Page 1

1/10 2WD On-Road Nitro Racer

No.6711

Thunder Tiger Corporation guarantees this model kit to be free from defects in both material and workmanship.

The total monetary value under warranty will in no case exceed the cost of the original kit purchased. This warranty

does not cover any components damaged by use or modification. Part or parts missing from this kit must be

reported within 60 days of purchase. No part or parts will be sent under warranty without proof of purchase.

To receive part or parts under warranty, the service center must receive a proof of purchase and/or the defective

part or parts. Should you find a defective or missing part, contact the authorized Thunder Tiger Service/Distributor

nearest you. Under no circumstances can a dealer or distributor accept return of a kit if assembly has started.

JD6211

Page 2

INTRODUCTION

Thank you for the purchase of this Thunder Tiger product. You should enjoy many hours of trouble free use

from this advanced R/C product. Thunder Tiger strives to bring you the highest level of quality and service we

can provide. We race and test our products around the world to bring you state-of-the-art items.

We offer on-line help 24-7 on our www.acehobby.com forum and our product specialists are ready to take your

call if you have any technical questions. Please read all instructions and familiarize yourself with the systems

and controls of this product before operating. Have fun and enjoy the exciting world of R/C.

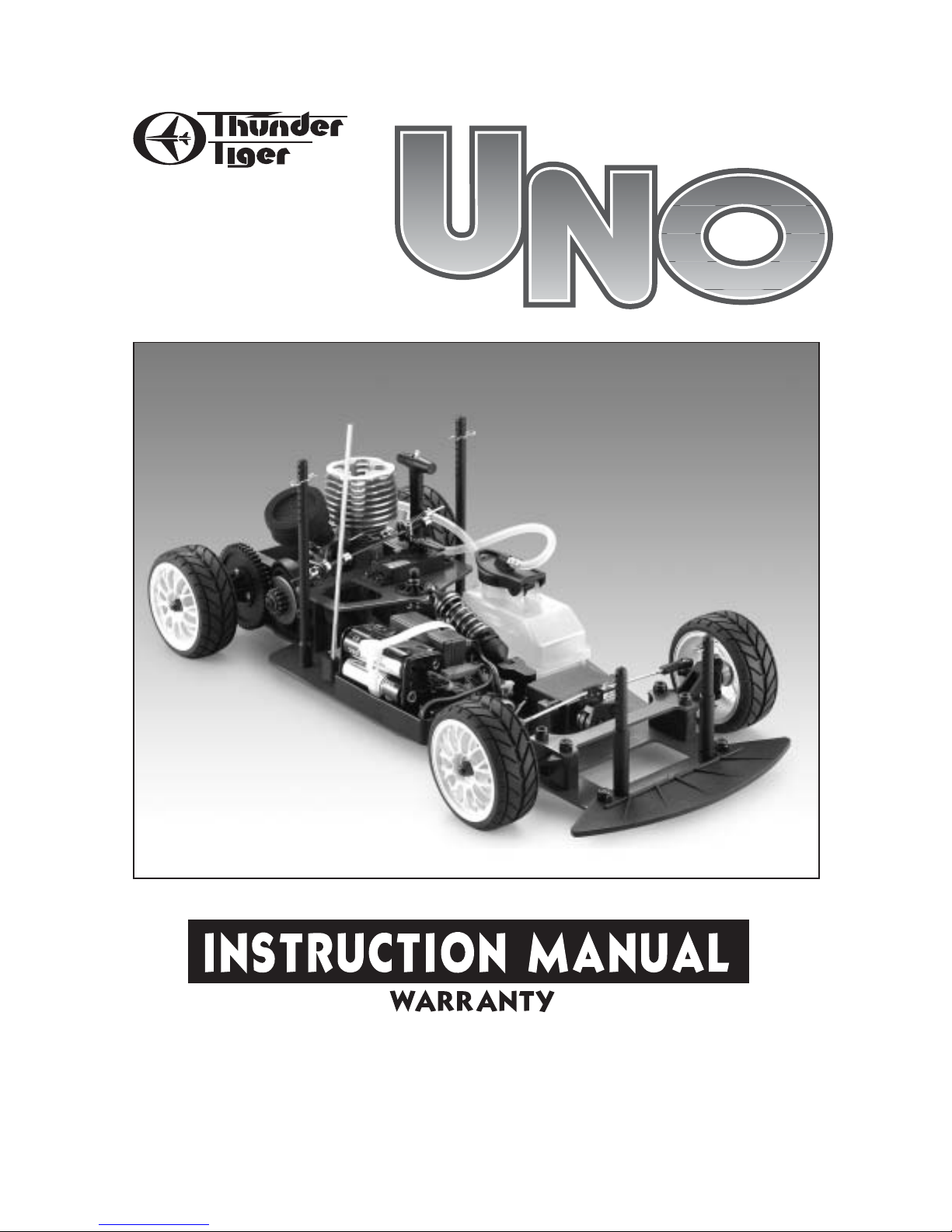

ITEMS REQUIRED FOR OPERATION

PURCHASED SEPARATELY

WITH ARTR MODELS

2-Channel, surface radio with 2 high torque servos

Alkaline Batteries

(12), AA-size

Glow Starter w/ Charger

TOOLS INCLUDED

Glow Fuel, Methanol

10% to 20% Nitro

5% to 18% Caster / Synthetic Oil

Fuel Bottle

5-Way Wrench

(300cc/600cc)

Hex Wrench Set 4-Way Wrench

Screw Drivers, Lexan Body Reamer, Hobby Knife,

Lexan Scissors, Rubber Bands.

1

Page 3

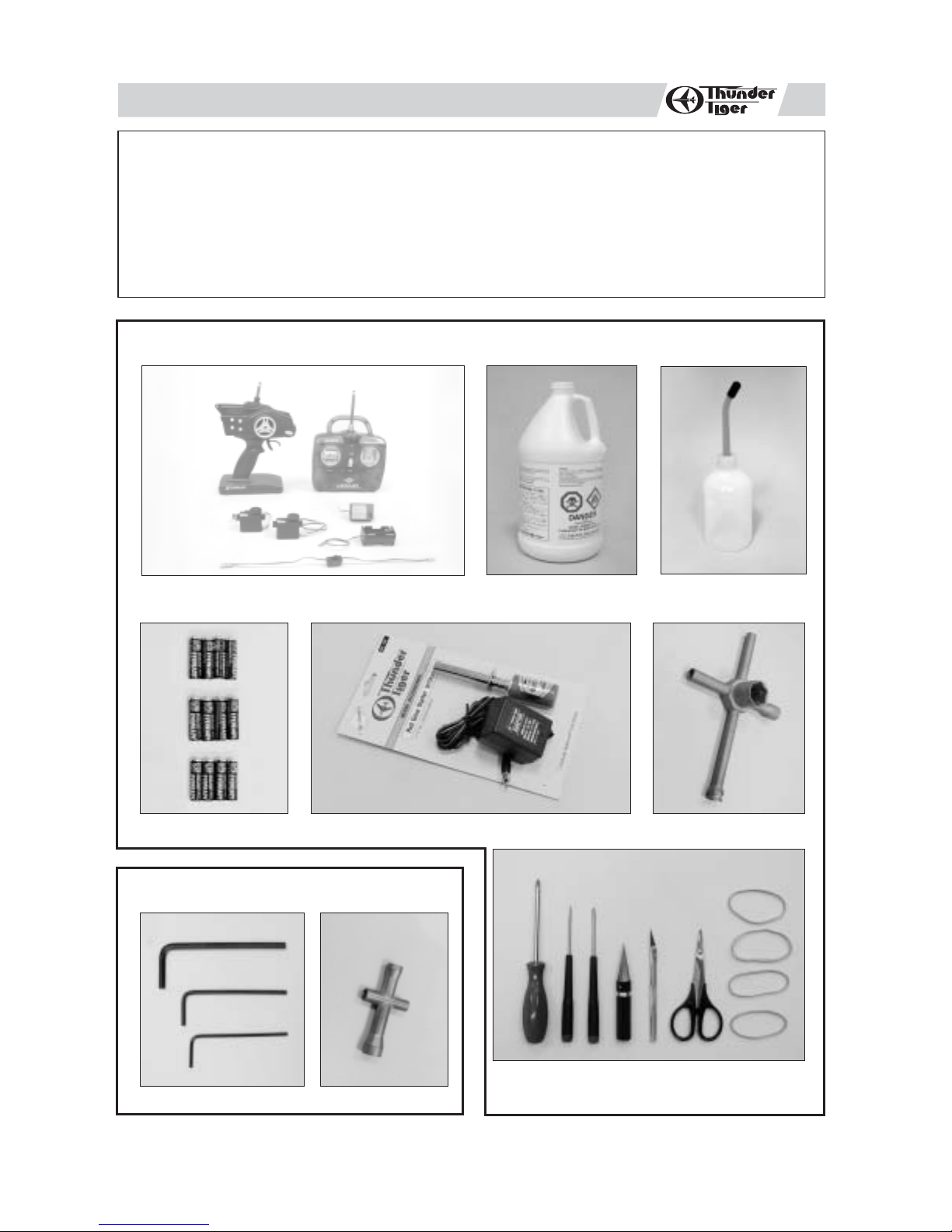

INSTALLING THE RADIO GEAR

skip if already assembled

1

a

b

ed

c

f

ihg

a.

b. Install the servos with tap screws. Notice the orientation of the steering and throttle servo output

shafts.

c. Install the receiver switch into the front of the battery mount with its original screws.

d. Properly plug the connectors/wires into the receiver: steering servo connector/wire into channel 1

slot, throttle servo connector/wire into channel 2 slot, and battery switch connector/wire into battery

slot.(Hint: Y ou can use small zip tie to arrange the rest of wires.)

e. Place the receiver antenna through the antenna mount and antenna tube as shown.

f. Press-fit the antenna tube into the mount, then secure the mount to the chassis using a 3x10 mm countersunk

screw.

g. Install 4 AA size alkaline batteries in receiver battery box.

h. Connect the receiver battery box wire/connector to the receiver switch wire/connector the receiver connector.

(Hint: Y ou can use small zip tie to arrange the rest of wires.)

i. Install the receiver and battery pack into the battery mount and use a large zip tie to secure. ( Note: It is strongly

suggested to cover receiver and battery pack with a balloon or plastic bag to protect against dirt and fuel )

2

Page 4

2

INSTALLING STEERING SERVO LINKAGE

a b

70 MM

AFTER INSTALLATION

a. Install the threaded of part of the linkage rod into the plastic tie-end. The linkage rod with tie-end should measure 70 mm when

finished.

b.

Install the steering linkage rod with tie-end onto steering servo horn

c.

Attach the tie-end onto the ball joint on the knuckle arms, making sure that the servo is centered and the axles have just a slight

amount of toe-in.

.

skip if already assembled

c

c

3

4

INSTALLING THROTTLE LINKAGE

To engine

carburetor

lever

To brake cam

a. Assemble the throttle and brake linkage as shown on the drawing.

b. Secure the brake linkage onto the brake lever with set screw.

c. Install the servo horn onto throttle servo output shaft.

skip if already assembled

cba

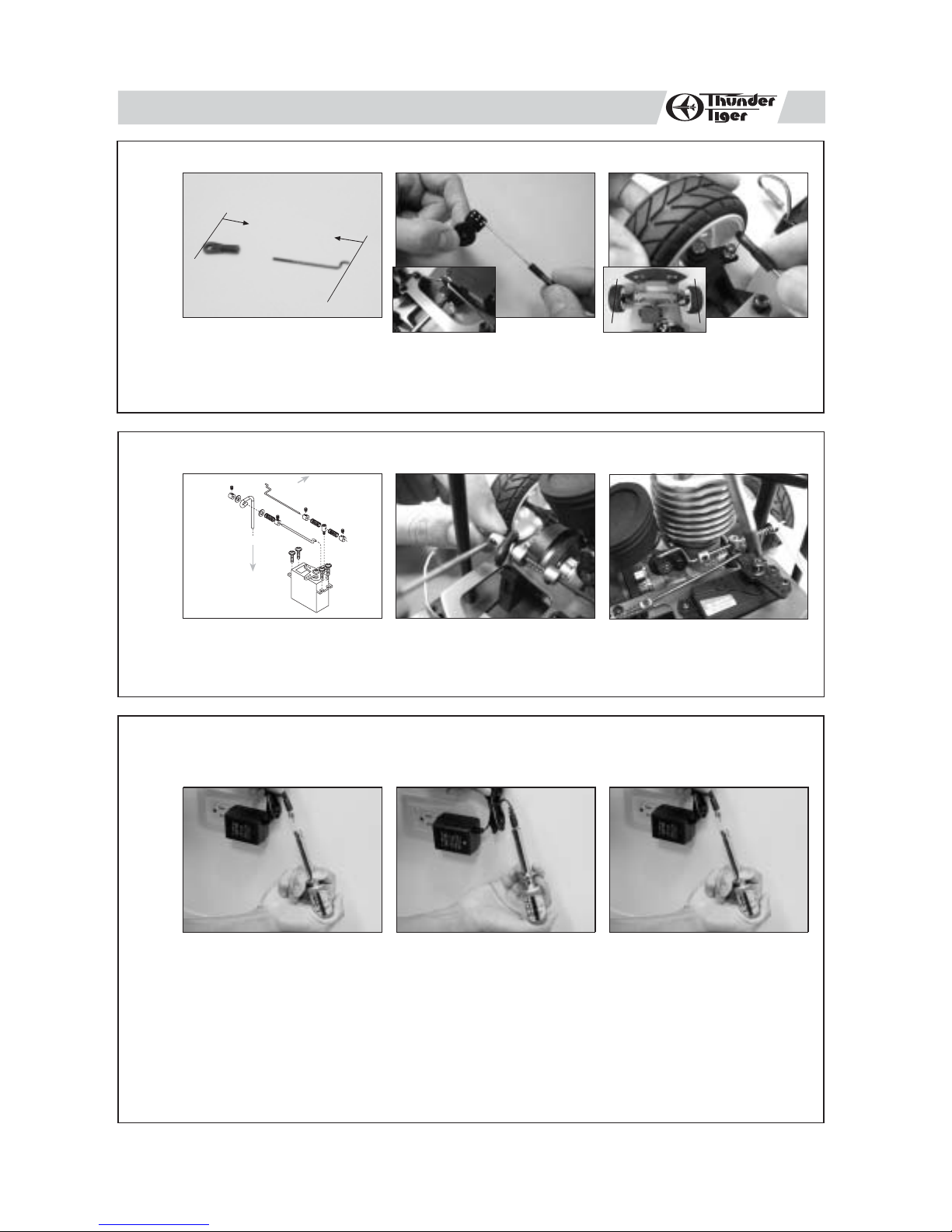

CHARGING THE GLOW PLUG IGNITER

Thunder Tiger Optional Part #2165, 1300MAH Glow Starter w/220V Charger.

Thunder Tiger Optional Part #2166, 1300MAH Glow Starter w/110V Charger.

a

b c

a. Plug the charger into an AC outlet, and then pull on the igniter lever to accept the charging adapter.

b. At this point, the small red LED indicator on the charger should light up indicating the charging sequence

is in progress.

c. When the charging complete, pull on the glow plug igniter lever to unplug the glow igniter.

Charge the new glow plug igniter for 16 to 24 hours on the first charge. For subsequent charges, charge

it about 12 hours before next use.

NOTE:

If the igniter gets warm or hot during the charge, unplug the igniter from charger immediately. A warm /

hot igniter means the igniter is overcharged. Overcharging can damage the internal battery in the igniter;

thus, shortening its life.

3

Page 5

PREPARING THE RADIO

5

6

a

a c

a. Check the frequency printed on the transmitter crystal.

b. Check the frequency printed on the receiver crystal, and make sure it matches with the transmitter

crystal. Make sure no one will operate on the same frequency when you are. When there is a radio

glitch, it will most likely be caused by improper crystal, damaged crystal, or people operating on the

same frequency.

c. Install the antenna into transmitter.

RADIO BATTERY INSTALLATION

b

c

abc

7

a. Install 8 AA-size alkaline batteries into transmitter.

b. Undo the large zip-tie, and remove the receiver battery box. Install 4 AA-size alkaline batteries into

receiver battery box.

c. Reinstall the battery box on the battery mount and tie with the receiver.

RADIO OPERATION

a

a.

When turning radio on, first turn on the transmitter.

b. Then, turn on the receiver. When turning off, first turn the receiver off, then the transmitter off.

c. To reverse the functions of servos, use the small, white servo reverse switches located on side of the

pistol transmitter (or the inset servo reverse switches located at the bottom of the stick transmitter). To

trim the servos on pistol transmitter, use the trim switches on side of the steering wheel (the ST. trims

steering, and the TH trims throttle/brake). On a stick transmitter, the trim levers are located accordingly

around the sticks.

For more details, please check the transmitter instruction manual.

b

c

4

Page 6

OPERATING RADIO STEERING FUNCTION

8

ab

a. Check the radio steering functions. With the radio transmitter and receiver on, turn the steering wheel/stick

to the left. The front tires/wheels should turn left accordingly. If not, flip the steering servo reverse

switch.

b. Return the steering wheel/stick to neutral. The front tires/wheels should point straight forward. If not,

use the steering trim lever to correct it.

c. Turn the steering wheel/stick to the right. The front tires/wheels should turn right accordingly.

c

9

OPERATING RADIO THROTTLE / BRAKE FUNCTION

a bc

a. Check the radio throttle/brake functions. With the radio transmitter and receiver on, pull the trigger/push

the stick forward. The carburetor should be fully opened and the brake disengaged. To reverse this

function, flip the throttle/brake servo reverse switch.

b. Return the trigger/stick to neutral. The carburetor should be closed to a point where the idle has

been set (see step for ADJUSTING THROTTLE/BRAKE LINKAGE), and the brake still disengaged. If

not, use the throttle/brake trim lever to correct it.

c. Push the trigger/pull the stick backward. The carburetor opening should still be the same at neutral,

throttle spring compressed slightly, and the brake engaged.

5

Page 7

ADJUSTING THROTTLE / BRAKE LINKAGE

10

a

a. To set the throttle/brake linkage, first the radio should be on and neutral; thus, the servo is at neutral

b. With the servo at neutral, turn and adjust the brake collar to a point where the brake lever almost

c. With the servo at neutral, loosen the throttle collars. Then, manually close the carburetor, and set

ADJUSTING CARBURETOR

b c

position.

engages the brake system, but not yet.

the collar (next to the spring) with the spring slightly compressed. Then, set the other collar next to

the linkage pivot.

11

a. To set the carburetor idle (small needle sticking out from the carburetor body), turn the screw as

b. To set the high speed needle (large needle sticking out from the carburetor body), turn the screw as

c. Remove the outer foam from filter and make it moist evenly with a few drops of fuel. If the vehicle

abc

pictured. Initial idle setting should leave 1mm carburetor gap. Clockwise turn will provide higher idle

(larger carburetor opening), and counterclockwise turn will provide lower idle (smaller carburetor

opening).

pictured. Initial high speed needle setting should be 2.5 turns (close the needle completely, then back

out 2.5 turns). Clockwise turn will provide leaner setting (lower fuel to air mixture), and counterclockwise

turn will provide richer setting (higher fuel to air mixture). Please refer to ENGINE BREAK-IN/SETTING

procedures to properly set the engine.

will be operated in an area with fine dust, use filter oil or caster oil instead of fuel. It is important that

the foam is only moist to trap dirt and allow air passage. With the foam too wet, limited air can pass

through; therefore, limiting engine performance. Finally, make sure the air cleaner boot is securely

fastened with a zip-tie.

6

Page 8

FUELLING

12

a

a. Remove the cap from fuel bottle nozzle.

b. Squeeze the fuel bottle, insert into fuel, and draw fuel into the fuel bottle. The fuel used should be

c. Fill car's fuel tank with glow fuel.

PREPARING THE ENGINE

13

b

methanol based model engine glow fuel (available at hobby shops) with 10% to 20% nitro content

and 5% to 18% caster/synthetic oil content for lubrication.

c

cba

d

a. To start an engine, first remove the glow plug.

b. Check the glow plug by plugging it into the glow plug igniter. The glow plug element should light up

brightly. If it lights up dimly, then the glow plug igniter is low (and it needs recharging). If it does not

light up or the plug element looks distorted, then the glow plug is bad (replace with new one). After

checking, reinstall the glow plug.

The glow plug used for this engine can be: Thunder Tiger 9281, McCoy #9 / #59,

Novarossi C4S / C5S / C6S,OS #8 / #A3 / #A5, and Picco P6S / P7S.

c. With the radio off, manually turn the servo to open the carburetor (open throttle).

d. Plug the tuned pipe exhaust tip.

e. Keeping the exhaust tip plugged, pull on the engine's starter . Keep doing it until fuel reaches engine's

carburetor, then pull it 3 more times to prime the engine.

f. Manually return the servo back to neutral.

e

7

f

Page 9

STARTING THE ENGINE

14

a b

a. Turn on the radio (transmitter first, then receiver).

b. Clip the glow plug igniter onto engine's glow plug.

c. Pull on the engine starter, release, repeat until the engine starts. Throttle maybe required to be opened momentarily, but

Remove the glow plug igniter from engine after engine has started and warmed up. If the engine stops right after the igniter is

removed, the carburetor setting is too rich. Please refer to engine setting section.

If engine starter becomes hard to pull, the engine maybe flooded. To unflood an engine, remove the glow plug from engine, flip

the car upside down, and pull on the starter to release excess fuel. Then, reinstall the glow plug and repeat the engine starting

procedure.

ENGINE BREAK-IN

For a new engine (break-in setting), the high speed needle needs to be set as rich as possible. Turn the high speed needle 1/4 turn

15

counterclockwise from initial setting (2.5 turns from fully closed). Repeat step 15b. Keep doing this until the engine stalls at full throttle,

then turn the high speed needle 1/4 turn clockwise. Run the car in an open parking lot with this rich engine setting for at least 5 tanks

of fuel to complete the break-in process. It is normal for a new engine to stall many times during this time due to the rich setting.

When it does, just restart the engine. After break-in, follow the ENGINE SETTING procedure to set the carburetor for normal operations.

ENGINE SETTING

Due to different fuel formula, operating elevation, humidity . . . etc., the engine may/may not operate properly at initial setting. Please

follow the following procedure to achieve proper carburetor setting. Do not perform this procedure until the engine has been properly

broken in.

a.Start the engine.

b.With a running engine, run the car back and foreth in a straight line (full throttle achieved furing each passage) in an open parking

lot. Repeat and note the sound of the exhaust. Do not hold the throttle open with car off the ground or the engine connecting rod

may break.

c.If the exhaust does not reach a high pitch note, turn the high speed needle (long needle, extending from carburetor body, pointing

up) 1/4 turn clockwise, and repeat step 15b.

d.Repeat step 15c until the engine reaches optimum setting (turning in the high speed needle will no longer have an effect at full

throttle and turning out the needle will cause the engine's full throttle rpm to drop a little). For normal operations, turn the high

speed needle 1/4 turn counterclockwise from the optimum setting.

e.To set the idle, turn the idle screw in (higher rpm) or out (lower rpm). Basically, the idle needs to be set at the lowest possible point

before the engine stalls.

f. To set the low speed needle (inside the throttle lever), the engine needs to be broken in and high speed needle needs to be set first.

g.Repeating step 15b every 10 seconds (1 second full throttle and 10 seconds idle). If the engine rpm at idle drops after a few seconds

and stalls, then turn in the low speed needle (clockwise) 1/4 turn. If the engine rpm stays the same or goes up at idle, then turn out

the low speed needle (counterclockwise) 1/4 turn.

h.Keep repeating step 15g until the engine rpm drops (goes to idle rpm, then drops a few more rpm after a few seconds) but does

not stall.

c

release throttle back to neutral immediately after the engine starts.

Thank you for purchasing a Thunder Tiger Product. Please read all instructions thoroughly before operation.

1. This product is not a toy. It is a high performance model product. It is important to familiarize yourself with the model, its manual, and its construction

before assembly or operation.

2. Do not operate model products in rain, on public roads, near crowds, near airport, or near areas with restricted radio operation.

3. Always keep fuel away from heat and open flame. Only operate in open, well-ventilated area. Store fuel in cool, dry area. Keep the fuel bottle

cap tightly closed. Clean up any leak or excess fuel before starting the engine.

4. This product, its parts, and its construction tools can be harmful to your health. Always exercise extreme caution when assembling and/or operating

this product. Do not touch any part of model which rotates.

5. Check your radio frequency with the proper operating frequency of the area or country. Always check to see if there are any modelers operating

on the same frequency as your are. Also, check your radio for proper operation before operating a mode.

6. Improper operations may cause personal and/or property damage. Thunder Tiger and its distributor have no control over damage resulting

from shipping, improper construction, or improper usage.

7. Thunder Tiger assumes and accepts no responsibility for personal and/or property damages resulting from the use of improper building materials,

equipment and operations. By the act of assembling or operating this product, the user accepts all resulting liability. If the buyer is not prepared

to accept this liability, then he/she should return this kit in new, unassembled, and unused condition to the place of purchase.

WARNING

8

Page 10

9437 PRO-12BXS Shown

28

19

10

7

15

13

16a

3

1

5

9222 CARBURETOR

C

17

27

11

12

8

4

16b

24

20

12

No. DESCRIPTION 9437 PRO-12BXS

25

17

22

1 PROP NUT AA0199B

23

26

32

21

17

33

3 DRIVE WASHER SET AA0245

4 CRANKSHAFT AA0244

5 CRANKCASE AN0195

6 BACKPLATE ******

13

7 CONNECTING ROD AN0433

8 WRIST PIN ASSEMBLY AN0188

10 CYLINDER & PISTON AN0547

11 CYLINDER HEAD AA1000

12 GASKET SET PN0009

13 CARB RETAINING BOLT PN0011

15 CARBURETOR ASSEMBLY 9222

16a BALL BEARING, FRONT AMV689Z

16b BALL BEARING, REAR AMV689

17 SCREW SET PN0012

19 AIR CLEANER SET 9262

20 ONE WAY CLUTCH SET AN0315

21 HANDLE SET PN0050

22 STARTING AXLE AA0313

23 STARTING SPRING AA0316

24 BACKPLATE AN0241

25 STARTING WHEEL WIRE AA0155

26 STARTING WHEEL AA0312

27 STARTING WHEEL COVER AN0314

F

H

J

28 STARTING SET PN0016

32 BACKPLATE & SCREW SET PN0017

33 STARTING WHEEL COVER SET PN0018

G

E

D

A

No. DESCRIPTION 9222

A CARBURETOR BODY W/ROTOR PN1123

B

B CARB. ROTOR ASSY PN1125

C NEEDLE VALVE ONLY PN1035

D SPRAY BAR ASSEMBLY PN1036

E NEEDLE VALVE ASSY. PN1037

F THROTTLE LEVER PN1038

I

G BOLT&FUEL INLET PN1039

H THROTTLE ROTOR SET PN1124

IO RING SET PN1041

J MIXTURE METERING SCREW SET PN1042

9

Page 11

For those who tired of their old lexan body,

we do have better choice!

All Touring car bodies are molded from crystal clear lexan and various

designs are available to meet your extreme demand. Thunder Tiger Corp.

guarantees that the items can fit all TS-N and UNO car series.

VOLVO S-40

PD0901 CLEAR BODY SET

PD1096 CLEAR BODY W/ DECAL

PD1097 PAINTED BODY SET

FORD FOCUS

PD1063 CLEAR BODY SET

PD1030 CLEAR BODY W/ DECAL

PD1065 PAINTED BODY SET

BENZ AMG C32

PD1394 CLEAR BODY SET

PD1395 CLEAR BODY W/ DECAL

PD1393 PAINTED BODY SET

MERCEDES BENZ

PD0903 CLEAR BODY SET

PD1098 CLEAR BODY W/ DECAL

PD1099 PAINTED BODY SET

DODGE STARTUS

PD1088 CLEAR BODY SET

PD1090 CLEAR BODY W/ DECAL

PD1091 PAINTED BODY SET

BMW M3 GT

PD1400 CLEAR BODY SET

PD1401 CLEAR BODY W/ DECAL

PD1399 PAINTED BODY SET

ALFA ROMEO

PD0905 CLEAR BODY SET

PD1100 CLEAR BODY W/ DECAL

PD1101 PAINTED BODY SET

PEUGEOT 206

PD1069 CLEAR BODY SET

PD1029 CLEAR BODY W/ DECAL

PD1071 PAINTED BODY SET

DODGE VIPER GTS-R

PD1403 CLEAR BODY SET

PD1404 CLEAR BODY W/ DECAL

PD1402 PAINTED BODY SET

SUBARU IMPREZA WRC

PD1406 CLEAR BODY SET

PD1407 CLEAR BODY W/ DECAL

PD1405 PAINTED BODY SET

OPEL ASTRA V8

PD1412 CLEAR BODY SET

PD1413 CLEAR BODY W/ DECAL

PD1411 PAINTED BODY SET

Page 12

UNO 1/10 2WD On-Road Nitro Racer

Thunder Tiger's new on-road nitro racer brings the feel

and excitement of nitro racing to parking lot racers

everywhere! Not only will this be the economical nitro

combo, it will also be the most convenient. With 100%

assembly, this new racer is ready to hit the asphalt when

it comes out of the box.

A durable pan-style chassis features independent front

A-arm suspension and rear T-plate with mono shock for

sure, precise handling. A straight axle rear end provides

instant power transfer to the pavement, and the

breaking system. supplies sure stopping power.

The included TT PRO-12BXS engine features a recoil

starting system for fast, easy starts, and the 75cc fuel

tank provides long run times between pit stops.

For details, it adds a reinforced rear shaft mount &

hub to enhance durability and rigidity of shaft. A muffler

protection wire assures the UNIQUE muffler keeping

away from unexpected damage.

PRO-12BXS

BMW M3 GT

SUBURU IMPREZA WRC 02'

2-channel Radio

THUNDER TIGER CORPORATION

DODGE VIPER GTS-R

www.thundertiger.com.tw

Loading...

Loading...