Page 1

Owner’s Manual

Notice d’utilisation

Manual del Propietario

Do not use this equipment before

reading this manual!

SPEEFLO

PowrLiner 2850

Model Number:

1-gun 0290008

2-gun 0290009

NOTE: This manual contains important

warnings and instructions. Please read

and retain for reference.

0117 • © Titan Tool Inc. All Rights Reserved. Form No. 0290919K

Page 2

Important Safety Information

Read all safety information before operating the

equipment. Save these instructions.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

To reduce the risks of re or explosion, electrical shock

and the injury to persons, read and understand all

instructions included in this manual. Be familiar with the

controls and proper usage of the equipment.

WARNING: EXPLOSION OR FIRE

Flammable vapors, such as solvent and paint vapors, in

work area can ignite or explode.

PREVENTION:

1. Use equipment only in well ventilated area. Keep a good

supply of fresh air moving through the area to keep the air

within the spray area free from accumulation of ammable

vapors. Keep pump assembly in well ventilated area. Do not

spray pump assembly.

2. Do not ll fuel tank while engine is running or hot; shut o

engine and allow to cool. Fuel is ammable and can ignite or

explode if spilled on a hot surface.

3. Eliminate all ignition sources, such as pilot lights, cigarettes,

portable electric lamps and plastic drop cloths (potential static

arc).

4. Keep work area free of debris, including solvent, rags and

gasoline.

5. Do not plug or unplug power cords, or turn power or light

switches on or o when ammable vapors are present.

6. Ground equipment and conductive objects in work area.

Make sure grounding chain is in place and reaches the

ground.

7. Use only grounded hoses.

8. Hold spray gun rmly to the side of a grounded pail when

triggering into pail.

9. If there is static sparking or if you feel a shock, stop operation

immediately.

10. Know the contents of the paint and solvents being sprayed.

Read all Material Safety Data Sheets (MSDS) and container

labels provided with the paints and solvents. Follow the paint

and solvent manufacturer’s safety instructions.

11. Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach, mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating supplier

about compatibility of material with aluminum.

12. Keep a re extinguisher in work area.

WARNING: INJECTION INJURY

A high pressure paint stream produced by this equipment

can pierce the skin and underlying tissues, leading to

serious injury and possible amputation. See a physician

immediately.

PREVENTION:

1. Do not aim the gun at, or spray any person or animal.

2. Keep hands and other body parts away from the discharge.

For example, do not try to stop leaks with any part of the

body.

3. Always use the nozzle tip guard. Do not spray without the

nozzle tip guard in place.

2 © Titan Tool Inc. All rights reserved.

English

4. Only use a nozzle tip specied by the manufacturer.

5. Use caution when cleaning and changing nozzle tips. In the

case where the nozzle tip clogs while spraying,

ALWAYS lock gun trigger, shut pump o, and release all

pressure before servicing, cleaning tip or guard, or changing

tip. Pressure will not be released by turning o the motor.

The PRIME/SPRAY valve or pressure bleed valve must be

turned to their appropriate positions to relieve system

pressure. Refer to PRESSURE RELIEF PROCEDURE described in

the pump manual.

6. Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn o the unit and

relieve the pressure in accordance with the manufacturer’s

instructions.

7. High-pressure spray is able to inject toxins into the body and

cause serious bodily injury. In the event that injection occurs,

seek medical attention immediately.

8. Check hoses and parts for signs of damage, a leak can inject

material into the skin. Inspect hose before each use. Replace

any damaged hoses or parts.

9. This system is capable of producing 3300 PSI / 22.8 MPa. Only

use replacement parts or accessories that are specied by the

manufacturer and that are rated a minimum of 3300 PSI. This

includes spray tips, nozzle guards, guns, extensions, ttings,

and hose.

10. Always engage the trigger lock when not spraying. Verify the

trigger lock is functioning properly.

11. Verify that all connections are secure before operating the

unit.

12. Know how to stop the unit and bleed pressure quickly. Be

thoroughly familiar with the controls. Pressure will not be

released by turning o the motor. The PRIME/SPRAY valve

or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure. Refer to PRESSURE

RELIEF PROCEDURE described in the pump manual.

13. Always remove the spray tip before ushing or cleaning the

system.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury which can lead

to possible amputation. It is important to treat the injury as

soon as possible. DO NOT delay treatment to research toxicity.

Toxicity is a concern with some coatings injected directly

into the blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

WARNING: GENERAL

Can cause severe injury or property damage.

PREVENTION:

1. Always wear appropriate gloves, eye protection, clothing

and a respirator or mask when painting. Hazardous vapors

– Paints, solvents, insecticides, and other materials can be

harmful if inhaled or come in contact with body. Vapors can

cause severe nausea, fainting or poisoning.

2. Do not operate or spray near children. Keep children away

from equipment at all times.

3. Do not overreach or stand on an unstable support. Keep

eective footing and balance at all times.

4. Stay alert and watch what you are doing.

5. Do not operate the unit when fatigued or under the inuence

of drugs or alcohol.

6. Do not kink or over-bend the hose. Airless hose can develop

leaks from wear, kinking and abuse. A leak can inject material

into the skin.

Page 3

Important Safety Information

7. Do not expose the hose to temperatures or pressures in excess

of those specied by manufacturer.

8. Do not use the hose as a strength member to pull or lift the

equipment.

9. Use lowest possible pressure to ush equipment.

10. Follow all appropriate local, state and national codes

governing ventilation, re prevention and operation.

11. The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act

(OSHA). These standards, particularly part 1910 of the General

Standards and part 1926 of the Construction Standards should

be consulted.

12. Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement

of couplings. Immediately replace hose if any of those

conditions exist. Never repair a paint hose. Replace with a

conductive high-pressure hose.

13. Do not spray outdoors on windy days.

14. Always unplug cord from outlet before working on equipment

(electric models only).

IMPORTANT: Do not lift cart handle when loading or unloading.

Gasoline Engine Safety

The engine exhaust from this unit contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

1. Gas engines are designed to give safe and dependable service

if operated according to instructions. Read and understand

the engine Owner’s Manual before operating the engine.

Failure to do so could result in personal injury or equipment

damage.

2. To prevent re hazards and to provide adequate ventilation,

keep the engine at least 1 meter (3 feet) away from buildings

and other equipment during operation. Do not place

ammable objects close to the engine.

3. Children and pets must be kept away from the area of

operation due to a possibility of burns from hot engine

components or injury from any equipment the engine may be

used to operate.

4. Know how to stop the engine quickly, and understand the

operation of all controls. Never permit anyone to operate the

engine without proper instructions.

5. Gasoline is extremely ammable and is explosive under

certain conditions.

6. Refuel in a well-ventilated area with the engine stopped. Do

not smoke or allow ames or sparks in the refueling area or

where gasoline is stored.

7. Do not overll the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

8. Be careful not to spill fuel when refueling. Fuel vapor or

spilled fuel may ignite. If any fuel is spilled, make sure the area

is dry before starting the engine.

9. Never run the engine in an enclosed or conned area. Exhaust

contains poisonous carbon monoxide gas; exposure may

cause loss of consciousness and may lead to death.

10. The muer becomes very hot during operation and remains

hot for a while after stopping the engine. Be careful not to

touch the muer while it is hot. To avoid severe burns or re

hazards, let the engine cool before transporting it or storing it

indoors.

11. Never ship/transport unit with gasoline in the tank.

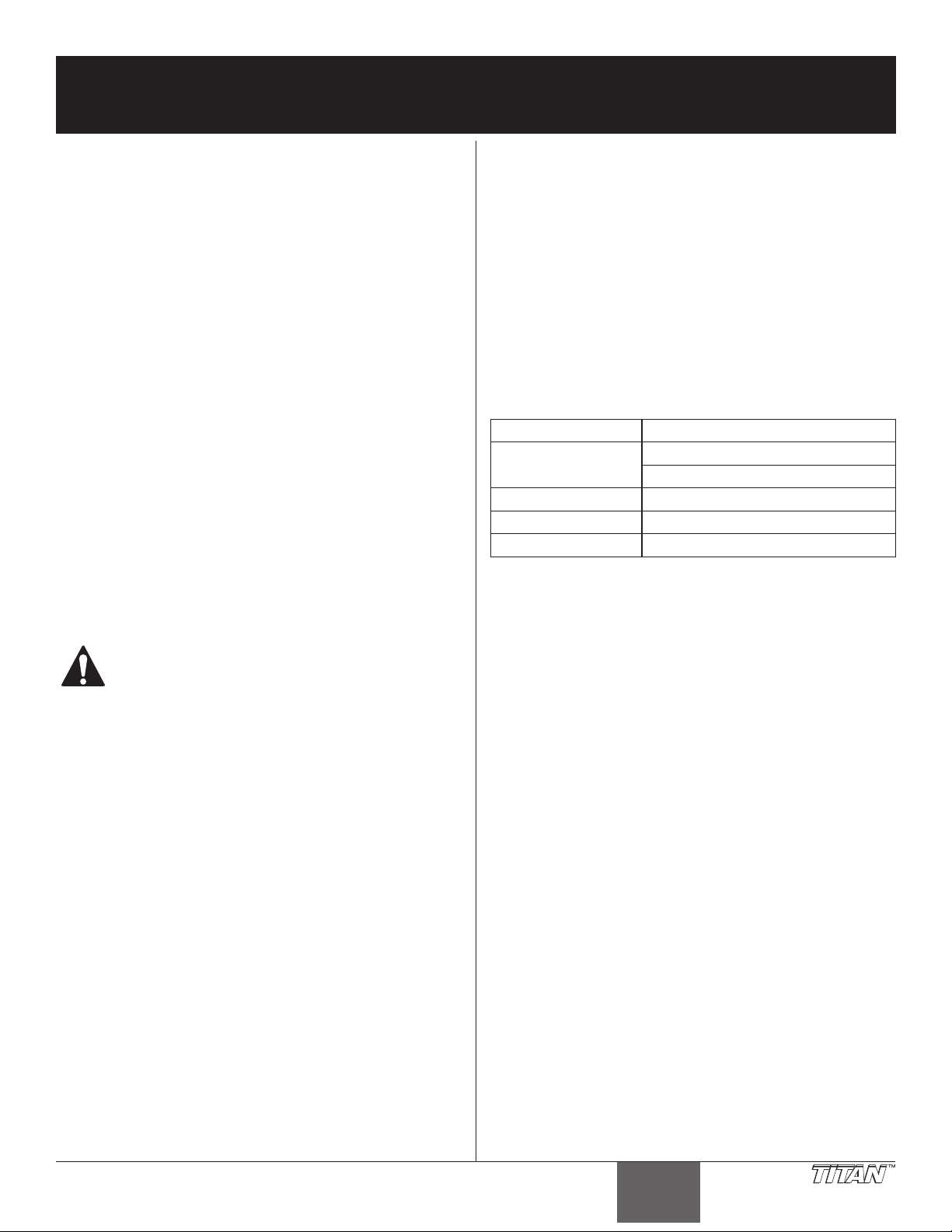

Specications

Gallons per minute (GPM) 0.85 (3.22 LPM)

Maximum tip sizes one gun = 0.030”

two guns = 0.021”

Maximum pressure 3300 PSI (22.8 MPa)

Power 3.5 HP Honda gas engine

Weight 138 lbs. (62.6 kg)

Table of Contents

Safety Precautions ........................................................................... 2

Français ..........................................................................................................18

Español ...........................................................................................................36

General Description ........................................................................ 4

Trigger Lock .................................................................................................... 4

Operation ......................................................................................... 4

Fueling .............................................................................................................. 4

Setup ................................................................................................................. 5

Preparing a New Sprayer ........................................................................... 6

Preparing to Paint.........................................................................................7

Painting ............................................................................................................ 7

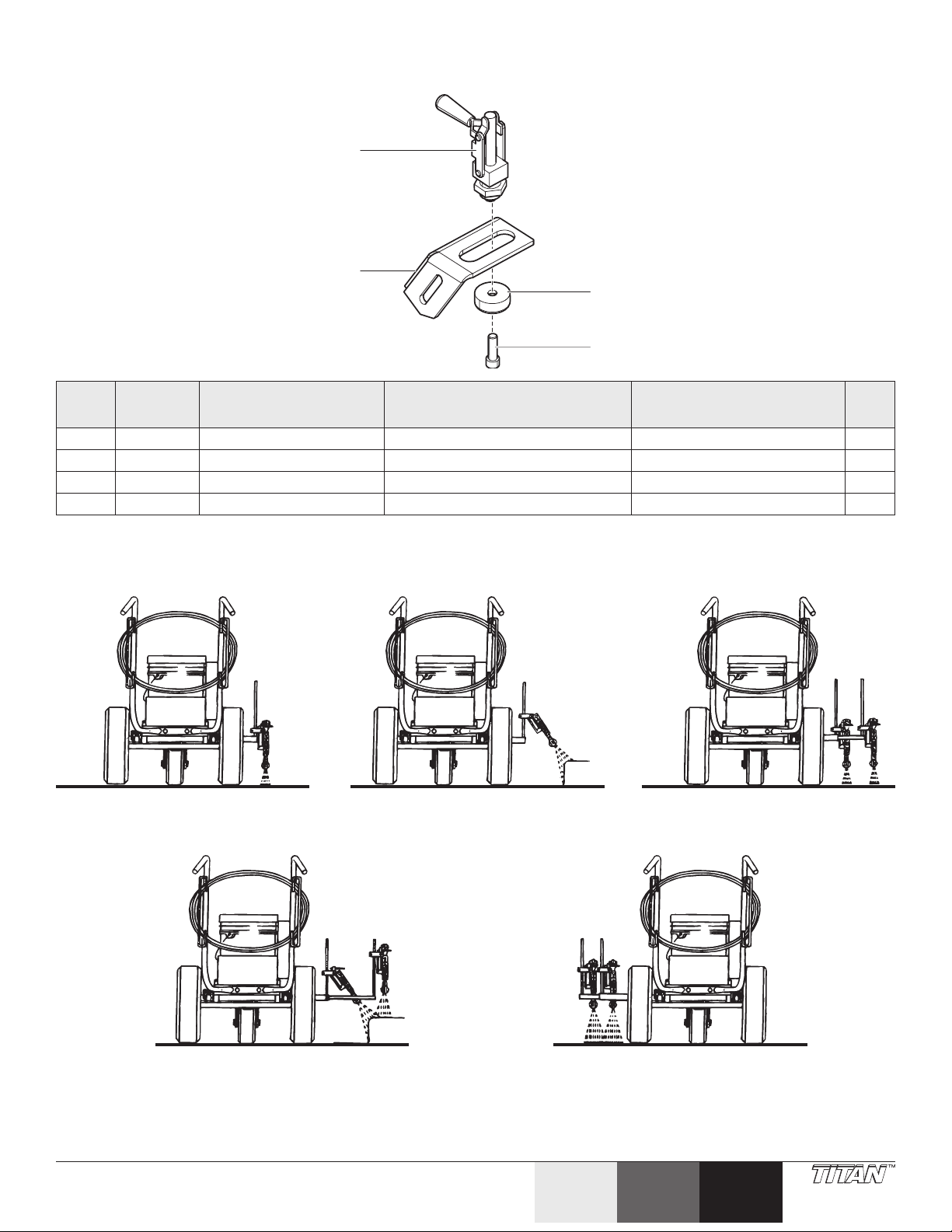

Operating the Front Caster ....................................................................... 8

Pressure Relief Procedure .......................................................................... 8

Cleanup ............................................................................................ 8

Cleaning the Spray Tip ................................................................................ 9

Maintenance .................................................................................... 9

General Repair and Service Notes .......................................................... 9

Maintaining the Engine .............................................................................. 9

Adjusting the Trigger Tension ................................................................. 9

Replacing the PRIME/SPRAY Valve .......................................................10

Cleaning or Replacing the Filters ..........................................................10

Replacing the Pump ON/OFF Switch ..................................................11

Replacing the Gears and/or Slider Assembly ............................ 11-12

Replacing the Transducer ........................................................................12

Servicing the Clutch Assembly ....................................................... 12-14

Servicing the Fluid Section ...............................................................15-16

Troubleshooting ............................................................................ 17

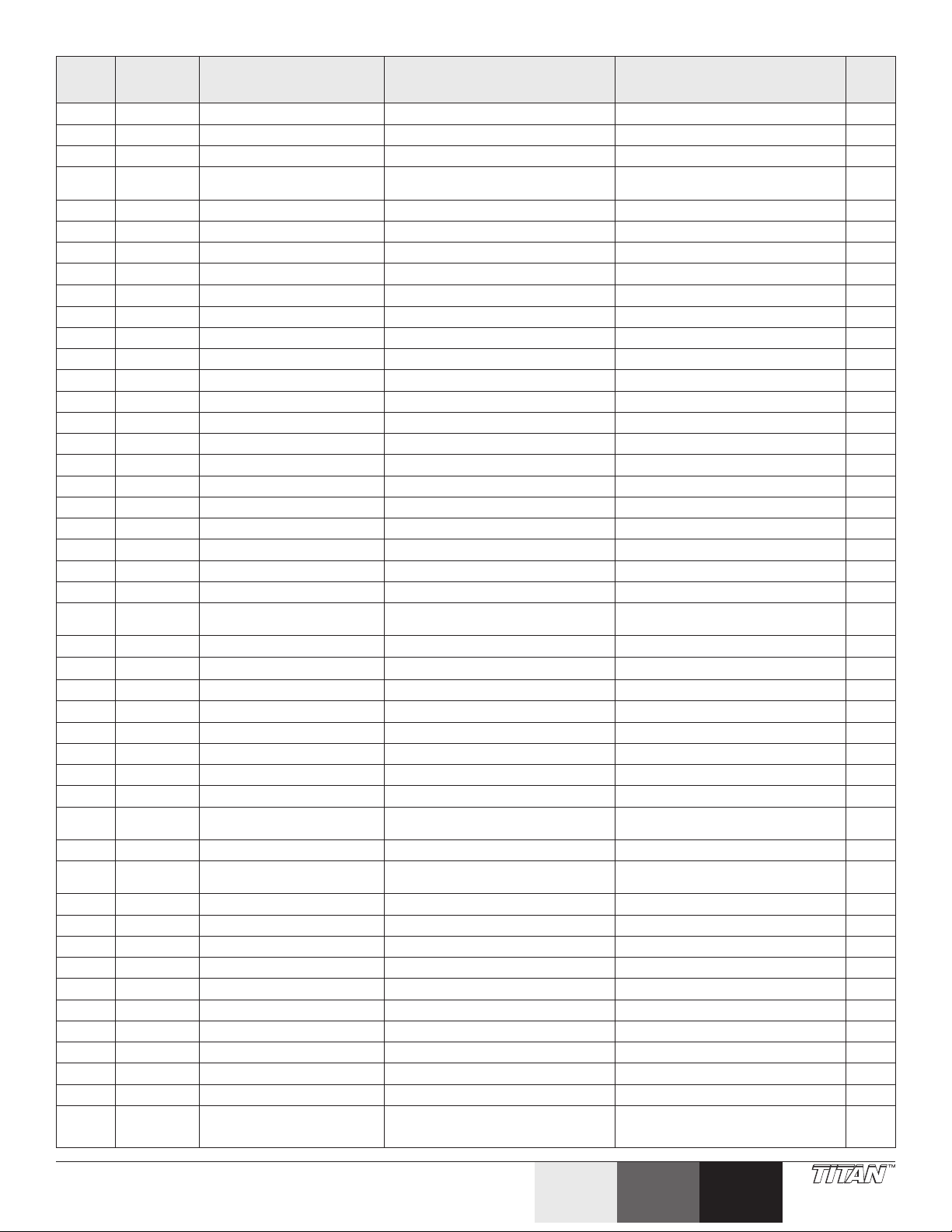

Parts Listings .................................................................................. 48

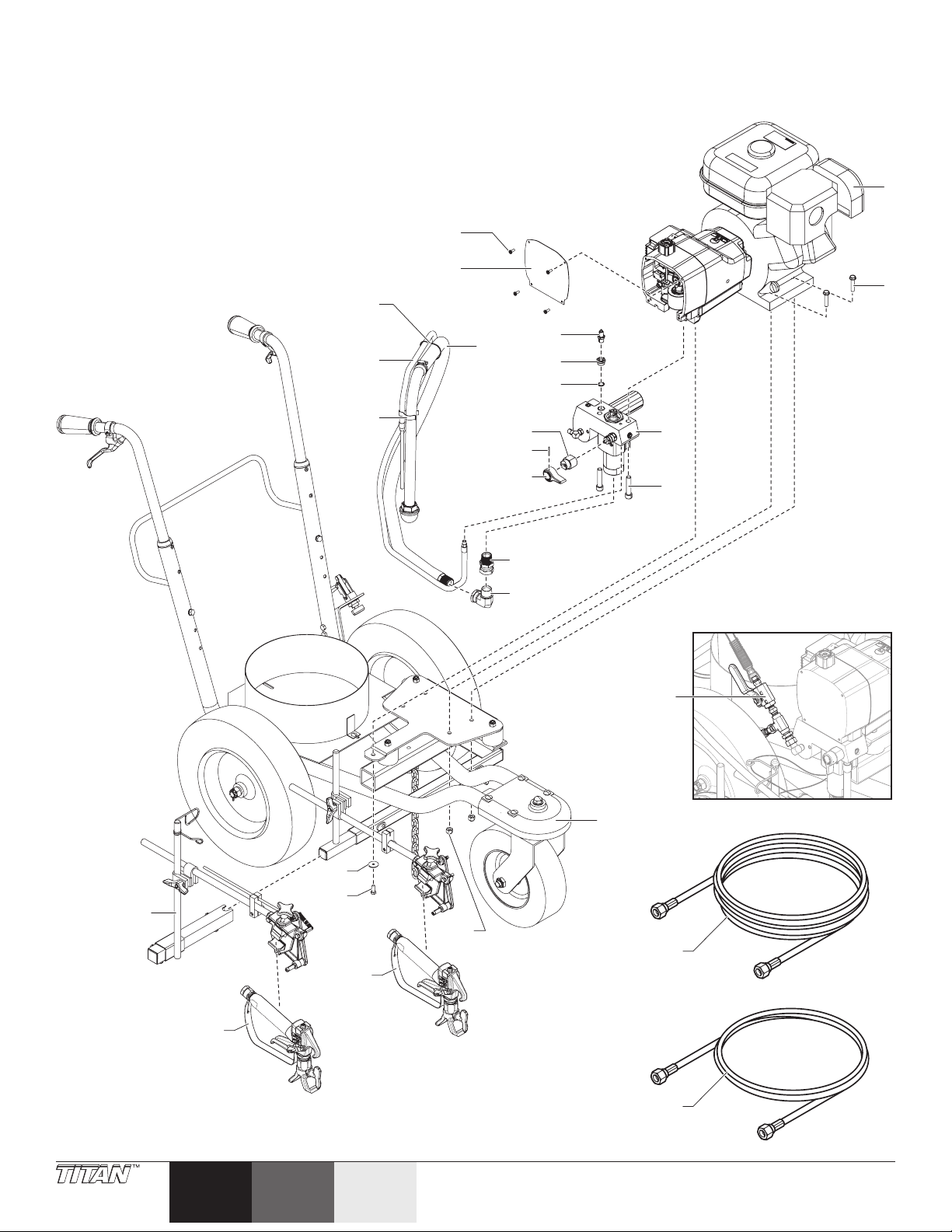

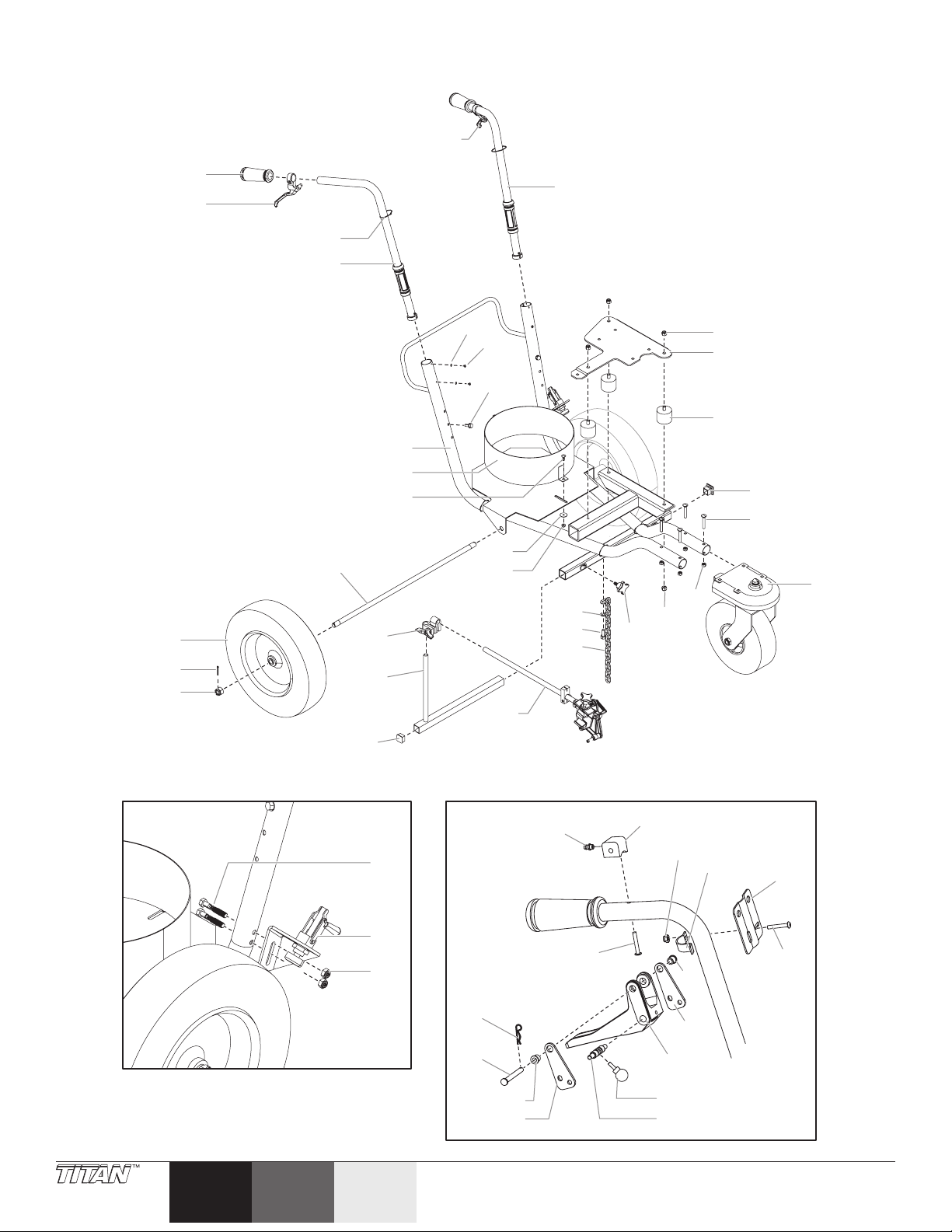

Main Assembly ............................................................................................48

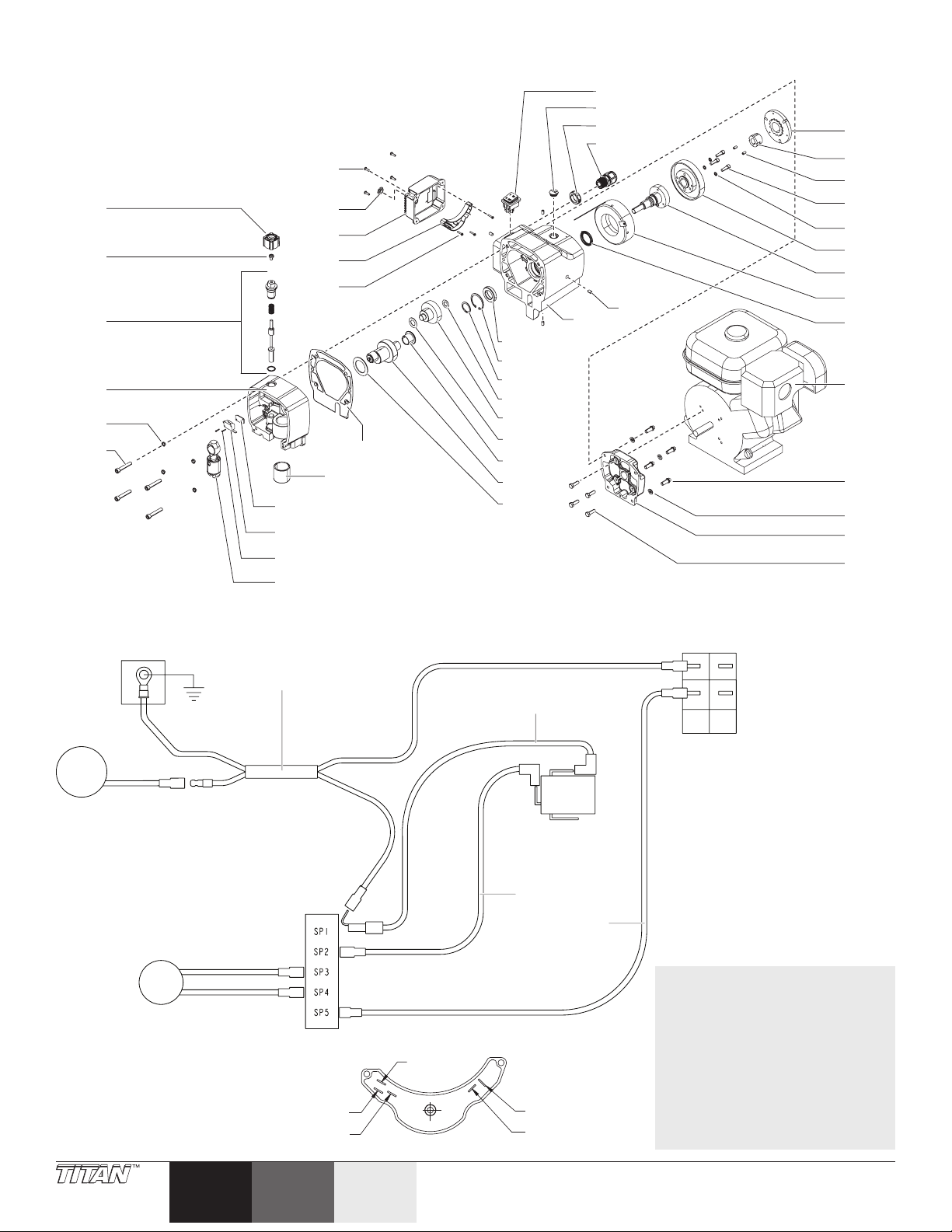

Drive Assembly ............................................................................................50

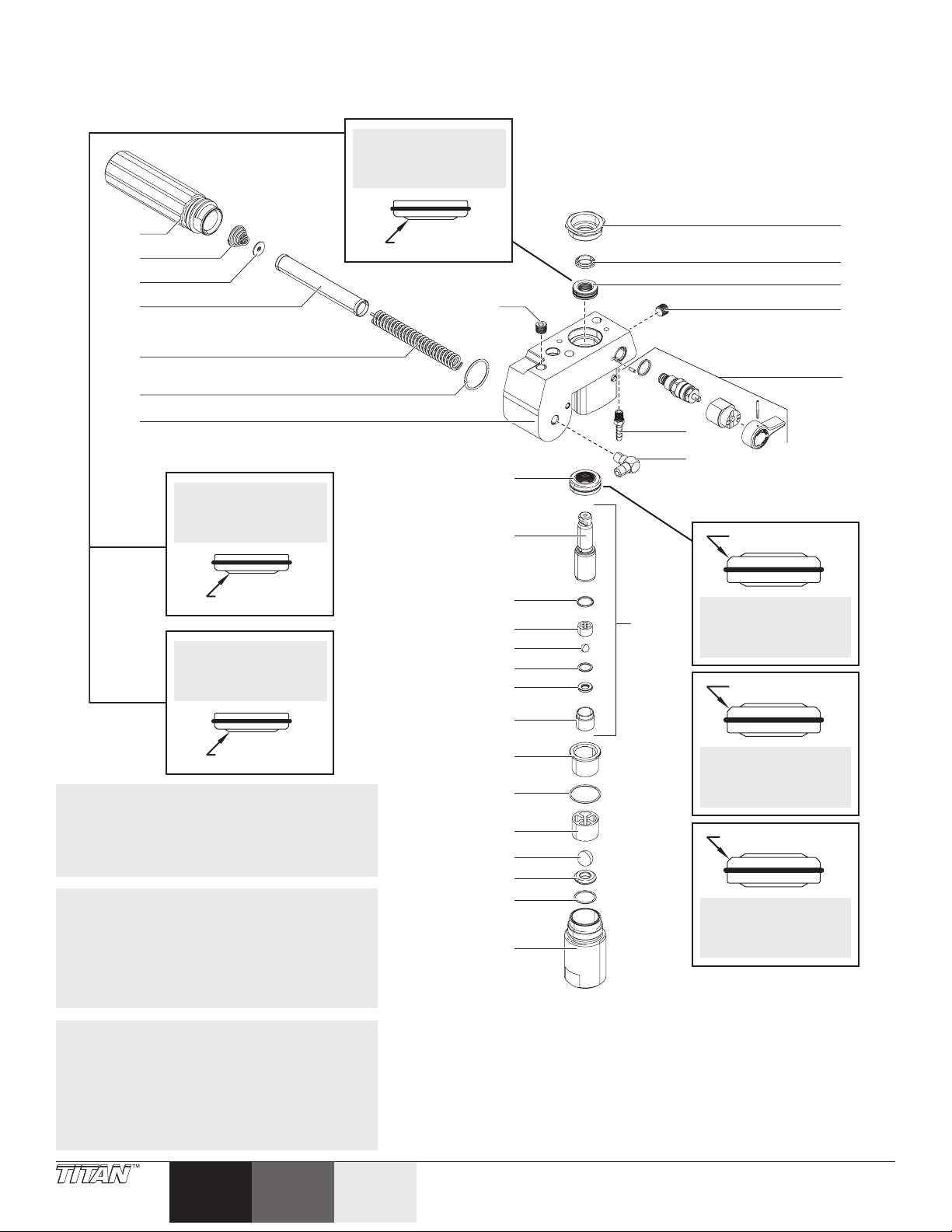

Fluid Section Assembly ............................................................................54

Cart Assembly ..............................................................................................56

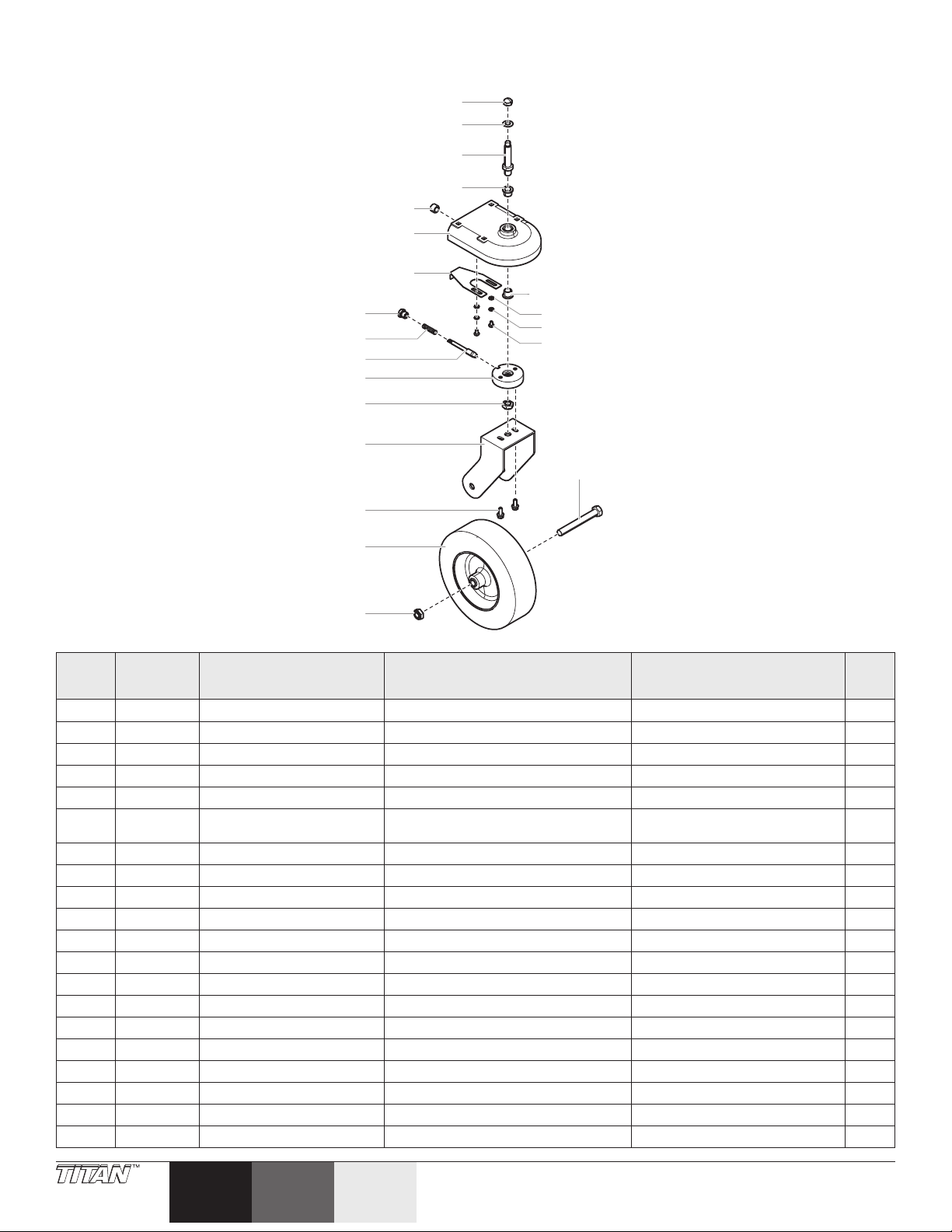

Front Wheel Assembly ..............................................................................58

Gun Holder Assembly ...............................................................................60

Brake Assembly ...........................................................................................60

Accessories ....................................................................................................62

Limited Warranty ........................................................................... 64

© Titan Tool Inc. All rights reserved. 3

English

Page 4

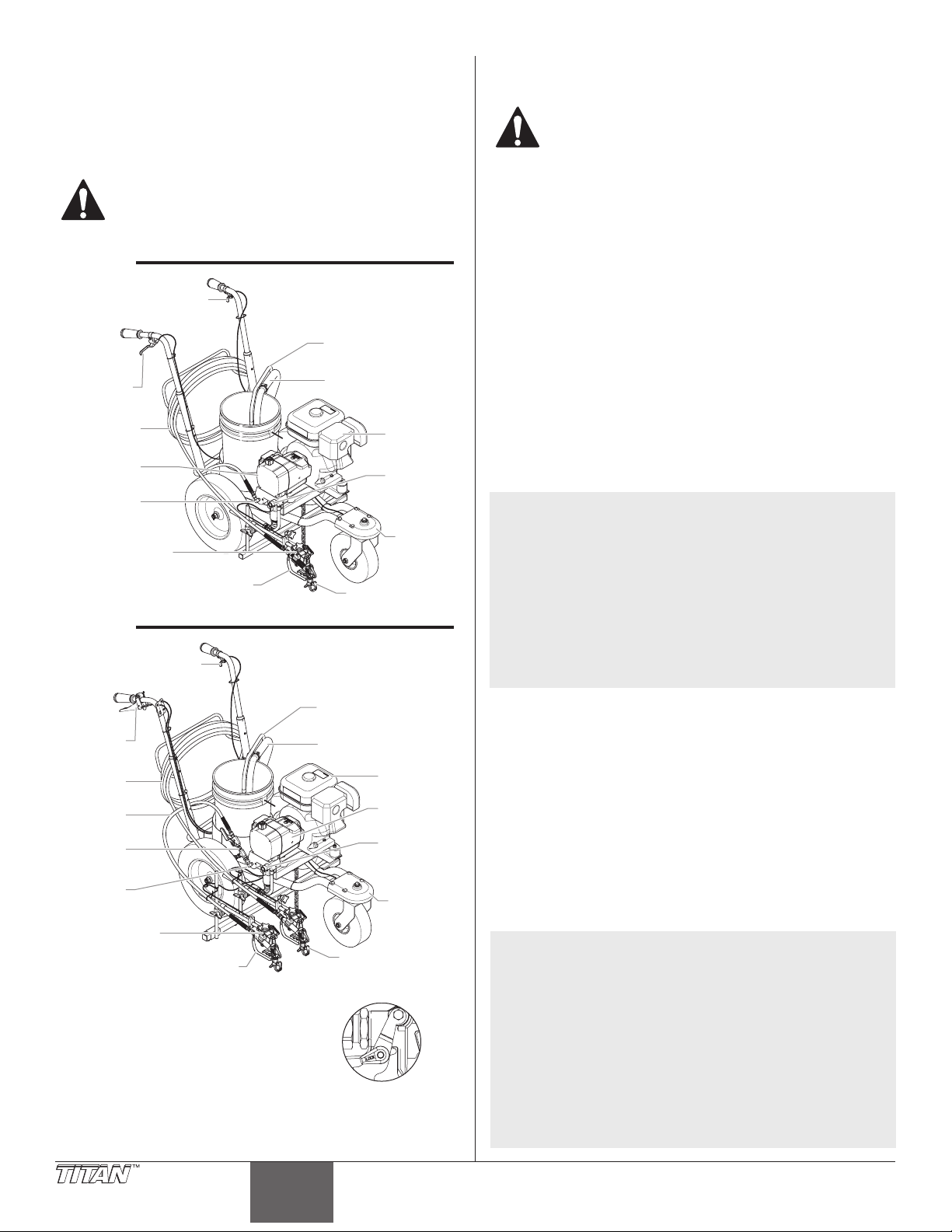

Ma

Tip Assembly

Assembly

Spray Gun (2)

Hose (50’)

Assembly

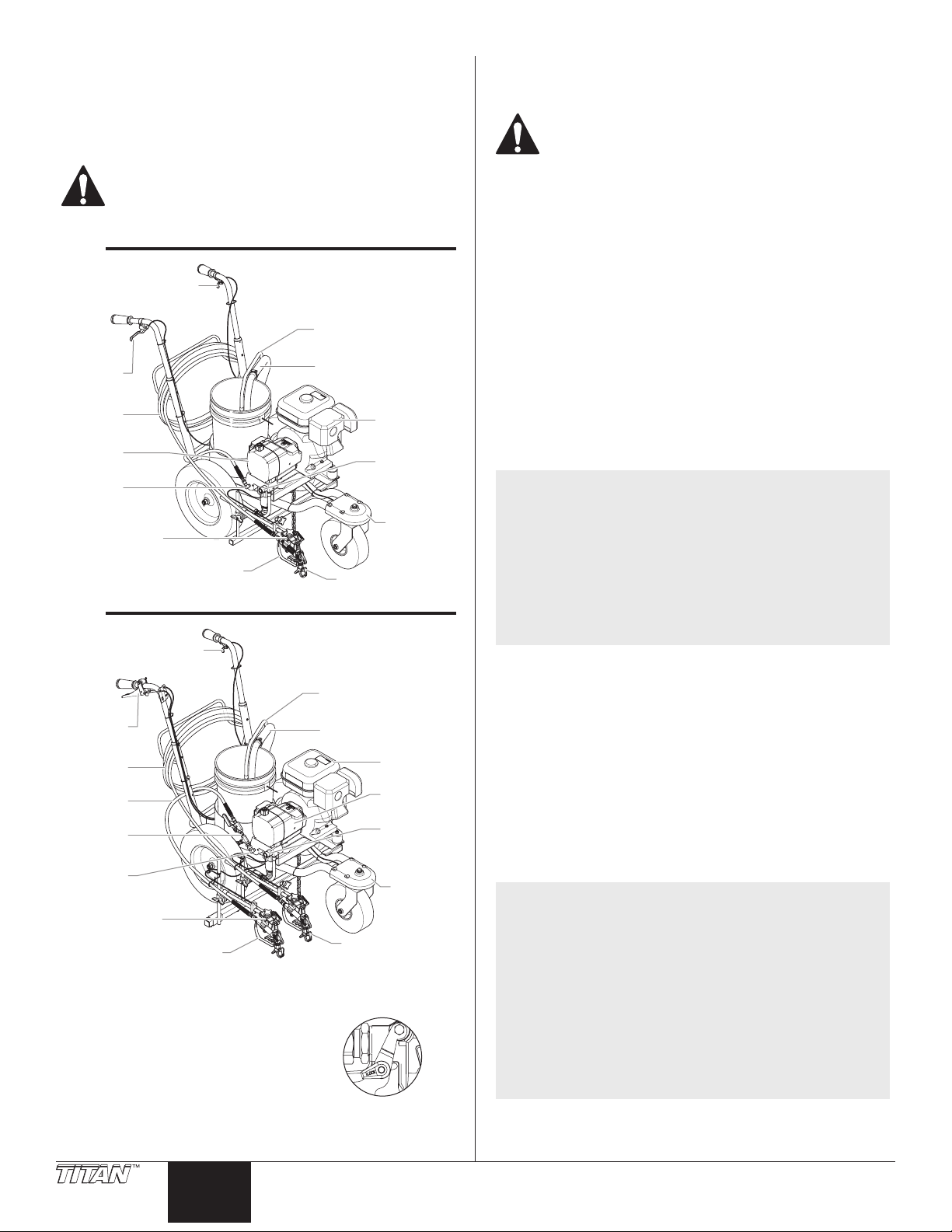

General Description

This airless line striper is a precision power tool used to spray many

types of material for many types of applications including parking

lots, curbs, and athletic elds. Read and follow this instruction

manual carefully for proper operating instructions, maintenance, and

safety information.

This equipment produces a fluid stream at extremely

high pressure. Read and understand the warnings

in the Safety Precautions section at the front of this

manual before operating this equipment.

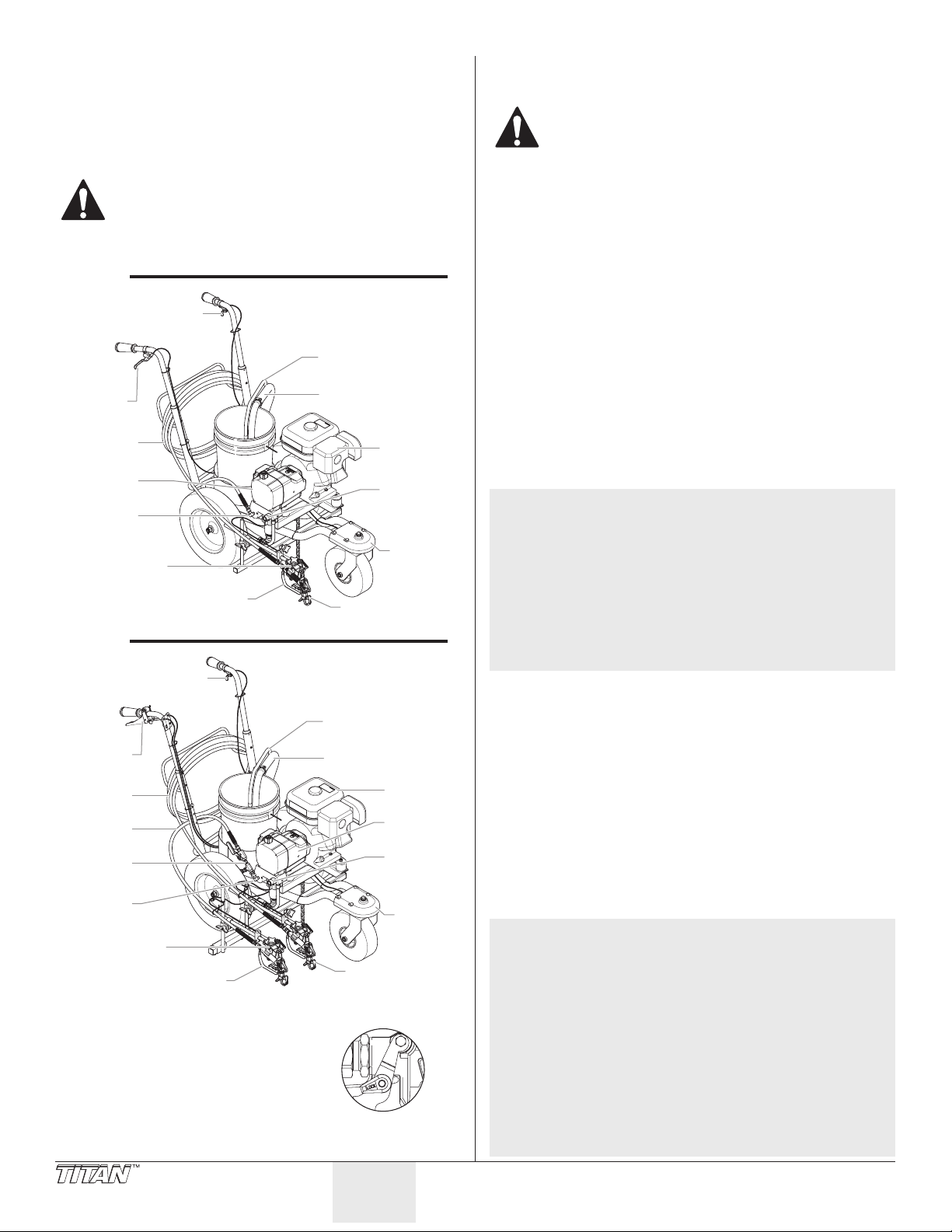

1-Gun

Caster Trigger

Return Hose

Gun

Trigger

terial

Hose

Airless

Sprayer

Outlet

Fitting

Gun Holder

Assembly

Spray Gun

2-Gun

Caster Trigger

Gun

Trigger

Material

Material

Hose (6’)

Valve

Assembly

Outlet

Fitting

Gun Holder

Assembly (2)

Trigger Lock

Engage the trigger lock whenever the gun

is not in use.

To lock the gun, turn the trigger lock

forward and slightly down until is stops.

Siphon Hose

Engine

PRIME/

SPRAY

Valve

Front

Caster

Return Hose

Siphon Hose

Engine

Airless

Sprayer

PRIME/

SPRAY

Valve

Front

Caster

Tip Assembly (2)

Trigger lock in

locked position.

Operation

Fueling (gas engine)

Gasoline is extremely flammable and is explosive

under certain conditions.

• ALWAYS turn the engine o before refueling.

• Refuel in a well-ventilated area.

• Do not smoke or allow ames or sparks in the refueling area or

where gasoline is stored.

• Do not overll the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

• Be careful not to spill fuel when refueling. Spilled fuel or fuel

vapor may ignite. If any fuel is spilled, make sure the area is

dry before starting the engine.

• Avoid repeated or prolonged contact with skin or breathing of

vapor.

• Keep out of the reach of children.

Fuel Specications

• Use automotive gasoline that has a pump octane number of

86 or higher, or that has a research octane number of 91 or

higher. Use of a lower octane gasoline can cause persistent

“pinging” or heavy “spark knock” (a metallic rapping noise)

which, if severe, can lead to engine damage.

NOTE: If “spark knock” or “pinging” occurs at a steady

engine speed under normal load, change brands of

gasoline. If spark knock or pinging persists, consult

an authorized dealer of the engine manufacturer.

Failure to do so is considered misuse, and damage

caused by misuse is not covered by the engine

manufacturer’s limited warranty.

Occasionally you may experience light spark knock

while operating under heavy loads. This is no

cause for concern, it simply means your engine is

operating eciently.

• Unleaded fuel produces fewer engine and spark plug deposits

and extends the life of the exhaust system components.

• Never use stale or contaminated gasoline or an oil/gasoline

mixture. Avoid getting dirt, dust, or water in the fuel tank.

Gasolines Containing Alcohol

If you decide to use a gasoline containing alcohol (gasohol), be

sure its octane rating is at least as high as that recommended by

the engine manufacturer. There are two types of “gasohol”: one

containing ethanol, and the other containing methanol. Do not use

gasohol that contains more than 10% ethanol. Do not use gasoline

containing methanol (methyl or wood alcohol) that does not also

contain co-solvents and corrosion inhibitors for methanol. Never

use gasoline containing more than 5% methanol, even if it has cosolvents and corrosion inhibitors.

NOTE: Fuel system damage or engine performance

problems resulting from the use of fuels that

contain alcohol is not covered under the warranty.

The engine manufacturer cannot endorse the use of

fuels containing methanol since evidence of their

suitability is incomplete at this time.

Before buying gasoline from an unfamiliar station,

try to nd out if the gasoline contains alcohol. If it

does, conrm the type and percentage of alcohol

used. If you notice any undesirable operating

characteristics while using a gasoline that contains

alcohol, or one that you think contains alcohol,

switch to a gasoline that you know does not contain

alcohol.

4 © Titan Tool Inc. All rights reserved.

English

Page 5

Setup

tting

suppor

Perform the following procedure before starting the engine of a gaspowered line striper.

NOTE: The PL2850 comes in two versions, a one-gun

version and a two-gun version. All information

given in this manual applies to both units, except

where noted.

1. Ensure that the siphon hose and the return hose are attached

and secure.

2. Turn the pressure control knob fully counterclockwise to its

lowest pressure setting.

3. Make sure the pump ON/OFF switch is in the OFF position.

4. Fill the uid section oil cup with approximately one

tablespoon of piston seal lubricant (Piston Lube).

IMPORTANT: Never operate unit for more than ten seconds

without fluid. Operating this unit without fluid will cause

unnecessary wear to the packings.

5. Check the engine oil level. The gasoline engine oil level

is determined by the manufacturer. Refer to the engine

manufacturer’s service manual (supplied).

6. Close the fuel shut-o lever and ll the gas tank with gasoline.

Use only high quality, unleaded gasoline.

One-Gun Setup

1. Using a wrench, thread the 50’ airless spray hose to the outlet

tting on the sprayer. Tighten securely.

2. Attach an airless spray gun to the spray hose. Using two

wrenches (one on the gun and one on the hose), tighten

securely.

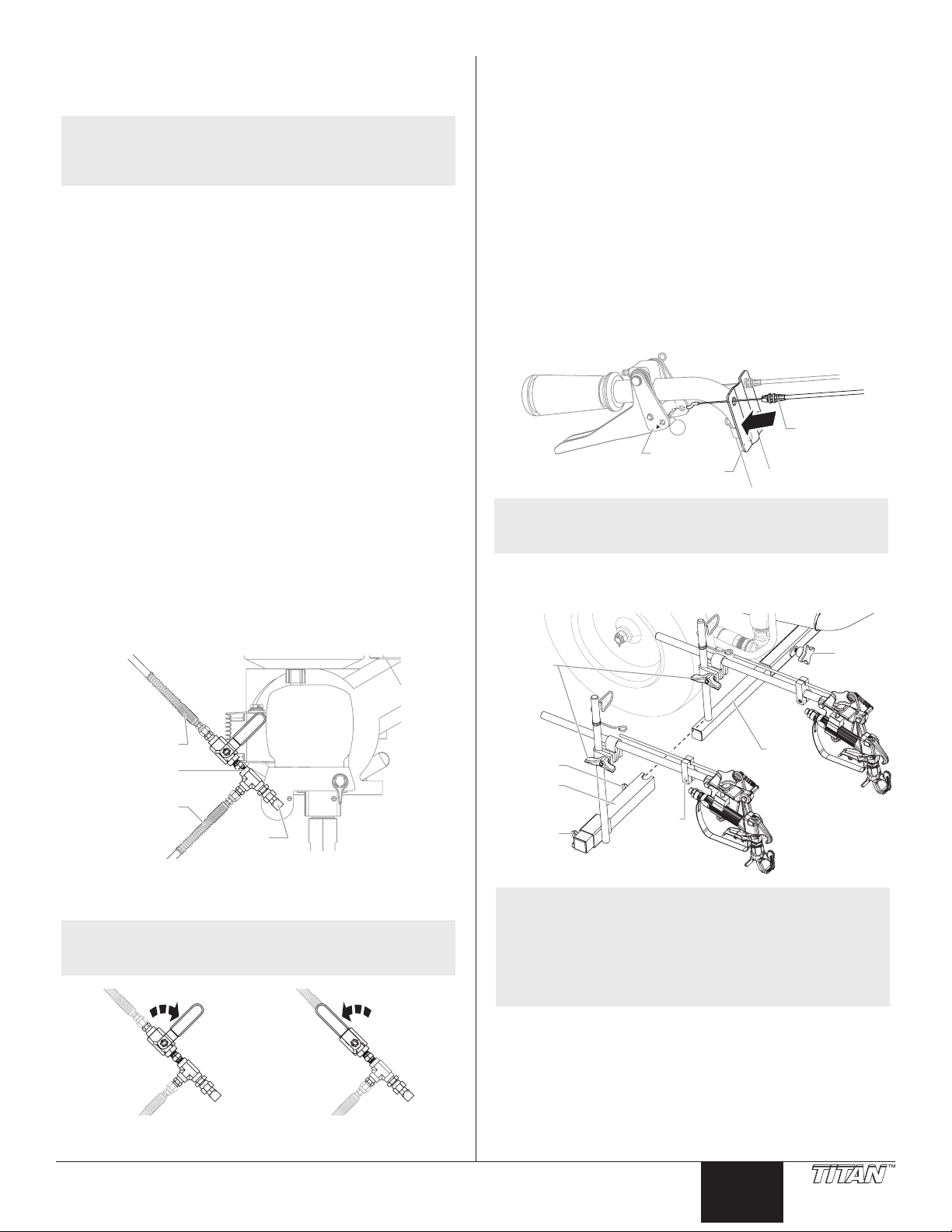

Two-Gun Setup

1. Using a wrench, thread the valve assembly (with 50’ hose

attached) to the outlet tting on the sprayer. Tighten

securely.

2. Using a wrench, thread the 6’ airless spray hose to the top

outlet tting on the valve assembly. Tighten securely.

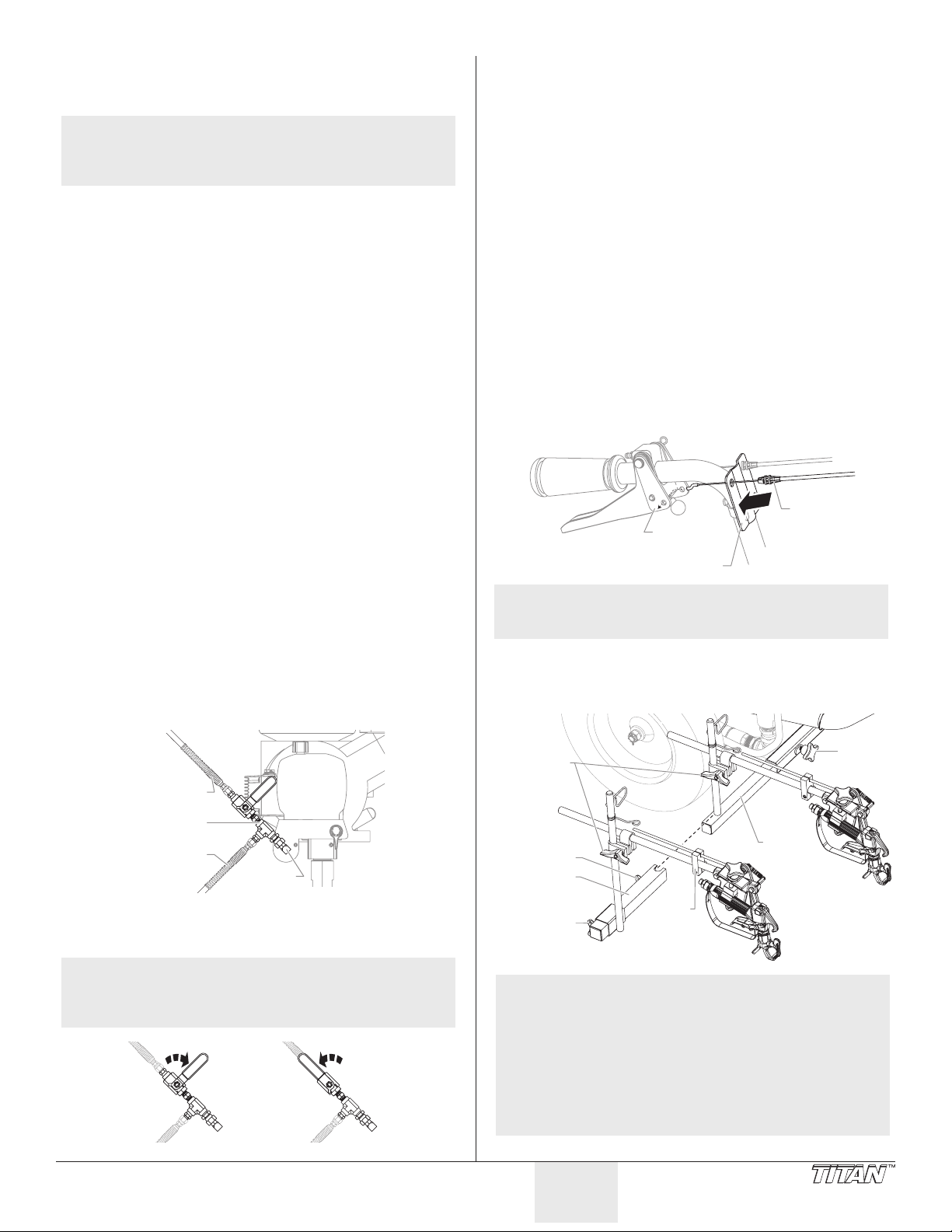

Positioning the spray guns (both units)

1. Loosen the support bar knob and slide the gun support bar

to the desired horizontal position. Make sure the gun is far

enough away from the cart so that the rear wheel does not

track over the fresh spray pattern.

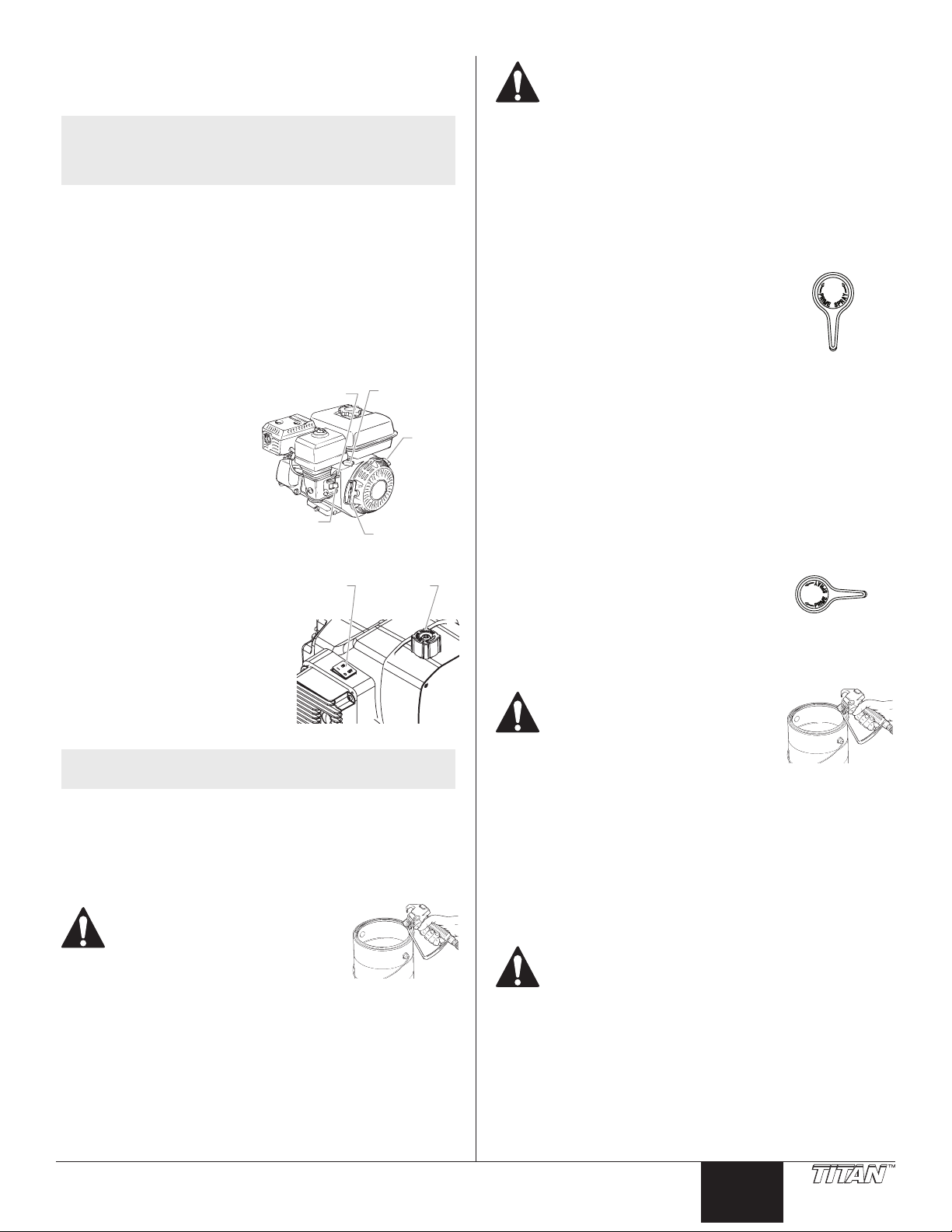

2. 2nd Gun Mounting (if equipped) -

a. Slide the 2nd gun support bar assembly over the end of the 1st gun

b. Loosen the 2nd gun post knob and slide the post to the desired

c. Run the 2nd gun cable through the block and cable guides,

IMPORTANT: Make sure the cable is not touching the tires or

interfering with the mobility of the cart in any way.

d. Insert the gun cable assembly into the hole of the control guide

e. Attach the hooked end of the cable into the hole of the lever plate.

3. Loosen the gun riser clamp(s) and slide the spray gun(s) to the

support bar. Secure in place by tightening the 2nd gun support

bar knob.

horizontal position.

underneath the frame and back towards the cart handle. Use the

tie wraps to secure the cable to the frame.

until it snaps into place.

Gun cable

Lever plate

Control guide

NOTE: See the “Adjusting the Trigger Tension” section in

order to verify that the cable is installed properly.

desired vertical position(s). A distance of 6” from the tip to the

spray surface is a good starting point.

Gun riser

clamps

Support

bar knob

6’ hose

Valve

assembly

50’ hose

Outlet

3. Attach an airless spray gun to each of the spray hoses. Using

two wrenches (one on the gun and one on the hose), tighten

securely.

NOTE: If you plan on using both guns, make sure the valve

handle is in the open position (handle is in line with

the 6’ hose)

Valve

closed

© Titan Tool Inc. All rights reserved. 5

Valve

open

Gun

Knob

2nd gun

t bar

2nd gun

post knob

Block

support

bar

NOTE: The gun support bar and the spray gun(s) can be

mounted on either side of the sprayer. Refer to the

“Spray Gun Positions” illustration near the back of

this manual.

NOTE: The height of the spray gun aects the width of the

spray pattern (i.e., the lower the gun, the smaller

the line width). Tip size also aects line width.

English

Page 6

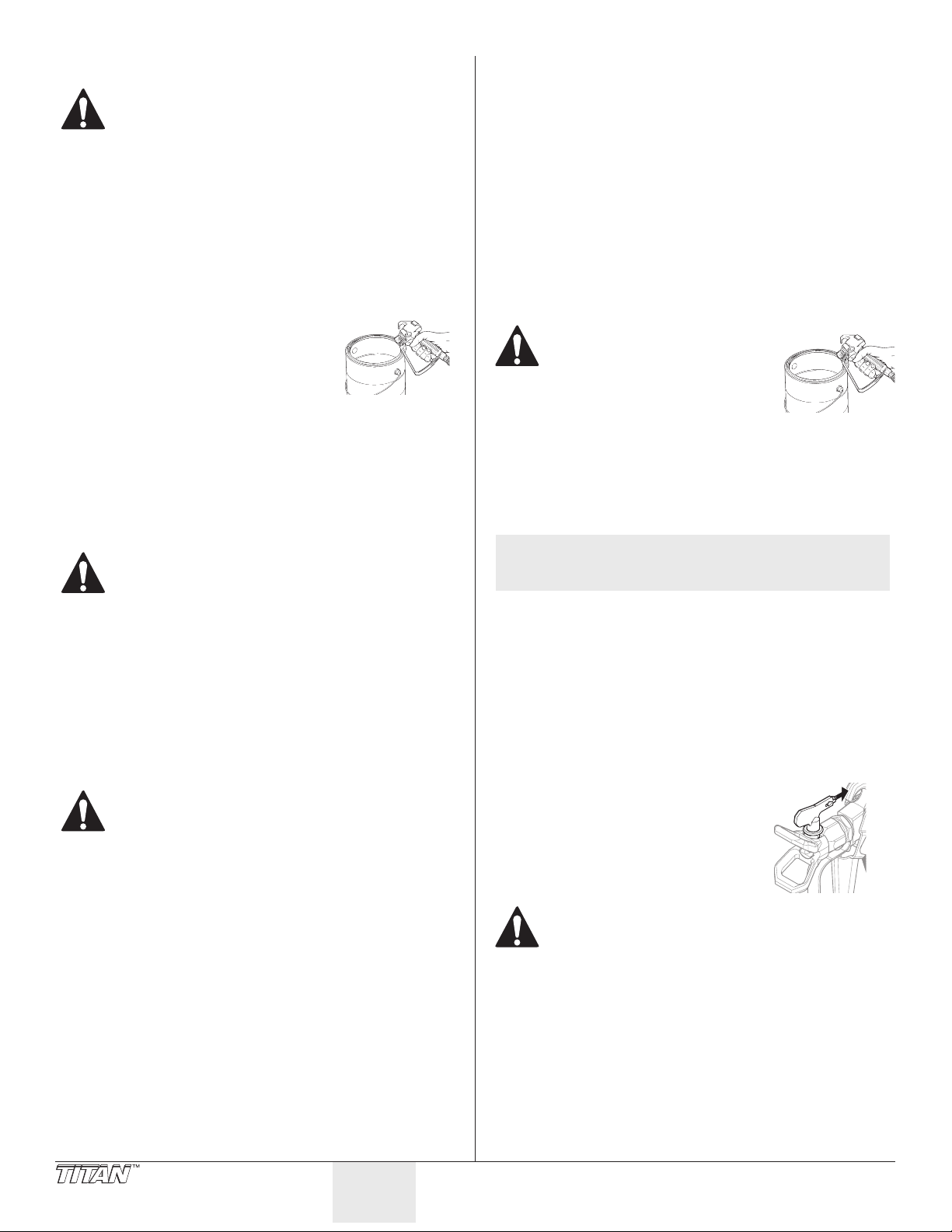

Trigger Selector (Two-Gun units)

locked position.

ON/OFF

1. Set the trigger selector for proper spray gun operation. The

gun lever on the right handlebar triggers the gun or guns.

The selector on the trigger must be set for the rst gun, both

guns, or the second gun .

IMPORTANT: Always turn the trigger lock on the spray gun to

the locked position before making any adjustments to the trigger

selector. Also, release the trigger cable from its block by lifting

the cable up and out of the block. There will be a brief triggering

of the gun while releasing the trigger cable.

a. First Gun — The rst gun

position is with the selector

in the left position. Push the

lever toward the inside of the

frame until the pin engages

the left plate.

b. Both Guns — The dual gun

position is with the selector

in the center position. Push

the lever toward the center

position until the pin engages

both plates. The pin must

engage both plates.

c. Second Gun — The second

gun position is with the

selector in the right position.

Push the lever away from the

inside of the frame until the

pin engages the right plate.

Preparing a New Sprayer

If this unit is new, it is shipped with test uid in the uid section to

prevent corrosion during shipment and storage. This uid must be

thoroughly cleaned out of the system with mineral spirits before you

begin spraying.

IMPORTANT: Always keep the trigger lock

on the spray gun in the locked position

while preparing the system.

1. Place the siphon tube into a container

of mineral spirits that has a ash point

of 60ºC (140ºF) or above.

2. Place the return hose into a metal

waste container.

3. Turn the pressure control knob fully

counterclockwise to its lowest pressure

setting.

4. Move the PRIME/SPRAY valve to the

PRIME position.

5. Move the engine ON/OFF switch to the

ON position.

6. Start the engine:

a. Open the fuel valve

lever.

b. Move the throttle lever

to its middle point.

c. Close the engine choke

lever.

d. Holding the frame

with one hand, pull the

starter rope rapidly and

rmly. Continue to hold

the rope as you let it

return. Pull and return

the rope until the engine starts.

7. Turn on the sprayer by moving

the pump ON/OFF switch to

the ON position.

Choke Lever

Fuel Valve

Lever

Sprayer

ON/OFF

Switch

8. Allow the sprayer to run for

15–30 seconds to ush the

test uid out through the

return hose and into the waste

container.

9. Turn o the sprayer by moving

the pump ON/OFF switch to

the OFF position.

Trigger lock in

PRIME

Throttle

Lever

Engine

Switch

Starter Rope

Pressure

Control

Knob

6 © Titan Tool Inc. All rights reserved.

English

Page 7

Preparing to Paint

Before painting, it is important to make sure that the uid in the

system is compatible with the paint that is going to be used.

NOTE: Incompatible uids and paint may cause the valves

IMPORTANT: Always keep the trigger lock on the spray gun in

the locked position while preparing the system.

1. Place the siphon tube into a container of the appropriate

2. Place the return hose into a metal waste container.

3. Turn the pressure control knob fully counterclockwise to its

4. Move the PRIME/SPRAY valve to the PRIME position.

5. Move the engine ON/OFF switch to the ON position.

6. Start the engine:

a. Open the fuel valve

b. Move the throttle lever

c. Close the engine choke

d. Holding the frame

7. Turn on the sprayer by moving

8. Allow the sprayer to run for

9. Turn o the sprayer by moving

NOTE: Make sure that the spray gun does not have a tip or

10. Move the PRIME/SPRAY valve to the SPRAY position.

11. Turn on the sprayer.

12. Turn the pressure control knob slowly clockwise to increase

13. Unlock the gun by turning the gun trigger lock to the

14. Trigger the gun into the metal waste container until the old

15. Lock the gun by turning the gun trigger lock to the locked

16. Set down the gun and increase the pressure by turning the

17. Check the entire system for leaks. If leaks occur, turn the

20. Follow the “Pressure Relief Procedure” in this manual before

© Titan Tool Inc. All rights reserved. 7

to become stuck closed, which would require

disassembly and cleaning of the sprayer’s uid

section.

solvent for the material being sprayed (refer to

recommendations of the material manufacturer). An example

of the appropriate solvent is water for latex paint.

lowest pressure setting.

Throttle

Lever

Engine

ON/OFF

Switch

Starter Rope

Pressure

Control

Knob

lever.

to its middle point.

lever.

with one hand, pull the

starter rope rapidly and

rmly. Continue to hold

the rope as you let it

return. Pull and return

the rope until the engine starts.

the pump ON/OFF switch to

the ON position.

Choke Lever

Fuel Valve

Lever

ON/OFF

Sprayer

Switch

15–30 seconds to ush the old

solvent out through the return

hose and into the metal waste

container.

the pump ON/OFF switch to

the OFF position.

tip guard installed.

pressure.

unlocked position.

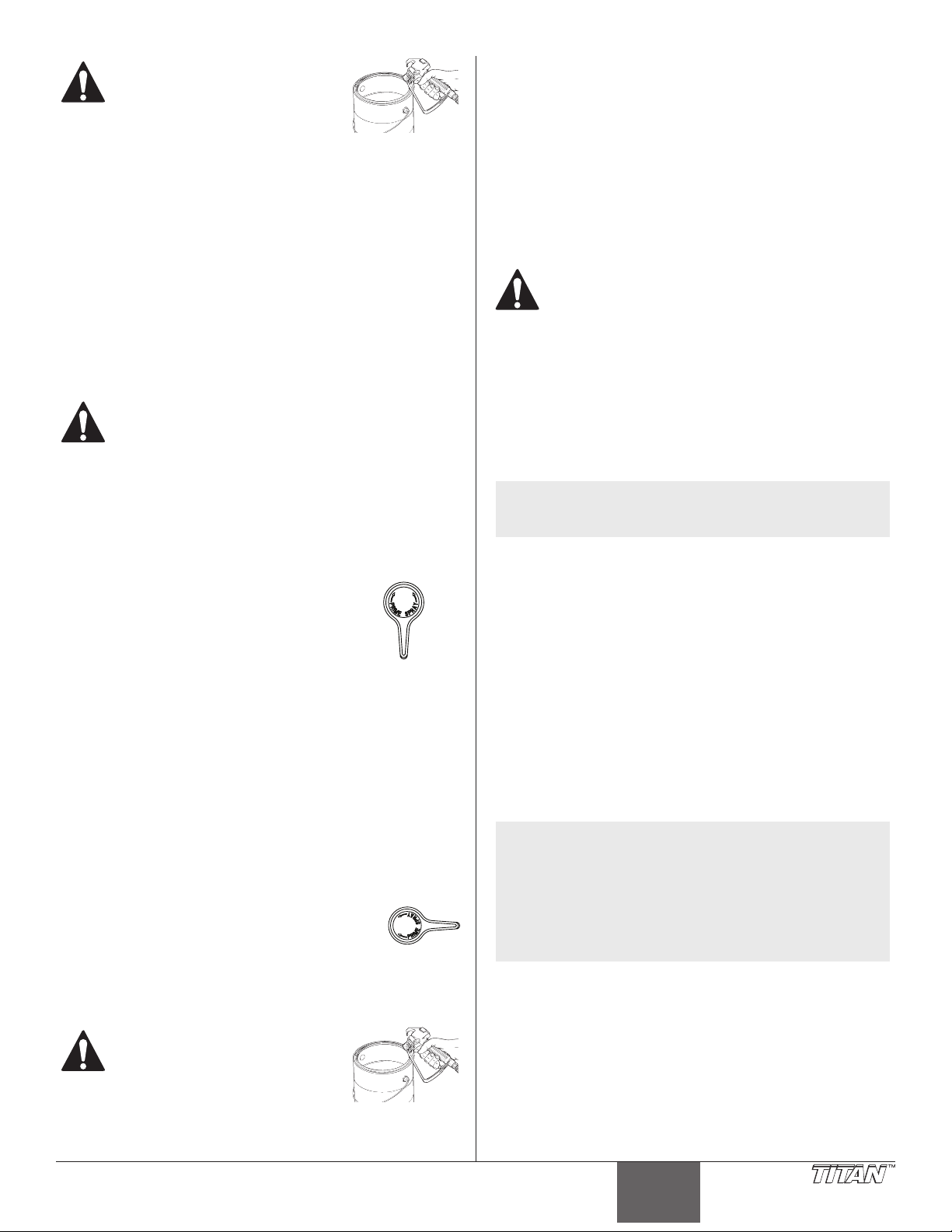

Ground the gun by holding it against

the edge of the metal container

while flushing. Failure to do so may

lead to a static electric discharge,

which may cause a fire.

solvent is gone and fresh solvent is coming out of the gun.

position.

pressure control knob slowly clockwise to its highest setting.

sprayer o and follow the “Pressure Relief Procedure” in this

manual before tightening any ttings or hoses.

changing from solvent to paint.

Be sure to follow the Pressure Relief Procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for

cleanup.

Painting

1. Place the siphon tube into a container of paint.

2. Place the return hose into a metal waste container.

3. Turn the pressure control knob fully counterclockwise to its

lowest pressure setting.

4. Move the PRIME/SPRAY valve to the

PRIME position.

5. Move the engine ON/OFF switch to the

ON position.

PRIME

6. Start the engine:

a. Open the fuel valve lever.

b. Move the throttle lever to its middle point.

c. Close the engine choke lever.

d. Holding the frame with one hand, pull the starter rope rapidly

and rmly. Continue to hold the rope as you let it return. Pull and

return the rope until the engine starts.

7. Turn on the sprayer by moving the pump ON/OFF switch to

the ON position.

8. Allow the sprayer to run until paint is coming through the

return hose into the metal waste container.

9. Turn o the sprayer by moving the pump ON/OFF switch to

the OFF position.

10. Remove the return hose from the waste container and place it in

its operating position above the container of paint.

11. Move the PRIME/SPRAY valve to the

SPRAY position.

12. Turn on the sprayer.

13. Turn the pressure control knob slowly

SPRAY

clockwise to increase pressure.

14. Unlock the gun by turning the gun trigger lock to the

unlocked position.

Ground the gun by holding it against

the edge of the metal container

while flushing. Failure to do so may

lead to a static electric discharge,

which may cause a fire.

15. Trigger the gun into the metal waste container until all air and

solvent is ushed from the spray hose and paint is owing

freely from the gun.

16. Lock the gun by turning the gun trigger lock to the locked

position.

17. Turn the pressure control knob fully counterclockwise to its

lowest setting.

18. Turn o the sprayer.

19. Attach tip guard and tip to the gun as instructed by the tip

guard or tip manuals.

POSSIBLE INJECTION HAZARD. Do not spray without

the tip guard in place. Never trigger the gun unless

the tip is in either the spray or the unclog position.

Always engage the gun trigger lock before removing,

replacing or cleaning tip.

20. Turn on the sprayer.

21. Increase the pressure by turning the pressure control knob

slowly clockwise. Test the spray pattern and line position on a

long piece of roong felt or cardboard.

a. Adjust the pressure control knob until the spray from the gun is

completely atomized. Try to keep the pressure control knob at the

lowest setting that maintains good atomization.

English

Page 8

NOTE: Turning the pressure up higher than needed to

atomize the paint will cause premature tip wear and

additional overspray.

b. Check for proper line width and position. If adjustment to the

position of the spray gun is required, refer to the “Setup” procedure

earlier in this section.

22. Make sure that the spray gun completely shuts o when the

gun trigger is released. If adjustment to the trigger tension

is required, refer to the “Adjusting the Trigger Tension”

procedure.

Operating the Front Caster

The front caster on the cart is designed to track the sprayer in either

a straight line or allow free motion. Standing behind the sprayer, the

trigger on the left handle of the cart controls the operation of the

front caster.

1. To lock the front caster in the straight line position, squeeze

then release the caster trigger and move the sprayer forward.

2. To allow free motion of the front caster, squeeze and hold the

caster trigger.

NOTE: To lock the front caster in free motion mode,

squeeze and hold the caster trigger and then push

in the locking button on the side of the trigger.

Once the locking button is pushed in, the caster

trigger can be released. To release the locking pin,

squeeze the caster trigger.

Pressure Relief Procedure

Be sure to follow the Pressure Relief Procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray nozzles, or preparing for

cleanup.

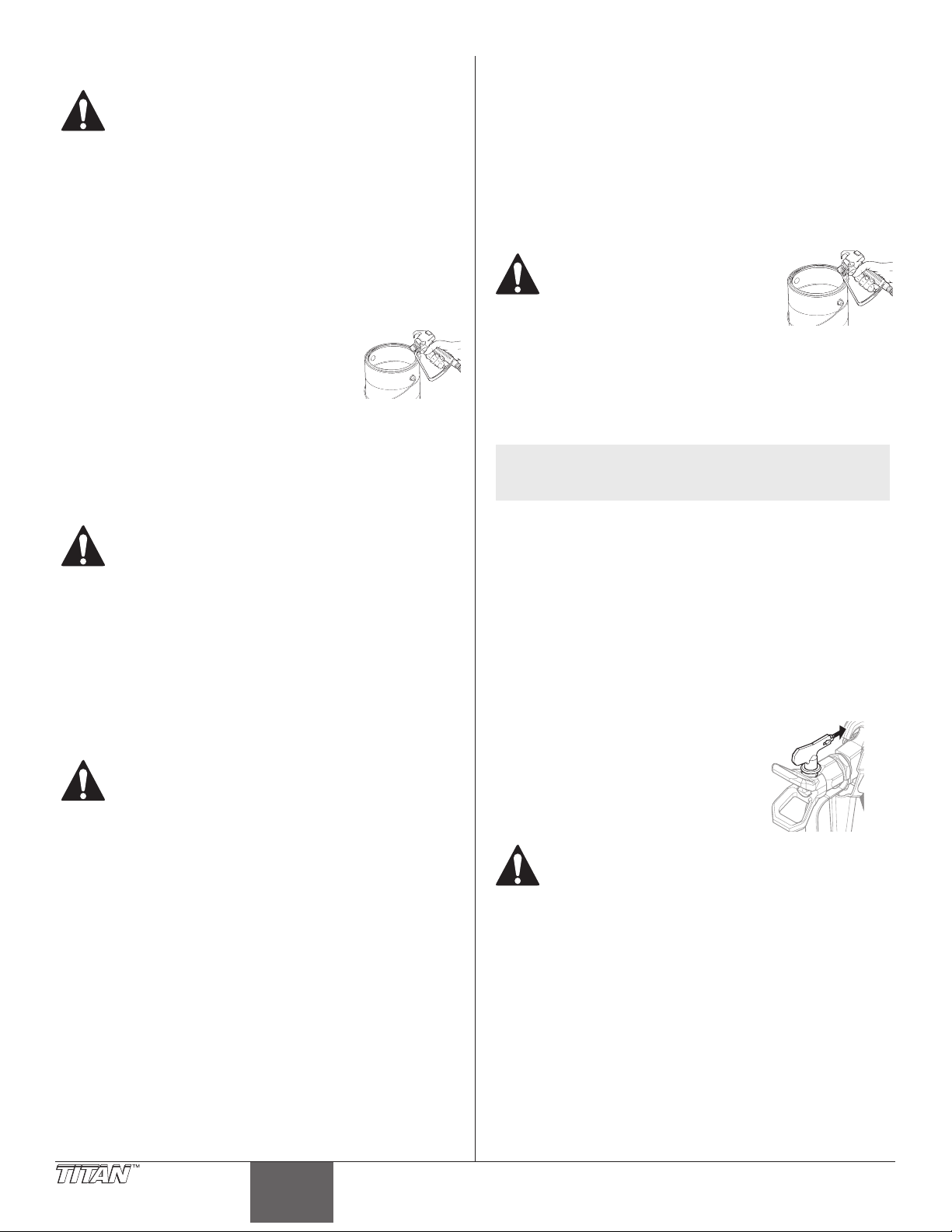

1. Lock the gun by turning the gun trigger lock to the locked

position.

2. Turn o the sprayer by moving the pump ON/OFF switch to

the OFF position.

3. Turn o the engine by moving the engine ON/OFF switch to

the OFF position.

4. Turn the pressure control knob counterclockwise to its lowest

setting.

5. Unlock the gun by turning the gun trigger lock to the

unlocked position.

6. Hold the metal part of the gun rmly to the

side of a metal container to ground the gun

and avoid a build up of static electricity.

7. Trigger the gun to remove any pressure that

may still be in the hose.

8. Lock the gun by turning the gun trigger lock to the locked

position.

9. Move the PRIME/SPRAY valve to the PRIME position.

Cleanup

Special cleanup instructions for use with flammable

solvents:

• Always ush spray gun preferably outside and at least one

hose length from spray pump.

• If collecting ushed solvents in a one gallon metal container,

place it into an empty ve gallon container, then ush

solvents.

• Area must be free of ammable vapors.

• Follow all cleanup instructions.

IMPORTANT: The sprayer, hose, and gun should be cleaned

thoroughly after daily use. Failure to do so permits material to

build up, seriously affecting the performance of the unit.

Always spray at minimum pressure with the gun

nozzle tip removed when using mineral spirits or any

other solvent to clean the sprayer, hose, or gun. Static

electricity buildup may result in a fire or explosion in

the presence of flammable vapors.

1. Follow the “Pressure Relief Procedure” found in the Operation

section of this manual.

2. Remove the gun tip and tip guard and clean with a brush

using the appropriate solvent.

3. Place the siphon tube into a container of the appropriate

solvent (refer to recommendations of the material

manufacturer). An example of the appropriate solvent is

water for latex paint.

4. Place the return hose into a metal waste container.

5. Move the PRIME/SPRAY valve to its PRIME position.

6. Move the engine ON/OFF switch to the ON position and start

the engine.

7. Turn on the sprayer by moving the sprayer ON/OFF switch to

the ON position.

8. Slowly turn the pressure control knob clockwise to increase

the pressure until uid starts to come out of the return hose.

9. Allow the solvent to circulate through the sprayer and

ush the paint out of the return hose into the metal waste

container.

10. Turn the pressure control knob fully counterclockwise to its

lowest setting.

11. Turn o the sprayer by moving the ON/OFF switch to the OFF

position.

12. Move the PRIME/SPRAY valve to its SPRAY position.

13. Turn on the sprayer.

14. Turn the pressure control knob slowly clockwise to increase

pressure.

Ground the gun by holding it against

the edge of the metal container

while flushing. Failure to do so may

lead to a static electric discharge,

which may cause a fire.

15. Trigger the gun into the metal waste container until the paint

is ushed out of the hose and solvent is coming out of the

gun.

16. Continue to trigger the spray gun into the waste container

until the solvent coming out of the gun is clean.

NOTE: For long-term or cold weather storage, pump

17. Follow the “Pressure Relief Procedure” found in the Operation

18. Store the sprayer in a clean, dry area.

IMPORTANT: Do not store the unit under pressure.

8 © Titan Tool Inc. All rights reserved.

English

mineral sprits through the entire system.

section of this manual.

Page 9

Cleaning the Spray Tip

1. Flush the gun with solvent immediately after the work is

completed.

2. Oil the sliding pins to prevent them from seizing up.

Should the spray tip become clogged,

reverse the spray tip with the lever and pull

the trigger. Once the obstruction comes out

of the spray tip, release the trigger, reverse

the spray tip back to the spray pattern

setting, and resume spraying.

Do not attempt to clean the tip

with your finger.

Do not use a needle or other

sharp pointed instrument

to clean the tip. The hard

tungsten carbide is brittle and

can be chipped.

Maintenance

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce the

risk of an injection injury, injury from moving parts or

electric shock.

Maintaining the Engine

When transporting a sprayer with a gas engine, make

sure the fuel is shut off.

NOTE: For detailed engine specications and maintenance,

refer to the separate engine manual supplied with

this sprayer.

Important Facts Concerning this Sprayer

This gas-powered sprayer contains a clutch that engages when

the sprayer is pumping. The sprayer’s pressure control system

engages and disengages the clutch to control pressure. To prevent

unnecessary wear to the clutch, it is advisable to adjust the engine

speed and pressure setting to limit the amount of times the clutch

engages and disengages. To reduce clutch wear, refer to the

following examples.

Example:

Operating one gun with a .019” tip — reduce the engine speed

by adjusting the throttle to a low or medium setting and increase

pressure only until the heavy ends of the spray pattern have been

eliminated.

Example:

Operating one gun with .025” tip — increase engine speed to a

higher setting and increase pressure until the heavy ends of the spray

pattern have been eliminated.

NOTE: All Honda engine work should be performed by a

Honda authorized service center.

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

Phillips screwdriver 3/8” hex wrench

needle-nose pliers 5/16” hex wrench

adjustable wrench 1/4” hex wrench

rubber mallet 3/16” hex wrench

at-blade screwdriver 1/8” hex wrench

1/2” open-end wrench 7/8” open-end wrench

1. Before repairing any part of the sprayer, read the instructions

carefully, including all warnings.

IMPORTANT: Never pull on a wire to disconnect it. Pulling on a

wire could loosen the connector from the wire.

2. Test your repair before regular operation of the sprayer to be

sure that the problem is corrected. If the sprayer does not

operate properly, review the repair procedure to determine if

everything was done correctly. Refer to the Troubleshooting

section to help identify other possible problems.

3. Make certain that the service area is well ventilated in case

solvents are used during cleaning. Always wear protective

eyewear while servicing. Additional protective equipment

may be required depending on the type of cleaning solvent.

Always contact the supplier of solvents for recommendations.

4. If you have any further questions concerning your Titan airless

sprayer, call Titan:

Technical Service (U.S.) ...................................... 1-800-526-5362

Fax ................................................................. 1-800-528-4826

Example:

Spraying light-bodied materials at low pressure — to reduce surging

at the gun and to decrease clutch wear, reduce the engine speed to

idle and reduce pressure until the desired spray pattern is achieved.

Routine Engine Maintenance

Daily

• Check and ll the gas tank.

• After the rst 20 hours of operation (or 1 month), drain the oil

and rell with clean oil. Check the engine oil level and ll as

necessary.

Weekly

• Remove the cover of the air lter and clean the element.

Replace the element if necessary. If operating in an unusually

dusty environment, check the lter daily and replace if

necessary. (Replacement elements can be purchased from

your local Titan dealer.)

• After each 50 hours (or 3 months) of operation: Change the

engine oil.

Spark Plug

• Use only a (NKG) BPR6ES plug.

• Gap the plug 0.028” – 0.031” (0.7 - 0.8 mm)

• Make sure to use a spark plug wrench when installing and

removing the plug.

© Titan Tool Inc. All rights reserved. 9

English

Page 10

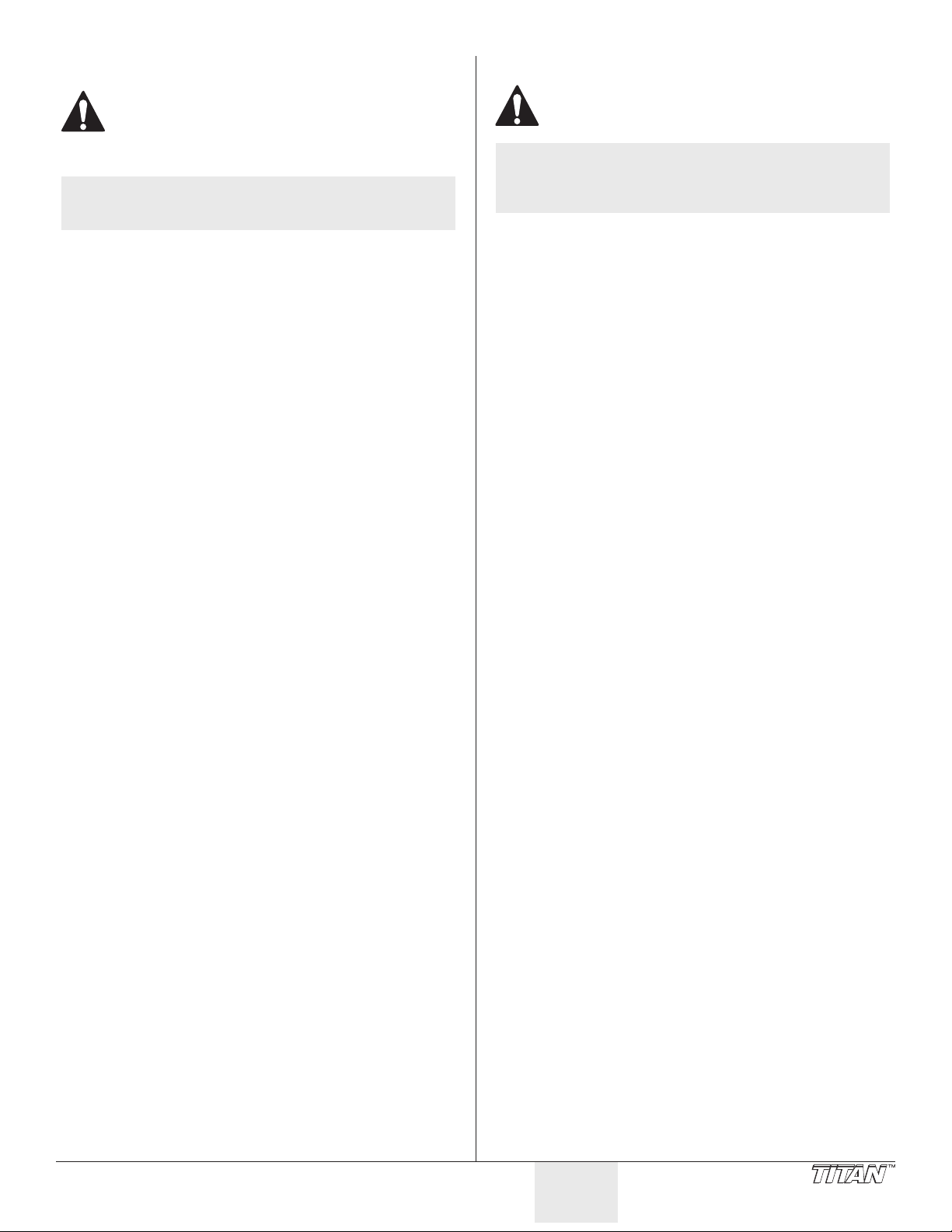

Adjusting the Trigger Tension

Trigger Lever

Cable Block

Groove

old

Handle

Housing

Handle

Use the following procedure to adjust the spring tension of the

trigger lever on the gun holder assembly. The trigger lever pulls and

releases the spray gun trigger when operated from the trigger on the

cart. The proper tension ensures that the gun will shut o when the

gun trigger is released. To ensure proper tension, there should be

approximately a 1/32” to 1/16” gap between the trigger lever and the

spray gun trigger.

IMPORTANT: Always keep the trigger lock on the spray gun in

the locked position while making adjustments to the system.

1. Using a wrench, loosen the bolt on the cable block.

2. Move the cable block in the appropriate direction to create a

gap of 1/32” to 1/16” between the trigger lever and spray gun

trigger.

a. Slide the cable block toward the gun to increase the gap between

the trigger lever and spray gun trigger.

b. Slide the cable block away from the gun to decrease the gap

between the trigger lever and spray gun trigger.

(bolt on back)

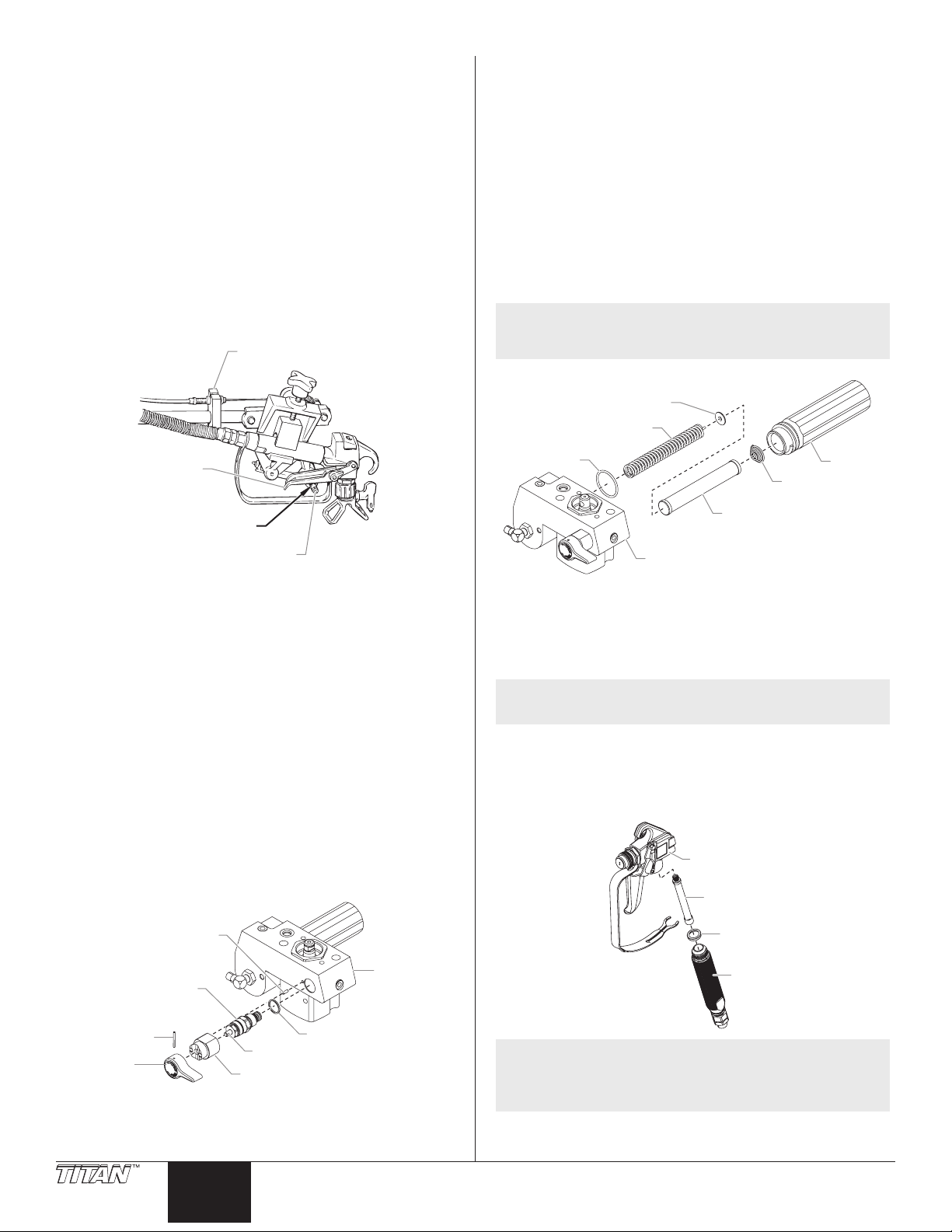

Cleaning or Replacing the Filters

Pump Filter

1. Loosen and remove the lter housing by hand. Pull the lter

out of the pump manifold.

2. Slip the lter o of the lter support spring.

3. Inspect the lter. Based on inspection, clean or replace the

lter.

4. Inspect the lter seal. Based on inspection, clean or replace

the lter seal.

5. Slide the new or cleaned lter over the lter support spring

with the adapter in place. Push the lter into the center of the

pump manifold.

6. Slide the lter housing over the lter and thread it into the

pump manifold until secure.

NOTE: The lter housing should be hand-tightened, but

make sure the lter housing is seated fully into the

pump manifold.

Adapter

Filter Support Spring

Spray Gun

Trigger

1/32" to 1/16" Gap

3. Tighten the set screw securely.

Replacing the PRIME/SPRAY Valve

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 800-915 or 700-258.

1. Drive the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly from the pump manifold.

4. Make sure the gasket is in place and thread the new valve

housing assembly into the pump manifold. Tighten securely

with a wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam with

the pump manifold using the dowel pin.

6. Line up the hole on the valve stem with the hole in the valve

handle.

7. Insert the groove pin into the valve handle and through the

valve stem to secure the valve handle in position.

Filter Seal

Filter

Spring

Filter

Pump Manifold

Filter

Gun Filter

1. Move the gun trigger lock to the unlocked position.

2. Loosen and remove the handle from the gun body.

3. Turning clockwise, unscrew the lter from the gun body.

NOTE: Left-handed threads require turning the lter

4. Turning counterclockwise, screw the new or cleaned lter into

5. Make sure the handle seal is in position and thread the handle

6. Move the gun trigger lock to the locked position.

clockwise to remove.

the gun body.

into the gun body until secure.

Gun

Housing

Filter

Dowel Pin

Pump

Valve Housing

Assembly

Pin

Valve

10 © Titan Tool Inc. All rights reserved.

English

Valve Stem

Cam Base

Gasket

Manif

NOTE: For more detail, part number information, and

complete assembly drawings, please see the LX-80II

Professional Airless Gun Owner’s Manual (P/N 313-

2293).

Handle

Seal

Page 11

Assembly

Assembly

Relay

Housing

Gear Housing

Pump Housing Socket Screw

P

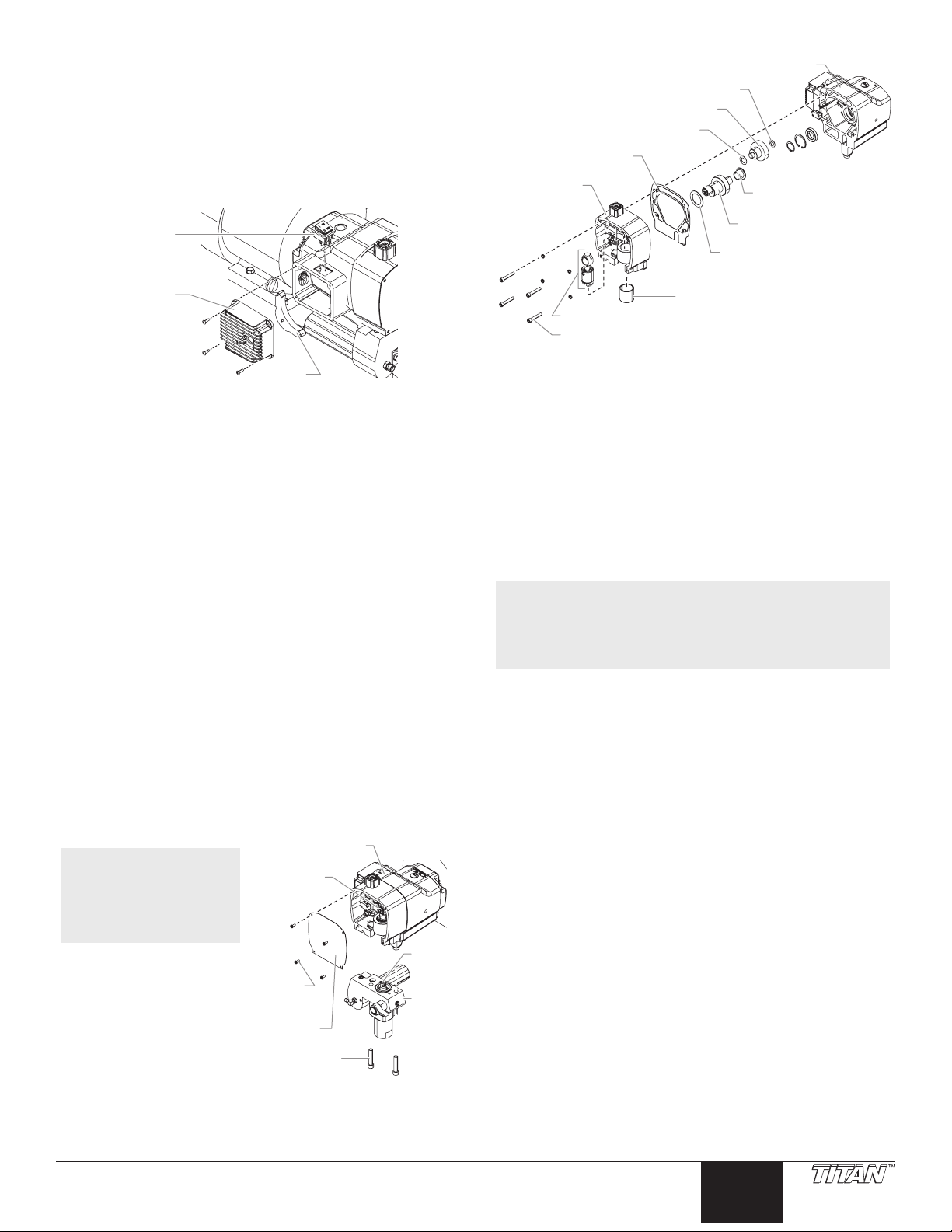

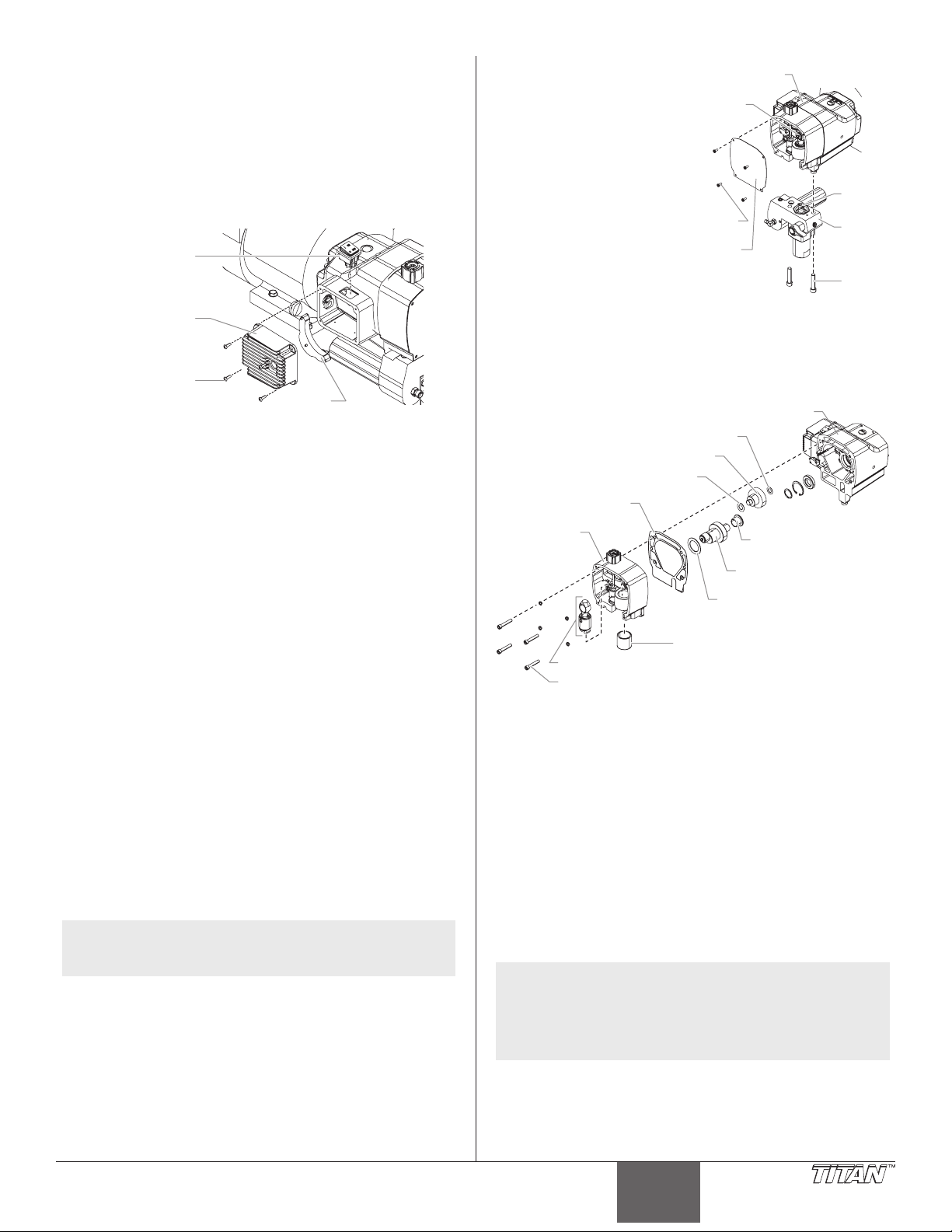

Replacing the Sprayer ON/OFF Switch

1. Perform the Pressure Relief Procedure.

2. Using a Phillips screwdriver, remove the four screws that

secure the heat sink assembly to the housing. Carefully

remove the heat sink assembly from the housing. Gently

move the assembly away from the sprayer and allow the

assembly to hang from the housing.

3. Locate the bottom of the sprayer ON/OFF switch inside the

housing.

ON/OFF

Switch

Heat Sink

Heat Sink

Screw

4. Disconnect the switch wires from the sprayer ON/OFF switch.

Remember the locations of each of the two wires (label the

wires, if necessary).

5. Depress the mounting tabs on each corner of the sprayer ON/

OFF switch inside the housing and remove the switch through

the top of the housing.

6. Snap the new sprayer ON/OFF switch into the switch hole in

the housing.

7. Connect the two switch wires to the new sprayer ON/

OFF switch. Make sure the wires are connected to the

corresponding terminals from which they were removed (refer

to the labels created earlier in this procedure or the electrical

schematic in the Parts List section of this manual).

8. Carefully place the heat sink assembly over the housing taking

care not to pinch any wires.

9. Install the four screws that secure the heat sink assembly to

the housing. Tighten securely.

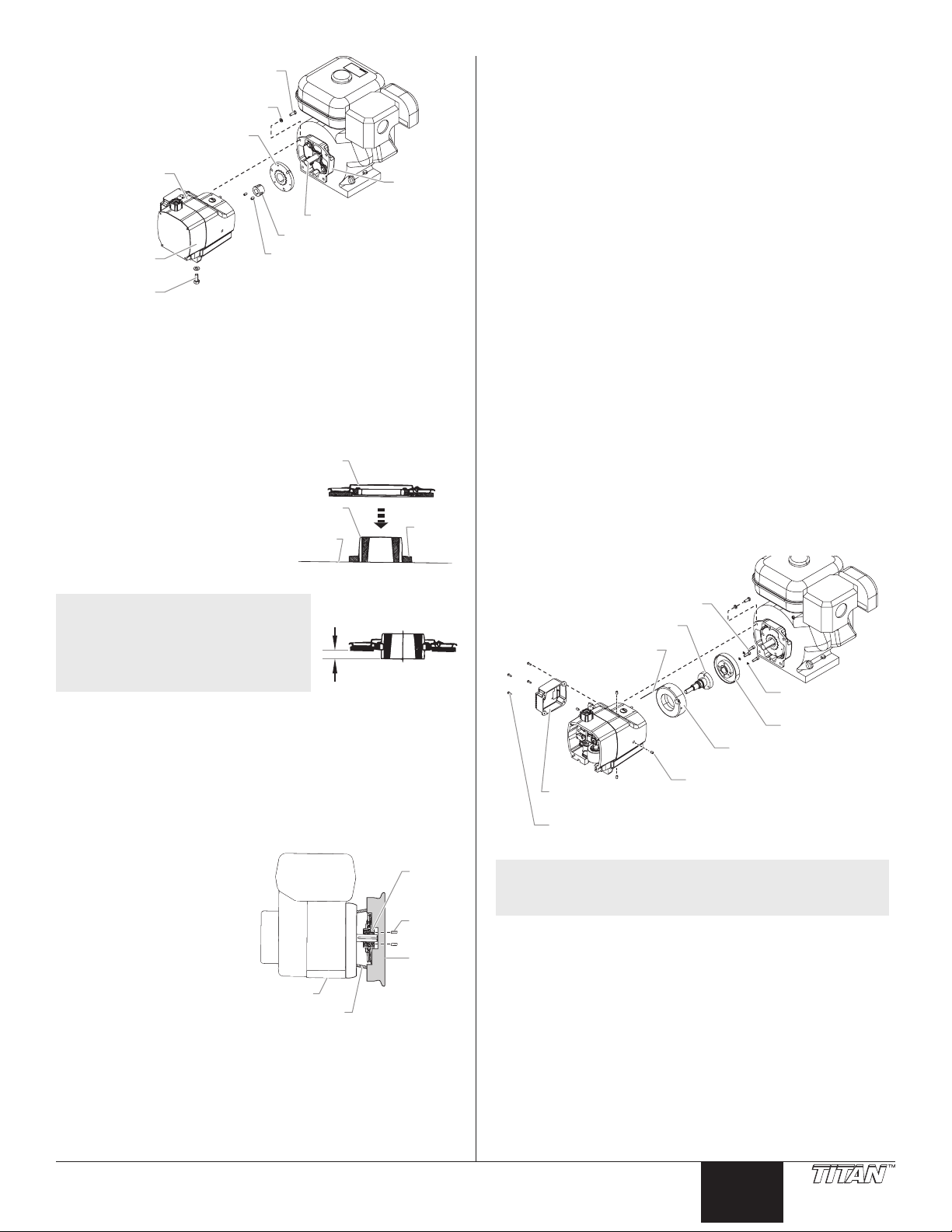

Replacing the Gears and/or Slider Assembly

1. Using a Phillips screwdriver, remove the four front cover

screws. Remove the front cover.

2. Start the engine (refer to the procedures in the Operation

section of this manual). Turn the pressure control knob

clockwise to its maximum pressure setting.

3. Toggle the sprayer ON/OFF switch between the ON and OFF

positions in short bursts until the slider assembly and piston

stop at the bottom of their stroke (in their lowest position).

4. Turn o the engine and perform the Pressure Relief Procedure.

Pump

Front

Front

Cover

Slider

Socket

Screw

Housing

Piston

Fluid

Section

NOTE: If replacing the

slider assembly,

the uid section

Assembly

must be removed

from the pump

housing.

5. Using a 3/8” hex wrench,

remove the two socket

screws that secure the

uid section to the pump

housing.

Cover

Screw

6. Pull uid section housing

down approximately

1/2” from the gear box

housing to clear the

transducer.

7. Slide the uid section housing and piston rod forward until

the piston rod is out of the T-slot on the slider assembly.

8. Using a 1/4” hex wrench,remove the four socket screws that

secure the pump housing to the gear housing.

© Titan Tool Inc. All rights reserved. 11

Thrust Washer

Output Gear Assembly

Thrust Washer

Housing Gasket

ump Housing

Cylindrical

Thrust Washer

Crankshaft

Assembly

Thrust

Washer

Slider Bushing

Slider Assembly

9. Slide the pump housing away from the gear housing.

10. Remove and clean the housing gasket. Replace if damaged.

11. Slide the crankshaft assembly, with the two thrust washers out

from the gear housing side of the pump housing.

12. Remove the output gear assembly with the two thrust

washers.

13. Thoroughly clean the crankshaft assembly, the output gear

assembly, and all the thrust washers.

14. Inspect all parts for excessive wear and replace if damaged or

worn. If the crankshaft or output gear assembly are replaced,

replace the corresponding thrust washers as well.

15. Inspect the pinion gear on the end of the drive shaft for wear.

Replace if damaged or worn (refer to the “Servicing the Clutch

Assembly” procedure in this section).

NOTE: If any of the gears are worn and require

replacement, check the grease in the gear housing

for metal particles or shavings. Remove the

contaminated grease. Replace the grease that has

been removed with fresh Lubriplate GR-132 grease.

16. Slide the slider assembly up and out of the slider bushing in

the front of the pump housing.

17. Check the parts for wear.

a. If the slider bushing is scored or out of round the pump housing

should be replaced.

b. If the slider assembly is scored or the connection between the

c. Any parts that will be reused should be cleaned thoroughly, including

connecting rod and slider assembly exhibits movement other than

pivoting movement, the slider assembly should be replaced. The

slider assembly also should be replaced if the connecting rod bearing

shows signs of wear.

the connecting rod. Also, clean the crankshaft pin that the connecting

rod bearing rides on.

18. Coat the output gear assembly and each side of its thrust

washers with fresh Lubriplate GR-132 grease. Place the thrust

washers on their proper shaft of the output gear assembly.

19. Lubricate the output gear assembly with fresh Lubriplate GR132 grease. Insert the gear assembly into its bore in the gear

housing, gear end rst. The teeth on the gear will mate with

the teeth on the drive shaft pinion.

20. Generously coat all surfaces of the cylindrical crankshaft

assembly thrust washer with fresh Lubriplate GR-132 grease.

21. Slip the at end of the cylindrical thrust washer behind the

gear on the output gear assembly, lining its bore up with the

gear housing bearing bore for the crankshaft assembly.

22. Lubricate the crankshaft assembly gear with fresh Lubriplate

GR-132 grease. Slide the gear side shaft of the crankshaft

through the cylindrical thrust washer and into its bore within

the gear housing.

23. Position the pin on the end of the crankshaft towards the bottom

of the gear housing (the bottom dead center position).

English

Page 12

24. Lubricate both faces of the large crankshaft assembly thrust

Pump

Assembly

ansducer

Screw

washer with fresh Lubriplate GR-132 grease. Place the thrust

washer onto the crankshaft against the gear.

25. Place the housing gasket over the gear housing dowel pins.

26. Lubricate the outside of the slider assembly and the inside of

the slider bushing with oil. Fill the slider cup with Lubriplate

1242 grease (the slider cup is the area on the slider assembly

where the connecting rod and slider join and pivot).

27. Insert the slider assembly into the slider bushing.

28. Carefully place the pump housing assembly in front of the

gear housing assembly, lining up the gear housing dowel pins

with their corresponding holes in the pump housing. Slide

the pump housing onto the gear housing until there is no gap

between the housings and gasket.

NOTE: While sliding the pump housing into place, the

crankshaft pin will begin to protrude from the

bearing in the center of the pump housing. Position

the slider assembly so that as the crankshaft pin

protrudes from the main bearing, it engages the

connecting rod bearing.

IMPORTANT: Do not force the pump housing and gear housing

together.

29. Locate the four socket screws and lock washers that secure

the pump housing to the gear housing.

30. Using a 1/4” hex wrench, snug and tighten the socket screws

in a crossing pattern. Torque to 200–230 in.-lbs.

31. Slide the top of the piston rod into the T-slot on the slider

assembly.

32. Position the pump block underneath the gear box housing

and push up until it rests against the gear box housing.

33. Insert the two socket screws that secure the uid section to

the pump housing and alternately snug, tighten, and torque

the screws to 400-440 in.-lbs.

34. Position the front cover over the pump housing. Secure the

front cover using the four front cover screws.

Replacing the Transducer

1. Loosen and remove the four front cover screws. Remove the

front cover.

2. Stop the sprayer at the bottom of its stroke so that the piston

is at its lowest position.

3. Perform the Pressure Relief Procedure.

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce the

risk of an injection injury, injury from moving parts or

electric shock.

4. Tilt the sprayer back for easy access to the uid section.

5. Using a 3/8” hex wrench, loosen and remove the two socket

screws.

6. Pull the uid section down approximately 1/2” from the

housing to clear the transducer.

7. Slide the uid section and piston rod forward until the piston

rod is out of the T-slot on the connecting rod.

8. Using a wrench, remove the transducer assembly from the

uid section.

9. Thread the new transducer assembly from the uid section.

Tighten securely with a wrench.

10. Reassemble the pump by reversing steps 1-8.

IMPORTANT: Make sure the transducer is aligned properly

with the hole in the fluid section during reassembly. Improper

alignment may cause damage to the transducer O-ring.

Housing

Slider

Tr

Front

Cover

Screw

Front

Cover

Assembly

Fluid

Section

Housing

Socket

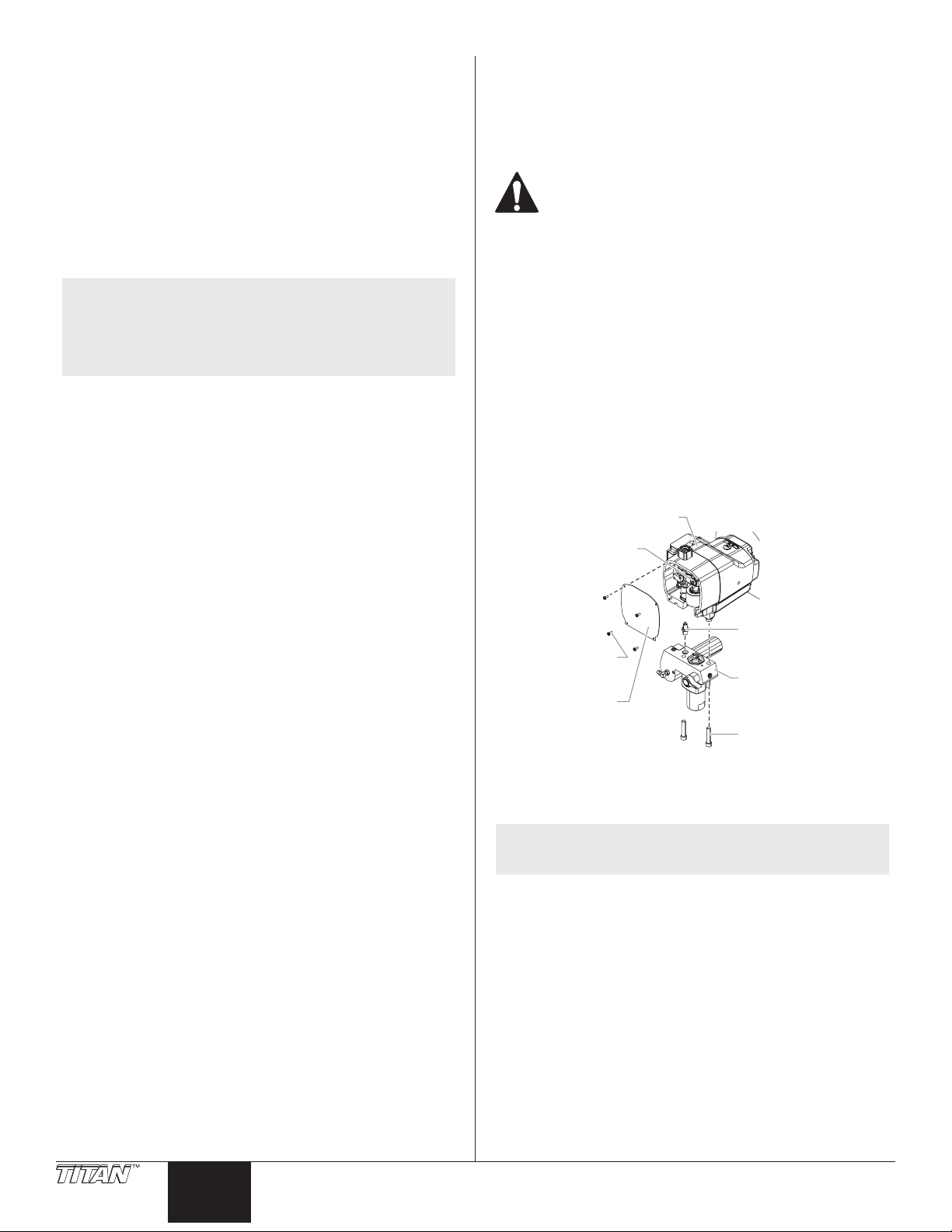

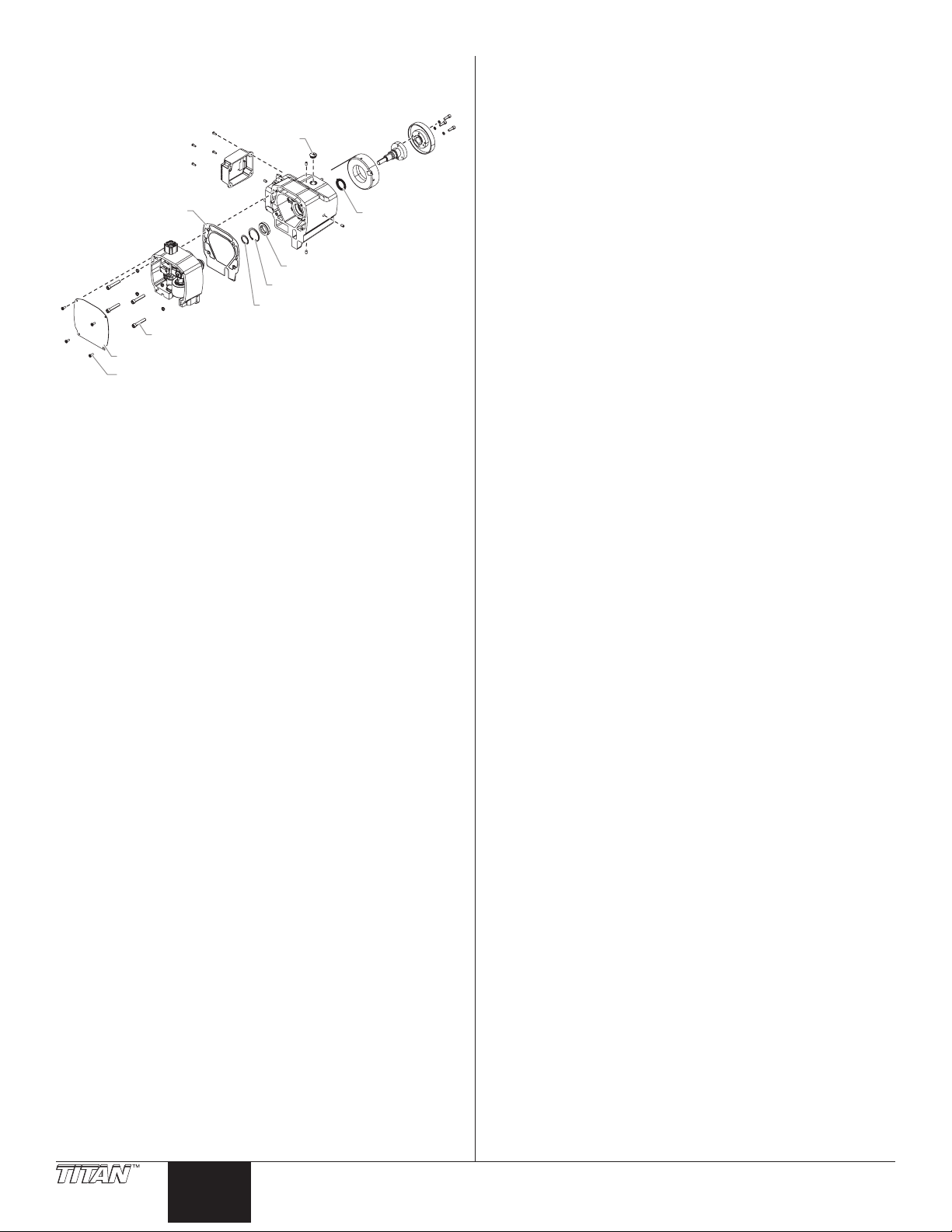

Servicing the Clutch Assembly

NOTE: When replacing the clutch armature, the clutch rotor

Removing/Replacing the Clutch Armature Assembly

1. Perform the Pressure Relief Procedure.

2. Locate the wire that exits the rear of the pressure control

12 © Titan Tool Inc. All rights reserved.

English

3. Using a 12 point, 5/16” wrench, remove the four screws

4. Using a 9/16” socket, remove the screw that secures the gear

5. Slide the pump and gear housings away from the engine to

must be replaced also. This will allow for even wear

and maximum life on clutch parts.

housing and connects to the wire harness on the engine.

Disconnect this wire from its connector at the engine wire

harness.

and lock washers that secure the clutch housing to the gear

housing.

housing to the cart.

disengage them from the clutch housing.

Page 13

Gear Housing

Screw

Clutch Housing

Housing

Clutch

Armatur

Bushing

Assembly Screw

Hex Screw

Lock Washer

Clutch Armature

Gear

Housing

Clutch

Engine Shaft

Taper Lock Bushing

Pump

Set Screw

Housing

6. Locate the clutch armature assembly on the end of the engine

shaft. Note the two set screws as well as the unused, threaded

hole in the taper lock bushing at the center of the clutch hub.

7. Using an 1/8” hex wrench, remove the two set screws from the

taper lock bushing

8. Thread one of the set screws into the unused, threaded hole

on the taper lock bushing. As the screw tightens, the bushing

will loosen. Once the bushing has loosened enough, slide the

clutch armature assembly o the engine shaft.

9. Before replacing the clutch

hub and armature assembly

the proper “set back” must be

created. Using the hub set-up

tool (P/N 0555926), create a

“set back” of 0.10” between the

friction surface of the clutch

armature and the forward face

of the clutch hub.

Clutch

Hub

Flat

Surface

e

Set-Up

Tool

Removing the Clutch Rotor, Clutch Field, and Drive Shaft

Assembly

1. Follow steps 1–7 in “Removing/Replacing the Clutch Armature

Assembly.”

2. Locate the clutch rotor assembly, which will be inside the

rear the gear housing. Note the locations of the three socket

screws and the two empty, threaded holes on the clutch rotor.

3. Using a 3/16” hex wrench, remove the three socket screws

and lock washers that secure the clutch rotor to the drive shaft

assembly.

4. Thread two of the socket screws into the empty, threaded

holes and tighten alternately. This will push the clutch rotor

away from the drive shaft assembly and pinion.

5. Using a Phillips screwdriver, remove the four screws that

secure the heat sink assembly to the housing. Carefully

remove the heat sink assembly from the housing.

6. Locate the two clutch eld wires that pass from the gear

housing into the control housing through a hole in the back

of the control housing. Remember the wire connection

terminals on the relay assembly (label if necessary) and

disconnect the wires. Gently move the heat sink assembly

away from the housing and rest it on the work surface by the

control housing.

7. Locate the four pairs of set screws that secure the clutch eld

to the gear housing. They are located on the exterior of the

gear housing at the 12, 3, 6, and 9 o’clock positions while

facing the clutch eld end of the gear housing. Using an 1/8”

hex wrench, remove the setscrews. Remember the location

of the two clutch eld wires with respect to the grommet and

EPC housing.

8. Carefully slide the clutch eld out of the gear housing, keeping

the eld square to the gear housing so it does not bind.

NOTE: A new clutch hub and

10. To replace the clutch armature assembly , line up the three

11. Line up the key on the taper lock bushing with the keyway on

12. Apply blue Loctite to the two set screws and insert the screws

13. Using the clutch set-up tool

14. While holding the clutch armature assembly against the tool,

15. Make sure the friction surface of the clutch armature is clean

armature assembly will come

pre-assembled, but the “set

back” may not be correct. The

“set back” must still be created

using the hub set-up tool.

holes in the taper lock bushing with the three holes in the

clutch armature and insert the bushing into the center of the

clutch armature.

the engine shaft and slide the assembly onto the shaft with

the holes facing out.

into the taper lock bushing. Tighten the set screws only two

turns at this time.

(P/N 0555926), position

the clutch armature on

the engine shaft. Hold the

tool across the face of the

clutch housing so that the

center, recessed portion

of the tool straddles the

clutch armature assembly.

Pull the clutch armature

assembly towards the

tool until the face of the

armature is against the

tool.

use an 1/8” hex wrench and alternately tighten the set screws

into the taper lock bushing. Torque to 65–75 in-lbs.

and free from oil or grease.

Engine

0.10"

Taper

Lock

Set

Screw

Set-Up

Tool

Clutch

Housing

Clutch Rotor Socket Screw

Drive Shaft Assembly

Clutch Field Wires

Lock

Washer

Clutch

Clutch

Field Assembly

Heat Sink

Assembly

Heat Sink

NOTE: To remove the drive shaft assembly, the pump

housing rst must be removed from the gear

housing.

9. Using a Phillips screwdriver, remove the four front cover

screws. Remove the front cover.

10. Using a 1/4” hex wrench, remove the four socket screws that

secure the pump housing to the gear housing.

11. Slide the pump housing away from the gear housing.

12. Remove and clean the housing gasket. Replace if damaged.

13. Locate the drive shaft pinion that is protruding from the front

side of the gear housing. Remove the small snap ring that is

located on the drive shaft hub in front of the ball bearing that

is supporting the drive shaft.

14. From the opposite side of the gear housing (clutch side) slide

the drive shaft assembly out of the gear housing.

15. Inspect the grease seal located inside the bore from which

the drive shaft was removed. Replace if worn or damaged.

Set Screw

Rotor

© Titan Tool Inc. All rights reserved. 13

English

Page 14

To remove the grease seal, use a at blade screwdriver to

Front Cover Screw

carefully pry the seal from the bore.

16. Clean the inside of the gear housing.

Plug

Housing Gasket

Bearing

Snap Ring

Small Snap Ring

Pump Housing Socket Screw

Front Cover

Grease Seal

Installing the Clutch Rotor Assembly, Clutch Field and

Drive Shaft Assembly

1. If the drive shaft grease seal was removed, press a new seal

into the bore from which the old seal was removed.

2. From the clutch side of the gear housing, insert the drive shaft

assembly into the bore, through the grease seal, and through the

ball bearing on the gear side of the gear housing.

3. From the gear side of the gear housing, insert the snap ring

into the groove on the drive shaft hub in front of the ball

bearing.

4. Place the housing gasket over the gear housing dowel pins.

5. Carefully place the pump housing assembly in front of the

gear housing assembly, lining up the gear housing dowel pins

with their corresponding holes in the pump housing. Slide

the pump housing onto the gear housing until there is no gap

between the housings and gasket.

IMPORTANT: Do not force the pump housing and gear housing

together.

6. Locate the four socket screws and lock washers that secure

the pump housing to the gear housing.

7. Using a 1/4” hex wrench, snug and tighten the socket screws

in a crossing pattern. Torque to 200–230 in.-lbs.

8. Line up the four holes around the outside of the clutch eld

with the four set screw holes in the gear housing. The clutch

eld wires should be at approximately the 1 or 2 o’clock

position.

9. Route the two clutch eld wires through the hole and into the

control housing.

10. Carefully slide the clutch eld into its bore in the gear housing

until it “bottoms out” within the housing. Do not pinch the

clutch eld wires during installation.

11. Thread one of the pointed set screws into its hole. Using an

1/8” hex wrench, rotate the screw slowly until it contacts the

clutch eld. Do not tighten the set screw. The tip of the set

screw should mate with the drill point hole in the eld. Check

the clutch eld for rotation. If it rotates within its bore, the set

screw is not seated within the drill point.

12. When the set screw is properly seated, install the remaining

three pointed set screws. Do not tighten the set screws.

13. Using a crossing pattern, tighten each of the pointed

setscrews until they are snug. Once all four pointed set screws

are snug, use a crossing pattern to tighten and torque the set

screws to 70–80 in.-lbs.

IMPORTANT: It is very important to evenly snug, tighten, and

torque the clutch field pointed set screws in a crossing pattern.

This ensures the clutch field will stay centered in the gear

housing.

15. Line up the three screw holes and dowel pin hole on the

clutch rotor with the screw holes and dowel pin on the drive

shaft assembly hub. Place the clutch rotor onto the hub.

16. Using a 3/16” hex wrench, thread the three socket screws and

lock washers through the clutch rotor and into the drive shaft

assembly hub. Evenly snug, tighten, and torque the socket

screws to 75–85 in-lbs.

17. Make sure the friction surface of the clutch rotor is clean and

free from oil or grease.

18. Locate the two clutch eld wires in the control housing.

Gently pull the wires fully into the EPC housing so that there

is no slack in the gear housing. Connect the wires to their

proper terminals on the relay (refer to the labels created

earlier in this procedure or the electrical schematic in the Parts

List section of this manual).

19. Carefully place the heat sink assembly over the control

housing taking care not to pinch any wires.

20. Install the four screws that secure the heat sink assembly to

the control housing. Tighten securely.

Mating the Gear Housing and the Clutch Housing

1. Place the gear housing assembly onto the cart in front of the

clutch housing. Line up the dowel pins in the gear housing

with their corresponding holes in the clutch housing. Slide

the gear housing assembly onto the clutch housing until there

is no gap between the housings.

2. Thread the four hex screws and lock washers through the

clutch housing and into the gear housing.

3. Using a 12 point, 5/16” wrench, snug and tighten the hex

screws in a crossing pattern. Torque to 140–155 in.-lbs.

4. Using a 9/16” socket, thread the hex screw that secures the

gear housing to the cart through the underside of the cart and

into the gear housing. Torque to 100–120 in.-lbs.

5. Connect the wire from the EPC housing to its mating

connector on the engine wire harness.

Checking the Clutch Gap

1. Remove the plastic plug from the top of the clutch housing.

Look through the port to locate the clutch armature and the

clutch rotor.

2. Check the gap between the clutch armature and the clutch

rotor using a .016” feeler gauge and a .035” feeler gauge.

a. Insert each feeler gauge through the port and into the gap

between the clutch armature and the clutch rotor. The .016”

feeler gauge should t in the gap. The .035” feeler gauge

should not t in the gap.

b. Pull the engine pull cord several times to rotate the clutch

armature, checking the gap with each feeler gauge between

each pull.

c. If the .016” gauge does not t or the .035” gauge does t at

any checkpoint, the gap must be readjusted. This is done

by relocating the clutch hub and armature assembly on the

engine shaft. Refer to the “Removing/Replacing the Clutch

Armature Assembly” procedure.

14 © Titan Tool Inc. All rights reserved.

English

Page 15

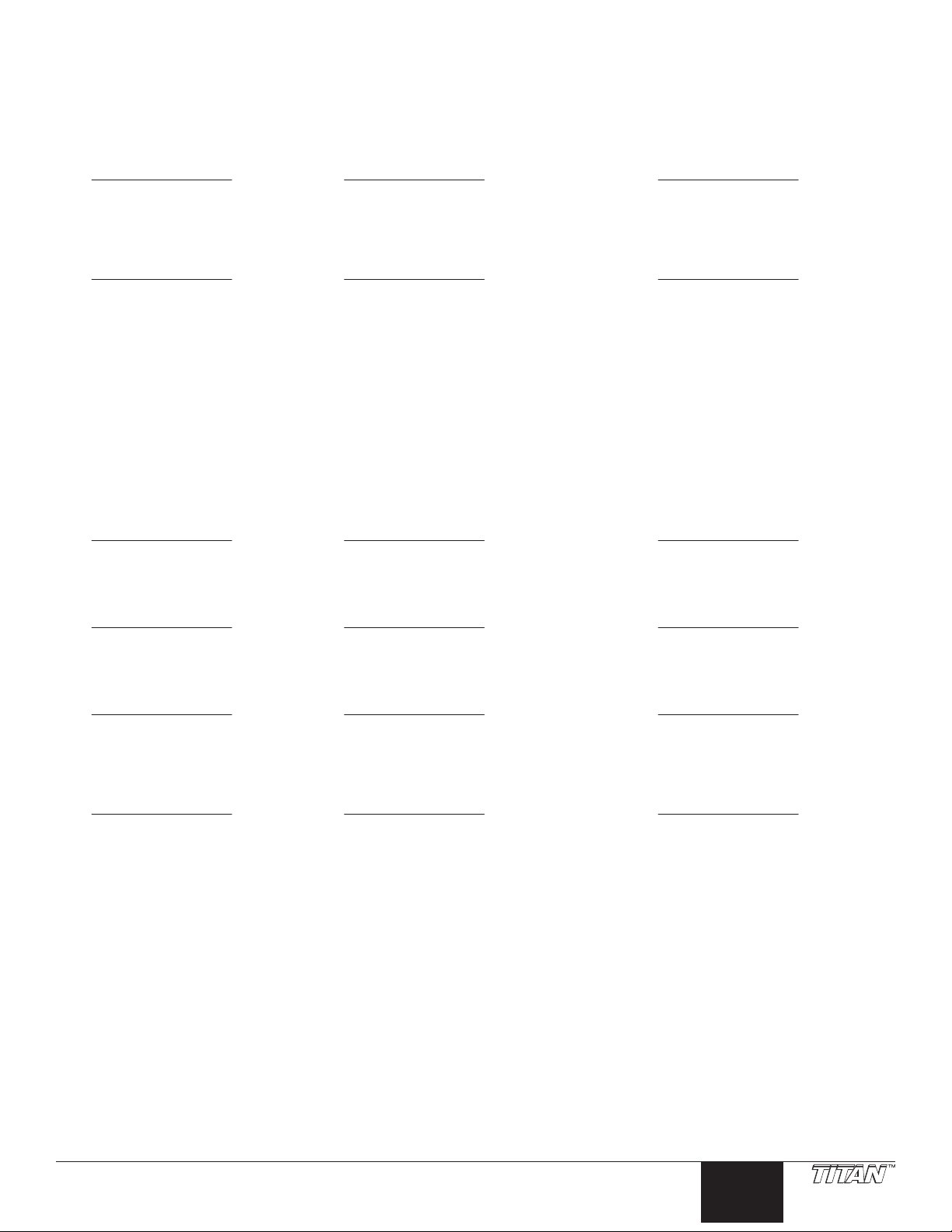

Servicing the Fluid Section

alve Seat

retainer

old

Use the following procedures to service the valves and repack the

uid section.

1. Using a Phillips screwdriver, remove the four front cover

screws. Remove the front cover.

2. Start the engine (refer to the procedures in the Operation

section of this manual). Turn the pressure control knob

clockwise to its maximum pressure setting.

3. Toggle the sprayer ON/OFF switch between the ON and

OFF positions in short bursts until the slider assembly and

piston rod stop at the bottom of their stroke (in their lowest

position).

4. Turn o the engine and perform the Pressure Relief

Procedure.

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce the

risk of an injection injury, injury from moving parts or

electric shock.

Servicing the Valves

The design of the uid section allows

access to the inlet valve and seat

as well as the outlet valve and seat

without completely disassembling

the uid section. It is possible that

the valves may not seat properly

because of debris stuck in the inlet

valve seat or outlet valve seat. Use

the following instructions to clean

the valves and reverse or replace the

seats.

NOTE: Keep the sprayer in the

upright position for this

procedure.

1. Using a wrench, loosen and remove the inlet valve housing

from the uid section housing.

2. Clean out any debris in the inlet valve housing and examine

the valve housing and seat. If the inlet valve seat is damaged,

reverse the seat to the unused side or replace the seat.

NOTE: If the inlet valve seat is reversed or replaced, the

inlet valve ball must be replaced.

3. Using a 3/8” hex wrench, loosen and remove the outlet valve

retainer from the piston rod.

NOTE: Always service the outlet

valve with the piston rod

attached to the pump. This

will prevent the piston

rod from rotating during

disassembly of the outlet

valve.

4. Clean out any debris and examine

the outlet valve retainer and seat.

If the outlet valve seat is damaged,

reverse to the unused side or

replace the seat.

NOTE: If the outlet valve seat is reversed or replaced, the

outlet valve ball must be replaced.

5. Remove, clean, and inspect the outlet cage and outlet valve

ball. Replace if they are worn or damaged.

6. Reassemble the valves by reversing the steps above. Apply

blue Loctite (P/N 426-051) to male threads of inlet valve

housing and torque to 450-500 in-lbs.

Fluid Section

Housing

Piston Bushing

Inlet Valve Seal

Inlet Cage

Inlet Valve Ball

Inlet V

PTFE O-Ring

Inlet Valve

Housing

Piston rod

Upper seal

Upper cage

Outlet valve

ball

Lower seal

Outlet valve

seat

Outlet valve

Repacking the Fluid Section

1. Remove the foot valve assembly using the steps in the

“Servicing the Valves” procedure above.

NOTE: The outlet valve does not need to be disassembled

2. Using 3/8” a hex wrench, loosen and remove the two pump

3. Pull the pump block down approximately 1/2” from the gear

4. Slide the pump block and piston rod forward until the piston

5. Slide the piston rod out through the bottom of the pump

6. Loosen and remove the retainer nut and piston guide from

7. Remove the upper and lower packings from the pump block.

8. Clean the pump block.

9. Locate the new upper and lower packings and pack the areas

10. Inspect the piston rod for wear and replace if necessary.

11. Insert the upper packing into the top of the pump block with

12. Insert the piston guide into the retainer nut. Thread the

13. Pre-form the lower packing using the lower packing sizing

14. Insert the lower packing partially into the bottom of the pump

15. Push the lower packing into position using the lower packing

16. Inspect the piston rod for wear and replace if necessary.

from the piston rod for this procedure.

Retainer Nut

Piston Guide

Upper Packing

Assembly

Pump Manif

Pump

Manifold

Mounting

Screw

Lower Packing

Assembly

Piston Rod

block mounting screws.

box housing.

rod is out of the T-slot on the slider assembly.

block

the pump block.

between the packing lips with grease. Lubricate the o-rings

on the exterior of the packings with grease.

the raised lip on the packing facing down.

retainer nut into the pump block until it is hand tight.

tool (included in the repacking kit).

block so that the side that has the o-ring closest to the face of

the packing faces up.

Install upper packing

with raised lip

facing down.

Raised Lip

Install lower packing

with large beveled

edge facing up.

Large Beveled Edge

insertion tool (see Fluid Section Assembly parts list for lower

packing insertion tool P/N).

© Titan Tool Inc. All rights reserved. 15

English

Page 16

NOTE: Coat the piston guide tool and the piston rod with

17. Place the piston insertion tool (included in the repacking kit)

18. Insert the piston rod into the bottom of the pump block,

grease before inserting them into the pump block.

over the top of the piston rod.

through the lower packing, through the upper packing, and

out through the retainer nut. Using a rubber mallet, tap the

bottom of the piston rod lightly until the piston rod is in

position in the pump block.

NOTE: When repacking the uid section, make sure the

19. Remove the piston insertion tool from the top of the piston

20. Using a wrench, tighten the retainer nut into the pump block.

21. Slide the top of the piston rod into the T-slot on the slider

22. Position the pump block underneath the gear box housing

IMPORTANT: Make sure the transducer is aligned properly

with the hole in the pump block during reassembly. Improper

alignment may cause damage to the transducer gasket.

23. Thread the pump block mounting screws through the pump

24. Reassemble the inlet valve assembly into the pump block.

NOTE: During reassembly, make sure the o-ring between

25. Reassemble suction set to uid section. If swivel is removed

raised lip on the bottom of the lower packing is fully

outside the packing around the piston rod after

insertion of the piston rod.

rod.

Torque to 300-360 in. lbs.

assembly.

and push up until it rests against the gear box housing.

block and into the gear box housing. Torque to 400-440 in.

lbs.

Apply blue Loctite (P/N 426-051) to male threads of inlet valve

housing and torque to 450-500 in-lbs.

the pump block and inlet valve housing is

lubricated with grease and in position.

from the inlet valve housing, add blue Loctite (P/N 426-051) to

male threads. Replace the return hose into the clamp on the

siphon tube.

NOTE: When adjusting the orientation of the suction

26. Thread the return hose into the pump block and tighten

27. Place the front cover on the gear box housing and secure in

28. Turn on the sprayer by following the procedure in the

NOTE: Repacking kit 0555960 is available. For best results

16 © Titan Tool Inc. All rights reserved.

tube, use two wrenches: one on the stationary hex

of the swivel and one on the movable hex of the

swivel. This will keep the inlet valve housing from

accidentally being loosened.

securely.

position using the four front cover screws.

“Operation” section of this manual and check for leaks.

use all parts supplied in this kit.

English

Page 17

Troubleshooting

Problem

A. The unit will not run.

B. The unit will not prime.

C. The unit will not build or

maintain pressure.

D. Fluid leakage at the upper end