TIME MARK is a division of

4.25"

7

.

0

"

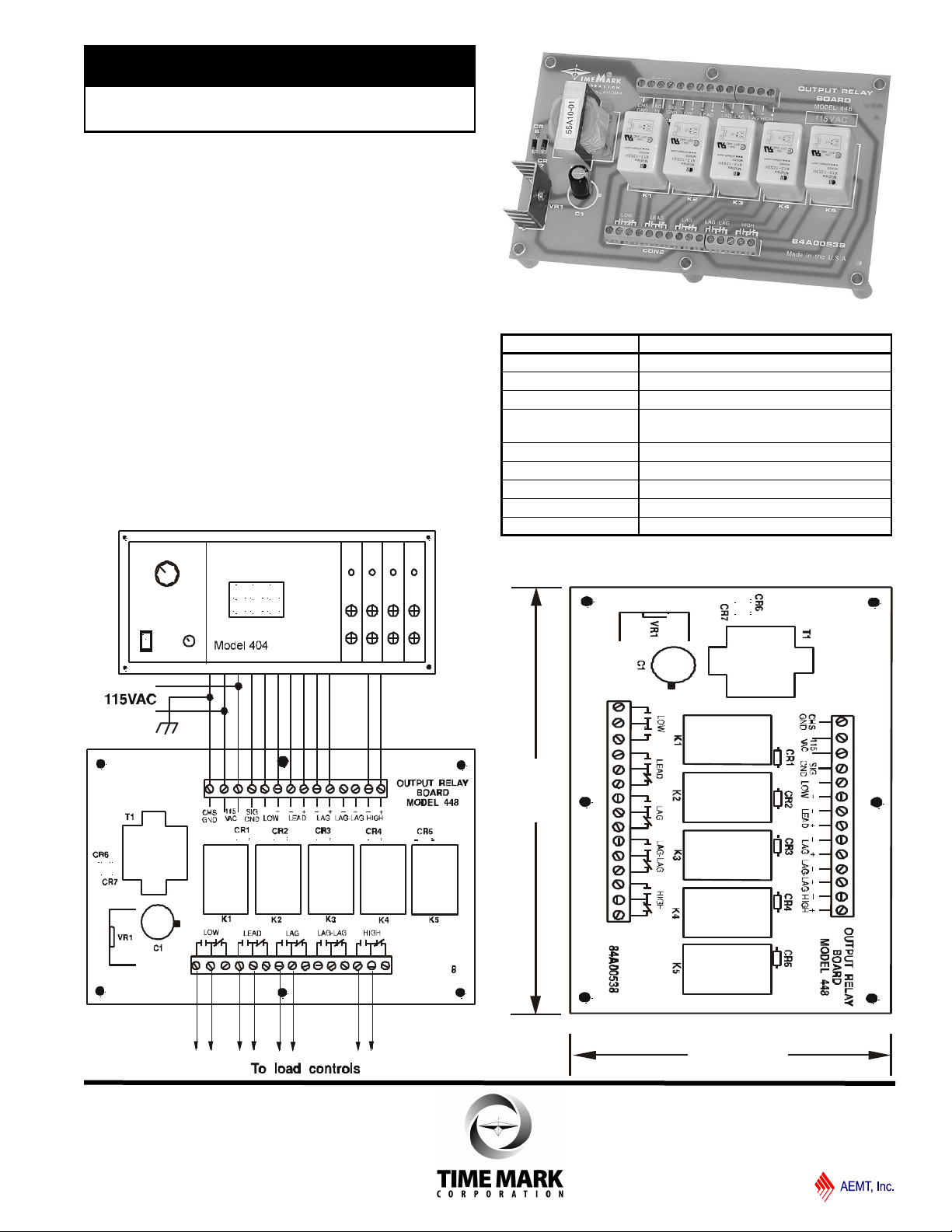

MODEL 448

Output Relay Board

Use with Models 404 & 408

5 Electromechanical Relay Contacts

DESCRIPTION

The Model 448 Output Relay Board provides electromechanical

relay contacts for the Model 404 or 408 Liquid Level Sensors,

allowing those models to be used as a control device.

The Model 448 consists of a power supply and five relays on the

surface-mounted printed circuit board. Four of the five relays are

used with the Model 404. All five relays are used on the Model

408, refer to the typical application.

Some liquid level control applications may not require the

alternating control, HOA switches, or run-time meters (see the

Model 403 or Model 407 data sheets).

The Model 404 and Model 408 Liquid Level Sensors uses the

Model 448 to meet the needs of direct relay control applications.

TYPICAL APPLICATION - Model 404

SPECIFICATIONS

Model 448

Input Voltage 105 to 130VAC

Input Frequency 47 to 65Hz

Power Consumption

Inputs

Outputs 5 SPDT

Output Rating 10 Amps at 240VAC resistive

Dimensions

Mounting Dimensions

Weight

Solid-state from Models 404 or 408

1.5W

or any contact closure

7”×4.25”×2”

6.625” × 3.875”

12.5 oz.

DIMENSIONS

11/2011

© 2011 TIME MARK CORPORATION

TIME MARK is a division of

MODEL 448

Output Relay Board

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

GENERAL SAFETY

POTENTIALLY HAZARDOUS VOLTAGES ARE PRESENT AT THE TERMINALS OF THE MODEL 448.

ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING WIRING.

THIS DEVICE SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

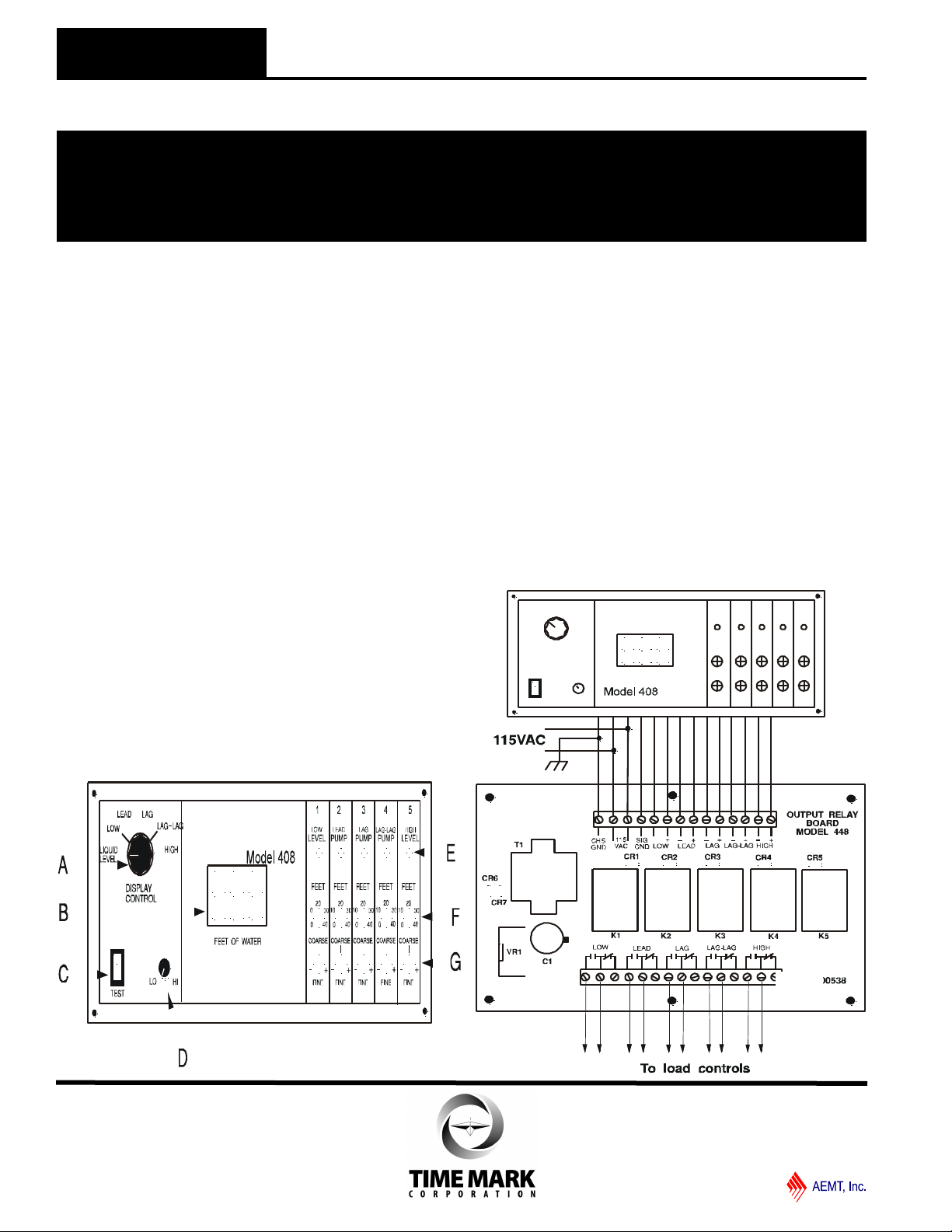

Installation Instructions

INSTALLATION

Mount the sensor Model 404/408 Liquid Level Sensor in a suitable

enclosure.

Mount the Model 448 relay module in a suitable enclosure, near the

Sensor assembly.

The terminals marked LIQUID LEVEL on the sensor assembly are the

4-20mA output.

If used, connect these terminals to the appropriate control circuitry.

They are not connected to the relay module. Observe Polarity.

Connect a 3/16” I.D. tubing to the air supply fitting on the back of the

Model 404/408. Connect the other end of the tubing to the air

compressor and the tank air tubes.

Apply operating power and proceed to the ADJUSTMENT procedure.

ADJUSTMENT

The trip points are set using COARSE and FINE adjustment pots; the

results are shown on the LED display.

To adjust the device, set the DISPLAY CONTROL knob (A) to LOW

and adjust the LOW LEVEL-COARSE adjustment (F) to the

approximate desired level.

The FINE adjustment (G) is located below the COARSE adjustment.

The trip level will be shown on the digital display (B).

Repeat these adjustments for the LEAD, LAG, LAG-LAG (Model 408

only) and the HIGH LEVEL adjustments.

Set the DISPLAY CONTROL knob to the LIQUID LEVEL position.

The Sensor is now ready to operate.

TROUBLESHOOTING

This device is not a field repairable unit. Should the unit not operate

properly during adjustment or testing procedure, insure that all

electrical connections and the air pressure are correct.

Verify that the proper voltage is applied and check all fuses. Contact

the factory should the unit fail during use.

WARRANTY

This product is warranted to be free from defects in materials and

workmanship for one year. Should this device fail to operate, we will

repair it for one year from the date of manufacture. For complete

warranty details, see the Terms and Conditions of Sales page in the

front section of the Time Mark catalog or contact Time Mark at 1-800-

862-2875.

TYPICAL APPLICATION - Model 408

11/2011

© 2011 TIME MARK CORPORATION

Loading...

Loading...