Time Mark 403 Data Sheet

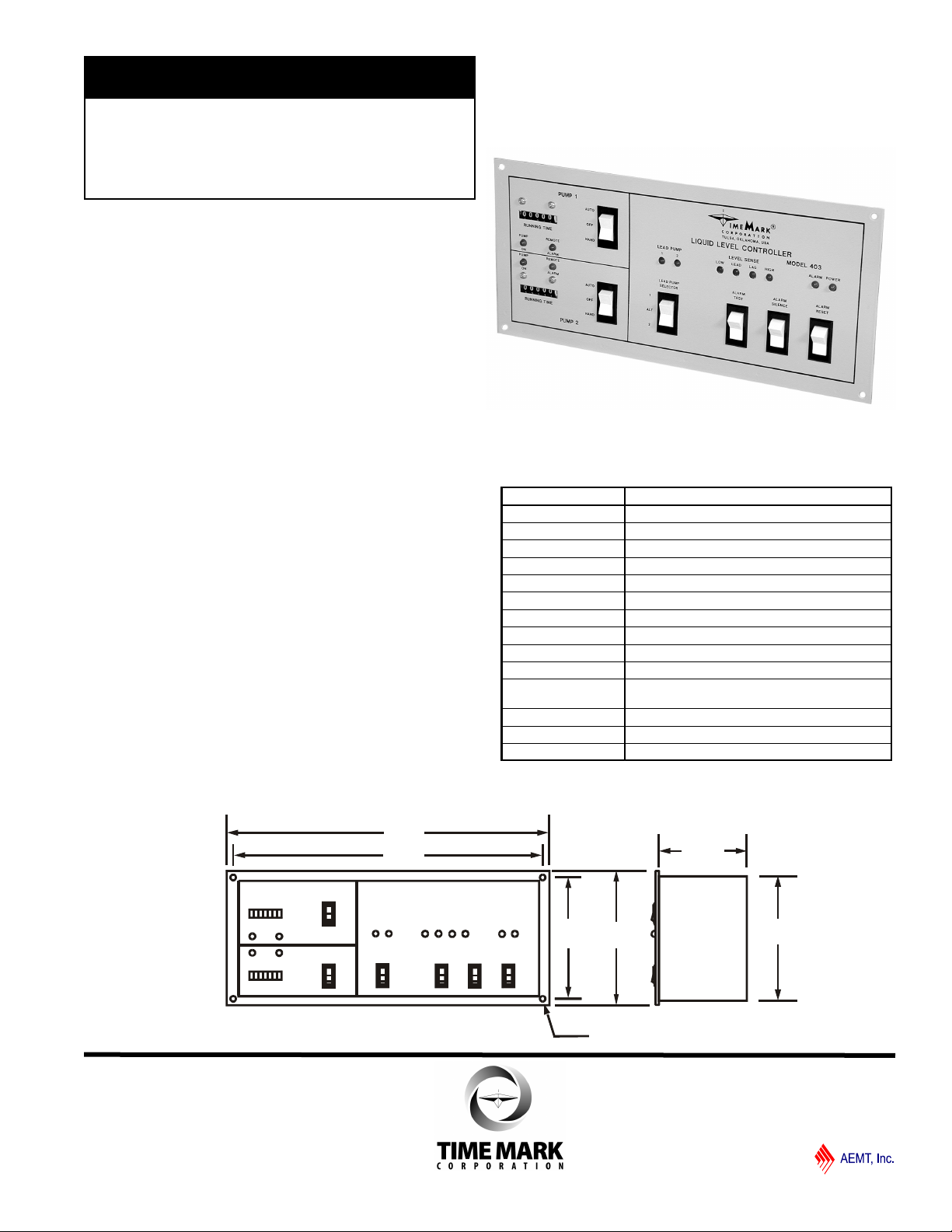

12.0"

11.5"

5.5"5.0"

.187" dia

4.62"

3.25"

TIME MAR K is a division of

MODEL 403

Liquid Level

Controller

Dual run-time meters

Selectable lead/lag or automatic

alternation

Four sensing levels

Alarm outputs

Hand-off-auto controls

DESCRIPTION

The Model 403 Liquid Level Controller provides central

control of duplex pumping systems. The Model 403

includes pump alternating, visual run-time meters, handoff-auto (HOA) controls and alarm outputs.

Four level-sense inputs interface with float switches,

pressure switches, or other level sensing devices which

can provide a contact closure.

A SPST, normally-closed internal power-fail contact opens

when AC power 120VAC is connected to the controller,

and closes if power is lost or removed. Connections for

external remote alarm contacts, which must remain closed

for normal operation (or jumpered if not required), are

supplied for each pump.

If either circuit opens, the corresponding pump will be

locked out until the problem is corrected and the ‘Alarm

reset’ switch is pressed.

SPECIFICATIONS

MODEL 403

Input voltage 105-130VAC

Input frequency 60Hz

Power consumption 10W max.

Contacts SPST relay

Contact rating 10A at 240VAC resistive

Float Switch Potential 12VDC at 1mA

Transient protection 2500 V for 10ms

Operating temperature - 20º to +140º F

Display

Humidity tolerance 0-97% without condensation

Expected relay life

Case material 20 gauge Steel

Termination Removable terminal strip

Weight

Mechanical: 10 million operations

Electrical: 100,000 operations at rated load

to 99,999.9 non-resettable

4.9 lbs

DIMENSIONS

Page 1 of 4 11/2011

© 2011 TIME MARK CORPORATION

TIME MAR K is a division of

MODEL 403

Liquid Level Controller

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

POTENTIALLY HAZARDOUS VOLTAGES ARE PRESENT AT THE TERMINALS OF THE MODEL 403.

ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING WIRING.

DO NOT EXCEED THE OUTPUT OR INPUT RATINGS, AS STATED IN THE SPECIFICATIONS.

PROTECT THE UNIT WITH PROPERLY RATED FUSES.

DO NOT INSTALL IN DAMP OR MOIST AREAS.

THIS DEVICE SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

GENERAL SAFETY

Installation Instructions

INSTALLATION

Mount the controller in a suitable enclosure. Unplug the

terminal connectors from the controller.

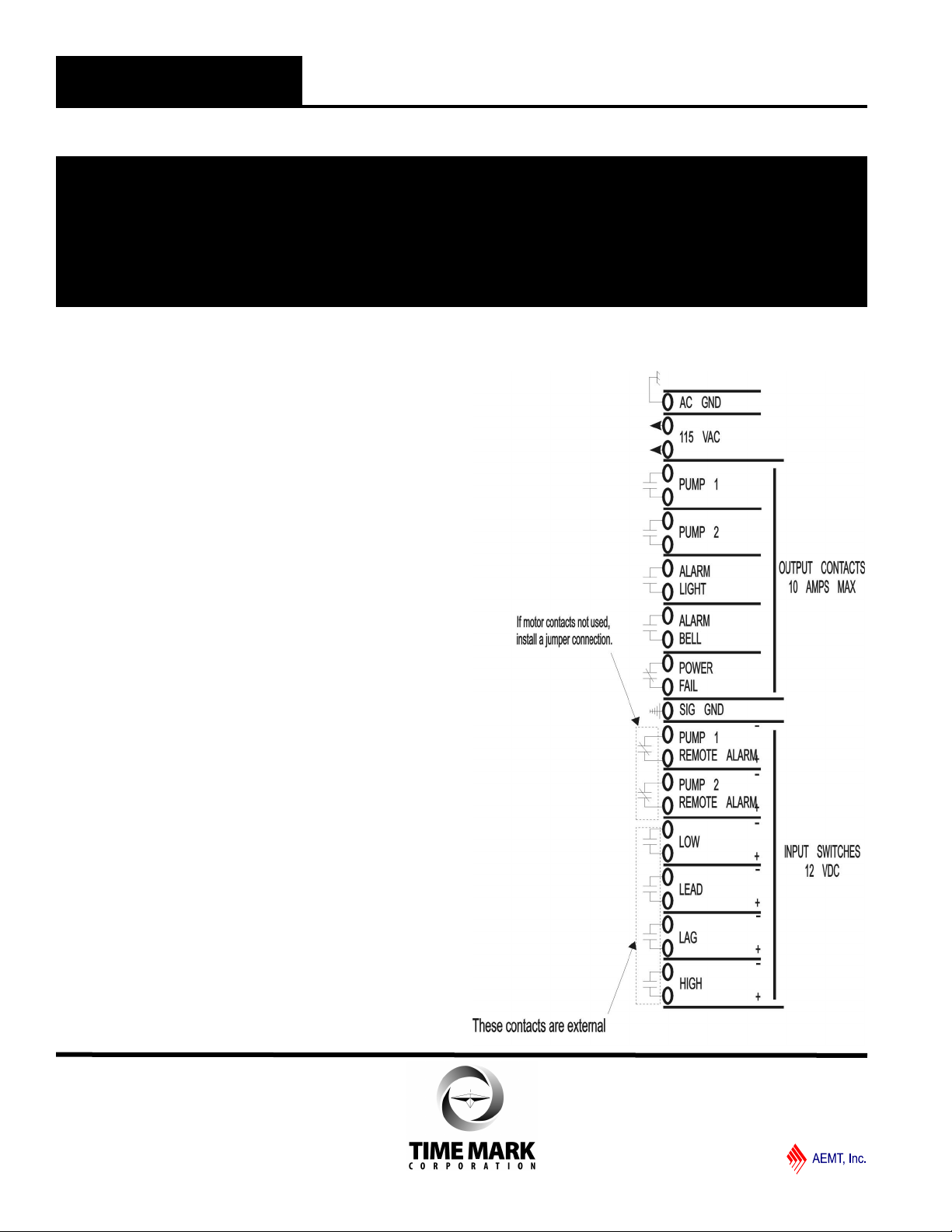

Referring to the terminal block decal on the controller and

the illustration on this page, make the following

connections.

1. Connect a chassis ground to the terminals marked AC

GND.

2. Connect 115VAC operating power to the terminals

marked 115VAC.

3. Connect the LOW float switch to the LOW terminals.

Polarity is not critical.

4. Repeat step 3 for LEAD, LAG and HIGH terminals.

5. The SIGNAL GROUND connection is a common

between the controller, (Model 403), and a Liquid

Level Sensor, ( Model 404), no connection is

necessary if the sensor is not used.

6. The PUMP 1 & 2 REMOTE ALARM terminals should

be connected to normally closed (NC) alarm contacts

in the motors. If none exist it is still necessary to

install a jumper connection between Pump 1 REMOTE

ALARM terminals & PUMP 2 REMOTE ALARM

terminals.

7. The POWER FAIL, ALARM BELL, & ALARM LIGHT

are not required for proper operation, but are provided

for your convenience. If used, connect an a u d i b l e /

visual alarm across the terminals. The POWER FAIL

contact is open while power is applied and closes

on loss of power. Connect audible and v i s u a l

alarms across the ALARM BELL and ALARM L i g h t

terminals respectively. These contacts are

normally open and will close on a fault (high or remote

alarm) condition.

8. Connect the PUMP 1 and the PUMP 2 contacts to the

appropriate motor control circuits. These contacts

start and stop the pump motors during operation.

Set the HOA (Hand-off-Auto) switches and the LEAD

PUMP selector switch as required. Apply operating power.

Test alarm LEDs and bells by pressing the ALARM TEST

switch.

Page 2 of 4 11/2011

© 2011 TIME MARK CORPORATION

Loading...

Loading...