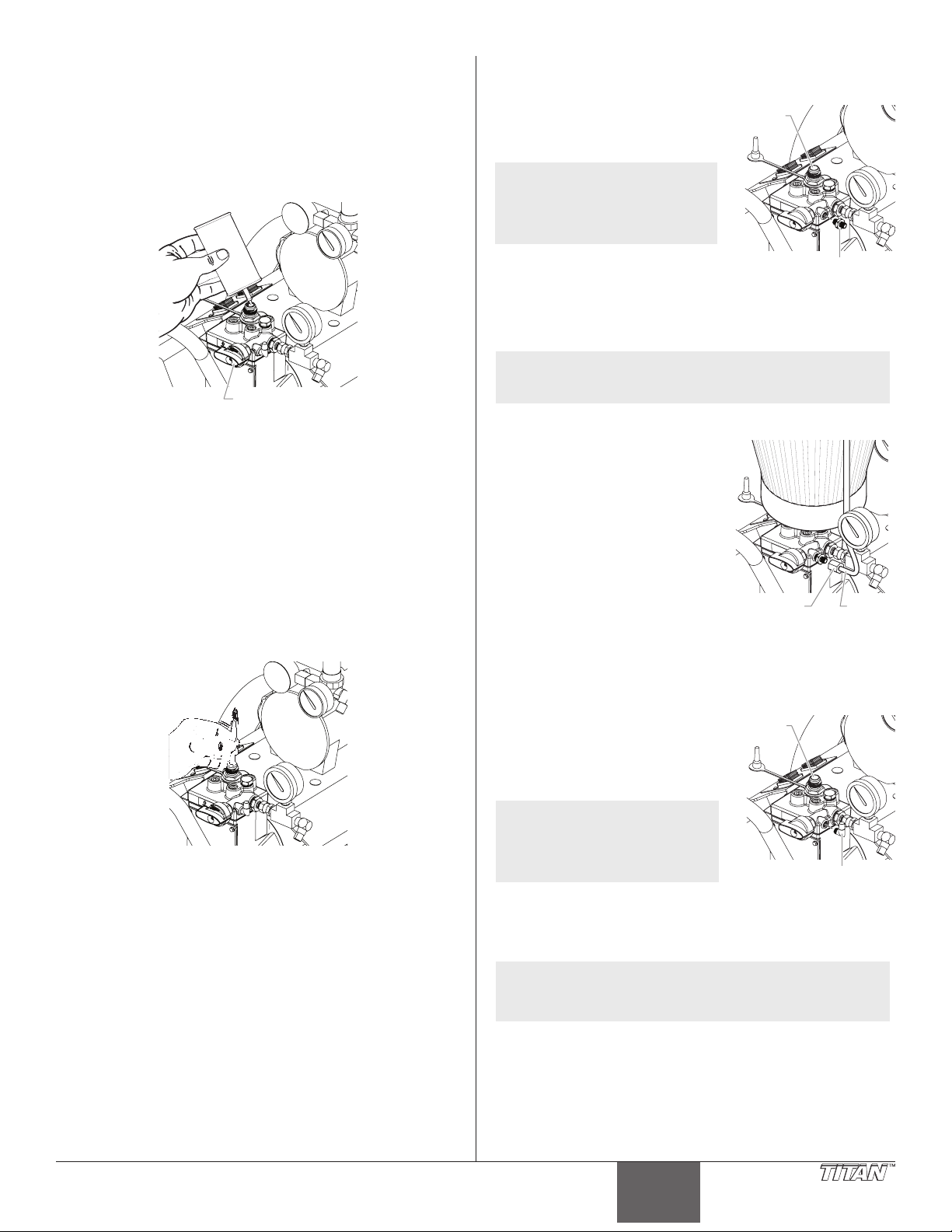

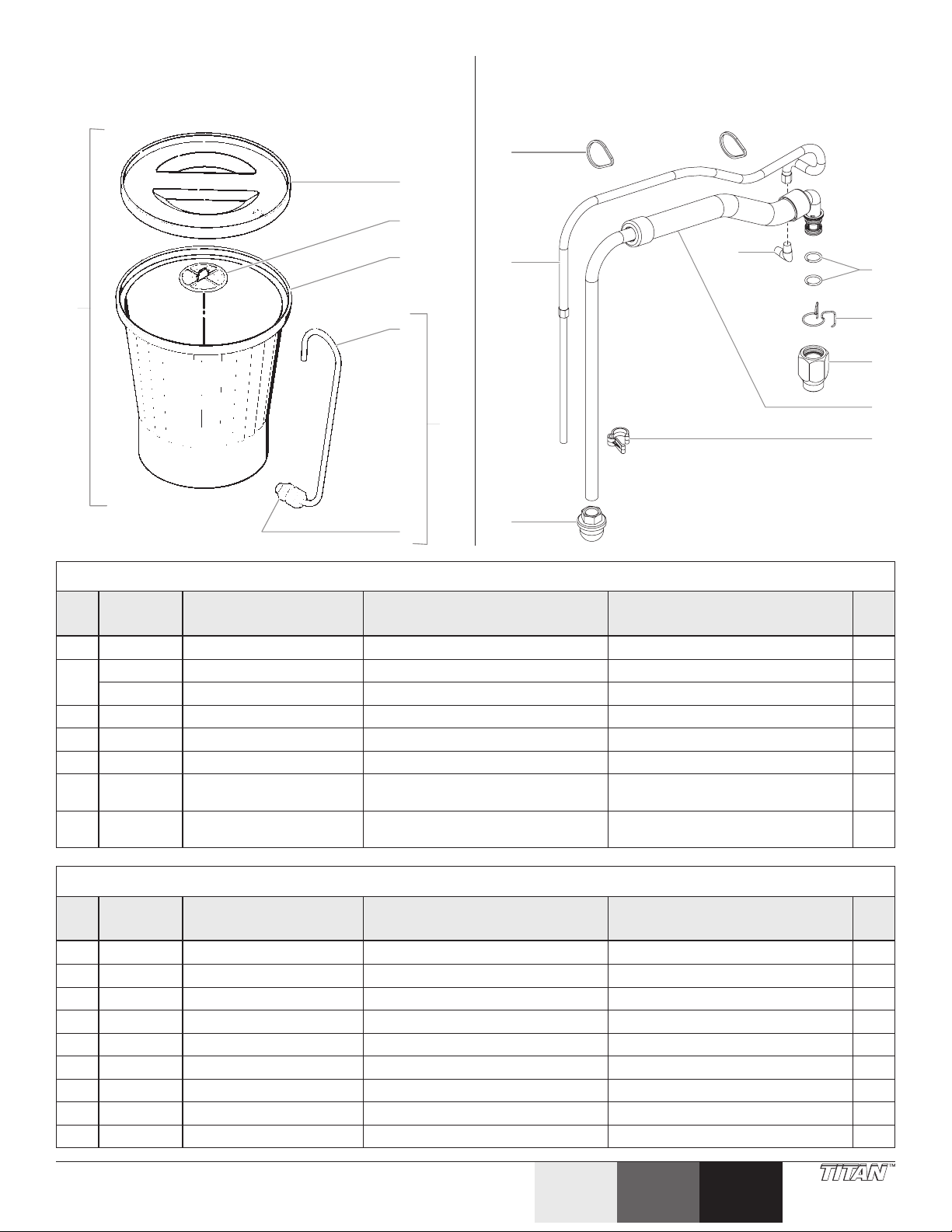

Mounting the Hopper Assembly

Use the following procedure to mount the paint hopper and attach

the return tube on a hopper unit.

1. Screw the return tube tting into

the return tube port on the side of

the pump.

NOTE: Do not over-tighten. Hand-

tighten only. Some threads

will be visible even when

fully tightened.

2. Align the bottom of the paint

hopper with the threaded inlet

valve on the paint pump block.

3. Turn the paint hopper clockwise to thread it onto the inlet

valve. Continue to turn the paint hopper until it is secure on

the inlet valve.

Valve

PRIME/SPRAY

2. Make sure that the PRIME/SPRAY valve is set to PRIME and that

the pressure control knob is turned counterclockwise to its

lowest pressure setting.

3. Turn on the pump by moving the pump ON/OFF switch to the

ON position.

4. Increase the pressure by turning the pressure control knob

clockwise 1/2 turn.

5. Force the inlet valve to open and close by pushing on it with

a screwdriver or the eraser end of a pencil. It should move up

and down about 1/16 of an inch. Continue until water or oil

is sucked into the pump. This will wet the moving parts and

break loose any old paint residue.

6. Put the palm of your hand over the inlet. Turn the pressure

control knob clockwise to its maximum setting. You should

feel suction coming from the inlet valve. If you do not, refer

to the “Removing and Cleaning the Outlet Valve” procedure in

the Maintenance section.

7. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

8. Turn the pump ON/OFF switch to OFF.

NOTE: Make sure the threads are straight and the hopper

4. Place the lter screen into the bottom of the paint hopper and

5. Make sure that the motor ON/OFF

6. Place the straight end of the return

7. Thread the nut on the return tube

8. Place the hook end of the return

turns freely on the inlet valve. Do not cross-thread.

snap it in position.

switch is turned to OFF.

tube into the return tube tting.

onto the return tube tting and

tighten until the return tube is

secure.

tube into the hole in the paint

hopper cover.

Nut

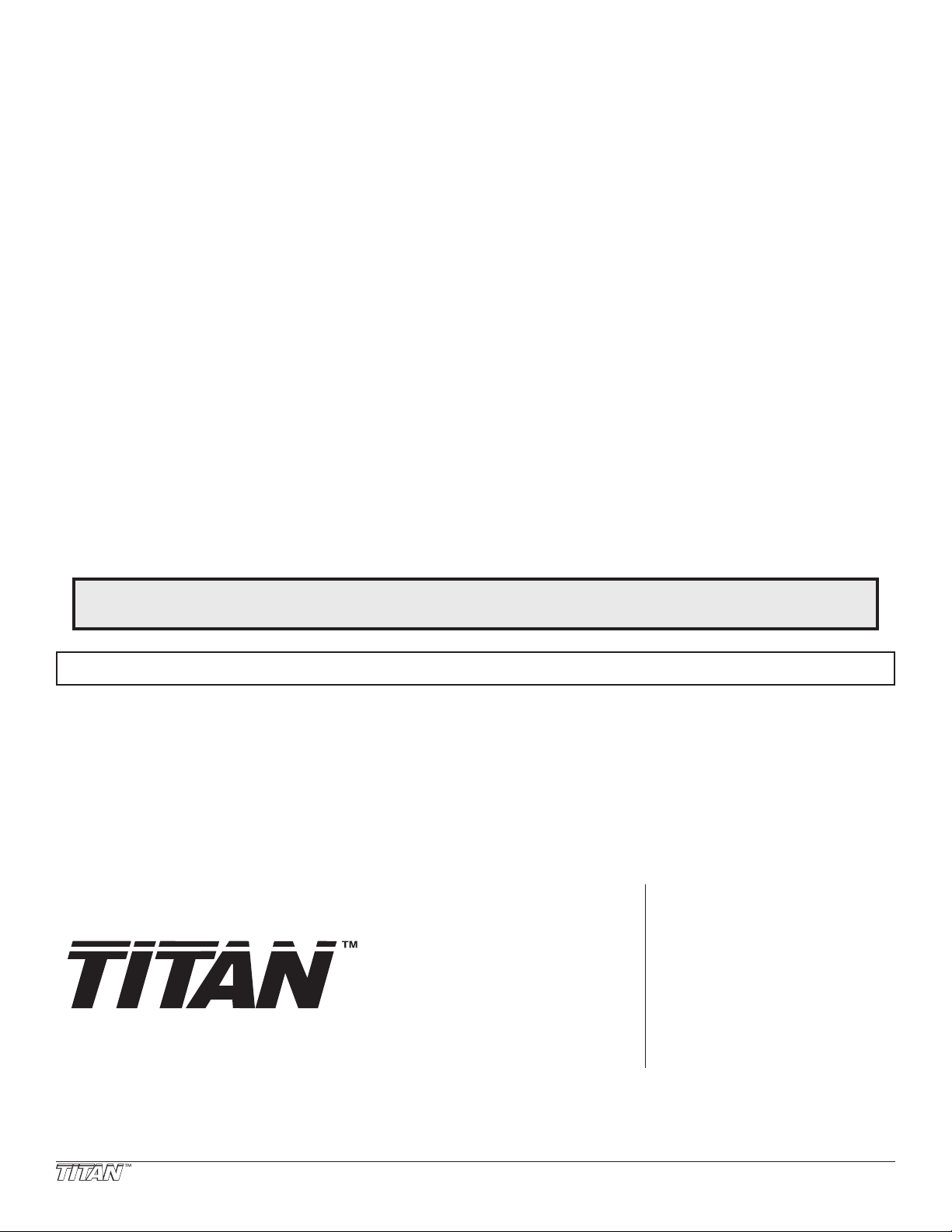

Attaching the Optional Suction Set

Use the following procedure to attach the suction set to a suction set

unit.

1. Remove the hopper return tube

tting. Screw the return tube tting

into the return tube port on the

side of the pump.

NOTE: Do not over-tighten. Hand-

tighten only. Some threads

will be visible even when

fully tightened.

2. Align the nut on the suction set

with the threaded inlet valve on the

pump block.

3. Thread the suction hose nut onto the inlet valve on the pump.

NOTE: Make sure the threads are straight and the nut turns

freely on the inlet valve. Do not cross-thread.

Valve

© Titan Tool. All rights reserved. 5

4. Thread the return tube onto the return tube tting on the

pump.

English

Page 6

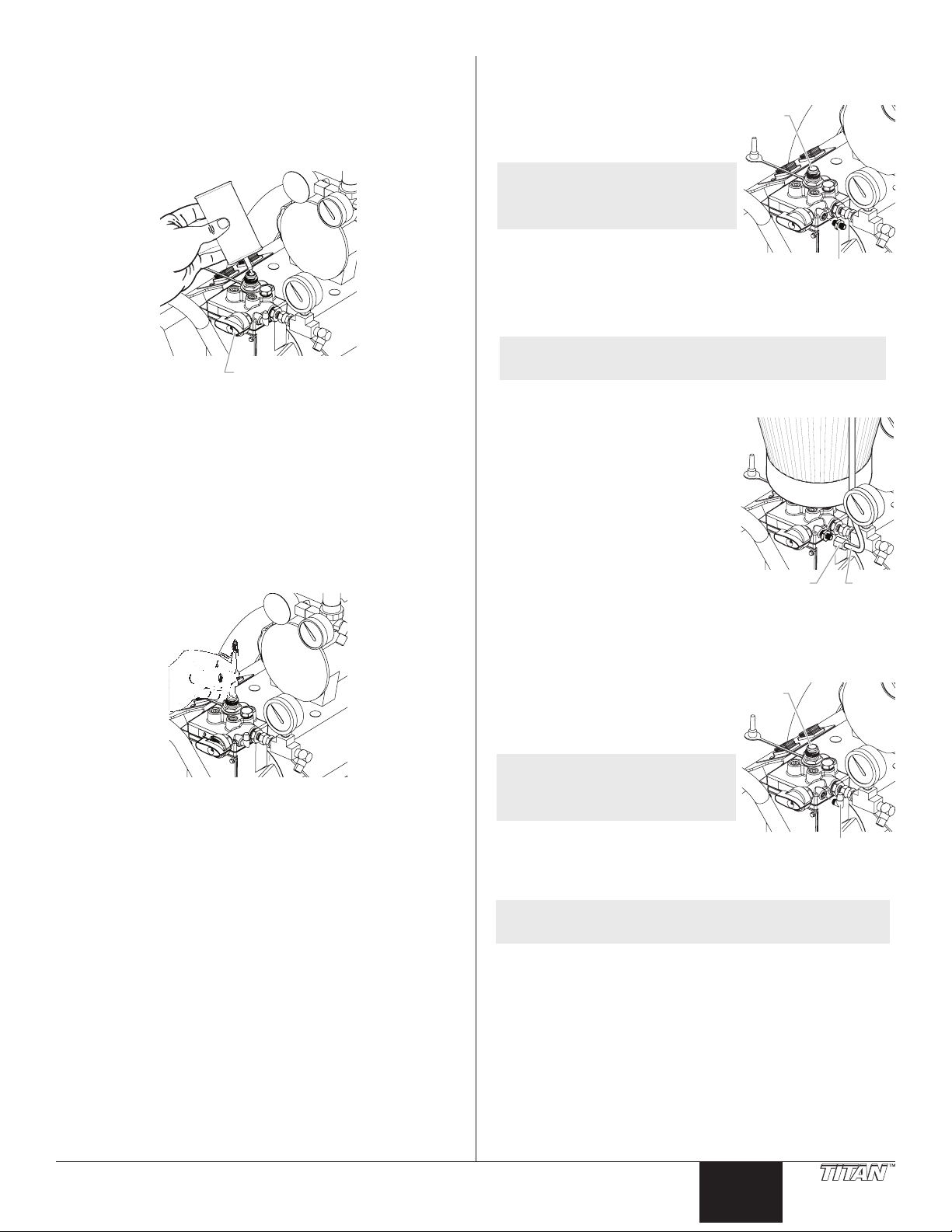

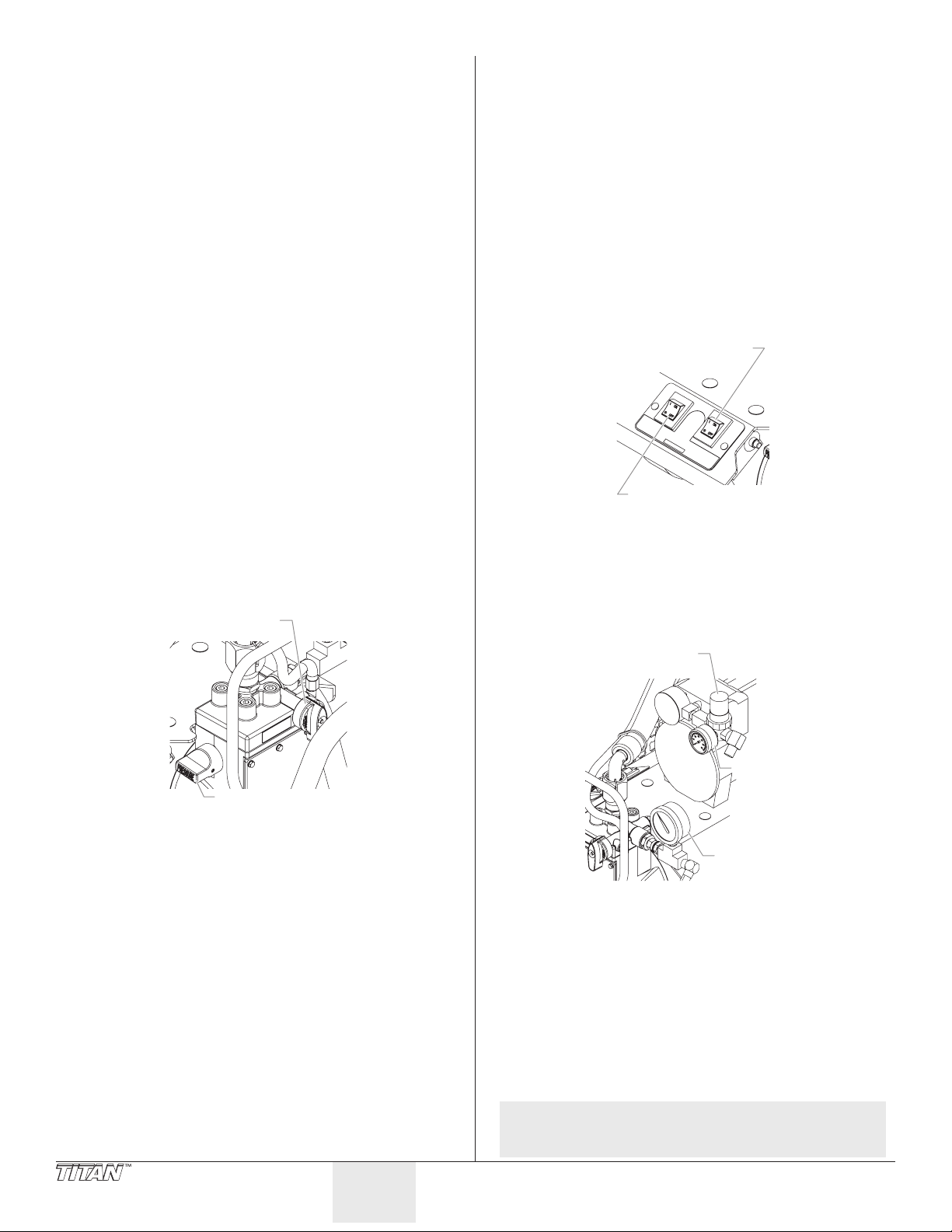

Priming with Hopper Assembly

PRIME/SPRAY

Control Knob

ON/OFF Switch

Pump ON/OFF

Air Pressure

1. Turn the pressure control knob counterclockwise to its lowest

pressure setting.

2. Remove the paint hopper cover and ll the paint hopper with

material or place the suction set into a bucket of material.

3. Turn the PRIME/SPRAY valve to PRIME.

4. Move the motor ON/OFF switch to ON.

5. Turn the pressure control knob clockwise to between half and

full pressure. Let the unit prime 1 to 2 minutes after material

begins to ow through the return tube.

IMPORTANT: Always reduce the pressure to zero before

changing the position of the PRIME/SPRAY valve. Failure to do

so may cause damage to the paint pump diaphragm.

IMPORTANT: If the pressure control knob is reduced to zero

and the PRIME/SPRAY valve is still on SPRAY while the sprayer is

operating, there will be high pressure in the hose and spray gun

until the PRIME/SPRAY valve is turned to PRIME or until the spray

gun is triggered to relieve the pressure.

Priming with Optional Suction Set

1. Place the suction set into a container of paint.

2. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

IMPORTANT: Always reduce the pressure to zero by triggering

the spray gun before changing the position of the PRIME/SPRAY

valve. Failure to do so may cause damage to the paint pump

diaphragm.

3. Turn the PRIME/SPRAY valve to PRIME.

Valve

Painting

The AirCoat spray system has two dierent painting modes. The

AirCoat mode is used for ne nish work with low to medium

viscosity materials (oil, stains, lacquers, etc...). The airless mode is

used for general painting with high viscosity materials (latex).

Painting in AirCoat Mode

Use the AirCoat mode for low-pressure ne nish work

(recommended pump pressure up to 1000 PSI).

1. Make sure that the airless spray hose is free of kinks and clear

of objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its lowest

setting.

3. Turn the compressor air pressure regulator counterclockwise

to its lowest setting.

4. Move the compressor ON/OFF switch to the ON position.

5. Move the pump ON/OFF switch to the ON position.

Switch

Compressor

6. Turn the PRIME/SPRAY valve to SPRAY.

7. Turn the pressure control knob clockwise until the material

pressure gauge reads 400 PSI. The paint hose should stien as

paint begins to ow through it.

8. Turn the air pressure regulator clockwise until the air pressure

gauge reads 20 PSI.

Pressure

4. Move the pump ON/OFF switch to the ON position.

5. Turn the pressure control knob clockwise to between half

and full pressure. Let the unit prime 1 to 2 minutes after paint

begins to ow through the return hose until no bubbles are

present.

6. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

7. Move the pump ON/OFF switch to the OFF position.

IMPORTANT: If the pressure control knob is reduced to zero

and the PRIME/SPRAY valve is still on SPRAY while the pump is

operating, there will be high pressure in the hose and spray gun

until the PRIME/SPRAY valve is turned to PRIME or until the spray

gun is triggered to relieve the pressure.

Regulator

Air

Air

Pressure

Pressure

Gauge

Gauge

Material

Material

Pressure

Pressure

Gauge

Gauge

9. Unlock the spray gun trigger.

10. Trigger the spray gun to bleed air out of the material hose.

11. When material reaches the spray tip, spray a test area to check

the spray pattern.

12. Adjust the spray pattern to the desired size and atomization.

a. Use the pressure control knob to control the ow of paint to the

gun.

b. Use the air pressure regulator to control the amount of atomization

air available to the gun.

c. Use the pattern adjustment knob on the gun to ne tune the spray

pattern.

NOTE: Refer to the spray gun Owner’s Manual for

information on the operation of the gun.

6 © Titan Tool. All rights reserved.

English

Page 7

Painting in Airless Mode

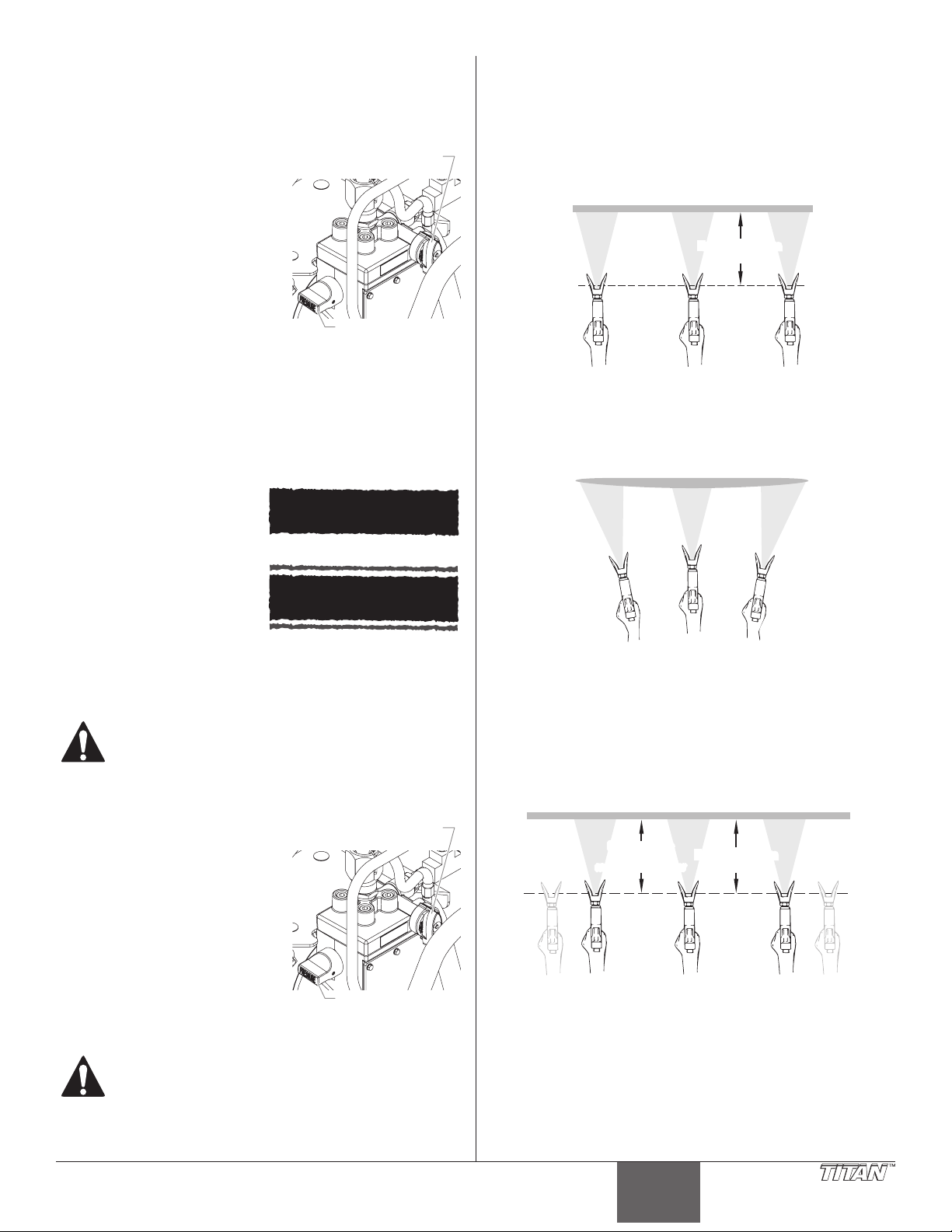

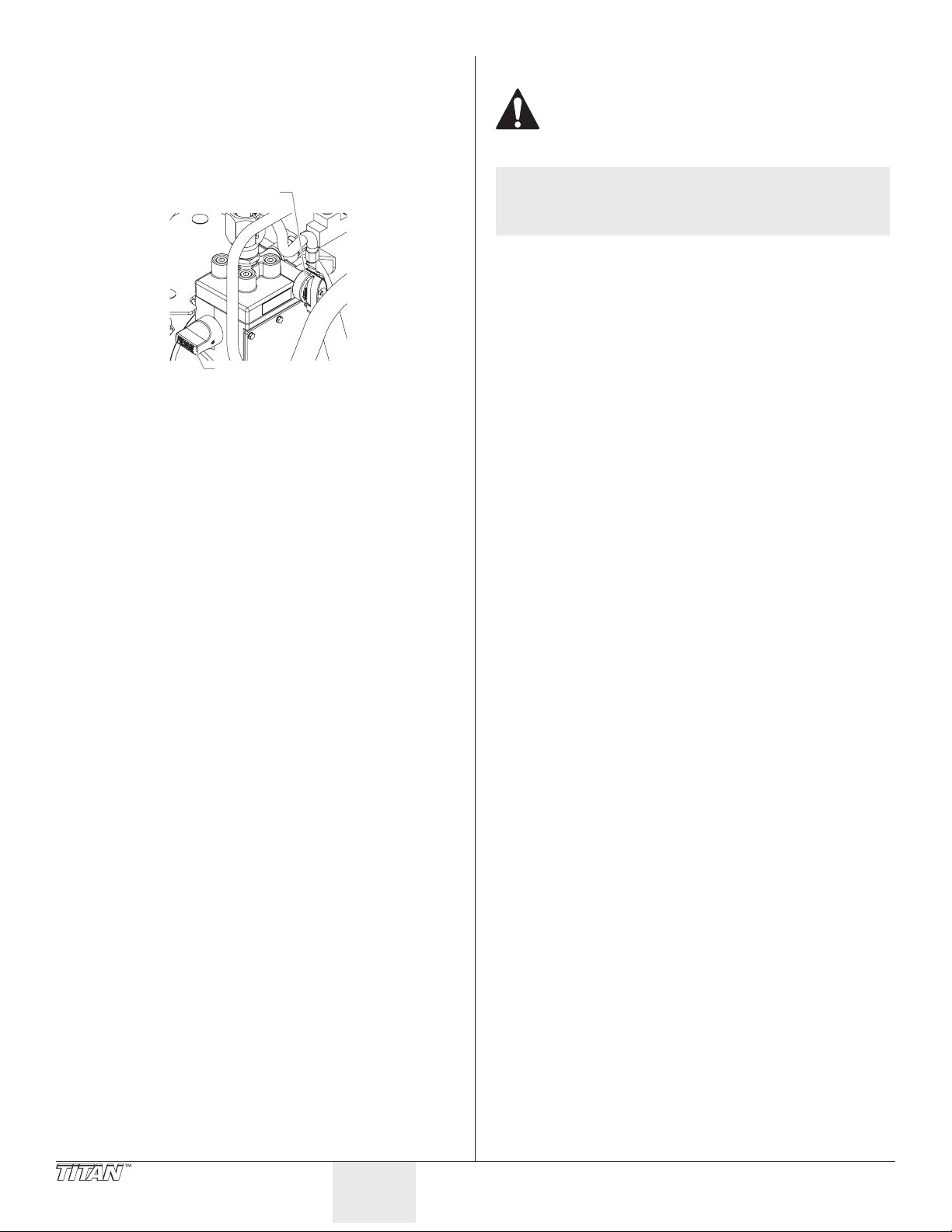

Paint tailing pattern

PRIME/SPRAY

Control Knob

Keep stroke smooth and at an even speed.

Even coat throughout

Heavy Coat

Do not ex wrist while spraying.

Light CoatLight Coat

Proper way to trigger the spray gun

Start stroke End strokePull trigger Release triggerKeep steady

Use the airless mode for general high-pressure spraying (pump

pressure from 500 to 2800 PSI).

1. Make sure that the airless spray hose is free of kinks and clear

of objects with sharp cutting edges.

2. Turn the pressure control

knob counterclockwise to its

lowest setting.

3. Turn the PRIME/SPRAY valve

to SPRAY.

4. Move the pump ON/OFF

switch to the ON position.

5. Turn the pressure control

knob clockwise to its highest

setting. The paint hose

should stien as paint begins

to ow through it.

6. Unlock the spray gun trigger.

7. Trigger the spray gun to

bleed air out of the material hose.

8. When material reaches the spray tip, spray a test area to check

the spray pattern.

9. Use the lowest pressure setting necessary to get a good spray

pattern. If the pressure is set too high, the spray pattern will

be too light. If the pressure is set too low, tailing will appear

or the paint will spatter out in “gobs” rather than in a ne

spray.

PRIME/SPRAY

Valve

Pressure

Control Knob

Spraying Technique

The key to a good paint job is an even coating over the entire surface.

This is done by using even strokes. Keep your arm moving at a

constant speed and keep the spray gun at a constant distance from

the surface. The best spraying distance is 10 to 12 inches between

the spray tip and the surface.

Approximately

10 to 12 inches

Keep the spray gun at right angles to the surface. This means moving

your entire arm back and forth rather than just exing your wrist.

Good spray pattern

Pressure Relief Procedure

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for

cleanup.

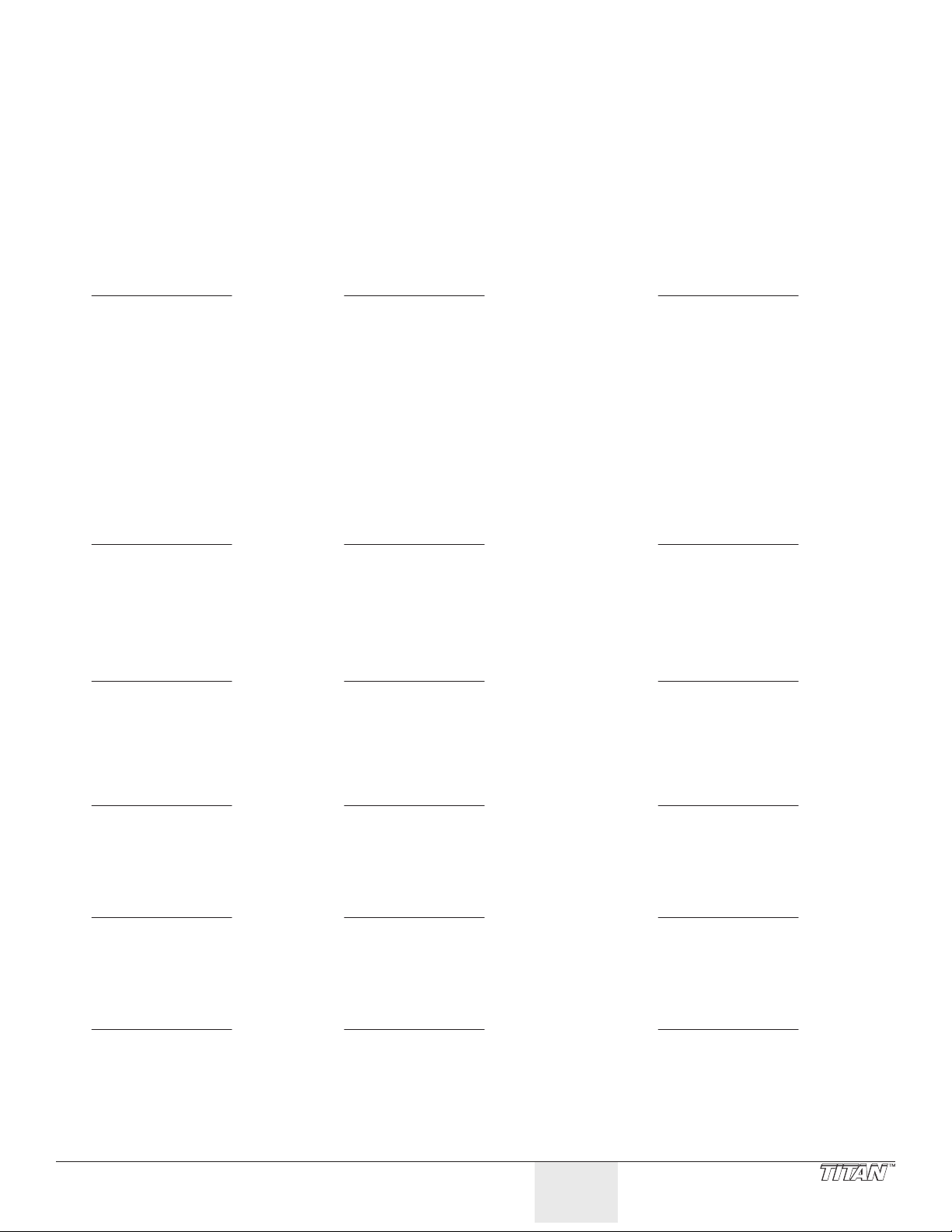

1. Turn the pressure control

knob counterclockwise to its

lowest setting.

2. Turn the PRIME/SPRAY valve

to the PRIME position.

3. Trigger the gun to remove

any pressure that still may be

in the hose.

4. Lock the gun by ipping the

trigger lock into lock position

(see spray gun manual).

Injection hazard. Do not spray without the tip guard

in place. NEVER trigger the gun unless the tip is

completely turned to either the spray or the unclog

position. ALWAYS engage the gun trigger lock before

removing, replacing or cleaning tip.

Valve

Pressure

Keep the spray gun perpendicular to the surface, otherwise one end

of the pattern will be thicker than the other.

The spray gun should be triggered by turning it on and o with each

stroke. This will save paint and avoid paint buildup at the end of the

stroke. Do not trigger the gun during the middle of a stroke. This will

result in an uneven spray and splotchy coverage.

Keep stroke

even

Aproximately

10 to 12 inches

Overlap each stroke by about 30%. This will ensure an even coating.

When you stop painting, lock the gun trigger lock, turn the pressure

control knob counterclockwise to its lowest setting and set the

priming knob to PRIME. Turn the motor switch to OFF and unplug

the sprayer.

If you expect to be gone more than 1 hour, follow the short term

clean up procedure described in the Cleanup section of this manual.

© Titan Tool. All rights reserved. 7

English

Page 8

Cleanup

PRIME/SPRAY

Control Knob

Long-Term Storage

Overnight Storage

Shutdown

1. Turn the pressure control knob counterclockwise to the

minimum setting.

2. Turn the PRIME/SPRAY valve to PRIME.

Valve

Pressure

3. Move the pump ON/OFF switch to the OFF position.

4. Move the compressor ON/OFF switch to the OFF position.

5. Wait a couple seconds, then trigger the gun into the material

container to release built up uid pressure from the pump and

air pressure from the compressor.

6. Lock the gun by ipping the trigger lock into lock position

(see spray gun manual).

7. Unplug the unit.

8. For latex materials only, pour 1/2 cup water slowly on the

top of the paint to prevent the paint from drying. For other

materials, seal the material container keeping the return hose

in the paint.

9. Wrap the spray gun assembly in a damp cloth and place it in a

plastic bag. Seal the bag shut.

10. Place the unit in a safe place out of the sun for short-term

storage.

Startup

1. Remove the gun from the plastic bag.

2. Stir the water into the paint for latex materials. Remove the

cover from the material container and stir the paint for all

other materials.

3. Perform the appropriate procedure in the “Painting” section of

this manual for the type of spraying that will be performed.

Do not allow paint to build up on the motor or the

motor will overheat. Do not allow flammable solvents

to come in contact with the motor or they could ignite.

NOTE: If spraying with latex paint, use warm soapy water

for cleaning. If using oil or alkyd-based paints, use

mineral spirits or paint thinner.

IMPORTANT: Do not use mineral spirits or paint thinner on latex

paint, or the mixture will turn into a jelly-like substance which is

difficult to remove.

Clearing the Paint Hopper

Use the following procedure to clear the material out of the paint

hopper of a hopper unit.

1. Lock the gun by ipping the trigger lock into lock position

(see spray gun manual).

2. Turn the pressure control knob counterclockwise to the

minimum setting.

3. Turn the PRIME/SPRAY valve to PRIME.

4. Move the motor ON/OFF switch to OFF.

5. Direct the return tube into the original material container.

6. Move the motor ON/OFF switch to ON.

7. Turn the pressure control knob to 1/2 maximum pressure.

This will draw the remaining material in the paint hopper

through the pump, up the return tube, and into the material

container.

8. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

9. Trigger the gun to relieve pressure and lock the gun.

10. Remove the spray tip and guard and place them into a

container of water or appropriate solvent for the type of

material with which you are painting.

11. Fill the paint hopper with water or an appropriate solvent for

the type of material with which you are painting.

12. Direct the return tube into a waste bucket.

13. Increase the pressure to 1/2 the maximum pressure. Let the

water or solvent circulate for 2-3 minutes to ush material out

of the pump, the paint hopper, and the return tube.

8 © Titan Tool. All rights reserved.

English

Page 9

Clearing the Suction Tube (optional)

PRIME/SPRAY

Control Knob

Valve

1. Turn the pressure control

knob counterclockwise to the

minimum setting.

2. Turn the PRIME/SPRAY valve to

PRIME.

3. Move the pump ON/OFF switch

to the OFF position.

4. Move the compressor ON/OFF

switch to the OFF position.

5. Wait a couple seconds, then

trigger the gun into the material

container to release built up uid

pressure from the pump and air

pressure from the compressor.

6. Lock the gun by ipping the trigger lock into lock position

(see spray gun manual).

7. Remove the suction hose from the material and hold it above

a bucket of water or solvent. Leave the return hose in the

material bucket.

IMPORTANT: Do not use mineral spirits or paint thinner on latex

paint, the mixture will turn into a jelly-like substance that is

difficult to remove.

8. Move the pump ON/OFF switch to the ON position.

9. Turn the pressure control knob to 1/2 maximum pressure.

This will draw the remaining material in the suction hose

through the pump, down the return hose and into the

material bucket.

10. Turn the pressure control knob counterclockwise to the

minimum setting.

11. Remove the spray tip and guard and place them into a

container of the appropriate solvent.

12. Place the attached suction hose and return hose into the

container of water or appropriate solvent.

13. Increase the pressure to 1/2 the maximum pressure. Let the

water or solvent circulate for 2-3 minutes to ush paint out of

the pump, the suction hose and the return hose.

Pump ON/OFF

Switch

Compressor

ON/OFF Switch

Clearing the Paint Hose

1. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

2. Turn the PRIME/SPRAY valve

to SPRAY.

3. Unlock the spray gun trigger.

4. Carefully trigger the gun with

the spray tip removed against

the inside of the material

container.

5. Turn the pressure control

knob slowly clockwise until

material starts to ow into

the container. As soon as

the water or solvent starts to

emerge from the spray gun,

release the trigger.

6. Change to clean water or solvent and continue circulating for

another 5 minutes to thoroughly clean the hose, pump and

spray gun.

7. Turn the pressure control knob counterclockwise to its lowest

setting.

8. Turn the PRIME/SPRAY valve to PRIME.

9. Trigger the gun into the water or solvent container to release

built up uid pressure from the pump.

10. Lock the gun by ipping the trigger lock into lock position

(see spray gun manual).

11. Move the pump ON/OFF switch to the OFF position.

Valve

Pressure

Final Cleanup

1. Remove the hopper assembly or optional suction set from the

inlet valve.

2. Clean the threads of the inlet valve with a damp cloth.

3. Fill the inlet valve with water or with a light household oil.

PRIME/SPRAY

4. Make sure that the PRIME/SPRAY valve is set to PRIME and that

the pressure control knob is turned counterclockwise to its

lowest pressure setting.

5. Turn on the pump by moving the pump ON/OFF switch to the

ON position.

6. Increase the pressure by turning the pressure control knob

clockwise 1/2 turn.

7. Turn the PRIME/SPRAY valve to SPRAY to distribute the oil.

NOTE: Proper cleaning and oiling of the pump after use are

the most important steps to perform to insure proper

operation after storage.

8. Turn the pressure control knob counterclockwise to its lowest

setting.

9. Turn the PRIME/SPRAY valve to PRIME.

10. Unlock and trigger the gun to remove any pressure that may

still be in the hose.

11. Lock the gun by ipping the trigger lock into lock position

(see spray gun manual).

12. Turn o the pump by moving the pump ON/OFF switch to the

OFF position.

13. Remove the material hose and air hose from the spray gun

using two adjustable wrenches. Refer to the spray gun

Owner’s Manual for gun cleaning instructions.

14. Wipe the entire unit, hose, and gun with a damp cloth to

remove accumulated paint.

© Titan Tool. All rights reserved. 9

English

Page 10

Maintenance

Ball stop

Follow these procedures when encountering problems indicated in

the troubleshooting section.

Removing and Cleaning the Inlet Valve

1. Perform the Pressure Relief Procedure, turn o and unplug the

unit.

2. Remove the inlet valve assembly using a 27 millimeter socket

or box end wrench.

3. Test movement of the valve by pushing on it from the open

end of the valve housing with a screwdriver or the eraser end

of a pencil. It should move about 1/16 of an inch. If it does

not move, it should be cleaned or replaced.

NOTE: The inlet valve must be oiled

after every job. This will reduce

or eliminate priming problems

the next time the unit is used

as well as extend the life of the

valve.

4. Thoroughly clean the valve assembly with

water or the appropriate solvent. Use a small brush.

5. If the valve has been properly cleaned and water drips out of

the bottom, the valve is worn and needs to be replaced. A

properly seated valve lled with water and held vertically will

not drip.

6. Install a new or cleaned valve in the pump block and then ll

the valve with light oil or solvent.

Removing and Cleaning the Outlet Valve

It may be necessary to remove and clean the outlet valve or to

replace parts inside the valve worn out through normal use.

1. Remove the outlet valve nut with a wrench.

2. Remove and clean the ball stop and small spring inside the

valve using a wire hook or tweezers. Replace the spring if it is

broken or worn.

NOTE: This spring is manufactured to a very specic

tension. Do not stretch the spring. Do not put in

an unauthorized substitute. See the paint pump

assembly parts diagram for the proper replacement

part number.

3. Remove the seat and ball assembly.

4. Clean all parts thoroughly. If the ball or seat show any sign of

wear or damage, replace them with new parts. This carbide

ball must seal tightly against its seat for the valve to function

properly.

5. Cover all parts with a thin coat of light oil before reassembling.

6. Drop in the valve ball.

7. Insert the protector and spring and replace the valve body.

Be sure that the O-ring is positioned properly and that the

tongue on the cap ts inside the spring.

8. Tighten the valve body securely with an adjustable wrench.

Do not over-tighten.

Nut

O-ring

Spring

Ball

Seat

Seal

NOTE: Wear on the ball is almost impossible to detect

visually. To test for a worn outlet valve assembly,

turn the pressure control knob clockwise to its

highest setting and run water only through the

pump for 10 to 15 minutes without triggering the

gun.

If the valve is defective, the end cap will get very hot

to the touch. If it is functioning properly, it will stay

approximately the same temperature as the water

running through it.

10 © Titan Tool. All rights reserved.

English

Page 11

Troubleshooting

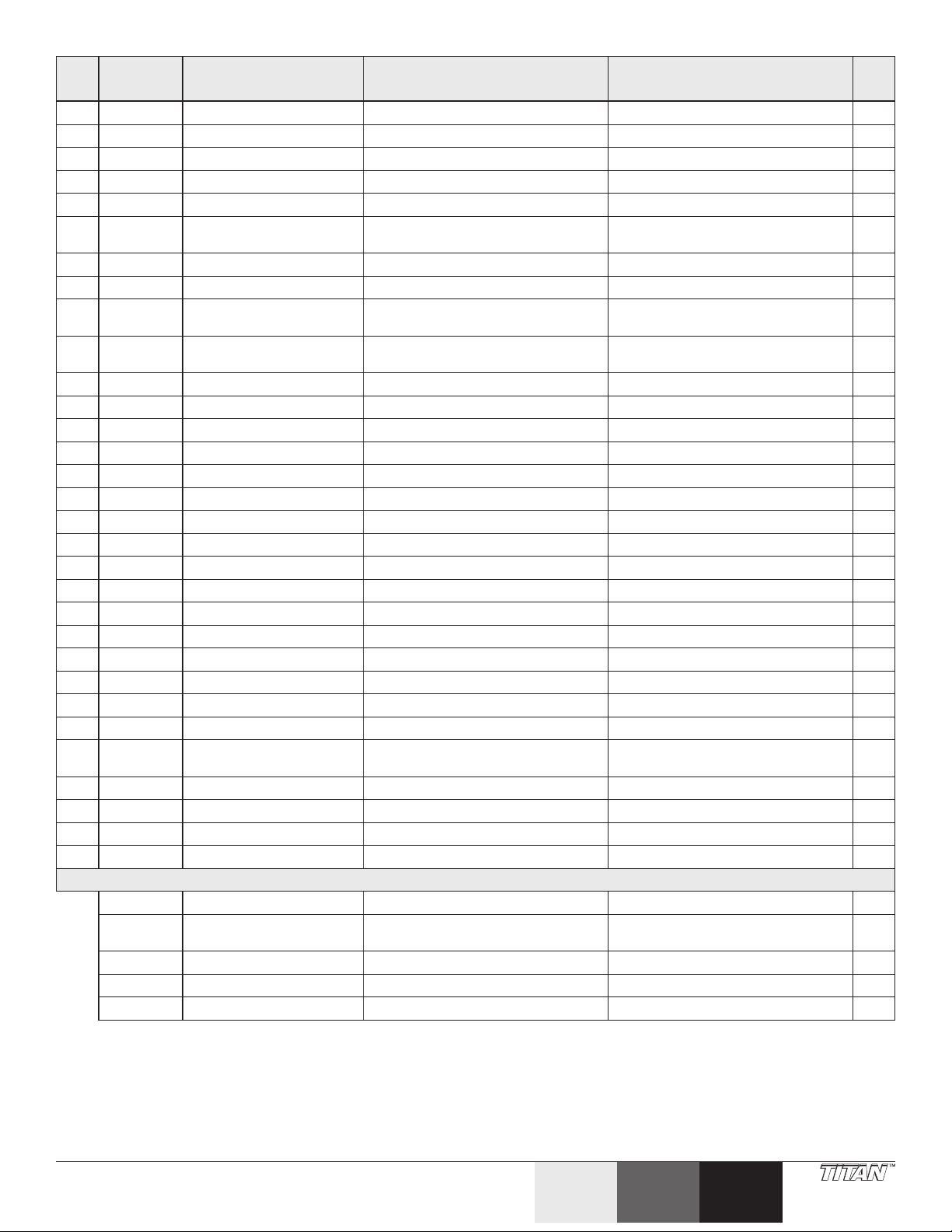

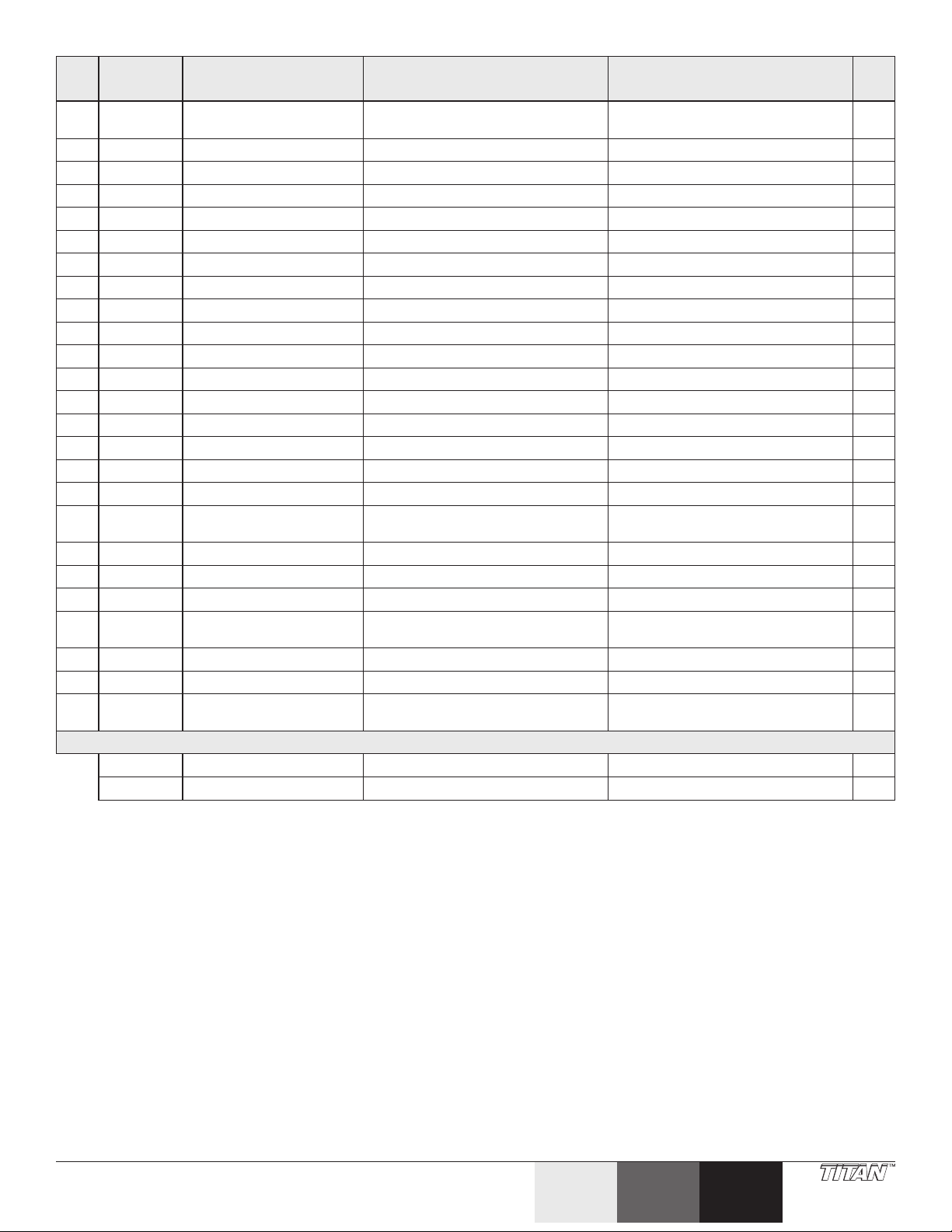

Problem

A. The unit does not start up.

B. The pump starts up but does

not draw in paint when the

PRIME/SPRAY valve is set to

PRIME.

C. The pump draws up paint but

the pressure drops when the

gun is triggered.

D. The paint pattern is tailing.

E. The thermal overload tripped

and shut o the pump.

F. Compressor does not start.

G. Compressor starts but not

enough air.

Cause

1. The unit is not plugged in.

2. The ON/OFF switch is set to OFF.

3. A fuse is blown in the unit.

4. Low or no voltage is coming from the wall

plug.

5. The unit was turned o while still under

pressure.

6. The extension cord is damaged or has too low

a capacity.

7. The thermal overload on the unit is tripped.

8. There is a problem with the motor.

1. The pump will not prime properly or has lost

prime.

2. The paint bucket is empty or the suction hose

is not totally immersed in the paint.

3. The suction lter is clogged.

4. The suction hose is loose at the inlet valve.

5. The inlet valve is stuck.

6. The outlet valve is stuck.

7. The PRIME/SPRAY valve is plugged.

8. The inlet valve is worn or damage.

9. There is a problem with the diaphragm.

10. The hydraulic oil level is low or empty.

1. The spray tip is worn.

2. The suction set lter is clogged.

3. The gun or spray tip lter is plugged.

4. The paint is too heavy or coarse.

5. The outlet valve assembly is dirty or worn.

6. The inlet valve assembly is damaged or worn.

1. The uid pressure is set too low.

2. The air pressure is set too low.

3. The gun, the tip, or the suction lter is

plugged.

4. The suction hose is loose at the inlet valve.

5. The tip is worn.

6. The paint is too thick.

1. The motor overheated.

2. The extension cord is too long or is too small

a gauge.

3. Paint has built up on the motor.

4. The motor was started while the unit was

under pressure.

5. The unit was sitting in the hot sun.

1. The compressor ON/OFF switch is in the OFF

position.

2. Compressor ON/OFF switch is faulty.

3. Compressor is faulty.

4. Relief hole under air regulator is blocked.

1. Air regulator setting is too low.

2. Paint is too thick.

3. Closed air valve on gun.

4. Faulty pressure relief valve.

Solution

1. Plug the unit in.

2. Turn the ON/OFF switch to ON.

3. Replace the blown fuse with the proper replacement.

4. Properly test the power supply voltage.

5. Turn the PRIME/SPRAY knob to PRIME.

6. Replace the extension cord.

7. Allow the motor to cool and move the unit to a cooler

spot.

8. Take the unit to a Titan Authorized Service Center.

1. Try to prime the pump again.

2. Immerse the suction hose in paint.

3. Clean the suction set lter.

4. Clean the tube connection and tighten it securely.

5. Clean the inlet valve.

6. Clean the outlet valve and replace any worn parts.

7. Take the unit to a Titan Authorized Service Center.

8. Replace the inlet valve.

9. Take the unit to a Titan Authorized Service Center.

10. Take the unit to a Titan Authorized Service Center.

1. Replace the spray tip with a new tip.

2. Clean the suction set lter.

3. Clean or replace the proper lter. Always keep extra

lters on hand.

4. Thin or strain the paint.

5. Clean or replace the outlet valve assembly.

6. Replace the inlet valve.

1. Increase the uid pressure.

2. Increase the air regulator setting.

3. Clean the lters.

4. Tighten the suction hose tting.

5. Replace the spray tip.

6. Thin the paint.

1. Allow to cool for 30 minutes.

2. Allow to cool for 30 minutes and replace the extension

cord with a shorter extension or a thicker gauge cord.

3. Clean the paint from the motor.

4. Restart the unit in the PRIME mode.

5. Move the unit out of the sun.

1. Move the compressor ON/OFF switch to the ON position.

2. Take the unit to a Titan Authorized Service Center.

3. Take the unit to a Titan Authorized Service Center.

4. Clean out the relief hole.

1. Increase the air regulator setting.

2. Thin the paint.

3. Open the gun air valve. Refer to gun Owner’s Manual.

4. Install a new pressure relief valve.

United States Sales & Service

Phone:

Fax:

1770 Fernbrook Lane

Minneapolis, MN 55447

www.titantool.com

© Titan Tool. All rights reserved. 11

1-800-526-5362

1-800-528-4826

International

international@titantool.com

Fax: 1-763-519-3509

1770 Fernbrook Lane

Minneapolis, MN 55447

English

Page 12

Consignes de sécurite important

Prise trilaire

Lire toutes ces consignes avant d’utiliser l’appareil.

Garder ces consignes.

Indique une situation à risque, laquelle, si elle n’est pas

évitée, peut entraîner des blessures graves, voire la mort.

Pour réduire les risques d’incendie ou d’explosion,

de choc électrique et de blessure, vous devez lire et

comprendre les directives gurant dans ce manuel.

Familiarisez-vous avec les commandes et l’utilisation

adéquate de l’équipement.

Directives de mise à la terre

Cet appareil doit être mis à la terre. En cas de court-circuit, cette

précaution réduit les risques de choc en procurant un parcours

au courant électrique. Le cordon de l’appareil est doté d’un l de

terre relié à la troisième broche de sa che. Cette dernière doit être

branchée dans une prise correctement câblée et mise à la terre

conformément aux codes et règlements locaux.

MISE EN GARDE - Le fait de ne pas brancher

correctement la che trilaire de l’appareil peut

entraîner des risques de choc électrique.

Si on doit réparer ou remplacer le cordon ou la che, ne pas raccorder

le l de terre à la borne des broches plates (lames) de cette dernière.

Ce l, normalement vert (avec ou sans rayures jaunes), doit être relié

à la broche de terre.

Consulter un technicien ou un électricien qualié à défaut de

comprendre l’ensemble des présentes directives ou en cas

d’incertitude quant à la mise à terre de l’appareil. Ne pas modier la

che de l’appareil; si elle ne s’adapte pas dans la prise voulue, la faire

remplacer par un électricien qualié.

Conçu pour les circuits de 120 V, cet appareil est doté d’une che

ressemblant à celle illustrée ci-dessous. S’assurer que le produit est

connecté à une prise électrique ayant la même conguration que la

che mâle. Ne pas utiliser d’adaptateur avec ce produit.

Broche de mise à la terre

Plaque murale de la prise

NOTA : On ne recommande pas l’utilisation de rallonges de

MESURES PRÉVENTIVES :

• Ne pulvérisez pas de matières inammables ou combustibles

• S’entourer de toutes les précautions possibles lorsqu’on utilise

plus de 31 m (100 pi); il est préférable de rallonger

le tuyau à peinture que le cordon d’alimentation.

Les rallonges plus courtes assureront la puissance

électrique requise pour un fonctionnement

adéquat.

MISE EN GARDE : EXPLOSION OU INCENDIE

Les émanations de certains produits peuvent exploser

ou s’enammer, et risquent d’entraîner des dommages

matériels ou de graves blessures.

près d’une amme nue, de voyants lumineux ou de sources

d’ignition telles que des objets chauds, cigarettes, moteurs,

matériel et appareils électriques. Évitez de produire des

étincelles en connectant et en déconnectant les cordons

électriques.

des produits ayant un point d’éclair inférieur à 38°C (100°F).

Le point d’éclair est la température à laquelle le liquide peut

créer susamment de vapeurs et s’enammer.

• L’écoulement de peinture ou de solvant dans l’équipement

peut produire de l’électricité statique. L’électricité statique

crée un risque d’incendie ou d’explosion en présence de

fumées de peinture ou de solvant. Toutes les pièces du

système du pulvérisateur, y compris la pompe, l’ensemble

du tuyau, le pistolet de pulvérisation et les objets dans et

autour de la zone de pulvérisation doivent être correctement

reliés à la terre pour protéger contre les décharges

d’électricité statique et les étincelles. N’utilisez que des

tuyaux conducteurs ou reliés à la terre pour pulvérisateurs de

peinture sous vide à haute pression, spéciés par le fabricant.

• Vériez que tous les conteneurs ou systèmes de stockage sont

reliés à la terre pour éviter les décharges d’électricité statique.

• Connectez à une prise électrique avec prise de terre et utilisez

des rallonges électriques reliées à la terre. N’utilisez pas

d’adaptateur 3 à 2.

• N’utilisez pas de peinture ou de solvant contenant du halon,

par exemple, le chlore, les agents antimoisissure à l’eau

de Javel, le chlorure de méthylène et le trichloroéthane.

Ils ne sont pas compatibles avec l’aluminium. Contactez le

fournisseur de revêtements pour connaître la compatibilité du

matériau avec l’aluminium.

• La zone de pulvérisation doit toujours être bien aérée. Une

bonne quantité d’air frais doit constamment traverser la zone

de pulvérisation pour éviter les accumulations de vapeurs

inammables. Le système de pompage doit être placé

dans une zone bien aérée. Ne pulvérisez pas le système de

pompage.

• Ne fumez pas dans la zone de pulvérisation.

• N’actionnez pas d’interrupteurs électriques, de moteurs ou

autres dispositifs produisant des étincelles dans la zone de

pulvérisation.

• Maintenez la propreté de la zone et veillez à ce qu’elle ne

contienne pas de conteneurs de peinture ou de solvant, de

chions et autres matières inammables.

• Sachez ce que contiennent la peinture et les solvants

pulvérisés. Lisez les ches de sécurité du matériel (MSDS) et

les étiquettes apposées sur les conteneurs de peintures et de

solvants. Respectez les consignes de sécurité du fabricant de

peinture et de solvant.

• Placez la pompe à une distance minimum de 7,62 mètres

(25 pieds) de l’objet à pulvériser, dans une zone bien aérée

(ajoutez de la longueur de tuyau si besoin est). Les vapeurs

inammables sont souvent plus lourdes que l’air. La zone près

du sol doit être très bien aérée. La pompe contient des pièces

qui produisent des arcs et émettent des étincelles pouvant

enammer les vapeurs.

• Le plastique peut causer des étincelles d’électricité statique.

N’accrochez aucun plastique dans une zone de pulvérisation

fermée. N’utilisez pas de toiles de protection en plastique

quand vous pulvérisez une matière inammable.

• Ayez un extincteur en bon état de fonctionnement à portée de

main.

MISE EN GARDE : INJECTION CUTANÉE

Le jet de haute pression produit par cet appareil peut

transpercer la peau et les tissus sous-jacents, causant des

blessures graves pouvant entraîner l’amputation.

MESURES PRÉVENTIVES :

• Ne dirigez pas le pistolet sur et ne pulvérisez pas les personnes

ou les animaux.

• N’approchez pas les mains ni d’autres parties du corps de la

sortie du produit. Par exemple, ne tentez pas d’arrêter une

fuite avec une partie du corps.

• NE JAMAIS mettre la main, même gantée, devant le pistolet

(les gants n’orent aucune protection contre les blessures par

injection).

12 © Titan Tool. Tous droits réservés.

Français

Page 13

Consignes de sécurite important

• TOUJOURS s’assurer que le protège-embout est en place avant

de pulvériser. Il est cependant à noter que, s’il assure une

certaine protection, ce dispositif joue surtout un rôle préventif.

• Utilisez exclusivement un embout de buse spécié par le

fabricant.

• Prenez garde quand vous nettoyez ou que vous changez

les embouts de buse. Si l’embout se bouche pendant que

vous pulvérisez, verrouillez TOUJOURS la détente du pistolet,

arrêtez la pompe et libérez toute la pression avant de réparer

ou de nettoyer l’embout ou le protecteur ou avant de changer

d’embout. La pression n’est pas libérée par l’arrêt du moteur.

La poignée du robinet-valve PRIME/SPRAY doit être placée sur

PRIME pour libérer la pression. Consultez la PROCÉDURE DE

DÉCOMPRESSION décrite dans le manuel de la pompe.

• Ne laissez pas l’appareil sous tension ou sous pression

quand vous vous en éloignez. Quand vous n’utilisez pas

l’appareil, éteignez-le et libérez la pression conformément aux

instructions du fabricant.

• La pulvérisation à haute pression peut injecter des toxines

dans le corps et causer de graves blessures corporelles. Si une

telle injection se produisait, consultez immédiatement un

médecin.

• Vériez les tuyaux et les pièces pour détecter des signes

d’endommagement : une fuite peut injecter le produit dans

la peau. Inspectez le tuyau avant chaque emploi. Changez

tous les tuyaux ou pièces endommagés. Pour des raisons

de fonctionnement, de sécurité et de durée de vie, utiliser

exclusivement des tuyaux exibles à haute pression d‘origine

de TITAN.

• Ce système peut produire une pression de 2 800 PSI / 193

Bar. N’utilisez que les pièces de rechange ou les accessoires

spéciés par le fabricant et ayant une pression nominale

minimum de 2 800 PSI. Ceci est valable pour les embouts

de pulvérisation, les protecteurs de buse, les pistolets, les

rallonges, les raccords et le tuyau.

• Verrouillez toujours la détente quand vous ne pulvérisez pas.

Vériez que le verrou de la détente fonctionne correctement.

• Vériez que toutes les connexions sont bien serrées avant

d’utiliser l’appareil.

• Sachez comment arrêter l’appareil et le dépressuriser

rapidement. Soyez bien familiarisé avec les commandes. La

pression n’est pas libérée lorsque le moteur est arrêté. La

poignée du robinet-valve PRIME/SPRAY doit être placée sur

PRIME pour libérer la pression. Consultez la PROCÉDURE DE

DÉCOMPRESSION décrite dans le manuel de la pompe.

• Retirez toujours l’embout de pulvérisation avant de rincer ou

de nettoyer le système.

• Porter des lunettes de protection.

• Porter les vêtements de protection prescrits par le fabricant du

produit utilisé.

MISE EN GARDE : GÉNÉRALITÉS

D’autres dangers peuvent entraîner des dommages

matériels ou des blessures graves.

MESURES PRÉVENTIVES :

• Portez toujours les gants, la protection oculaire, les vêtements

et un respirateur ou masque appropriés quand vous peignez.

• Ne travaillez pas et ne pulvérisez pas près d’enfants. Éloignez

toujours les enfants de l’équipement.

• Ne travaillez pas avec les bras au-dessus de la tête ni sur un

support instable. Appuyez-vous bien sur les deux pieds pour

toujours conserver l’équilibre.

• Soyez attentif et regardez ce que vous faites.

• N’utilisez pas l’appareil quand vous êtes fatigué ou sous

l’inuence de drogues ou d’alcool.

• Ne faites pas de nœuds avec le tuyau et ne le tordez pas trop.

Le tuyau à vide peut présenter des fuites suite à l’usure, les

nœuds ou les mauvais traitements. Une fuite risque d’injecter

du produit dans la peau.

• N’exposez pas le tuyau à des températures ou des pressions

supérieures à celles spéciées par le fabricant.

• N’utilisez pas le tuyau pour tirer ou soulever l’équipement.

• Utilisez la plus basse pression possible pour rincer

l’équipement.

• Respectez tous les codes locaux, étatiques et nationaux

qui régulent la ventilation, la prévention d’incendies et le

fonctionnement.

• Les normes de sécurité du gouvernement des États-Unis ont

été adoptées dans la loi Occupational safety and Health Act

(OSHA). Ces normes, en particulier la partie 1910 des Normes

générales et la partie 1926 des Normes de construction,

doivent être consultées.

• Avant chaque emploi, vériez tous les tuyaux pour détecter

d’éventuelles coupures, fuites, abrasion ou couvercle bombé.

Vériez l’état ou le mouvement des accouplements. Changez

immédiatement le tuyau si l’une de ces conditions est vériée.

Ne réparez jamais un tuyau de peinture. Remplacez-le par un

tuyau conducteur à haute pression.

• Ne pulvérisez pas à l’extérieur par temps venteux.

• Débranchez toujours le cordon électrique de la prise avant de

travailler sur l’équipement.

REMARQUE À L’INTENTION DES MÉDECINS : Les injections

cutanées sont des lésions traumatiques; il importe donc de

les traiter sans délai. On NE DOIT PAS retarder ce traitement

sous prétexte de vérier la toxicité du produit en cause, celle-ci

n’étant conséquente que dans le cas d’injection directe de

certains produits dans le système sanguin. Il pourrait s’avérer

nécessaire de consulter un plasticien ou un spécialiste en

chirurgie reconstructive de la main.

MISE EN GARDE : ÉMANATIONS DANGEREUSES

Certains produits (peintures, solvants, insecticides ou

autres) peuvent être nocifs s’ils sont inhalés ou entrent en

contact avec l’organisme. Les émanations de ces produits

peuvent provoquer de graves nausées, évanouissements

ou empoisonnements.

MESURES PRÉVENTIVES :

• Se servir d’un masque ou d’un respirateur s’il y a risque

d’inhalation (lire toutes les directives concernant ces

dispositifs an de s’assurer qu’ils orent la protection requise).

© Titan Tool. Tous droits réservés. 13

IMPORTANT: La pompe à diaphragme est dotée d’un dispositif

de remise en marche automatique avec protection thermique.

En cas de surcharge, ce dispositif débranche le moteur du bloc

d’alimentation.

• Le moteur se remet en marche sans avertissement lorsque le

protecteur est réarmé automatiquement.

• Débranchez toujours le moteur du bloc d’alimentation avant

d’utiliser l’équipement.

• Lorsque le dispositif de remise en marche automatique

débranche le moteur du bloc d’alimentation, libérez de la

pression en tournant la soupape de PRIME/SPRAY à la position

PRIME.

• Placez l’interrupteur MARCHE/ARRÊT (ON/OFF) de la pompe

en position ARRÊT (OFF).

NOTA : Il faut remédier à la cause de la surcharge avant

de faire redémarrer la pompe. Voir la section

Dépannage.

Français

Page 14

Table des matières

Pompe à diaphragme

Jauge de

Régulateur

Jauge de pression

MAR

du compresseur

Bouton de réglage de la pression

Interrupteur

t

C

t

Consignes de sécurité ..............................................................12-13

Description générale ..................................................................... 14

Installation ..................................................................................... 14

Fonctionnement ............................................................................ 15

Amorçage de la pompe ............................................................................15

Peinture ..........................................................................................................15

Procédure de limitation de la pression ...............................................17

Technique de pulvérisation .......................................................... 17

Nettoyage ...................................................................................... 18

Rangement pour la nuit ...........................................................................18

Rangement à long terme .................................................................. 18-19

Maintenance .................................................................................. 20

Démontage et nettoyage de la soupape d’admission ..................20

Démontage et nettoyage de la soupape de sortie ........................20

Dépannage ..................................................................................... 21

Liste de pièces ................................................................................ 32

Garantie Limitée ............................................................................ 40

Description générale

Ce système de pulvérisation à haute précision est un outil polyvalent

pouvant être utilisé tant pour des travaux de nition à basse pression

que pour la pulvérisation haute pression sans air comprimé. Le

système comprend une pompe à peinture à diaphragme et un

compresseur à air qui fonctionnent ensemble et lui donne ce

caractère polyvalent.

de pression

de l'air

du produit

Soupape de

PRIME/SPRAY

Compresseur

d'air

Raccord

de sortie

d'air

pression

de l'air

3. Verrouillez le pistolet en enclenchant le cran de sûreté (voir le

Guide d’utilisation du pistolet).

4. À l’aide d’une clé, xez un tuyau de pulvérisation sans air en

nylon d’un diamètre de 6,4 mm (1/4 po) et d’une longueur

minimale de 15 m (50 pi) sur le raccord de sortie du produit de

la pompe. Serrez fermement.

5. Fixez le tuyau de pulvérisation sur le raccord d’entrée du

produit. À l’aide de deux clés (une sur le pistolet et l’autre sur

le tuyau), serrez fermement.

onguration standard

Avec l'option de

Tuyau d’air

des tuyaux:

d'admission de l'air

Raccord

Tuyau d’air

fouet tuyau :

d'admission de l'air

Fouet tuyau

Raccord

Raccord

d’air

Raccord

Raccord

d’entrée

du produi

Tuyau du

produit

Fouet tuyau

de produit

Raccord

d’entrée

du produi

Installation

Procédez comme suit pour mettre le système de pulvérisation en

marche.

1. Assurez-vous que l’interrupteur MARCHE/ARRÊT de la pompe

2. Assurez-vous que le bouton de réglage de la pression est

14 © Titan Tool. Tous droits réservés.

Raccord de sortie

du produit

et que l’interrupteur MARCHE/ARRÊT du compresseur se

trouvent sur la position ARRÊT (OFF).

MARCHE/ARRÊT

(ON/OFF)

de la pompe

Interrupteur

CHE/ARRÊT

(ON/OFF)

complètement tourné dans le sens inverse des aiguilles d’une

montre, réglé sur la pression la plus basse.

Français

Courroies

Tuyau du produit

Assurez-vous que tous les tuyaux sans air comprimé

et les pistolets de pulvérisation sont bien raccordés

électriquement et peuvent fonctionner à une pression

de fluide d’au moins 2,800 PSI (19 MPa).

6. Montez le tuyau d’air sur le raccord de sortie d’air du

compresseur. Serrez fermement.

7. Montez le raccord du tuyau d’air sur le raccord d’entrée

d’air du pistolet. Montez le tuyau d’air sur le raccord. Serrez

fermement.

L’inversion des raccords de tuyaux peut occasionner

des lésions corporelles graves. Assurez-vous que le

tuyau de pulvérisation sans air comprimé est bien

branché à la pompe à diaphragme sur le raccord

d’entrée du produit du pistolet et que le tuyau à air

est bien branché entre le compresseur et le raccord

d’entrée d’air du pistolet.

8. Assurez-vous que le réseau électrique est de 120 V, et au

minimum de 15 A.

9. Branchez le cordon d’alimentation sur une prise reliée à la

terre à une distance minimale de 7,6 m (25 pi) cm de la zone

de vaporisation.

IMPORTANT: Utilisez toujours une rallonge électrique trifilaire

de calibre 12 munie d’une fiche mise à la terre. Vous ne devez

jamais enlever la troisième broche ni utiliser un adaptateur.

Page 15

Fonctionnement

PRIME/SPRAY

Soupape

Tube de

retour

Soupape

Raccord de tube de retour

Procédez comme suit pour mettre le système de pulvérisation en

marche.

Amorçage de la pompe

Préparation de l’amorçage

1. Remplissez la soupape d’entrée d’eau ou d’huile ménagère

légère.

Assemblage de la trémie de peinture

Procédez comme suit pour assembler la trémie de peinture et xer le

tube de retour sur la trémie.

1. Vissez le raccord du tube de

retour dans l’orice du tube de

retour, sur le côté de la pompe.

NOTA : Ne serrez pas trop. Serrez

seulement à la main.

Certains lets seront

visibles même après

avoir serré à fond.

2. Alignez le bas de la trémie

de peinture avec le robinet

d’entrée leté du bloc de la pompe à peinture.

3. Tournez la trémie dans le sens des aiguilles d’une montre pour

la visser sur le robinet d’entrée. Continuez à tourner la trémie

jusqu’à ce qu’elle soit bloquée sur le robinet d’entrée.

d’entrée

Raccord de tube de retour

Soupape de

2. Assurez-vous que la soupape de PRIME/SPRAY est bien

placée sur la position PRIME et que le bouton de réglage de

la pression est complètement tourné dans le sens inverse des

aiguilles d’une montre, réglé sur la pression la plus basse.

3. Allumez la pompe en plaçant l’interrupteur MARCHE/ARRÊT

(ON/OFF) de la pompe à la position MARCHE (ON).

4. Augmentez la pression en faisant tourner le bouton de

réglage de la pression dans le sens des aiguilles d’une montre

d’un demi-tour.

5. Ouvrez la soupape d’admission et fermez-la en appuyant

dessus avec un tournevis ou la gomme à eacer de l’extrémité

d’un crayon. Elle doit monter et descendre d’environ 1,6

mm (1/16 po). Poursuivez cette action jusqu’à ce que l’eau

ou l’huile soit aspirée dans la pompe ce qui humidiera les

parties mobiles et délogera toute trace de peinture résiduelle.

6. Placez la paume de votre main sur l’orice d’entrée. Tournez

complètement le bouton de réglage de la pression dans le

sens des aiguilles d’une montre. Vous devriez sentir qu’il y a

une aspiration dans la soupape d’admission. Si ce n’est pas

le cas, consultez la rubrique Démontage et nettoyage de la

soupape de sortie dans la section Maintenance.

7. Tournez le bouton de réglage de la pression dans le sens

inverse des aiguilles d’une montre jusqu’à ce que la valeur de

pression minimum soit atteinte.

8. Placez l’interrupteur MARCHE/ARRÊT (ON/OFF) de la pompe

en position ARRÊT (OFF).

NOTA : Vériez que les lets sont droits et que la trémie est

4. Placez le crépine dans le bas de la trémie de peinture. Il se met

5. Assurez-vous que l’interrupteur

6. Placez l’extrémité droite du tube

7. Vissez l’écrou du tube de retour

8. Placez l’extrémité en forme de

libre de tourner sur le robinet d’entrée. Veillez à ne

pas visser de travers.

en place par un coup sec.

ON/OFF du moteur est placé sur

OFF.

de retour dans le raccord du tube.

sur le raccord du tube de retour et

serrez jusqu’à ce que le tube soit

xé.

crochet du tube de retour dans le

trou du couvercle de la trémie de

peinture.

Écrou

Assemblage le optional ensemble d’aspiration

Procédez comme suit pour xer le ensemble d’aspiration à l’unité

d’aspiration.

1. Retirez le raccord de tube de

retour de trémie. Vissez le

raccord du tube de retour dans

l’orice du tube de retour sur le

côté de la pompe.

NOTA : Ne serrez pas trop. Serrez

seulement à la main.

Certains lets seront

visibles même après

avoir serré à fond.

2. Alignez l’écrou du groupe d’aspiration avec le robinet d’entrée

leté du bloc de la pompe à peinture.

3. Montez et serrez l’écrou du tuyau d’aspiration sur la soupape

d’admission de la pompe.

NOTA : Vériez que les lets sont droits et que l’écrou tourne

sans problème sur le robinet d’entrée. Veillez à ne

pas visser de travers.

d’entrée

© Titan Tool. Tous droits réservés. 15

4. Montez et serrez le tuyau de retour sur le raccord du tuyau de

retour de la pompe.

Français

English

Page 16

Amorçage avec de la trémie de peinture

Soupape de

de la pression

T

(ON/OFF) du compresseur

Interrupteur MARCHE/ARRÊT

Régulateur de pression de l'air

Jauge de pression

1. Tournez le bouton de commande de pression dans le sens

contraire des aiguilles d’une montre jusqu’au réglage de

pression le plus bas.

2. Retirez le couvercle de la trémie de peinture et remplissez la

trémie ou bien placez le groupe d’aspiration dans un seau de

peinture.

3. Tournez le soupape de PRIME/SPRAY sur PRIME.

4. Placez l’interrupteur ON/OFF du moteur sur ON.

5. Tournez le bouton de commande de pression dans le sens

des aiguilles d’une montre sur la position intermédiaire entre

demi-pression et pression totale. Laissez l’unité s’amorcer

pendant 1 à 2 minutes après que la peinture commence à

s’écouler dans le tube de retour.

IMPORTANT : Abaissez toujours la pression à zéro avant de

modifier la position du soupape de PRIME/SPRAY. Vous pourriez

sinon endommager la membrane de la pompe à peinture.

IMPORTANT : Si le bouton de commande de pression est placé

sur zéro et que le soupape de PRIME/SPRAY est encore sur

SPRAY pendant que le pulvérisateur est en marche, il y aura une

pression élevée dans le tuyau et dans le pistolet de pulvérisation

jusqu’à ce que le soupape de PRIME/SPRAY soit placé sur la

position PRIME ou jusqu’à ce que la pression soit dégagée sur le

pistolet.

Amorçage avec optional l’ensemble d’aspiration

1. Placez le tuyau d’aspiration dans un contenant de peinture.

2. Tournez le bouton de réglage de la pression dans le sens

inverse des aiguilles sur le réglage de pression minimale.

IMPORTANT: Réduisez toujours la pression à zéro par le

déclenchement de pistolet avant de changer la position de

la soupape de PRIME/SPRAY. Le diaphragme de la pompe à

peinture pourrait s’endommager si cette consigne n’est pas

respectée.

3. Placez la soupape de PRIME/SPRAY en position PRIME.

PRIME/SPRAY

Peinture

Le système de pulvérisation AirCoat dispose de deux modes de

peinture diérents : le mode AirCoat, utilisé pour les travaux de

nition précis exécutés avec des produits peu ou moyennement

visqueux (huile, vernis, laques, etc.) Le mode sans air, utilisé pour la

peinture général avec des matériaux très visqueux (latex).

Peinture en mode AirCoat

Utilisez le mode AirCoat pour les travaux de nition à basse pression

(pression de la pompe recommandée de 1 000 PSI maximum).

1. Assurez-vous que le tuyau de pulvérisation sans air n’est pas

plié et qu’il ne touche pas des objets aux bords coupants.

2. Tournez le bouton de réglage de la pression dans le sens

inverse des aiguilles d’une montre jusqu’au réglage minimum.

3. Tournez le régulateur de pression de l’air du compresseur

dans le sens inverse des aiguilles d’une montre jusqu’au

réglage minimum.

4. Placez l’interrupteur MARCHE/ARRÊT (ON/OFF) du

compresseur en position MARCHE (ON).

5. Placez l’interrupteur MARCHE/ARRÊT (ON/OFF) en position

MARCHE (ON).

(ON/OFF) de la pompe

Interrupteur MARCHE/ARRÊ

6. Placez la soupape de PRIME/SPRAY en position SPRAY.

7. Tournez le bouton de réglage de la pression dans le sens des

aiguilles d’une montre jusqu’à ce que la jauge de pression

du produit atteigne 400 PSI. Le tuyau à peinture doit goner

lorsque la peinture commence à s’y écouler.

8. Tournez le bouton de réglage de la pression dans le sens des

aiguilles d’une montre jusqu’à ce que la jauge de pression de

l’air atteigne 20 PSI.

4. Placez l’interrupteur MARCHE/ARRÊT (ON/OFF) en position

MARCHE (ON).

5. Tournez le bouton de réglage de la pression dans le sens des

aiguilles d’une montre et placez-le entre la pression maximale

et pression moyenne. Amorcez la pompe pendant 1 à 2

minutes après que la peinture a commencé à couler par le

tuyau de retour et jusqu’à ce qu’il n’y ait plus de bulles.

6. Tournez le bouton de réglage de la pression dans le sens

inverse des aiguilles sur le réglage de pression minimale.

7. Placez l’interrupteur MARCHE/ARRÊT (ON/OFF) en position

ARRÊT (OFF).

IMPORTANT: Si le bouton de réglage de la pression est tourné à

zéro et que la soupape de PRIME/SPRAY est toujours en position

spray pendant que la pompe fonctionne, il y aura une pression

élevée dans le tuyau et dans le pistolet de pulvérisation jusqu’à

ce que la soupape de PRIME/SPRAY soit placée en position prime

ou que le pistolet de pulvérisation soit enclenché pour réduire la

pression.

16 © Titan Tool. Tous droits réservés.

Bouton de réglage

Français

de l'air

Jauge de pression

du produit

9. Débloquez le détente de pistolet.

10. Enclenchez le pistolet de pulvérisation pour purger l’air du

tuyau réservé au produit.

11. Lorsque le produit atteint la tête de pulvérisation, il faut peindre

une zone d’essai pour vérier la forme du jet de pulvérisation.

12. Réglez la forme de pulvérisation selon la taille et l’atomisation

souhaitées.

a. Utilisez le bouton de réglage de la pression pour contrôler le jet de

peinture vers le pistolet.

b. Utilisez le bouton de réglage de la pression de l’air pour contrôler

la quantité d’air de pulvérisation disponible vers le pistolet.

c. Utilisez le bouton de réglage de forme du pistolet pour aner la

forme de pulvérisation.

NOTA : Consultez le manuel de l’utilisateur du pistolet de

pulvérisation pour plus de détails concernant le

fonctionnement du pistolet.

Page 17

Peinture en mode sans air

Revêtement également répartit

régulier et à vitesse constante.

Couche épaisse

Ne échissez pas votre poignet pendant la pulvérisation.

Couche légèreCouche légère

Manière correcte d'enclencher le pistolet de pulvérisation

Début du

assage

du passage

sur la gâchette

la gâchette

itesse constante

Utilisez le mode sans air pour les travaux de pulvérisation généraux à

haute pression (pression de la pompe variant entre 500 à 2 800 PSI).

1. Assurez-vous que le tuyau de pulvérisation n’est pas plié et

qu’il ne touche pas des objets aux bords coupants.

2. Tournez le bouton de réglage

de la pression dans le sens

inverse des aiguilles d’une

montre jusqu’au réglage

minimum.

3. Placez la soupape de PRIME/

SPRAY en position SPRAY.

4. Placez l’interrupteur

MARCHE/ARRÊT (ON/OFF) en

position MARCHE (ON).

5. Tournez le bouton de réglage

de la pression dans le sens

des aiguilles d’une montre

au maximum. Le tuyau à

peinture doit goner lorsque

la peinture commence à s’y écouler.

6. Débloquez le détente de pistolet.

7. Enclenchez le pistolet de pulvérisation pour purger l’air du

tuyau réservé au produit.

8. Lorsque le produit atteint la tête de pulvérisation, il faut

peindre une zone d’essai pour vérier la forme du jet de

pulvérisation.

9. Pulvérisez toujours à

la pression minimale

nécessaire pour obtenir

les résultats souhaités. Si

la pression du système

Forme de pulvérisation correcte

est trop élevée, la forme

de pulvérisation sera trop

légère. Si la pression est

trop faible, des traînées

apparaissent ou la peinture

est projetée en « gouttes »

au lieu d’être pulvérisée.

Traînées de peinture

Procédure de limitation de la pression

Assurez-vous de bien suivre la procédure de limitation

de pression lorsque vous arrêtez l’appareil pour une

raison quelconque, y compris lors de l’entretien ou

du réglage d’une pièce du circuit de vaporisation,

du remplacement ou du nettoyage des embouts de

vaporisation ou lors de la préparation au nettoyage.

1. Tournez le bouton de réglage

de la pression dans le sens

inverse des aiguilles d’une

montre jusqu’au réglage

minimum.

2. Tournez la soupape PRIME/

SPRAY en position SPRAY.

3. Enclenchez le pistolet pour

éliminer toute pression qui

pourrait se trouver dans le

tuyau.

4. Verrouillez le pistolet en

enclenchant le cran de sûreté

(voir le Guide d’utilisation du

pistolet).

Danger de blessure par injection. Ne vaporisez pas

si l’embout de protection de la tête n’est pas en

place. Ne déclenchez JAMAIS le pistolet si la tête de

pulvérisation n’est pas en position de pulvérisation

ou de décolmatage. Engagez TOUJOURS le dispositif

de verrouillage de la gâchette du pistolet avant de

démonter, de remplacer ou de nettoyer la tête.

Soupape de

PRIME/SPRAY

Bouton de réglage

de la pression

Soupape de

PRIME/SPRAY

Bouton de réglage

de la pression

Technique de pulvérisation

Pour obtenir une peinture d’un ni impeccable il est essentiel que le

produit soit également réparti sur toute la surface. Pour y parvenir,

procédez par applications régulières. Déplacez votre bras à vitesse