Page 1

WARRANTY

Thunder Tiger Model Company guarantees this model kit to be free from defects in both material and

workmanship at date of manufacture. This warranty does not cover any components damaged by use

or modification and in no case shall Thunder T iger’s liability exceed the original purchase price of the kit.

Thunder Tiger also reserves the right to change or modify this warranty without notice.

Since Thunder T iger Model Co. has no control over possible shipping damages, construction techniques

or materials used for construction by the modeler, no liability can be assumed nor accepted for damage

resulting from the use by the user of the final user-assembled product. By the act of using this userassembled product, the user accepts all resulting liability. If the buyer is not prepared to accept this liability, he should return this kit in new and unused condition to the place of purchase for a full refund.

Assembly Instructions

&

No. 4517

No. 4518

Page 2

2

INTRODUCTION

INTRODUCTION

All of us at Thunder Tiger want to thank you for choosing the best-looking, lightest-weight,

and best -flying ARF available in this category of R/C, the profile fuselage Fun Fly. This kit features

state-of-the-art engineering that provides quick and easy assembly of a strong, yet lightweight airplane

that will provide you with an enjoyable experience. The Fun Tiger will do every maneuver in the book!

To gain the most from this airplane kit, it is important that you read the instructions thoroughly and

then follow them exactly. This instruction manual has been written with an inexperienced modeler in

mind, but includes many hints and modeling tips that even experienced modelers can benefit from.

We strongly suggest that you read through the instructions completely before beginning construction.

This will give you a good idea of the construction sequence and eliminate many questions you might

have if you did not read the manual prior to starting the actual construction.

The first thing you should do before beginning assembly is to check the contents of your kit against

the parts list on pages 4 and 5. If any parts are missing, contact your dealer immediately for

replacement. Customers in the United States and Canada may contact Ace Hobby Distributors direct-

ly at 116 W. 19th Street, Higginsville, MO 64037 660-584-6704 for replacement parts.

Under no cir-

cumstances can a kit be returned if assembly has already been started.

Introduction . . . . . . . . . . . . . . . . . . . . . . .2

Other Items Required . . . . . . . . . . . . . . .2

Items Needed Check List . . . . . . . . . . . .3

Parts Sketches . . . . . . . . . . . . . . . . . . .4-5

Pre-Assembly Fuselage . . . . . . . . . . . . .6

Pre-Assembly Wing . . . . . . . . . . . . . . .7-8

Pre-Assembly Hinging . . . . . . . . . . . . . . .8

Landing Gear . . . . . . . . . . . . . . . . . . . . .9

Install the Engine . . . . . . . . . . . . . . . . . .9

Install the Fuel Tank . . . . . . . . . . . . . . . . .9

Install the Linkage

. . . . . . . . . . . . . . . . . . . . . . .

10-12

Set-Up . . . . . . . . . . . . . . . . . . . . . . . . .13

Flying Hints . . . . . . . . . . . . . . . . . . . . . .13

Balance . . . . . . . . . . . . . . . . . . . . . . . .13

Pre-Flight Checks . . . . . . . . . . . . . . . . .14

Safety Precautions . . . . . . . . . . . . . . . .14

Post-Flight Check List . . . . . . . . . . . . .14-15

A checklist is also provided on the next page

which willmake shopping for these items easier.

TABLE OF CONTENTS

OTHER ITEMS REQUIRED

FOR ASSEMBLY

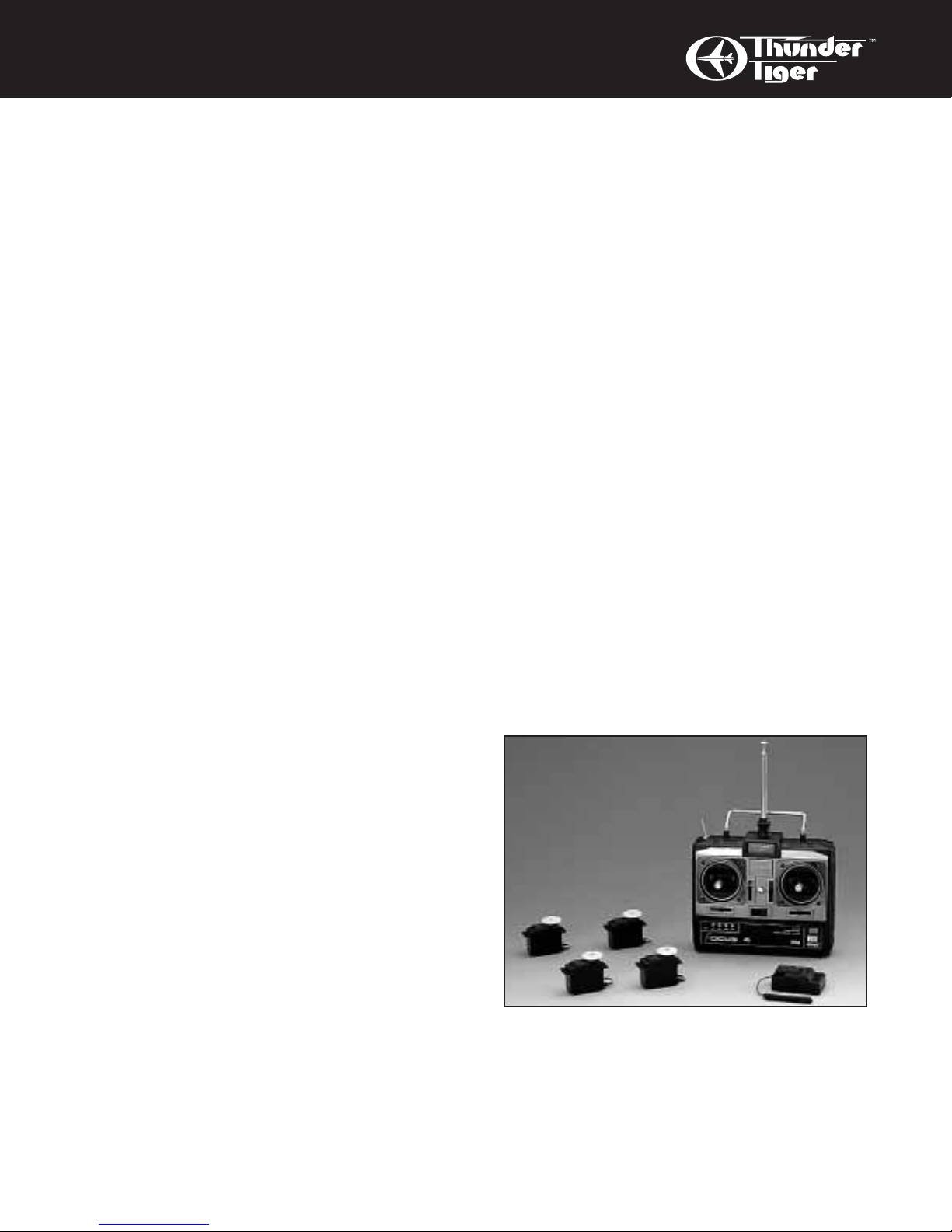

Radio - A 4-channel radio with five standard

servos is required. To achieve the maximum

maneuverability from this plane, we recommend

you use a computer-based radio for

elevator/flapperon mixing.

Page 3

3

ITEMS NEEDED

Adhesives - You will need two types of adhe-

sives for the Fun Tiger - Epoxy and Instant

(cyanoacrylate) adhesives. We recommend that

you purchase both 5-minute and 30-minute

epoxy to cut down on assembly time, but you

can get by with only 30-minute epoxy if time is

not important. You will also need a small bottle

of both “Thick” and “Thin” instant adhesive.

Tools - Model assembly can be much easier if

the proper tools are used. Therefore, we have

included in our checklist to the right, a complete

listing of all the tools we used to assemble our

prototype models. As you will notice, many household tools can be utilized during construction.

Engine - The Thunder Tiger GP-42, PRO-40/46

and F-54S are the ideal engines for this airplane. These quiet-running engines are easy to

start, require no special break-in periods, are

very easy to maintain and will last for years.

Flight Equipment - There are several “support”

items that you will need to purchase in order to

get your engine running and your plane in the

air. These are listed at the bottom of the page.

Comprehensive Items Needed

Check List

❏ 40 Size Engine

❏ 4-Channel Radio with 5 Standard Servos

❏ 5-minute Epoxy (4 ounces)

❏ 30-minute Epoxy (4 ounces)

❏ “Thin” Instant Adhesive (1/2 ounce)

❏“Thick” Instant Adhesive (1/2 ounce)

❏ Hobby Knife and Blades

❏ Epoxy Mixing Sticks and/or Brushes

❏ Sandpaper (150 grit)

❏ Masking Tape

❏ Rubbing Alcohol

❏ Paper Towels

❏ Ruler

❏ 90 Degree Triangle

❏ Waxed Paper

❏ Fine-Point, Felt-Tip Pen

❏ Misc. Household Tools

❏ Drill and Bits (1/16", 5/64", 3/32", 5/32", 3/16")

Flight Equipment

❏ Foam Rubber Padding for the Radio

❏ Stick on Lead Strip for Balancing the Plane

❏ 3 or 4 Props (see engine instructions)

❏ 10%-15% Glow Fuel

❏ Fuel Pump or Bulb

❏ Electric Starter or “Chicken Stick”

❏ Glow Plug Clip and Battery

❏ Extra Glow Plug(s)

Page 4

4

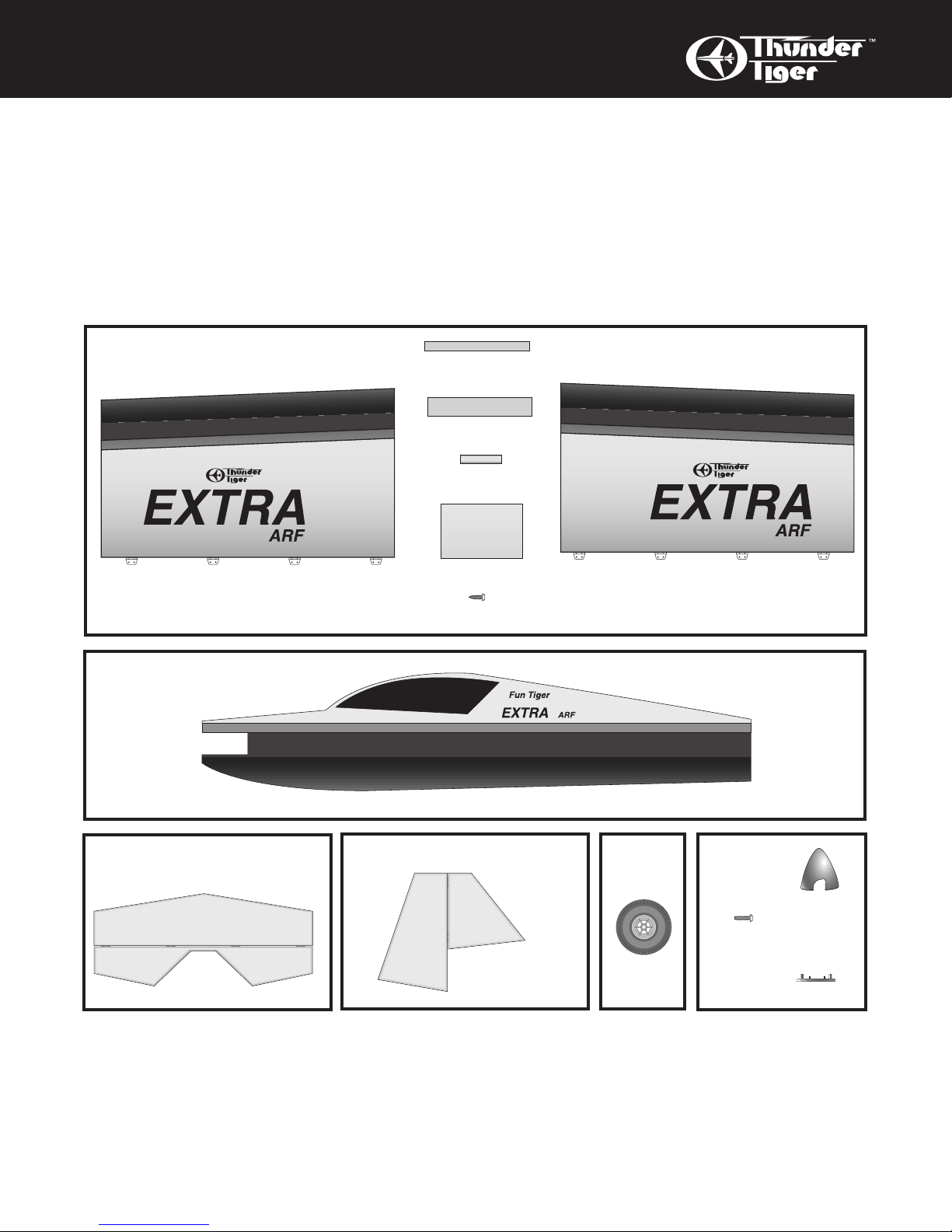

PARTS SKETCHES

IMPORTANT

Please check the contents of your kit box with these part sketches before beginning

construction. This will not only familiarize you with the parts and their names, but it will

also give you a head start in the unlikely event that you are missing a part.

If parts are missing, call (660) 584-6704.

Parts are not necessarily drawn actual size!

Left Wing (1)

Right Wing (1)

Spinner (1)

(2)

Tapping

Screw (2)

Backplate (1)

Wing Joiner (2)

Balsa Stick (2)

Balsa Hatch (2)

Dowel (1)

Wood Screw (4)

WING SET #AS6009

(#AS6002)

FUSELAGE #AS6008

(#AS6001)

HORIZONTAL TAIL #AS6011

(#AS6004)

VERTICAL TAIL #AS6010

(#AS6003)

WHEEL

#3256

SPINNER

#3284W

Page 5

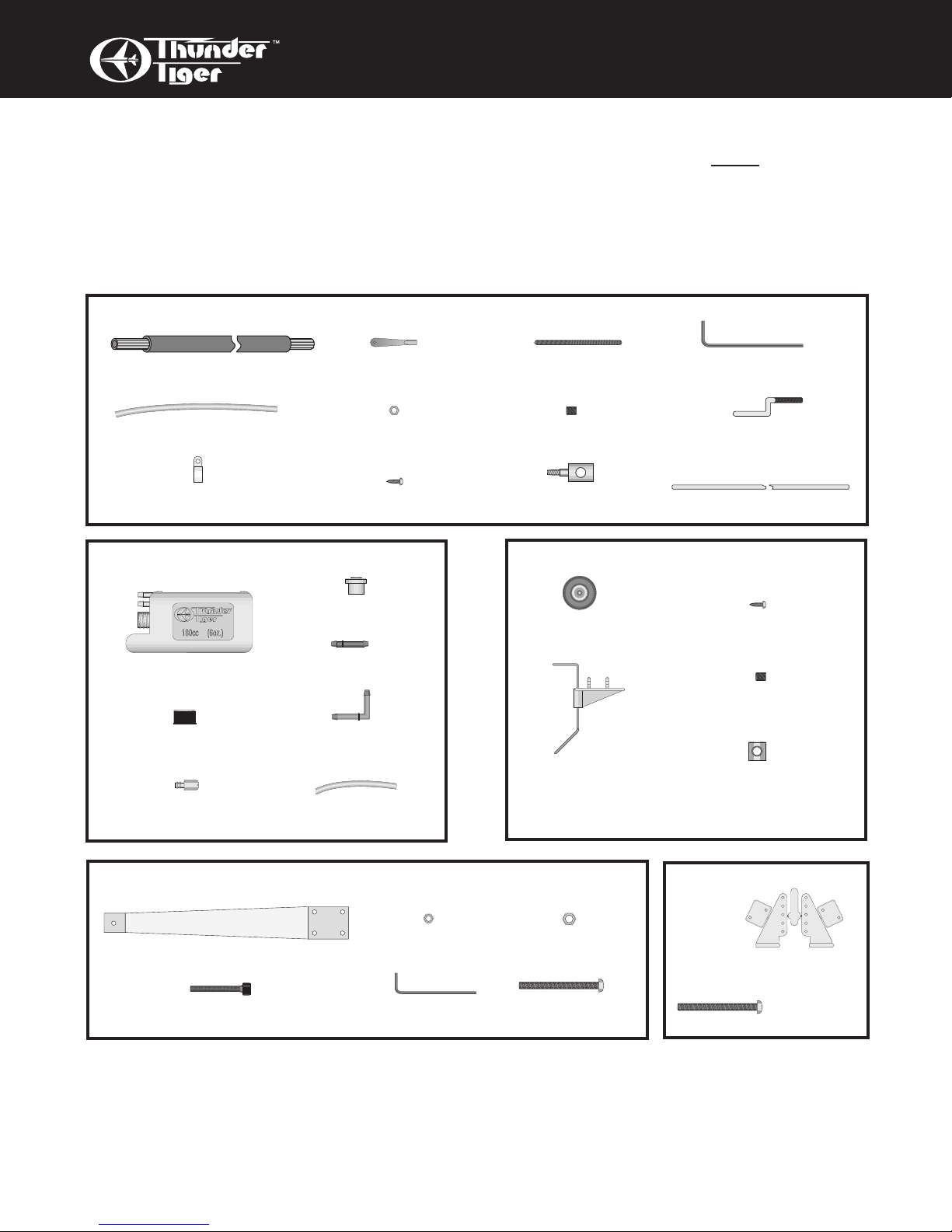

LINKAGE BAG #AS6006

5

PARTS SKETCHES

Parts are not necessarily drawn actual size!

Replacement parts can be ordered by Set Number Only.

Individual parts not available.

Screw (8)

Landing Gear (2)

Socket Screw (2)

Allen Wrench (1)

Horn &

Backplate (2 pr)

MAIN LANDING GEAR #AS6005

CONTROL HORN

#3151

Screw (2)

3mm Hex Nut (4) 4mm Hex Nut (4)

FUEL TANK #3261

TAIL WHEEL SET #AS6007

Inner/Outer Nyrod (2)

Plastic Guide Tube (1)

180cc Tank (1)

Cap (1)

Clunk (1)

Fuel Stopper (1)

Silicone Tube (1)

Straight Nipple (1)

90˚ Nipple (1)

Pushrod Clamp (4)

Clevis (4)

2mm Nut (1)

Set Screw (1)

Set Screw (1)

Wheel Collar (1)

Tail Gear (1)

Piano Wire (1)

Z-Bent

Threaded End (2)

“EZ” Connect (1)

Threaded Stud (2) Allen Wrench (1)

Wood Screw (4)

Wood Screw (2)

Tail Wheel (1)

Page 6

6

PRE-ASSEMBLY

INTRODUCTION

1. The Fun Tigers are designed for the experienced R/C pilot. If you do not yet have the skills

to fly this outrageously maneuverable machine,

set it aside until you have progressed through

the trainer and intermediate stages of R/C flight;

you will then be ready for this plane.

2. Please assemble your model according to

these instructions. Do not attempt to modify or

change in any way as doing so may adversely

change its flying characteristics.

3. Before you begin, please check the entire

contents of this kit against the parts list and

drawings to make sure that no parts are missing

or damaged. This will also help you to become

familiar with each component of your plane. If

you find that any of the parts are either missing

or damaged, please contact your dealer immediately for replacement.

Note: Your dealer cannot accept kits for

return if construction has begun.

Note: Each step of these instructions is preceded by a box which can be checked off as you

complete the step. This will allow you to follow

your progress and quickly find your starting

place after any interruptions or breaks.

The following instruction manual

depicts the Fun Tiger Extra. If you are

building the Fun Tiger G-200, it builds

exactly the same; just disregard the differences in the color scheme.

PRE-ASSEMBLY-Fuselage

1

❏ Using a sharp modeling knife, cut away the

covering film from both the wing joiner slot and

the 1/4”D alignment hole in the wing area on

both sides of the fuselage.

2

❏ Also cut away the film at the rear of the fuselage where the stab slot is. Notice that this

reveals the balsa tail post between the flaired

part of the stab slot. Use a razor saw or repeatedly cut with a hobby knife to remove the tail

post in this area.

3

❏ Locate the full size drill template. Cut away

the paper where indicated. Locate it on the left

side of the fuselage and tape in place. Using a

center punch or an awl, mark and drill four 5/32"

holes for mounting the landing gear then mark

and drill three 5/64" holes for the tank mounting

wires. Be careful to keep the drill perpendicular

to the fuselage.

4/5

❏ Position your engine in the cut-out area in the

front of the fuselage so the spinner will clear the

nose by about 1/8". Firmly holding the engine in

place, mark the four engine mounting hole locations. Drill four 5/32" holes where marked,

being careful to keep the drill perpendicular to

the fuselage.

Using medium CA glue or epoxy, coat the

exposed wood in the fuselage’s engine slot for

fuel proofing.

Page 7

7

WING ASSEMBLY

6

❏ Drill 3/16” holes in the bottom of the rear of

the fuselage to accommodate the barbed pins in

the tailwheel mounting bracket. Locate the

holes using the bracket/tailwheel assembly as a

guide. Line up the bracket so the “tiller arm”

portion of the wire is flush with the rear edge of

the fuselage.

PRE-ASSEMBLY-Wing

7

❏ Using epoxy, laminate the two plywood wing

joiners together. Clamp together keeping the

edges aligned; wipe off excess glue before it

sets. Allow to cure. When dry, sand all edges

of the joiner, removing any bumps or irregularities. Test fit the joiner into the slots of both wing

halves and trim as necessary for a good fit.

8/9

❏ Observe that there is an open bay in the top

of each wing. This is where the radio will go. To

gain access to this area, you will need to cut

away the covering film.

Begin by cutting the film diagonally across

the bay with a sharp modeling knife from corner

to corner.

Fold the material down into the wing and

press it down so it sticks to the vertical edge of

the wing sheeting. Note there is a 3/16" wide

ledge on both sides of the opening; press the

material down to this ledge and use your fingernail to burnish the material into the corners of

the ledge. Trim away the excess material.

Permanently stick the covering material to the

edges with a heat sealing iron set on low temperature.

10

❏ Locate the two 3-1/8" X 4-5/8" balsa hatches

and the two 1/4" X 4-3/8" balsa hatch tongues.

Using thin CA, glue a hatch tongue along the

long edge of one of the hatches leaving 1/8"

overlapping the edge and centering it lengthwise. Repeat for the other hatch.

11/12

❏ Put one of the hatches into place in the open

bay of one of the wing panels...the hatch tongue

is to fit into the rear edge of the opening; you

may have to do a bit of trimming on the tongue

for it to fit. With the hatch in position, drill a

1/16" pilot hole through both the hatch and the

plywood mounting platform about 1/2" from the

side and 1/8" back from the front edge of the

hatch. Remove the hatch and expand both

holes to 1/8". Now the hatch can be secured

with two self-tap screws furnished. Repeat for

the other hatch.

13

❏ Locate the paper template for cutting the

pushrod/nyrod slots. Trim along the lines that

indicate the center and the rear of the wing. Put

the template on top of the left wing panel and

line up the edges...tape the template in place.

Using a sharp modeling knife, cut two slots in

the wing sheeting in the location indicated;

make a few shallow cuts instead of one cut

Page 8

8

WING ASSEMBLY

all the way through. These are where the

pushrod and Nyrod will exit the wing when the

radio is installed. Repeat for the right wing

panel by putting the template on the wing

upside down.

PRE-ASSEMBLY-Cutting away

covering material

❏ In the following steps, you will be cutting

away covering material in preparation for gluing.

You have to be careful here. When cutting way

the covering, you need to use a sharp modeling

knife and only score the film itself. DO NOT cut

into the wood below the covering. If you do, the

structure of the airplane will be compromised

and failure may occur. Use a felt-tip pen to mark

the cutting locations as instructed.

14/15

❏ Begin with the fuselage/wing joint. Slip the

wing joiner into the slot in the fuselage and the

1/4" alignment dowel into the hole at the rear of

the wing location. It helps insertion if you round

over the edges of both the joiner and the dowel.

Slide both wing halves onto the wing

joiner/dowel until they butt up to the fuselage

side. Mark the fuselage around the outer

perimeter of wing. Remove the wing and carefully score the covering about 1/8" on the

INSIDE of these marks and peel off the covering to reveal raw wood at the wing/fuselage

joint. DO NOT GLUE THE WING IN PLACE!

YET.

6

❏ Put the fin into place in the slot in the rear of

the top of the fuselage. Mark the fin on both

sides where it meets the top edge of the fuse.

Take the fin out and remove the covering material about 1/32" below your mark.

❏ Slip the stabilizer into its slot in the fuselage.

Using a ruler to center the stabilizer and a Tsquare to make sure it is perpendicular to the

fuselage, mark where the fuselage meets the

stabilizer on the top and bottom. Slide the stab

out and remove the covering material about

1/32” on the inside of your marks.

PRE-ASSEMBLY-Hinging

❏ In the following steps, you will be mounting

the control surfaces by gluing the hinges in

place. All of the slotting has been done for you,

so it requires very little work. Begin by test fitting the ailerons to the wing, the elevator to the

stabilizer and the rudder to the fin.

17

❏ To help prevent glue from restricting the

hinge action, put a small drop of oil on the

moveable part of each hinge, being careful not

to get any oil on the flat surfaces of the hinges.

Lay them on a paper towel to absorb the excess

oil.

18

❏ We prefer to use 30 minute epoxy and do all

the hinging at one time.

The easiest way to accomplish this task is

to evenly coat the top and bottom surfaces of

one half of a hinge and slip it into its slot in the

control surface; do the same for the other

hinges in the control surface. This lets the control surface itself be your holding fixture. Then

coat both sides of the exposed half of all the

hinges. Next, slide the control surface in place,

starting at one end or the other.

Keep paper towels and some rubbing alcohol handy to clean up epoxy fingerprints on the

covering material before it sets.

Page 9

Page 10

Page 11

Page 12

Page 13

9

LANDING GEAR/TANK/ ENGINE

❏ Using epoxy, glue the tailwheel assembly in

place. Secure the tailwheel in place with the

wheel collar and set screw furnished.

❏ Mount the engine in place with four M3 X

30mm bolts, nuts, and washers.

❏ Mount the tank in place with “U” and “L”

shaped music wire brackets furnished. They

are inserted from the right side of the fuselage

through the holes you drilled earlier and then

bent over with a needle nosed pliers to form a

hook for rubber bands which in turn, secure the

tank.

❏ Now that your Fun Tiger is “up on its feet”,

use a triangle to check and see if it sits perpendicular to the work surface; slightly bend the

landing gear as necessary. Now, as you install

the wing and tail, you can easily check alignment.

ASSEMBLY-Wing

❏ Once again, test fit the wing onto the fuselage with the wing joiner and the alignment

dowel in place. When satisfied, use 30-minute

epoxy to glue the wing in place, making sure

you generously butter both sides of the wing

joiner plus where the wing root surfaces meet

the fuselage sides. Use a paper towel dampened with alcohol to remove the excess epoxy.

Make sure the wing remains in complete

contact with the fuselage as the glue sets.

❏ Using epoxy, join the control surfaces to the

flight surfaces with the hinges: rudder/fin, stabilizer/elevator, right wing/right aileron, and left

wing/left aileron. Keep the gap between the surfaces at a minimum.

When the epoxy has set, remove any

excess and check for free movement of the surfaces. Give a firm tug to each surface to make

sure the hinges are securely glued in; remember, this is a wild airplane and much stress is

placed on the control surfaces.

ASSEMBLY

Tank/Landing Gear/Engine

❏ Assemble the fuel tank by first cutting the silicone tube to 2-1/2" in length. Press the straight

plastic nipple (the 90 degree nipple is not used

in this plane) into the rubber stopper until the

molded-in ring is against the stopper. Rubbing

alcohol applied to the nipple will make it slip

inside the stopper easier. Now slip the silicone

tubing onto the nipple and insert the metal clunk

into the other end of the tubing. Insert this

assembly into the tank (clunk first) and securely

tighten the threaded cap to hold everything

together.

❏ Bolt the right and left aluminum landing gear

onto the fuselage using four M3 X 30mm bolts

and nuts. Note that the straight edge of the

landing gear goes to the front of the fuselage.

❏ Mount the wheels using M4 X 30mm socket

head bolts as an axle and two nuts on either

side of the landing gear to secure it.

Page 14

10

LINKAGE

ASSEMBLY-Tail Group

❏ Test fit the Fin/Rudder assembly into place

on the fuselage. Mark and drill a 3/32" hole

into the leading edge of the rudder to accommodate the tiller arm portion of the tailwheel

assembly. Test fit again and (if necessary)

notch the leading edge of the rudder to accommodate the tailwheel wire.

❏ Epoxy the stabilizer and fin onto the fuselage,

making sure the stabilizer stays in alignment

with the fuselage and the fin stays perpendicular

to the stab. Also make sure the tailwheel

assembly tiller arm slips into the hole you just

drilled in the leading edge of the rudder.

SERVO INSTALLATION

❏ Study the radio installation drawing.

Note that three servos are installed in the right

wing: the outermost servo is one of the two

aileron servos, in the middle is the throttle servo

and the rudder servo is on the inside.

In the outboard position in the left wing is

the other aileron servo; the elevator servo is on

the inside. Receiver and battery are foam

wrapped in-between these two servos and the

switch and charge jack are mounted to the

hatch in such a way that they don’t interfere with

the internal components.

❏ Use self-tap screws and grommets to mount

the servos to the rails in the wing so the output

arm will be in line with the slots you have

already cut. The throttle linkage will be dealt

with soon. Simply install the throttle servo

halfway between the aileron and rudder servo.

LINKAGE INSTALLATION

Elevator/Rudder Linkage

Hookup to the rudder and elevator is done

with “nyrod” pushrods consisting of an inner and

outer nylon tube. Athreaded stud and clevis on

each end connect to both the servo arm and the

control horns.

❏ Take a piece of 120 grit sandpaper and

roughen up about 2" of the outside of one end

of each of the two outer nyrods. Slip this end

into the slot in the LEFT wing that you cut earlier.

Rudder

Servo

Aileron

Servo

Aileron

Servo

Throttle

Servo

Elevator

Servo

Rudder/Elevator Linkage

Throttle Linkage

Aileron Linkage

Z-Bent

Threaded

End

Clevis

Music Wire

Threaded

Rod

Nylon Tube

“EZ” Connect

w/Nut & Set

Screw

Inner/Outer Nyrod

Control

Horn

Control

Horn

Page 15

11

LINKAGE

❏ You will need to drill a 3/16" hole through

the balsa webbing on the inside of the wing

to allow the inner nyrod to reach the servo.

Use the servo itself and the outer nyrod you

just slipped into place to determine the location.

❏ Next, thread one of the studs furnished

into one of the inner nyrods for about 3/8".

Screw a clevis onto this stud for about 3/8".

From the inside of the wing out, slip the inner

rod into the outer rod and hook the clevis up

to the servo arm. NOTE: a small screwdriver inserted between the forks of the clevis and carefully rotated will spread the forks

for installation. Route the nyrod down the

fuselage to the tail. The other end of this

nyrod will link to the elevator via a control

horn.

Page 16

12

LINKAGE

❏ Locate the nylon control horns. Cut them

apart and remove any flashing. Put a control

horn in position on the elevator so the nyrod

lines up nicely and the holes in the control horn

line up with the hinge line. Make sure the horn

is located on solid wood. Drill 5/64" holes in the

elevator to accommodate the mounting screws

for the horn. (A drop of CyA glue will hold the

horn in position while drilling.) Mount the horn

in place with two 2mm X 12mm screws and the

nylon screw plate.

❏ Making sure the other end of the inner nyrod

is still hooked to the servo, cut the outer nyrod

to within about 1-1/2" of the elevator control

horn. Next, cut the inner nyrod to the proper

length to accommodate the threaded stud and

clevis so you get neutral elevator when you

snap the clevis onto the control horn. Make

sure you allow for threading the stud into both

the inner nyrod and the clevis for about 3/8".

After you cut the nyrod, go ahead and thread

the stud and clevis in place and hook the clevis

up to the control horn.

❏ Secure the outer nyrod to the sides of the

fuselage in two places using the furnished

clamps and screws. These two places are, one:

where the vertical support member exists inbetween the two large open bays in the fuselage and, two: where there is “meat” right below

the front of the elevator.

❏ Repeat this procedure for the rudder nyrod

linkage on the right side of the fuselage.

Aileron Linkage

Hookup to the aileron is done with two

threaded rods with clevises/control horns on

the control surface end and a “Z-Bend” on the

servo end.

❏ You will need to drill a 1/8" hole through the

balsa webbing on the inside of the wing to allow

the wire to reach the servo

❏ Slip one of the threaded rods for the aileron

linkage through the slot in the wing and thread

on a clevis. Mount a control horn on the aileron

surface in the same manner as you did for the

elevator and rudder, keeping it parallel with the

fuselage.

❏ Put a “Z” bend in the servo end at the proper location so you get neutral aileron when the

servo is in neutral. Cut away the excess wire

and install the servo arm on the servo with the

linkage in place.

❏ Repeat for the other aileron.

Throttle Linkage

Throttle linkage consists of a piece of music

wire inside a nylon tube with a “Z-Bend” on the

servo end and an “EZ Connector” on the carburetor arm.

❏ First, a 1/8" hole needs to be drilled through

the leading edge of the wing to accommodate

the nylon tubing. The easiest way to do this is

with a long drill bit from the outside of the wing

through the the radio compartment. “Eyeball”

the hole so the linkage will be a straight line

between the throttle arm on the engine and the

servo arm.

❏ Install the nylon tube in the hole you just

drilled and glue in place.

❏ Complete the linkage using the furnished

“EZ Connector” secured to the throttle arm with

nut furnished. Aset screw locks the music wire

where needed. A“Z” bend links the music wire

at the servo end.

Receiver/Battery/Switch

❏ The receiver and battery pack are located in

the area between the two servos in the left

wing. Use as much foam as you can in the

limited room available but make sure there is no

bind on the linkage.

❏ Mount the switch on the left hatch cover,

making sure it clears the internal components.

Page 17

Remove or add weight as needed to balance

the airplane at the root of the wing(near the

fuselage) as follows:

Initial Set-up: 4-1/4" back from leading edge

of the wing, measured at the fuselage.

Advanced Set-up: maximum of 4-3/4" back

from leading edge...work in 1/4" increments.

FUN FLYING HINTS

Take a close look at your Fun Tiger. Notice

it’s thick airfoil, large control surfaces, generous

vertical fuselage area, short coupled nose and

tail, and BIG engine. Now pick it up and feel

how light it is. All of these attributes contribute

to the flight characteristics of this airplane which

you are about to discover when you take your

new Fun Tiger to the flying field.

There is a very good reason this category of

airplanes is called “Fun Fly”; flown properly , they

can be an outrageous amount of fun because of

the outrageous things they will do. Following

are a few hints to maximize the Fun out of your

Fun Tiger.

FIRST and FOREMOST, this airplane is

not designed to fly fast. DO NOT fly this air-

plane straight and level at full throttle with a

PRO 46.! If you do, the control

surfaces may

flutter with loss of the airplane

. It is necessary to

continually change the throttle and only apply

full throttle when you are going straight up or at

other times when needed (loops, rolls, etc.),

then backing down to idle when you are going

straight down. The rest of the time, you will be

in the mid-range.

Due to the enormously large ailerons, you

will find the roll rate so fast it will startle you the

first time you give full aileron. Forget about

feeding in down while you’re in the inverted

position....there’s no time.

Loops are so tight, you’ll think the prop is

going to chew off the tail. This is especially true

if you couple elevator to flapperons with a computer radio. Follow the programming sequence

for your radio to set up flapperons then mix

elevator to flapperons 100% or 1:1.

13

SET-UP

SET-UP

Initially, set-up the throws for your control

surface as indicated in the following chart. They

are measured at the rearmost point of each control surface. Of course, make sure transmitter

command directions correspond with surface

movement; i.e., up is up and right is right!

Non-computer radios:

Lo Rate Hi Rate*

Aileron: 3/4" Up/Dn 1-1/2" Up/Dn

Elevator: 1" Up/Dn 2" Up/Dn

Rudder: 1-1/4" Rt/Lt 3" Rt/Lt

Computer radio notes: Engage flapperon mixing and mix flaps with elevator; we suggest 1 to

1 in opposite directions (up elevator/down flaps)

*Exponential is recommended instead of

dual rates....set max throw to these limits.

Center Of Gravity (Balance Point)

Low Throttle/Low Throttle Trim

Low Throttle/Mid Throttle Trim

High Throttle/Mid Throttle Trim

Set-up your throttle as

shown.

Page 18

14

PRE-FLIGHT/POST-FLIGHT

POST-FLIGHT CHECK LIST

❏ 1. Be sure that both the transmitter and

receiver switches are turned off.

❏ 2. Drain all excess fuel from the tank.

Fuel left in the tank for extended periods

can “gunk up” the tank, fittings and

carburetor.

❏ 3. Clean the plane with paper towels and a

light-duty spray cleanser. Keeping your

plane clean will make it last longer and

keep it looking nice.

❏ 4. Put a few drops of after-run or light oil in

the carburetor and turn the prop over a

few times (without the glow plug ignited)

to distribute the oil throughout the

engine.

❏ 5. Inspect the prop and replace it if any

chips or cracks are found.

❏ 6. Inspect the entire plane for covering

tears, new dings and dents, loose

screws and connectors and any other

wear and tear.

SAFETY PRECAUTIONS

1. Wear safety glasses when starting and

running all model engines.

2. Model engine fuel is very flammable and the

flame is very dangerous because it is

almost invisible! Do not smoke or allow

sparks, high heat or other flames near

the fuel.

3. Do not run model engines inside a garage

or other closed room as they give off large

amounts of deadly carbon monoxide gas.

4. Do not run model engines around gravel,

sand or other loose debris. These materials

will be ingested through the carburetor and

can also be kicked up by the prop.

Make sure the flaps go DOWN when you

give UP elevator! Put the mixing on a switch so

you can engage it when you want. Experiment

at altitude initially.

Snaps and spins are dramatically quick and

tight; knife edge flight and knife edge loops are

relatively easy; plus lightweight makes hovering

possible and acceleration instant.

Quick response is the main reason we

recommend exponential control on the flight

surfaces with a computer radio. With exponential,

you get full response at the extremes of control

stick movement, yet a softer feel for smooth

control around neutral. We suggest you set the

dual rate switches the same for both HI and LO

so they can’t be in the wrong position at the

wrong time. Set the throw limits as indicated in

“Set-Up” under the “Hi Rate” column and

program the exponential for 50% to begin with.

PRE-FLIGHT CHECK LIST

❏ 1. Check all control surfaces for possible

looseness or deterioration.

❏ 2. Check all screws, clevises, nuts and all

other connectors to make sure they are

securely fastened.

❏ 3. Check which radio frequencies are

being used. Do not turn on your radio

until absolutely sure you are the only

one operating on that frequency.

❏ 4. Check for proper operation of all control

surfaces.

❏ 5. Check the level of charge in both the

transmitter and receiver batteries before

flying.

❏ 6. Range check the radio both with and

without the engine running! Follow the

radio manufacturers instructions for this.

Page 19

THE PERFECT ENGINE FOR YOUR

FUN TIGER!

15

5. Always stay behind the propeller when the engine is running. Make all engine adjustments

from behind the engine. Under no circumstances should you allow your face or body near the

plane on rotation of the propeller when the engine is running.

6. Do not allow loose clothing or other loose objects close to the prop.

7. To stop an engine, cut off the fuel or air supply to the engine. Do not throw rags or other

objects into the prop to stop the engine.

8. Do not touch the engine or muffler during or right after it has been running–It gets very hot!

CHOOSE THESE FINE PRODUCTS FOR YOUR FIELD EQUIP-

TTR9141 Thunder Tiger PRO-46

The PRO-46 is the perfect engine for your Fun

Tiger, with plenty of power and a great sound.

TTR2702 Thunder Tiger Power Monitor

The perfect device to distribute the power of a 12V field

box battery: metered hi efficiency glow driver, fuel pump,

and starter.

TTR3302 Thunder Tiger Tiger Tote™

Keep all your stuff organized with a Tiger Tote, with a

pre-cut power panel slot and available with or without

Remote Starting System.

TTR1102 Thunder Tiger 4-Way Wrench

Thunder Tiger’s lightweight 4-way wrench fits all glow

plugs and prop nuts, plus has room to store extras.

TTR1658 Thunder Tiger Fuel Pump

Our most popular fuel pump; fuel and defuel from a 12V

source; fuel filter and fuel line included.

TTR2674-2675 Thunder Tiger Starters

Keep all those fingers on your hands with budget-priced

Thunder Tiger starters, available in two sizes, starting

engines from 1/2A to 1.20.

Copyright 1998 by Thunder Tiger Corporation, all rights reserved.

Thunder Tiger, Fun Tiger, Fun Tiger Extra, Fun Tiger G-200, Champion 45-S, Champion 45L, Tiger Stick, Regular Combo

Plus, Regular Combo+, Tiger Tote, their logos and likenesses thereof are trademarks of the Thunder Tiger Corporation.

Page 20

16

Tiger Stick RCP

TTR4509-A+

Thunder Tiger

PRO-46

Thunder Tiger

PRO-46

The “Regular combo Plus”(RCP) is a new concept in R/C. If you have some flying experience

under your belt and already have a couple of

radios, you may not want to buy another. Check

this out.

When you get a Regular Combo Plus, the

engine, servos, and switch harness is included and

all of the work is

done for you.

The engine is installed, the servos are

secured and hooked up to the control surfaces

and the switch harness is mounted. All you have

to do is plug in your existing receiver and battery

pack, join the wing halves, install the stab, bolt on

the landing gear and you are ready to fuel and fly!

Three of Thunder Tiger’s more advanced airplanes

are available in the Regular Combo Plus lineup.

Thunder Tiger

PRO-40

Champion 45L RCP

TTR4456-A+

Champion 45-S RCP

TTR4512-A+

FOR YOUR NEXT PROJECT:

Loading...

Loading...