Page 1

1

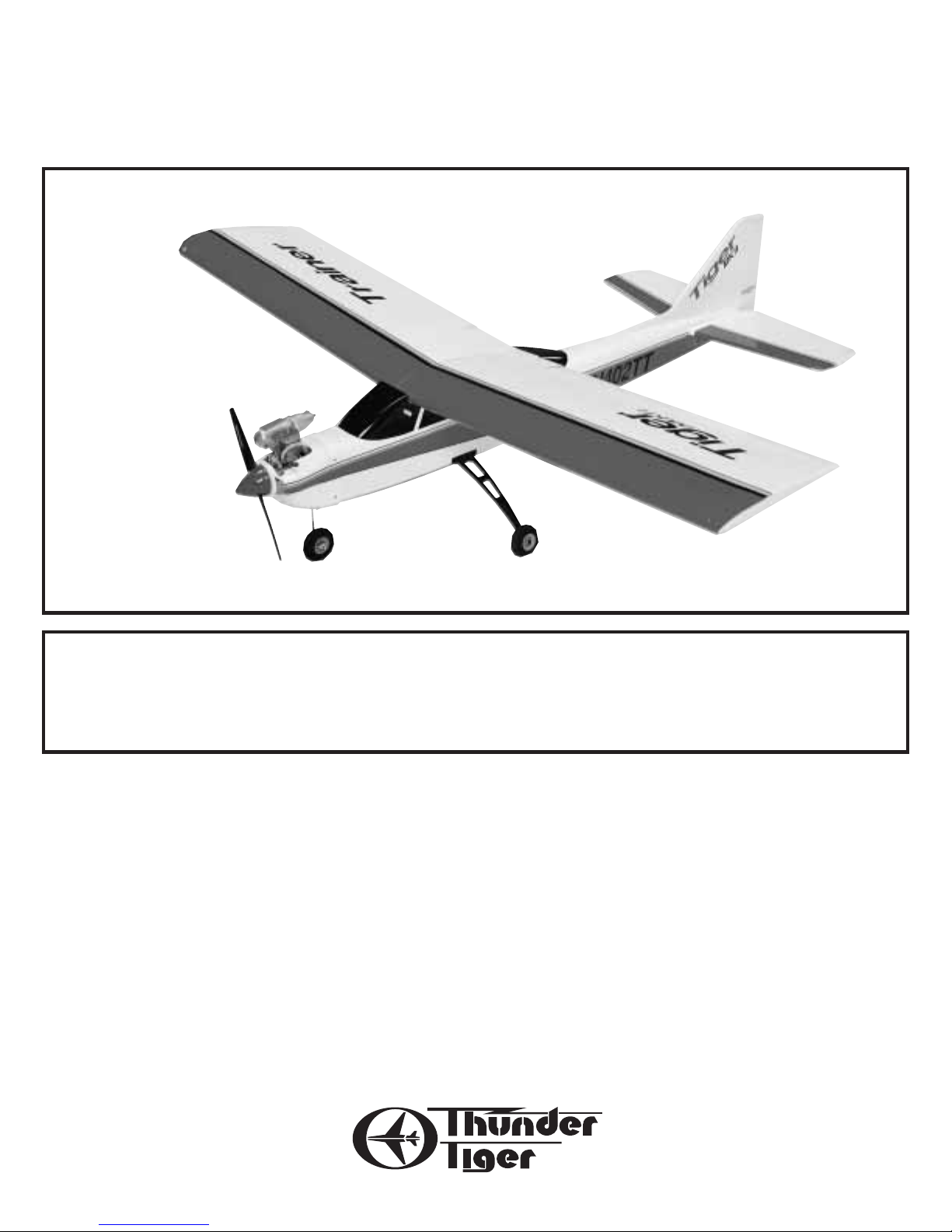

Thunder Tiger Trainer MK II Super Combo/Combo Plus/TRTF (TTR4523)

Distributed in North America by Ace Hobby Distributors, Inc.

116 W. 19th ST, Higginsville, MO 64037

Phone: (660)-584-7121 • www.acehobby.com • email: service@acehobby.com

Tiger Trainer MK II

Assembly Manual

Wingspan: 61”

Length: 51”

Wing area: 675 in

2

Weight: 5-5.5lbs

Engine: .40-45

Radio: 4 Channel

Specifications:

Warranty

This kit is guaranteed to be free from defects in material and workmanship at the date of purchase.

It does not cover any damage caused by use or modification. The warranty does not extend beyond the

product itself and is limited only to the original cost of the kit. By the act of building this user-assembled

kit, the user accepts all resulting liability for damage caused by the final product. If the buyer is not

prepared to accept this liability,it can be returned new and unused to the place of purchase for a refund.

99211/JE6131

Notice: Adult Supervision Required

This is not a toy. Assembly and flying of this product requires adult supervision.

Read through this book completely and become familiar with the assembly and flight of this airplane.

Inspect all parts for completeness and damage. If you encounter any problems, call 660-584-6724 for help.

Page 2

2

Notes

Page 3

You have purchased the most pre-fabricated radio control model

airplane on the hobby market. Three versions of this airplane are

available:

TRTF Version: This will require installation of a .40 sized engine and

a four channel radio.

Combo Plus Version: This will require installation of a four channel

radio receiver and battery pack; of course you will need the matching

transmitter. The servos and GP-42 engine are included and installed.

Super Combo: If you have the Super Combo version,it will only take

you a few minutes to get your Tiger Trainer MK II ready for flight plus

no tools or glue are required for completion. Complete radio system

and GP-42 engine are included and installed.

Please read and understand this instruction manual completely

before starting assembly. It will give you an understanding of what you

are about to do and can eliminate the possibility of mistakes. Check

the contents of your airplane for completeness. If any parts are missing, customers in the U.S. and Canada can contact Ace Hobby

Distributors, Inc. for replacement parts at the below address:

Ace Hobby Distributors, Inc.

116 W. 19th ST

Higginsville, MO 64037

(660) 584-6704

NOTE: The batteries in your radio system must be charged

for 24 hours before use. Do not attempt to fly this

airplane without charging the batteries.

3

INTRODUCTION

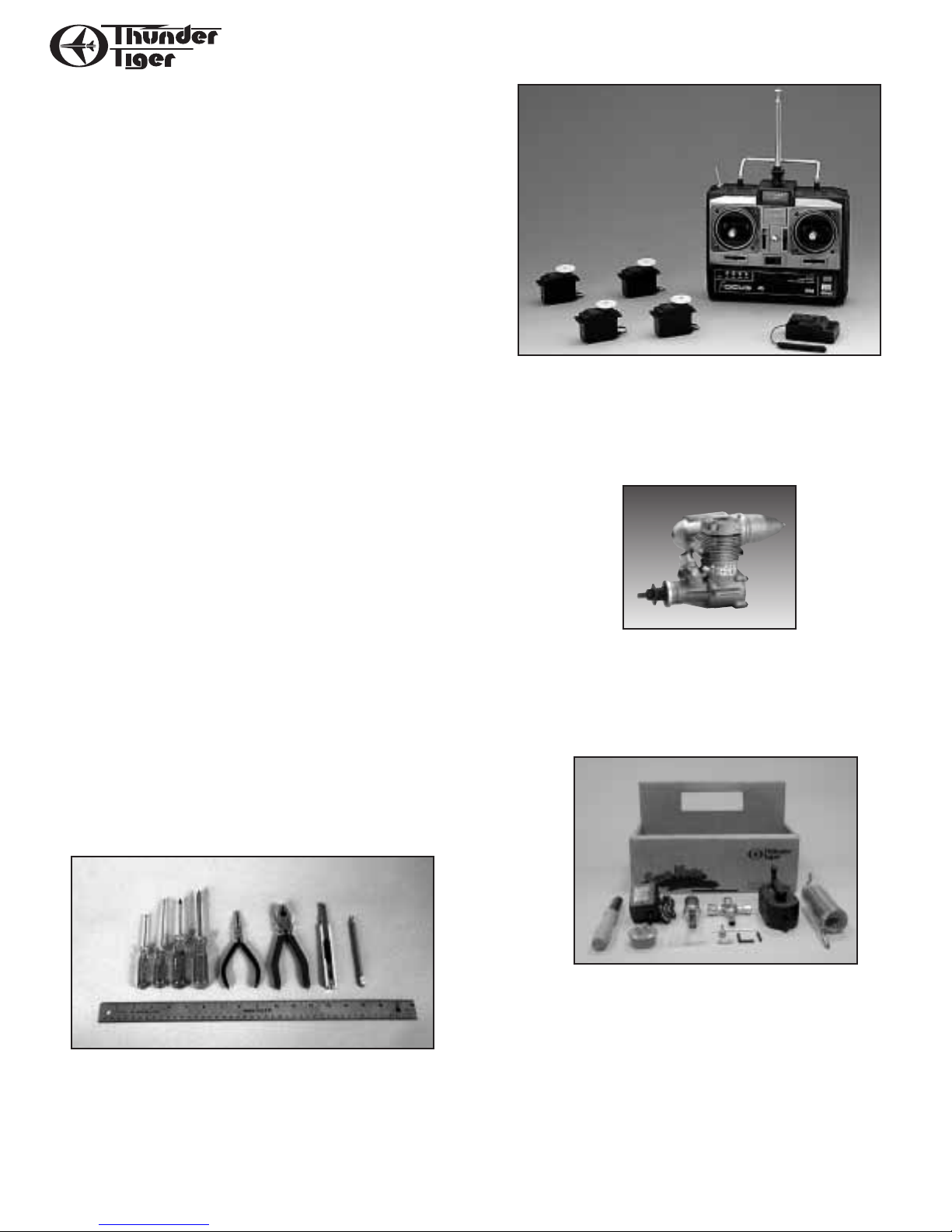

You will need the following to complete your Tiger Trainer MKII:

Super Combo: Nothing; no tools, no glue.

Combo Plus: Four Channel Transmitter, Receiver, and Battery Pack

TRTF: Four Channel Radio w/4 servos, Engine (.40-.46 cu. in.),

Household tools.

NEEDED FOR FLIGHT:

You will need “support” equipment to fly your MK II. This

includes model engine fuel (10% nitro recommended),a fuel pump or

bulb with fuel line, a glow plug clip and battery (or glow starter), electric starter or “chicken stick.”

Thunder Tiger makes a product called the “Side Kick” which contains all of the support equipment you need (except fuel) in a convenient tote box. You may want to consider this economical package if

you are just starting out.

Adhesives:

Instant setting Cyanoacrylate adhesive (thin CA)

Tools:

Model knife

Small and medium screwdrivers

Long nose pliers

Drill and drill bits

Fine felt tip pen and soft lead pencil

R/C System:

A 4-channel radio with standard servos is required for the TRTF version. Transmitter, receiver, and battery pack required for Combo Plus

Version. Radio furnished in Super Combo.

Engine:

The Thunder Tiger GP-42 is the ideal engine for this airplane.This quietrunning engine is easy to start, requires no special break-in period,

is very easy to maintain and will last for years.

Propeller appropriate for engine type and preferred performance.

Page 4

4

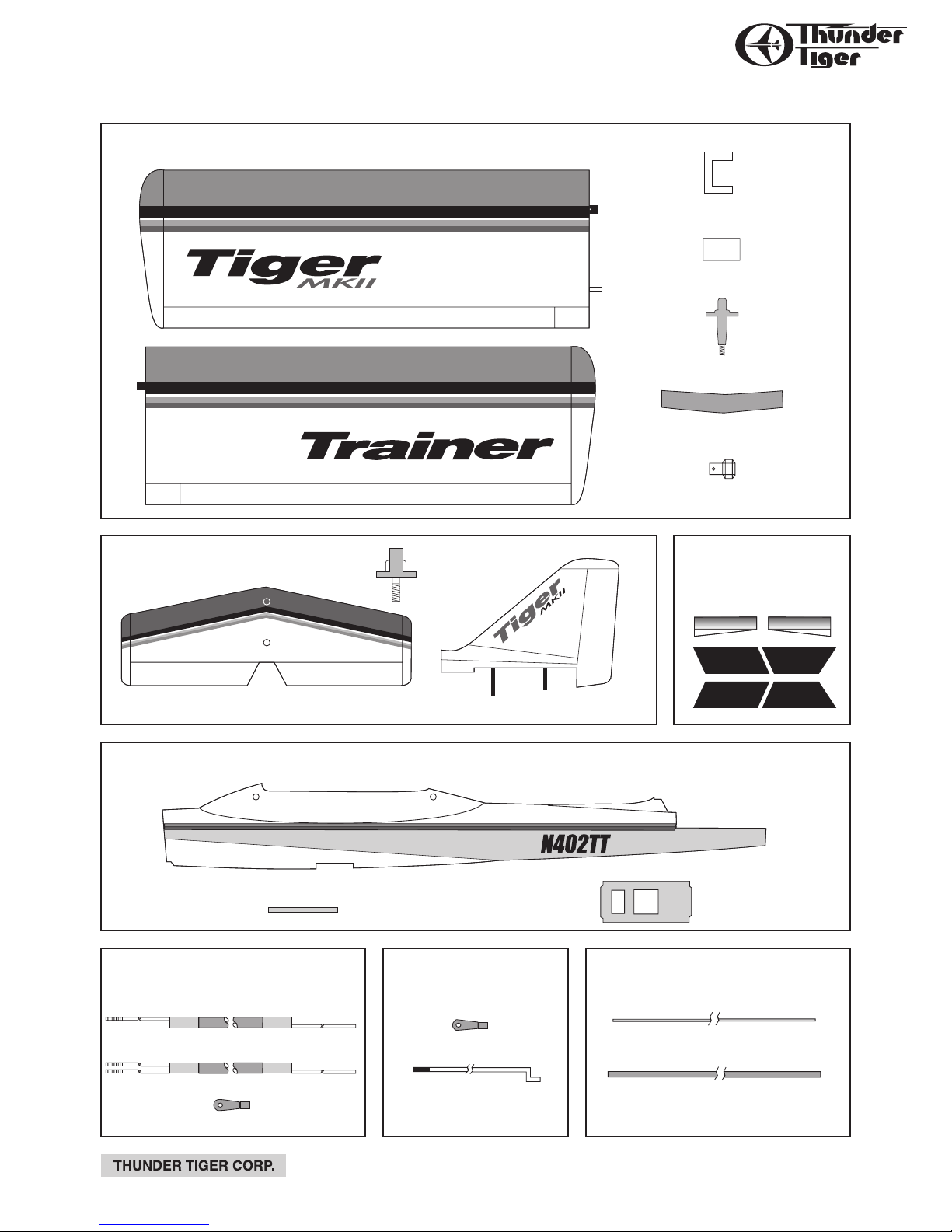

PARTS DRAWINGS

1999.10 V.1

ORDER BY BAG NUMBER ONLY

INDIVIDUAL PARTS NOT AVAILABLE

Left Wing (1)

AS6052 Wing Set

AS6053 Tail Feathers

AS6054 Fuselage Set

PE0005 Decal Set

0.05" Metal Pushrod

Plastic Guide Tube (2)

PE0577 Forward Pushrods

AS6056

Aileron Pushrods

Clevis (2)

Threaded Rod (2)

Aileron Servo Tray (1)

Plywood Wing Joiner

Torque Rod Horn (2)

Wing Dowels (2)

Fuselage (1)

Servo Tray (1)

Stabilizer/Elevator (1)

Vertical Fin/Rudder (1)

Right Wing (1)

AS6055 AFT Pushrods

Rudder Pushrods (1)

Clevis (3)

Retaining Screw (1)

Retainning Screw (2)

Wing Protector (2)

Stab Pushrod (1)

Page 5

5

PARTS DRAWINGS

1999.10 V.1

ORDER BY BAG NUMBER ONLY

INDIVIDUAL PARTS NOT AVAILABLE

Straight

Nipple (1)

Cap (1)

PE0004 Hardware Set

3mm x 3mm

Set Screw (1)Push Rod Connector (2)

2mm Hex Nut (2) Allen Wrench (1)

3263 Fuel Tank Set

Silicone Tube (1)

Clunk (1)

90˚ Nipple (1)

(Not Used)

Rubber Stopper (1)

300 c.c. Tank (1)

3150 Control Horn Set

2mm x 12mm Screw(6)

Wood Screw

2.6mm x 8mm (4)

3296 Wheels Set

(sold in pairs)

Wheel (3)

3162 Hinge Set

Point Style Hinges (15)

Windshield (1)

PE0002 Window Set

Rear Window (1)

3mm Hex Nut (2)

Spinner (1)

Self-Tapping Screw

3mm x 12mm (2)

3222R Spinner Set

Spinner Back Plate (1)

AS6050 Nose Gear Set

Steering Arm Collar (1)

Wheel Collar (2)

Steering Arm (1)

Nose Gear Wire (1)

Screw

3mm x 5mm (3)

PE0003 Cowl Set

Left Cowl (1) Right Cowl (1)

Control Horn (3) Nut Plate (3)

3102 Adjustable Engine Mount

Engine Mount Plate (1)

Beams (2, left/right)

Screw

3mm x 15mm (4)

6/32 x 18mm

Screw (6)

6/32 Blind Nut (6)

Nose Gear Bearing (1)

300 c.c.

AS6051 Main Landing Gear Set

AS6057 Decal Set

Main Landing Gear

4x32mm Screw (2)Mounting Plate (1) 4mm Locknut (1)

3x18mm

Self-Tapping Screw (4)

Page 6

6

ASSEMBLY

I. IF YOU HAVE A SUPER COMBO:

Skip to Section IV: ASSEMBLY on page 9.

II. IF YOU HAVE A COMBO PLUS:

Before performing the final assembly steps, it is necessary to

install your receiver and battery pack in the airplane, following your

radio system’s instructions.

The connectors on the servos and switch harness are compatible

with Futaba “J” style radios. If you are using a different type radio,you

will need to either modify the connectors or obtain adapters. The

small polarizing ear on the servo and switch harness connectors can

be carefully trimmed off with an Xacto knife to allow it to be plugged

into JR,Hitec, and Airtronics (Sanwa) “Z” receivers. If you have an older

style Airtronics (Sanwa) radio, you MUST obtain adapters because the

polarity is opposite all other brand radios.

Remember to wrap the receiver and battery pack in at least 1/4”

thick foam. Route the receiver antenna out the rear of the wing opening; if you wish, drill a 1/16” hole in the rear window for an antenna

exit. MAKE SURE you don’t put any strain on the antenna wire coming out of the receiver; have some sort of strain relief. Also, make sure

you don’t lengthen or shorten the antenna; performance will be

affected. Continue the antenna wire to the top of the fin and hook

with a straight pin and a small rubber band. Any excess can just trail

out the back of the plane.

Skip to Section IV: ASSEMBLY on page 9.

III. IF YOU HAVE THE TRTF VERSION:

A. Install the Main Gear

Referring to Sec. IV, Step A, secure the Main Gear in place. It will

help stabilize the fuselage as you work on it.

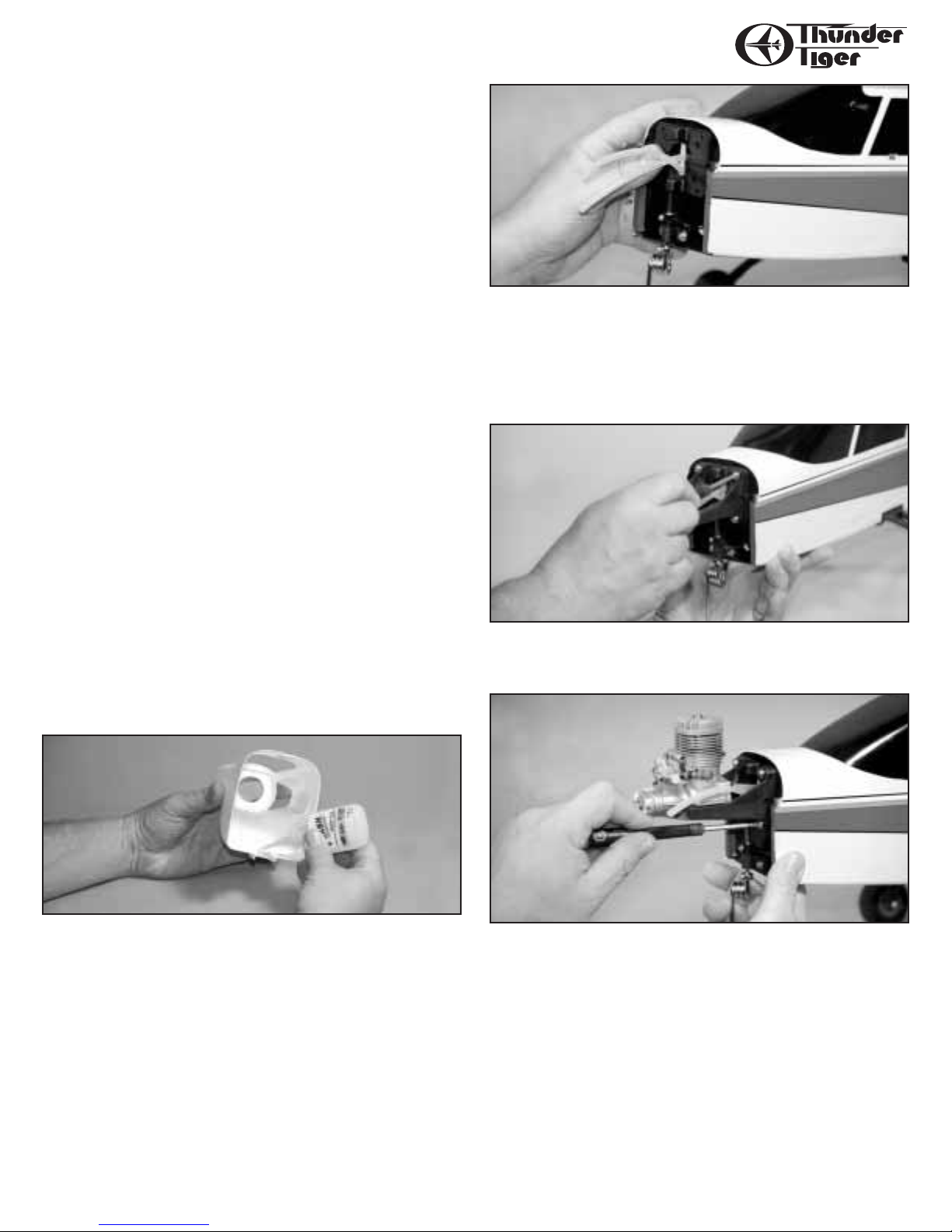

B. Engine/Cowl Installation

1. Test fit the two halves of the injection molded cowl together.

Trim away any molding “flash” that prevents a good fit. With the two

halves pressed tightly together,sparingly apply thin CyA glue along the

joint. Prevent runs by applying most of the glue from the inside.

2. Locate the three black nylon engine mount parts and the four

3X16 mm bolts. Position the engine mount plate on the firewall by

threading the fuel line coming from the fuel tank through the large

hole in the middle of the plate. Next, slip the bottom bracket on the

plate over the top of the nose gear assembly. You should now be able

to position the plate against the firewall and lined up with the four

mounting holes.

3. Place the left and right engine mount beams in position and

loosely hold in place with the four 3X16 mm bolts. The reinforcing

‘web’ on both beams should face upward and outward as shown.

4. Set your engine in place and adjust the engine mount beams so

they are centered on the plate and almost touching both sides of the

engine crankcase. Securely tighten the four bolts.

Page 7

7

ASSEMBLY

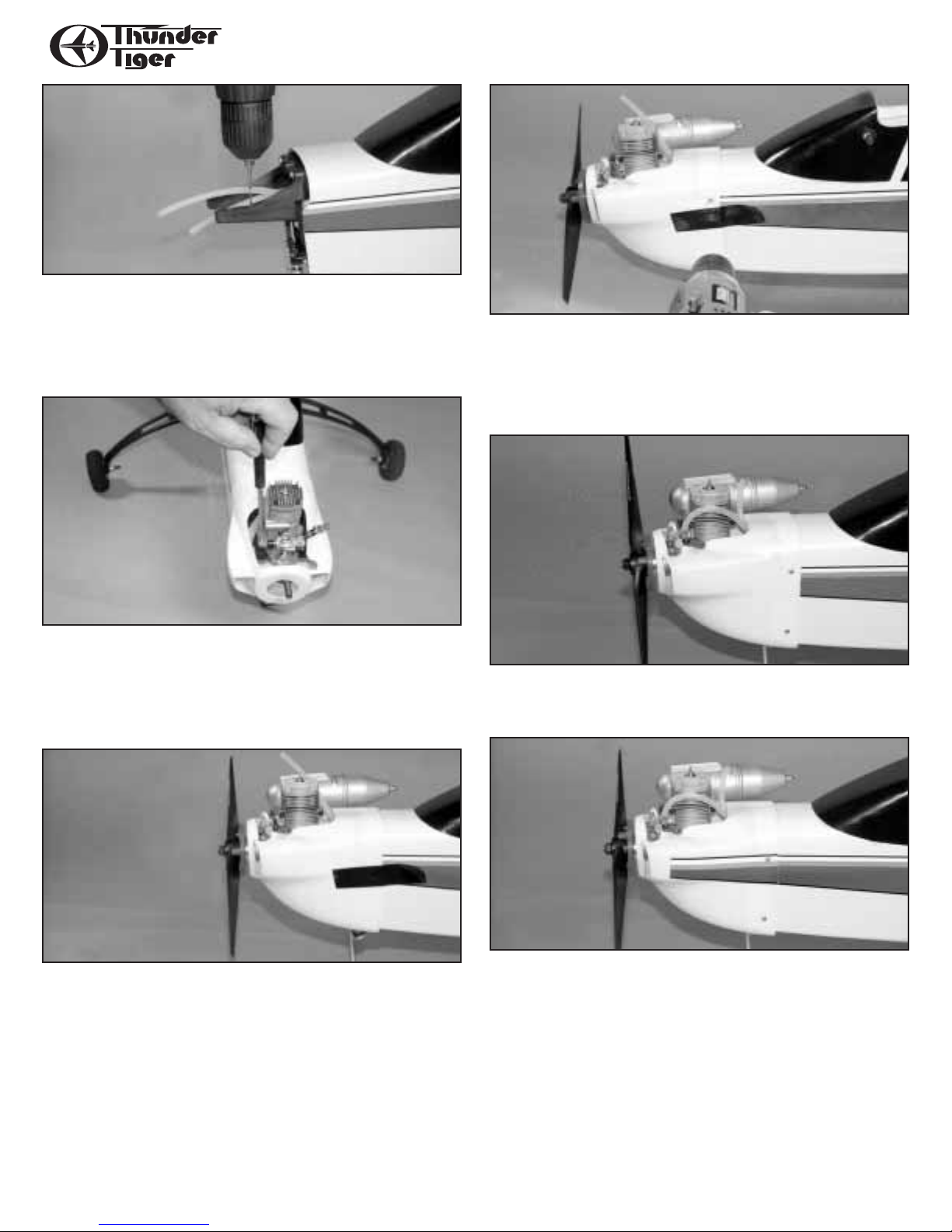

5. Position the engine so the thrust washer is 4 1/4” from the firewall. Making sure the engine is square on the mount, mark the four

hole positions on the beams with a pencil. Remove the engine and

drill 3/32”holes at each of the marked locations,making sure the holes

are perpendicular with the beams. Run the 3 X 15 mm self-tapping

engine mount screws in and out of these holes to establish threads.

6. There is a ‘z’ bend on the end of the throttle linkage. It connects the engine’s throttle arm to the linkage. Hook the ‘z’bend into

the throttle lever’s innermost hole, slip the cowl over the engine

cylinder head and move this assembly into position on the engine

mount (you will probably have to remove the needle valve). Secure

the engine with four 3 X15 mm self-tapping screws.

7. Install the muffler onto the engine. If needed, trim the cowl

for at least 1/8” clearance around the muffler and needle valve. Place

the spinner backplate on the engine prop shaft and temporarily secure

it with the prop, prop washer,and prop nut. Adjust the cowl until it is

centered behind the spinner with about 1/8” clearance between the

backplate and the cowl. Use a couple pieces of tape to hold it in place.

8. Drill four 1/16” holes through the cowl and into the fuselage

about 1/4” deep. Locate these holes about 3/8” forward of the rear

edge of the cowl. The bottom holes should be about 1/2”from the bottom edge of the fuselage and the upper hole should center in the yellow pin-stripe. Secure the cowl with the four 2X10 mm wood screws

furnished.

9. Route the fuel and vent lines to their correct fitting. The top

line is the vent line and goes to the pressure tap on the muffler; the

bottom line is the fuel line and goes to the carburetor.

10. Apply the cowl decals to the cowl, lined up with the stripes

on the fuselage. Note there is a right and a left.

Page 8

8

ASSEMBLY

11. Complete the spinner installation. Loosen the prop nut and

rotate the spinner backplate so the two little posts rest against the

prop trailing edge; then tighten the prop nut. Use the two special

screws furnished to secure the spinner nose cone onto the backplate.

12. Secure the wheel onto the nose gear using the wheel collar

and set screw furnished. Make sure it turns freely.

C. Install the Radio

1. Refer to your radio system’s instruction manual for complete

installation instructions. Prepare your servos by putting the rubber

grommets in the mounting ears. Install three of the servos in the fuselage’s servo tray, positioning them as shown. As you install each servo,

pass the connector end of the cable through to the forward compartment so you can plug into the receiver later. Drill 1/16” pilot holes

before securing the servos using the screws furnished with your radio.

Next,cut a hole in the side of the fuselage and drill holes to mount the

switch, using the switch cover as a template. Mount the switch.

2. Hooking your servos to the linkage is done according to the above

drawing. The pushrods are secured to

the servo wheels or arms with “z”

bends. (Note: the elevator pushrod has

two rods exiting the tail; the rudder

pushrod has only one.)

The throttle pushrod and the

nosegear pushrod are connected to the

servos with “EZ” connectors. The “EZ”

Connector barrel is attached to the

servo wheel/arm with the furnished

nut. The pushrod is secured in the barrel with a set screw and Allen

wrench, which makes the pushrod length easily adjustable.

3. Install your aileron servo in the tray that is glued into the left

wing half as shown. Linkage to the ailerons is done via two pushrods

with a “z” bend on the servo end and a nylon clevis on the aileron

torque rod end. Hook up the “z” bend ends of the two aileron

pushrods to both sides of the servo wheel/arm and secure the

wheel/arm to the servo. Snap the clevis onto the nylon torque rod

horn on the left aileron. You will attach the clevis to the right aileron

torque rod horn when the wing is joined.

4. Plug the servos into the proper receiver outlets. Wrap the

receiver and battery pack in at least 1/4”thick foam. Route the receiver antenna out the rear of the wing opening; if you wish, drill a 1/16”

hole in the rear window for an antenna exit. MAKE SURE you don’t

put any strain on the antenna wire coming out of the receiver; have

some sort of strain relief. Also, make sure you don’t lengthen or shorten the antenna; performance will be affected. Continue the antenna

wire to the top of the fin and hook with a straight pin and a small rubber band. Any excess can just trail out out the back of the plane.

Z-bend

to throttle arm

receiver

to nose gear

throttle servo

elevator servo

EZ connector

pushrod

to elevator

to rudder

rudder servo

allen wrench

set screw

barrel

nut

servo wheel or arm

Page 9

9

ASSEMBLY

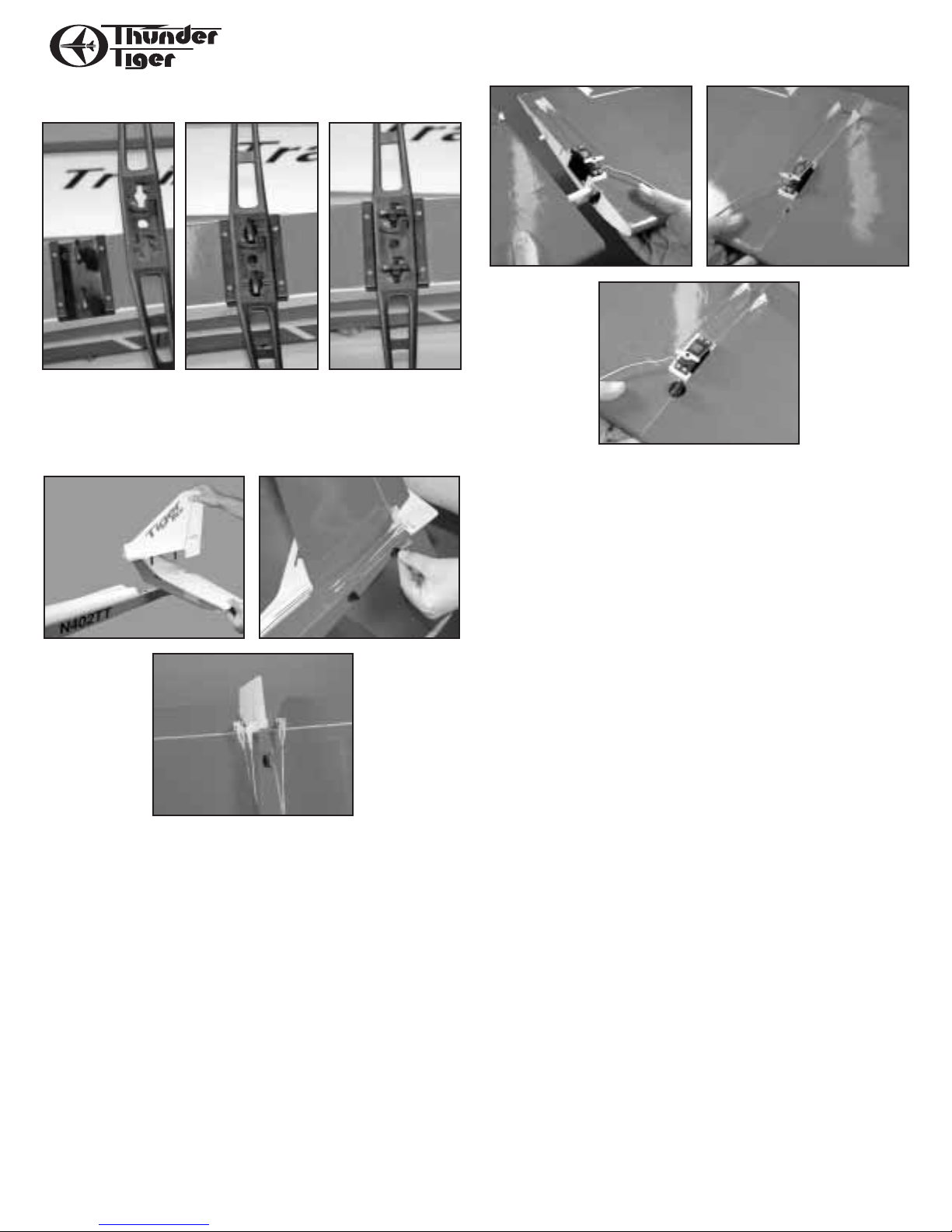

IV. ASSEMBLY

A. Secure the main landing gear

The main landing gear is secured by a “twist ‘n lock” system.

Simply put the landing gear into position on the belly of the airplane

then rotate the thumb tab 1/4 turn clockwise until it snaps into the

groove.

B. Attach the tail

The vertical fin and horizontal stabilizer attach to the fuselage

with the two thumb screws furnished. Insert the plastic posts that

protrude out the bottom of the fin through the sleeves in the stabilizer as shown,then slip them into the sleeves in the rear of the fuselage.

Secure the tail assembly to the fuselage with the two special thumb

screws, making sure they are firmly tightened and the tail assembly is

securely attached to the fuselage.

Snap the pushrod clevises into the holes in the control horn as

shown.

C. Join the wing

Insert the dihedral brace into one wing half. Slip the other wing

half into place, lining up both the plastic joiner blocks and the rear

alignment dowel as the wing comes together.

Secure the connection with the special tapered thumb bolt,

screwing it in until it is snug to the bottom of the wing. Do not overtighten!

Snap the servo linkage clevises into the holes in the nylon horns

that are pre-installed on the aileron torque rods.

D. Charge the batteries

Refer to the Radio’s Instruction Manual.

Note that there is an unoccupied two-wire connector coming

from the receiver switch. It is your charging jack. The switch must be

OFF in order to charge the batteries. Plug the Receiver output from

your radio system charger into this connector. Plug the Transmitter

output into the charge jack on your transmitter. Now plug the

charger into a wall outlet. The two LED indicator lights should be lit,

indicating that current is flowing into the batteries. If not, double

check that connections are secure and both switches are off.

The first time you charge your batteries,leave them on charge for

24 hours. For all subsequent charges, charge the batteries overnight

(14-16 hours).

Page 10

E. Radio Check

Note that there is an unoccupied three wire cable coming from

your receiver. This is the receiver output for the aileron servo in the

wing. Plug the aileron servo into this cable’s connector and put the

wing in its place on the fuselage. Hold it in place with a few rubber

bands. Turn on your transmitter and then the receiver. Move the sticks

and observe the motion of the control surfaces on the airplane.

Referring to Drawing Four, make sure the direction of travel of

the control surfaces matches the proper direction of stick movement.

If it is opposite, refer to your radio system instructions on how to

reverse the servo travel.

Also make sure the surfaces are in neutral when both the stick

and the trim lever are in the center. If not, unsnap the clevis from the

control horn and screw it in or out until neutral is achieved.

Also make sure the amount of movement (throw) is proper. If the

throw is too much,move the clevis out on the control horn. If it is two

little, move the clevis in on the control horn. You will have to re-neutralize the surface when you’ve made a throw adjustment.

F. Balance Check

With the wing on the airplane, use your two index fingers to suspend the model in the air. Locate your fingers 3 3/4” back from the

leading edge of the wing,about 4” out from the fuselage. At this point,

a right angle is formed where the leading edge and the center balsa

sheeting ends. You can feel this point with your finger tips.

The plane should hang level or slightly nose down at this point.

If the tail drops, you need to redistribute or even add weight to the

nose until the plane balances. You can move the receiver battery pack

10

RADIO CHECK

to above the fuel tank if you need to. If the plane’s nose drops dramatically, add a little weight to the tail as a remedy. Stick-on weights

are available at your hobby shop for this purpose.

V. PRE-FLIGHT

A. Charge your batteries if it has been over two weeks since

they were charged last.

B. Rubber band the wing on:

Plug the aileron servo into the aileron cable coming from the

receiver. Making sure the excess cable is down inside the fuselage,

attach the wing to the fuselage using the rubber bands furnished. Use

eight rubber bands to secure the wing. Use two on both the right and

left side, then crisscross two more from the right front to the left rear

and crisscross the final two from the left front to the right rear.

C. Radio Check

MAKE SURE NO ONE IS OPERATING ON YOUR FREQUENCY

(Channel number). Any flying field has rules to govern frequency

usage. Make sure you abide by them.

Refer to your radio instruction manual for the proper ground

range you can expect from your system. Perform this range check

each flying session.

Move the transmitter sticks and verify that all control surfaces are

moving in the proper direction relative to stick motion. Make sure all

are working smooth and nothing is loose or binding.

Make sure all servo wheel/arm screws are in place. It is a common problem for a servo wheel to fall off a servo because the screw

was not re-installed after an adjustment!

Check the engine and engine components; make sure all screws

are tight.

D. Fuel-up the engine

Remove the fuel line from the engine’s carburetor. Plug your fuel

pump or bulb into this line. Pump fuel into the tank until you see it

coming out the line that is going to the engine’s muffler. (You may

want to remove this line from the muffler to prevent fuel from getting

into the muffler.)

high throttle killidle

3-3/4"

1/2"

down elevator up elevator

7/8"

right rudder right aileron

3/8"

1/2"

3/8"

pick up model at arrows

Page 11

11

FLYING

NOTE: If you get these fuel lines mixed up, look down into the

engine compartment and observe the fuel tank. The fuel line going

to the lowest part of the tank is the “fuel” line;it goes to the carb. The

other line that goes to the upper part of the tank is the “vent” line; it

goes to the muffler. Realize that the fuel system is a “closed loop” system; the back pressure in the muffler maintains a positive fuel flow

to the engine. Any air leaks in the system will degrade performance.

E. Start the engine

Carefully read and understand the Engine Operating Instructions

furnished so you are familiar with the operation of a model airplane

engine. As it comes in your Super Combo or Regular Combo Plus, it

should be ready to start as installed. Simply “choke” the engine, hook

up a hot 1.2V-1.5V battery to the glow plug, and flip the prop with a

“chicken stick” or an electric starter. Follow the break-in procedures

in the Engine Operating Instructions for the first 4 or 5 flights.

VI. FLYING

It is strongly recommended that you have a qualified instructor

teach you to fly. Without training, the likelihood of having a mishap is

increased greatly, just as if you were flying a real airplane. Also, there

are several good computer simulators on the market that can help

teach you the skills necessary for success. Talk to your hobby dealer

about instructors available in your area plus the simulators that he has

available.

You should join the Academy of Model Aeronautics. This membership is required by most clubs plus it provides liability insurance in

the case of an accident. Contact the AMA at:

5151 East Memorial Dr., Muncie, IN 47302

GETTING ORIENTED

We recommend that you find a large smooth and clear surface to

practice taxing your airplane around in before you try a take off.

To taxi, you only need to use the rudder stick. At the slow speeds

encountered during taxing, the elevator and ailerons will not be

effective. The first and most important thing to remember when controlling model aircraft is:the model controls are set up to operate as if

you were sitting in the cockpit of the model. This means that when

you pull back (down) on the elevator stick the nose of the plane will

go up. Moving the rudder stick to the right will “yaw”the plane to the

right and moving the aileron stick to the right will “roll” the plane to

the right. Pretty simple right? Well, not quite. Since you are really standing on the ground and not sitting in the plane,this is how the controls

work when you are facing the same direction the plane is flying.The

problem is that when the plane is flying towards you, the rudder and

aileron controls seem reversed to the inexperienced pilot.This is the

reason we recommend that you practice taxing around in a large open

area to try and get used to the control reversal.

During your first few flights, try to face the direction that the plane is

flying and looking over your shoulder as needed.This makes it a little

easier to pretend that your sitting in the cockpit.

FIRST FLIGHT

When you are comfortable with the controls,you should be ready

for your first flight. Go over the Pre-Flight Check List one more time

for good measure and taxi out to the runway (hopefully with an experienced pilot by your side). Point the model directly into the wind and

gradually increase the throttle to full throttle. As the model starts

rolling forward it may try to turn to the left due to the engine torque.

Apply enough right rudder to keep the plane rolling relatively straight

into the wind. If you built the model with right thrust, this tendency

may not be noticeable.As the plane picks up speed, the right rudder

input can be reduced.

Once the plane reaches flying speed, it will probably try to fly by

itself.If the grass seems to be impeding takeoff,a very slight amount of

“up” elevator can be applied, but it is very important that you do not

apply too much up elevator too early or the plane will stall and roll

over into the ground.

As the plane becomes airborne, reduce the “up” elevator and

allow the plane to pick up flying speed while gently gaining altitude.

Once a safe flying speed and altitude has been obtained, feel free to

turn the airplane back toward the flying field. Make all control inputs

smoothly and gradually so you can see the effect they have on the

plane.A small amount of “up” elevator will need to be applied to keep

the plane level during turns.You should be able to reduce the throttle

to about 1/2 throttle for normal cruising flight which will reduce the

flying speed and give you more time to think about what is going on.

You will find that once airborne, you can fly the plane with only the

aileron and elevator sticks.This is perfectly fine and will make it much

easier for you to learn.

If the plane has a tendency to turn, roll, climb, or dive, you can

adjust the transmitter trims to correct this. On your first flights, it

might be a good idea to have an experienced pilot make the adjustments for you while you fly the plane.

If you get disoriented or the plane gets out of control,simply take

your hands off all the controls and allow the plane to stabilize. Clear

your head and try to picture yourself sitting in the cockpit.Then input

Page 12

12

the required control movements to get the plane back on the correct

flight path. If you run out of time or flying space and realize the plane

is going to hit something (ground, tree, etc), pull the throttle back to

idle and pull the elevator stick back about half way.This will reduce

the speed of the plane and minimize the damage sustained.

When you are ready to land, do a couple of slow fly-bys at a safe

altitude to get familiar with the plane’s slow-flying characteristics.An

important factor to remember here is that you should regulate your

altitude with the throttle not the elevator as you might expect.Practice

raising the nose of the plane slightly with a touch of “up” elevator and

then using the throttle to regulate the plane’s altitude.When you are

ready to land,fly downwind past the runway.When the plane is a hundred yards or so downwind, reduce the throttle to almost an idle and

turn 90 degrees towards the runway. Fly straight for a second or two

until the plane is almost even with the runway.Turn 90 degrees again

and fly directly toward the runway using the throttle to govern how

quickly the plane is descending. Keep the nose of plane up slightly

with the elevator and allow the plane to fly gently onto the runway.

Do not try to stretch the glide path without increasing the throttle or

the plane may stall.

VII. POST-FLIGHT

Turn off all switches and if you are done for the day, de-fuel the

tank. Clean-up your plane with some spray cleaner (such as 409) and

paper towels. While you are cleaning the plane up, inspect it for damage...check the prop for dings or chips. Spray some WD40 on and in

the engine for protection.

If you want, you can disassemble your airplane for easy transportation. Disassembly is as simple as assembly. You can remove the

landing gear, break the wing down in two pieces, and remove the tail.

Just make sure you don’t lose any of the hardware, especially the special thumb screws.

When you get home, ALWAYS charge your batteries overnight,

even if you only flew once.

VIII. SAFETY PRECAUTIONS

1. Wear safety glasses when starting and running all model engines.

2. Model engine fuel is very flammable and the flame is very dan-

gerous because it is almost invisible! Do not smoke or allow

sparks, high heat or other flames near the fuel.

3. Do not run model engines inside a garage or other closed room

as they give off large amounts of deadly carbon monoxide gas.

4. Do not run model engines around gravel, sand or other loose

debris.These materials will be ingested through the carburetor

and can also be kicked up by the prop.

5. Always stay behind the propeller when the engine is running.

Make all engine adjustments from behind the engine. Under no

circumstances should you allow your face or body near the

plane on rotation of the propeller when the engine is running.

6. Do not allow loose clothing or other loose objects close to the

prop.

7. To stop an engine, cut off the fuel or air supply to the engine.

Do not throw rags or other objects into the prop to stop the

engine.

8. Do not touch the engine or muffler during or right after it has

been running–It gets very hot!

IX. REPAIR

In the event of a minor mishap, the MKII usually can be repaired.

Begin by completely cleaning the area being repaired with alcohol to

remove any oil residue.

• Balsa components can be glued back together with CA glue.

• If you need to repair around the firewall/engine area,use epoxy.

• The plastic parts can be taped back together,deleted, or rebuilt out

of balsa.

• Use Carl Goldberg Models’ Ultracote® to patch the covering film.

Loading...

Loading...