Page 1

INSTRUCTION MANUAL

INSTRUCTION MANUAL

Electric Version . Flybarless Edition

組裝說明書

組裝說明書

No.4757

This radio control model is not a toy! Before beginning assembly, please read

this manual thoroughly.

本產品為高性能模型非一般玩具,組裝與操作前請詳閱本產品說明書。

The contents are subject to change without prior notice due to product

improvements and specification changes.

本套件所附之零件可能跟圖示有所差異。因產品後續之設計研發或功能不斷改善之原

因,我們將保留產品規格變更權力,不再另行通知使用者。

Page 2

CONTENTS

INTRODUCTION

INTRO & CAUTION / 簡介與注意事項

OTHER ITEMS REQUIRED / 其餘必須配件

MANUAL FORMAT / 說明書使用方式

ASSEMBLY / 組裝步驟

Main Rotor System / 主旋翼機構組裝

Main Rotor Head Linkage Rod Installation / 主旋翼頭連桿組裝

Tail Boom Bracket Assembly / 尾管固定座組裝

Main Frame / 本體組裝

Landing Skid / 腳架組組裝

Main Gear Set / 主齒輪組裝

Control Arm Set / 控制臂組裝

Tail Rotor System / 尾旋翼機構組裝

Tail Unit / 尾部總成組裝

Servo Installation / 伺服機裝配

Linkage Rod Installation / 連桿組裝

Power Motor Installation / 動力馬達安裝

Electric Device Installation / 電子設備配置

Main Rotor Blade / 主旋翼安裝

Electric Version . Flybarless Edition

2

4

5

6

7

8

9

11

12

13

14

16

17

18

19

20

21

SET-UP SECTION / 設定程序說明

Radio System Setup / 遙控系統設定

Swashplate Type Setting / 十字盤模式設定

Electric Device Connection / 電子設備連接說明

Index of Linkage Length / 連桿長度索引

Swashplate & Servo Movement Setting / 十字盤及伺服機動作設定

Tail Control And Gyro Setup / 尾舵控制及陀螺儀控制

Setting Up Data For Your Reference / 參數設定參考

Blade Tracking Adjustment / 主旋翼軌跡調整

Cautions of Li-Po Battery Pack Using / 鋰聚電池使用注意事項

After Flight Checklist / 飛行後的檢查項目

Regular Maintenance / 定期保養事項

SPARE PARTS / 維修零件包

SPARE PARTS LIST / 維修零件包表格

OPTIONAL PARTS / 改裝零件包

OPTIONAL PARTS – FLYBAR EDITION / 改裝零件包-平衡翼旋翼頭

Exploded View / 爆炸圖檢索

22

22

22

23

23

24

25

26

27

27

27

28

32

39

40

41

-1-

Page 3

INTRODUCTION / 簡介

Thank you for purchasing the Thunder Tiger Titan X50 R/C helicopter. This new helicopter is the latest

innovation by Thunder Tiger. It has the perfect combination of flying stability and the agility for 3D flying.

This helicopter is an excellent choice for flying enthusiasts like you. For convenient assembly and safe

operation of the helicopter, please read the instructions carefully. Retain the user manual in case you need

it for any information or reference.

感謝您購買雷虎科技Titan X50直昇機產品,本項產品為雷虎科技全新開發機種,兼具高度穩定性與3D飛行特性,是

熱衷引擎直昇機的您不可錯過的選擇。請於使用本產品前詳盡閱讀使用手冊,以利於組裝工作順暢進行與安全操控本

產品。請妥善保存使用說明書,以利後續調整與維修參考用途。

CAUTION / 警告

1. R/C models are not toys. This product is a high-precision flying machine. Possibilities of unexpected

crashes may occur due to electronic interference, incorrect operation, or poor mechanical maintenance.

Although it is a small-sized helicopter, the rotor blades rotate at high speeds, which may cause serious

damage, injury, or death if the model hits people or property. Therefore, extreme caution must be

exercised during operation.

2. Thunder Tiger ensures parts packaged in this product is of the highest quality. However, after assembly

and usage, parts damaged due to wear or misuse will not be replaced under any circumstances. If you

have any questions regarding its operation and repair, Thunder Tigers service agents are able to

provide free technical guidance.

3. This product is only recommended for users ages 16 and up. Because flying a R/C helicopter is difficult,

beginners must receive guidance and supervision from experienced pilots to minimize unexpected danger.

Practice in spacious areas, far away from obstacles such as buildings, trees, electrical towers, or crowds.

4. To decrease the cost of repair and maintenance for beginners, it is recommended to fly the helicopter

with a practice rack and to learn basic flying skills with a computer R/C flying simulator. (Crashes in

simulators are free to repair!)

1. 本項遙控直昇機產品並不是玩具,是一項結構精密、高專業度模型產品,如果未經正確組裝與操控,將可能對操控

者或其他人造成身體傷害。使用者必須了解,若未確實進行飛行前安全檢查或操控不當,而造成人員受傷或物體損

壞,使用者必須負起法律責任。

2. 本產品由高品質零組件組成,雷虎科技對於安裝過程、使用過後..等人為因素造成損壞事件不負損壞賠償之責。如您

需要本產品相關組裝、調整或其他協助,可與雷虎科技全省經銷商聯繫。

3. 本項產品禁止十六歲以下青少年與孩童使用。強烈建議初學者應取得技術支援後再進行飛行,以避免危險發生。請

於空曠地區操控本產品,並避免於建築物、樹木、電塔..等障礙物區域飛行。

4. 建議初學者可安裝練習架或透過電腦模擬軟體練習,可達到實際練習效果與符合經濟效益。

AMA INFORMATION / 特別注意事項

Operating a model helicopter requires a high degree of responsibility and skill. If you are a newcomer to the

hobby, it is best to seek help and guidance from accomplished model helicopter pilots. This will greatly

speed up the learning process and have you flying successfully in a reasonable amount of time. We also

would strongly urge you to join the Academy of Model Aeronautics. The AMA is a non-profit organization

that provides its members with a liability insurance plan as well as monthly magazine entitled Model Aviation.

All AMA charter aircraft clubs require all pilots to hold a current AMA sporting license prior to operation of

their models at club fields. For further information, contact the AMA at:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(317) 287-1256

操控遙控直昇機對於飛行安全要求極高,需要高度的負責任態度配合,以及較高的操控技巧。如果您是一位初學者,

建議您必須向當地專業模型經銷商,或是遙控直昇機相關組織以及經驗豐富的玩家尋求相關協助,以獲得您所需要的

訊息以及專業知識。如此可有效協助您縮短學習的時間,更容易學會遙控直昇機的組裝、設定與操控技巧。

-2-

Page 4

FLIGHT SAFETY CHECKLIST / 飛行前安全確認工作項目

1. Make sure that the transmitter battery is fully charged before flying.

2. Make sure all control surfaces are operated properly before flying.

3. Do a range check of the radio before the first flight. The electronic equipment must operate properly

at a range of at least 5 meters (18 ft) even with the transmitter antenna collapsed.

4. Make sure there are no other pilots using the same radio frequency with yours and that there are no

other radio interference on your frequency.

5.

Be sure to turn on the transmitter first with the throttle stick in the idle position. Plug the battery into the

ESC last.

6. The main rotor and the tail rotor spin at very high RPM. Make sure nothing can come in contact with

the rotor blades during flight.

7. Always maintain a safe distance from the helicopter during flight.

8. Never fly the helicopter in the rain or in excessive wind conditions.

9. Always operate and fly the helicopter in a safe and responsible manner.

10. Never fly the helicopter over other pilots, spectators, cars or anything that could result in injury or

property damage.

1. 確認接收機與發射機電池,均已確實充電完成。

2. 確認所有操控介面運作順暢。

3. 確認無其他無線電波干擾,且不與其他同好同時使用相同頻率。

4. 確實將油門搖桿放置於低速,再將發射機電源開啟,然後再將電池接上。

5.

確認遙控器發射器與接收機工作正常,將機體放至於距離5公尺外,確認遙控器是否正常,機體控制動作是否正確。

6. 主旋翼與尾旋翼轉速相當高,運轉時須避免任何障礙物與旋翼接觸。

7. 飛行時,需與遙控直升機保持安全距離。

8. 勿於下雨天或是強風的狀態下操控遙控直升機。

9. 請以安全為第一考量,並以高度負責任的態度參與遙控直升機活動。

10. 禁止於人群、車輛..或任何其他障礙物上方飛行遙控直升機,避免意外發生。

POST FLIGHT INSPECTION / 飛行結束安全檢查事項

1. Inspect the model thoroughly to insure no parts have come loose or become damaged during the flight

and landing. Replace damaged parts and tighten loose screws before flying again.

2. Clean the helicopter body.

3. Lubricate all moving parts to ensure smooth operation for the next flying.

4. Replace any worn ball links and damaged bearings.

5. Store the model in a cool, dry place. Avoid putting it under direct sunlight or near a source of heat.

Following these simple rules will allow you to enjoy the thrill of model helicopter flying for many years.

1. 飛行結束後確認機體所有的零件與螺絲是否有損壞或鬆動,更換損壞零件與確實固定鬆動的螺絲。

2. 機體清潔乾淨。

3. 檢查所有活動零組件是否運作順暢,以利下次飛行。

4. 更換所有鬆動的連桿、接頭,以及損壞的軸承。

5. 將機體存放於陰涼通風處,避免機體放置於陽光直射處或接近熱源。

確實執行上述幾項簡單的步驟,將可確保您的愛機維持數年的壽命!

CAUTION / 注意事項

When the model has crashed, inspect the flybar, rotor shaft and the blade spindle to make sure they are

not bent. If any item is damaged, it must be replaced with a new part to ensure safe operation. Do not

glue any broken or damaged plastic parts. Do not repair broken rotor blades. It is very important to

inspect the motor, speed control and the battery.

Always inspect the following items:

Gears, Ball links, Link rods, Bearings, Main shaft, Flybar, Spindle, Tail boom and support, Fins, Tail rotor

shaft, Belt, Main blades, Tail blades, the Motor, the Speed control and the Battery.

機體一但發生墜落事件,請確實檢查平衡桿、主軸、橫軸是否有彎曲變形,如果有任何的損壞,請立即更換原廠新

的零組件,確認機體操作安全!切勿使用任何接著劑嘗試黏合塑膠零件;請勿使用修復過的主旋翼。馬達、速控器

、電池的安全檢查工作亦相當重要。

發生機體墜落事件後,請確實檢查下列項目:

齒輪組、球頭連桿、連桿頭、軸承、主軸、橫軸、尾軸、平衡桿、平衡片、尾管、尾管支撐架、垂直與水平尾翼、

尾驅動輪、皮帶、主旋翼、尾旋翼、馬達、速控器、電池。

-3-

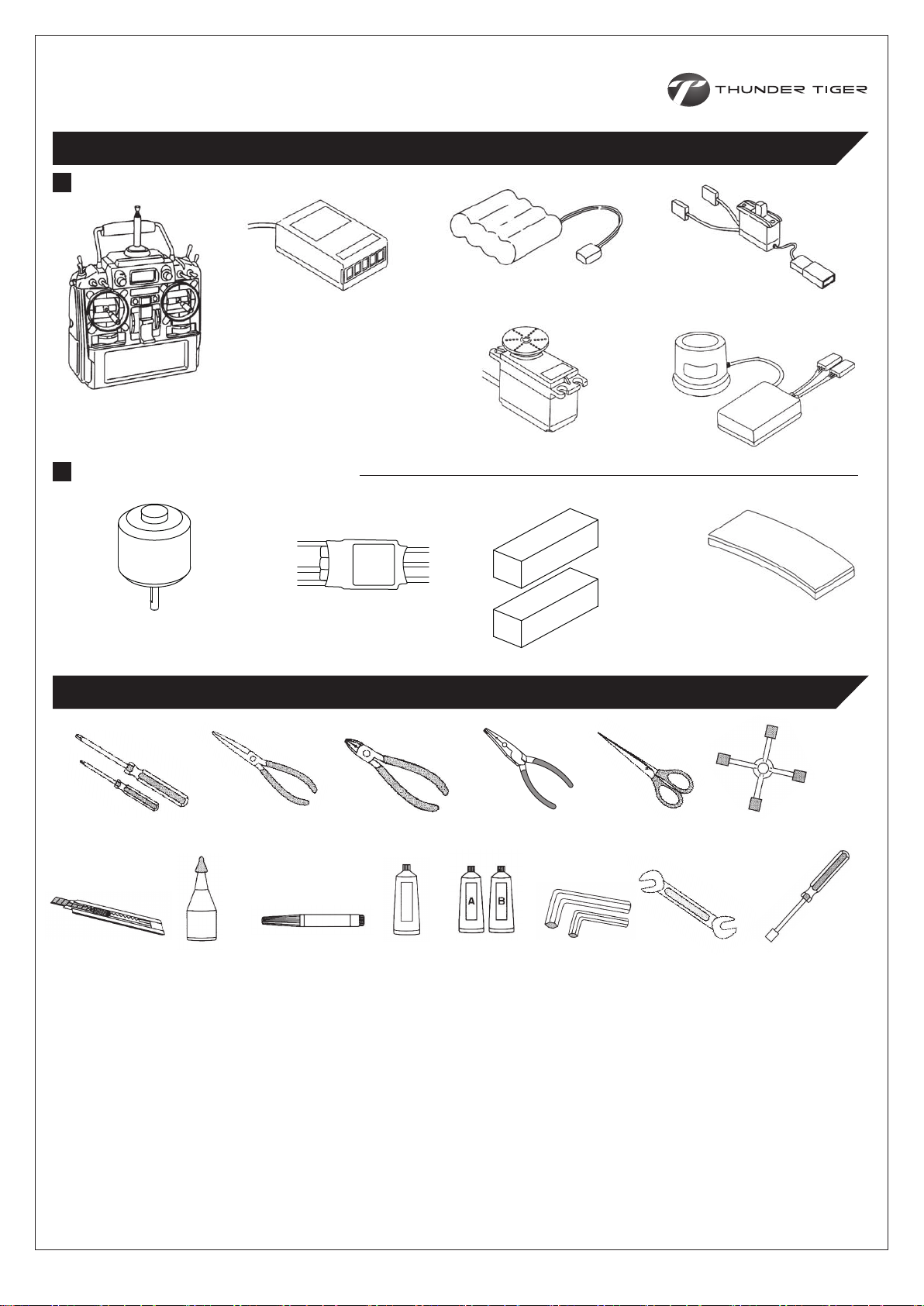

Page 5

OTHER ITEMS REQUIRED 需自行準備的配件

RADIO SET / 遙控系統

Receiver

接收機

Transmitter (helicopter type

only, 6 or more channels)

發射機(需具備直昇機控制功能

的6動以上遙控器)

Battery 接收機電池

1000mAh

Servo

伺服機

Switch Harness

具備充電線的開關組

Gyro

陀螺儀

POWER SYSTEM / 動力系統

Electric Brushless Motor

無刷馬達

Electronic Speed Controller

速控器

8~12S Li-Po Battery Pack

鋰聚電池組

TOOLS REQUIRED FOR ASSEMBLY 需要準備的工具

Foam

雙面膠帶

Screw Driver

各種規格的螺絲起子

Hobby Knife

美工刀

C.A Glue

瞬間膠

Needle Nose Pliers

尖嘴鉗

Threadlocker

螺絲防鬆膠

Nipper

斜口鉗

Grease

潤滑油

Ball Link Pliers

拆連桿頭的專用鉗子

Epoxy

環氧樹酯

Hex Wrench

六角板手

Scissors

剪刀

5.5mm

Metric 4-way Wrench

十字套筒板手

7mm

Wrench

開口板手

Socket Drivers

套筒螺絲起子

5.5mm

7mm

8mm

5.5mm

7mm

8mm

10mm

-4-

Page 6

MANUAL FORMAT / 說明書使用方式

How to read the instruction manual?

說明書導讀

A: Indicates the assembly step number and the parts bags

that are to be assembled.

B: Displays actual size drawings, and part quantities used.

C: All parts, except screws, are identified by its order

numbers. When purchasing spare parts, identify the part

required and cross reference this to the spare parts list in

the end of this maunal, which shows the purchasable

spare parts and the corresponding order numbers.

D: This instruction manual uses several symbols. Pay careful

attention to them during construction. Details are given

at the bottom of each page.

E: If a label marked here indicates the page is the exclusive

assembly steps for a particular model type; please follow

the exclusive instructions according to the model type you

purchased.

A: 顯示組立步驟及需組立之零件包順序。

B: 零件實際對照尺寸及使用數量。

C: 請比對零件形狀以及後附零件料號對照圖示找出需求零件料號。

D: 操作說明符號可更有效協助組裝者使用此說明書,請依說明書符

號指示進行組裝步驟。

E: 出現此標籤表示本頁為特定模型版本之專屬組裝說明,請依您所

購買之版本依說明進行組裝步驟。

Example 說明範例

E

B

C

D

A

B

C

SYMBOLS USED THROUGHOUT THE MANUAL / 符號說明

The parts in the KIT are packed according to each major assembly steps. The part number and quantity are always

shown in the square box on each page. As good practice, only open up the bag that you need for the paticular assembly.

零件均依照組裝步驟包裝,請依照組裝程序,逐一開啟零件包,避免零件遺失。

Note / 注意

Assembly drawings will contain icons that indicate use of

Threadlocker or CA glue as needed.

Examples of the icons are as right shown:

請依組裝步驟圖示,使用防鬆膠或接著劑。

圖示範例如右:

Apply C.A Glue

使用快乾膠黏合

Apply threadlocker

使用螺絲防鬆膠

Assemble as many times as specified

依指示組裝所需數量

Assemble left and right side the same way

左右側組件相同

Assemble in right order

依標示順序組裝

Cut off shaded portion

依標示部分裁切

Ensure smooth, non-binding movement when assembling

確認組件靈活度

Drill holes with the specified diameter

依標示尺寸鑽孔

Must be purchased separately

改裝品需另購

T22(#262) THREADLOCKER / 螺絲防鬆膠

CA CA GLUE / 快乾膠

Cut off excess

裁剪多餘部分

Apply grease

使用潤滑油膏(黃油)

Pay close attention here

注意組裝步驟

Hint

組裝提示

-5-

Page 7

Bag A

Main Rotor System / 主旋翼機構組裝

Material No. Description

No.

1

BV2574

BK2575

2

BK2576

3

HMC3-8B

4

BK0649-1

5

HSA3-6

6

BK2216

7

HMX0612

8

BK2214

9

HMC3-10B

SOCKET SCREW,M3x10

內六角螺絲,M3x10

BK0649-1

LINKAGE BALL(A)

內六角連接頭螺絲(A)

BK2525

FLAP COLLAR,d7xD10xW1.5

避震軸環,d7xD10xW1.5

METAL MAIN ROTOR GRIP SET

FL METAL ROTOR GRIP LEVER

FL METAL ROTOR GRIP POST

SOCKET SCREW, M3×8

LINKAGE BALL(A)

BUTTON HEAD SOCKET SCREW, M3X6

THRUST WASHER, d10xD13xW0.5

THRUST BEARING,d6xD12xW4.5

HARDENED FEATHERING SHAFT

名稱

金屬旋翼轉座組

無平衡翼金屬轉座擺臂

無平衡翼金屬連接座

內六角螺絲, M3×8

內六角連接頭螺絲(A)

半圓頭內六角螺絲, M3x6

止推墊片, d10xD13xW0.5

止推軸承,d6xD12xW4.5

強化固定軸(D7)

Qty

2

2

2

2

2

4

2

2

1

No.

10

BK2573

11

BK2572

12

BK2525

13

BK0435

14

HMC4-8B

15

HMV1370ZZWY

16

BK2510

17

BK2182

18

HMC25-8B

OUTER DAMPER, 7mm

INNER DAMPER, 7mm

FLAP COLLAR, d7xD10xW1.5

WASHER, d4xD11xW1.7

SOCKET SCREW, M4×8

BEARING, d7xD13xW5

METAL MAIN ROTOR HUB

METAL HEAD BUTTON

SOCKET SCREW, M2.5×8

Secure all screws shown on this page with a drop of thredlocker.

本頁顯示之螺絲請使用適量防鬆膠鎖固。

Apply some amount of silicon oil or

Vaseline on the Spindle for easy

assembly.

在橫軸上塗抹此許矽膠油脂或凡士林可

使組裝更為容易。

(5)

(6)

(3)

(18)

(17)

(2)

L

R

(9)

(10)

(12)

(6)

名稱

外避震墊圈, 7mm

內避震墊圈,7mm

避震軸環, d7xD10xW1.5

墊圈, d4xD11xW1.7

內六角螺絲, M4×8

滾珠軸承, d7xD13xW5

金屬主旋翼固定座

金屬旋翼頭制動器

內六角螺絲, M2.5×8

(1)

(4)

QtyMaterial No. Description

2

2

2

2

2

4

1

1

1

HMC4-8B

SOCKET SCREW M4×8

內六角螺絲M4×8

HMV1370ZZWY

BEARING,d7xD13xW5

滾珠軸承,d7xD13xW5

BK2216

THRUST WASHER,d10xD13xW0.5

止推墊片,d10xD13xW0.5

The bearings (#15) come with the grips which had been assembled by Factory.

主旋翼夾座內軸承

(16)

Assemble the main rotor pitch housing as drawing

主旋翼轉座組裝示意圖

Diagram for Thrust Bearing Assembly

止推軸承安裝示意圖

Large Internal

Diameter

always go toward the

Main Rotor Hub

內徑較大的一側,面向

主旋翼中心座組。(內

側)

Small Internal

Diameter

always go toward the

Blade

內徑較小的一側,面向

主旋翼組(外側)。

(#15)

已由原廠壓配完成。

(11)

(8)

(7)(15)(15)

Completed View

組裝完成

(13)

(14)

HMX0612

THRUST BEARING,d6xD12xW4.5

止推軸承,d6xD12xW4.5

BK0435

WASHER,d4xD11xW1.7

墊圈,d4xD11xW1.7

HSA3-6

BUTTON HEAD SOCKET SCREW,M3x6

半圓頭內六角螺絲,M3x6

HMC25-8B

SOCKET SCREW,M2.5x8

內六角螺絲,M2.5x8

Checking Tips: >

轉動角度: >

(轉動角度大者,內孔大;轉動角度小者,內孔小)

Apply grease

使用潤滑油膏(黃油)

Ensure smooth, non-binding movement when assembling

確認組件靈活度

Assemble left and right side the same way

L

左右側組件相同

R

Apply threadlocker

使用螺絲防鬆膠

-6-

Page 8

Bag A

Main Rotor Head Linkage Rod Installation / 主旋翼頭連桿組裝

No.

1

BK2236

2

BK2219

3

HMV6800ZZY

4

BK2206

5

HME4-3B

6

BK2596

7

BK1925

8

HSA3-14

9

BK0077

10

BV2508

HMV6800ZZY

BEARING,d10xD19xW5

滾珠軸承,d10xD19xW5

HME4-3B

SET SCREW,M4x3

無頭內六角螺絲,M4x3

Description

UPPER BRG

FRAME SPACER

BEARING, d10xD19xW5

MAIN SHAFT LOCK RING

SET SCREW, M4x3

LINKAGE ROD, 52L

BALL LINK

BUTTON HEAD SOCKET SCREW, M3x14

COLLAR, d3xD4xW6

FB Metal CONTROL LEVER SET

名稱

上軸承座

六角連接支柱

滾珠軸承, d10xD19xW5

止檔圈

無頭內六角螺絲, M4x3

連接桿, 52L

單頭連接桿

半圓頭內六角螺絲, M3x14

軸環, d3xD4xW6

無平衡翼金屬控制搖臂組

QtyMaterial No.

1

2

1

1

2

2

4

2

2

2

No.

11

12

13

14

15

16

17

18

19

BK0088

BK0171

HMS15

BK0016-1

BK0616

HMM3Z

BV2188A

BK2209

BK2277

Description

WASHER, d3xD5xW0.5

PIN

E RING

WASHOUT LINKAGE

SOCKET SCREW, M3x20

NYLON NUT, M3

METAL SWASHPLATE

SWASHPLATE CONTROL ROD

HARDENED MAIN SHAFT

Secure all screws shown on this page with a drop of thredlocker.

本頁顯示之螺絲請使用適量防鬆膠鎖固。

(7)

(10)

(16)

(11)

名稱

墊片, d3xD5xW0.5

插銷

E型扣環

連接座

內六角螺絲(半牙), M3x20

止鬆螺帽,M3

金屬十字盤組

十字盤穩定桿

強化主軸

Scale=1:1 (unit:mm)

(7)

(15)

(15)

40

QtyMaterial No.

2

2

2

2

2

2

1

1

1

76

BK1925

BALL LINK

單頭連接桿

HMS15

E RING

E型扣環

HSA3-14

BUTTON HEAD SOCKET SCREW,M3x14

半圓頭內六角螺絲,M3x14

BK0077

COLLAR,d3xD4xW6

軸環,d3xD4xW6

BK0088

WASHER,d3xD5xW0.5

墊片,d3xD5xW0.5

BK0171

PIN

插銷

Apply threadlocker

使用螺絲防鬆膠

(9)

(6)

(A)

(8)

BK0616

SOCKET SCREW, M3x20

內六角螺絲(半牙), M3x20

HMM3Z

NYLON NUT, M3

止鬆螺帽, M3

(2)

(3)

(12)

(5)

(14)

(18)

(13)

(4)

(5)

(1)

(19)

(6)

(17)

The distance

form the Lock

Ring to the end of the Main Shaft is

about 95.0 mm.

The actual position may need to be

adjusted after mounting the head into

the frames to eliminate the play,

therefore, do not secure the screw #5

tightly at this step.

主軸末端至止擋圈距離約為95.0 公釐。

當旋翼頭安裝至側板時,實際位置可能需調

整,此步驟可暫不鎖緊螺絲#5。

(7)

(A)x2

95mm

The length may vary when using different servos, please re-adjust the length as actual condition.

搭配不同品牌伺服機時,連桿長度或有不同,調機時,請再依實際狀況進行微調。

-7-

Page 9

Bag B

Tail Boom Bracket Assembly /

尾管固定座組裝

No.

1

BK2531

2

BK2532

3

BK2219

4

HMC3-20B

5

HMM3Z

6

BV2269

7

BK2268

8

BK2509

9

BV2265

HMC3-20B

SOCKET SCREW,M3x20

內六角螺絲,M3x20

HMM3Z

NYLON NUT,M3

止鬆螺帽,M3

BK2509

WASHER, d12xD14.5xW0.2

墊片, d12xD14.5xW0.2

TAIL BOOM BRACKET-L

TAIL BOOM BRACKET-R

FRAME SPACER

SOCKET SCREW, M3x20

NYLON NUT, M3

TAIL GEAR MOUNT SET

TAIL GEAR-B

WASHER, d12xD14.5xW0.2

BEARING BLOCK SET

名稱

尾管固定座(左)

尾管固定座(右)

六角連接支柱

內六角螺絲, M3x20

止鬆螺帽, M3

傘齒輪固定座組

傘齒輪B-25T

墊片, d12xD14.5xW0.2

軸傳軸承座組

QtyMaterial No. Description

1

1

4

3

6

1

1

2

2

Assemble the Tail Boom Bracket

as drawing. Secure the Screws

but do not tighten at this step.

參考圖示組裝尾管固定座,螺絲只需

稍事固定,暫無需鎖緊。

(9)

(14)

(11)

(13)

No.

10

11

12

13

14

15

16

17

BK2583

BK2267

BK2506

BK2554

BD7143

HMY2-12

BK0539-1

HMC3-25B

Description

TAIL DRIVE GEAR-22T

TAIL GEAR-A

TAIL DRIVE GEAR SHAFT

COLLAR

FIXED SCREW

PIN, d2x12

SERVO MOUNT

SOCKET SCREW, M3x25

Completed View

組裝完成

(1)

名稱

軸傳尾驅動輪-22T

傘齒輪 A-25T

軸傳驅動軸

軸套

傳動軸固定螺絲(長)

軸承滾針, d2x12

伺服機固定板

內六角螺絲, M3x25

QtyMaterial No.

1

1

1

1

1

1

1

3

BD7143

FIXED SCREW

傳動軸固定螺絲(長)

HMY2-12

PIN, d2x12

軸承滾針, d2x12

(15)

(8)

(6)

Check the mesh of Gears (#7&

#10) after this step accomplished,

if the mesh is too much play, please

add the Washers (#8) to eliminate

the play for a proper mesh.

完成尾管固定座組裝步驗後,請檢查齒

輪間隙 (#7& #10) ,若間隙過大,請

加裝所附墊片 (#8) 進行調整,以獲得

適當的齒輪間隙。

(12)

(7)

(5)

(5)

(10)

(9)

(2)

(5)

(3)

(4)

(3)

(16)

HMC3-25B

SOCKET SCREW,M3x25

內六角螺絲,M3x25

(17)

-8-

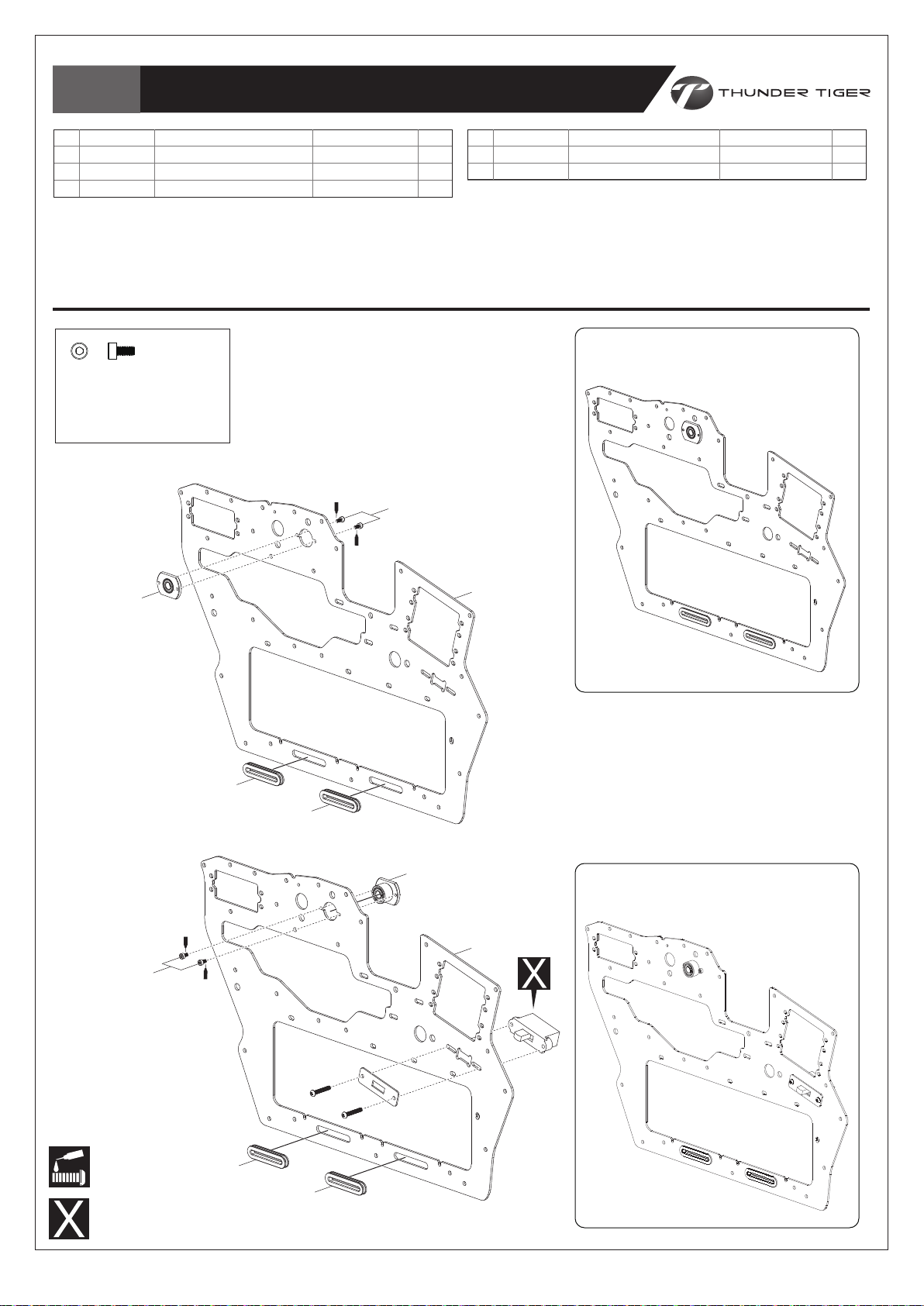

Page 10

Bag C+D

Main Frame /

本體組裝

No.

1

BK2255

2

HMC2-4B

3

BK2551

HMC2-4B

內六角螺絲,M2x4

SOCKET SCREW,M2x4

SIDE FRAME

SOCKET SCREW,M2x4

RUBBER GROMMETS

Left Frame / 左側板

名稱

機身側板

內六角螺絲,M2x4

橡膠墊圈

(2)

QtyMaterial No. Description

No.

4

2

4

4

5

BV2238

BV2237

ELEVATOR WASHER MOUNT SET(L)

ELEVATOR WASHER MOUNT SET(R)

名稱

升降舵墊片座組(左)

升降舵墊片座組(右)

QtyMaterial No. Description

1

1

Completed View

組裝完成

(4)

(3)

Right Frame / 右側板

(2)

(1)

(3)

(5)

Completed View

組裝完成

(1)

Apply threadlocker

使用螺絲防鬆膠

Must be purchased separately

改裝品需另購

(3)

(3)

-9-

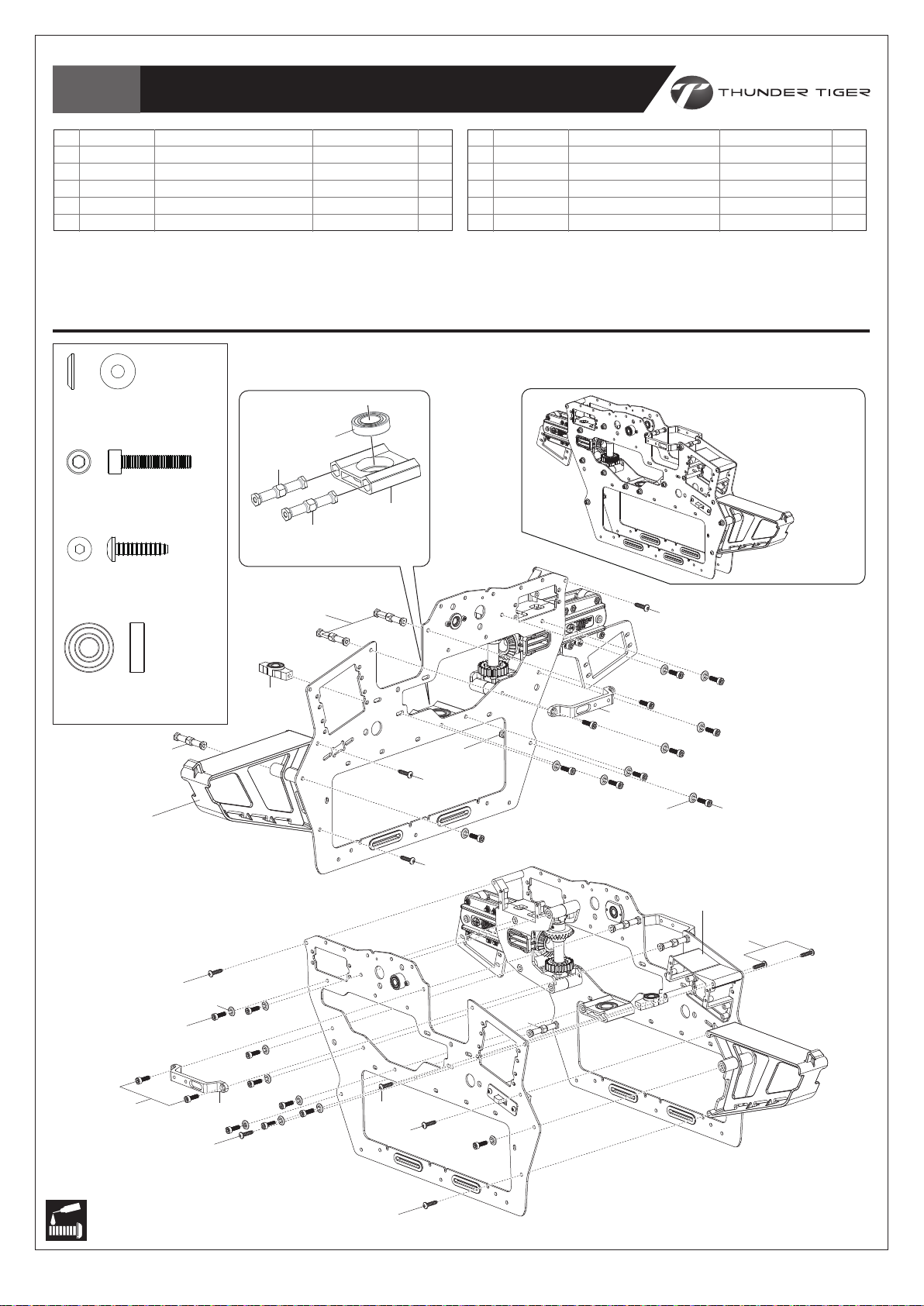

Page 11

Bag D

Main Frame / 本體組裝

No.

1

BK2225

2

HMV6800ZZY

3

BK2219

4

BV2262

5

BK2270

BK0087

WASHER,d3xD8xW1.4

墊片,d3xD8xW1.4

HMC3-10B

SOCKET SCREW,M3x10

內六角螺絲,M3x10

HNX3-12B

S.B.H SELF TAPPING SCREW

半圓頭內六角自攻螺絲

LOWER BRG

BEARING, d10xD19xW5

FRAME SPACER

LOWER MOTOR MOUNT SET

RECEIVER TRAY

名稱

下軸承座

滾珠軸承, d10xD19xW5

六角連接支柱

馬達下座組

接收機座

QtyMaterial No. Description

No.

6

1

1

6

1

1

BK2273

7

HNX3-12B

8

HMC3-10B

9

BK0087

10

BK2259

CONTROL ARM TRAY

S.B.H SELF TAPPING SCREW

SOCKET SCREW,M3x10

WASHER,d3xD8xW1.4

SERVO FRAME B

Secure all screws shown on this page with a drop of thredlocker

除螺絲#7之外,本頁顯示之螺絲請使用適量防鬆膠鎖固。

(2)

(3)

(1)

(3)

(3)

名稱

控制搖臂座

半圓頭內六角自攻螺絲

內六角螺絲, M3x10

墊片, d3xD8xW1.4

伺服機座B

except the screws #7.

Completed View

組裝完成

(7)

QtyMaterial No. Description

2

10

22

18

1

HMC6800ZZY

BEARING, d10xD19xW5

滾珠軸承, d10xD19xW5

(3)

(5)

(7)

(8)

(8)

(7)

(9)

(6)

(4)

(7)

(7)

(7)

(7)

(3)

(3)

(3)

(6)

(9)

(8)

(10)

(7)

Apply threadlocker

使用螺絲防鬆膠

(7)

-10-

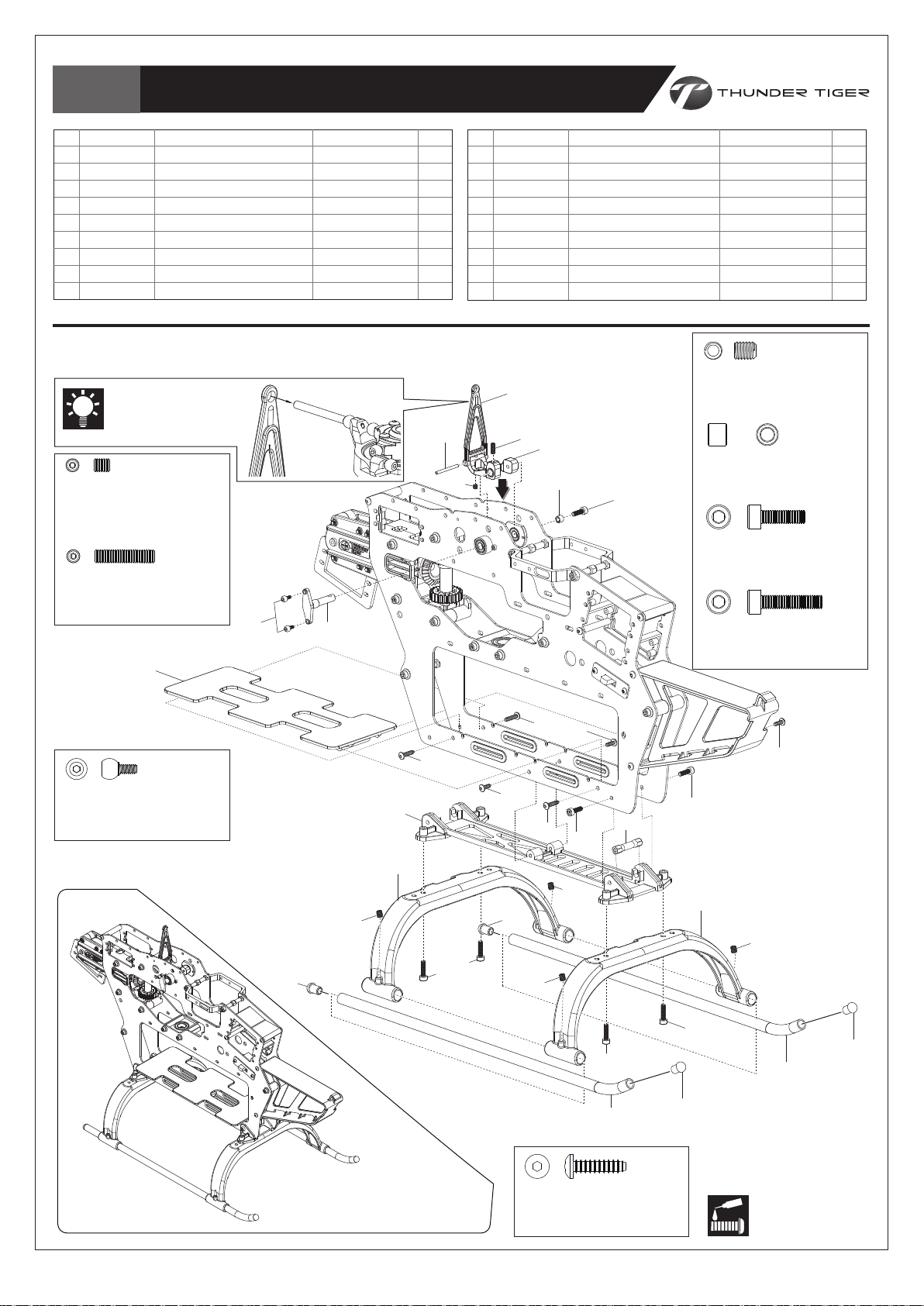

Page 12

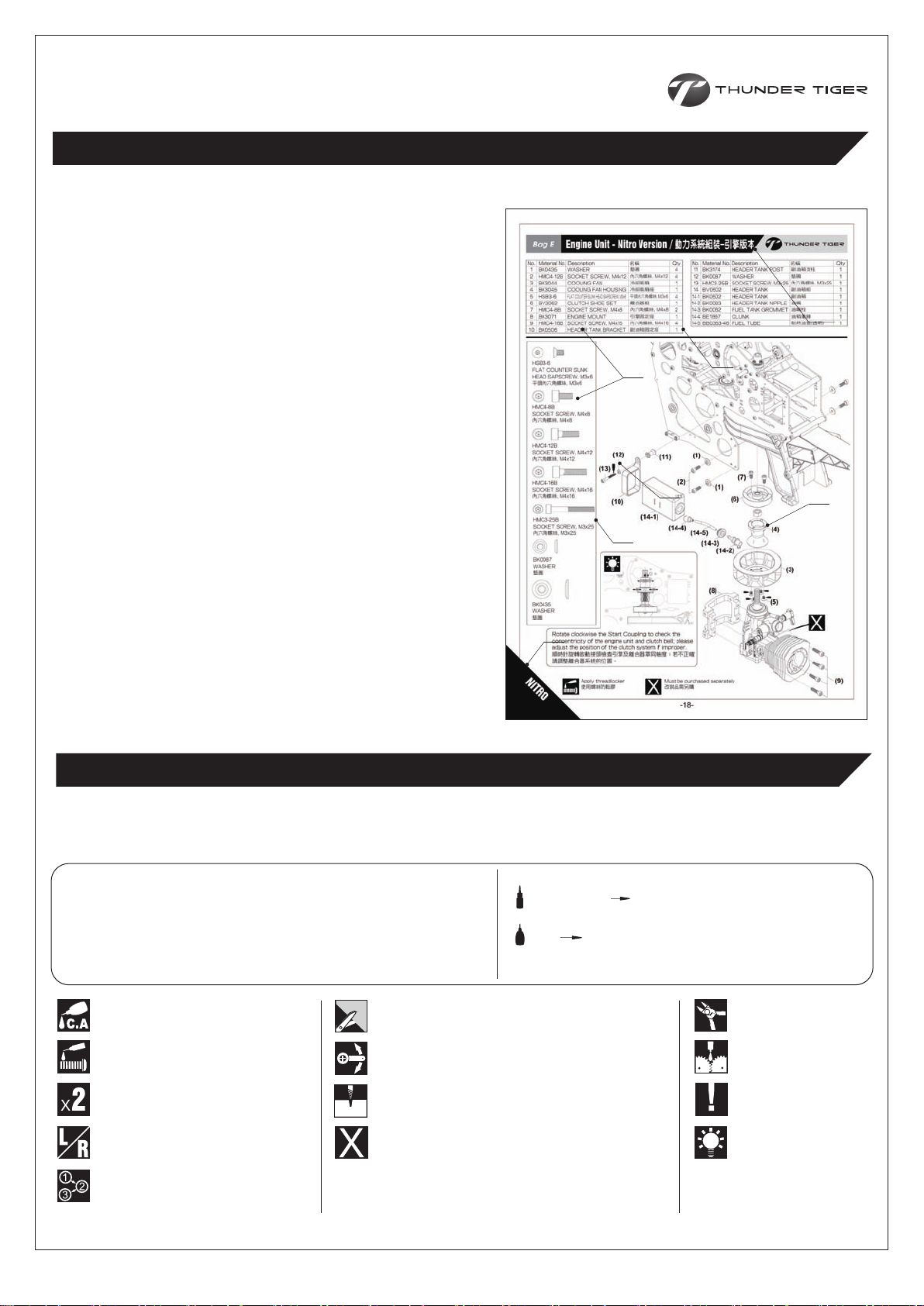

Bag E

Landing Skid /

腳架組組裝

No.

1

2

3

4

5

6

7

8

9

BK0023

BK0084

BK2514

HME3-3B

HME3-8B

BK2571

BK0649-1

BK2515

HMC3-10B

名稱

ELEVATOR CONTROL ARM LINK

PIN

,D2x22.8

METAL ELEVATOR CONTROL ARM

SET SCREW.M3x3

SET SCREW,M3x8

FL ELEVATOR LEVER ROD, 4757

LINKAGE BALL(A)

COLLAR,d3xD5xW4.2

SOCKET SCREW,M3x10

升降舵連接座

固定銷,D2x22.8

金屬升降舵控制臂

無頭內六角螺絲,M3x3

無頭內六角螺絲,M3x8

無平衡翼升降舵推拉桿, 4757

內六角連接頭螺絲(A)

控制臂軸環,d3xD5xW4.2

內六角螺絲,M3x10

QtyMaterial No. Description

No.

10

1

1

1

1

1

1

2

1

3

BK2261

11

BK0064T

12

BK0065

13

HME4-5B

14

HMC3-14B

15

BK2258

16

BK2274

17

BK2253

18

HNX3-12B

LANDING SKID

SKID PIPE

SKID PIPE END CAP

SET SCREW,M4x5

SOCKET SCREW,M3x14

BOTTOM FRAME

BATTERY TRAY

FRAME SPACER

S.B.H SELF TAPPING SCREW

Secure all screws shown on this page with a drop of thredlocker except the screws #13, 14 & 18.

除螺絲#13, 14及18之外,本頁顯示之螺絲請使用適量防鬆膠鎖固。

The larger hole goes toward

(1)

the swashplate.

較大孔面朝十字盤

HME3-3B

SET SCREW.M3x3

無頭內六角螺絲,M3x3

HME3-8B

SET SCREW,M3x8

無頭內六角螺絲,M3x8

(7)

(6)

(2)

(4)

(5)

(3)

(8)

(9)

(16)

名稱

腳架

底座圓管

圓管塞

無頭內六角螺絲,M4x5

內六角螺絲,M3x14

底盤

電池座

六角支柱

半圓頭內六角自攻螺絲

HME4-5B

SET SCREW,M4x5

無頭內六角螺絲,M4x5

BK2515

COLLAR,d3xD5xW4.2

控制臂軸環,d3xD5xW4.2

HMC3-10B

SOCKET SCREW,M3x10

內六角螺絲,M3x10

HMC3-14B

SOCKET SCREW,M3x14

內六角螺絲,M3x14

QtyMaterial No. Description

2

2

4

4

4

1

1

1

6

BK0649-1

LINKAGE BALL(A)

內六角連接頭螺絲(A)

(12)

(13)

(15)

(10)

(18)

(14)

(18)

(12)

(13)

(18)

(18)

(18)

(9)

(13)

(14)

(11)

(18)

(9)

(17)

(10)

(13)

(14)

(12)

(11)

(12)

Completed View

組裝完成

-11-

HNX3-12B

S.B.H SELF TAPPING SCREW

半圓頭內六角自攻螺絲

Apply threadlocker

使用螺絲防鬆膠

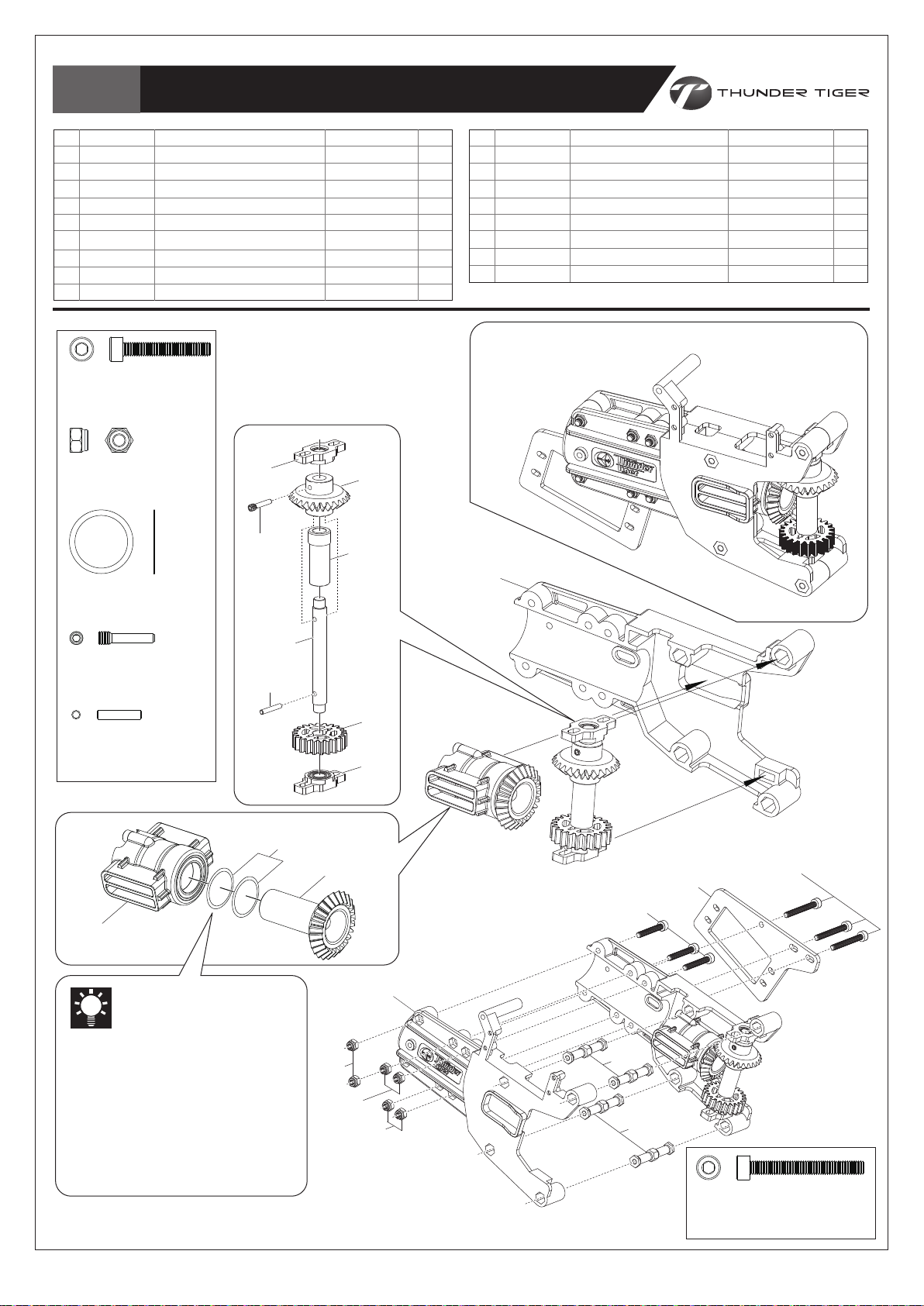

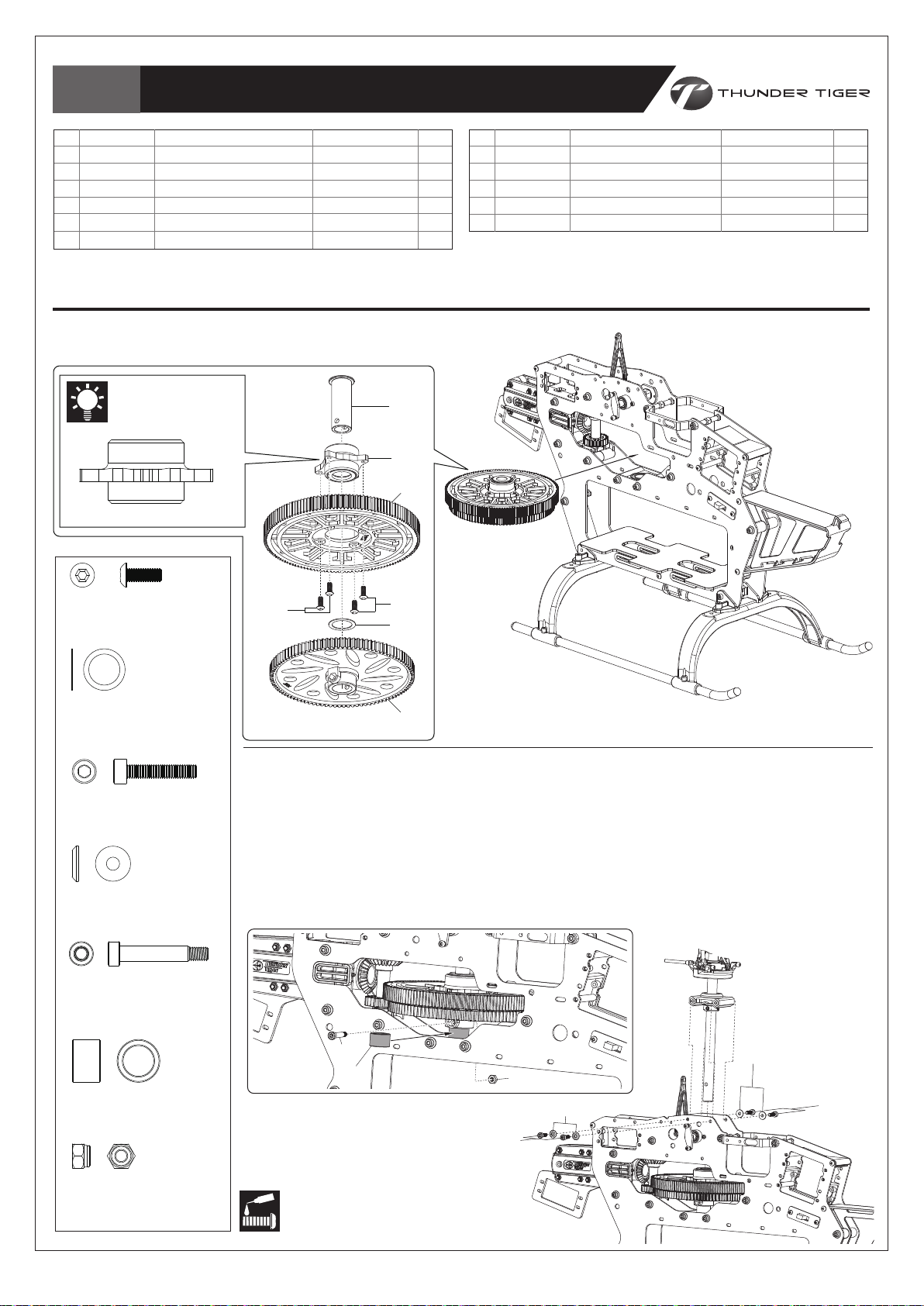

Page 13

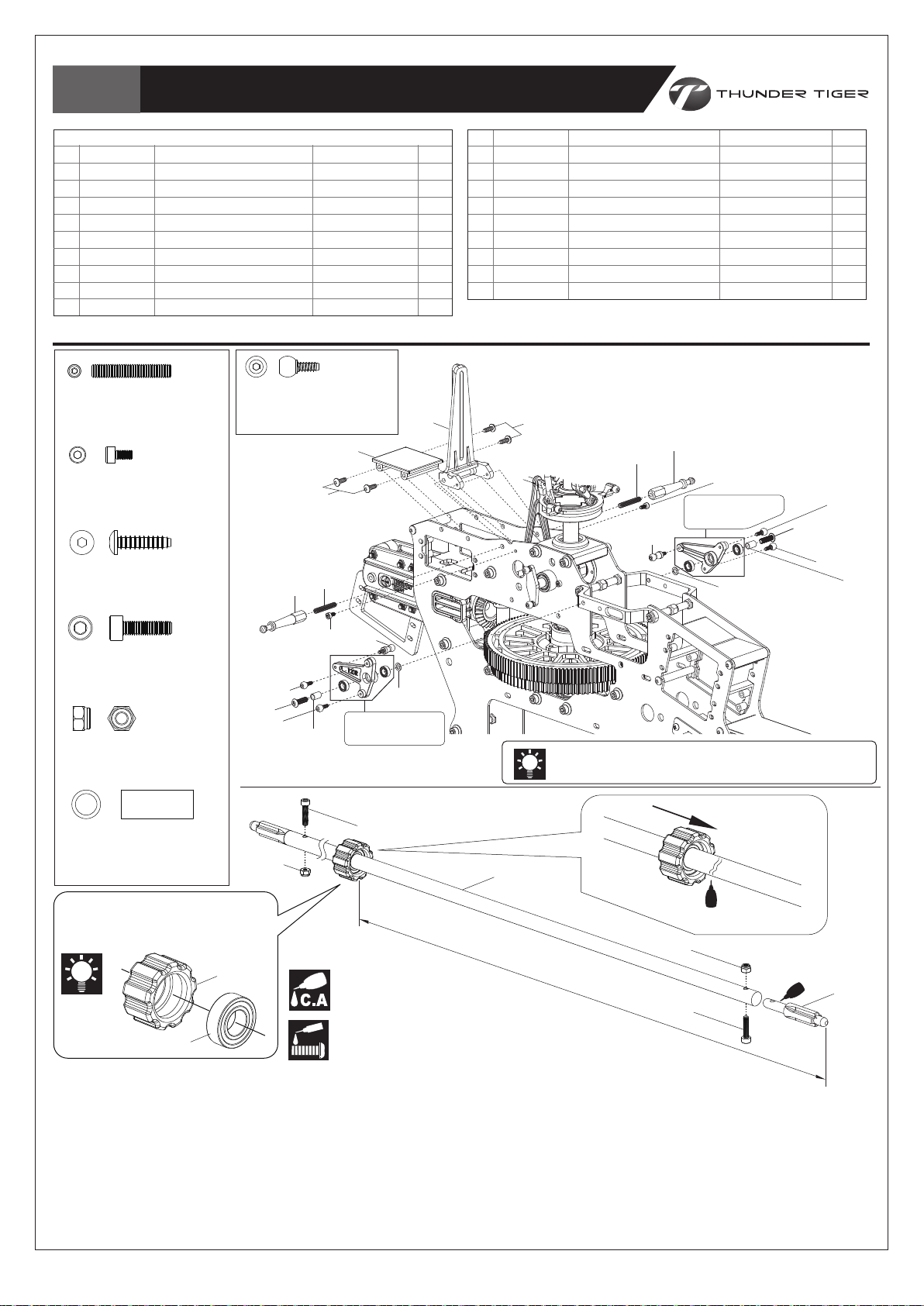

Bag F

Main Gear Set /

主齒輪組裝

No.

1

2

3

4

5

6

BK2282

BV2281

BK2581

HSA3-8

BK2524

BK2582

ONE WAY BEARING SHAFT

ONE WAY CLUTCH HOUSING

MAIN GEAR, 135T

BUTTON HEAD SOCKET SCREW,M3x8

MAIN GEAR WASHER

AUTOROTATION TAIL DRIVE PULLEY,100T

名稱

單向軸套

單向離合組

主齒輪, 135T

半圓頭內六角螺絲,M3x8

主齒輪墊片

軸傳尾驅動主齒,100T

QtyMaterial No. Description

No.

1

1

1

10

4

11

1

1

Secure all screws shown on this page with a drop of thredlocker.

本頁顯示之螺絲請使用適量防鬆膠鎖固。

Note the chamfer

should point up.

(1)

注意有倒角端朝上

(2)

(3)

BV2281

7

HMC3-10B

8

BK0087

9

BK1197

BK2290

HMM3Z

SOCKET SCREW,M3x10

WASHER,d3xD8xW1.4

MAIN SHAFT BOLT,M3x20

COLLAR

NYLON NUT,M3

名稱

內六角螺絲,M3x10

墊片,d3xD8xW1.4

內六角半牙螺絲,M3x20

軸環

止鬆螺帽,M3

QtyMaterial No. Description

4

4

1

1

1

HSA3-8

BUTTON HEAD SOCKET SCREW,M3x8

半圓頭內六角螺絲,M3x8

BK2524

MAIN GEAR WASHER,d14.2xD19xW0.5

主齒輪墊片,d14.2xD19xW0.5

1. Insert the Main Shaft into Main Gear Set, Main Gear Washer & Lower Bearing Block.

2. Line up the holes of the Autorotation Tail Drive Gear, One Way Bearing Shaft & Main

HMC3-10B

SOCKET SCREW,M3x10

內六角螺絲,M3x10

3. Adjust the position of Lock Ring to eliminate play of the Main Shaft, and then secure the

1. 將主軸依序穿過主齒輪組、主齒輪墊片及下軸承座。

BK0087

WASHER,d3xD8xW1.4

墊片,d3xD8xW1.4

BK1197

MAIN SHAFT BOLT,M3x20

內六角半牙螺絲,M3x20

2. 對正尾驅動齒、單向軸套及主軸上孔位後,穿入內六角螺絲並加上螺帽,並使用適量防鬆劑固定。

3. 調整止擋環位置以消除主軸間隙後,著以適量防鬆膠鎖固。

(4)

(4)

(5)

(6)

Shaft, and then insert the Socket Screw to fix them with a Nut. Add a drop of threadlocker

when securing, but do not over tighten.

set screws tightly with a drop of threadlock.

注意! 請勿過度緊迫螺絲。

BK2290

COLLAR,d10xD14xW9

軸環,d10xD14xW9

HMM3Z

NYLON NUT,M3

止鬆螺帽,M3

(9)

(10)

Apply threadlocker

使用螺絲防鬆膠

-12-

(7)

(11)

(8)

(8)

(7)

Page 14

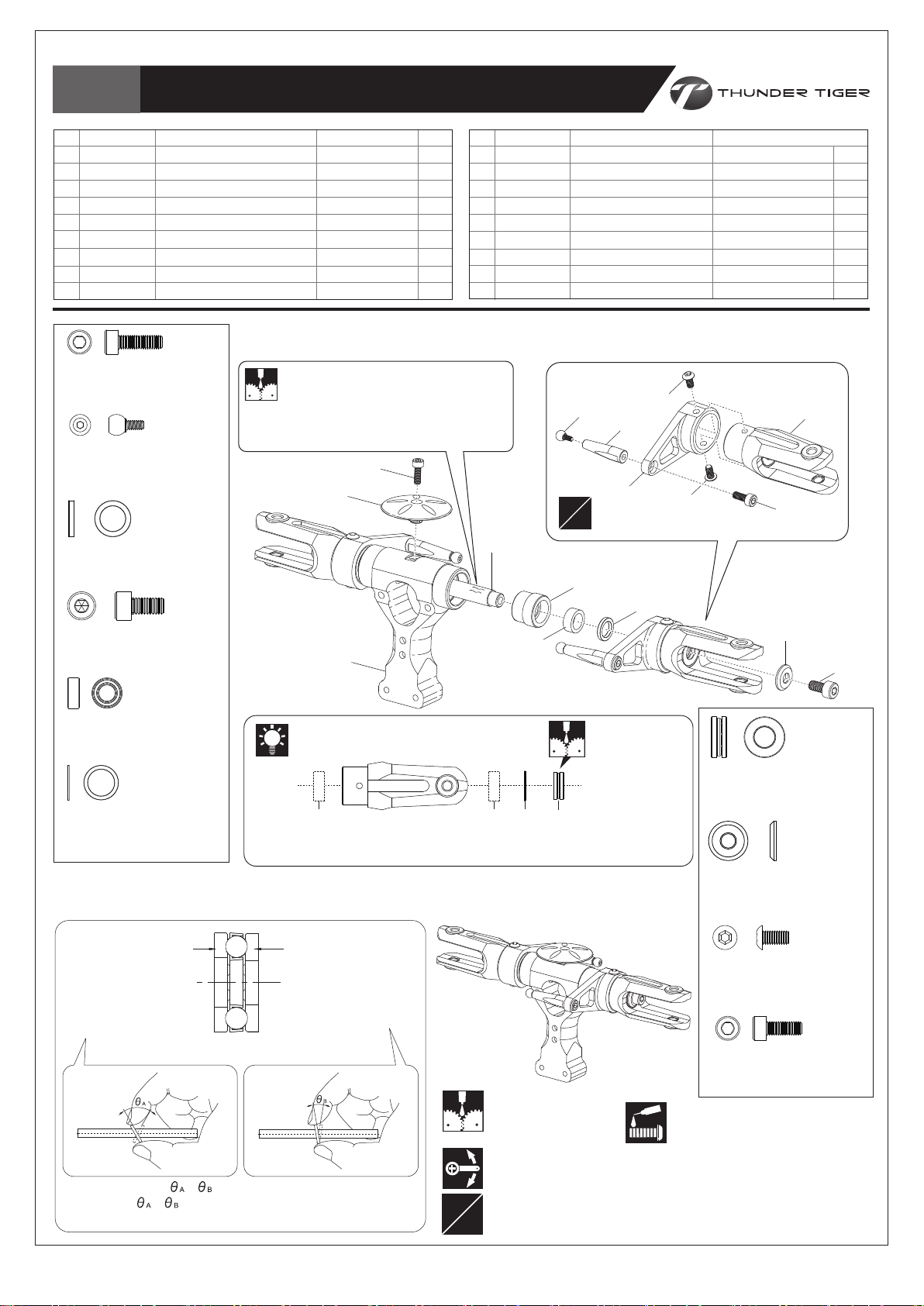

Bag F+I

Control Arm Set /

控制臂組裝

No.

1

BK2248

2

BK2249

3

HME3-18B

4

HMC2-4B

5

BK2271

6

HNX3-12B

7

BV2569-R

8

BV2570-L

9

BK2279

10

BK0649-1

HME3-18B

SET SCREW,M3x18

無頭內六角螺絲,M3x18

HMC2-4B

SOCKET SRCEW,M2x4

內六角螺絲,M2x4

HNX3-12B

S.B.H SELF TAPPING SCREW

半圓頭內六角自攻螺絲

PHASING CONTROL TRACK

CANOPY RETAINING POST

SET SCREW,M3x18

SOCKET SRCEW,M2x4

GYRO TRAY

S.B.H SELF TAPPING SCREW

120° FB CONTROL ARM SET-R, 4757

120° FB CONTROL ARM SET-L, 4757

HEX POST

LINKAGE BALL

名稱

相位控制導軌

機殼固定鋁柱

無頭內六角螺絲,M3x18

內六角螺絲,M2x4

陀螺儀座

半圓頭內六角自攻螺絲

120° 無平衡翼控制搖臂組(右), 4757

120° 無平衡翼控制搖臂組(左), 4757

內六角連接頭

內六角連接頭螺絲

BK0649-1

LINKAGE BALL

內六角連接頭螺絲

(5)

(6)

(3)

(2)

(1)

QtyMaterial No. Description

No.

11

1

2

2

2

1

4

1

1

2

4

BK0088

12

BK0077

13

HSA3-10

14

BK2552

15

BK0367

16

BK2529

17

HMV1680ZZY

18

HMC2512B

19

HMM25Z

WASHER, d3xD5xW0.5

COLLAR, d3xD4xW6

BUTTON HEAD SOCKET SCREW, M3x10

TAIL DRIVE SHAFT

TAIL DRIVE SHAFT LINKER

TAIL DRIVE SHAFT BRG

BEARING, d8xD16xW5

SOCKET SCREW,M3x12

NYLON NUT,M2.5

名稱

墊片, d3xD5xW0.5

軸環, d3xD4xW6

半圓頭內六角螺絲, M3x10

尾驅動軸

尾驅動連接棒

傳動軸軸承套

滾珠軸承, d8xD16xW5

內六角螺絲, M2.5x12

止鬆螺帽, M2.5

QtyMaterial No. Description

2

2

2

1

2

1

1

2

2

Secure all screws shown on this page with a drop of

thredlocker

除螺絲#4及6之外,

except the screws #4 and 6.

本頁顯示之螺絲請使用適量防鬆膠鎖固。

(6)

(2)

(3)

(4)

(9)

(8)

Left Side

左側

(10)

(13)

(10)

(12)

(11)

HMC3-12B

SOCKET SCREW,M3x12

內六角螺絲,M3x12

(13)

(10)

HMM25Z

NYLON NUT,M2.5

止鬆螺帽,M2.5

Tail

尾座

BK0077

COLLAR,d3xD4xW6

軸環,d3xD4xW6

(19)

The hole with a round chamfer

goes toward the tail。

有倒角的孔徑朝向尾座。

(16)

(17)

(10)

(9)

(4)

(7)

(12)

Apply C.A Glue

使用快乾膠黏合

Apply threadlocker

使用螺絲防鬆膠

(11)

Right Side

右側

(18)

Note the “120L”/”120R” mark on the arms.

請按照控制臂左、右方向安裝。

(14)

350mm / 13.78”

CA

(19)

CA

(15)

(18)

Nose

機頭

1. Attach the Bearing into the Rubber Bearing Support.

2. Screw the Shaft End onto the Tail Drive Shaft with a drop of threadlocker

as the drawing, but do not over tighten.

3. Add a drop of thin CA glue on the Tail Drive Shaft next to where the

bearing should be, and then slide the bearings over the position quickly;

the distance from the Shaft Drive End to the Rubber Shaft Bearing

Support is approx. 350mm / 13.78”.

4. Apply some amount of silicon oil or Vaseline onto the rubber surface for

easy install into the tail boom later.

-13-

1. 將軸承擠壓入橡膠軸套內。

2. 參考圖示,塗抹些許防鬆膠將尾傳動軸接頭

鎖在尾傳動軸,但勿過度鎖緊。

3. 在尾傳動軸上軸承固定位置前方,塗抹少量

快乾膠,迅速滑動軸承至定位固定;該定位

大約距離軸傳動接頭350mm / 13.78”處。

4. 塗抹些許矽膠油脂或凡士林於橡膠軸套表面

上,稍後將尾驅動軸組裝入尾管時,會較為

容易。

Page 15

Bag G

Tail Rotor System /

尾旋翼機構組裝

No.

1

BK0028

2

HMV1060ZZY

3

BK0027

4

BK0025

5

HMF2-8N

6

BK0075

7

BK2280

8

HME3-3B

9

BK2284

10

BK2580

HMF2-8N

PHILLIPS MACHINE SCREW,M2x8

圓頭十字螺絲(細),M2x8

HMC2-10B

SOCKET SCREW,M2×10

內六角螺絲,M2×10

HMC25-6B

SOCKET SCREW,M2.5×6

內六角螺絲,M2.5×6

HME3-3B

SET SCREW,M3x3

無頭內六角螺絲,M3x3

TAIL PITCH CONTROL SLIDER BUSHING

BEARING,d6xD10xW3

TAIL PITCH CONTROL SLIDER

TAIL PITCH CONTROL FORK

PHILLIPS MACHINE SCREW,M2x8

LINK BALL

TAIL ROTOR SHAFT

SET SCREW,M3x3

TAIL ROTOR HUB

METAL TAIL GRIP

名稱

尾旋翼控制軸套

滾珠軸承,d6xD10xW3

尾旋翼控制滑座

尾旋翼控制座

圓頭十字螺絲(細),M2x8

,

Ø

4.8

HMV940ZZY

BEARING,d4xD9xW4

滾珠軸承,d4xD9xW4

HMX0409Y

THRUST BEARING, d4xD9xW4

止推軸承,d4xD9xW4

連接頭

尾旋翼橫軸(軸傳)

無頭內六角螺絲,M3x3

尾旋翼T型座

金屬尾旋翼座

QtyMaterial No. Description

,

Ø

4.8

Secure all screws shown on this page with a drop of thredlocker

No.

11

1

2

1

1

1

1

1

2

1

2

HMV1050ZZWY

12

BK0082

13

HMC2-10B

14

BK0083

15

BK0026

16

HMC25-6B

17

HMO26

18

BK2276

19

HMV940ZZY

20

HMX0409Y

BEARING, d5xD10xW3

COLLAR, d2xD3xW4.2

SOCKET SCREW, M2×10

PIN, D2x8.8

TAIL PITCH CONTROL LINK

SOCKET SCREW, M2.5x6

WASHER, d2.8xD5xW0.5

WASHER, d4xD6xW0.5

BEARING, d4xD9xW4

THRUST BEARING, d4xD9xW4

名稱

滾珠軸承, d5xD10xW3

軸環, d2xD3xW4.2

內六角螺絲, M2×10

固定銷

, D2x8.8

尾旋翼連接頭

內六角螺絲, M2.5x6

墊片,d2.8xD5xW0.5

尾旋翼轉座墊片,d4xD6xW0.5

滾珠軸承,d4xD9xW4

止推軸承,d4xD9xW4

QtyMaterial No. Description

2

2

2

2

2

2

4

2

2

2

except the screws #5.

除螺絲#5之外,

本頁顯示之螺絲請使用適量防鬆膠鎖固。

1. Note the orientation of the Thrust Bearings; please

refer page 6, Diagram for Thrust Bearing Assembly.

2. Line up the concave of Tail Rotor Shaft and the hole

of Hub when securing the Tail Rotor Hub onto the Tail

Rotor Shaft.

3. Assemble the tail unit as drawing. Secure the screws

with a drop of threadlocking but not over tighten,

ensure the moveable parts run effortlessly.

1. 請參考第 6 頁止推軸承安裝示意圖,注意安裝方向性。

2. 將尾旋翼固定座鎖上尾旋翼主軸時,請注意軸上凹槽需對

正固定座上螺絲孔。

3. 依圖示順序組裝。使用適量防鬆劑固定,但請勿過度鎖緊

,確保每個可動機構皆作動順暢。

(8)

(9)

BK0083

PIN,D2x8.8

固定銷,D2x8.8

HMO26

WASHER,d2.8xD5xW0.5

墊片,d2.8xD5xW0.5

BK0082

COLLAR,d2xD3xW4.2

軸環,d2xD3xW4.2

BK2276

WASHER,d4xD6xW0.5

尾旋翼轉座墊片,d4xD6xW0.5

HMV1060ZZY

BEARING,d6xD10xW3

滾珠軸承,d6xD10xW3

HMV1050ZZWY

BEARING,d5xD10xW3

滾珠軸承,d5xD10xW3

(1)

(8)

(14)

(7)

(4)

(2)

(2)

(3)

(6)

(5)

Apply threadlocker

使用螺絲防鬆膠

Ensure smooth, non-binding movement when assembling

確認組件靈活度

(12)

(13)

(15)

(11)

(10)

(20)

(18)

(17)

Completed View

組裝完成

Apply grease

使用潤滑油膏(黃油)

(19)

(16)

-14-

Page 16

Bag H+I

Tail Rotor System /

尾旋翼機構組裝

No.

1

BK2594-1

2

BK2595-1

3

HMC25-8B

4

HMV1350ZZY

5

HMV6701ZZY

6

BK2291

7

BK0372

8

BK0373-2

9

BA1144-1

10

HMY2-10

11

BK2512

12

HMV740ZZY

13

BK0649-2

14

BK0077

HMC25-8B

SOCKET SCREW, M2.5x8

內六角螺, M2.5x8

HMC1350ZZY

BEARING, d5xD13xW4

滾珠軸承, d5xD13xW4

HMV6701ZZY

BEARING, d12xD18xW4

滾珠軸承, d12xD18xW4

BK2291

COLLAR, d15xD18x6.8L

軸環, d15xD18x6.8L

METAL TAIL UNIT HOUSING

METAL TAIL PITCH CONTROL HOUSING

SOCKET SCREW, M2.5x8

BEARING, d5xD13xW4

BEARING, d12xD18xW4

COLLAR, d15xD18x6.8L

TAIL INPUT GEAR

TAIL OUTPUT GEAR

WASHER, d5xD8xW0.15

PIN, d2x10

TAIL PITCH CONTROL LEVER

BEARING, d4xD7xW2.5

LINKAGE BALL(B)

COLLAR, d3xD4xW6

(19)

HMC3-10B

SOCKET SCREW, M3x10

內六角螺絲, M3x10

HME3-4B

SET SCREW,M3x4

無頭內六角螺絲,M3x4

Apply threadlocker

使用螺絲防鬆膠

名稱

金屬尾座

尾旋翼控制桿座

內六角螺絲, M2.5x8

滾珠軸承, d5xD13xW4

滾珠軸承, d12xD18xW4

軸環, d15xD18x6.8L

尾齒輪/INPUT-20T

尾齒輪/OUTPUT-20T

軸承墊片, d5xD8xW0.15

固定銷, d2x10

尾旋翼控制桿

滾珠軸承, d4xD7xW2.5

內六角連接頭自攻螺絲(B)

軸環, d3xD4xW6

BA1144-1

WASHER, d5xD8xW0.15

軸承墊片, d5xD8xW0.15

HMY2-10

PIN, d2x10

固定銷, d2x10

HMV740ZZY

BEARING, d4xD7xW2.5

滾珠軸承, d4xD7xW2.5

BK0649-2

LINKAGE BALL(B)

內六角連接頭自攻螺絲(B)

BK0077

COLLAR, d3xD4xW6

軸環, d3xD4xW6

(16)

(18)

(17)

(17)

(20)

(22)

HMC3-6B

SOCKET SCREW, M3x6

內六角螺絲, M3x6

QtyMaterial No. Description

No.

15

1

1

1

2

2

1

1

1

1

1

1

2

1

1

HMC3-10B

16

BK2190

17

HMC3-6B

18

BK2530

19

HMC3-8B

20

BK2556

21

BK2559

22

HNN2-6B

23

HMC3-16B

24

HMM3Z

25

BK0404-B

26

HME3-4B

27

BK0088

SOCKET SCREW, M3x10

CARBON VERTICAL FIN

SOCKET SCREW, M3x6

TAIL STOPPER

SOCKET SCREW, M3x8

CARBON TAIL BOOM

ROD GUIDE

TAPPING SCREW, M2×6

SOCKET SCREW, M3x16

NYLON NUT(M3)

TAIL BLADE(BLACK)

SET SCREW M3x4

WASHER, d3xD5xW0.5

名稱

內六角螺絲, M3x10

碳纖維垂直尾翼

內六角螺絲, M3x6

尾管止檔塊

內六角螺絲, M2x5

碳纖尾管

固定環

墊圈自攻螺絲, M2×6

內六角螺絲, M3x16

止鬆螺帽(M3)

尾旋翼(黑)

無頭內六角螺絲, M3x4

墊片, d3xD5xW0.5

Secure all screws shown on this page with a drop of thredlocker except the screws #13, 22 & 23.

除螺絲#13,22及23之外,本頁顯示之螺絲請使用適量防鬆膠鎖固。

(1)

(4)

(2)

(25)

(3)

(5)

(4)

(6)

(5)

(7)

(24)

(27)

(26)

(12)

(8)

(9)

(10)

(13)

(11)

(12)

(24)

(25)

(14)

Check the mesh of #7 & #8, please

add the Washers (#9) for a proper

mesh if too much play.

(15)

請檢查#7及#8的齒輪間隙,間隙過大時

請酌加墊片(#9)。

(21)

(21)

BK0088

WASHER,d3xD5xW0.5

墊片,d3xD5xW0.5

HMC3-8B

SOCKET SCREW, M3x8

內六角螺絲, M3x8

HNN2-6B

TAPPING SCREW(W/WASHER) M2×6

圓頭墊圈自攻螺絲

M2×6

(21)

(22)

HMC3-16B

SOCKET SCREW, M3x16

內六角螺絲, M3x16

(22)

Apply C.A Glue

使用快乾膠黏合

HMM3Z

NYLON NUT(M3)

止鬆螺帽(M3)

QtyMaterial No. Description

1

1

2

1

1

1

3

3

2

2

2

1

1

(23)

(23)

-15-

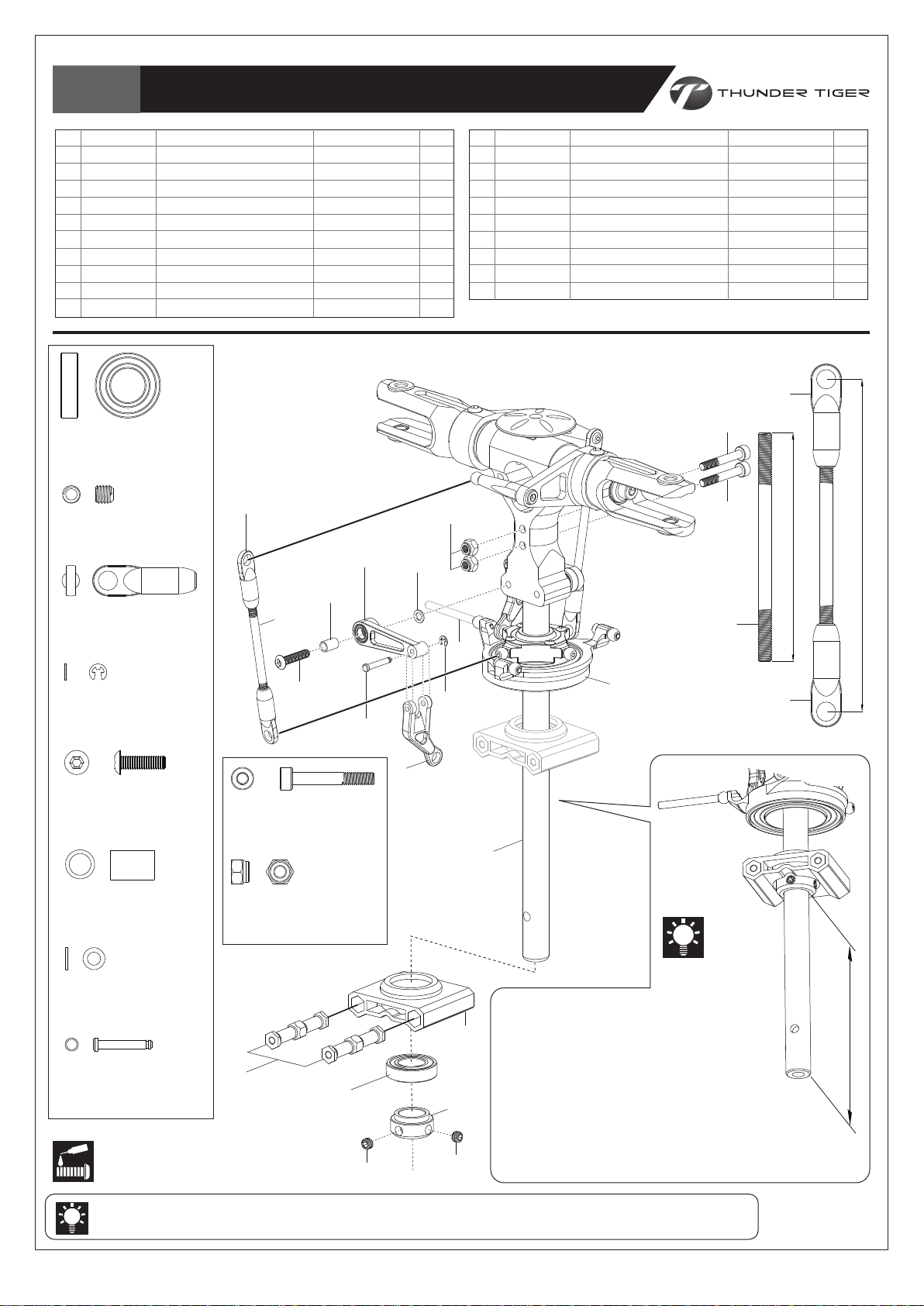

Page 17

Bag H+I

Tail Unit /

尾部總成組裝

No.

1

BK2253

2

HMC3-14B

3

HSA3-6

4

BK2563

5

BK2564

6

BK0524-T

7

BK0447

HMM3Z

NYLON NUT,M3

止鬆螺帽,M3

名稱

FRAME SPACER

SOCKET SCREW , M3x14

BUTTON HEAD SOCKET SCREW, M3X6

METAL TAIL SUPPORT BRACKET(UPPER)

METAL TAIL SUPPORT BRACKET(LOWER)

TAIL SUPPORT ROD

TAIL SUPPORT ROD END

六角支柱

內六角螺絲, M3x14

半圓頭內六角螺絲, M3x6

金屬固定座(上)

金屬固定座(下)

尾管支撐架

尾管支撐架接頭

(3)

(3)

(2)

QtyMaterial No. Description

No.

8

1

2

2

1

1

2

4

HMJ2-8N

9

HMC3-16B

10

HMM3Z

11

BK2553

12

HMC3-10B

13

HNJ-1

SELF TAPPING SCREW, M2x8

SOCKET SCREW, M3x16

NYLON NUT, M3

SUPPORT BRACKET

SOCKET SCREW, M3x10

NYLON STRAP,100mm

名稱

自攻螺絲(細), M2x8

內六角螺絲, M3x16

止鬆螺帽, M3

支撐架

內六角螺絲, M3x10

束帶(小)

Ensure the setting screws (#3) line up to the retaining hole.

鎖固時,請確認鎖固螺絲#3正確對正定位孔。

Stick some cycles of thin tape properly onto

the position where the Brackets clip to prevent

any indentation on the tail boom caused by

over tighten or vibration.

纏繞適當圈數薄膠帶於尾管固定座夾持位置上,可

避免因夾持過緊或機體震動而造成尾管上壓痕。

(9)

(4)

QtyMaterial No. Description

4

2

3

2

1

4

(2)

HMJ2-8N

SELF TAPPING SCREW-M2x8

自攻螺絲(細)-M2x8

HSA3-6

BUTTON HEAD SOCKET SCREW, M3X6

半圓頭內六角螺絲, M3x6

HMC3-14B

SOCKET SCREW,M3x14

內六角螺絲,M3x14

HMC3-16B

SOCKET SCREW,M3x16

內六角螺絲,M3x16

(1)

(7)

(8)

Rear View 後視圖

Secure the screws into the Frame

Spacer when attaching the Tail

Support Rod End on the Main Frames.

安裝尾管支撐桿於側板上時,請注意需將

鎖固螺絲鎖固於六角固定支柱上。

This hole (Left & Right side

both) is design for 140°Control

Arms(PV1409)

此孔位(左右二側)用於140°控

制搖臂(PV1409)

(8)

(6)

(7)

(7)(2) (1) (2)(7)

(5)

(10)

Apply threadlocker

使用螺絲防鬆膠

(13)

(13)

HMC3-10B

SOCKET SCREW,M3x10

內六角螺絲,M3x10

Must be purchased separately

改裝品需另購

(10)

(11)

(11)

(12)

-16-

Page 18

Bag J

Servo Installation / 伺服機裝配

No.

1

HSE2614N

2

BK0104

3

BK2205

HSE2614N

BUTTON PHILLIPS TAPPING SCREW, M2.6X14

扁圓自攻螺絲( 粗 )

HSE2620N

BUTTON PHILLIPS TAPPING SCREW, M2.6X20

扁圓自攻螺絲( 粗 )

BUTTON PHILLIPS TAPPING SCREW, M2.6X14

SERVO MOUNTING

SERVO BLOCK

, M2.6X14

, M2.6X20

The distance from the

center of the servo

horn to both sides of

the linkage balls should

be the same.

伺服機擺臂中心至兩邊球

頭距離必需相等。

名稱

扁圓自攻螺絲, M2.6x14

伺服機固定片

伺服機墊塊

QtyMaterial No. Description

No.

8

8

4

4

HSE2620N

5

BK3132

(2)

(3)

(2)

(1)

(2)

(4)

(2)

Attach the Servos onto the Servo Trays

of Main Frame Set as drawing.

參考圖示將伺服機裝入主側板組上伺服機座。

BUTTON PHILLIPS TAPPING SCREW, M2.6X20

SERVO NUT

(3)

名稱

扁圓自攻螺絲( 粗 )

伺服機螺帽

, M2.6X20

QtyMaterial No. Description

8

2

(2)

(2)

//

//

(1)

(5)

(5)

(3)

(2)

Must be purchased separately

改裝品需另購

(3)

(2)

(4)

-17-

Page 19

Bag I+J

Linkage Rod Installation / 連桿組裝

No.

1

BK0086

2

BK2555

3

BK0092

The length may vary when using different servo, please re-adjust the length as actual condition.

連桿長度可能因搭配伺服機品牌不同而有所差異,可依實際情況調整。

BK0086

BALL LINK, d4.8x20

單頭連接桿, d4.8x20

BALL LINK, d4.8x20

TAIL SERVO LINKAGE ROD, 580mm

LINKAGE ROD, 30mm

Assemble the Linkage Rods as drawings. The linkage length is measured by the center of

the 2 Ball Links. These drawings are printed actual size; you can lay the linkage sets on the

left drawings to measure the correct length.

請參考圖示組裝連桿及連桿頭。連桿長度距離的計算應以兩端連桿頭中心點為基準。圖示尺寸與實物

相同,您可直接對照左方圖示以快速獲得正確長度。

名稱

單頭連接桿

雙頭推拉桿, 580mm

連接桿, 30mm

, d4.8x20

QtyMaterial No. Description

18

No.

4

BK0436

5

1

2

BK0294

LINKAGE ROD, 55mm

LINKAGE ROD, 64mm

名稱

連接桿, 55mm

連接桿, 64mm

QtyMaterial No. Description

4

2

(D)

(A)

(1)

Scale=1:1 (unit:mm)

55

30

(B)

(2)

(A) x2

(1)

(3)

(B) x2

76.6

(4)

55

(C) x2

79.9

55

82.6

64

(4)

(D) x2

(C)

(5)

-18-

Page 20

Bag K

Power Motor Installation / 動力馬達安裝

No.

1

2

3

HMC3-10B

BK0087

BK2260

SOCKET SCREW,M3x10

WASHER,d3xD8xW1.4

UPPER MOTOR MOUNT

名稱

內六角螺絲, M3x10

墊片, d3xD8xW1.4

馬達上座

QtyMaterial No. Description

4

4

1

Secure all screws shown on this page with a drop of thredlocker.

本頁顯示之螺絲請使用適量防鬆膠鎖固。

(1)

(2)

(2)

(2)

(1)

HME4-3B

SET SCREW M4×3

無頭內六角螺絲

(2)

M4×3

Motor Recommended for Stock Gear Ratio:

使用原廠設定齒比時,馬達KV值建議:

Power動力

Gear Raito齒輪比

10S

12S

Gear Raito齒輪比

(135T/15T)

9

9

Applicable motor

適用馬達

600~680KV

520~580KV

No.

4

5

6

BK2584

HMC3-8B

HME4-3B

(4)

(3)

名稱

MOTOR PINION-15T

SOCKET SCREW,M3x8

SET SCREW M4×3

16.5mm

(6)

10S及12S動力設定;請注意實際搭配可能因馬達效率值

(6)

而有所不同。

Applicable to a 6 mm diameter as standard, and 25

mm long shaft & above is recommended; The

Motor Mount for both M4x30 mm and M3x25/ 30

mm bolt position

標準使用6 mm圓徑及建議長度25 mm以上軸心之馬達

。馬達螺絲鎖固位置可分別適用於M4x30 mm及M3x25/

(5)

30 mm規格。

馬達齒-15T

內六角螺絲, M3x8

無頭內六角螺絲, M4x3

The motor pinion comes with

the kit is 15T, which is

applicable both to 10S and

12S power. Note the actual

configuration may vary due to

the efficiency of motors.

套件內附15T馬達齒,可適用於

Add the Motor Mount Adaptor

when mounting if the shaft of the

motor features a stage.

當馬達主軸具有錐度時,請加裝馬達

固定座墊片。

BK2557

MOTOR MOUNT ADAPTOR

馬達固定座墊片

QtyMaterial No. Description

1

4

2

HMC3-8B

SOCKET SCREW,M3x8

內六角螺絲,M3x8

HMC3-10B

SOCKET SCREW,M3x10

內六角螺絲,M3x10

BK0087

WASHER,d3xD8xW1.4

墊片,d3xD8xW1.4

Must be purchased separately

改裝品需另購

1

Apply threadlocker

使用螺絲防鬆膠

2

Paper strip

紙片

For proper mesh, insert a paper strip

between the Pinion and Main Gear,

and then push the Motor/Main Gear

together. Remove the paper strip.

在驅動齒輪及主齒盤插入一紙片可取得兩者

間適當的間隙,完成後請記得抽出紙片。

Assemble in right order

依標示順序組裝

-19-

Page 21

Bag L

Electric Device Installation / 電子設備配置

No.

1

2

3

BK0102

BK2278

HNX3-12B

Li-po Battery

鋰聚合物電池

RUBBER GROMMET

CANOPY BRACKET

S.B.H SELF TAPPING SCREW

名稱

機身固定墊圈

機殼固定座

半圓頭內六角自攻螺絲

QtyMaterial No. Description

No.

2

1

2

4

BK2177A-G

5

BK1125

ABS CANOPY-GREEN

ZIP TIDE

名稱

ABS機殼-綠色

魔鬼束帶

QtyMaterial No. Description

1

2

Receiver / 接收機

Double Sided Tape / 雙面膠布

Battery Pack / 接收機電池

Double Sided Tape / 雙面膠布

HNX3-12B

S.B.H SELF TAPPING SCREW

半圓頭內六角自攻螺絲

(5)

(1)

(2)

(1)

Must be purchased separately

改裝品需另購

(4)

(3)

-20-

Page 22

Bag KPI

Main Rotor Blade / 主旋翼安裝

No.

1

HMC4-27B

2

HMM4Z

HMC4-27B

SOCKET SCREW,M4x27

內六角螺絲,M4x27

HMM4Z

NYLON NUT,M4

止鬆螺帽,M4

SOCKET SCREW,M4x27

NYLON NUT,M4

名稱

內六角螺絲, M4x27

止鬆螺帽, M4

1. You may need to adjust the linkage to ensure the blade tracking. Please refer

page 26, 〝Blade Tracking Adjustment.〞

2. Install the main blades with the Socket Screw (HMC4-27B). Do not over

tighten and ensure the blades run effortlessly.

3. For safety the rpm of using carbon blades should not exceed 2400.

1. 您可能必需調整相關的連桿來確保旋翼旋轉軌跡正常。請參閱第26頁〝主旋翼軌跡調

整〞說明。

2. 以內六角螺絲安裝上主旋翼。請勿過度鎖緊。

3. 安全起見,碳纖維主旋翼轉速請勿超過2400rpm。

QtyMaterial No. Description

2

2

(1)

(2)

(2)

Completed View

組裝完成

-21-

Page 23

Radio System Setup /

遙控系統設定

Warning! / 警告!

For safety, please ensure the motor has been deactivated and will not drive the main rotor head before

performing following setting processes. You may just unplug 2 of the wires from the motor and the ESC or move

the motor with pinion away from the main gear to avoid a rotating rotor head.

安全起見,執行下列設定程序時,請確認馬達不會驅動主旋翼頭。您可拔除馬達與速控器間任兩條連接線,或將馬達驅動齒

與主齒盤脫離。

Swashplate Type Setting / 十字盤模式設定

Before starting, make sure the following preparation is done.

1.

Set all trims, knobs, and switches to the neutral and zero position.

2. Reset the radio to its factory preset position.

3. Choose the 120°E-CCPM swashplate control mode.

Please refer your Transmitter manual to find a proper setting.

Electric Device Connection /

電子設備連接說明

開始設定之前,請先確認下列注意事項

1.

發射機上所有的調整旋鈕、機構均位於中立點。

2. 重新設定原廠內建數據。

3. 選擇E-CCPM 120°模式。

請參閱遙控器說明書,進行設定。

Nose / 機首方向

120°

120°

120°

E-CCPM system requires 3 channel for aileron, elevator and an AUX(for pitch). But people may get confused because

the 3 channels are not referred to any independent movement. They are operated together to carry out the rolling,

flipping and collective controlling. As a result, the following connecting manner is recommended.

The following chart is the E-CCPM connecting for your reference. Please also consult your radio instruction manual.

E-CCPM系統需要使用三個通路予副翼、升降舵、與螺距(使用AUX通道)。許多愛好者可能會對於此設定感到困惑,但是在混控

模式下,必須藉由三顆伺服機同時完成動作,因此建議依照下列說明完成伺服機與接收機連結。

下列圖示為安裝範例,實際接線方式,請參照您的遙控器使用說明書。

ACE RC / FUTABA / HITEC Radio SysymJR Radio Sysym

AUX1 (CH6) / CH2* CH6 / CH1* CH1 / CH6*CH2 / AUX1 (CH6)*

*CH2 & Aux1(CH6) are

Interchangeable

*CH2 & Aux1(CH6) 可互換

*CH1 & CH6 are

Interchangeable

*CH1 & CH6 可互換

Pitch

螺距

Aileron

左右/副翼

CH3

CH4

AUX 1

AUX 2

Batt

7 channel receiver

七動作接收器

CH2

CH1

CH3

CH2

CH3

CH2

CH1

Aileron

左右/副翼

ESC

速控器

Elevator

前後/升降舵

Gyro Gain Wire Gyro Gain Wire

Batteay of receiver 4.8-5.8V

接收器電池 4.8-5.8V

Rudder

尾舵

Gyro

陀螺儀

Pitch

螺距

Elevator

前後/升降舵

CH4

CH5

CH6

AUX 1

(Batt)

7 channel receiver

七動作接收器

-22-

ESC

速控器

陀螺儀訊號線

Batteay of receiver 4.8-5.8V

接收器電池 4.8-5.8V

Rudder

尾舵

Gyro

陀螺儀

Page 24

Index of Linkage Length /

76 mm / 2.992”

55 mm / 2.1655”

76.6 mm / 3.015”

79.9 mm / 3.145”82.6 mm / 3.252”

連桿長度索引

Swashplate & Servo Movement Setting / 十字盤及伺服機動作設定

As going through these setup procedures, ensure there is none of the controls bind at full travel.

Next, please refer below illustrations to ensure the direction of servo movement and swash mixing settings are correct

for the controls properly.

在繼續設定之前,請先確認伺服機及連桿作動皆順暢可達最大作動量。

然後,請參考下表圖示,確認伺服機動作及十字盤混控設定可正確對應撥桿動作。

Aileron

副翼

Elevator

升降舵

Pitch

螺距

Model 1 Model 2

Servo Horn movement

伺服機擺臂動作

Right Side/右側

Right Side/右側

Right Side/右側 Right Side/右側

Left Side/左側

Right Side/右側

Check Point

機構動作確認

Front View / 前視圖

Right View / 右視圖

Front View / 前視圖

Right Side/右側

Rudder

尾舵

If the movements of servos or swashplate are not correct, please adjust the servo reverse settings for one or more

channels in your Transmitter.

若伺服機或十字盤作動方向不正確,請調整您遙控器上個別的伺服機逆轉功能。

-23-

Page 25

Tail Control and Gyro Setup 尾舵控制及陀螺儀控制

It is recommended to use a Heading Lock Gyro. With a Heading Lock Gyro, you may not use the trim and the revolution

mixing function of tail control.

First, choose the length of the tail servo arm referring to the manual of the Gyro. You may try 13.5mm as the starting

setting. Then mount the servo arm for the moment and check the movement of the tail servo:

1. While giving the right rudder control, the servo arm should move toward the nose of helicopter.

2. Rotate the helicopter with your hand counterclockwise, the servo arm should move toward the nose of helicopter.

建議搭配鎖頭式陀螺儀,可使您無需額外設定微調及混控功能來控制尾舵 。

首先,參考陀螺儀說明書來選用尾舵伺服機擺臂長度,建議初始可先設定為13.5mm。暫將伺服機擺臂固定後進行尾舵伺服機作動確

認:

1. 當執行右舵時,伺服機擺臂應朝機頭方向作動。

2. 將整台直昇機逆時針旋轉時,伺服機擺臂應朝機頭方向作動。

Rudder Servo

尾舵伺服機

After ensuring the moving direction of tail servo, you have to mount the servo arm in the correct position. Please reset

the receiver power and do not move the helicopter. While the tail control stick and trim are centered, mount the servo

arm vertically. If you cannot mount the servo arm vertically, please try another servo arm. Next, two points may be your

concern:

1. The traveling limit of the rudder servo may not go beyond the mechanical movement.

2. The rudder servo arm should be vertical while the tail rotor are at 0 pitch or with a little offset to the right. (Referring

to the photo below)

確認尾舵伺服機動作正確後,即可將伺服機擺臂確實安裝固定;請勿移動直昇機並重新啟動接收機電源。

當尾舵撥桿與微調置中時,將伺服機擺臂垂直尾管安裝固定。若無法正確垂直,請更換合適的擺臂。接著,請特別注意下列兩者:

1. 尾舵伺服機最大行程量切勿大於機械行程量。

2. 當尾旋翼螺距為0或稍偏向右時,尾舵伺服機擺臂應在垂直位置。(請對照下圖)

Rudder Servo

尾舵伺服機

90°

Note1: To find the traveling limit, you have to adjust the Gyro referring to its manual.

Note2: To adjust the pirouetting speed of the helicopter, please use the "Travel Adjustment" or the "D/R & EXP" function

of your transmitter.

說明1:請參考陀螺儀說明書調整陀螺儀以確認伺服機最大行程量。

說明2:調整尾舵自旋速度,請設定發射機上“行程設定(Travel Adjustment )”或“大小動(D/R)、指數值(EXP)”功能。

-24-

Page 26

Setting Up Data for Your Reference 參數設定參考

The following is the setting up data of pitch curve and throttle curve for your reference only. Please ask experienced

pilot to help you if you have never done this before.

下列參數設定僅供參考,請依實際狀況進行調整,或詢求有經驗的玩家協助。

■ Beginner / 一般飛行

Throttle Curve 油門曲線

Thro.

油門

100

75

50

25

0 25

50 75 100 Stick

Pitch Curve 螺距曲線

Pitch

螺距

100

75

50

25

撥桿

0 25 50 75 100 Stick

■ 3D

Throttle Curve 油門曲線

Thro.

油門

100

75

50

25

0 25

◎ Normal / 一般飛行 ◎ Idle / 特技模式 1

50 75 100 Stick

撥桿

100

75

50

25

0 25

Thro.

油門

撥桿

50 75 100 Stick

撥桿

Throttle Curve 油門曲線

00253550507565100

Normal 一般飛行

Pitch Curve 螺距曲線

03525-507075-100

Normal 一般飛行

Pitch Curve 螺距曲線

0

Normal 一般飛行

-4°25-

Throttle Curve 油門曲線

0

25

0

Normal 一般飛行

Idle-up 1 特技模式 1

35

100

Pitch Curve 螺距曲線

0

25

Normal 一般飛行

Idle-up 1 特技模式 1

Hold 鎖定模式

35

0

0

-

-

-

-

50

+6°75-

50

50

60

50

70

-

-

75

65

75

-

-

-

-

100

85

100

+10°

100

100

100

100

85

100

100

Pitch Curve 螺距曲線

Pitch

螺距

100

75

50

25

0 25

50 75 100 Stick

◎ Normal / 一般飛行

Pitch

螺距

◎ Hold / 鎖定模式

100

75

50

25

撥桿

0 25

◎ Idle / 特技模式 1

Pitch Curve 螺距曲線

Pitch

螺距

50 75 100 Stick

撥桿

Normal 一般飛行

Idle-up 1 特技模式 1

Hold 鎖定模式

0

-4°

-15°

-15°

25

50

75

100

-

+6°

-

+10°

-

-

-

+15°

-

-

-

+15°

WARNING 警告

1. Too much collective pitch will bring about too much loading to the motor

and drive system.

2. Too much headspeed will lead to blades (grips) explosion.

3. It's very dangerous for setting the headspeed over the blades (grips) limit.

4. Please do not set the collective pitch to the maximam (±15) unless you

have very good collective pitch management skill.

1.過大的聚合螺距設定會使動力及傳動系統超載。

2.過快的主旋翼轉速會造成主旋翼轉座崩裂或射槳。

3.將旋翼轉速設定超過槳片負載極限極端危險!

4.請勿將聚合螺距設定超過最大值(+15度角)。

-25-

Page 27

Blade Tracking Adjustment / 主旋翼軌跡調整

CAUTION / 警告

For safety, ensure to keep a safe distance from the helicopter at least 10 meter (30 feet) while making tracking

adjustment.

安全起見,進行主旋翼軌跡調整時,請至少與直昇機保持10米(30呎)的安全距離。

color tape / 色標貼

Out of Track / 雙槳

Adjustment is

necessary.

需要調整

1. Use a color tape at the tip of main

blades for tracking identification easily.

2. Increase the main blade speed to just

before the helicopter lifts-off.

3. Observe which blade appears to be

lower than the other, and increase the

pitch of the lower blade one turn of the

Linkage Rod A (refer Page 7) at a time

until each blade runs in track. If both

main blades rotate in the same path, it

doesn,t need to be adjusted.

1. 在主旋翼前端貼上色標可方便辨識軌跡。

2. 提高主旋翼轉速使機體稍懸浮於地面。

3. 觀察兩支旋翼軌跡是否有落差(雙槳),調

整軌跡較低旋翼上的連桿A (參閱第7頁) 長

度,一次調整一圈,直至兩支旋翼軌跡一致

。若軌跡一致則無需調整。

color tape / 色標貼

In Track / 軌跡正確

Adjustment is

unnecessary.

不需要調整

A

Linkage Rod A

(refer Page 7)

連桿A (參閱第7頁)

CAUTION / 警告

Out of track causes vibration, instability and a loss of power due to additional drag. Please adjust the tracking

repeatedly until the blades are in track properly.

旋翼軌跡落差(雙槳)會造成直昇機震動、不平衡及損失動力。請務必進行調整以使旋翼軌跡精準正確。

-26-

Page 28

Cautions of Li-Po Battery Pack Using / 鋰聚電池使用注意事項

Lithium Polymer (Li-Po) battery is volatile. Failure to read and follow the safety instructions or the instruction manual

offered by manufacturers may result in fire, personal injury and damage to property if charged or used improperly.

Please READ your Li-Po battery manual thoroughly before using. Some precaution and information for your reference

below:

1. ONLY use a charger specifically designed for Li-Po battery packs to charge/discharge your Li-Po battery packs.

Failure to use an improper charger may cause a fire, which may result in personal injury and property damage.

2.

A parallel charging process is strongly recommended, otherwise, the balancer is necessary if using a serial charging process.

3.

Gernally DO NOT over charge the battery over the maximum voltage of 4.2V/per cell and over discharge drop below 3.0V/per cell.

4. Always keep the voltage of every cell at 3.8V if the pack will be stored for a long term.

5. Always avoid any puncture of the battery pack at all times.

Neither Thunder Tiger nor our distributoers/retailers assume liability for failures to comply with these cautions, safety

recommended and instruction manual. Users assume all risks associated with Li-Po battery packs.

鋰聚電池具有相當之危險性。疏於詳閱以下注意事項及電池廠商所提供的說明書,或未依據正確操作方式使用,可能會引發火災、

人身傷害及財產損失。

請務必在使用前詳閱並遵守使用說明。以下注意事項及訊息提供您參考:

1. 請務必使用鋰聚電池專用充電器充/放電鋰聚電池組。使用不正確的充電器可能會引發火災、人身傷害及財產損失。

2. 強烈建議使用平行充電式的充電器充電。若使用串充方式請務必加裝平衡器。

3. 請勿過度充電使電壓超過4.2伏特/單一電池蕊,或過度放電使電壓低於3.0伏特/單一電池蕊。

4. 如需長期儲存電池,請保持單一電池蕊電壓在3.8伏特。

5. 任何情況下,皆勿擠壓電池。

雷虎科技或授權經銷商/模型店對未依照正確方式使用或安並規定之意外具免責條款,使用人應自負使用鋰聚電池所可能衍生的風險。

After Flight Checklist /

(1) Check every screw and bolt to make sure none has loosened due to vibration.

(2) Check every rotating and movable part to ensure they still move smoothly and normally.

(3) Clean off the exhaust residue from the muffler, motor, and helicopter.

(4) Check all movable parts, such as gears, ball links, etc. for unusual wear.

(1) 每次飛行後必須詳細的檢查機體的各部位螺絲有無鬆動情形,若發生鬆動必須確實鎖緊再進行下飛行。

(2) 每次飛行後檢查每一個轉動部位(含單頭連接桿)均能順暢的運作。

(3) 排氣管、馬達、直昇機本體必須確實的清潔。

(4) 檢查每一個動作部位,齒輪、球頭等是否有不正常磨損。

Regular Maintenance /

Warning! / 警告!

Lack for regular maintenance or apply a wrong type of grease/oil onto the parts may cause damage and model

crash, which may cause series injury or death if the model hits people or property.

疏於定期保養,或塗抹不正確類型的潤滑油皆可能損壞零件造成摔機,因而導致人員受傷或財產損失。

For safety, to check and maintain the parts every 5~10 flights is strongly recommended. Please re-apply the proper

grease or oil onto the bevel bears and bearings as the illustrations.

強烈建議您每飛行5~10趟需執行下列定期保養事項。 請依圖示說明重新在傘齒及軸承上塗抹潤滑油。

飛行後的檢查項目

定期保養事項

PV0269

Grease for Plastic Parts

塑膠零件用潤滑油

PV0269

Grease for Plastic Parts

塑膠零件用潤滑油

-27-

PV0270

Grease for Bearings

金屬軸承用潤滑油

Page 29

PARTS LIST SECTION / 零件包目錄

SPARE PARTS / 維修零件包

PV0035-2

LANDING SKID SET

腳架組

PV0052

TAIL SLIDER BRG, d6xD10xW3

軸承組, d6xD10xW3

PV0062

RUBBER GROMMETS(WHITE)

機身固定墊圈組

PV0035-3

LANDING SKID

腳架

PV0053

ROTOR BOLT

主旋翼螺絲組

M2x6, M2x8

M2x10, M2x14

M2x22, M2x6

M2x10, M2.6x12

M3x12, M3x18

M3x5

PV0088

SCREW BAG(6 PCS EACH)

圓頭十字螺絲組

PV0041

BALL LINK

單頭連接桿

PV0054

SERVO MOUNTING PLATE

伺服機固定片組

M3x10, M3x12

M3x14, M3x20

M3x25, M3x32

M3x8

M3x20

M3x10, M3x18

M4x5

PV0089

SCREW BAG(6 PCS EACH)

內六角螺絲組

PV0050

BEARING SET, d5xD13xW4

軸承組, d5xD13xW4

PV0058

LINKAGE BALL

連接頭

PV0115-1

WASHOUT LINKAGE

連接座

PV0051

LEAVER BRG, d4xD7xW2.5

軸承組, d4xD7xW2.5

PV0060

INSTALLATION SET

組合附件包

PV0149-1

TAIL GEAR,X50

尾齒輪,X50

PV0197

B

ALL BEARING, d12xD18XW4

滾珠軸承組, d12xD18xW4

PV0365

THRUST BRG. d6xD12xW4.5

止推軸承組 d6xD12xW4.5

PV0665

ELEVATOR A ARM

升降舵A臂

PV0244

BALL BEARING, d10xD19XW5

滾珠軸承組, d10xD19XW5

PV0407

TAIL PITCH SLIDER

尾旋翼滑座

PV0678-1

CARBON VERTICAL FIN

碳纖維垂直安定面

(20)

PV0261

SELFTAPPING SCREW (M2.6x14 )

扁圓型自攻螺絲組

PV0454

SKID PIPE END CAP

圓管塞

PV0679-T

TAIL SUPPORT

尾管支撐架組

(M2.6x14 )

PV0268

LOCTITE #262

高強度防鬆劑(紅)

PV0504

TAIL PITCH SLIDER SET

尾旋翼滑座組

PV0681

MAIN HUB BOLT

主旋翼頭固定螺絲

PV0270

THRUST BEARING GREASE

止推軸承潤滑脂

PV0523-1

CARBON TAIL BOOM

碳纖維尾管

PV0682

MAIN SHAFT BOLT

主軸齒輪固定螺絲

-28-

Page 30

SPARE PARTS / 維修零件包

(20)

PV0769

THRUST BEARING, d4xD9xW4

止推軸承組, d4xD9xW4

PV1314-1

METAL ELEVATOR WASHER MOUNT SET(L)

金屬升降舵墊片座組(左)

PV1318

TAIL BLADE SET (BLACK)

尾旋翼組(黑)

PV0771

BEARING, d4xD9xW4

滾珠軸承組, d4xD9xW4

PV1314-2

METAL ELEVATOR WASHER MOUNT SET(R)

金屬升降舵墊片座組(右)

PV1323

METAL HEAD BUTTON

金屬旋翼頭制動器

PV0234

NUT, M2

六角螺帽,M2

PV1315

MAIN SHAFT LOCK RING

主軸止檔圈

PV1326

METAL SWASHPLATE SET

金屬十字盤組

PV1310-1

CANOPY BRACKET

機殼固定座

PV1316

ONE WAY CLUTCH HOUSING

單向離合器組

PV1327

SWASHPLATE CONTROL ROD

十字盤穩定桿

PV1314

ELEVATOR ARM SET

升降舵控制組

PV1317

CYCLIC SERVO TRAY

循環螺距伺服機座

PV1330

METAL TAIL ROTOR HUB

金屬尾旋翼固定座

PV1331-1

METAL TAIL GRIP,X50

金屬尾旋翼座(軸傳),X50

PV1341-1

MAIN GEAR COLLAR-X50

主齒輪組軸環-X50

(12) (6) (6)

(12)

(6)

(6)

PV1357

SCREW BAG

螺絲零件包

(6) (6)

PV1335

MAIN SHAFT BEARING BLOCK

主軸上下軸承座

PV1342

ONE WAY CLUTCH SHAFT

單向離合器軸組

PV1358

FRAME SPACER

六角連接支柱

PV1339

OUTER DAMPER(7mm)

外避震墊圈(7mm)

PV1345

PHASING CONTROL TRACK

相位控制導軌

PV1361

SPINDLE(7mm) SET, X50

固定軸(7mm)組,X50

-29-

PV1339-1

INNER DAMPER(7mm)

內避震墊圈(7mm)

PV1346

CANOPY RETAINING POST

機殼固定鋁柱

PV1362

SPINDLE(7mm) BRG. SET d7xD13xW5

固定軸(7mm)軸承組,d7xD13xW5

PV1340

MAIN GEAR WASHER

主齒輪墊片

PV1356

BLADE SUPPORT

主旋翼固定架

PV1363

TAIL GRIP BAG, d7xD10xW3

尾旋翼座軸承組

, d7xD10xW3

Page 31

SPARE PARTS / 維修零件包

PV1366

TAIL GEAR MOUNT SET

傘齒輪固定座

PV1376

TAIL DRIVE SHAFT BRG SET

傳動軸軸承套組

PV1389

Tail Boom Bracket

尾管固定座

PV1367

TAIL PITCH CONTROL LEVER SET

尾旋翼控制桿組

PV1377

ROD GUIDE

固定環

PV1390

Tail Drive Gear Shaft

軸傳驅動軸

PV1368

BEARING BLOCK SET

軸傳軸承座組

PV1378

TAIL ROTOR SHAFT

尾旋翼橫軸組(軸傳)

PV1391

Front Tail Drive Gear Set 22T

軸傳尾驅動輪-22T

PV1371

TAIL GEAR SET

傘齒輪-25T

(10)(10)

PV1379

LINKAGE BALL SCREW SET

球頭螺絲組

PV1392

METAL MOTOR MOUNT

金屬馬達固定座

PV1375

TAIL DRIVE SHAFT SET

尾驅動軸組

PV1388

Hardened Main Shaft

主軸

PV1393

METAL MOTOR PINION BLOCK

金屬馬達齒輪固定座

PV1394

MOTOR PINION 15T

馬達齒-15T

PV1399

GYRO TRAY & SERVO MOUNTING

陀螺儀座及墊塊組

PV1420

BATTERY TRAY

電池座

PV1395

MAIN GEAR 135T

主齒輪-135T

PV1400

METAL CONTROL ARM BRACE

金屬控制臂支架

PV1421

BOTTOM FRAME

底盤

PV1396

AUTOROTATION TAIL DRIVE PULLEY 100T

軸傳尾驅動主齒-100T

PV1415

METAL TAIL SUPPORT BRACKET

金屬尾支撐桿固定座

PV1422

LONG LINKAGE BALL SCREW SET

加長型球頭螺絲組

PV1397

STRAP RUBBER

束帶橡膠墊圈

(x2)

PV1418

METAL MAIN ROTOR GRIP

金屬旋翼轉座(本體)

PV1423

TAIL SUPPORT BRACE

尾管支撐架連接座

-30-

PV1398

CARBON FRAME (1)

碳纖側板-單片

PV1419

REVEIVER TRAY

接收機座

PV1424

DOUBLE LINKAGE SET

雙頭推拉桿

Page 32

SPARE PARTS / 維修零件包

PV1425

METAL TAIL CASE

金屬尾座

PV1383

METAL FB CONTROL LEVER SET

金屬無平衡翼控制搖臂組

(2)

PV0572

VELCRO

魔鬼氈組

PV1431-G

ABS CANOPY-GREEN

ABS 機殼 (綠色)

PV1384

METAL FB ROTOR GRIP LEVER SET

金屬無平衡翼轉座擺臂組

PV0512-W

SKID DAMPER (WHITE)

腳架墊圈(白)

PV1604

SERVO MOUNTING SET

伺服機墊片組

PV1385

METAL FB ELEVATOR LEVER ROD

金屬無平衡翼升降舵推拉桿

PV1242

VELCRO STRAPE

新式魔鬼粘束帶

3915

FBL CARBON BLADE 600mm

無平衡翼碳纖彩槳600mm

PV1386

METAL 120° FB CONTROL ARM SET

金屬 120° 無平衡翼控制搖臂組

PV1433

LINKAGE ROD SET

連接桿組(電動版)

PV1382

METAL FB MAIN ROTOR HUB

金屬無平衡翼主旋翼固定座

PV1387

TITANIUM LINKAGE ROD SET, 76mm

鈦合金連接桿組, 76mm

PV1434

BALL LINK

單頭連接桿

(20)

PV0256

SOCKET SCREW,M3x6

內六角螺絲,M3x6

PV0321-1

REAR TAIL SERVO TRAY

後置伺服機座

-31-

Page 33

SPARE PARTS LIST / 維修零件包表格

No. Description Part No.中文名稱 Description Qty

3915

PV0035-2

PV0035-3

PV0041

PV0050

PV0051

PV0052

PV0053

PV0054

PV0058

PV0060

PV0062

PV0088

PV0089

PV0115-1

FBL CARBON BLADE 600mm

LANDING SKID SET

LANDING SKID

BALL LINK

BEARING SET

LEAVER BRG

TAIL SLIDER BRG

ROTOR BOLT

SERVO MOUNTING PLATE

LINKAGE BALL

INSTALLATION SET

RUBBER GROMMETS(WHITE)

SCREW BAG(6 PCS EACH)

SCREW BAG(6 PCS EACH)

WASHOUT LINKAGE

無平衡翼碳纖彩槳600mm

腳架組

腳架

單頭連接桿

軸承組

軸承組

軸承組

主旋翼螺絲組

伺服機固定片組

連接頭

組合附件包

機身固定墊圈組

圓頭十字螺絲組

內六角螺絲組

連接座

BV6054

BK2261

BK0064T

BK0065

HME4-5B

HMC3-14B

BK2261

HME4-5B

HMC3-14B

BK0086

HMV1350ZZY

HMV740ZZY

HMV1060ZZY

HMC4-27B

HMM4Z

BK0104

BK0075

BE1052

BK0106

BK0109

HNI15

HNI2

HNI25

HNI3

HNJ-1

BK0102

HMF2-6N

HMF2-8N

HMJ2-10N

HMJ2-14N

HMJ2-6B

HMJ3-22B

HSE2-10B

HSE2612N

HSE3-12B

HSE3-18B

HSE3-5B

BK0616

HMC3-10B

HMC3-12B

HMC3-14B

HMC3-20B

HMC3-25B

HMC3-32B

HMC3-8B

HME3-10B

HME3-18B

HME4-5B

BK0016-1

BK0171

FBL CARBON BLADE 600mm

LANDING SKID

SKID PIPE

SKID PIPE END CAP

SET SCREW

SOCKET SCREW, M3x14

LANDING SKID

SET SCREW, M4x5

SOCKET SCREW, M3x14

BALL LINK

BALL BEARING, d5xD13xW4

BEARING, d4xD7xW2.5

BEARING, d6xD10xW3

CAP SCREW, M4x27

LOCK NUT, M4

SERVO MOUNTING PLATE

LINKAGE BALL

ANTENNA TUBE

DOUBLE SIDE TAPE

RUBBER BAND, 5x3 20xT1

HEX WRENCH 1.5m/m

HEX WRENCH 2m/m

HEX WRENCH 2.5m/m

HEX WRENCH 3m/m

TIE BAND 2.5x100

BODY MOUNT RUBBER

SCREW, M2x6

SCREW, M2x8

SELFTAPPING SCREW, M2x10

SELFTAPPING SCREW, M2x14

SELFTAPPING SCREW, M2x6

SELFTAPPING SCREW, M3x22

SELFTAPPING SCREW, M2x10

SELFTAPPING SCREW, M2.6x12

SELFTAPPING SCREW, M3x12

SELFTAPPING SCREW, M3x18

SELFTAPPING SCREW, M3x5

SOCKET SCREW, M3x20

SOCKET SCREW, M3x10

SOCKET SCREW, M3x12

SOCKET SCREW, M3x14

SOCKET SCREW, M3x20

SOCKET SCREW, M3x25

SOCKET SCREW, M3x32

SOCKET SCREW, M3x8

SET SCREW, M3x10

SET SCREW, M3x18

SET SCREW, M4x5

WASHOUT LINKAGE

PIN

,

M4x5

中文名稱

無平衡翼碳纖彩槳600mm

腳架

底座圓管

圓管塞

無頭內六角螺絲, M

內六角螺絲, M3x14

腳架

無頭內六角螺絲, M4x5

內六角螺絲, M3x14

單頭連接桿

滾珠軸承, d5xD13xW4

滾珠軸承, d4xD7xW2.5

滾珠軸承, d6xD10xW3

內六角螺絲, M4x27

止鬆螺帽, M4

伺服機固定片

連接頭

油門拉桿導管

雙面膠布

耐熱橡皮圈, 5x3 20xT1

六角扳手

六角扳手

六角扳手

六角扳手

固定束帶

機身固定墊圈

圓頭十字螺絲, M2x6

圓頭十字螺絲, M2x8

自攻螺絲, M2x10

自攻螺絲, M2x14

圓頭十字自攻螺絲, M2x6

自攻螺絲, M3x22

扁圓型自攻螺絲, M2x10

扁圓型自攻螺絲, M2.6x12

扁圓型自攻螺絲, M3x12

扁圓型自攻螺絲, M3x18

扁圓型自攻螺絲, M3x5

內六角螺絲(半牙), M3x20

內六角螺絲, M3x10

內六角螺絲, M3x12

內六角螺絲, M3x14

內六角螺絲, M3x20

內六角螺絲, M3x25

內六角螺絲, M3x32

內六角螺絲, M3x8

無頭內六角螺絲, M3x10

無頭內六角螺絲, M3x18

無頭內六角螺絲, M4x5

連接座

插銷

4x5

1

2

2

4

4

4

2

4

4

12

2

4

2

2

2

10

12

1

2

2

1

1

1

1

3

5

6

6

6

6

6

6

6

6

6

6

6

2

6

6

6

4

6

6

6

6

6

6

2

2

Index Page

21

11

11

11

11

11

11

11

11

18

15

15

14

21

21

17

14

-

-

-

-

-

-

-

-

20

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

7

7

-32-

Page 34

SPARE PARTS LIST / 維修零件包表格

No. Description Part No.中文名稱 Description Qty

PV0149-1

PV0197

PV0244

PV0261

PV0268

PV0270

PV0365

PV0407

PV0454

PV0504

PV0523-1

PV0665

PV0678-1

PV0679-T

PV0681

PV0682

PV0769

PV0771

PV0234

PV1310-1

PV1314

TAIL GEAR,X50

BALL BEARING, d12xD18XW4

BALL BEARING, d10xD19XW5

SELFTAPPING SCREW (M2.6x14 )

LOCTITE #262

THRUST BEARING GREASE

THRUST BRG. d6xD12xW4.5

TAIL PITCH SLIDER

SKID PIPE END CAP

TAIL PITCH SLIDER SET

CARBON TAIL BOOM

ELEVATOR A ARM

CARBON VERTICAL FIN

TAIL SUPPORT

MAIN HUB BOLT

MAIN SHAFT BOLT

THRUST BEARING

BEARING

NUT,M2

CANOPY BRACKET, X50

ELEVATOR ARM SET

HMS15

尾齒輪,X50

滾珠軸承組

滾珠軸承組

扁圓型自攻螺絲組

高強度防鬆劑(#262/紅色)

止推軸承潤滑脂

止推軸承組 d6xD12xW4.5

尾旋翼滑座

圓管塞

尾旋翼滑座組

碳纖維尾管

升降舵A臂

碳纖維垂直安定面

尾管支撐架組

主旋翼頭固定螺絲

主軸齒輪固定螺絲

止推軸承組

滾珠軸承組

六角螺帽,M2

機殼固定座, X50

升降舵控制組

BA1144-1

BK0372

BK0373-1

BD7143

HMV6701ZZY

HMV6800ZZY

HSE2614N

BV0450

BV0452

HMX0612

BK0026

BK0027

BK0075

BK0082

HMJ2-8N

HSE2-10B

BK0065

BK0025

BK0026

BK0027

BK0028

BK0075

BK0082

BK0546

HMF2-8N

HSE2-10B

HMS15

HMV1060ZZY

BK2556

BK0023

BK0084

BK2190

HMC3-25B

HMM3Z

HMC3-6B

BK0447

BK0524-T

HMJ2-8N

BK0616

HMM3Z

BK1197

HMM3Z

HMX0409Y

HMV940ZZY

HML2

BK0102

BK2278

HNX3-12B

BK0023

E RING

WASHER(d5xD8xW0.15)

Tail Input Gear

Tail Output Gear

FIXED SCREW

BALL BEARING, d12xD18XW4

BALL BEARING, d10xD19XW5

BUTTON PHILLIPS TAPPING SCREW , M2.6x14

LOCTITE #262

THRUST BEARING GREASE

THRUST BEARING

TAIL PITCH CONTROL LINK

TAIL PITCH CONTROL SLIDER

LINKAGE BALL

COLLAR, d2xD3xW4.3

SCREW, M2x8

SELF TAPPING SCREW, M2x10

SKID PIPE END CAP

TAIL PITCH CONTROL FORK

TAIL PITCH CONTROL LINKAGE

TAIL PITCH CONTROL SLIDER

TAIL PITCH CONTROL SLIDER BUSHING

LINKAGE BALL

COLLAR, d2xD3xL4

PIN, 2mm

SCREW, M2x8

SELFTAPPING SCREW, M2x8

E RING

BEARING, d6xD10xW3

CARBON TAIL BOOM(663mm)

ELEVATOR CONTROL ARM LINK

PIN

CARBON VERTICAL FIN

SOCKET SCREW, M3x25

NYLON NUT, M3

SOCKET SCREW, M3x6

TAIL SUPPORT ROD END

TAIL SUPPORT ROD

SELFAPPING SCREW

SOCKET SCREW, M3x20

LOCK NUT, M3

MAIN SHAFT BOLT

LOCK NUT, M3

THRUST BEARING

BEARING, d4xD9xW4

NUT,M2

FRUBBER GROMMET

CANOPY BRACKET

S.B.H SELF TAPPING SCREW

ELEVATOR CONTROL ARM LINK

中文名稱

E 型扣環

軸承墊片, d5xD8xW0.15

尾齒輪/INPUT-20T

尾齒輪/OUTPUT-20T

傳動軸固定螺絲(長)

滾珠軸承組,d12xD18xW4

滾珠軸承組, d10xD19XW5

扁圓型自攻螺絲組(粗) , M2.6x14

高強度防鬆劑(#262/紅色)

止推軸承潤滑脂

止推軸承組

尾旋翼連接頭

尾旋翼控制滑座

連接頭

軸環, d2xD3xW4.3

自攻螺絲(粗), M2x8

扁圓自攻螺絲(細), M2x10

圓管

尾旋翼控制座

尾旋翼連接頭

尾旋翼控制滑座

尾旋翼控制軸套

連接頭

軸環, d2xD3xL4

插銷, 2mm

圓頭十字螺絲, M2x8

扁圓自攻螺絲(細), M2x8

E 型扣環

滾珠軸承, d6xD10xW3

碳纖維尾管(663mm)

升降舵連接座

插銷

碳纖維垂直安定面

內六角螺絲, M3x25

止鬆螺帽, M3

內六角螺絲, M3x6

尾管支撐架接頭

尾管支撐架

自攻螺絲(細), M2x8

內六角螺絲, M3x20

止鬆螺帽, M3

凸肩內六角螺絲

止鬆螺帽, M3

止推軸承, d4xD9xW4

滾珠軸承, d4xD9xW4

六角螺帽,M2

機身固定墊圈

機殼固定座

半圓頭內六角自攻螺絲

升降舵連接座

2

4

1

1

1

1

2

20

1

1

2

2

1

1

2

1

2

8

1

2

1

1

1

2