Page 1

Airless, high-pressure

sprAying system

With surefire™ heAting system

OperAting mAnuAl

Models: 0138010 0138010 AP

0138057 0138057 AP

0138061 0138061 AP

0138062 0138062 AP

0117 • Form No. 0138874L

Page 2

original operating manual

Airless units develop extremely high spraying pressures.

1

HELIXHELIX

Warning!

Attention: Danger of injury by injection!

Never put your ngers, hands or any other parts of the body into

the spray jet!

Never point the spray gun at yourself, other persons or animals.

Never use the spray gun without safety guard.

Do not treat a spraying injury as a harmless cut. In case of injury

to the skin through coating materials or solvents, consult a doctor

immediately for quick and expert treatment. Inform the doctor

about the coating material or solvent used.

2

3

The operating instructions state that the following points must

always be observed before starting up:

1. Faulty units must not be used.

2. Secure the spray gun using the safety catch on the trigger.

3. Ensure that the unit is properly earthed.

4. Check allowable operating pressure of high-pressure hose set and spray

gun.

5. Check all connections for leaks.

The instructions regarding regular cleaning and maintenance of

the unit must be strictly observed.

Before any work is done on the unit or for every break in work the

following rules must be observed:

1. Release the pressure from spray gun and hose.

2. Secure the spray gun using the safety catch on the trigger.

3. Switch o unit.

4. Unplug the power cord from the unit.

Be safety conscious!

2

Page 3

ContentS

HELIX

1 SAFETY REGULATIONS ___________________ 4

1.1 Explanation of symbols used _____________________4

1.2 Isocyanate (ISO) Conditions _____________________6

1.3 Electric safety _________________________________7

2 GENERAL DESCRIPTION __________________ 8

2.1 System congurations __________________________ 8

2.2 Clearance diagram _____________________________ 8

2.3 Electrical / generator requirements _______________9

3 SYSTEM DESCRIPTION __________________ 10

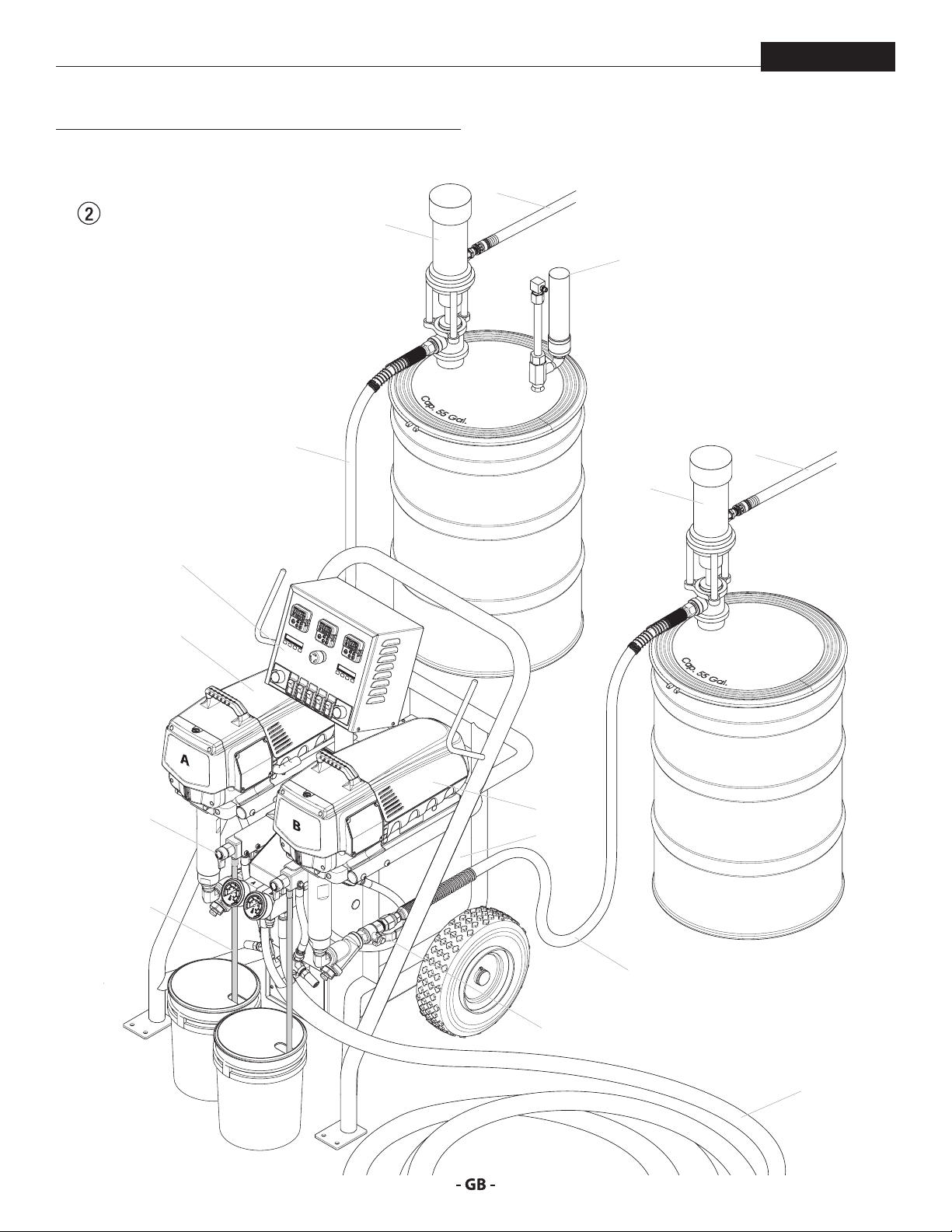

3.1 System diagram - without circulation _____________ 10

3.2 Component description - without circulation ______11

3.3 System diagram - with circulation _______________12

3.4 Component description - with circulation _________13

3.5 Installing the circulation kit (optional) ____________13

4 CONTROL PANEL _______________________ 14

4.1 Surere™ heater block control __________________15

4.2 Surere™ heated hose temperature control ________ 15

4.3 Component pump pressure control ______________16

4.4 Control Displays ______________________________ 16

4.5 Control Displays Error Messages _________________ 19

5 SETUP _________________________________ 20

5.1 Locate the system ____________________________20

5.2 Install the transfer pumps ______________________20

5.3 Connect the Surere™ heated hoses _____________21

5.4 Connect the electrical cord _____________________22

5.5 Ground the system ___________________________22

5.6 Lubricate the component pumps ________________22

7 SHUTTING DOWN _______________________ 25

7.1 Parking _____________________________________25

7.2 Flushing ____________________________________25

8 TROUBLESHOOTING ____________________ 26

8.1 Component pump ____________________________26

8.2 Surere™ heater block /

hose heater controller errors ____________________ 27

9 SERVICING _____________________________ 30

9.1 Replacing the motor assembly __________________30

9.2 Replacing the gears ___________________________31

9.3 Replacing the transducers ______________________ 31

9.4 Replacing the PRIME/SPRAY valve _______________32

9.5 Inlet and outlet valves _________________________33

9.6 Packings ____________________________________34

9.7 Electrical schematic

(model 0138010 / 0138010 AP) _______________ 36/37

9.8 Electrical schematic

(model 0138057 / 0138057 AP) _______________ 38/39

SPARE PARTS LISTS __________________________ 40

Spare parts list for main assembly __________________ 40/41

Spare parts list for component pump assembly _______ 42/43

Spare parts list for drive assembly __________________ 44/45

Spare parts list for Surere™ heater block system _____ 46/47

Spare parts list for display assembly ________________ 48/49

Spare parts list for uid section ____________________ 50/51

Spare parts list for cart assembly ______________________ 52

Spare parts list for PRIME/SPRAY valve assembly _________53

Spare parts list for Surere™ heater block _______________ 54

6 OPERATION ____________________________ 23

6.1 Startup _____________________________________23

6.2 Set temperature ______________________________ 23

6.3 Spraying ____________________________________24

6.4 Pressure relief procedure _______________________ 24

WARRANTY _________________________________ 55

3

Page 4

SaFetY regulationS

At

i

or solvents, consult a doctor immediately for

quick and expert treatment. Inform the doctor

1 SAFETY REGULATIONS

HELIX

1.1

This manual contains information that must be read and

understood before using the equipment. When you come to

an area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

EXPLANATION OF SYMBOLS USED

This symbol indicates a potential hazard

that may cause serious injury or loss of life.

Important safety information will follow.

This symbol indicates a potential hazard

to you or to the equipment. Important

tention

information that tells how to prevent

damage to the equipment or how to avoid

causes of minor injuries will follow.

Danger of skin injection

Danger of re from solvent and spray fumes

Danger of explosion from solvent, spray

fumes and incompatible materials

Danger of injury from inhalation of harmful

vapors

Danger of injury from burns

HAZARD: INJECTION INJURY

Attention: Danger of injury by injection! A high

pressure stream produced by this equipment can

pierce the skin and underlying tissues, leading to

serious injury and possible amputation.

Do not treat a spraying injury as a harmless cut. In

case of injury to the skin through coating materials

about the coating material or solvent used.

PREVENTION:

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to touch the uid stream.

DO NOT allow body to touch a leak in the uid hose.

• NEVER put your hand in front of the gun.

• ALWAYS lock the gun trigger, shut the uid pump o

and release all pressure before servicing, cleaning the tip

guard, changing tips, or leaving unattended. Pressure

will not be released by turning o the engine. The PRIME/

SPRAY valve(s) or pressure bleed valve must be turned to

their appropriate positions to relieve system pressure.

• All accessories must be rated at or above the maximum

operating pressure range of the sprayer. This includes

guns, extensions, and hose.

HAZARD: EXPLOSION OR FIRE

Solvent and material fumes can explode or ignite.

Severe injury and/or property damage can occur.

Danger of injury from electric shock

Notes give important information which

should be given special attention.

4

PREVENTION:

• Only spray coating materials with a ash point of at least

5 kelvin higher than the set temperature (minimum ash

point is 38°C). The ash point is the lowest temperature

at which vapors develop from the coating material. These

vapors are sucient to form an inammable mixture over

the air above the coating material.

• Do not use a material or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating supplier

about compatibility of material with aluminum.

• Do not use the unit in work places which are covered by

the explosion protection regulations.

• Provide extensive exhaust and fresh air introduction to

keep the air within the spray area free from accumulation

of ammable vapors.

Page 5

SaFetY regulationS

Solvents and other materials can be harmful if

inhaled or come in contact with body. Vapors

Heated uids, when in conned areas such as

spray hoses, can create a rapid rise in pressure

due to thermal expansion. Over-pressurization

The spray hose can develop leaks from wear,

i

HELIX

• Avoid all ignition sources such as static electricity sparks,

electrical appliances, ames, pilot lights, hot objects, and

sparks from connecting and disconnecting power cords or

working light switches.

HAZARD: BURN HAZARD

Certain components of the equipment are heated

and become hot during operation.

• Do not smoke in spray area.

• Place sprayer sucient distance from the spray object in a

well ventilated area. Flammable vapors are often heavier

than air. Floor area must be extremely well ventilated. The

pump contains arcing parts that emit sparks and can ignite

vapors.

PREVENTION:

• To avoid severe burns and injury, do not touch heated uid

or equipment. Wait until the equipment has completely

cooled.

• The equipment and objects in and around the spray area

must be properly grounded to prevent static sparks.

HAZARD: THERMAL EXPANSION

• Use only conductive or earthed high pressure uid hose.

Gun must be earthed through hose connections.

• Power cord must be connected to a grounded circuit

(electric units only).

can lead to a rupture and serious injury.

• Follow material and solvent manufacturer’s warnings and

instructions. Be familiar with the coating material’s SDS

sheet and technical information to ensure safe use.

• Use lowest possible pressure to ush equipment.

• When cleaning the unit with solvents, the solvent should

never be sprayed or pumped back into a container with

a small opening (bunghole). An explosive gas/air mixture

can arise. The container must be earthed.

PREVENTION:

• During system heating, make sure PRIME/SPRAY valves are

set to SPRAY.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a spray hose. Replace it with

another earthed high-pressure hose.

HAZARD: HAZARDOUS VAPORS

can cause severe nausea, fainting, or poisoning.

PREVENTION:

• Wear respiratory protection when spraying. Read all

instructions supplied with the mask to be sure it will

provide the necessary protection.

• All local regulations regarding protection against

hazardous vapors must be observed.

• Wear protective eyewear.

• Protective clothing, gloves and possibly skin protection

cream are necessary for the protection of the skin. Observe

the regulations of the manufacturer concerning coating

materials, solvents and cleaning agents in preparation,

processing and cleaning units.

HAZARD

kinking and abuse. A leak can inject material into

the skin. Inspect the hose before each use.

PREVENTION:

: HIGH PRESSURE HOSE

• High-pressure hoses must be checked thoroughly before

they are used.

• Replace any damaged high-pressure hose immediately.

• Never repair defective high-pressure hoses yourself!

• Avoid sharp bends and folds: the smallest bending radius

is about 20 cm.

• Do not drive over the high-pressure hose. Protect against

sharp objects and edges.

• Never pull on the high-pressure hose to move the device.

• Do not twist the high-pressure hose.

• Use only compatible cleaning solutions.

• Lay the high-pressure hose in such a way as to ensure that

it cannot be tripped over.

5

Only use approved original-high-pressure hoses

in order to ensure functionality, safety and

durability.

Page 6

SaFetY regulationS

HELIX

1.2 ISOCYANATE ISO CONDITIONS

HAZARD: GENERAL

This product can cause severe injury or property

damage.

PREVENTION:

• Follow all appropriate local, state, and national codes

governing ventilation, re prevention, and operation.

• Pulling the trigger causes a recoil force to the hand that is

holding the spray gun. The recoil force of the spray gun is

particularly powerful when a high pressure has been set on

the airless pump. When cleaning, set the pressure control

to the lowest pressure.

• Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specications and safety devices of the pump

manufacturer.

• ALWAYS follow the material manufacturer’s instructions

for safe handling of chemicals.

• Clean up all material and solvent spills immediately to

prevent slip hazard.

• Never leave this equipment unattended. Keep away from

children or anyone not familiar with the operation of airless

equipment.

• Device weighs in excess of 36 kg. Three-person lift is

required.

• The device and all related liquids (i.e. hydraulic oil) must be

disposed of in an environmentally friendly way.

Important Information Regarding TwoComponent Material. Read before using the

equipment.

ISOCYANATE ISO CONDITIONS

• Use only Methyldiisocyanates (MDI).

• Spraying materials that contain isocyanates (ISO) creates

mists, vapors and atomized particulates that are potentially

harmful.

• Be familiar with the spray material’s SDS in order to

understand specic hazards and necessary precautions

that are related to the use of spray materials containing

isocyanates.

• Provide extensive exhaust and fresh air introduction

to keep the air within the spray area free from harmful

isocyanate vapors. If sucient ventilation is not available,

a supplied-air respirator must be available to everyone in

the work area.

• AVOID ANY BARESKIN CONTACT WITH ISOCYANATES.

To prevent contact with isocyanates, all persons located

within the spray area must be wearing the appropriate

protective equipment, including chemically impermeable

gloves, boots, aprons and goggles.

MATERIAL IGNITION

• Some materials may become self-igniting if applied too

thickly. Read material manufacturer’s warnings and

material SDS.

KEEP SPRAY COMPONENTS SEPARATE

• Cross-contamination of individual spray materials can

result in cured material in uid lines which can cause severe

injury and/or damage to the equipment.

• To prevent cross-contamination of the equipment wetted

parts, NEVER interchange Component A (isocyanate) parts

with Component B (resin) parts.

MOISTURE SENSITIVITY

Isocyanates (ISO) are catalysts used in two-component foam

and polyurea coatings. ISO will react with moisture (such as

humidity) to form small, hard abrasive crystals. These crystals

will then contaminate the uid. Eventually a lm will form

on the uid surface and the ISO will begin to gel, increasing

in viscosity. Fluid contaminated with partially cured ISO , if

used, will reduce spray performance and the overall life of the

component wetted parts.

6

Page 7

SaFetY regulationS

i

HELIX

1.3 ELECTRIC SAFETY

Electric models must be earthed. In the event of an electrical

The amount of lm formation and the rate of

crystalization varies depending upon the blend

of ISO, the humidity and the temperature.

short circuit, earthing reduces the risk of electric shock by

providing an escape wire for the electric current. Connection

to the mains only through a special feed point, e.g. through an

error protection insallation with INF < 30 mA.

PREVENTION:

• Always use a sealed container with a desiccant dryer in

the vent, or a nitrogen atmosphere. NEVER store ISO in an

open container.

• Use ONLY the moisture-proof hoses specically designed

for ISO that are supplied with your system. If new hoses

need to be ordered, contact Titan Technical Service.

• Never ush reclaimed solvents through the system.

Reclaimed solvents can contain moisture. Always keep

solvent containers closed when not being used to prevent

moisture contamination.

• Never use solvent on one side if it has been contaminated

from the other side.

• Always lubricate threaded parts with ISO pump oil or

grease when reassembling.

• Always circulate a hose and pump that contains ISO at least

once a week to prevent the ISO from crystalizing.

CHANGING MATERIALS

• When changing spray materials, thoroughly ush the

equipment multiple times to ensure that it is fully clean.

• Always clean the uid inlet strainers after ushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO with Component A, but some use

ISO with Component B.

• Epoxies often have amines (hardener) with Component B.

Polyureas often have amines with Component B (resin).

FOAM RESINS WITH 245FA BLOWING AGENT

Some blowing agents will froth at temperatures above 90º

F (33ºC) when not under pressure, especially if agitated. To

reduce frothing, minimize preheating in a circulation system.

DANGER — Work or repairs at the electrical

equipment may only be carried out by a skilled

electrician. No liability is assumed for incorrect

installation. Switch the unit o. Before all repair

work, unplug the power plug from the outlet.

Danger of short-circuits caused by water

ingressing into the electrical equipment. Never

spray down the unit with high-pressure or highpressure steam cleaners.

OPERATING TEMPERATURE

This equipment will operate correctly in its intended ambient,

at a minimum between +10°C and +40°C.

RELATIVE HUMIDITY

The equipment will operate correctly within an environment

at 50% RH, +40°C. Higher RH may be allowed at lower

temperatures.

Measures shall be taken by the Purchaser to avoid the harmful

eects of occasional condensation.

ALTITUDE

This equipment will operate correctly up to 2100 m above

mean sea level.

TRANSPORTATION AND STORAGE

This equipment will withstand, or has been protected against,

transportation and storage temperatures of -25°C to +55°C and

for short periods up to +70°C.

It has been packaged to prevent damage from the eects of

normal humidity, vibration and shock.

7

Page 8

general DeSCription

i

i

2 GENERAL DESCRIPTION

HELIX

The Helix Plural Component System is a dual, high pressure

airless sprayer system that can be linked in order to spray multicomponent uids.

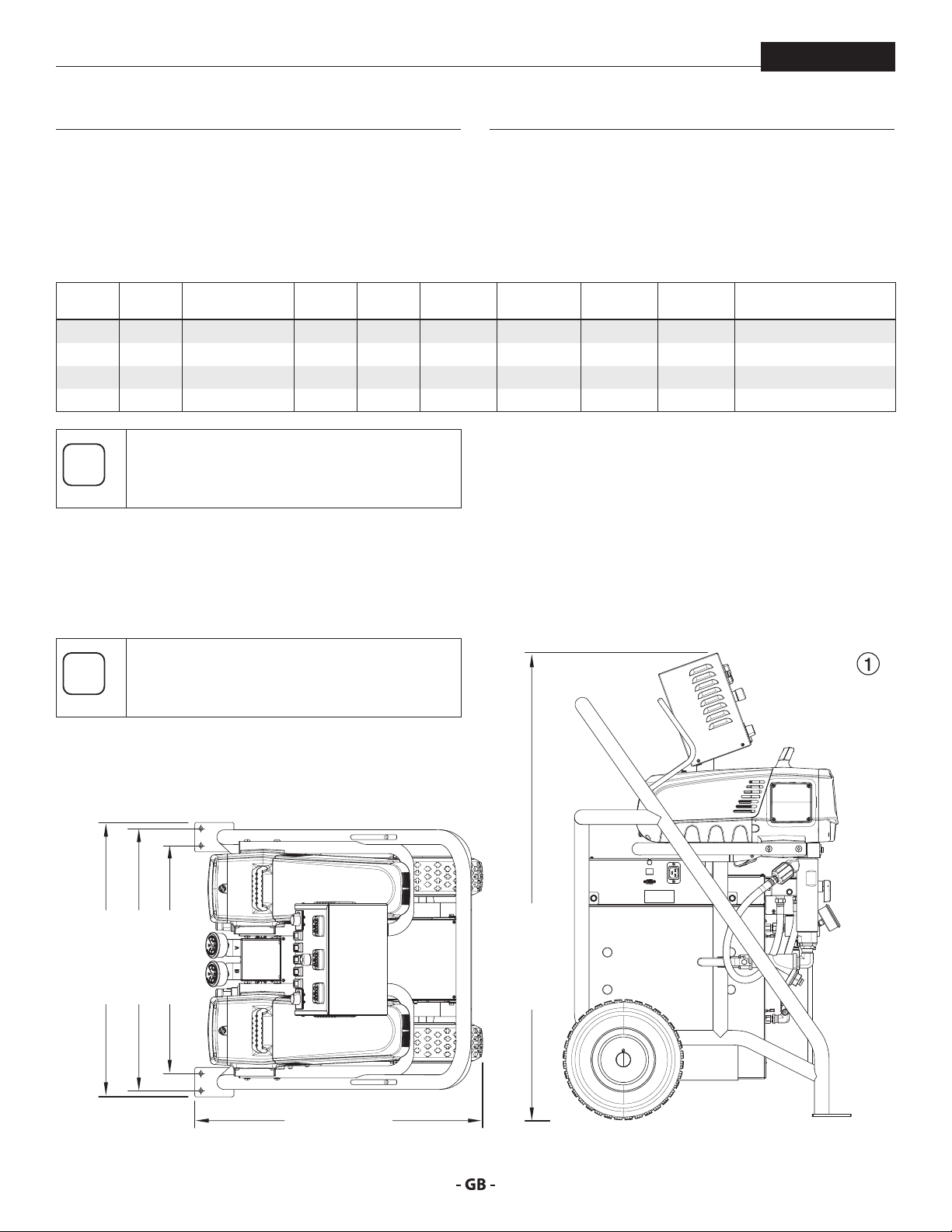

Model Voltage

(phase)

0138010 230V (1) 50A minimum 2200 13200 3 200’ (61 m) 2.2 2000 PSI 6 (13.7), 3 wire + ground

0138057 208V (3) 40A minimum 1800 11850 3 200’ (61 m) 2.2 2000 PSI 8 (8.0), 3 wire + ground

0138061 230V (1) 50A minimum 2890 13890 3 100’ (31 m) 2.2 2000 PSI 6 (13.7), 3 wire + ground

0138062 208V (3) 40A minimum 2360 12810 3 100’ (31 m) 2.2 2000 PSI 8 (8.0), 3 wire + ground

The spray gun provided with this system or sold

individually is not Intertek approved.

Circuit breaker Hose

Watts

System

Watts

# Heating

Elements

2.1 SYSTEM CONFIGURATIONS

The Plural Component System is available in the following

conguration(s) which is based upon the number of heating

elements, hose length, electrical phases and the required

power cord (not supplied). Refer to the chart below.

Heated

Hose

Max Flow

(gal/min)

Max Fluid

Pressure

Cord Specication

AWG (mm)

2.2 CLEARANCE DIAGRAM

When determining the location of the Helix

system, use the diagram below to determine

space clearance and mounting hole dimensions.

26.7” (678 mm)

28” (711 mm)

23.2” (589 mm)

47.2” (1199 mm)

29.4” (747 mm)

8

Page 9

general DeSCription

i

i

i

At

HELIX

2.3 ELECTRICAL / GENERATOR REQUIREMENTS

It is recommended that the Helix System be used

with a generator. This provides the exibility

with not having to use the public power grid.

When connected to the public, low-voltage

network, it is possible that an approval of

the network operator is required. Check the

regulations in your country and contact your

network operator before connecting the unit to

a public electricity grid.

The Helix System requires a 208-240V capacity.

Make sure the power source is rated to this

specication.

When working at altitudes above 2100m, check

the generator manufacturer’s specications for

power loss oset.

If powering the Helix system with a generator,

make sure the generator has ample power to

tention

Follow the steps below to determing if your generator is able to

supply sucient power to the Helix system.

1. Perform this equation:

System Watts 13,300 x 1.25 = kVA (kilovolt / amperes)

2. If your generator’s kVA rating is higher than what was

If your generator’s kVA rating is lower than what was

run the system. An inadequate generator will

cause RPM uctuations in the Component Pump

motors during usage and can cause damage.

determined in the equation above, the generator will be

able to power the system.

determined in the equation above, the generator WILL

NOT be able to power the system. A larger generator is

required.

9

Page 10

SYStem DeSCription

L

3 SYSTEM DESCRIPTION

HELIX

3.1

SYSTEM DIAGRAM WITHOUT CIRCULATION

J

H

D

K

L

J

A

E

F

B

C

H

G

Waste containers

(not included) must

be closed at the top.

10

I

Page 11

SYStem DeSCription

HELIX

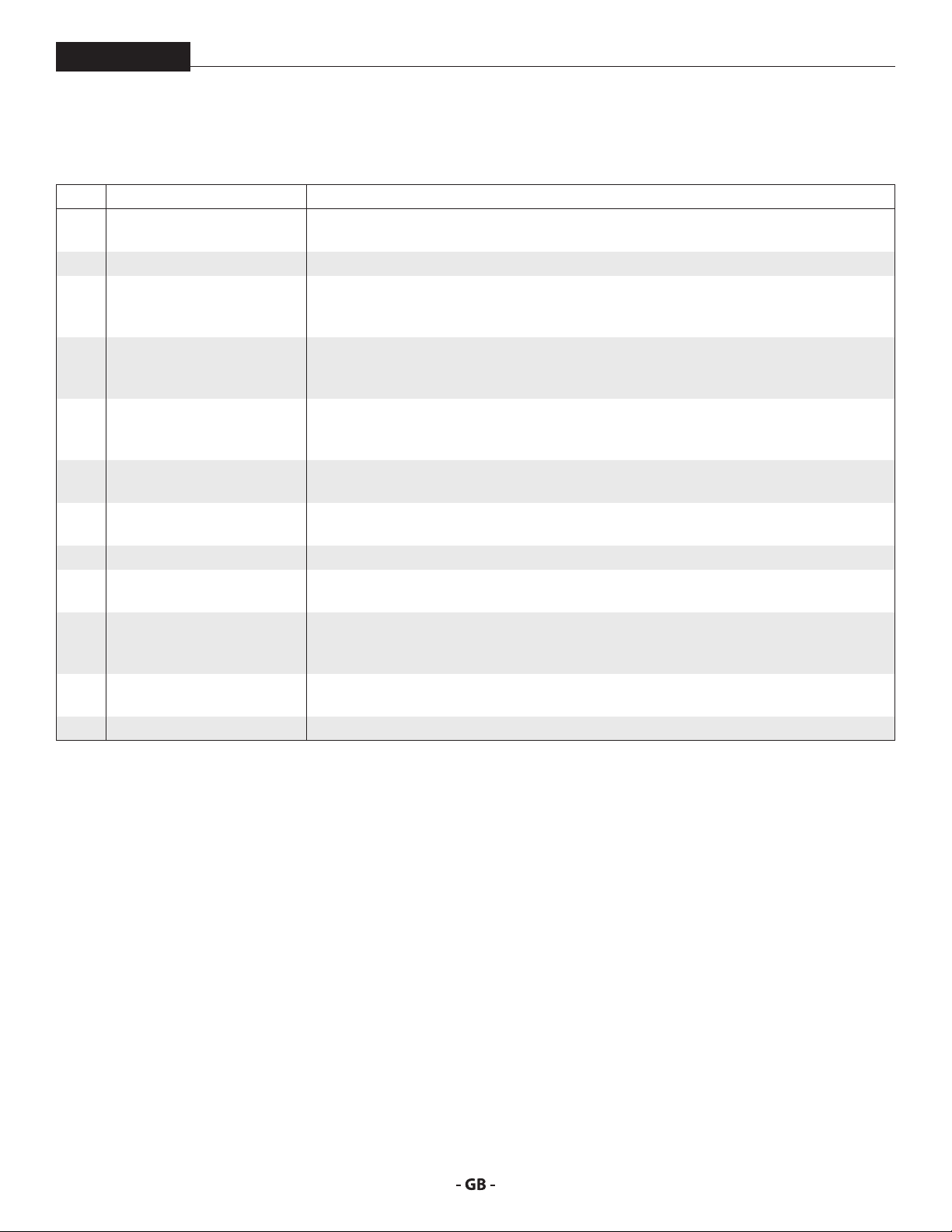

3.2 COMPONENT DESCRIPTION WITHOUT CIRCULATION

ITEM DESCRIPTION FUNCTION

A Component Pump A In a two-component system, Component Pump A typically pumps the ISO or activator

material.

B Component Pump B In a two-component system, Component Pump B typically pumps the resin material.

C Surere™ Heater Block Material ows from the supply containers into the uid pumps, where the material is

pressurized to the desired pressure(s), based on the Control Panel settings. The Surere™

heater block heats the material on its way to the material pumps.

D Control Panel The control panel contains all of the system controls that allow the sprayer to function

properly, as well as being the main display panel that gives information about the

system.

E PRIME/SPRAY knob The PRIME/SPRAY knob directs material to the spray hose when in the SPRAY position

and to the prime hoses when in the PRIME position. Turning the PRIME/SPRAY knob will

relieve any pressure built up in the system.

F Prime hoses When the PRIME/SPRAY knobs are set to PRIME, spray material will circulate into the

Component pumps and then out of the prime hoses.

G Inlet valves The inlet valves allow material to be drawn from the material containers into the system.

They can be turned o in order to prevent material from entering the system.

H Supply hoses The two supply hoses deliver uid from the supply drums to the Component pumps.

I Dual heated hose The dual heated hose delivers spray material from the two Component Pumps to the

spray gun.

J Transfer pump The two transfer pumps pump material from the supply containers, into the supply

hoses and then to the Component Pumps. The transfer pumps are powered by an air

compressor.

K Desiccant dryer The Desiccant dryers remove any moisture that is present in the air pockets left by the

removal of material from the supply drums.

L Transfer pump air hose The transfer pump air hose delivers air from the compressor to the transfer pumps.

11

Page 12

SYStem DeSCription

K

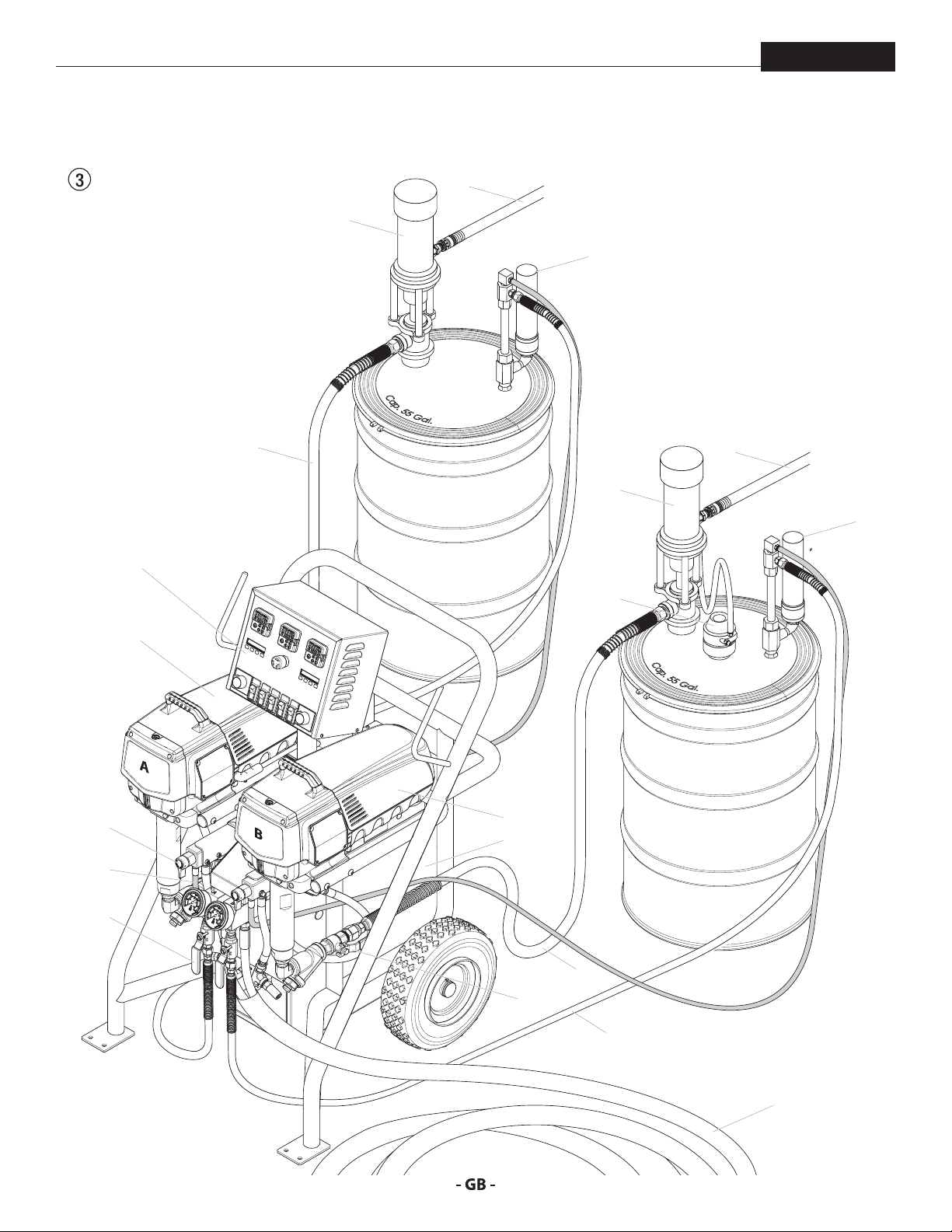

3.3 SYSTEM DIAGRAM WITH CIRCULATION

J

HELIX

M

K

H

J

D

N

A

E

F

B

C

M

12

L1

H

G

L2

I

Page 13

SYStem DeSCription

i

i

HELIX

3.4 COMPONENT DESCRIPTION WITH CIRCULATION

This conguration is only possible with the purchase of

circulation kit P/N 0138914, sold separately. The parts

included in the kit are labeled with an asterisk (*).

ITEM DESCRIPTION FUNCTION

A Component Pump A In a two-component system, Component Pump A typically pumps the ISO or activator material.

B Component Pump B In a two-component system, Component Pump B typically pumps the resin material.

C Surere™ Heater Block Material ows from the supply containers into the uid pumps, where the material is pressurized to

the desired pressure(s), based on the Control Panel settings. The Surere™ heater block heats the

material on its way to the material pumps.

D Control Panel The control panel contains all of the system controls that allow the sprayer to function properly, as

well as being the main display panel that gives information about the system.

E PRIME/SPRAY knob The PRIME/SPRAY knob directs material to the spray hose when in the SPRAY position and to the

prime hoses when in the PRIME position. Turning the PRIME/SPRAY knob will relieve any pressure

built up in the system.

F Prime hoses When the PRIME/SPRAY knobs are set to PRIME, spray material will circulate into the Component

pumps and then out of the prime hoses.

G Inlet valves The inlet valves allow material to be drawn from the material containers into the system. They can

be turned o in order to prevent material from entering the system.

H Supply hoses The two supply hoses deliver uid from the supply drums to the Component pumps.

I Dual heated hose The dual heated hose delivers spray material from the two Component Pumps to the spray gun.

J Transfer pump The two transfer pumps pump material from the supply containers, into the supply hoses and then

to the Component Pumps. The transfer pumps are powered by an air compressor.

K Desiccant dryer The Desiccant dryers remove any moisture that is present in the air pockets left by the removal of

material from the supply drums.

L* Circulation valves / hoses When open, the circulation valves (L1) allow material to circulate through the heater block and

back through the hoses (L2) into the supply containers. This allows the material to be heated more

quickly.

M Transfer pump air hose The transfer pump air hose delivers air from the compressor to the transfer pumps.

N Agitator The agitator stirs the material on the resin (B) side material container.

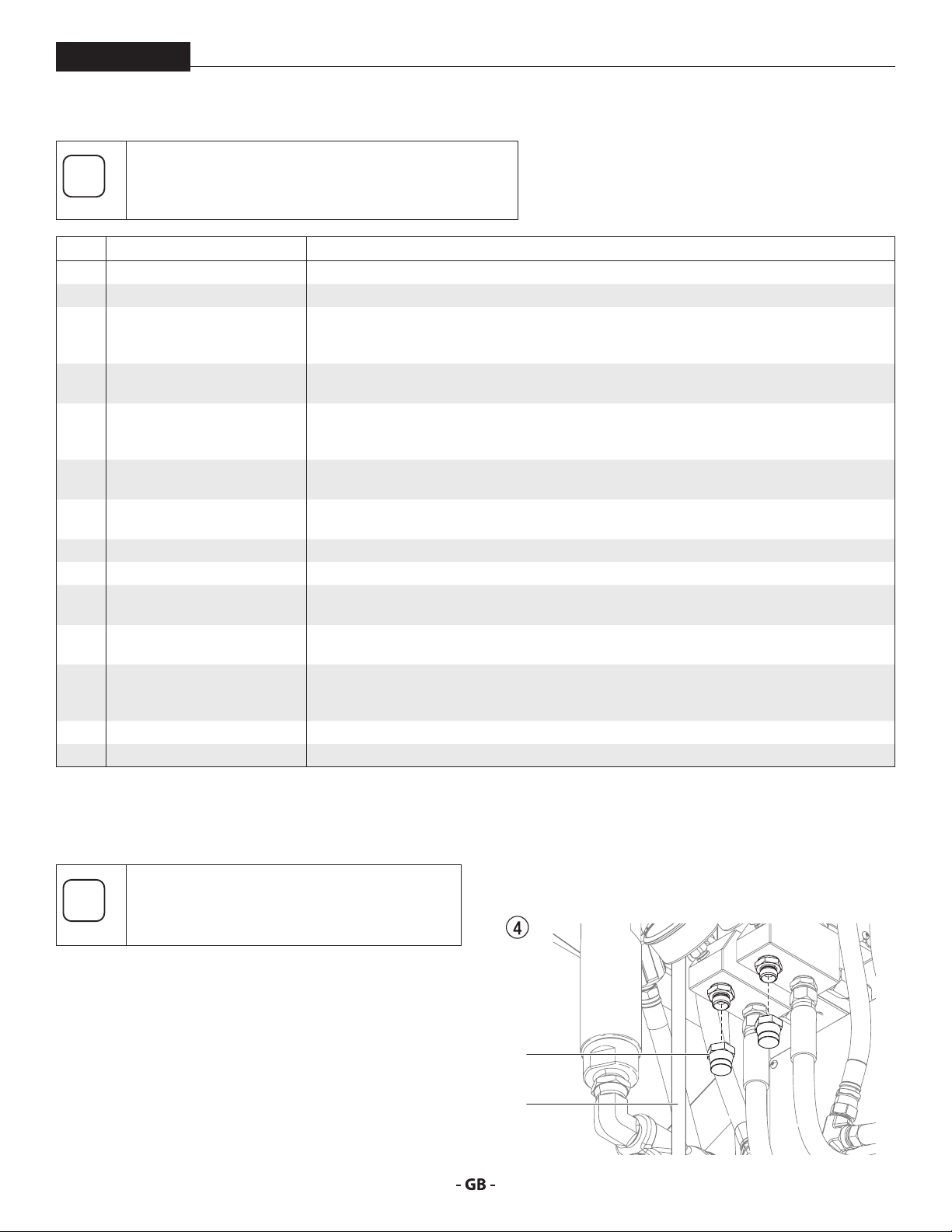

3.5 INSTALLING THE CIRCULATION KIT

OPTIONAL

The circulation kit is available for separate

purchase. Follow the steps below to install it.

Refer to section 2.2 for Clearance Diagram.

1. Make sure the system is turned o and depressurized.

2. Remove the two inlet plugs (Fig. 4, item 1) from the bottom

of the hose heater manifold. Remove return tubes (2).

3. Thread a shut-o valve (Fig. 3, item L1) from the circulation

kit into each of the ports underneath the hose heater

manifold. Thread the longer return tubes (Fig. 2, item F)

underneath each of the PRIME/SPRAY valve manifolds.

4. Attach a hose to each of the shut-o valves. Run the

hoses (Fig. 3, item L2) and return hoses (Fig. 3, item F)

13

back towards the material containers and thread into their

respective ports on the desiccant dryers.

1

2

Page 14

Control panel

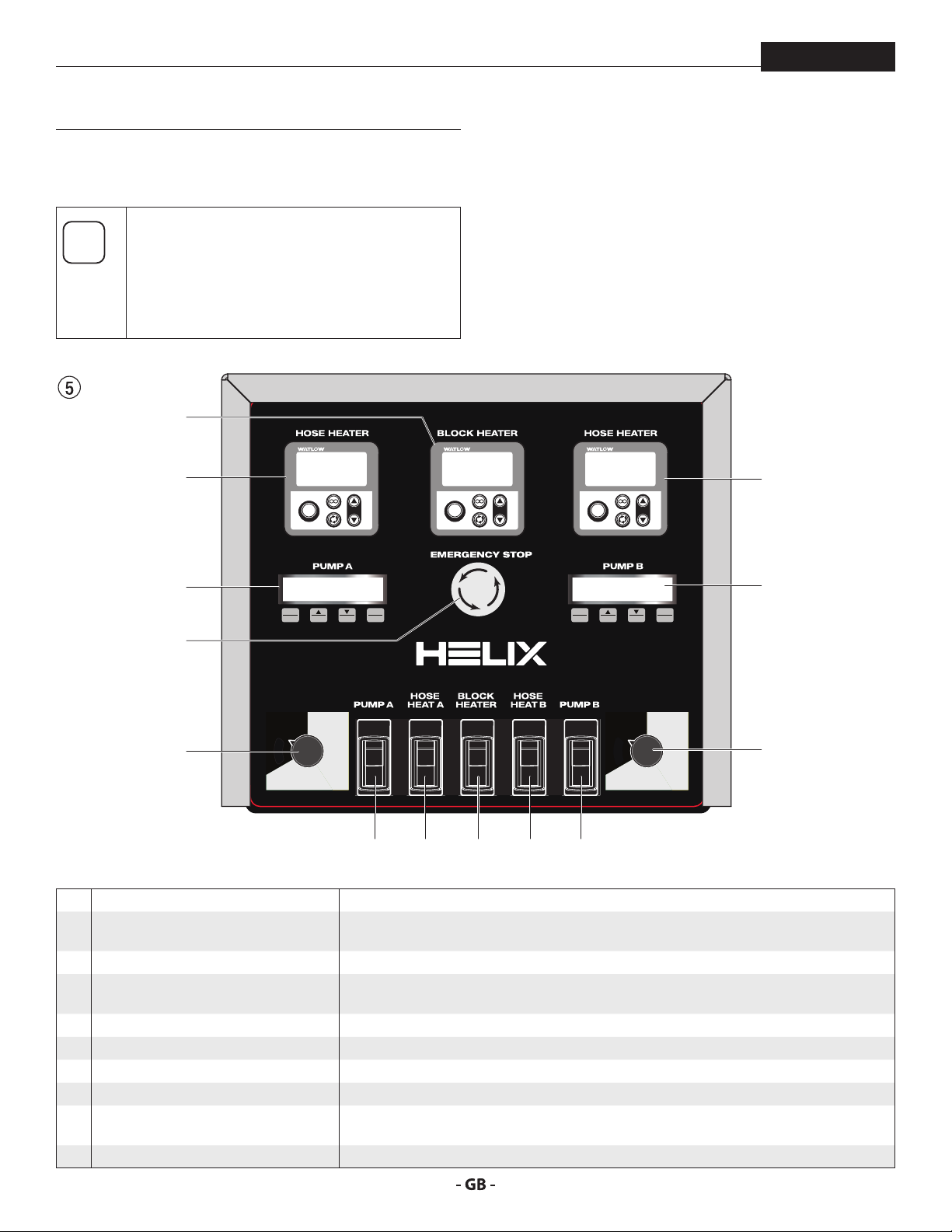

i

854 45

4 CONTROL PANEL

The control panel contains all of the system controls that allow

the sprayer to function properly, as well as being the main

display panel that gives information about the system.

Items 1 - 5 below are duplicated - one for each

pump. If they are located on the left side of the

panel, they serve the “A” side of the system. If

they are located on the right, they serve the “B”

side. If it is located in the middle, it serves the

entire system.

6

HELIX

1a

2a

7

3a

MAX

MENU

1

Clean

MAX

PSI

PSI

EZ-ZONE

8.8:8.8

Z

O

N

8 8.8:8.8

E

EZ

2 3

MIN

MIN

PSI

PSI

EZ-ZONE

1

ºF

ºC

8.8:8.8

Z

O

N

8 8.8:8.8

E

EZ

1

ºF

ºC

EZ-ZONE

8.8:8.8

Z

O

N

8 8.8:8.8

E

EZ

1

ºF

ºC

1b

2b

SEL

4

MENU

1

2 3

SEL

4

Clean

MIN

MIN

PSI

PSI

3b

MAX

MAX

PSI

PSI

1 Heated hose temperature control This panel regulates the spray material temperature for the applicable heated hose.

2 Control Displays The displays show various menu screens that allow the user to customize and monitor pump

operation using the function keys (1 - 4).

a A-side independent controller When the component pumps are unlinked, this controls Component Pump A.

b Master controller / B-side independent

controller

When the component pumps are linked, the master controller controls both component

pumps. When the component pumps are unlinked, this controls Component Pump B only.

3 Component pump pressure control Adjusts the pump pressure of the applicable Component Pump.

4 ON/OFF switch, Component Pump This switch turns the applicable Component Pump ON and OFF.

5 ON/OFF switch, hose heater This switch turns the applicable hose heater ON and OFF.

6 Surere™ heater block control This panel regulates the temperature of the Surere™ heater block

7 Emergency Shuto Pushing this button will instantly shut down the system. However, pressing this button

WILL NOT depressurize the system. Follow the Pressure Relief Procedure.

8 ON/OFF switch, heater block This switch turns the heater block ON and OFF

14

Page 15

Control panel

i

i

i

i

i

HELIX

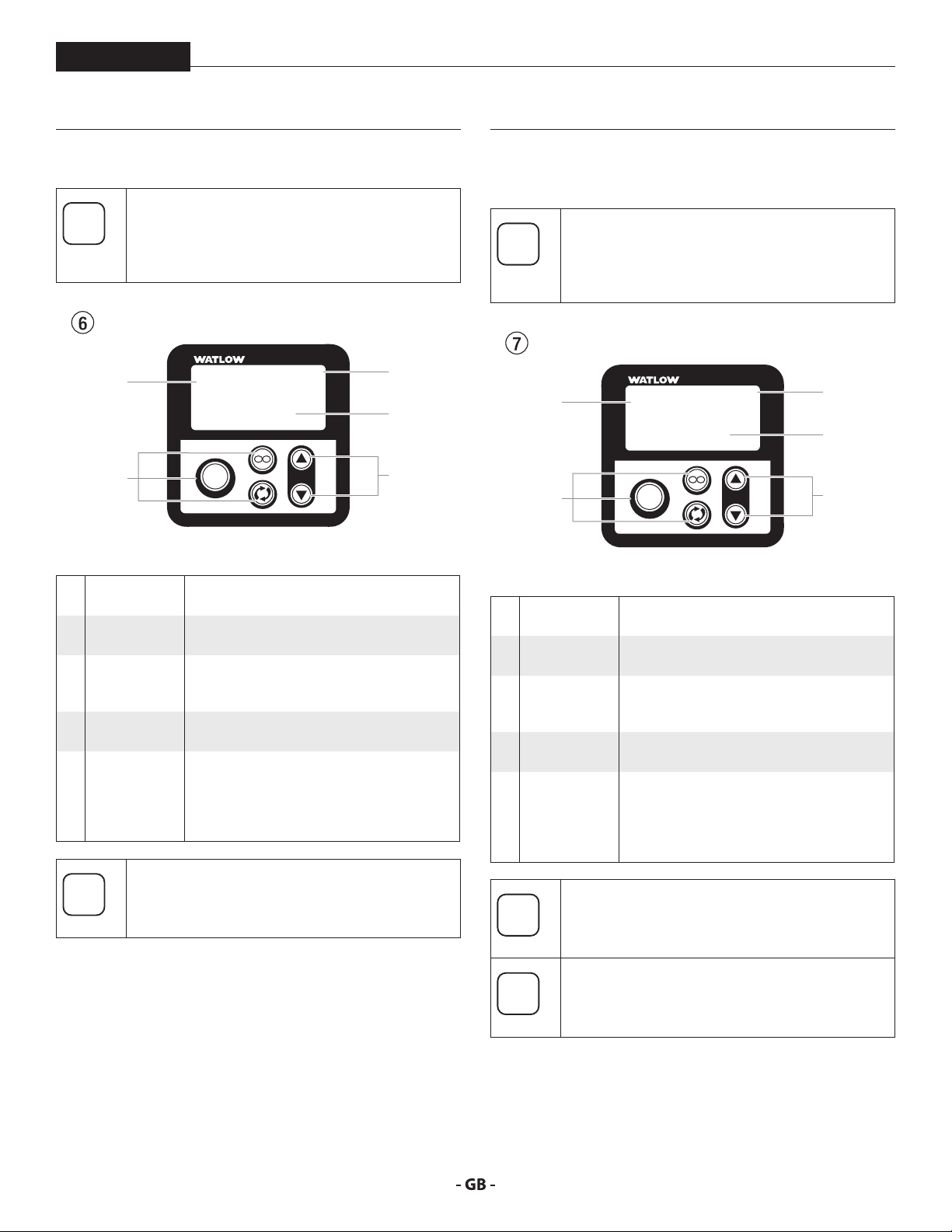

4.1 SUREFIRE™ HEATER BLOCK CONTROL

Refer to item 8 in section 4. The block heater

control regulates the temperature of spray

material as it passes through the heater block,

prior to it reaching the heated hoses.

1

2

1 Temperature

display

2 Programming

buttons

3 Power

indicator

4 Temperature

setting

5 Temperature

adjustment

EZ-ZONE

8.8:8.8

Z

O

N

8 8.8:8.8

E

EZ

Shows actual temperature of the heater

block.

These are non-functioning factory

programming buttons. Do not use.

The ashing or steady “1” indicates sucient

power is being delivered to the system’s

electrical relay.

Shows the desired temperature of the heater

block set by the operator

These buttons will increase ( p) or decrease

( q ) the temperature of the heater block.

The temperature will change in increments

of 1ºF. Press and hold the button to increase

the increments by 1ºF and then 10ºF.

1

ºF

ºC

4.2 SUREFIRE™ HEATED HOSE TEMPERATURE

CONTROL

Refer to item 1 in section 4. The heated hose

temperature control maintains the temperature

of the spray material once it passes through the

heater block and into the heated hoses.

3

4

1

8.8:8.8

Z

O

N

8 8.8:8.8

E

5

2

1 Display Displays the current temperature of the

2 Programming

buttons

3 Power

indicator

4 Temperature

setting

5 Temperature

adjustment

EZ

heated hose set

These are non-functioning factory

programming buttons. Do not use.

The ashing or steady “1” indicates sucient

power is being delivered to the system’s

electrical relay.

Shows the desired temperature of the

heated hoses set by the operator

These buttons will increase ( p) or decrease

( q ) the temperature of the heated hose set.

The temperature will change in increments

of 1ºF. Press and hold the button to increase

the increments by 1ºF and then 10ºF.

EZ-ZONE

1

ºF

ºC

3

4

5

Refer to section 8.2 to review the controller error

messages.

15

Refer to section 8.2 to review the controller error

messages.

Decreased voltage under 230V AC may increase

initial heat time.

Page 16

Control panel

i

i

i

i

HELIX

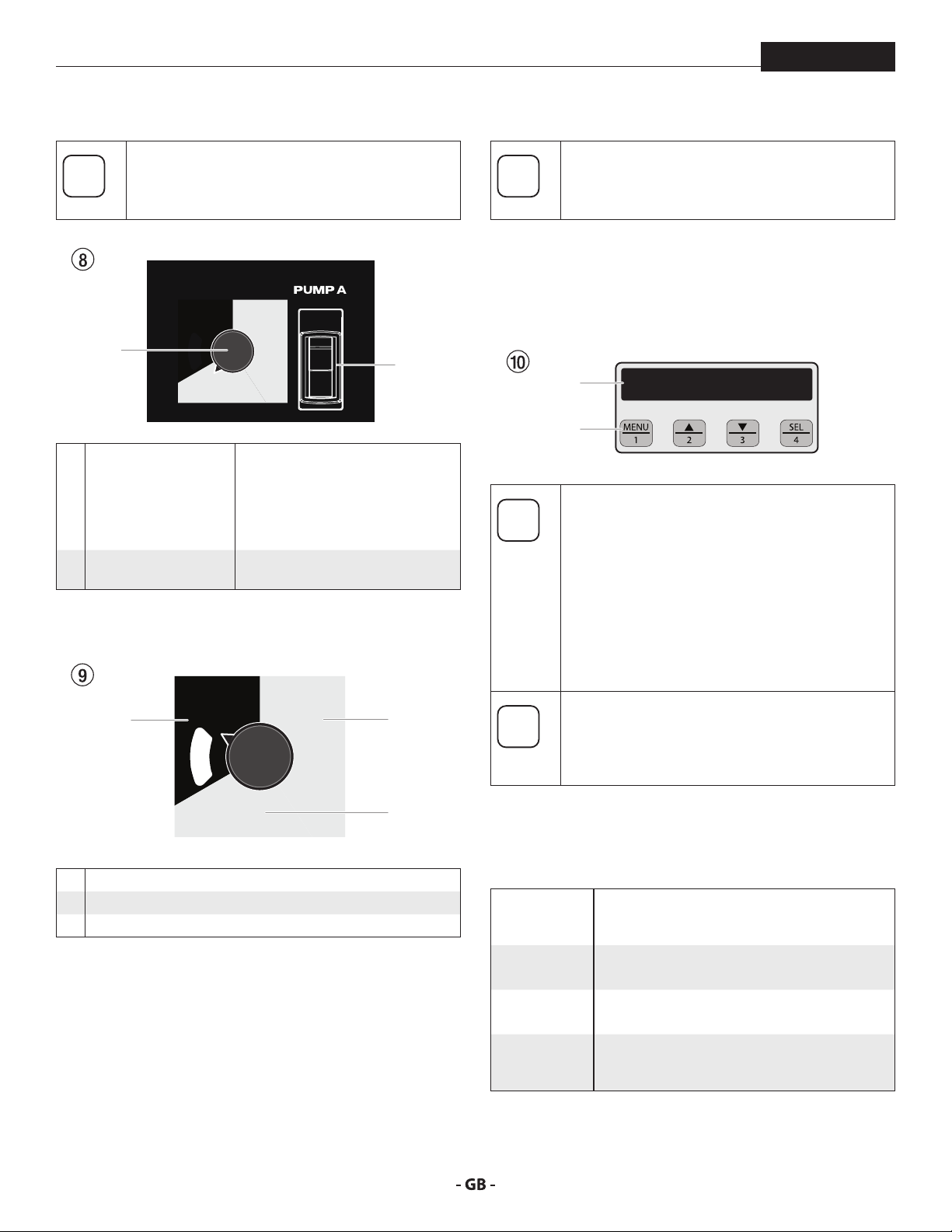

4.3 COMPONENT PUMP PRESSURE CONTROL

Refer to item 2 in section 4. The following items

control the pressure of the individual Component

Pumps.

MIN

PSI

1

MAX

PSI

1 Pressure control knob Adjusts the pump pressure of the

applicable Component Pump when

unlinked. When Component pumps

are linked, the (B) pump pressure

control knob will control the

pressure of both pumps.

2 Component Pump ON/

OFF switch

PRESSURE CONTROL KNOB SETTINGS

Switches the Component Pump ON

and OFF.

MIN

PSI

2

2

1

4.4 CONTROL DISPLAYS

Refer to item 2 in section 4. The graphic below

applies to both the Component Pump (A) and

Component Pump (B).

The Control Displays increase the functionality of the applicable

Component Pump.

It consists of a display (1) and four function keys (2). The display

shows various menu screens that allow the user to customize

and monitor sprayer operation using the function keys.

1

2

When both component pumps are turned

ON, the system will automatically link the two

Component Pumps after 10 seconds. This means

the Component Pump (A) control display will be

controlled by the Component Pump (B) control

display. When the component pumps are linked,

the Component Pump (A) control display keys

are disabled and will only be functional when the

two Component Pumps are unlinked (see “Status

Screen”).

The pressure control knob overrides the Control

Display settings. Anytime the pressure control

knob is turned, the sprayer pressure will change

accordingly.

SET PSI 0

ACTUAL PSI 0

MAX

PSI

1 Minimum pressure setting

2 Black zone – no pressure generation

3 Maximum pressure setting

16

3

FUNCTION KEYS

The function keys are numbered 1–4. Each key is labeled with

an additional function as well.

#1/Menu Key Pressing the #1 key scrolls through the available

menu screens or performs a function described on

the active menu screen.

#2/p Key

#3/q Key

#4/Select Key Pressing the #4 key selects the active menu screen

Pressing the #2 key performs a function described

on the active menu screen or increases a value.

Pressing the #3 key performs a function described

on the active menu screen or decrease a value.

or performs a function described on the active

menu screen.

Page 17

Control panel

i

SET PSI 0

L-SET PSI 0

ACTUAL PSI 0

i

VIS-COMP NEXT-1 +2 -3

STATUS = LINKED

STATUS = UNLINKED

ALARM RANGE

+/- 750 PSI

ALARM STATUS: OFF

i

TOTAL CYCLES

SELECT-4MENU-1

CYCLES XXXX

RESET-3MENU-1

HELIX

MENU SCREENS

Several menu screens are available for the user to customize

and monitor sprayer operation. They include Main Screen, VisComp (Viscosity Compensation)*, Status* Alarm Range*, Alarm

Status*, Total Cycles*, Job Cycles*, Unit Serial #, Timers, Job

Timers, Service Time, Security Code*, and Prime.

Screens noted with an asterisk (*) are screens that

apply to Component Pump (B) only. All other

screens apply to both (A) and (B) pumps.

Main Screen

The Main Screen is the default screen

for the control system at sprayer

startup.

Pressing the #2 key switches between PSI, Bar, and MPa units

of measure. Press the #1 key to scroll through the remaining

menu screens.

(A) Pump Only - The “L-” before the

“Set PSI” text on the Main Screen

indicates that the two Component Pumps are linked.

For sprayers equipped with an nine-language

Control Display:

Pressing the #2 key at the Main Screen switches

between PSI, Bar and MPa units of measure.

Pressing the #3 key at the Main Screen changes

the language of the text on the display. There

are a total of nine languages available. Each time

the #1 key is pressed, a dierent language will

appear. The languages, in order of appearance,

are: English, Spanish, Dutch, Danish, Swedish,

German, French, Italian, and Portuguese.

Vis-Comp (Viscosity Compensation) Screen*

The Vis-Comp screen on the (B) pump

allows the user to see and/or adjust

slight dierences in viscosity between the (A) pump material

and the (B) pump material.

Pressing the #2 key will increase the spraying ratio in

increments of 1% (up to 5%). Pressing the #3 key will decrease

the spraying ratio in increments of 1% (up to 5%). Pressing the

#4 key will increase the ratio by increments of .250.

ACTUAL PSI 0

1%

Status Screen*

The Status Screen shows the link

status of the (A) pump and (B) pump.

When turning the system on, the two

pumps will automatically be linked,

which means the (A) pump is controlled by the (B) pump.

When the Status Screen is showing, pressing the #3 key will

unlink the two pumps, and the (A) pump and (B) pump will

operate independently and the (A) pump control display keys

will be enabled.

If the pumps have been unlinked, pressing the #2 key will link

the two pumps back together, and the (A) pump will now be

controlled by the (B).

Alarm Range Screen*

The Alarm Range Screen allows the

user to adjust the allowable pressure

discrepancy between the (A) and (B) pumps.

Pressing the #2 key will increase the allowable pressure

discrepancy by 50 psi. Pressing the #3 key will decrease the

allowable pressure discrepancy by 50 psi. The range is 250 psi

- 1000 psi.

Alarm Status Screen*

The Alarm Status Screen allows

the user to switch ON or OFF the

internal alarm that alerts the user to a non-allowable pressure

imbalance.

Pressing the #2 key will turn the alarm ON. Pressing the #3 key

will turn the alarm OFF.

If a pressure imbalance is detected in the system

with the alarm status set to ON, the system will

automatically shut down and the display will

show a PSI Imbalance. Refer to Control Display

Error Messages.

Total Cycles Screen*

The Total Cycles Screen shows the

total number of piston cycles a

component pump has performed during its lifetime.

Pressing the #3 key will reset the

cycle count to zero. Pressing the #1

key will bring the control panel back to the Main Screen.

LINK-2 UNLINK-3

LINK-2 UNLINK-3

ON-2 OFF-3 EXT-4

17

Page 18

Control panel

SECURITY CODE

i

ENTER OLD CODE

ENTER NEW CODE

i

PRIME

i

JOB CYCLES

CYCLES XXXX

UNIT SERIAL #

SELECT-4MENU-1

SER # XXXXXXXXXX

MENU-1

TIMERS

ON TIME

XXXX

JOB TIMERS

SELECT-4MENU-1

JOB ON X

SERVICE TIME

SERVICE @ XX

HELIX

Job Cycles Screen*

The Job Cycles Screen shows the total

number of piston cycles a component

pump performs during a spray job.

Pressing the #3 key will reset the

cycle count to zero. Pressing the #1

key will bring the control panel back to the Main Screen.

Unit Serial # Screen

The Unit Serial # screen shows the

sprayer’s serial number.

To select the Unit Serial # screen,

press the #4 key.

Timers Screen

The Timers screen shows the total

time the sprayer has been turned on

as well as the total time the sprayer

has been running (pumping).

To select the Timers screen, press the

RUN TIME

#4 key.

Job Timers Screen

The Job Timers screen allows the

user to reset the “ON TIME” and “RUN

TIME” to track time on specic jobs.

To select the Job TImers screen, press

the #4 key. “JOB ON” screen will

appear. Press #3 to reset. Press #1 to

JOB RUN X

continue to “JOB RUN” screen. Press

#3 to reset. Press #1 to scroll through the remaining menu

screens.

Service Time Screen

The Service Time screen allows the

user to set a service time interval

(in hours). Below the set time, the

screens shows the current amount

of hours on the sprayer since the last

activation of the service timer. To select the Service Timer

screen, press the #4 key.

To set the service time, press the #2

RUN HOURS XX

(up) and/or the #3 (down) keys to the

desired time (run hours will increase/

decrease in increments of 1 for each

time you press a key).

When the service time interval is set and met by the run hours,

the display will show a “Service Required” screen. The pump

will remain functional. To return to the Main Screen, press the

#1 key. Doing so will reset the “Service @” and “Run Hours”

displayed on the Service Screen back to 0.

18

Security Code Screen*

SELECT-4MENU-1

The Security Code screen allows the

CHANGE-2MENU-1

user to set a four digit security code

to prevent unauthorized use of the sprayer. If a security code

RESET-3MENU-1

has been set, the control system display will ask for the code

at startup. If the correct code is entered, the display will show

the Main Screen and the sprayer will operate. If the wrong

code is entered, the display will continue to ask for the correct

code and the sprayer will be disabled. To set or change the

security code, press the #2 key.

If the sprayer is new, no security code is set and

the Main Screen will appear at startup. When

setting a security code for the rst time, the

“Enter Old Code Number” screen will appear, and

you will need to enter “1111”.

SELECT-4MENU-1

Enter the old security code number

NUMBER

to access the screen that allows the

code change. If the wrong code is

XXXX

entered, the display will continue

to ask for the correct code and the security code cannot be

changed.

Enter the new security code. Once

the new code is entered, the display

will automatically ask that the new

code be re-entered for verication.

If the same new code is re-entered,

RESET-3MENU-1

the display will conrm that the new

NUMBER XXXX

RE-ENTER NEW

NUMBER XXXX

NEW CODE NUMBER

ACCEPTED

code has been accepted and return to the Main Screen. If the

RESET-3MENU-1

new code is re-entered incorrectly, the display will return to

the “Enter New Code Number” screen and the process will

repeat.

If you forget or misplace your security code, you can call Titan

customer service for assistance.

SELECT-4MENU-1

To inactivate the Anti-Theft Digital Lockout

security function, enter “1111” at the “Enter New

Code Number” screen (this is the default code

that leaves the sprayer unlocked). As a result, the

Main Screen will appear at sprayer startup.

Prime Screen

The Prime screen appears when the

pressure control knob is set at the

“MIN” setting.

If there is no action at any menu screen for 10

seconds, the display will go back to the Main

Screen.

Page 19

Control panel

CHECK

TRANSDUCER

CHECK

LOW

VOLTAGE

HIGH MOTOR

TEMPERATURE

HIGH MECHANICAL

PSI IMBALANCE

UNLINK 3

HELIX

4.5 CONTROL DISPLAYS ERROR MESSAGES

The following error message screens appear whenever the

Control Display detects a problem with the system. Once a

problem occurs and the error message appears, the system will

shut down.

Before proceeding, follow the Pressure Relief

Procedure outlined in this manual. Additionally,

follow all other warnings to reduce the risk of

an injection injury, injury from moving parts or

electric shock. Always unplug the system before

servicing!

Check Transducer Screen

The Check Transducer screen appears

when the transducer has become

disconnected or is defective. Take the sprayer to a Titan

authorized service center for repair.

Check Potentiometer Screen

The Check Potentiometer screen

POTENTIOMETER

appears when the potentiometer has

become disconnected or is defective. Take the sprayer to a

Titan authorized service center for repair.

Low Voltage Screen

The Low Voltage screen appears

when the sprayer shuts down

because of low input voltage. Check the power supply and

correct the problem. Restart the system.

High Motor Temperature Screen

The High Motor Temperature screen

appears when the temperature of

the motor has risen too high. Take the sprayer to a Titan

authorized service center for repair.

High Mechanical Load

The High Mechanical Load screen

LOAD

appears when the sprayer shuts

down because of high current or when the sprayer goes into

current fold back mode. Take the sprayer to a Titan authorized

service center for repair.

PSI Imbalance

The PSI Imbalance screen appears

when there is a non-allowable

pressure discrepancy between the (A) and (B) pumps while

linked. If a PSI imbalance occurs, press the #3 key to unlink the

two pumps. Once the pumps are unlinked, press the #1 key to

return to the Main Screen.

19

Page 20

Setup

i

i

i

HELIX

5 SETUP

In order to prevent accidental startup, make sure

the system’s power cord is not connected during

setup, until instructed to do so.

Make sure the air pressure supply is shut o while

connecting any air hoses to the air supply.

5.1 LOCATE THE SYSTEM

1. Locate the system on a level surface. Refer to dimensions

in section 2.2 for clearance and mounting hole dimensions.

2. Mount in a dry area.

3. For best results, the machine should be bolted into place.

5.2 INSTALL THE TRANSFER PUMPS

The transfer pumps draw material directly from

the spray material container to component

pumps in the system. The transfer pumps are

powered by an air compressor.

5. Attach the transfer pump air hose to their individual air

ttings.

6. Connect the other end of the transfer pump air hose to the

powered air pressure supply.

Do not install shuto valves downstream of the

prime tubes. The PRIME/SPRAY valves function

as overpressure relief valves when set to SPRAY.

Refer to section 3.1 for the corresponding illustrations to the

steps below.

1. Install the transfer pumps into Component A and

Component B supply containers.

a. With certain exceptions, the “A” component (hardener)

b. With certain exceptions, the “B” component (resin)

2. Seal the container holding Component A material and

3. If necessary, install an agitator into the Component B

4. Make sure the Component A and Component B inlet

should be located on the “A” side of the system.

should be located on the “B” side of the system.

Consult the spray material’s manufacturer

if you are unsure about which Component

Pump is compatible with each individual spray

component.

install the desiccant dryer in the vent hole.

material container.

valves are in the closed position (handle should be 90º to

the valve).

20

Page 21

Setup

At

i

AB

At

HELIX

5.3 CONNECT THE SUREFIRE™ HEATED HOSES

CONNECT THE HEATED HOSES

The heated hose assembly and dual whip hose

come pre-installed with the system and should

tention

1. Attach the JIC ttings (packaged separately with the

a. Connect the smaller JIC tting to the “A” side whip hose.

b. Connect the larger JIC tting to the “B” side whip hose.

2. Remove the coupling block from the spray gun (refer to

3. Close gun manifold valves A and B.

tention

not be removed or disassembled unless it is

being completely replaced.

Refer to the Helix Surere™ Dual Heated Hose

Manual included with your system.

heated hose set) to their appropriate whip hoses.

the spray gun manual).

Always close the manifold valves if the system is

idle for more than 1 minute under heat and/or

pressure. Failure to do so can cause a pressure

imbalance which can then lead to a material

“crossover” inside the gun, leaving the gun

inoperable.

4. Attach the dual heated whip hose to the coupling block.

a. Secure the “A” hose to the “A” side of the coupling block.

b. Secure the “B” hose to the “B” side (or “R” side) of the

coupling block.

B (Resin)

A (ISO)

5. Tighten both hose connections with a wrench.

CONNECT THE SUPPLY HOSES

1. Make sure the valve handles on the inlet valves for both

Component pumps are in the OFF position (see g. 11).

2. Attach one end of the feed hose to the inlet valve of

Component pump A. Repeat for Component pump B with

another hose.

3. Connect the other end of each hose to their appropriate

transfer pumps (i.e. the “A” hose should run from

Component pump A to the transfer pump installed into

material supply drum “A”).

4. Make sure all connections are wrench tight.

5. Arrange the return hoses:

a. For non-circulation congurations (see gure 2, section

3.1), place a waste bucket underneath each of the return

hoses.

b. For circulation conrgurations (see gure 3, section 3.3)

Attach the return hoses tubes to the dessicant dryers of

the appropriate material supply drum (i.e. the “A” return

tube for should run from Component pump A to the

dessicant dryer installed into material supply drum “A”.

21

Page 22

Setup

At

i

i

i

5.4 CONNECT THE ELECTRICAL CORD

HELIX

A 230V power cord is not included with the

system. Make sure a grounded, 230V outlet is

available in order to power the system.

It is recommended that the Helix System be used

with a generator. This provides the exibility

with not having to use the public power grid.

When connected to the public, low-voltage

network, it is possible that an approval of

the network operator is required. Check the

regulations in your country and contact your

network operator before connecting the unit to

a public electricity grid.

Power Cord Connector Requirements

Models 0138010 / 0138061 0138057 / 0138062

Connector Twistlock Twistlock

AMP 50 50

Number of Poles 3 3

Number of Wires 4 4

Phases 1 3

Voltage 125 / 250 VAC 250 V

Recommended

Manufacturer

Pass & Seymour, P/N

CS6364

LEVITON P/N

CS8364

Spray Gun The spray gun is grounded through the whip

hose ground wire. Do not spray without using

the whip hose.

Fluid Supply

Chambers

Object being

sprayed

Waste

Containers

Follow the local code.

Follow the local code.

Follow the local code. Only use metal containers

placed on a grounded surface when ushing the

system. Do not place metal waste containers on

paper or cardboard surface. A non-conductive

surface such as these can interrupt grounding

continuity.

While ushing or relieving system pressure,

ground the gun by holding it against the edge of

the metal container. Failure to do so may lead to

a static electric discharge, which may cause a re.

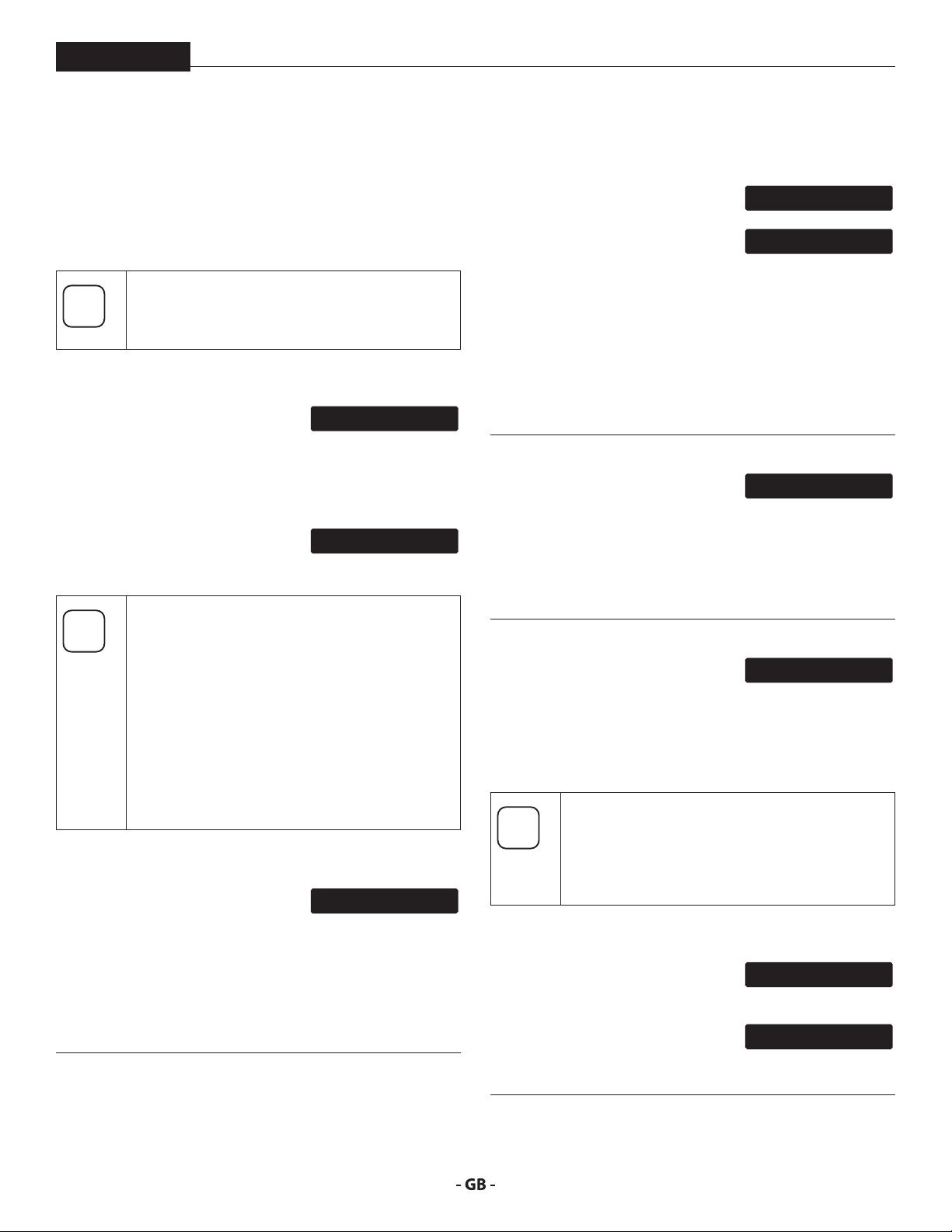

5.6 LUBRICATE THE COMPONENT PUMPS

1. Remove the cup cap with a straight-slot screwdriver.

2. Fill the cup reservoir with DOP (Dioctylphthalate) or

compatible plasticizer (Fig. 15) until the gauge (1) is

showing that it is full.

If using a generator to power the system, refer to

section 2.2 prior to plugging in the power cord.

1. First plug the adapter end of the supplied power cord

into the power cord port located on the side of the block

heater.

2. Plug the other end of the supplied power cord into a

grounded, 230V outlet.

5.5 GROUND THE SYSTEM

Proper grounding (earthing) is important. The

passage of some materials through the nylon

uid hose will build up a static electric charge,

which if discharged, could ignite solvent vapors

present and create an explosion.

Component Grounding Method

System The system and heated hoses are grounded

through the power cord.

DOP (Dioctylphthalate) or a compatible

plasticizer prevents increased wear and tear to

tention

3. Replace cup cap.

4. Press button (2) 2-5 times to prime the dispenser. Press

the packings and will keep spray material from

crystalizing on the uid section.

once for every eight hours of usage to lubricate and

protect the uid section.

1

2

22

Page 23

operation

At

At

i

i

i

HELIX

6 OPERATION

Prior to startup, make sure the generator has

fuel. Running out of fuel will cause electrical

tention

uctuations in the system that could result in

damage to the electrical components of the

system.

6.1 STARTUP

1. If using a generator, make sure the main breaker on the

generator is in the OFF position.

2. If using a generator, start the generator. Allow it to run to

full power.

3. If using an air compressor to power the transfer pumps,

start the compressor, making sure the bleed valve is in the

closed position on the compressor.

4. Turn the breaker on the generator to ON. Switch both of

the Component Pump ON/OFF switches to ON. (these are

the outermost ON/OFF switches located on the control

panel).

Do not turn on the block heater or hose heater

ON/OFF switches ON yet. Turning the hose

tention

heaters on when there is no uid in the hoses can

cause damage to the hoses.

6.2 SET TEMPERATURE

Refer to section 4 to review temperature controls.

Equipment surfaces can become hot. To avoid

severe burn injury:

1) Do not touch hot uid or equipment.

2) Allow equipment to cool completely

3) Wear gloves when dealing with

1. Set the temperature of the heater block:

a. Switch the heater block ON/OFF switch to ON (this is the

ON/OFF switch in the middle of the control panel).

b. Using the heater block controls, set the heater block

to the desired temperature. Press the (p) button

until the bottom set of numbers (1) shows the desired

temperature.

before coming into contact with it.

temperatures in excess of 110ºF (43ºC)

EZ-ZONE

65

Z

O

N

8 110

E

1

ºF

ºC

2

13

5. Turn the PRIME/SPRAY valves on both of the Component

Pumps to SPRAY.

6. Open the uid inlet valves. Check for leaks.

7. Place the coupling block (with hoses attached) over two

separate, grounded waste containers. Make sure the ports

on the manifold each aim into a dierent container.

NEVER mix components A and B during startup.

Use two separate grounded waste containers to

keep Component A and Component B separate.

8. While holding the coupling block over the waste

containers, slowly open uid valves A then B. Allow them

to remain open until clean, air-free uid comes from the

valves.

9. Close uid valves A then B.

23

2. Set the temperature of the heated hoses (repeat each of

a. Switch the heated hose ON/OFF switches to ON (these

b. Using the heated hose controls, set the heated hoses

c. The temperature settings of the heated hoses can also

The top number (2) on the heater block displays

the actual temperature. When the light (3) goes

out, the block heater is suciently heated.

the following steps for both A and B hoses):

are the switches immediately on either side of the heater

block switch in the middle of the control panel).

to the desired temperature. Press the (

until the bottom set of numbers (1) shows the desired

temperature.

be adjusted to balance spraying pressures as well as the

desired Viscosity Compension (Vis-Comp).

Adjusting the hose heat should ONLY be a

secondary method of achieving the correct VisComp. Use the Vis-Comp Screen on the Control

Display rst.

EZ

p)

button

Page 24

operation

i

At

At

HELIX

6.3 SPRAYING

Refer to the safety information in the beginning

of this manual for injury prevention guidelines.

Refer to the safety and operation instructions of

the gun manual.

1. Engage the trigger safety (refer to the spray gun instruction

manual).

2. Make sure the valves A / B on the coupling block are closed.

3. Reattach the coupling block (with hoses attached) to the

spray gun.

4. Connect the end of the air hose that is closest to the

pump to an air supply (the air hose is housed within the

velco sheathing that also contains the dual heated hoses).

Connect the other end of the air hose to the spray gun.

Make sure the air valve on the air hose (if any) is open.

5. Make sure the PRIME/SPRAY valves on the component

pumps are set to SPRAY.

6. Verify that the temperature readings are showing the

desired temperatures.

7. Verify pressure readings:

a. Check pressure gauges mounted on the front of the

system, or

b. For each component pump, go to the Control Display

Main Screen on the control panel.

Always close the manifold valves if the system is

idle for more than 1 minute under heat and/or

tention

pressure. Failure to do so can cause a pressure

imbalance which can then lead to a material

“crossover” inside the gun, leaving the gun

inoperable.

Make sure the Component Pump pressures are

balanced prior to opening the manifold valves

and resuming spraying.

6.4 PRESSURE RELIEF PROCEDURE

Perform the Pressure Relief Procedure when

shutting down for any reason.

1. Engage the trigger safety (refer to the spray gun instruction

manual).

2. Close the manifold valves A and B on the spray gun.

3. Perform all of these steps on both component pumps:

a. Turn the pressure control knob fully counterclockwise to

b. Turn the PRIME/SPRAY knob to PRIME.

4. Disconnect the spray gun air supply line.

minimum.

The pressures shown on either the gauges or the

Control Display Screens should be within 200

PSI. If pressure is unbalanced, unlink the pumps,

and then adjust the pressure to desired balanced

pressure. Once pressure is balanced, re-link the

pumps.

8. Open the coupling block valves A and B on the spray gun.

NEVER open the manifold valves on the coupling

block or trigger the spray gun if the pressure

tention

9. Disengage the trigger safety (refer to the spray gun

10. Test your spray on a piece of scrap wood or cardboard.

readings are unbalanced.

instruction manual).

Adjust pressure and temperatures as necessary to achieve

desired results.

24

Page 25

Shutting Down

At

i

i

HELIX

7 SHUTTING DOWN

7. Turn the ON/OFF switches for both Component Pumps to

It is important to the system’s electrical reliability

to maintain steady electrical voltage during

tention

1. Perform the Pressure Relief Procedure (section 6.4).

2. Turn the block heater ON/OFF switch to OFF (this is the

3. Turn both hose heater A and B ON/OFF switches to OFF

4. Switch o the air compressor and any other auxiliary

5. Open the bleed valve on the air compressor in order to

6. Turn the Component (A) and Component (B) inlet valve

7. Shut down the transfer pumps as required.

shutdown. Failure to follow these procedures

can cause voltage uctuations that can damage

the equipment and void the warranty.

switch located in the center of the control panel).

(these are the switches on either side of the heater block

ON/OFF switch).

equipment, if being used.

relieve pressure and remove any water that may have

formed in the tank.

handles to the closed position (handle should be 90º to

the valve).

7.1 PARKING

OFF.

8. Switch the generator OFF. Allow generator dwell time, per

the manufacturer recommendations.

7.2 FLUSHING

Flush the system in a well-ventilated area. Do

not turn on hose heaters or block heater when

ushing with ammable solvents.

If the new Isocyanate being introduced is

compatible with Polyol, it is not necessary to

ush the (A) side.

1. Flush out the old uid with new uid, or ush the old uid

with a compatible solvents prior to introducing a new

uid (check with the old uid manufacturer in order to

determine a compatible ushing solvent).

2. Always use the lowest possible pressure when ushing the

sprayer. Make sure the Component Pump pressure control

knobs are turned as far counterclockwise as possible in the

“MIN PSI” yellow zone.

3. Use only moisture-free solvents when ushing the system.

Perform the following steps on the (A)

Component Pump ONLY unless otherwise

specied. The following must be done in order

to prevent spray material build-up on the (A) side

Component Pump uid section.

1. Turn the pressure control knob to “MIN PSI” setting in the

yellow zone. The Control Display should say “PRIME”.

2. Press the #1 key on the Control Display. The “CREEP

MODE” screen will now appear.

3. Slowly turn the pressure control knob clockwise to increase

the pressure. The crankshaft/slider assembly will begin to

move very slowly.

4. Wait until the crankshaft/slider starts moving downward.

When it begins its downstroke, turn the Component (A)

PRIME/SPRAY valve to SPRAY.

5. When the crankshaft/slider reaches the bottom, deadcenter of its stroke, turn the pressure control knob fully

counterclockwise. The crankshaft/slider assembly should

stop.

6. Press the cup button 6-8 times to lubricate the piston on

both (A) and (B) Component Pumps.

25

Page 26

troubleShooting

8. TROUBLESHOOTING

HELIX

8.1

COMPONENT PUMPS

Problem Cause Solution

A. The unit will not run. 1. The unit is not plugged in to a power source.

B. The unit will not build or

maintain pressure.

C. Fluid leakage at the upper

end of the uid section.

2. Tripped breaker.

3. The pressure is set too low (pressure control knob

set at minimum setting does not supply power to

unit).

4. Faulty or loose wiring.

5. Excessive motor temperature.

6. ON/OFF switch is defective.

1. The pressure control knob is not set properly.

2. Material ows from the return hose when the

PRIME/SPRAY valve is in the SPRAY position.

3. Air leak in material feed hoses.

4. There is external uid leak.

5. There is an internal uid section leak (packings are

worn and/or dirty, valve balls are worn).

6. Worn valve seats

7. Motor powers but fails to rotate

8. Transfer pumps not supplying material.

1. The upper packings are worn.

2. The piston rod is worn.

1. Plug the power cord into a grounded, 230V outlet.

2. Reset the breaker.

3. Turn the pressure control knob clockwise to

4. Inspect or take to an authorized service center.

5. Allow motor to cool.

6. Replace the ON/OFF switch.

1. Turn the pressure control knob clockwise to

2. Clean or replace the PRIME/SPRAY valve.

3. Check the inlet valve / feed hose connection.

4. Check for external leaks at all connections.

5. Clean the valves and service the uid section

6. Reverse or replace the valve seats following the

7. Take unit to a authorized service center.

8. Check air supply and valves, or service the transfer

1. Repack the pump following the steps in section

2. Replace the piston rod following the steps in

supply power to the unit and increase the

pressure setting.

increase the pressure setting.

Tighten or wrap the threads with Teon tape.

Tighten connections, if necessary.

following the steps in section 9.5 and 9.6 in this

manual.

steps in section 9.5 and 9.6 in this manual.

pumps.

9.5 and 9.6 in this manual.

section 9.5 and 9.6 in this manual.

26

Page 27

troubleShooting

HELIX

8.2 SUREFIRE™ HEATER BLOCK / HOSE HEATER CONTROLLER ERRORS

Problem Cause Solution

A. Alarm will not clear or Reset with

keypad or digital input.

B. Alarm will not activate output. 1. Alarm silencing is active

C. Alarm Error. Alarm status cannot

be determined due to a lack of

sensor input.

AL.E 1 AL.E 2 AL.E 3 AL.E 4

D. Alarm Low. Sensor input below

low alarm set point.

AL.L 1 AL.L 2 AL.L 3 AL.L 4

1. Alarm latching is active

2. Alarm set to incorrect output

3. Alarm is set to incorrect source

4. Sensor input is out of alarm set point range

5. Alarm set point is incorrect

6. Alarm is set to incorrect type

7. Digital input function is incorrect

2. Alarm blocking is active

3. Alarm is set to incorrect output

4. Alarm is set to incorrect source

5. Alarm set point is incorrect

6. Alarm is set to incorrect type

1. Sensor improperly wired or open

2. Incorrect setting of sensor type

3. Calibration corrupt

1. Temperature is less than alarm set point

2. Alarm is set to latching and an alarm occurred

in the past

3. Incorrect alarm set point

4. Incorrect alarm source

1. Reset alarm when process is within range or

disable latching

2. Set output to correct alarm source instance

3. Set alarm source to correct input instance

4. Correct cause of sensor input out of alarm

range

5. Set alarm set point to correct trip point

6. Set digital input function and source instance

1. Disable alarm silencing, if required

2. Disable alarm blocking, if required

3. Set output to correct alarm source instance

4. Set alarm source to correct input instance

5. Set alarm set point to correct trip point

6. Set alarm type to correct type

1. Correct wiring or replace sensor

2. Match setting to sensor used

3. Check calibration of controller

1. Check cause of under temperature

2. Clear latched alarm

3. Establish correct alarm set point

4. Set alarm source to proper setting

E. Alarm High. Sensor input above

high alarm set point.

AL.H 1 AL.H 2 AL.H 3 AL.H 4

F. Error Input. Sensor does not

provide a valid signal to controller

Er. ,1

G. Limit will not clear or Reset with

keypad or digital input

H. Limit Error. Limit status cannot be

determined due to a lack of sensor

input, limit will trip.

L ,.E 1

I. Limit Low. Sensor input below low

limit set point.

L ,.L 1

J. Limit High. Sensor input above

high limit set point.

L ,.h 1

1. Temperature is greater than alarm set point

2. Alarm is set to latching and an alarm occurred

in the past

3. Incorrect alarm set point

4. Incorrect alarm source

1. Sensor improperly wired or open

2. Incorrect setting of sensor type

3. Calibration corrupt

1. Sensor input is out of limit set point range

2. Limit set point is incorrect

3. Digital input function is incorrect

1. Sensor improperly wired or open

2. Incorrect setting of sensor type

3. Calibration corrupt

1. Temperature is less than limit set point

2. Limit outputs latch and require Reset

3. Incorrect alarm set point

1. Temperature is greater than limit set point

2. Limit outputs latch and require Reset

3. Incorrect alarm set point

1. Check cause of over temperature

2. Clear latched alarm

3. Establish correct alarm set point

4. Set alarm source to proper setting

1. Correct wiring or replace sensor

2. Match setting to sensor used

3. Check calibration of controller

1. Correct cause of sensor input out of limit range

2. Set limit set point to correct trip point

3. Set digital input function and source instance

1. Correct wiring or replace sensor

2. Match setting to sensor used

3. Check calibration of controller

1. Check cause of under temperature

2. Clear limit

3. Establish correct limit set point

1. Check cause of over temperature

2. Clear limit

3. Establish correct limit set point

27

Page 28

troubleShooting

HELIX

K. Loop Open Error. Open Loop

Detect is active and the process

value did not deviate by a userselected value in a user specied

period with PID at 100%.

LP.o1 LP.o2

L. Loop Reversed Error. Open Loop

Detect is active and the process

value is headed in the wrong

direction when the output is

activated based on deviation value

and user-selected value.

LP.r1 LP.r2

M. Ramping Error. Controller is

ramping to new set point.

rP 1 rP 2

N. Autotuning Error. Controller is

autotuning the control loop.

F U

U 1

O. No heat/cool action. Output does

P. No display indication or LED

Q. No serial communication. Cannot

F U

U 2

not activate load.

illumination.

establish serial communications

with the controller.

1. Setting of Open Loop Detect Time incorrect.

2. Setting of Open Loop Detect Deviation

incorrect.

3. Thermal loop is open.

4. Open Loop Detect function not required but

activated.

1. Setting of Open Loop Detect Time incorrect.

2. Setting of Open Loop Detect Deviation

incorrect.

3. Output programmed for incorrect function.

4. Thermocouple sensor wired in reverse polarity.

1. Ramping feature is activated. 1. Disable ramping feature if not required.

1. User started the autotune function.

2. Digital input is set to start autotune.

1. Output function is incorrectly set.

2. Control mode is incorrectly set.

3. Output is incorrectly wired.

4. Load, power or fuse is open.

5. Control set point is incorrect.

6. Incorrect controller model for application.

1. Power to controller is o

2. Fuse open

3. Breaker tripped

4. Safety interlock switch open

5. Separate system limit control activated

6. Wiring error

7. Incorrect voltage to controller

1. Address parameter incorrect

2. Incorrect protocol selected

3. Baud rate incorrect

4. Parity incorrect

5. Wiring error

6. EIA-485 converter issue

7. Incorrect computer or PLC communications

port

8. Incorrect software setup

9. Termination resistor may be required

1. Set correct Open Loop Detect Time for

application.

2. Set correct Open Loop Devation value for

application.

3. Determine cause of open thermal loop:

misplaced sensors, load failure, loss of power to

load, etc.

4. Deactivate Open Loop Detect feature.

1. Set correct Open Loop Detect Time for

application.

2. Set correct Open Loop Devation value for

application.

3. Set output function correctly.

4. Wire thermocouple correctly (red wire is

negative).

1. Wait until autotune completes or disable

autotune feature.

2. Set digital input to function othe than

autotune, if desired.

1. Set output function correctly.

2. Set control mode appropriately (Open vs.

Closed Loop).

3. Correct output wiring.

4. Correct fault in system.

5. Set control set point in appropriate control

mode and check source of set point: remote,

idle, prole, closed loop, open loop.

6. Obtain correct controller model for application.

1. Turn on power

2. Replace fuse

3. Reset breaker

4. Close interlock switch

5. Reset limit

6. Correct wiring issue

7. Apply correct voltage, check part number

1. Set unique addresses on network

2. Match protocol between devices

3. Match baud rate between devices

4. Match parity between devices

5. Correct wiring issue

6. Check settings or replace converter

7. Set correct communication port

8. Correct software setup to match controller

9. Place 120 resistor across EIA-485 on last

controller

28

Page 29

troubleShooting

HELIX

R. Process does not control to set

point. Process is unstable or never

reaches set point.

S. Temperature runaway. Process

value continues to increase or

decrease past set point.

T. Device Error. Controller displays

internal malfunction message at

power up.

100 rETn

U. Heater Error.

h. Er

V. Current Error. Load current

incorrect.

C. Er

W. Menus inaccessible. Unable to

access:

Set Oper FCtY ProF

menus or particular prompts in

Home Page.

X. EZ-Keys do not activate required

function.

Y. Value too low to be displayed in 4

digit LED display.

1. Controller not tuned correctly.

2. Control mode is incorrectly set.

3. Control set point is incorrect.

1. Controller output incorrectly programmed

2. Thermocouple reverse wired

3. Controller output wired incorrectly

4. Short in heater

5. Power controller connection to controller

defective

6. Controller output defective

1. Controller defective

2. Miss wired input or ground loop

1. Current through load is above current trip set

point.

2. Current through load is below current trip set

point.

1. Short solid-state or mechanical relay.

2. Open solid-state or mechanical relay.

3. Current transformer load wire associated to

wrong output.

4. Defective current transformer or controller.

5. Noisy electrical lines.

1. Lockout or Security set to incorrect level

2. Digital input set to lockout keypad

3. Custom parameters incorrect

1. EZ-Key function incorrect

2. EZ-Key function instance not correct

3. Keypad malfunction

1. Incorrect setup 1. Check scaling of source data

1. Perform autotune or manually tune system.

2. Set control mode appropriately (Open vs.