Page 1

JE6911

Assembly Instructions

Warranty

Thunder Tiger Corp. guarantees this model kit to be free from defects in both material and

workmanship at date of manufacture. This warranty does not cover any components

damaged by use or modification, and in no case shall Thunder Tiger's liability exceed the

original purchase price of the kit. Thunder Tiger also reserves the right to change or

modify this warranty without notice.

Since Thunder Tiger Corp. has no control over possible shipping damages or construction

by the modeler, no liability can be assumed nor accepted for damage resulting from the

use by the user or the final user-assembled product. By the act of using this userassembled product, the user accepts all resulting liability. If the buyer is not prepared to

accept this liability, he should return this kit in new and unused condition to the place of

purchase for a full refund.

1

No.4582

16

POST-FLIGHT CHECK

SAFETY PRECAUTIONS

1.Wear safety glasses when starting and running all

model engines.

2.Model engine fuel is very flammable and the flame is

very dangerous because it is almost invisible! Do not

smoke or allow sparks, high heat or other flames near the

fuel.

3.Do not run model engines inside garage or other closed

room as they give off large amounts of deadly carbon

monoxide gas.

4.Do not run model engines around gravel, sand or other

loose debris. These materials will be ingested through

the carburetor and can also be kicked up by the prop.

5.Always stay behind the propeller when the engine is

running. Make all engine adjustments from behind the

engine. Under no circumstances should you allow your

face or body near the plane on rotation of the propeller

when the engine is running.

6.Do not allow loose clothing or other loose objects close

to the prop.

7.To stop an engine, cut off the fuel or air supply to the

engine. Do not throw rags or other objects into the prop to

stop the engine.

8.Do not touch the engine or muffler during or right after it

has been running-It gets very hot!

9.If you hear any unusual noises while your plane is flying,

land at once and determine the problem before returning

to the air. Control surface flutter, which often emits a lowpitched Buzz, can quickly destroy an airplane and

should not be ignored. Flutter is usually caused by sloppy

control surfaces and is generally relatively easy to cure.

If you get disoriented or the plane gets out of control,

simply take your hands off all the controls and allow the

plane to stabilize. Clear your head and try to picture

yourself sitting in the cockpit. Then input the required

control movements to get the plane back on the correct

flight path. If you run out of time or flying space and

realize the plane is going to hit something (ground, tree,

etc), pull the throttle back to idle and pull the elevator

stick back about half way. This will reduce the speed of

the plane and minimize the damage sustained.

When you are ready to land, do a coupler of slow fly-bys

at a safe altitude to get familiar with the plane's slowflying characteristics. An important factor to remember

here is that you should regulate you altitude with the

throttle not the elevator as you might expect. Practice

raising the nose of plane slightly with a touch of “up”

elevator and then using the throttle to regulate the

plane’s altitude. When you are ready to land, fly

downwind past the runway. When the plane is a

hundred yards or so downwind, reduce the throttle

almost an idle and turn 90 degrees towards the runway.

Fly straight for a second or two until the plane is almost

even with the runway. Turn 90 degrees again and fly

directly toward the runway using the throttle to govern

how quickly the plane is descending. Keep the nose of

plane up slightly with the elevator and allow the plane to

fly gently onto the runway. Do not try to stretch the glide

path without increasing the throttle or the plane may

stall.

1.Be sure that both the transmitter and receiver switches

are turned off.

2.Drain all excess fuel from the tank. Fuel left in the tank

for extended periods can “gunk up” the tank, fittings and

carburetor.

3.Clean the plane with paper towels and a light-duty

spray cleanser. Keeping your plane clean will make it last

longer and keep it looking nice.

4.Put a few drops of after-run or light oil in the carburetor

and turn the prop over a few times (without the glow plug

ignited) to distribute the oil throughout the engine.

5.Inspect the prop and replace it if any chips or cracks

are found.

6.Inspect the entire plane for covering tears, new dings

and dents, loose screws and connect connectors and

any other wear and tear.

7.Use a voltmeter to check the receiver battery voltage.

If it is low, you now know not to fly so long next time. If it

is still high, you should be able to fly a little longer next

session.

POST-FLIGHT CHECK LIST

Page 2

INTRODUCTION

Tools-Model assembly can be much easier if the proper

tools are used. Therefore we have included in our

checklist to above, a complete listing of all the tools we

used to assemble our prototype models. As you will

notice, many household tools can be utilized during

construction.

Engine The Thunder Tiger GP-61 and F-75S are the ideal

engines for this airplane. These quiet running engines are

easy to start, require no special break in periods, are very

easy to maintain and will last for years.

Flight Equipment There are several “support” items

that you will need to purchase in order to get your engine

running and your plane in the air. These are listed at the

bottom.

ITEMS NEEDED

Introduction

A checklist is also provided on the next page which

will make shopping for these items easier.

OTHER ITEMS REQUIRED FOR

ASSEMBLY

Radio - A 4- channel radio with 4 standard servos is

required. Most lower priced 4-channel radios only

come with three standard servos so you may need to

purchase the fourth servo separately.

Comprehensive Items Needed Check List

4-Channel Radio with 4 Standard Servos

5-Minute Epoxy (4 ounces or so)

30-Minute Epoxy (4 ounces or so)

“Thin” Instant Adhesive (1/2 ounce)

“Thick” Instant Adhesive (1/2 ounce)

Hobby Knife and Blades

Epoxy Mixing Sticks and/or Brushes

Sandpaper (150 grit)

Masking Tape

Rubbing Alcohol

Paper Towels

Ruler

90 Degree Triangle

Waxed Paper

Fine-Point, Felt-Tip Pen

Misc. Household Tools

Drill and Bits (1/16", 5/64", 9/64”)

Flight Equipment Needed Check List

Foam Rubber Padding for the Radio

Stick on Lead Strip for Balancing the Plane

3 or 4 Props (see engine instructions)

10%-15% Glow Fuel

Fuel Pump or Bulb

Electric Starter or “ Chicken Stick”

Glow Starter

Extra Glow Plug(s)

Silicon Tubing

Adhesives- You will need two types of adhesives for the

Tiger Trainer - Epoxy and Instant ( cyanoacrylate )

adhesives. We recommend that you purchase both 5minute and 30-minute epoxy to cut down on assembly

time, but you can get by with only 30-minute epoxy if time

is no important. You will also need a small bottle of both

"Thick" and "Thin" instant adhesive.

All of us at Thunder Tiger want to thank you for choosing the best looking, easiest building and best flying ARF trainer

available, the Tiger Trainer 60 MKII.The kit features state-of-the-art engineering that provides quick and easy

assemble of a strong, yet lightweight airplane that will give you an enjoyable and educational experience.

To gain the most from this airplane kit, it is important that you read the instructions thoroughly and then follow them

exactly. This instruction manual has been written with a novice modelers in mind, but includes many hints and

modeling tips that even experienced modeler can benefit from. We strongly suggest that you read through the

construction sequence and eliminate many questions you might have if you did not read the manual prior to starting the

actual construction.

The first thing you should do before beginning assembly is to check the contents of your kit against the parts list on

pages 4 and 5. If any parts are missing, contact your dealer or authorised Thunder Tiger Distributors immediately for

replacement.

32

No.9060

No.9802

Introduction...........................................................................................2

Other Items Required..........................................................................2

Items Need Check List ............................................................................3

Parts List..............................................................................................4-5

Pre-assemble Notes............................................................................6

Wing..........................................................................................7

Fuselage..............................................................................................7-8

Install the Engine................................................................................8-9

Install Fuel Tank..........................................................................................9

Tail....................................................................................................10-12

Install The Radio..........................................................................................12-13

Balance & Final Assembly Flight.................................................14-16

TABLE OF CONTENTS

Carry Master-Thunder

Tiger offer a complete

organizer of field

equipment. All you

need is included.

No.1263-65

ACCESSORIES

12V DC Starter- Provides high

torque starting power to start

your outboard engine.

Sealed Battery- 7Ah 12V

Sealed Battery.

No.2674

No.2624

GP-61

F-75S

Page 3

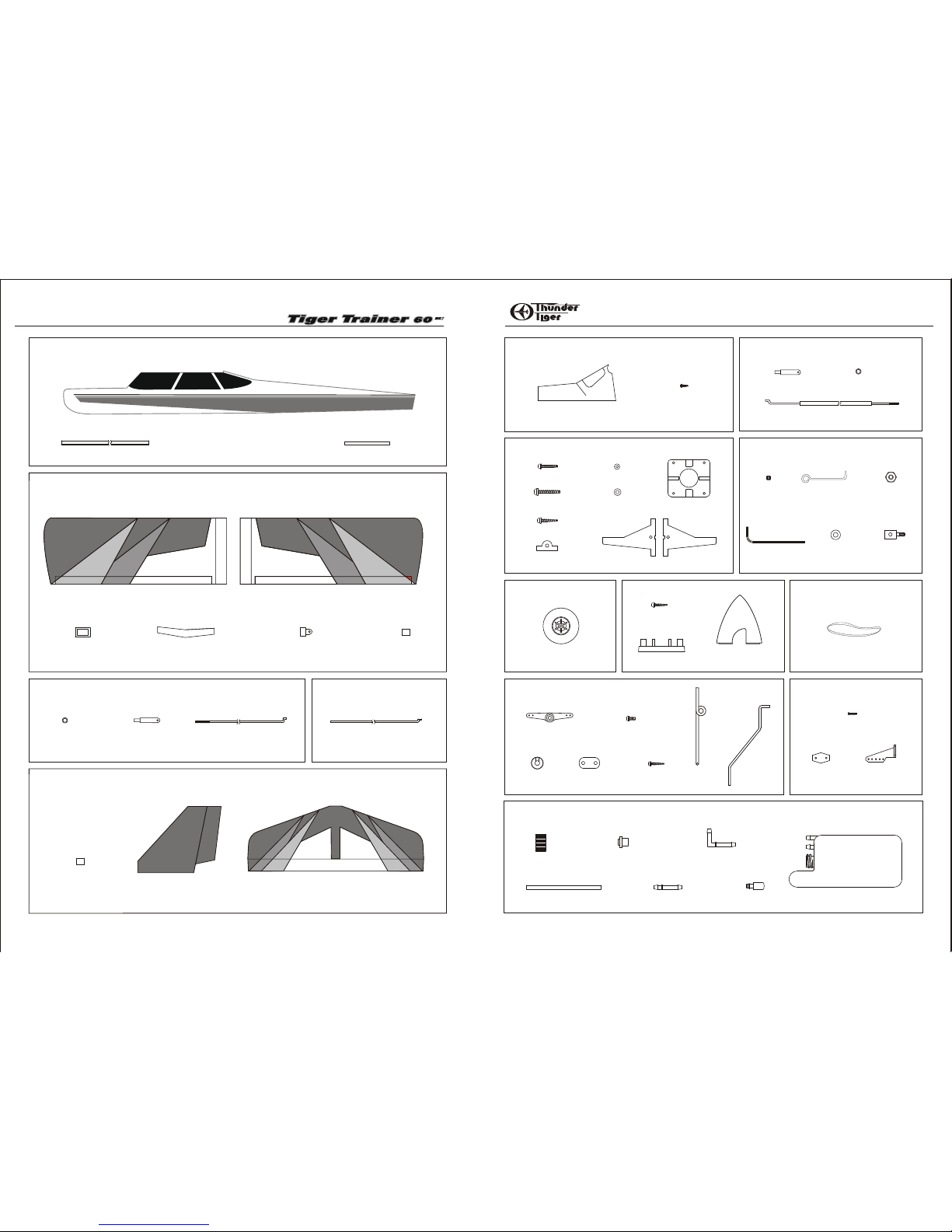

N

6

0TT

Fuselage (1)

PARTS DRAWINGS

AS6600 Aileron Pushrod

PARTS DRAWINGS

AS6595R Fuselage

AS6595L

AS6596R Main Wing

AS6596L

AS6599 Forward Pushrod

54

Dowel (2)

Left Wing (1)

Right Wing (1)

Aileron Servo Tray (1)

Wing Joiner (1)

Aileron Torque Horn (2)

CA Hinge (10)

Tig

e

r

CA Hinge (9) Fin/Rudder (1)

Stab./Elevator (1)

Clevis (2) Pushrod (2)

Plastic Guide Tube (2)

0.05" Piano Wire (2)

AS6597R Tail Feathers

AS6597L

2 1/4” Spinner (1)

AS6598 Windshield

3103 Adjust Engine Mount

AS6602 Hardware Set

AS6604 Spinner

AS6606 Control Horn

AS6605 Landing Gear

3266 Fuel Tank

3x3mm

Set Screw (2)

Allen Wrench (1)

Push Rod

Connector (2)

2mm Washer (4)

2mm Hex Nut (2)

3x12mm Self

-Tapping Screw (2)

Backplate (1)

Nose Gear Mount (1)

Engine Mount Plate (1)

Beams (L/1, R/1)

AS6601 Rudd/Elev. Pushrod

AS6603 Wheels

Wheel (3)

Pushrod (2)

Clevis (2)

2.3x15mm Screw (4)

Nut Plate (2)

Control Horn (2)

Main Gear (2)

Nose Gear (1)

3x5mm Screw (1)

3x12mm Self Tapping Screw (4)

Steering Horn (1)

Collar (8)

Mounting Strap (2)

420cc Fuel Tank (1)

Clunk (1)

Cap(1)

90-degree Nipple (1)

Rubber Stopper (1)

Silicone Tube (1) Straight Nipple (1)

2.3x8mm

Wood Screw (10)

Windshield (1)

4x24mm Screw (4)

Silicon Ring(2)

Silicon Ring(2)

4x25mm Wood Screw (4)

3x20mm Screw (2)

AS6607 Rubber Bands

Rubber Bands(8)

4mm Washer (4)

3mm Washer (2)

Switch Pushrod (1)

Tiger Sport

Page 4

WINGPREASSEMBLY

PRE-ASSEMBLY NOTES

1. If you are not an experienced R/C pilot, plan to have a

fully competent pilot check your completed model and

help you with your first flights. Even though we have tried

to provide you with a very thorough instruction manual,

R/C models are rather complicated and an experienced

modeler can quickly check over your model to make sure

your first flights are successful.

2. Please assemble your model exactly according to these

instructions. Do not attempt to modify or change the Tiger

Trainer in any way as doing so may adversely change

its flying characteristics.

3. Before you begin, please check the entire contents of

this kit against the parts drawing make sure that no parts

are missing or damaged. This will also help you to

become familiar with each component of your plane. If

you find that any of the parts are either missing or

damaged, please contact your dealer immediately for

replacement.

Note: Your dealer cannot accept kits for return if

construction has begun.

4. Trial fit each part before gluing it in place. Make sure

you are using the correct part and that it fits well before

assembling. No amount of glue can make up for a poor

fitting part.

WING ASSEMBLY

76

1.Before gluing the two wing halves, trail-fit the wing

joiner into the wing panels. If it is not easy to slide into

the wing, sand it until it will.

2. With 30-minute epoxy, liberally coat all sides and

edge of the wing joiner and slip it into one wing half.

Now coat the inside edge of the center wing rib where it

will join to the other wing half. This is called the “root” of

the wing.

Join the two wing halves and firmly press wing panels

together. Wipe off any excess epoxy with a paper towel

and rubbing alcohol. Make sure the two panels are

accurately aligned with each other. You may hold

together with several strips of masking tape.

3. Place the servo tray centered over the cutout in the

bottom of the wing. Mark around the servo tray with a

marker.

4. Remove the tray, and use a sharp knife to score the

covering material where marked. Remove the covering

material to expose the wood underneath. Use thick CA

or epoxy to glue the servo tray securely in place.

5. You may apply tape(not furnished) to center wing joint.

Start at the servo tray and work around the wing. Gently

pull on the tape while pressing it down onto the wing to

slightly stretch the tape into place and provide a smooth

seam.

6. To hinge the ailerons, remove the clear tape that

holds one of the ailerons in place. Pull the aileron off the

wing, revealing five hinges. Center these hinges in their

slots in the AILERON and secure them with THIN CA,

letting it wick into the joint. Glue both sides of the hinge.

7. When the glue has set, re-install the aileron onto the

wing. Hint: While flexing the aileron one way or the other

and while holding the wing up on its front edge, carefully

wick CA into the slot where the hinge goes into the wing.

Do so on both sides of the hinge. After the glue has set,

tug on the aileron at each hinge location to make sure

the hinges are securely glued in place. Also, make sure

the aileron is free to move up and down.

Note: you can remove any residue from the tape with

alcohol. Set your wing aside, for now.

FUSELAGE ASSEMBLY

8. Insert the throttle tubing first. It runs along the right

side of the fuselage and goes from the up corner of the

firewall back through the right hole in the first former and

then through second and third formers. Glue it securely

in place with thick CA.

9. Same way to the nose gear tubing. Insert the tube

through the first former and second former. Glue the tube

in place with thick CA.

Page 5

FUSELAGE

ENGINE

98

INSTALL THE MAIN GEAR

10. Locate the main landing gear channel in the bottom

of the fuselage. Use a sharp hobby knife to remove any

covering from the slot. You might lightly coat the

exposed wood in the landing gear slot with 5-minute

epoxy to prevent the wood from becoming fuel soaked.

11.Position the two plastic landing gear straps across

the landing gear strut. Using a felt tipped pen, mark the

location for the four landing gear mounting strap holes.

Drill the four mounting holes as marked with 5/64” drill

bit. Secure the mounting strap by four 2.3X12 screws.

12. Install the wheels onto the main gear using the

supplied two wheel collars and 3X5mm set screws.

Make sure the wheel rotates freely.

INSTALL THE ENGINE

13.Attach the engine mount plate, both mounting beams

and the nose gear bearing to the fire wall using the 4

X24mm screws provided. Make sure the mounting beam

“webs” are near the outside of the mount. It is not

necessary to fully tighten the four engine mount screws

at this time. Also temporarily install the nose gear, using

the steering arm to secure it. A special collar and

Phillips head screw inserts in the steering arm, which

secures it to the nose gear. The screw should contact

the “flat” that is ground into the nose gear. Note the

orientation of the coil on the nose gear. The nose wheel

is secured with two wheel collars and phillips head

screws.

14.Set the engine on the mount and adjust the beams, if

necessary, so that they are almost touching both sides

of the engine crankcase and are centered in relation to

the engine mount. Now position the engine so that the

front of the thrust washer is approximately 5” from the

firewall.

15.Remove the engine and drill a 3.5mm(9/64'') hole at

each of the four marks you just made. “Break-in'' the

mounting holes by inserting a 4X20mm wood screw into

each hole without the engine in place. A drop of oil in

each hole may help the screws thread in easier.

16. Using either Z-bend pliers or a regular pair of pliers,

make a “Z” bend in one end of one .050'' piece of wire.

Slide it into the throttle linkage tube.

Hook the “Z” bend onto your engine's throttle arm and

move the engine into position. You may have to bend

some jogs in the wire to prevent binding of the linkage.

Screw the engine in place on the mount.

17.In a similar fashion, make a “Z” bend in the remaining

piece of .050'' music wire for the nose gear steering

arm. You will need to remove the nose gear so the

steering arm is loose and “Z” bend can engage the outer

tube and re-install the nose gear. Make sure the 3X5mm

screw firmly tightens on the “flat” that is ground on the

nose gear. Rotate the nose wheel back and forth a few

times to make sure it rotates freely without binding. You

may need to bend the pushrod wire slightly to eliminate

any binding in the pushrod. If the alignment between the

nose gear bearing and the engine mount seems to be

causing some binding, loosen the mounting screws and

adjust the mounts until it rotates smoothly.

INSTALL THE FUEL TANK

18.Assemble the fuel tank by first cutting the silicone

tube to 3-3/4’' in length. Press the straight plastic nipple

into the rubber stopper (Saliva will ease insertion.) Now

slip the silicone tubing onto the nipple and insert the

metal clunk into the other end of the tubing. Insert this

assembly into the tank (clunk first) and securely tighten

the threaded cap on to hold everything together.

19. Attach two 7’' standard fuel lines (not furnished) to

both the fuel outlet nipple and the vent nipple on the tank.

Slide the fuel tank (cap end first) into the front of the

fuselage, threading the fuel lines through the oblong

hole in the firewall. The tubing coming from the tank's

fuel outlet (center) goes to the carb and the tubing from

the vent (upper) goes to the muffler's pressure fitting.

Trim the length as needed. The tank fits tightly in the

former.

20.Trim the windshield along with the molded cutting line

with curved scissors. Apply the windshield decal.

Page 6

TAILSTAILS

1110

21. Put the windshield on the front fuselage. It is held in

place with eight 2.3X8mm wood screws. You will need to

drill a 1/16'' pilot hole for each screw first. Next install

the wing dowels.

INSTALL THE TAIL GROUP

22.Remove the elevator and rudder and glue the hinges

into the control surfaces using the same technique

outlined for the ailerons.

23. Trim away the covering from the slot and pushrod

exit hole at the rear of fuselage where vertical fin and

horizontal stab go.

24.Use ruler to decide the center of stab and make

marks. With the main wing centered on the fuselage,

position the horizontal stab. Draw lines at both sides of

stab.

25.Remove the stab and fin from the fuselage and use a

hobby knife to carefully score the covering material

where marked. Make the score approximately 1/16''

inside the lines you drew. It is very important that you do

not press hard enough to cut into the wood itself or the

stabilizer may fail in flight. Just score the covering and it

will peel away nicely.

In a similar fashion, remove the covering material on the

vertical fin.

26. Glue the stab and fin to the fuselage with epoxy,

keeping the stab and fin in position as diagram shown.

o

90

A

A'

A=A'

The fin is perpendicular to the stab. Both stab tips to the

main wing are equal from the rear view (A=A').

27.The rudder and elevator pushrods have already

been pre-assembled at the factory. Insert the rudder

pushrods which is bent at the thread end , thread end

first, into the fuselage and exits the slot on the top of the

rear fuselage. Locate the clevis, thread the clevis onto

the threaded end at least 1/4'' in length.

28.Locate the control horns and 2X20mm screws. Snap

the clevis onto the control horns. Now position this horn

onto the Rudder in such a way that the nyrod runs

straight and the holes in the control horn are in line with

the hinge line of the stabilizer. Mark the location of the

control horn mounting holes on the elevator. Next, drill

5/64'' holes where marked.

29.Cut the control horn as photo shown.

30. Carefully cut a hole with hobby knife at the tail as the

elevator pushrod exit.

31.Use control horn as template and drill 5/64'' holes

with the control horn in line with the hinge line of

elevator and right at the pushrod exit.

Page 7

RADIO

1312

CONTROL THROWS

INSTALL THE RADIO

33. Mount three servos on the servo tray which is

already installed in your fuselage. Note their orientation

in the photo. Follow your radio's instruction manual and

make sure you use the grommets, eyelets, and screws

furnished with your radio. Drill 1/16'' pilot holes for the

mounting screws before insertion.

34.Now it is time to hook the servos up to the control

surface. Install the pushrod connector onto the

outermost hole in the rudder servo arm as shown. To do

so, remove the servo arm from the servo place the

pushrod connector so the threaded portion exits the

bottom of the servo arms. Secure in place using a 2mm

washer and nut. You may need to apply tiny glue to keep

nut in place but make sure connector rotates freely.

35. Do the same procedure on throttle servo arm.

Ensure that the hole for the pushrod wire is parallel to

the length of the fuselage. Align the pushrod tube with

the servo. The pushrod tube should not extend all the

way to the servo as this would cause the pushrod to

bind during operation. To shorten the pushrod tube,

remove any excess length with a sharp hobby knife

accordingly. Insert the pushrod wire through the

pushrod connector. Secure in place using a 3mm set

screw. Carefully adjust the control throws as page 13

and 14 shown.

36.Hookup to the ailerons is via a nylon horn that is

threaded onto the torque rod that is already installed in

the wing. Screw the horn down until there is about 1/16''

of threads exposed above the horn. Use threaded rods

with clevises on the end for the linkage. Apply a small

piece of silicone and slide it onto the clevis. Bend a “Z”

bend on the servo end of the rod at the proper length so

you have neutral aileron when the servo is centered.

37.Mount the switch on the servo tray. Drill a 2mm hole

on the fuselage for the switch extension rod to control

the switch.

38. Wrap your receiver and battery with packing foam

which is available at local hobby shop. Install the

receiver and battery in the front of the servo tray.

Receiver is near the servo tray and battery is far from

the servo tray as shown.

Drill a 1/16'' hole through the fuselage side, about one

inch behind the switch mount. From the inside out,

thread the receiver antenna through this hole. You may

want to tie a knot in the antenna 3'' or 4'' from the

receiver to act as a strain relief. Attach the end of the

antenna to the top of the vertical fin with a small #10

rubber band and a T-pin. Maintain only a slight amount

of tension on the antenna wire.

39.Correctly install the prop in front of the spinner

backplate using the engine prop washer and prop nut.

Note that the spinner backplate has two little posts that

must be rotated up against the prop blade before the

spinner will fit on. Rotate the prop counter clockwise

until it is vertical when it is against the engine's

compression stroke. Securely tighten the prop nut using

a prop wrench or correctly fitting wrench. It is not a good

idea to use pliers when tightening the prop nut! Attach

the spinner to the spinner backplate using the two

3x12mm self tapping screws provided.

Make sure the direction of servo moves correctly. If not

switch the reversing switch on the transmitter. If the

control surface does not move far enough, either move

the pushrod out farther on the servo horn or move the

clevis in farther on the control horn. If the control

surface moves too much, either move the pushrod in on

the servo horn or move the clevis out farther on the

control horn. Adjust the control throws as following

suggested.

CONTROL THROWS

Elevator-High Rate

1/2",12mm

1/2",12mm

Elevator-Low Rate

3/8",9.5mm

3/8",9.5mm

Aileron-High Rate

5/8",18mm

5/8",18mm

Aileron-Low Rate

1/2",12mm

1/2",12mm

Rudder

7/8",22mm

7/8",22mm

1/4” 6mm

Nose Wheel

32. Mount the control horn with 2X20mm screws. Insert

the elevator pushrod with clevis threaded on. Apply a

small piece of silicone and slide it onto the clevis. Then,

snap the clevis on the outmost hole of control horn.

40. Place the wing onto the fuselage and tuck the

aileron extension into the radio compartment. Use at

least 8(eight) rubber bands to hold the wing in place. A

good method of doing this to apply 2 rubber bands from

the left front dowel to the left rear dowel, 2 from the right

front dowel to the right real dowel . 2 from the right front

dowel to the left rear dowel and the remaining 2 from

the left front dowel to the right rear dowel .

Congratulations ! Now your Tiger Trainer 60 is

ready to fly. Please do the radio movement check as

well as the balance and control throw before you go to

fly. All Thunder Tiger staffs hope you enjoy flying your

new Tiger Trainer 60.

1/4” 6mm

Page 8

1514

PRE-FLIGHT CHECKSBALANCE

With the radio system still on, move the throttle trim

lever up the middle. This should open the carburetor

barrel up slightly(1/32"-1/16") and allow the engine to

idle satisfactorily. To shut the engine off from the

transmitter, simply move the throttle stick and trim lever

all the way down. Now move the throttle stick up and

watch the carburetor barrel. It should reach full open at

the same time the stick reaches it end point. If it does

not follow the instructions below. If the barrel does not

open all the way, move the pushrod in one hole in the

carburetor throttle arm. If the carburetor barrel reaches

full open and makes the servo " hum" very early in the

transmitter sticks movement, move the pushrod

connector in on the servo horn( to a hole that is closer to

the center of horn).

Grasp the throttle pushrod, and while looking at the

opening in the top of the carburetor, adjust the pushrod

until the throttle barrel( inside ) is all the way closed.

Tighten the setscrew in the pushrod connector to secure

the pushrod in that postion. Cut off the excess throttle

pushrod approximately 1/2" past the EZ connector.

Barrel Closed

Open Slightly

Barrel Open

N

60TT

Tiger

IMPORTANT- Do not attempt to fly your model before

completing this every important section. A model that is

not properly balanced will be unstable and could cause

serious damage and /or injury.

The balance point for this model is 3” behind the leading

edge of the wing. Measure this distance and mark it on

both sides of the fuselage right under the wing. With

your model fully assembled but without fuel, pick it up

with your index fingers at each of the two balance marks

you made earlier. If balanced properly, the plane will

hang horizontally. If the plane hangs with the tail down,

then you need to add (or redistribute) some weight in the

nose. Usually the plane will either balance or hang

slightly tail heavy. The easiest cure for a tail-heavy plane

is to move the receiver and battery forward as far as

possible. If the plane hangs nose down, then you need to

add some weight to the tail. Stick-on lead weights are

available from your hobby dealer that will make adding

weight a simple task. Once you have everything

positioned as necessary, wrap your receiver and battery

pack in 1/4'' or 1/2'' thick foam for protection.

BALANCING YOUR PLANE

If you are an experienced pilot, some of the following

text will not apply to you. Simply disregard references

to “your first flights”.

LOCATE A GOOD FLYING SITE

Generally, the best place to fly your model is at AMA

(Academy of Model Aeronautics) charactered club field.

Your local hobby dealer can tell you if there is such a

club a club in your area or write the AMA for information.

It is also a good idea to join this organization before

flying your model since they offer liability insurance that

can protect you if your model causes damage or injury

to others.

If there is not a chartered club field in your community,

you will need to find a large area free of obstructions,

which has a smooth grass or asphalt surface to be used

as a runway. For safety's sake, it should be located well

away from houses, building schools, power lines and

airport. If you will be flying within 6 mile of an airport,

you should check with the airport manager before flying

your model.

PRE-FLIGHT

Academy of Model Aeronautics

5151 East Memorial Dr.

Muncie, In 47302-9252

The batteries are the heart of your radio system. Make

sure you have fully charged batteries! With

rechargeable batteries, follow the manufacturers

instructions to make sure the batteries are fully charged,

especially the first time the radio is used.

If your radio uses dry cells, make sure your batteries are

in new condition. You have a lot of money invested in

this project so it is not worth the risk of using old

batteries.

A NOTE ON BATTERIES

You should perform these checks before each flying

session.

1. Check all control surfaces for possible looseness or

deterioration.

2. Check all screws, rubber band, clevises, nuts and all

other connectors to make sure they are securely

fastened.

3. Check which radio frequencies are being used. Do not

turn your radio until absolutely sure you are the only one

operating on that frequency.

4. Check for proper operation of all control surfaces.

5. Check the level of charge in both the transmitter and

receiver batteries before flying.

6. Range check the radio both with and without the

engine running! Follow the radio manufacturer's

instructions for this.

PRE-FLIGHT CHECKS

Learning to fly a radio control aircraft can be very exiting,

but it is important that you thoroughly understand the

basics of flight and controls before you attempt your first

flights. Therefore, we highly recommend that you seek

the expertise of an experienced instructor pilot for the

first few flights. He (or she ) can get you in the air much

more smoothly than trying everything yourself for the

first time.

FLYING

GETTING ORIENTED

We recommend that you find a large smooth and clear

surface to practice taxing your airplane around in before

you try to take off. To taxi, you only need to use the

rudder stick. At the slow speeds encountered during

taxing, the elevator and ailerons will not be effective.

The first and most important thing to remember when

controlling model aircraft is: the model controls are set

up to operate as if you were sitting in the cockpit of the

model. This means that when you pull back (down) on

the elevator stick the nose of the plane will go up.

Moving the rudder stick to the right will “yaw” the plane

to the right and moving the aileron stick to the right will

“roll” the plane to the right. Pretty simple right? Well, not

quite. Since you are really standing on the ground and

not sitting in the plane, this is how the controls work

when you are facing the same direction the plane is

flying. The problem is that when the plane is flying

towards you, the rudder and aileron controls seem

reversed to the inexperienced pilot. This is the reason

we recommend that you practice taxing around in a large

open area to try and get used to the control reversal.

During your first few flights, try to face the direction that

the plane is flying and looking over your shoulder as

needed. This makes it a little easier to pretend that your

sitting in the cockpit.

FIRST FLIGHT

When you are comfortable with the controls, you should

be ready for your first flight. Go over the Pre-Flight

Check List one more time for good measure and taxi out

the runway (hopefully with an experienced pilot by your

side). Point the model directly into the wind and

gradually increase the throttle to full throttle. As the

model starts rolling forward it may try to turn to the left

due to the engine torque. Apply enough right rudder to

keep the plane rolling relatively straight into the wind. If

you built the model with right thrust, this tendency may

not be noticeable. As the plane picks up speed, the right

rudder input can be reduced.

Once the plane reaches flying speed, it will probably try

to fly by itself. If the grass seems to be impeding take off ,

a very slight amount of “up” elevator can be applied, but

it is very important that you do not apply too much up

elevator too early or the plane will stall and roll over into

the ground.

As the plane becomes airborne, reduce the “up” elevator

and allow the plane to pick up flying speed while gently

gaining altitude. Once a safe flying speed and altitude

has been obtained, feel free to turn the airplane back

toward the flying field. Make all control inputs smoothly

and gradually so you can see the effect they have on the

plane. A small amount of “up” elevator will need to be

applied to keep plane level during turns. You should be

able to reduce the throttle to about ½ throttle for normal

cruising flight which will reduce the flying speed and

give you more time to think about what is going on. You

will find that once airborne, you can fly the plane with

only the aileron and elevator sticks. This is perfectly fine

and will make it much easier for you to learn.

If the plane has a tendency to turn, roll, climb, or dive,

you can adjust the transmitter trims to correct this. On

your first flights, it might be a good idea to have an

experienced pilot make the adjustments for you while

you fly the plane.

3”

Loading...

Loading...