Page 1

Page 2

INTRODUCTION

2

IMPORTANT NOTES & WARNING

3

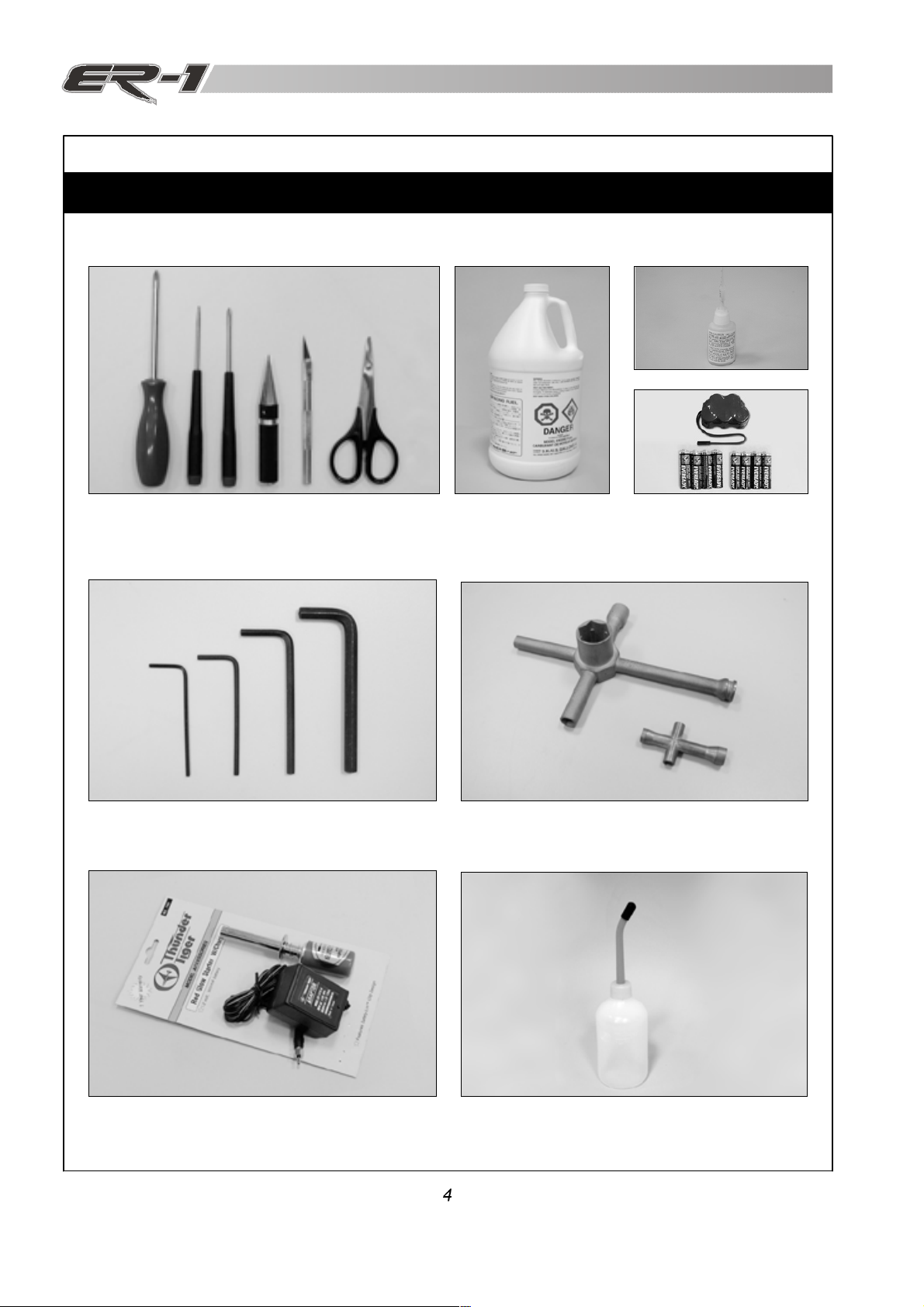

ITEMS REQUIRED FOR OPERATION

4

UNWRAPPING CONTENTS FROM BOX

5

CHARGING THE GLOW PLUG IGNITER

5

INSTALLING TIRES / WHEELS

5

PREPARING THE RADIO

6

RADIO BATTERY INSTALLATION

6

RADIO OPERATION

6

OPERATING RADIO STEERING FUNCTION

7

OPERATING RADIO THROTTLE/BRAKE FUNCTION

7

ADJUSTING THROTTLE/BRAKE LINKAGE

8

ADJUSTING CARBURETOR

8

FUELLING

9

PREPARING THE ENGINE FOR STARTING

9

STARTING THE ENGINE

10

ENGINE BREAK-IN & ENGINE SETTING

10

SHOCK AND REAR TOE-IN ADJUSTMENT

11

BODY CUTTING

11

2 SPEED ADJUSEMENT

11

TROUBLESHOOTING

12

Thank you for purchasing the Thunder Tiger ER-1 Nitro Powered 4WD All Road Car. Thunder Tiger

strives to bring you the highest level of quality and service we can provide. We race and test our

products around the world to bring you state-of-the-art items.

This user guide contains the steps you will use to prepare and use your new vehicle. Please read

all instructions and familiarize yourself with the systems and controls of this product before operating.

You should enjoy many hours of trouble free use from this advanced R/C product. We offer online help 24-7 on our www.acehobby.com forum and our product specialists are ready to take your

call if you have any technical questions. Have fun and enjoy the exciting world of R/C.

Thank you for purchasing a Thunder Tiger Product.

Please read all instructions and familiarize yourself with the products and controls before

operation.

1. This product is not a toy. It is a high performance model product. It is important to familiarize

yourself with the model, its manual, and its construction before assembly or operation. A child

operating under the supervision of the adults is necessary.

2. Always keep this instruction manual ready at your hand for your assembling and operating

reference, even after completing the assembly.

3. Make sure all the screws are properly tightened and all the parts are checked after running the

car for a long period of time.

4. For the best performance, it is important to make sure all the moveable parts work free without

binding.

5. Do not operate model products in rain, on public roads, near crowds, near airport, or near areas

with restricted radio operation.

6. Always keep fuel away from heat and open flame. Only operate in open, well-ventilated area.

Store fuel in cool, dry area. Keep the fuel bottle cap tightly closed. Clean up any leak or excess

fuel before starting the engine.

7. This product, its parts, and its construction tools can be harmful to your health. Always exercise

extreme caution when assembling and/or operating this product. Do not touch any part of the

model that rotates.

8. Check your radio frequency with the proper operating frequency of the area or country. Always

check to see if there are any modelers operating on the same frequency as yours. Also, check

your radio for proper operation before operating a model.

CAUTION

INDEX

INTRODUCTION

Page 3

1. Choose a fuel from a reputable, brand name company that is approved for car/truck use.

Do not use airplane or boat fuels in your car/truck. Choose methanol based model engine

glow fuel that has a nitro content in the range 10%-30% and 5% to 18% caster/synthetic oil

content for lubrication. Lower nitro percentages will generally result in a cooler engine running

temperature and therefore last longer before needing a rebuild; cooler-running engines also

generally produce less power. 20% nitro is the most widely used fuel.

2. Fuel color is for identification purpose only and is not important to performance or durability

of your engine.

3. Be careful. If the tank overflows it might get on your radio gear or on your brakes and it may

create an unsafe driving situation. Always keep your fuel bottle closed when not in use.

4. Do not dispose of fuel or empty fuel containers in a fire. It may possibly cause fire or explosion.

1. For proper engine break-in procedure, please refer to the manual of your engine.

2. Never run your vehicle without the air filter .If the vehicle will be operated in an area with

fine dust, use filter oil or caster oil on the air filter element. It is important that the foam is

only moist to trap dirt and allow air passage. With the foam too wet, limited air can pass

through; therefore, limiting engine performance.

3. The parts around engine could be dangerously hot after operation. Do not touch it without

any protection!

1. When turning radio on, first turn on the transmitter and extend the transmitter antenna.

2. Then, turn on the receiver. When turning off, first turn the receiver off, then the transmitter

off.

1. If you drink nitro fuel by accident, immediately drink large quantities of water and try to induce

vomiting. Consult with physician right after then.

2. If the nitro fuel gets into your eyes, rinse them well with water. Consult with physician right

after then.

3. If the fuel gets onto your skin, wash it well with soap and water.

FUEL SELECTION

1. Improper operations may cause personal and/or property damage. Thunder Tiger and its

distributor have no control over damage resulting from shipping, improper construction, or

improper usage.

2. Thunder Tiger assumes and accepts no responsibility for personal and/or property damages

resulting from the use of improper building materials, equipment and operations. By the act

of assembling or operating this product, the user accepts all resulting liability. If the buyer is

not prepared to accept this liability, then he/she should return this kit in new, unassembled,

and unused condition to the place of purchase.

ENGINE

RADIO OPERATION

FIRST AID

WARNING

IMPORTANT NOTES & WARNING

Page 4

5-WAY WRENCH

ITEMS REQUIRED FOR OPERATION

Fuel Bottle

Glow Starter w/ Charger

Hex Wrench Set, 1.5mm / 2.0mm / 2.5mm / 5.0mm

4-Way, 5-Way Wrench

CA Glue / Instant Glue

Screw Drivers, Lexan Body Reamer, Hobby Knife,

Lexan Scissors.

Glow Fuel, Methanol

10% to 30% Nitro

5% to 18% Caster / Synthetic Oil

RX Battery pack and battery

charger

Page 5

a.

Plug the charger into an AC outlet, and then pull on the igniter lever to accept the charging adapter.

b.

At this point, the small red LED indicator on the charger should light up indicating the charging sequence

is in progress.

c.

When the charging complete, pull on the glow plug igniter lever to unplug the glow igniter.

Charge the new glow plug igniter for 16 to 24 hours on the first charge. For subsequent charges, charge

it about 12 hours before next use.

NOTE:

If the igniter gets warm or hot during the charge, unplug the igniter from charger immediately. A warm /

hot igniter means the igniter is overcharged. Overcharging can damage the internal battery in the igniter;

thus, shortening its life.

CHARGING THE GLOW PLUG IGNITER

a b c

1

a.

Contents of the box are secured with reusable zip-ties. To unlock zip-tie, press on the small lever.

b.

Pull on the zip-tie while keeping the small lever pressed. Pull the zip-tie out completely.

UNWRAPPING CONTENTS FROM BOX

a b

b

a

INSTALLING TIRES / WHEELS

a.

Insert the axle pin into the hole.

b.Apply the supplied lock nuts onto the wheel axle.

c.

Turn the wrench to tighten the wheel nuts

c

2

3

Page 6

b

a.

Install 8 AA-size alkaline batteries into transmitter.

b.

Connect the battery connectors from the switch with battery pack.

c.

Install the battery into the receiver box. secure the box with a long body clip.

RADIO BATTERY INSTALLATION

a

b

c

a.

Check the frequency printed on the transmitter crystal.

b.

Remove the radio receiver from box with a screw driver. Check the frequency printed on the receiver

crystal, and make sure it matches with the transmitter crystal. Make sure no one will operate on the

same frequency when you are. When there is a radio glitch, it will most likely be caused by improper

crystal, damaged crystal, or people operating on the same frequency. After checking, place the receiver

back in the box and secure the receiver box top.

c.

Install the antenna into transmitter.

PREPARING THE RADIO

a

c

5

4

a. When turning radio on, first turn on the transmitter.

b.

Then, turn on the receiver. When turning off, first turn the receiver off, then the transmitter off.

c.

To reverse the functions of servos, use the small, white servo reverse switches located on side of the

pistol transmitter (or the inset servo reverse switches located at the bottom of the stick transmitter). To

trim the servos on pistol transmitter, use the trim switches on side of the steering wheel (the ST. trims

steering, and the TH trims throttle/brake). On a stick transmitter, the trim levers are located accordingly

around the sticks.

d.

For more details, please check the transmitter instruction manual.

RADIO OPERATION

a b c

6

Page 7

a.

Check the radio steering functions. With the radio transmitter and receiver on, turn the steering wheel

/ stick to the left. The front tires/wheels should turn left accordingly. If not, flip the steering servo reverse

switch.

b.

Return the steering wheel / stick to neutral. The front tires/wheels should point straight forward. If not,

use the steering trim lever to correct it.

c.

Turn the steering wheel / stick to the right. The front tires/wheels should turn right accordingly.

a b c

OPERATING RADIO STEERING FUNCTION

a.

Check the radio throttle/brake functions. With the radio transmitter and receiver on, pull the trigger /

push the stick forward. The carburetor should be fully opened and the brake disengaged. To reverse

this function, flip the throttle/brake servo reverse switch.

b.

Return the trigger / stick to neutral. The carburetor should be closed to a point where the idle has

been set (see step 9 & 10 for settings), and the brake still disengaged. If not, use the throttle/brake

trim lever to correct it.

c.

Push the trigger / pull the stick backward. The carburetor opening should still be the same at neutral,

throttle spring compressed slightly, and the brake engaged.

a

b

c

OPERATING RADIO THROTTLE / BRAKE FUNCTION

8

7

Page 8

a b c

ADJUSTING CARBURETOR

a.

To set the high speed needle (large needle sticking out from the carburetor body), turn the screw as

pictured. Initial high speed needle setting should be 2.5 turns (close the needle completely, then back

out 2.5 turns). Clockwise turn will provide leaner setting (lower fuel to air mixture), and counterclockwise

turn will provide richer setting (higher fuel to air mixture).

b

.

To set the carburetor idle (small needle sticking out from the carburetor body), turn the screw as pictured.

Initial idle setting should leave 1mm carburetor gap. Clockwise turn will provide higher idle (larger

carburetor opening), and counterclockwise turn will provide lower idle (smaller carburetor opening). For

more details about the engine setting, please refer to ENGINE BREAK-IN/SETTING procedures to

properly set the engine.

c.

To set the low speed needle (The low-speed mixture screw is located in the end of the carburetor).

turn the screw as pictured. This screw controls how much fuel enters the engine at idle and low throttle.

This adjustment will smooth the idle and improve the acceleration to mid speed. Make this adjustment

with the throttle closed, after setting the idle. Turn the screw clockwise gently until it bottoms out. DO

NOT over tighten. Now turn the low-speed mixture screw counter-clock 6 1/2 turns.

d.

Remove the outer foam from filter and make it moist evenly with a few drops of fuel. Put the filter in a

plastic bag and knead it until the foam is saturated, but not soaked.

e.

Finally, make sure the air cleaner boot is securely fastened with a zip-tie.

Never run your vehicle without the air filter .If the vehicle will be operated in an area with fine dust, use

filter oil or caster oil instead of fuel. It is important that the foam is only moist to trap dirt and allow air passage.

With the foam too wet, limited air can pass through; therefore, limiting engine performance.

d e

d

a.

To set the throttle/ brake linkage, first the radio should be on and neutral; thus, the servo is at neutral

position.

b.

With the servo at neutral, loosen the brake linkage collar and move it to a point where the brake levers still

have 2mm of space before brakes are engaged.

c.

With the servo at neutral, use a 1.5mm hex wrench to set the outer collar next to the plastic lever (servo

horn).

ADJUSTING THROTTLE / BRAKE LINKAGE

a

a

b c

9

10

Page 9

a

b

c

a.

Remove the cap from fuel bottle nozzle.

b. Squeeze the fuel bottle, insert into fuel, and draw fuel into the fuel bottle. The fuel used should be

methanol based model engine glow fuel (available at hobby shops) with 10% to 30% nitro content and

5% to 18% caster/synthetic oil content for lubrication.

c.

Fill car's fuel tank with glow fuel.

FUELLING

PREPARING THE ENGINE FOR STARTING

cba

f

d e

a.

To start an engine, first remove the glow plug with the included wrench.

b.

Check the glow plug by plugging it into the glow plug igniter. The glow plug element should light up

brightly. If it lights up dimly, then the glow plug igniter is low (and it needs recharging). If it doesn't

light up, or the plug element looks distorted, then the glow plug is bad (replace with new one). After

checking, reinstall the glow plug.

The glow plug used for this engine can be: Thunder Tiger 9281, McCoy #9 / #59,

Novarossi C4S / C5S / C6S,OS #8 / #A3 / #A5, and Picco P6S / P7S.

c.

With the radio off, manually turn the servo to open the carburetor (open throttle).

d.

Plug the tuned pipe exhaust tip.

e. Keeping the exhaust tip plugged, pull on the engine's starter. Keep doing it until fuel reaches engine's

carburetor, then pull it 3 more times to prime the engine.

f.

Manually return the servo back to neutral.

11

12

Page 10

a. Turn on the radio (transmitter first, then receiver)

b. Clip the glow plug igniter onto engine's glow plug.

c. Pull on the engine starter, release, repeat until the engine starts. Throttle maybe required to be opened

momentarily, (release back to neutral immediately after it starts).

Remove the glow plug igniter from engine after engine has started and warmed up. If the engine stops right after

the igniter is removed, the carburetor setting is too rich. Please refer to engine setting section.

If engine starter becomes hard to pull, the engine maybe flooded. To unflood an engine, remove the glow plug from

engine, flip the car upside down, and pull on the starter to release excess fuel. Then, reinstall the glow plug and

repeat the engine starting procedure.

ENGINE BREAK-IN

For a new engine (break-in setting), the high speed needle needs to be set as rich as possible. Turn the high speed

needle 1/4 turn counterclockwise from initial setting (2.5 turns from fully closed). Repeat step 14b. Keep doing this

until the engine stalls at full throttle, then turn the high speed needle 1/4 turn clockwise. Run the car in an open parking

lot with this rich engine setting for at least 5 tanks of fuel to complete the break-in process. It is normal for new engines

to stall many times during this time due to the rich setting. When it does, just restart the engine. After break-in, follow

the engine setting procedure to set the carburetor for normal operations.

ENGINE SETTING

Due to different fuel formula, operating elevation, humidity . . . etc. The engine may / may not operate properly at initial

setting. Please follow the following procedure to achieve proper carburetor setting. Do not perform this procedure until

the engine has been properly broken in.

a. Start the engine.

b. With a running engine, run the car back and foreth in a straight line (full throttle achieved during each passage) in an

open parking lot. Repeat, and note the sound of the exhaust. Do not hold the throttle open with car off the ground or

the engine connect rod may break.

c. If the exhaust does not reach a high pitch note, turn the high speed needle (long needle, extending from carburetor,

pointing up) 1/4 turn clockwise, and repeat step 14b.

If the exhaust reaches a high pitch note immediately, turn the high speed needle 1/4 turn counterclockwise, and repeat

step 14b.

d. Repeat step 14c until the engine reaches optimum setting (turning in the high speed needle will no longer have an

effect at full throttle and turning out the needle will cause the engine's full throttle rpm to drop a little).

For normal operat ions, turn the high speed needle 1/4 turn counterclockwise from the optimum high speed needle

setting.

e. To set the idle, turn the idle screw in (higher rpm) or out (lower rpm).

Basically, the idle needs to be set at the lowest possible point before the engine stalls.

f. To set the low speed need le (larger needle on the side of carburetor body), the engine needs to be broken-in and

high speed needle needs to be set first.

g. Repeating step 14b every 10 seconds (1 second of full throttle and 10 seconds of idle). If the engine rpm at idle

drops after a few seconds and stalls, then turn in the low speed needle (clockwise) 1/4 turn. If the engine rpm stays

the same or goes up at idle, then turn out the low speed needle (counterclockwise) 1/4 turn.

h. Keep repeating step 14g until the engine rpm drops (goes to idle rpm, then drops a few more rpm after a few seconds)

but does not stall at idle.

STARTING THE ENGINE

a b c

13

14

Page 11

a

SHOCK AND REAR TOE-IN ADJUSTMENT

b

a. Use the included shock clips to adjust for spring pre-load. Pressing the entire car down, release,

and the car should return to ride height (indicated on set-up page). More pre-load clips will produce

higher ride height, and less clips will produce lower ride height. Amount of clips used for front and

rear shocks can be different, but clips should be the same for left and right.

b.

Use the included plastic toe-in plates to adjust for rear toe-in. The toe-in angles are indicated on

each plates.

BODY CUTTING

It is recommended to cut

the windows out to let

cool air in for good

circulation.

b

TWO-SPEED ADJUSTMENT

a. Your truck's two-speed shift point is preset at factory. It

should shift into 2nd gear within 16-19 feet(5-6 m) on a

full-throttle, standing-start acceleration.

b.

If the shift point needs to be re-adjusted, please shut down

the engine. First align the BLACK adjustment set screw

with the opening on the 2nd gear as shown on the diagram.

c. Using a 2mm Allen wrench, turn the black adjustment set

screw clockwise to make the two-speed shift later; turn it

counter-clockwise to make the two-speed shift earlier. Only

use 1/4turn increments whenever you adjust your twospeed. Do not screw out the black set screw too much or

it may cause set screw and spring to fall out.

d.

If it is screwed in or out too much, reset the black set screw

as following.

First, screw in the black set screw clockwise gently until

it is fully compressed. Be careful not over-tighten the black

set screw; otherwise the spring inside the shoes may be

damaged. And then turn the black set screw counterclockwise about 5 turns.

15

16

17

Shift timing becomes slower.

Shifts at higher RPM

Shift timing becomes quicker.

Shifts at lower RPM

Shift

Earlier

Shift

Later

Page 12

Description Problem Solution

Engine will not Out of fuel ................................................................. Fill fuel tank

start Contaminated fuel .................................................... Replace fuel

Glow plug igniter not charged ................................... Charge glow igniter

Glow plug bad .......................................................... Replace glow plug, see "Glow Plug Problems"

section below.

Fuel not getting to carburetor ................................... Open and close fuel tank lid twice.

Engine flooded ......................................................... See "Flooding" section below.

Engine overheating................................................... Allow engine to cool, richen fuel mixture,

see "Fuel Mixture" section below.

Carburetor incorrectly adjusted................................. Re-adjust carburetor, see "Fuel Mixture" or

"Factory Carburetor Settings" section below.

Exhaust blocked ....................................................... Check exhaust, remove blockage.

Air cleaner blocked ................................................... Check air cleaner, remove blockage.

Engine starts, Idle speed set to low................................................. Adjust idle speed screw, see "Fuel Mixture"

then stalls section below.

Air bubbles in fuel line............................................... Check for leaks in fuel line

Glow plug is fouled.................................................... Replace glow plug, see "Glow Plug Problems"

Section below.

Starter rope will Engine is flooded....................................................... See "Flooding" section below.

not pull Engine is seized........................................................ Examine engine for damage

TROUBLESHOOTING

If you have trouble star ting or keeping your ER-1 running,

here's a quick checklist of what to look for first.

Glow Plug Problems.

The glo w plug in your eng ine must be repl ac ed

periodically to maintain peak performance and easy

starting. Most starting problems or erratic performance

can be traced back to the glow plug. The easiest way

to check for a faulty glow plug is to simply install a new

one and see if the problem is

corrected. However, to test the

glow plug, remove the glow

plug form the cylinder

head with a 8mm nut driver

(make sure there is no dirt

on top of the head which could

fall into the engine. Do not lose

the copper gasket which seals the glow plug.)

Connect the glow plug to the glow igniter. All of the coils

should glow bright white. Sometimes, the first few coils

will not glow, while the rest are bright orange. This

indicates a bad glow plug or low igniter battery. Try

recharging the igniter, or replacing the glow plug.

Flooding

Symptoms of a flooded engine include difficulty in starting,

muffled sounds coming from the exhaust, pull starter

won't operate, and excess fuel draining from the exhaust

outlet. Remove the glow plug with a 8mm nut driver and

also remove the air cleaner. Turn the car upside down

and pull the starter a couple of times to drain the excess

fuel out of the engine and carburetor. Re-install the glow

plug and try starting again.

Fuel Mixture

The fuel mixture is controlled by three different

adjustments on the carburetor, and should come preset

from the factory (see photos below). Your engine should

start and run slightly rich with these settings (rich is

good for break-in). Tuning Tip: Always make sure

you can see some exhaust smoke coming out of the

exhaust outlet during operation. This is a good sign

that enough fuel is getting to the engine.

Factory Carburetor Settings.

Low speed mixture

6

1/2

turns out

Clockwise=Leaner

Counterclockwise-Richer

Idle speed:

.020" (.5mm)

Adjust Idle Screw until

.5mm is obtained.

High speed mixture:

2

3/4

turns out

Clockwise = Leaner

Counterclockwise-Richer

Richer

Richer

Leaner

Leaner

Richer

(More Fuel)

Leaner

(Less Fuel)

Richer

(More Fuel)

Leaner

(Less Fuel)

JD6664

Low Speed Screw

Low Speed Screw

Idle Screw

Idle Screw

0.020" (0.5mm)

0.020" (0.5mm)

Loading...

Loading...