Page 1

Round Pattern 24 Hour

Electromechanical

Time Controllers with

Half Day & Day Omit

Cat Nos. RTS113/RTS113Q/RTS114/RTS114Q

Installation & Operating Instructions

Page 2

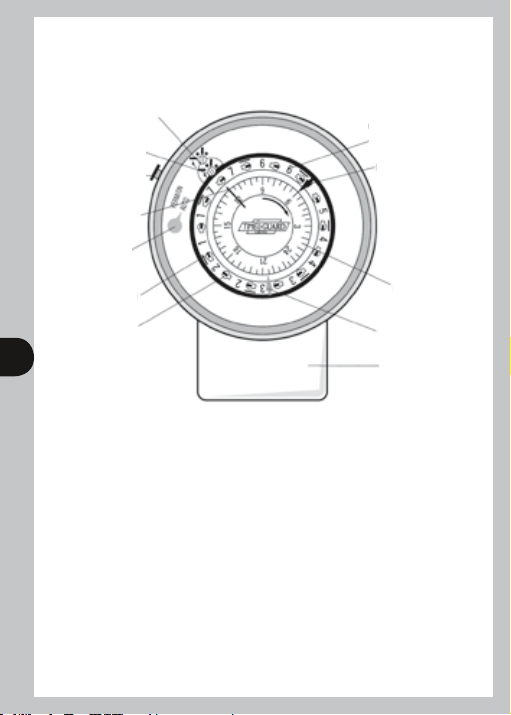

RTS113/RTS113Q/RTS114/RTS114Q

Round Pattern Electromechanical Timeswitches

7 day control (blue)

24 hour control

(Red)

Permanent ON

override

push button

Time marker

Permanent

override

indicator

AM segment

PM segment

1 2

7 day programming

ring (divided into

12 hour steps)

Blue tappet (OFF)

24 hour

programme

Red tappet (ON)

Terminal cover

ring

1.0 Description:

1.1 Application

The RTS113/RTS113Q/RTS114/RTS114Q round pattern electromechanical, double insulated time

controllers come with a 3 or 4 pin plug-in wirable base. They are compatible with the bases used

for the single channel ON/OFF mains linked and voltage free industry standard round pattern

timeswitches. Consequently the RTS113/RTS113Q/RTS114/RTS114Q can be considered as plug-in

service replacements for these units as well as for new installations.

1.2 Features

The timeswitch comes in four forms all driven by quartz controlled stepping motors –

with mains linked contacts, the RTS113 and the RTS113Q with battery back-up and with voltage

free contacts, the RTS114 and the RTS114Q with battery back up.

• Override to next programme change (daily programme only).

• Permanent ON facility.

• RTS113Q/RTS114Q only – battery power reserve continuously charged while the unit

is connected to mains.

• Daily operation with half day(s) and day(s) omit.

Page 3

1.3 Technical Data

Type: RTS113/RTS113Q/RTS114/RTS114Q

Type of programme: Daily with half day(s) and day(s) omitted

over a 7 day period if required

Operating voltage: 220-240V AC 50Hz

*Switching capacity: 20A, 240V~ for resistive loads

Contact material: Hard silver

Type of contact: ON/OFF mains linked RTS113/RTS113Q,

voltage free RTS114/RTS114Q

Time base: Quartz

Operating accuracy: ≤ ± 1 sec./day at 23°C

Min. switching interval: 30 min, which can be increased in 15 minute steps.

Max. no. of switchings: 48 (in a 24 hour period)

Power reserve: Rechargeable battery giving 72 hours back up

RTS113Q/RTS114Q only

Ambient temp. range: -10 to 40°C

Class of shock protection: Class 2

Dirt and moisture protection: IP20

2 3

Conforms to directives: Conforms to latest directives

Control type: 1B

Cable capacity: 1 x 6mm, 2 x 4mm, 3 x 2.5mm. 1mm and 1.5mm

can also be used but it is recommended these are

folded back

*For all other loads please contact Timeguard on 020 8450 0515

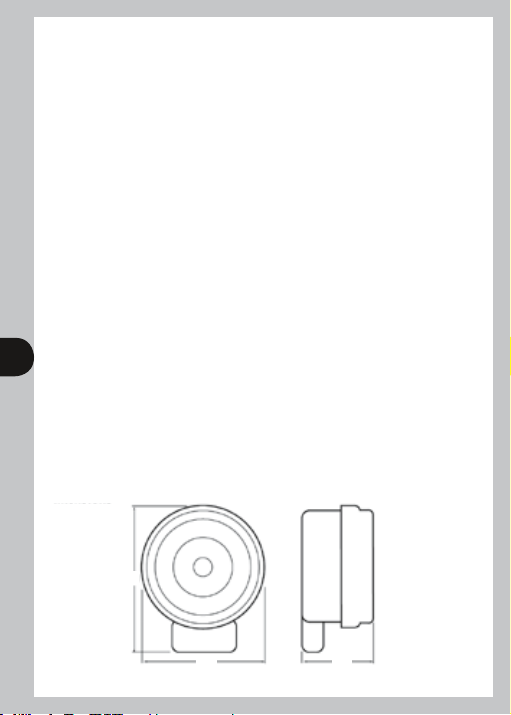

1.4 Dimensions

131

100 76

Page 4

2.0 Installation Instructions:

2.1 Safety Information

The RTS113/RTS113Q/RTS114/RTS114Q should only be installed by a trained electrician.

The I.E.E. wiring regulations must be observed. The supply must be disconnected before

wiring commences and a means of isolation with a separation of 3mm in each current

path must be provided in the supply to the RTS unit. This product must not be installed

where it may come into direct contact with liquids. The RTS unit is suitable for fixed

wiring applications only.

2.2 Electrical Interference

Despite elaborate safety precautions, exceptionally strong electrical fields may interfere

with any electronically controlled timeswitch. We therefore recommend that you observe

the following points before installation:

• Suppress interference caused by inductive loads by means of an RC filter and/or

varistor (VDR).

• Do not install the RTS unit in close proximity to sources of interference,

eg transformers, contactors, Pcs and TV sets.

2.3 Wiring Diagrams

Fig 1a

RTS113/

RTS113Q

3 4

2

3

1

L SL

N N

2.4 Installation

Three fixing holes B

countersunk with

central knock out

Load

Fig 1b

RTS114/

RTS114Q

Voltage between V

and COM – any AC

voltage up to 250V

V

COM COM

L

N

Fixing screw A for terminal cover which also retains

the plug-in timeswitch assembly

Transparent

cover

SV

LOAD

Lug D

on cover

Lug C

on base

Fig 2

Three cable holes leading

to terminals 1, 2 and 3

(terminal cover removed)

Fig 4a RTS113/RTS113Q Fig 4b RTS114/RTS114Q

Base

Base

Terminal

cover

Fig 3

Base

Three cable holes leading

to terminals 1, 2 and 3

(terminal cover removed)

4 cable/conduit knock outs in terminal

cover (2 at the bottom, 1 at each side)

Base

Page 5

Remove the transparent cover from the RTS unit by rotating it anticlockwise through 30° and

then pulling it clear. Unscrew the screw A (see fig. 3), remove the terminal cover and pull the

timeswitch plug-in assembly clear of the base. Drill out the three fixing screw holes in the base

(see fig. 2) and use 3 x No. 8 woodscrews (with wall plugs if necessary) to fix the RTS unit to the

mounting surface. Alternatively the unit may be fixed to panelling using 2B.A. or 5mm screws but

if the panelling is conducting it must be adequately earthed in accordance with the I.E.E. wiring

regulations. In either case ensure that the screws are countersunk and tightened fully so that

there is no projection above the surface of the base. Strip 8mm of insulation from the end of each

wire and insert in the appropriate terminal (see figs 1 and 4). Securely tighten the terminal screws

onto the wires and push the timeswitch plug-in assembly fully home into the base to ensure

electrical safety. Remove the appropriate knock-outs in the terminal cover and locate the cover

over the cables or conduit, securing with screw A. After commissioning the installation replace the

transparent cover by pushing over the base and rotating clockwise ensuring that lugs C and D on

the base and cover are lined up as in fig. 2.

If the transparent cover is required to be locked this can be achieved by a padlock through the

lug C with lugs C and D in the position shown in fig 2. Alternatively the holes in lugs C and D can

be lined up, wired and sealed. The fixing screw A (fig 3) securing the terminal cover can also be

secured by wiring and sealing.

3.0 Programming:

3.1 24 hour programming and clock time/day of week setting.

Insert red tappets into the programme ring to set the required ON times and the blue

4

tappets to set the required OFF times (see examples in fig 5). Up to 24 complete ON/OFF

programmes can be set over a 24 hour period.

The correct day of the week (Wed) can now be set by referring to fig 5 and rotating the 24 hour

programme ring in a clockwise direction until the first digit of the appropriate half day marker

e.g. (Wed AM 1st digit 2) is opposite the time marker. The correct clock time (1500 hours

– see fig 5) can now be set by continuing to rotate the ring in a clockwise direction until the

appropriate marker on the 24 hour ring is above the time marker.

The condition of the red (24 hour) control now needs to be checked and changed if necessary by

turning the red control shaft in an anticlockwise direction using a small screwdriver. If the last

tappet on the 24 hour ring to pass the time marker in a clockwise direction is blue the slot in the

red control shaft needs to be aligned with any

tappet is red. Next ensure that all the seven day segments have their screwdriver slots parallel to

the 7 day ring If not, turn in a clockwise direction with a small screwdriver until they are.

Note: Excess force used to turn a segment in an anticlockwise direction will damage

the timeswitch. Finally set the 7 day (blue) output control to ON if necessary by turning the

blue control shaft with a small screwdriver in a clockwise direction until the screwdriver slot in

the shaft is aligned with any ■ symbol. Finally ensure permanent override indicator is set to AUTO.

The RTS113/RTS113Q is now ready for service as a 24 hour timeswitch.

Note: Excess force used to rotate the programme ring and the blue control shaft

in an anticlockwise direction or the red control shaft in a clockwise direction will

damage the timeswitch.

symbol (OFF) and any ■ symbol (ON) if the last

•

Page 6

7 day output

control (blue)

24 hour output

control (red)

Time marker

Permanent override

indicator

Segment set to change

7 day output

Fig 5

3.2 Half day and day omit programming and 7 day control setting.

This is required only if the programme set on the 24 hour ring is not needed for one or more half

days. An example is shown in fig 5 where the requirement is to have no operation on Thursday

(day 4) afternoon and all day Friday (day 5). The 7 day switch segments between 4 and 4 (midday

Thursday) as well as between 5 and 6 (midnight Friday) have been turned anti-clockwise with a

small screwdriver until the segment slot is aligned radially

changed as each of these segments passes the time marker. Excessive force used to turn a

segment anticlockwise will cause damage.

The 7 day (blue) output will also need to be set manually in the right initial condition. In the

example shown in fig 5 when the time marker points within the period midday Thursday – to

midnight Friday the setting will be

by using a screwdriver to turn the 7 day control in a clockwise direction until the slot points to

a • for OFF or a ■ for ON. In the situation shown in fig 5 the control needs to be set ON.

Finally ensure permanent override indicator is set to AUTO. The 7 day control must only be

rotated in a clockwise direction. The screwdriver slot in the control is shaped to

prevent rotation in the opposite direction.

3.3 Override to next programme change.

The red 24 hour control can be turned anticlockwise by one click. This will change the

present output of the RTS unit and will last until the next programme change.

The 7 day control must only be rotated in a clockwise direction. The screwdriver

slot in the control is shaped to prevent rotation in the opposite direction.

3.4 Permanent Override ON.

The RTS unit can be permanently overridden ON by pressing the red button on the outside of

the case and transparent cover adjacent to the 7 day and 24 hour controls. The override can be

terminated by pressing the button again. The state of the timeswitch either permanently ON

or in Auto is indicated by the pointer adjacent to the 7 day and 24 hour controls.

– OFF and outside this time period ■ – ON. This is achieved

•

OFF at 1200 (blue tappet)

ON at 0900 (red tappet)

AM marker bar

ON at 2000 (red tappet)

OFF at 2200 (blue tappet)

so that the 7 day output will be

Page 7

3.5 Programming Overview

7 day output

control (blue)

24 hour control

(red)

Red tappet

Blue tappet

2 segments set to give

changes to 7 day control

at midday Thursday and

midnight Thursday. With

7 day control set at

above no 24 hour operation

will occur between midday

and midnight each Thursday.

24 Hour Ring

Red tappet for ON operation.

6

Blue tappet for OFF operation.

Fig 2 shows an ON period starting at 1200 and ending at 1500.

24 Hour Control

If last tappet past time marker was blue 24 hour control

should show

7 Day Ring

Segments with screwdriver slots positioned radially cause a change on the 7 day control.

The 7 day contacts are in series with the 24 hour contacts controlling the timeswitch output,

so the 7 day contacts need to be closed (

Finally ensure permanent override indicator is set to AUTO.

4.0 5 Year Guarantee

In the unlikely event of this product becoming faulty, due to defective material or manufacture,

within 5 years of the date of purchase, please return it to your supplier with proof of purchase

and it will be replaced free of charge.

Should you encounter any difficulty please contact our helpline on 020 8450 0515.

5.0 Additional Tappets

4 red and 4 blue tappets are supplied with the RTS unit. If further tappets are required they may

be obtained from Timeguard quoting the numbers 934 3 311 BLUE, 934 3 035 RED.

Please ring 020 8450 0515.

■

(ON)

(OFF) and ■ (ON) if it was red.

•

Fig 6

■

– ON) for the 24 hour contacts to be operational.

Clockwise direction for 24

Note: all other 7 day ring segments

are in the no change orientation

and are not shown for clarity

Time marker

hour and 7 day rings

Sunday markers

(in red)

7 day ring

24 hour ring

Radial slot

Page 8

For assistance with the product please contact:

HELPLINE

020 8450 0515

or email helpline@timeguard.com

For a product brochure please contact:

Timeguard Limited.

Victory Park, 400 Edgware Road,

London NW2 6ND

Sales Office: 020 8452 1112

or email csc@timeguard.com

67-058-78 (issue 3).

Zerofour – November 2013

Loading...

Loading...