Page 1

3.1 Select the required location

3.1.1 Sensor adjustment

Fig. 2 shows the way coverage alters with ceiling height and with

adjustments of the METER dial setting.

Section 4.2.3 shows how tilting and rotating the sensor can produce

different fields of coverage.

Ceiling Height (H) Detection Coverage Diameter (D)

with METER on +

2m 7m

2.5m 7m

3m 10m

3.5m 12m

4m 12m

4.5m 12m

If the METER control is turned to – the coverage diameter is

substantially reduced.

We do not recommend the use of these units with ceiling heights

greater than 4.5m.

3.1.2 Helpful tips for installation

As the sensor responds to temperature change or moving heat sources,

please avoid the following conditions:

• Avoid highly reflective surfaces within the detection range.

• Avoid movable objects e.g. curtains and plants in the detection range

(these may cause erroneous detections when moved by air flow from

fans or air conditioner).

• Avoid heat sources (e.g. heating vents, radiators, air conditioners

and filament lamps) in detection range.

• Avoid fans drawing air across the sensor lens.

3.3 Installation procedure

3.3.1 To install the detector, cut a hole with diameter of 65mm in the

ceiling board and bring the power cable through the hole. Strip off

cable sheath and core insulation according to Fig. 6.

3.3.2 Unscrew protection covers on power box with a cross point

screwdriver. The RJ11 socket (use sensor A only) is for sensor connection

and screw terminals are for power and load(s). (See Fig. 7).

1 Package Contents

2 Product Description

3 Installation and Wiring

Visual I.D.

Item Sensor Power Unit Instructions IR10

(optional

purchase)

Quantity 1 1 1

Technical Specifications

Rated Voltage: 230V ~ ±10% 50Hz

Loads: PDFM362:

Load I (L

) for Lighting: µ contact gap

Mains halogen lamp: max. 1000W

Incandescent lamp: max. 2000W

LV halogen lamp: max. 600VA

Fluorescent lamp: max. 900VA/100µF

LED lamp: max 400W

Load II (D1-D2) for HVAC:

Voltage free contacts:

Max. 5A for 250V AC~ or 30V DC (resistive)

Motor: 1/10HP (approx. 73W)

PDFM361:

Load I (L

) for Lighting: µ contact gap

Incandescent lamp: max. 2000W

Mains halogen lamp: max. 1000W

LV halogen lamp: max. 600VA

Fluorescent lamp: max. 900VA/100µF

LED lamp: max 400W

Delay Time Adjustment: PDFM362:

TIME1 (for lighting):

Adjustable from 5 sec. to 20 min.

(continuously adjustable)

Extendable to 30 min. and 60. min when

in use with the IR10 remote control

TIME2 (for HVAC):

Continuously adjustable from 10 sec. to

60 min. (independent of light level)

PDFM361:

TIME: Adjustable from 5 sec. to 20 min.

(continuously adjustable)

Extendable to 30 min. and 60 min. when

in use with the IR10 remote control

LUX (light level) Adjustable from 10 LUX to 2000 LUX

Adjustment: (continuously adjustable)

Max. Detection Coverage: 360º cone shape from ceiling height of

2.5m giving 7m dia. coverage at floor

level (for affect of ceiling height on

coverage see section 3.1.1)

Conforms To

EC Directives

All procedures indicated in this manual must be

carried out by a professional installer.

METER Adjustment: Adjustable continuously from +

giving maximum detection

coverage at floor level to –

giving substantially reduced

detection coverage at floor level

Connection between 1m flying lead from sensor

Sensor and Power Unit: terminated in an RJ11 plug.

RJ11 socket on power unit

(use socket A for PDFM362)

Operating Temperature: 0ºC to +45ºC

Environmental Protection: Sensor: IP40

Power unit: IP20

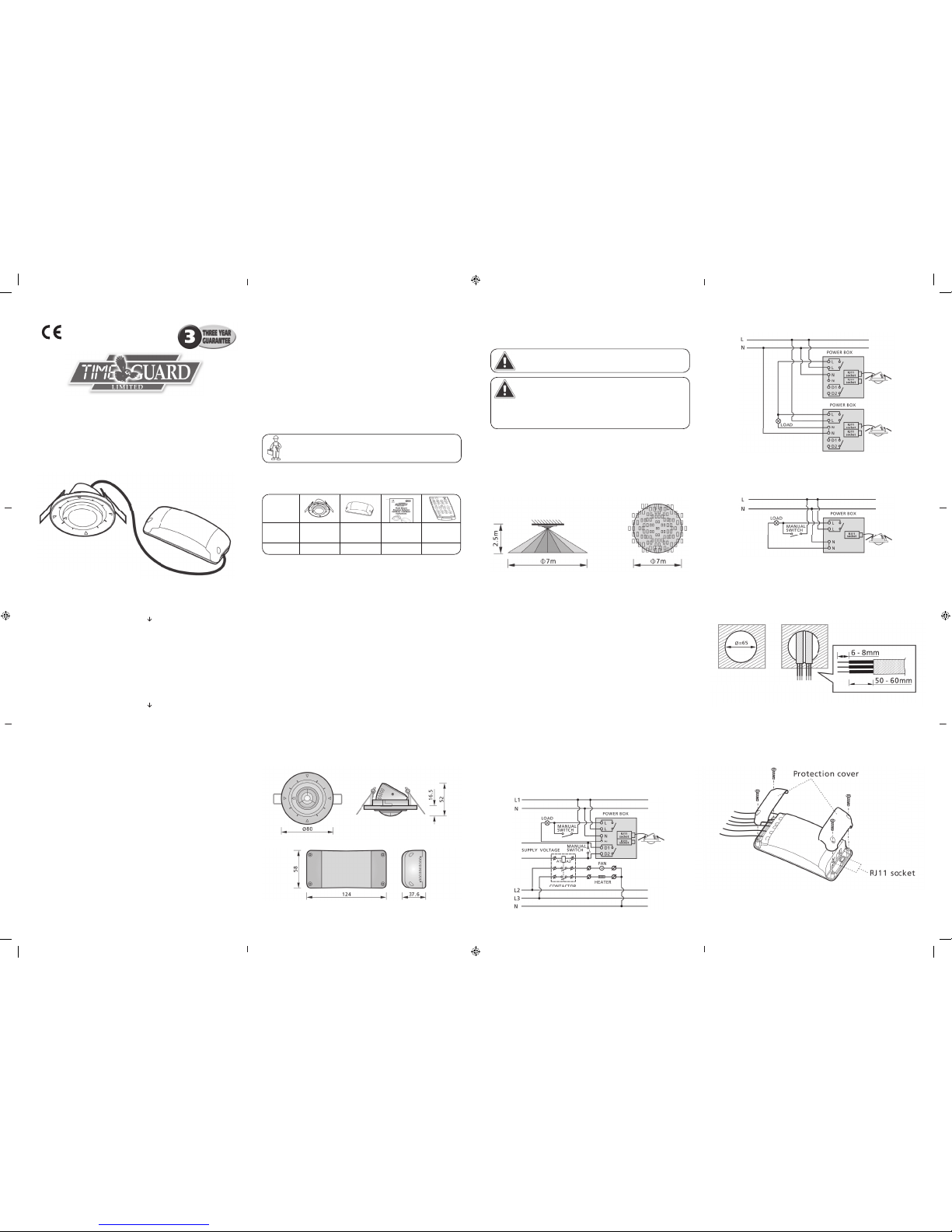

Fig. 1-A

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 1-B

Side View Top View (showing individual

beam pattern at floor level)

Drill a hole 65mm dia.

in the ceiling.

3.2.2 One load is controlled by two sensors (see Fig. 4).

3.2.3 PDFM361 for one sensor (see Fig. 5).

Fig. 7

Flush Mount

Presence Detector

PDFM362/PDFM361

Instructions

2.1 Features

The PDFM362 PDFM361 controller is a ceiling flush mount

presence detector for indoor applications in commercial and

domestic locations. PDFM361 covers lighting applications only,

whereas PDFM362 can control lighting and HVAC

(heating, ventilating and air conditioning) applications.

Adjustment of Time and LUX value can be made either by the dial

controls on the sensor body or by the IR10 Infrared remote control.

• PDFM362 has two relays for outputs load I and load II:

load I is for lighting control and load II has voltage free contacts

for HVAC control which operate at all LUX (light) levels.

• Automatically adjusts to fit in a wide range of ceiling thicknesses.

• The sensor has a very high density of sensitive beams covering the

detection area. These are evenly distributed ensuring no dead spots

and detection of the smallest movements.

• RJ11 plug and socket for quick and easy connection.

• Built in LED in sensor giving confirmation of remote control settings

and easy test operation.

2.2 Dimension (see Fig. 1-A & Fig. 1-B)

Sensor: 80 dia. x 52mm

Power unit: 124 x 58 x 37.6mm

Models PDFM362 PDFM361

3.2 Wiring diagrams

3.2.1 PDFM362 controller (see Fig. 3).

Please disconnect power completely and read the

entire instruction manual carefully before installation.

PDFM362 – 6A breaker

A circuit breaker (250VAC,6A) type C according to EN60898-1

of load shall be installed in the fixed wiring for protection of load II.

PDFM361, PDFM362 – 10A breaker

A circuit breaker (250VAC,10A) type C according to EN60898-1

of load shall be installed in the fixed wiring for protection of load I.

This product must be

protected by a fuse or

circuit breaker with a

maximum rating of

10A or lower.

Page 2

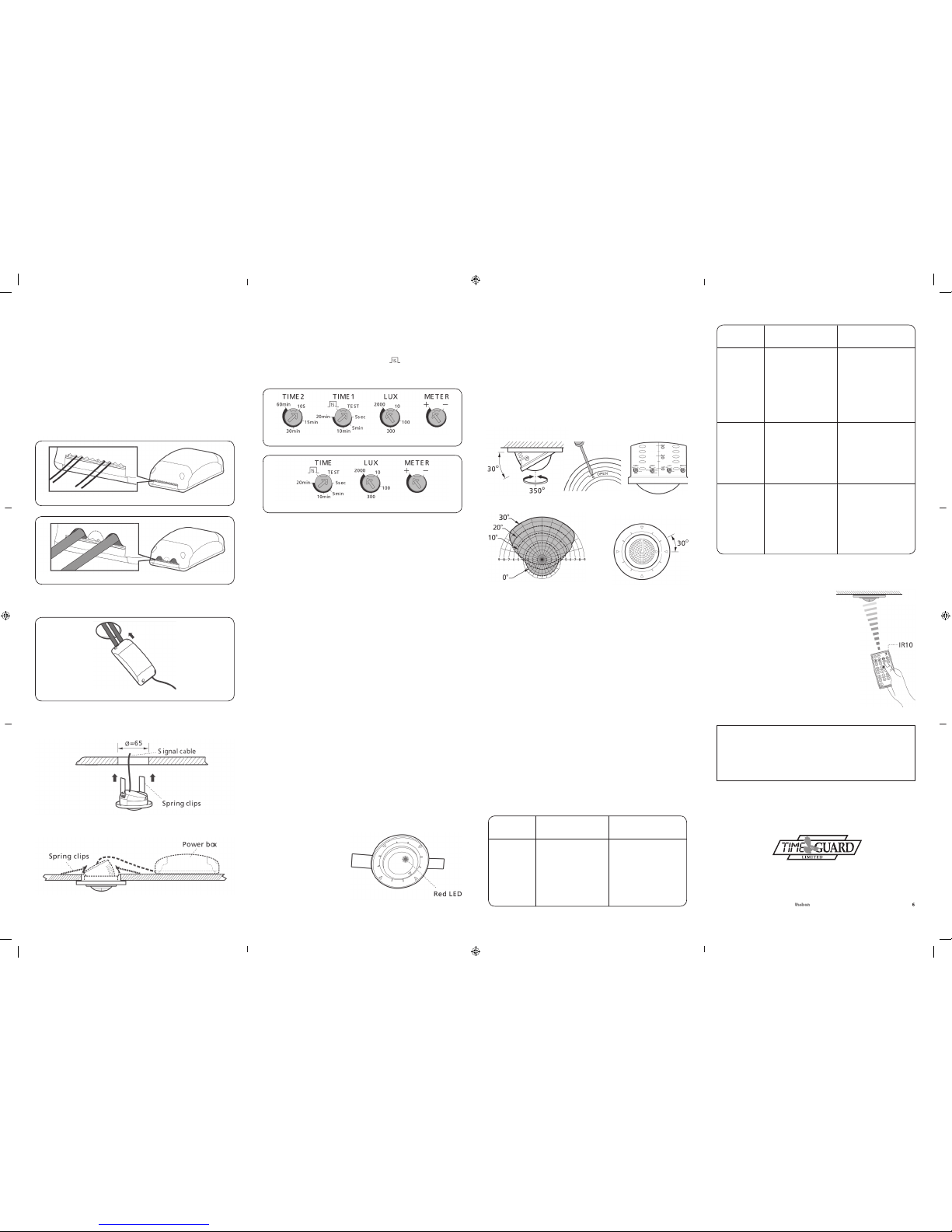

PDFM362 PDFM361 can also be

controlled by the infrared remote

controller IR10. As well as allowing

remote setting of times and light level

the IR10 also enables continuous

operation for 8 hours in ON or OFF

modes as well as continuously in

detection mode controlled by or

independent of light level.

The IR10 is invaluable during

commissioning enabling changes to

be made without resorting to ladders.

Further to this the IR10 can download

stored settings from one sensor to

additional sensors in the same area.

3.3.2 (cont). The protection covers have teeth (see Fig. 8-A) giving

a degree of cable clamping if power and load are connected by

individual wires (0.8 –1.8mm dia.).

If connection is by cable (9 – 11mm dia.) then use of a coarse rat-tailed

file to open out as many of the holes as necessary using the markings

on the inside of the protection cover as an approximate guide

(see Fig. 8-B).

Referring it to the appropriate wiring diagram insert the wires into the

correct screw terminals and tighten fully. Then plug the sensor lead into

SENSOR A socket only.

Use the coarse rat-tailed file to open a single hole (smaller than that

above) in the remaining protection cover to take the sensor cable with

a degree of strain relief. Secure down the protection covers.

3.3.3 Feed the wires/cables followed by the power unit through the

65mm dia. ceiling hole (see Fig. 9).

4.1.1 TIME control adjustment

These are delay times between the sensor being triggered and the

controller switching off assuming no further detections are made.

If there are additional detections the time delay applies from the

latest detection.

PDFM362:

TIME 1: Adjustable from 5 sec. to 20 min. (lighting). (Extendable to

30 min. and 60 min. when in use with the IR10 remote controller).

TIME 2: Adjustable from 10 sec. to 60 min. (HVAC).

PDFM361:

TIME: Adjustable from 5 sec. to 20 min. (lighting). (Extendable to

30 min. and 60 min. when in use with the IR10 remote controller).

4.1.2 LUX control adjustment

The LUX level below which the sensor will operate is adjustable from

10 LUX (operation only after dusk) to 2000 LUX (operation at any

light level).

4.1.3 METER control adjustment

This control sets the diameter of detection coverage at floor level.

Assuming a ceiling height of 2.5m at the + end of the scale the

coverage diameter will be 7m, at the – end of the scale the coverage

diameter will be 1m.

The affect of METER control at other ceiling heights is shown in section 3.1.

4.2 Test Mode

4.2.1 Sensor warm up

The detector will take a minimum of 60 seconds to warm up when the

power is connected to it for the first time or if the power is being

re-connected after being turned off.

During this period load I and the sensor LED will both be on. After the

warm up is finished the sensor will revert to operation according to the

settings of the controls on the sensor body.

4.2.2 LED function

There is a red LED (see Fig. 12) built into the sensor and visible through

the PIR lens that shows the status of the loads and enables testing to be

carried out without the loads

being connected.

If the IR10 remote controller

is in use the LED will flash to

give confirmation of the

commands and adjustments

made by the IR10.

3.3.4 Force the spring clips back until they can feed into the ceiling hole

(see Fig. 10-A) and then push the sensor upwards into place so that its

flange fits tightly against the ceiling (see Fig. 10-B).

Fig. 8-A

Fig. 8-B

Fig. 9

Fig. 10-A

Fig. 10-B

4 Test and Operation

5 Troubleshooting

6 Optional Remote Control – IR10

4.1 Time, LUX and Meter Controls

Following marked values (excepting TEST and

) are approximate,

the values are continuously adjustable over the control range

(see Fig. 11-A & Fig. 11-B).

Fig. 11-A (PDFM362 control dials)

Fig. 11-B (PDFM361 control dials)

4.2.3 Adjusting sensor head

The sensor head can be tilted by as much as 30º off axis as shown

in Fig. 13A. This can be achieved by using a flat blade screwdriver

as shown in Fig. 13B.

Fig. 13C shows the tilt angle markings on the sensor body. The tilt

angle is read off against the edge of the mounting flange.

Fig. 13D shows the detection coverage for various tilt angles.

The tilt angle can be used in conjunction with rotation of the

sensor head within the flange up to 350º to give the required

coverage in any direction. The markings on the sensor mounting

flange (see Fig. 13E) giving 30º per division provide a useful

way of adjusting angular position.

When the PDFM362 PDFM361 is not working as expected go

through the troubleshooting guide below.

4.2.4 Walk test

Turn supply on and wait at least 60 seconds for the system to

settle down.

Turn Time 1 control to the Test position. This means that the sensor

LED and load I will turn on for 2 seconds after triggering and then

be off for 3 seconds after which the sensor can be re-triggered.

The triggering is independent of light level.

The installer should move around in the detection area to establish

that it is all covered. If necessary the tilt and rotation of the sensor

should be adjusted, after which the area should be walk tested

again to confirm coverage is as required.

To confirm that load 2 (HVAC) is operating correctly for a

PDFM362, carry out the following:-

Turn LUX (light level) to its minimum value (10 lux) to stop

load 1 (lights) from turning on. Then turn TIME 2 (HVAC) to

minimum value (10s) and carry out a limited walk test to

confirm correct operation of load 2.

Fig. 12

Fig. 13A

Fig. 13B Fig. 13C

Fig. 13D

Fig. 13E

Problem Possible Suggested

Cause Solution

Problem Possible Suggested

Cause Solution

Lighting or

HVAC does not

turn off.

LED does not

turn on.

Nuisance

triggering.

Lights do not

turn on.

1. Incorrect time setting.

2. Incorrect wiring.

1. Out of detection range.

2. Power supply not on.

3. ‘TIME’ knob setting

isn’t on ‘Test’.

4. Incorrect wiring.

There are heat sources,

HVAC vents/fans,

highly reflective surfaces

or anything which may

be swayed by air

movement within the

detection coverage.

1. Power is not turned on.

2. Incorrect control

dial setting.

3. Incorrect wiring.

4. Faulty load.

1.

Check that the correct delay

time is set on either TIME 1

or TIME 2 control dial.

Then determine if

nuisance triggering is

keeping the unit turned on.

2. Make sure supply and

load wires are connected

correctly.

1. Walk within the effective

detection range.

2. Switch the power on.

3. Turn the control position

to ‘Test’.

4. Refer to wiring diagrams

(Fig. 3 to Fig. 5).

Avoid aiming the sensor

toward any heat sources,

such as air conditioners,

electric fans, heaters or any

highly reflective surfaces.

Make sure there are no

swaying objects within the

detection coverage.

1. Switch on the power.

2. Check if control dials are

set to the correct position,

then supply the power to

check if the LED will turn on.

3. Refer to wiring diagrams

(Fig. 3 to Fig. 5)

4. Replace the faulty load.

3 Year Guarantee

In the unlikely event of this product becoming faulty due to defective

material or manufacture within 3 years of the date of purchase, please

return it to your supplier in the first year with proof of purchase and it will

be replaced free of charge. For years 2 and 3 or any difficulty in the first year

telephone the helpline on

020 8450 0515.

HELPLINE

020-8450-0515

or email helpline@timeguard.com

For a product brochure please contact:

Timeguard Ltd.

020-8452-1112

or email csc@timeguard.com

A Group company

67-058-277 (Iss. 5)

For assistance with the produc t please contact:

Fig. 14

3.28.0206204670103

Loading...

Loading...