Page 1

1

Sparky ARF Airplane (TTR4307)

Distributed in North America by Ace Hobby Distributors,Inc.• 116 W 19th ST,Higginsville,MO 64037

Phone:660-584-7121 • www.acehobby.com • E-mail:service@acehobby.com

Sparky ARF

Assembly Manual

Wing Span: 57”(1450mm)

Wing Area: 360sq.in.(23.2dm2)

Length: 34”(865mm)

Weight: 1.6 lbs.(700-750g)

Motor: 400 Motor req’d

Radio: 2~3 channel

Specifications:

Warranty

This kit is guaranteed to be free from defects in material and workmanship at the date of purchase.

It does not cover any damage caused by use or modification. The warranty does not extend beyond the product itself and is limited only to the original cost of the kit. By the act of building this user-assembled kit,the

user accepts all resulting liability for damage caused by the final product. If the buyer is not

prepared to accept this liability,it can be returned new and unused to the place of purchase for a refund.

JE6454

Notice: Adult Supervision Required

This is not a toy. Assembly and flying of this product requires adult supervision.

Read through this book completely and become familiar with the assembly and f light of this airplane.

Inspect all parts for completeness and damage. If you encounter any problems,call 660-584-6724 for help.

Page 2

ITEM NEEDED FOR COMPLETION

Motor - Thunder Tiger Electric

Power System includes 400 motor,

1:2 gear reduction set,9 x 6 propeller and spinner.

2

INTRODUCTION

The Sparky is reminiscent of a time when things were more relaxed and life happened at slower pace;

everything was simpler...easier.

Now you can enjoy this "old-timer" feeling with these Almost-Ready-To-Fly planes. A large wing span,high

aspect ratio eliptical wing provides ultra-stable and slow flight, perfect for the beginner or an experienced

pilot looking for relaxation.

Pre-Assembly Notes

Before beginning the assembly r ead the instructions thoroughl y to give an understanding of the sequence

of steps and a general awareness of the recommended assembly procedures.

By following these instructions carefully and ref erring to the corresponding pictures,the assembly of your

model will be both enjoyable and rewarding. The result will be a well built, easy to assemble ARF model,

which you will be proud to display and also provide you considerable enjoyment.

If you are not an experienced R/C pilot,plan to have a fully competent pilot c hec k y our completed model

and help you with your first flights. Even though we have tried to provide you with a very thorough instruction manual, R/C models are rather complicated and an experienced modeler can quickly check over your

model to help make sure your first flights are successful.

Before you begin,check the entire contents of your kit against the parts list and photos at back cover to

make sure that no parts are missing or damaged. This will also help you to become familiar with each component of your plane. If you find that any of the parts are either missing or damaged, please contact Ace

Hobby Distributors,Inc.,Customer Service (660-584-6704) immediately for replacements.

Trial fit each part before gluing it in place. Make sure you are using the correct part and that it fits well

before assembling. No amount of glue can make up for a poor-fitting part.

Charger - Ace R/C 8.4V 60 min.

DC Quick Charger

8.4V Battery Pack - AcePower

8.4V 900mAh NiMH battery Pack

Radio - A 3-channel radio with three standard

or mini servos is required. The Ace R/C

Commander is ideal.

ESC - Ace R/C Electric Speed

Control Unit ESC-30

N0.8301

AS6162

8012AC

2604AC

2919AC

Page 3

3

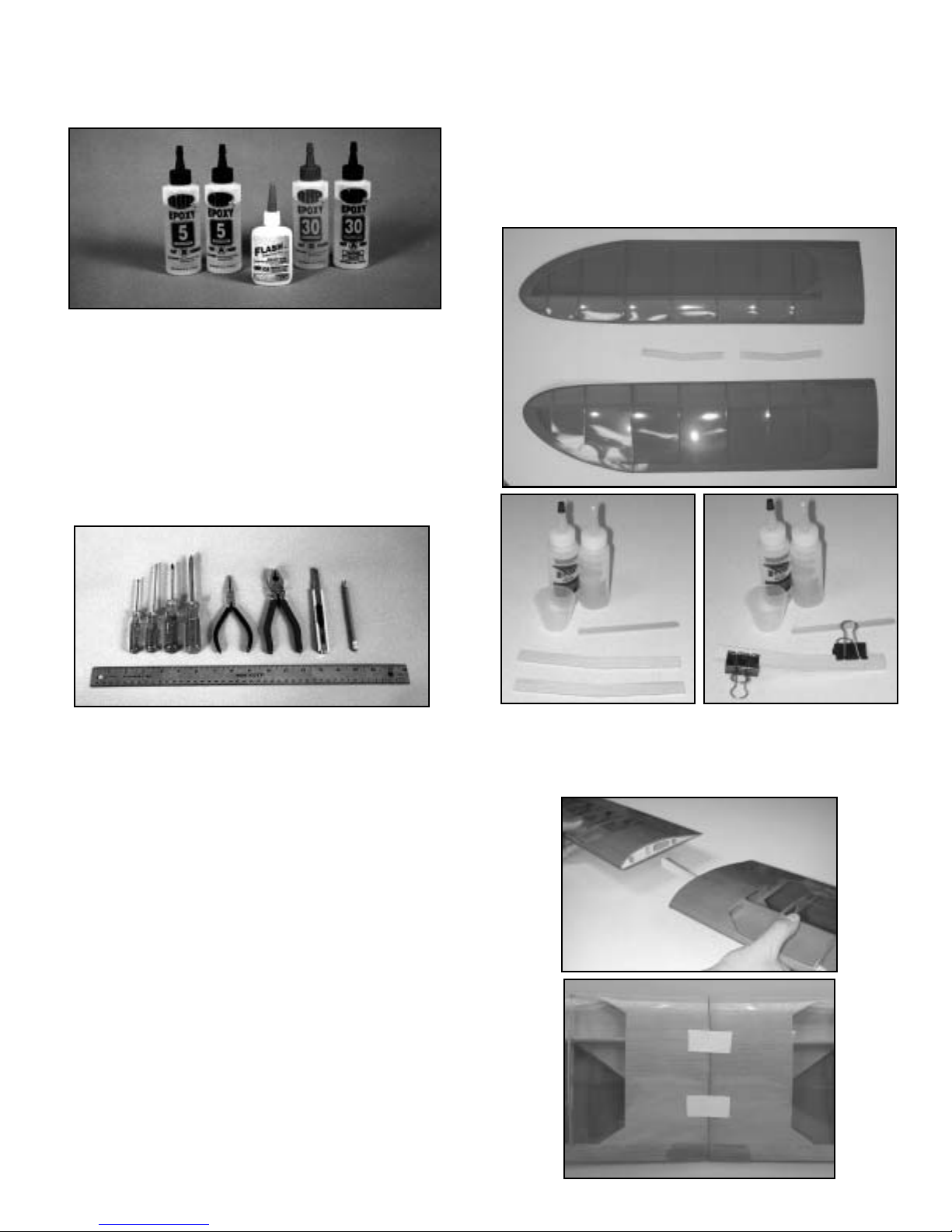

WING ASSEMBLYTOOLS & MATERIALS

Adhesives -You will need two types of adhesives for the

Sparky - Epoxy and Instant (cyanoacrylate) adhesives. We

recommend that you purchase both 10-minute and

30-minute epoxy to cut down on assembly time,but you

can get by with only 30-minute epoxy if time is not

important. You will also need a small bottle of both

“Thick”and “Thin”instant adhesive.

Tools - Model assembly can be much easier if the proper tools are used. As you will notice, many household

tools can be utilized during construction. Besides above

tools, some other tools or materials like T-Pins, Scissors,

Drill and Drill Bits, Fine Felt Tip Pen, Rubbing Alcohol,

Masking Tape will be used when assembling.

I. Wing Assembly

A. Locate both wing halves and the two dihedral braces.Mix a small

amount of 5-minute epoxy and glue both dihedral braces together.

With the two dihedral braces together trial fit the braces in each wing

half.With dihedral brace in one wing panel,trial fit it to the other wing

panel,assuring no gaps from leading edge to trailing edge.

B. Mix up a small amount of 30 minute epoxy and apply to both

sides of both inner ribs and dihedral brace slot.Insert brace into one

wing panel before putting wing panels together. After wings are

together,wipe off excess epoxy,tape and set aside to cure.After epoxy

is cured,glue the wing protector at the joint of the trailing edge.

Page 4

hold pushrod tubes in place.

III. Motor Installation

A. File the motor mount at the beam as shown for better fitness.

4

FUSELAGE

II. Pushrod Housing Installation

A. Carefully install rudder and elevator pushrod tubes;insert the elevator pushrod tube through the hole in the rear former through the

fuselage and out the pre-drilled hole in the right of the rear cabin former.

B. With a hobby knife,remove covering from existing slot in top rear

of fuselage and insert rudder pushrod tube through fuselage and out

pre-drilled hole in left rear cabin former. Use just a dab of CA glue to

R

L

Page 5

5

STABILIZER

B. Secure the motor tightly with enclosed Zip-Tie.

IV. Wing Hold Down Dowel Installation

A. Cut away the covering film from the predrilled holes in the fuselage with a hobby knife.

B. Install dowels and place a drop of medium CA to hold dowels in

place.

V. Stab and Rudder Installation

A. Center the main wing on the fuselage and attach using the rubber

bands provided.

B. Determine the top and bottom of the stab like this: the sealed

edge of the elevator should be on top,and the beveled edge be on the

bottom.

C. Place the stab on the tail of the plane and measure from points

shown above. This will square the stab in the saddle. Pin the stab in

Page 6

6

STABILIZER

place with T-pins,and mark the bottom of the stab.

D. Remove the stab and place top-down on a flat surface so you can

see the markings you just made. With a small steel rule,place it on the

inside of the lines about 1/16". Using an Xacto knife,cut to remove the

covering from the stab.BE CAREFUL NOT TO CUT TOO DEEP AS YOU

MAY WEAKEN THE STABILIZER. TRY TO CUT ONLY THE COVERING.

E. Use a hobby knife to remove the covering film from the fin slit in

the tail of the plane.

F. Trial fit stab and fin to fuselage before gluing. Mix a small amount

of 15 minute epoxy and glue the stabilizer into place,rechecking your

alignment marks by remeasuring as shown in previous step to insure

proper alignment of stab and wing.

G Insert the fin into the slot in the tail and mark the fin as shown.

Remove the fin and use a hobby knife and straightedge to remove the

covering film from the bottom of the fin.AGAIN,BE CAREFUL NOT TO

CUT TOO DEEP AS YOU MAY WEAKEN THE STABILIZER. TRY T O CUT

ONLY THE COVERING.

H. Apply some thick CA to the bottom rear of the fin and insert it

into the slit. Use a 90 degree triangle to square up the fin with the stabilizer. Next wick some thin CA in the joint where the fin meets the

slit.

I. Mount the rear control horns;place the control horn on the bottom center of the elevator in line with the pushrod tube. Mark the

Page 7

7

LANDING GEAR

holes for the control horn using a felt marker.

J. Attaching the control horn using two 2mm screws and backing

plate.It might be wisely to connect the pushrod at the z bent end and

insert the pushrod to the tube before installing the control horn.

Attach the rudder control horn in the same manner.

Note: The longer pushrod is for elevator, the short one is for rudder.

VI. Landing Gear Installation

A. Landing gear is assembled with 4 wheel collars,2 bushing,and 2

wheels. Install one wheel collar on to the landing gear,then slide the

brass bushing on,slide the wheel over the bushing, and finally install

the second wheel collar. Repeat process for other wheel.

B. Using a hobby knife remove the covering over the landing gear

slot. Push the landing gear down into the slot. Apply a few of drops

of medium CA into the slot and slide the former into place. WARNING:

WHEN YOU INSERT THE FORMER,IT WILL SQUIRT EXCESS CA OUT

THE HOLES NEAR THE LANDING GEAR,SO BE CAREFUL!!

VII. Servo, Radio,Battery,& Switch Installation

A. Using a hobby knife remove the cov ering film from the s witch cut

out on the left side of the fuselage.

B. Glue the two plywood pieces as the servo tray if you use the mini

servo. You might place your mini servo as a guide then glue the ply-

Page 8

8

RADIO

wood in place.

C. Secure the mini servo in place as shown.Install the EZ connector

on the servo horn.Insert the pushrod first then place the hor n on the

servo. Make sure the servos are in neutral position then screw the

horn.

D. Install the receiver,ESC,battery back as shown.Please refer to the

manufacturer's instruction manual for correct connection.Poke a hole

in the bottom of the cabin and run the antenna out and down the bottom of the fuselage and attach to the tail using whatever method you

prefer.

E. Install the ESC switch

VIII. Balancing

E. Balance the plane. With the wing on the airplane, use your two

index fingers to suspend the model in the air. Locate your fingers 1

1/4”back from the leading edge of the wing,about 4”out from the fuselage. At this point,a right angle is formed where the leading edge and

the center balsa sheeting ends. You can feel this point with your finger

tips.

The plane should hang level or slightly nose down at this point. If

the tail drops,you need to redistribute or even add weight to the nose

until the plane balances.

IX. Control Throws

Make sure that all control surfaces move in the proper direction.

Set the control surface throws as indicated for the initial flights.

These may be altered later for personal preference.

3/4”

neutral

3/4”

1/2”

neutral

1/2”

Rudder

Elevator

Page 9

9

RADIO/PREFLIGHT

X. Pre-Flight

❐ Prior to the first flight ensure that all batteries are properly

charged,that controls all move in the proper direction,and that a

thorough range check is made with and without the motor running.

❐ Rubber band the wing on using six rubber bands to secure the

wing. Use one on both the right and left side,then crisscross two

more from the right front to the left rear and crisscross the final

two from the left front to the right rear.

❐ Choose a calm day for your first flights. Also,choose an open field

with no obstacles or people.

❐ Make sure there are no other pilots operating on on the same

channel (frequency) as you are. If you turn your radio on while

he is flying, you will cause him to crash.

❐ Check you radio for good range (50 ft. with the antenna

collapsed) and proper operation.

❐ MAKE SURE NO ONE IS OPERATING ON YOUR FREQUENCY

(Channel number). Any flying field has rules to govern frequency

usage. Make sure you abide by them.

❐ Refer to your radio instruction manual for the proper ground

range you can e xpect from y our system. Perform this range check

each flying session.

❐ Check the motor,gear & propeller to make sure that everything

are secured.

❐ The rotating propeller is very dangerous, always switch on the

THE DIRECTION OF MOVEMENT (RUDDERAND ELEVATOR)

NEUTRAL RIGHTTURN LEFTTURN

Check the position of rudder and

elevator (if these are in neutral).

Set the trim in neutral position.

Move the stick to the right. Move the stick to the left.

Set the sticks in neutral position

Move the stick up. Move the stick down.

UPDOWN RIGHTAND UP

Move the stick down and right.

Page 10

10

GENERAL FLYING

transmitter first and make sure the throttle control stick or slide

throttle( ACE T3S) is at idle position.

XII. Flying

You should have a flight instructor teach you how to fly the

Sparky. Like a real airplane,you must have an understanding of how to

fly the model before launch, or you will probably not be successful.

Check at your hobby shop or call the AMA (800-435-9262) or surf its

website at www.modelaircraft.org for flying clubs in your area.

Take-off

A proper hand-launch of the airplane is necessary for flight. It

must be launched into the wind with a firm toss. The airplane must be

tossed level or even pointed a little down. It should never be thrown

upward,or it will stall and crash.

Flight

Steer very gently right and left to keep the wings level. Let the airplane climb out gradually and gently until it reaches a comfortable

cruise altitude at full flight speed. Always keep the airplane upwind of

yourself and within a reasonable distance so you can see what it is

doing. Remember,when the plane is coming toward you,when you

move the stick to the right, the aiplane will go to the left from your

point of view. This is the hardest thing to learn. Initially,you can keep

your body pointed in the same direction as the airplane and look over

your shoulder

Usually,only small stick movements are required.Try to keep your

flying smooth. You can turn the plane by bumping small amounts of

rudder and then return to neutral. Use the elevator to keep the airplane at the desired altitude. After a while,coordinate your turns with

the elevator;i.e., bank the plane with a little bit of r udder,then feed in

some up elevator to maintain the turn at the same altitude. If the plane

tends to turn one way or the other use the trim lever on the control

stick to neutralize the flight. Same thing applies if the place wants to

climb or dive.

Landing

Set up your landing approach. Always try to land INTO THE

WIND. Keep your turns gradual and only use elevator to maintain a

gradual glide. Since the motor is off,you can no longer climb and the

plane slows down. If you feed in too much up elevator,the plane will

stall and may crash.

Just before touchdown,“f lare” the plane by adding up elevator.

The plane should slow down even more and come in for a g entle landing. Don’t add too much elevator,too soon!

Walk over to the plane and turn of f the switch on the plane,then

the transmitter switch. Check over the plane to make sure nothing

loosened up or broke.

In Case of Trouble

If the radio is erratic (glitches), check that the transmitter and

receiver antennas are extended to their full length. Make sure the

transmitter batteries are fresh. Make sure no one else is operating on

your channel (frequency) in the immediate vicinity.

If the plane does not fly properly,make sure you are being gentle

with the control inputs. Make sure the plane is balanced properly.

If your trouble persists,call 660-584-6724 for technical help.

Conclusion

To defeat the laws of gravity and take to the wing is both

challenging and thrilling. We hope you enjoy your entry into the

fascinating world of R/C flight and make it your hobby for a lifetime.

Please let Ace R/C and Thunder Tiger be your chosen brand,no matter

what direction you progress.

XIII. Post-Flight

Turn off all switches and if you are done for the day,clean-up your

plane with some spray cleaner (such as 409) and paper towels. While

you are cleaning the plane up,inspect it for damage...check the prop

for dings or chips. Spray some WD40 on and in the gear section and

motor shaft for better lubrication.

XIV. Safety Precautions

1. Take great attention to the motor and propeller as they might be

deadly weapon when rotating.

2. Always switch on the Transmitter first and make sure the throttle

at the “Down”position then switch on the ESC switch.

3. Always stay behind the propeller when the motor is running.

Only switch on the motor when you are ready for launching.

Under no circumstances should you allow your face or body

near the plane on rotation of the propeller when motor is run-

ning.

4. Do not allow loose clothing or other loose objects close to the

prop.

5. To stop a motor,switch off the power or move the throttle stick

down.

6. Move the throttle stick (slide throttle) down to switch off the

power immediately in case of any CRASH,HEAVY LANDING and

NOSE DOWN or any situation that prop could not rotate freely as

it might damage the ESC and motor.

XV. Repair

In the event of a minor mishap, the Sparky usually can be

repaired. Begin by completely cleaning the area being repaired with

alcohol to remove any oil residue.

* Balsa components can be glued back together with CA glue.

* If you need to repair around the firewall/motor mount area, use

epoxy.

* Locate the covering film and heat iron for patching at your local

hobby shop if necessary.

Page 11

11

FLYING

Wind Direction

Example of a turn using

only rudder

Example of a turn using

rudder then elevator

Launch

Landing

Launch firmly into wind straight and level.

Do not throw upwards or the plane will

stall and crash!

Correct

Straight

level with ground

and

Incorrect

Wind

Wind Direction

3 ft.

Page 12

PARTS DRAWINGS

AS6159 Wing Set

AS6023 Control Horn Set

PE0009 Hardware Set

AS6160 Pushrod Set

AS6164 Decal

IMPORTANT

Please check the contents of your kit box with these part sketches before beginning

construction. This will not only familiarize you with the parts and their names, but it

will also give you a head start in the unlikely event that you are missing a part.

Parts are not necessarily drawn actual size

AS6166 Vertical T ail

AS6158 Fuselage

AS6142 Landing Gear Set

AS6165 Horizontal Tail

Fuselage(1)

Wheel (2)

Z Bent Pushrod (2)

2mm HEX Nut (2)

Control Horn Back Plate(2)

Plastic Guide Tube (2)

Main Landing Gear (1)

3mmx5mm Screw (2)

Collar (2)

2mmx8mm Screw (4)

Pushrod Connector (2)

Allen Wrench (1)

3mmx3mm Screw (2)

(Left/1,Right/1)

Dihedral Brace (2)

Wing Protector (1)

Servo T ray (2)

Bushing (2)

JE6452

Loading...

Loading...