TIME MARK is a division of

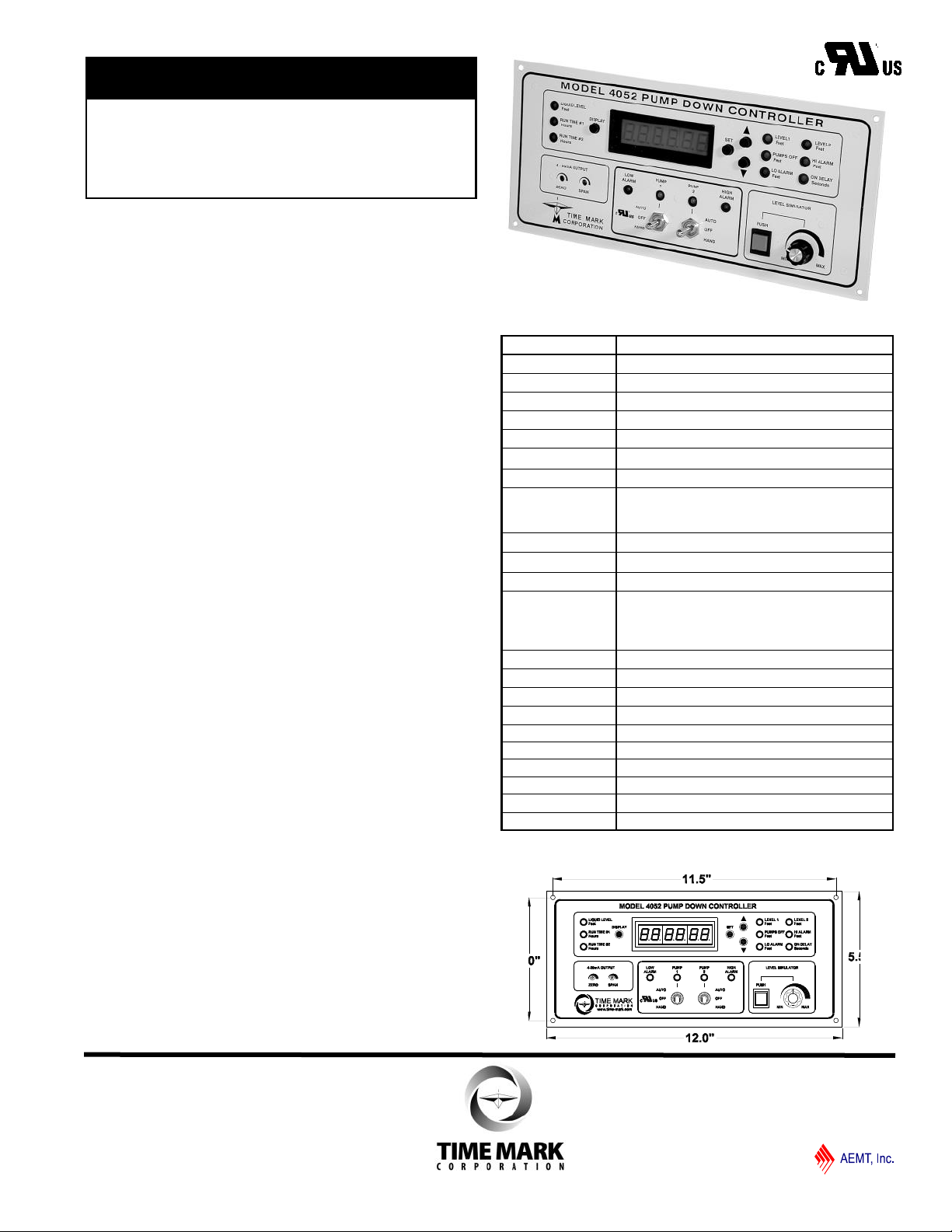

MODEL 4052

Pump-Down

Controller

4-20mA Input/Scalable Output

Seal Fail Monitoring

Duplex Pump Alternation

Hand-Off-Auto Controls

Dual Run-time Meters

RS-485/Modbus Communications

DESCRIPTION

The Model 4052 Pump-Down Controller provides total

control for duplex pumping systems. The Model 4052

monitors, controls and displays the liquid level in a tank

or reservoir. Maximum selectable depth is from 11.5 ft.

to 346 ft.

The input to the Model 4052 can be from any 2 or 3-wire

transducer with a 4-20mA output representing the

selected depth. A 24VDC regulated probe supply is

included. A Level Simulator is provided to aid in

programming these five set points; Low Alarm, Pumps

Off, Level 1, Level 2 and High Alarm.

A universal zero to 30 second On Delay can be

programmed to prevent outputs from closing due to

input fluctuations caused by turbulent conditions. An

additional 4-20mA output with zero and span controls is

provided for a chart recorder or other external device.

Four heavy-duty 10 amp, 120V contacts are provided

for pump control and alarm activation. An auto-dialer or

other emergency device can be activated with the SPDT

power loss relay. This relay is held open when power is

applied.

Pump outputs include duplex alternation as well as

hand-off-auto switches. Pump run-time can be

displayed for each pump with tenth of an hour

resolution, up to 99,999.9 hours. The Model 4052 can

be panel-mounted (11 1/8” x 4 5/8) or surface-mounted

using the optional surface-mounting kit (Model 4000).

SPECIFICATIONS

MODEL 4052

Input Voltage 120VAC ± 10% 50/60Hz

Pwr Consumption 8W max.

Signal Input 4-20mA (optional 0-5V), 2 or 3 wire

Signal Input Load 250 ohms max.

Dead Band 1% of full scale

Repeat Accuracy ± 1% of scaled max. (fixed conditions)

Display Type 6 digit red LED display

Display Ranges Level: 00.0 to 346 ft

Runtime: zero to 99,999.9 hours

Delay: zero to 30 seconds

Display Resolution 1 decimal place

Control Contacts 4 SPDT 10A at 120VAC resistive

Power Loss Relay 1 SPDT 5A at 120VAC resistive

Signal Output Output is factory set to track the 4-20mA input.

Zero and span adjustments are provided: as

little as a 2mA change can cause a full swing of

the output.

Signal Output Load 300 ohms max.

Probe Supply 24VDC regulated

Setpoints 3 levels, 2 alarms, all user-adjustable

Operating Temp +14º to +122º F

Humidity Tolerance 0-97% w/o condensation

Enclosure Material 16 gauge steel

Termination removable terminal strips

Dimensions H: 5.5” W: 12.0” D: 4.75”

Weight 6.0 pounds

Agency Approvals UL Recognized (U.S. & Canadian)

DIMENSIONS

11440 Ea s t Pi n e St r e e t

Tu l s a , O k l a h o m a 74 1 1 6

Page 1 of 8 01/2017

© 2017 TIME MARK CORPORATION

TIME MARK is a division of

MODEL 4052

Pump Down Controller

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

POTENTIALLY HAZARDOUS VOLTAGES ARE PRESENT AT THE TERMINALS OF THE MODEL 4052.

ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING WIRING.

DO NOT EXCEED THE OUTPUT OR INPUT RATINGS, AS STATED IN THE SPECIFICATIONS.

PROTECT THE UNIT WITH PROPERLY RATED FUSES.

DO NOT INSTALL IN DAMP OR MOIST AREAS.

THIS DEVICE SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

GENERAL SAFETY

Installation Instructions

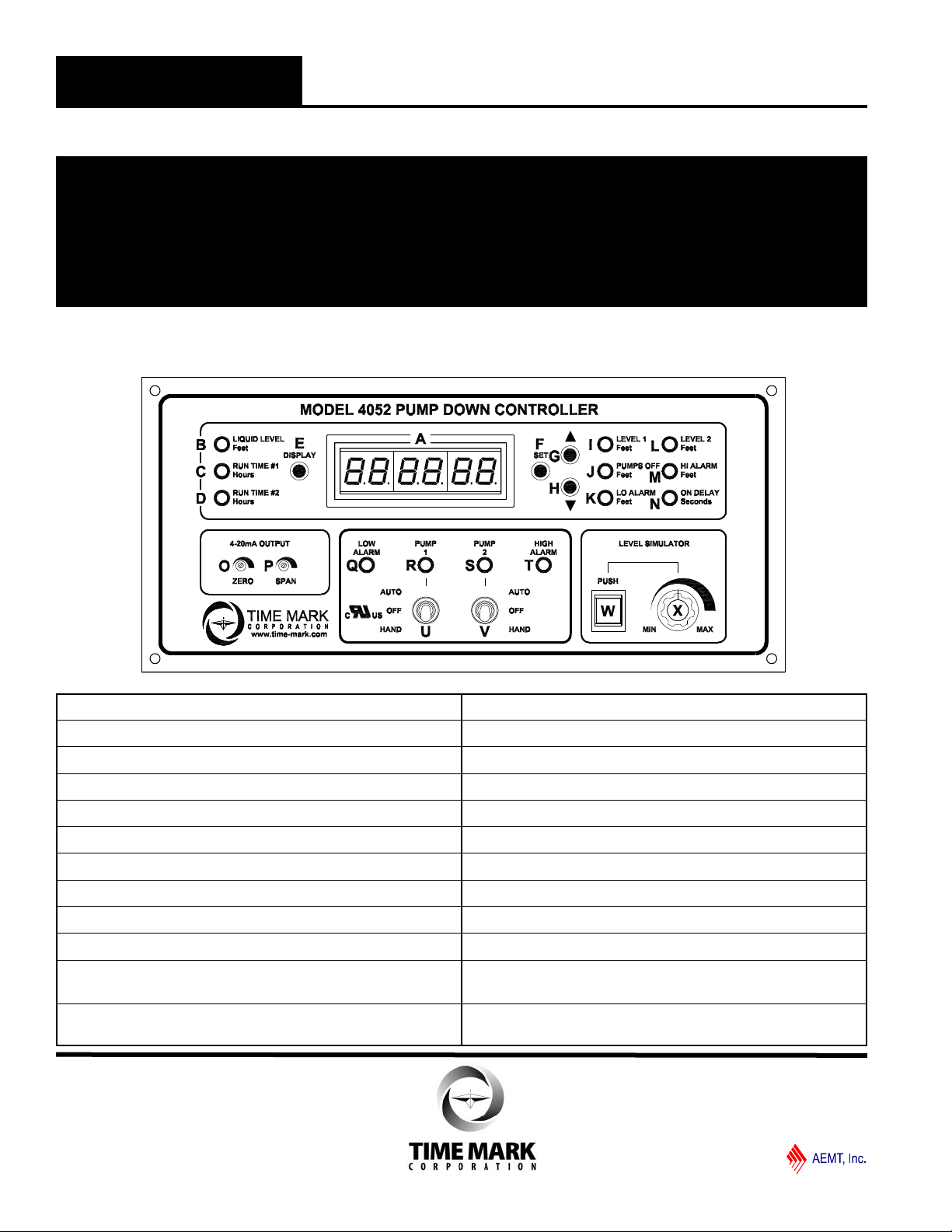

figure 1. Front Panel Controls

6 digit LED display

A

Indicates display is showing LIQUID LEVEL

B

Indicates display is showing PUMP #1 runtime

C

Indicates display is showing PUMP #2 runtime

D

Switches display between B, C and D

E

Push to enter SET mode

F

Push to INCREASE setting

G

Push to DECREASE setting

H

Indicates display is showing LEVEL 1 setting

I

Indicates display is showing PUMPS OFF setting

J

Indicates display is showing LOW ALARM setting

K

Indicates display is showing LEVEL 2 setting

L

Indicates display is showing HIGH ALARM setting

M

Indicates display is showing ON DELAY setting

N

Controls ZERO setting for 4 to 20mA output

O

Controls SPAN setting for 4 to 20mA output

P

Indicates LOW ALARM ACTIVE (low alarm relay-closed)

Q

Indicates PUMP #1 RUNNING (pump #1 relay-closed)

R

Indicates PUMP #2 RUNNING (pump #2 relay-closed)

S

Indicates HIGH ALARM ACTIVE (high alarm relay-closed)

T

3-position switch HAND-OFF-AUTO Pump #1

U

3-position switch HAND-OFF-AUTO Pump #2

V

Momentary pushbutton

W

engages LEVEL SIMULATOR

Controls SIMULATED LEVEL

X

(when SIMULATOR button is engaged)

11440 Ea s t Pi n e St r e e t

Tu l s a , O k l a h o m a 74 1 1 6

Page 2 of 8 01/2017

© 2017 TIME MARK CORPORATION

MODEL 450

3-WIRE

TRANSDUCER

+24VDC

4-20mA

PIN 5

PIN 8

4-20mA

IN

+ -

GND

PIN 4

4-20mA

OUT

+ -

+24VDC

OUT

+ -

GND

GND

4-20mA

IN

+ -

4-20mA

OUT

+ -

+24VDC

OUT

+ -

- EXCITATION (BLK)

+ EXCITATION (RED)

MODEL 456-15

PRESSURE

TRANSDUCER

TIME MARK is a division of

MODEL 4052

Pump Down Controller

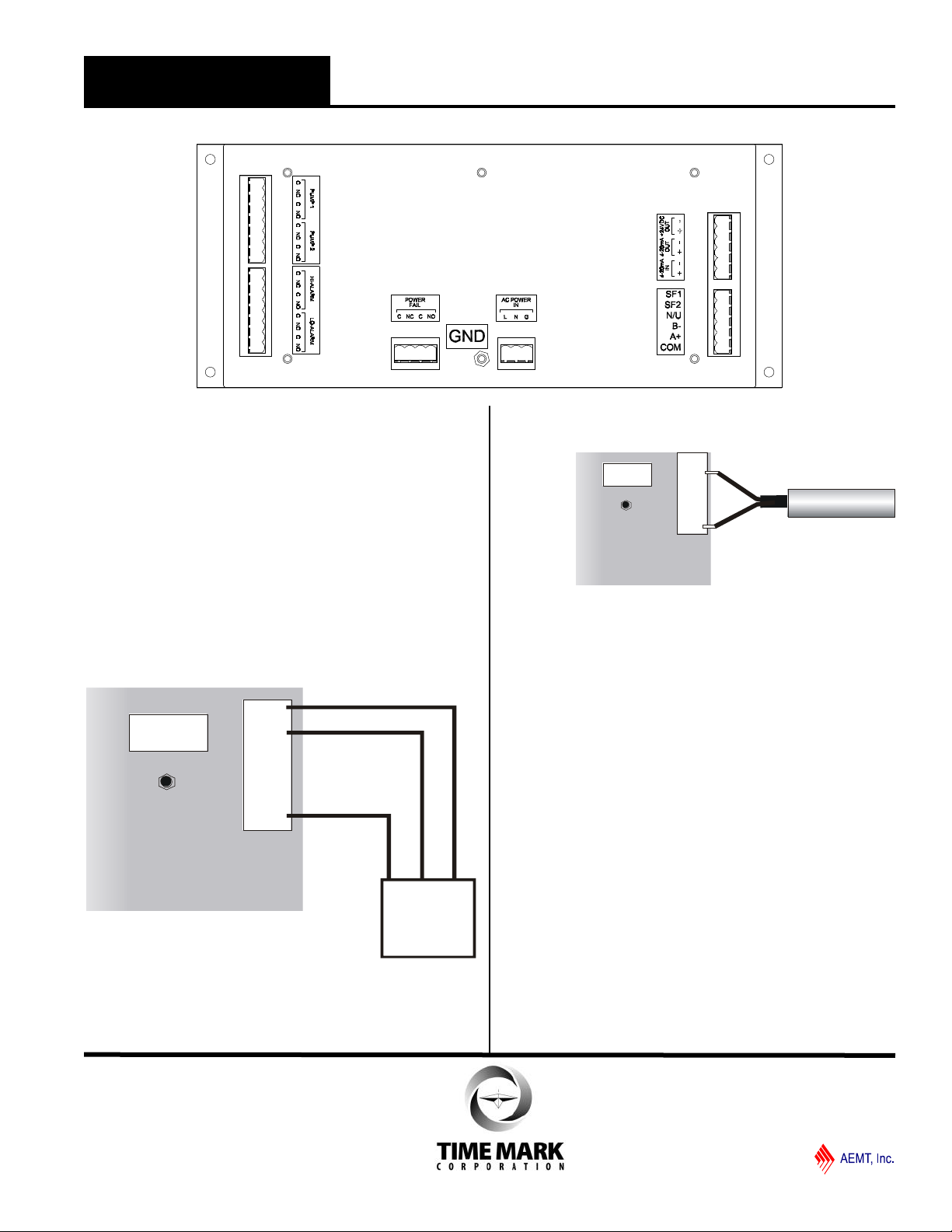

figure 2. Back Panel Controls

MOUNTING & WIRING

Mount the Model 4052 Pump-Down Controller in a

panel or suitable enclosure (see Time Mark’s Model

4000 Surface Mount kit).

Referring to the terminal block decals on the unit, and

Figure 2, make the following connections:

SIGNAL INPUT

With a 3-wire 4-20mA transducer (see Time Mark

Model 450) remotely mounted, connect the +24VDC

OUT terminal to the voltage input of the transducer

(figure 3). Connect the 4-20mA IN terminals to the loop

terminals of the transducer. OBSERVE POLARITY.

figure 3.

Connect a 2-wire transducer (pressure, ultrasonic, etc.)

as shown in figure 4.

figure 4.

SIGNAL OUTPUT

The 4-20mA output is proportional to the input signal.

This allows for very accurate remote monitoring of level

changes. The factory default is for the output to track

the input; that is, a 4mA signal represents 00.0 feet, and

a 20mA signal represents 34.6 feet. However, the

output can be zeroed and spanned to a specific range,

not necessarily the same as the reading on the LED

display.

The 4-20mA OUT terminals may be connected to a

remote display or other devices. Connect these

terminals as required for your application. OBSERVE

POLARITY of the connections.

RELAY OUTPUTS

SPDT contacts are provided for PUMP 1, PUMP 2, HIALARM, LO-ALARM and POWER FAIL relays. Make

wiring connections as required.

OPERATING POWER

Connect a chassis ground to the lug marked GND and

the terminal marked G.

Connect 120VAC operating power to the terminals

marked L (line) and N (neutral).

11440 Ea s t Pi n e St r e e t

Tu l s a , O k l a h o m a 74 1 1 6

Page 3 of 8 01/2017

© 2017 TIME MARK CORPORATION

TIME MARK is a division of

MODEL 4052

Pump Down Controller

USER SELECTABLE PROBE SETTINGS

This unit is factory set to 15 psi. To change probe

values, press and hold the following buttons

while powering up:

Press &

Hold

Use or keys to select probe values according

SET

150 0-150 346 360

& Restore unit to factory settings*.

DISPLAY

Press Display to exit setup mode.

PROGRAMMING - SET mode

to the chart below:

Display Range PSI Max Ft. Max Display

5 0-5 11.5 18

10 0-10 23.0 30

15* 0-15 34.6 40

20 0-20 46.1 55

30 0-30 69.2 75

40 0-40 92.3 99.9

50 0-50 115 120

60 0-60 138 160

70 0-70 162 175

80 0-80 185 200

90 0-90 208 225

100 0-100 230 250

Select a Modbus address between 0—247 using

the or keys. Unit is initially factory set to 1.

The Model 4052 Controller has been factory tested and

calibrated. Factory settings are as follows:

HIGH ALARM

LEVEL 2 8.0 ft

LEVEL 1 6.0 ft

PUMPS OFF 4.0 ft

LOW ALARM 2.0 ft

NOTE: Both Hand-Off-Auto (H.O.A.) switches MUST

be in the OFF position before entering the SET

mode.

To enter the SET mode, push the button marked SET

Result:

1

0.0 ft

PROGRAMMING - SET mode (Cont’d)

The display will now show the LOW ALARM setpoint.

Change the LOW ALARM setpoint to the desired level,

using the or keys (figure 1 G,H) to the right of the

SET button. After setting the LOW ALARM setpoint,

press the SET button again. The display now shows the

PUMPS OFF setting.

Using this same procedure, set the PUMPS OFF,

LEVEL 1, LEVEL 2, and HIGH ALARM settings (in that

order).

After setting the HIGH ALARM, press the SET button, to

display the factory setting for the ON DELAY timer. Use

the or keys (figure 1 G,H) to set the ON DELAY to

the desired setting (0 to 30 seconds).

After setting the ON DELAY time period, press the SET

button again to enter the setting into memory.

Review all settings by cycling through the setpoints

before proceeding to the DISPLAY mode. Finally, press

the DISPLAY button, to enter all settings into memory.

OPERATION - DISPLAY mode

While in DISPLAY mode, the LIQUID LEVEL is shown

on the LED display. Pushing the DISPLAY button, while

in the DISPLAY mode will change the LED display from

LIQUID LEVEL to RUN TIME #1 to RUN TIME #2, and

back to LIQUID LEVEL.

If the DISPLAY button is not pushed for 60 seconds, the

LED display will automatically return to the LIQUID

LEVEL setting.

NOTE: The LOW ALARM, PUMPS OFF LEVEL 1 and

LEVEL 2 settings must move up in value from LOW

ALARM to LEVEL 2, to be properly set.

The Model 4052 will not enter the DISPLAY mode if

these settings are improper. When trying to move to the

DISPLAY mode with improper settings, the LED display

will automatically return to the SET mode. Adjust the

improper setpoint, then continue.

The HIGH ALARM setpoint can be set anywhere within

the scale.

VERIFYING SETTINGS

Before entering automatic operation, the program

setting should be reviewed and verified using the

following procedure.

While in the DISPLAY mode (with H.O.A. switched in

the OFF position), the LEVEL SIMULATOR can be

engaged.

11440 Ea s t Pi n e St r e e t

Tu l s a , O k l a h o m a 74 1 1 6

Page 4 of 8 01/2017

© 2017 TIME MARK CORPORATION

TIME MARK is a division of

MODEL 4052

VERIFYING SETTINGS (Cont’d)

Pump Down Controller

Push the LEVEL SIMULATOR momentary push-button

(fig. 1 W), and hold it down. The input to the external

transducer will be disabled and internal level simulator

will take its place.

Turning the potentiometer (figure 1 X ), will simulate

changes to the liquid level being monitored.

In this mode, simulated changes in liquid level will

cause the alarm relays to open and close, the liquid

level to change on the numeric display, and all LEDs to

operate (PUMP 1 and PUMP 2 LEDs will flash).

NOTES: RETURN THE SIMULATOR KNOB TO THE

MINIMUM SETTING BEFORE RELEASING THE

SIMULATOR BUTTON. The PUMP 1 and PUMP 2

relays will not energize in the LEVEL SIMULATOR

mode.

AUTOMATIC OPERATION

For fully automatic operation, set the display to monitor

the liquid level, and move the HAND-OFF-AUTO

switches to the AUTO position.

MANUAL OPERATION

To manually operate either of the pumps, push the

momentary HAND-OFF-AUTO toggle switch for the

appropriate pump down to the HAND position, and hold.

COMMUNICATION CONNECTOR

Pin Label Name

1 COM Ground (Top Terminal)

2 A+ RS-485(A+)

3 B- RS-485(B-)

4 N/U Not Used

5 SF2 Seal Fail Pump 2 when grounded

6 SF1 Seal Fail Pump 1 when grounded

SEAL FAIL

For fully automatic operation

Connect one side of a normally open dry contact from

seal fail sensor for pump 2 to pin 5 and the other to pin

1.

Run Time #2 will flash when contacts close and pump

will operate normally.

Connect one side of a normally open dry contact from

seal fail sensor for pump 1 to pin 6 and the other to pin

1.

Run Time #1 will flash when contacts close and pump

will operate normally.

Note: Seal Fail monitoring is not available on the Model

4052MC configuration

RS-485 COMMUNICATION

See Appendix A: RS-485 Communication for RS-485

Communication settings.

WARRANTY

This product is warranted to be free from defects in

materials and workmanship for one year. Should this

device fail to operate, we will repair it for one year from

the date of manufacture. For complete warranty details,

see the Terms and Conditions of Sales page in the front

section of the Time Mark catalog or contact Time Mark

at 1-800-862-2875.

11440 Ea s t Pi n e St r e e t

Tu l s a , O k l a h o m a 74 1 1 6

Page 5 of 8 01/2017

© 2017 TIME MARK CORPORATION

TIME MARK is a division of

MODEL 4052

Pump Down Controller

TYPICAL APPLICATION - Transducer

TYPICAL APPLICATION - Float Switches

INSTALLATION WORKSHEET

JOB NAME:

DATE:

SET AT

LEVEL:

NOTES

SETPOINTS

FACTORY

SETTING

High Alarm 10 ft

Level 2 8 ft

Level 1 6 ft

Pumps Off 4 ft

Low Alarm 2 ft

Tu l s a , O k l a h o m a 74 1 1 6

© 2017 TIME MARK CORPORATION

11440 Ea s t Pi n e St r e e t

Page 6 of 8 01/2017

TIME MARK is a division of

MODEL 4052MC Optional Configuration

INSTALLATION DRAWING

MC1/MC2 CONNECTIONS

Monitor Motor Control Contacts

Disable Run Time Meters In Fault Condition

4052MC Connector

The 4052MC option replaces seal fail monitoring with motor starter

monitoring. When the 4052MC calls for a pump to run the

corresponding MC contact should close. If the MC contact closes,

the pump controller will increment the run time for that pump. If the MC contact does not close, or opens after the

pump has been started, the pump controller will not increment the run time for that motor and will flash the Run Time

light on the left side of the controller for the corresponding pump.

MODEL 4000 Surface-Mount Kit

20 Ga. CRS Enclosure

Removable Access Panel

Designed to easily install Time Mark Models 403, 404, 4042, 4052, 4062, or 408 Liquid Level Controllers.

This 20 gauge steel enclosure features a removable top panel for easy access to wiring connections. The mounting

kit comes complete with everything you need, including steel support brackets. This model is designed specifically

for applications that require surface-mounting these Time Mark Liquid Level Controllers.

For more information, see the full data sheet in the Time Mark standard products catalog.

11440 Ea s t Pi n e St r e e t

Tu l s a , O k l a h o m a 74 1 1 6

Page 7 of 8 01/2017

© 2017 TIME MARK CORPORATION

TIME MARK is a division of

MODEL 4052

APPENDIX A: RS-485 Communications

Pump Down Controller

Connect RS-485 A+ to pin 2.

Connect RS-485 B- to pin 3

Connect RS-485 GND to pin 1

Modbus holding registers (Function 03)

Address Register in Pump Controller

0 Level

1 Low alarm

2 Pumps off

3 Level 1

4 Level 2

5 High Alarm

6 On delay

7 Run time pump1 low 16 bits

8 Run time pump1 high 16 bits

9 Run time pump2 low 16 bits

10 Run time pump2 high 16 bits

11 Run time pump1 0.1 seconds

12 Run time pump2 0.1 seconds

13 System status

Bit Decimal Signal If bit = 1

15 32768 L2ON Level 2 is on

14 16384 L1ON Level 1 is on

13 8192 L2EN Level 2 is enabled

12 4096 L1EN Level 1 is enabled

11 2048 ELED2 Pump 2 LED is on

10 1024 ELED1 Pump 1 LED is on

9 512 TESTF Test button not pressed

8 256 SETF Set mode

7 128 HAND_2 Pump 2 in HAND |

6 64 AUTO_2 Pump 2 in AUTO |-- 00 pump 2 off

5 32 HAND_1 Pump 1 in HAND |

4 16 AUTO_1 Pump 1 in AUTO |-- 00 pump 1 off

3 8 HI_AL High alarm on

2 4 M2RUN Pump 2 running

1 2 M1RUN Pump 1 running

0 1 LO_AL Low alarm on

RS-485 Communications (Cont’d)

Discrete Read (Function 02)

Seal fail when bit = 1.

Address Bit Status

0 0 SEAL1

0 1 SEAL2

Coils Write (Function 05)

Set coil to 1. Unit will perform function and reset coil.

Address Bit Function

0 0 Reset delta runtime pump1

0 1 Reset delta runtime pump2

0 2 Reset Max High and Min Low

14 Controller software version

15 Min low

16 Max high

17 Delta runtime pump1 low 16 bits

18 Delta runtime pump1 high 16 bits

19 Delta runtime pump2 low 16 bits

20 Delta runtime pump2 high 16 bits

11440 Ea s t Pi n e St r e e t

Tu l s a , O k l a h o m a 74 1 1 6

Page 8 of 8 01/2017

© 2017 TIME MARK CORPORATION

Loading...

Loading...