MODEL 408

"

"

"

"

"

"

"

TIME MARK is a division of

Liquid Level

Sensor

Digital display of water depth

Solid-state outputs

Five adjustable trip points

4-20 mA output

Moisture protected circuits

DESCRIPTION

The Model 408 Liquid Level Sensor operates in conjunction

with a Model 407 Controller for bubbler-type triplex pumping

systems. The 408 contains an air pressure-to-voltage transducer

and requires only a small compressor capable of 15 psi (pounds

per square inch) to operate the system down to approximately

35 feet.

The Model 408’s five outputs are designed to replace the float

switch inputs to a Model 407, or to be used with a Model 448

Output Relay Board. A 4-20 mA signal output provides for other

control applications.

A 3-digit LED display continuously shows the liquid level to a

tenth of a foot when the Display Control switch is in the Liquid

Level position. Other settings of the switch allow setting of the

liquid level trip points. LED Indicators illuminate as the levels are

exceeded. A test control allows the trip settings to be checked

without actually raising or lowering the liquid level.

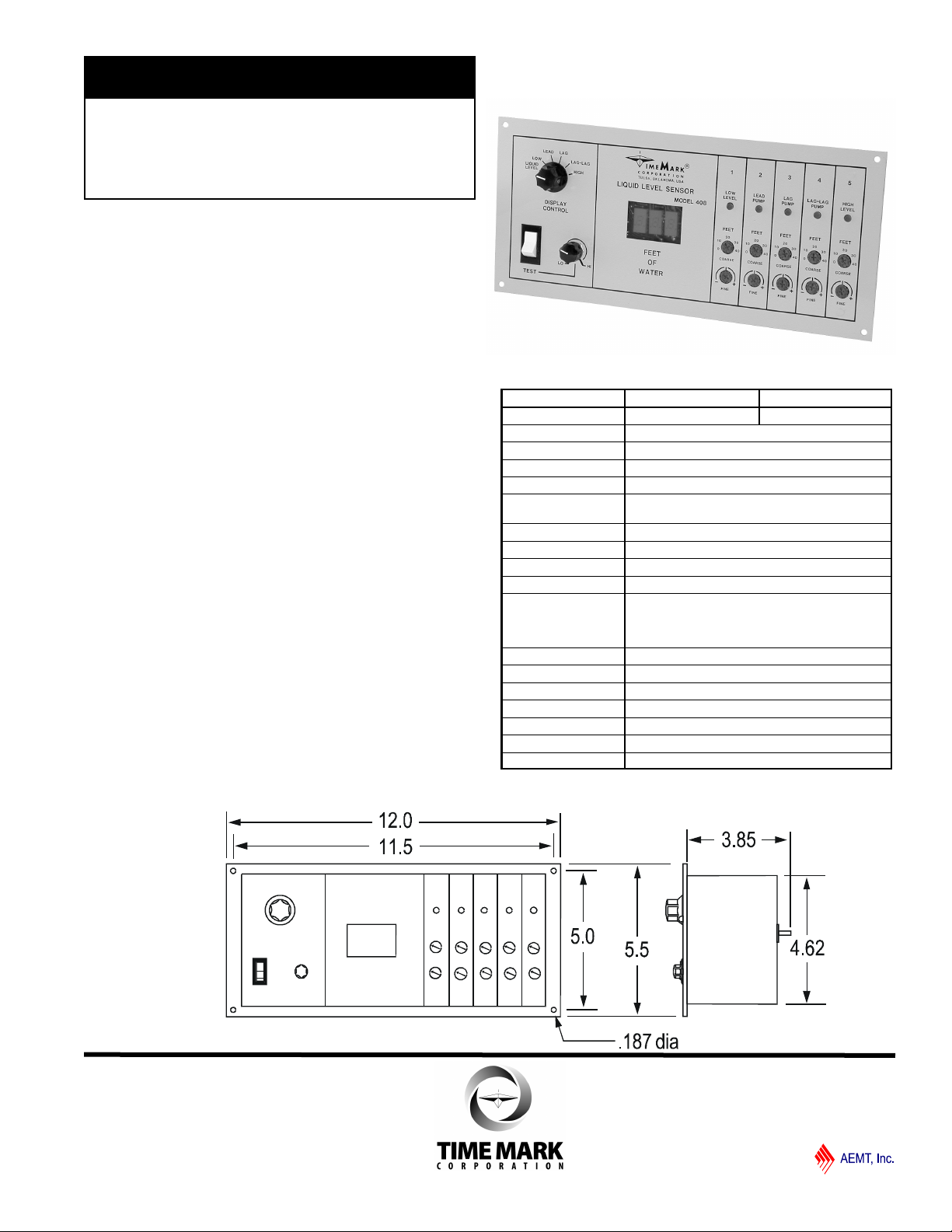

DIMENSIONS

SPECIFICATIONS

MODEL 408-24V 408-115V

Input voltage 20-28 VAC 105-130 VAC

Input frequency 47-65 Hz

Power consumption 2 Watts

Air pressure input 0-15 psi max.

Input air supply fitting Requires 3/16” I.D. tubing

Maximum liquid level

displayed

Calibration accuracy ± 2%

Repeat accuracy ± 1% in fixed condition

Repeat accuracy ± 2% at 32º -140º F

Dead band 0.1 foot

Switching outputs 5 open-collector transistors rated for regulated

12VDC, 10 mA, maximum. Designed as inputs

for the Model 407 Liquid Level Controller or

Model 448 Output Relay Board

Signal outputs 4-20 mA output proportional to 0-40 feet of water

Operating temperature - 20º to +122º F

Storage temperature - 4º to +158º F

Humidity tolerance 0-97% without condensation

Case material 20 gauge Steel

Termination Removable terminal strip

Weight 3.5 lbs

34.6 feet

01/2012 page 1 of 4

© 2012 TIME MARK CORPORATION

MODEL 408

TIME MARK is a division of

Liquid Level Sensor

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

POTENTIALLY HAZARDOUS VOLTAGES ARE PRESENT AT THE TERMINALS OF THE MODEL 408.

ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING WIRING.

DO NOT EXCEED THE OUTPUT OR INPUT RATINGS, AS STATED IN THE SPECIFICATIONS.

PROTECT THE UNIT WITH PROPERLY RATED FUSES.

DO NOT INSTALL IN DAMP OR MOIST AREAS.

THIS DEVICE SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

GENERAL SAFETY

Installation Instructions

INSTALLATION

Mount the Sensor in a suitable enclosure. If a Model 448

relay module is being used, mount it in a suitable location near the Sensor.

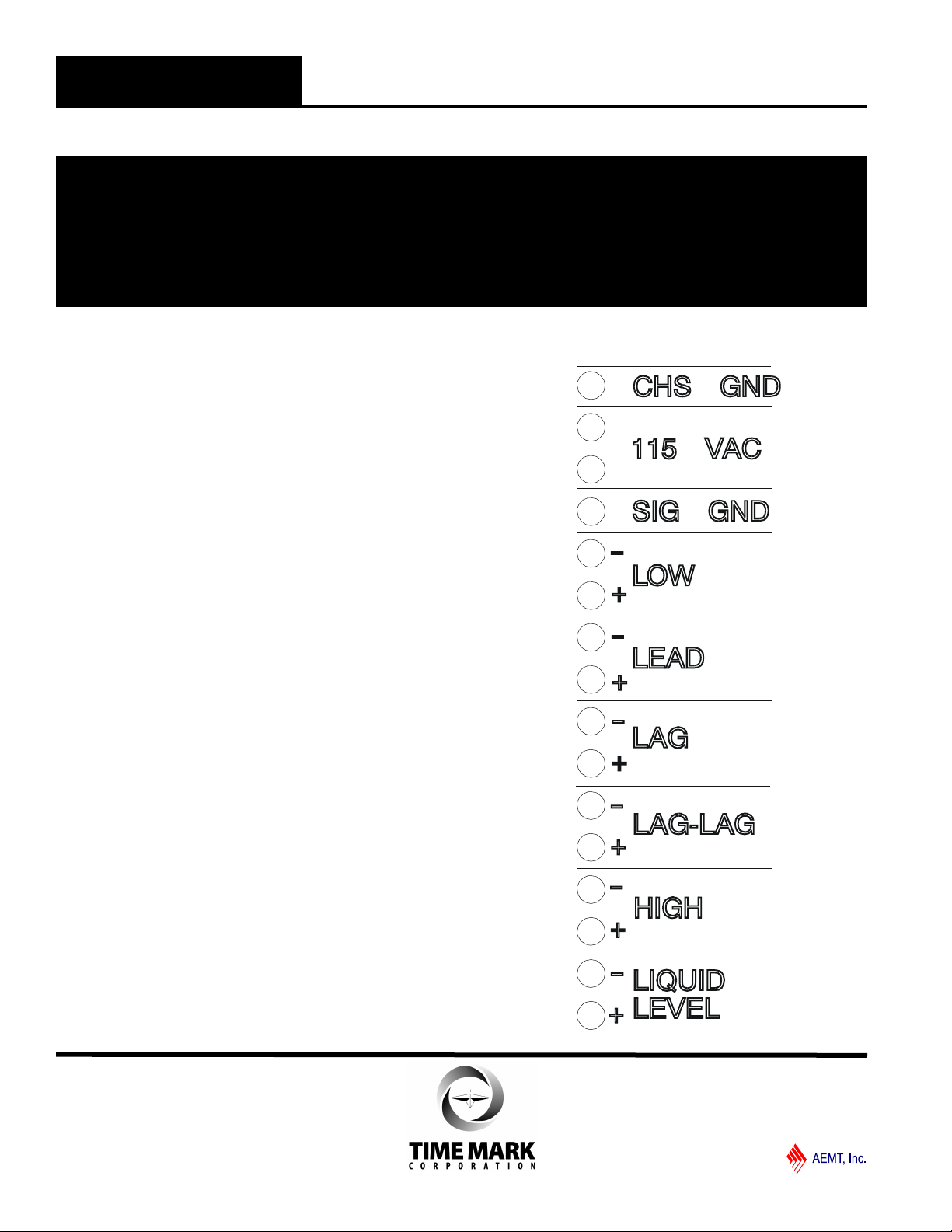

Referring to the terminal block decal on the sensor and

the illustration on this page, make the following connections

1. Connect a chassis ground to the terminals marked

CHS GND.

2. Connect operating power (24 or 120 VAC) to the

terminals marked for input voltage.

3. Observing polarity, connect the LOW terminals to the

LOW terminals on the 407. For connections to 448,

refer to connection chart on page 4.

4. Repeat step 3 for the LEAD, LAG, LAG-LAG, and

HIGH terminals.

5. The terminals marked LIQUID LEVEL are the 4-20

mA output. If used, connect these terminals to the

appropriate control circuitry. Observe polarity.

Connect a 3/16” I.D. tubing to the air supply fitting on the

back of the 408. Connect the other end of the tubing to

the air compressor and the tank or well .Apply operating

power and proceed to the adjustment procedure.

01/2012 page 2 of 4

© 2012 TIME MARK CORPORATION

MODEL 408

TIME MARK is a division of

Liquid Level Sensor

Model 408 Panel

PANEL LAYOUT

A. Display control switch used to select liquid level or

level setting.

B. 3-Digit LED indicator reads depth in feet.

C. Test switch enables simulated level change by

rotating control D.

D. Simulates liquid level change when switch C is

pressed.

E. Indicator LED shows when level is reached (one

per level)

F. Coarse adjustment for setting level trip point (one

per level)

G. Fine adjustment for setting level trip point (one per

level)

ADJUSTMENT

1. The trip points are set using coarse and fine

adjustment pots; the results are shown on the LED

display. To adjust the device, set the display control

knob (A) to LOW and adjust the low level coarse

adjustment (F) to the approximate desired level. A fine

adjustment (G) is located below the coarse adjustment.

The trip level will be shown on the LED display (B).

2. Repeat step 1 for the lead, lag, lag-lag, and high

level adjustments.

3. Set the display control knob to the LIQUID LEVEL

position. The Sensor is now ready to operate.

TESTING

For testing purposes a test switch (C) and LO_HI

adjustment (D) are provided. Set the adjustment to LO,

then press and hold the test switch. As the adjustment

is turned clockwise (HI), the LED display will show an

increasing simulated liquid depth. As each level is

reached the appropriate LED indicator (E) will illuminate

and the output should activate (pump will turn on,

output relay will energize, or alarm will sound).

TROUBLESHOOTING

Problem: Erratic and/or unstable operation when

used with 407.

Cause: Signal ground wire between the two units is

not connected.

Solution: Connect signal ground.

Problem: In test position, display reads other than

zero with adjustment fully counterclockwise

Cause: This is a normal condition; fully

counterclockwise on the adjustment may be

below zero.

Solution: Turn the adjustment slightly clockwise; the

display should read zero (or higher).

Note: This device is not a field repairable unit. Should the unit not

operate properly during installation or testing, insure that all electrical,

ground, and physical connections are correct. Verify that the proper

voltage is applied and check all fuses. Contact the factory if

everything is correct and the device still fails to operate. Should the

sensor fail during use, contact the factory for instructions on returning

the device for repair.

WARRANTY

The Model 408 Liquid Level Sensor is warranted to be free

from defects in materials and workmanship for one year.

Should this device fail to operate, we will repair or replace it for

one year from the date of purchase. Contact the Time Mark

Sales department, Monday through Friday; 8 a.m. to 5 p.m.,

CST, for further details.

01/2012 page 3 of 4

© 2012 TIME MARK CORPORATION

MODEL 408

TIME MARK is a division of

Liquid Level Sensor

TYPICAL APPLICATIONS

Note:

1. Remote alarm contacts

are normally closed

contacts located at the

motor controllers.

Jumper closed if not

used.

2. Power fail contacts close

on power failure.

3. Alarm Bell and Alarm

Light contacts close on

alarm condition.

Model 408 to Model 407

Model 408 to Model 448

01/2012 page 4 of 4

© 2012 TIME MARK CORPORATION

Loading...

Loading...