Page 1

-*

rgu

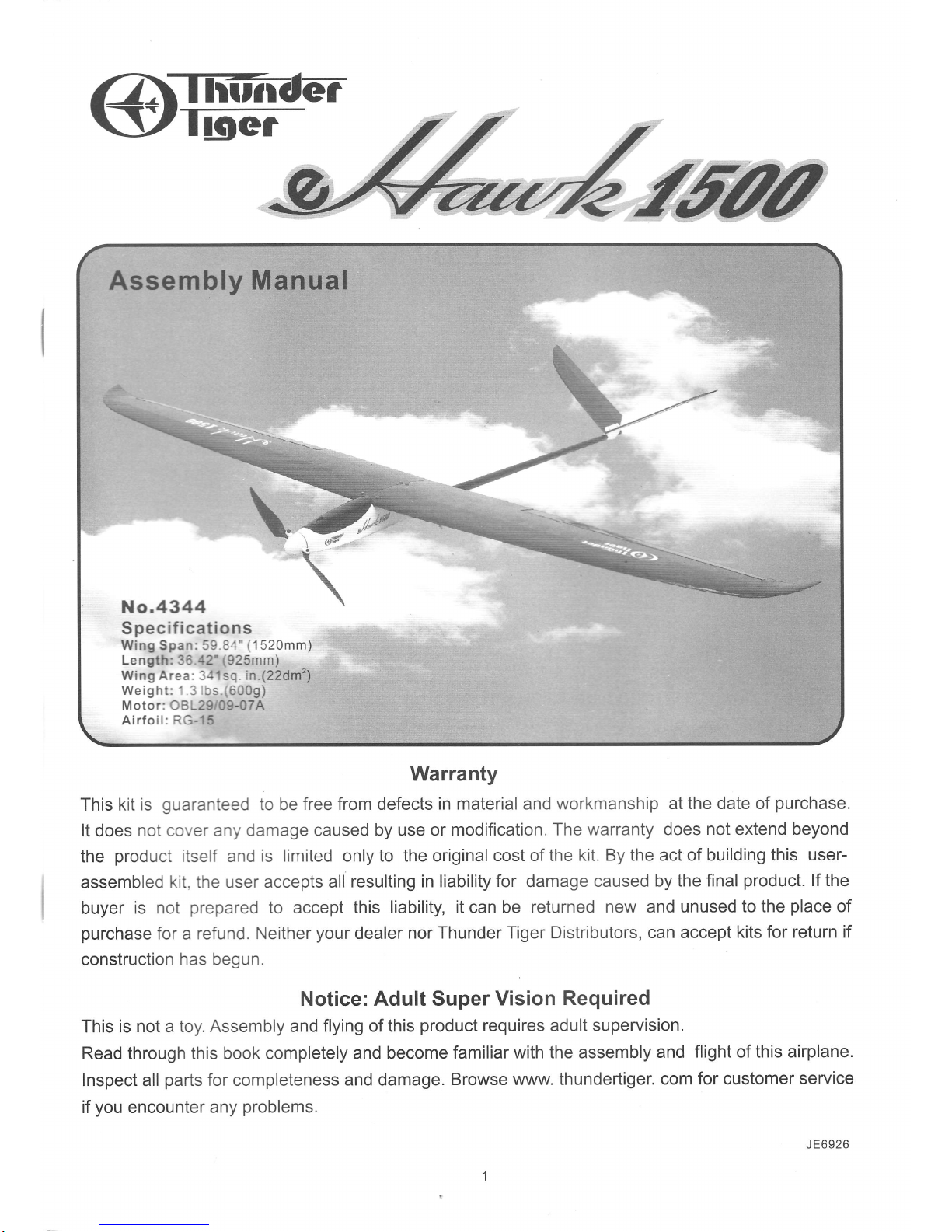

Assembly Manual

Specif

ications

Wing Span: :? 3

j'

'1

520mm)

Length:

ja

:2"

r925mm)

Wing

Area i.:,sr in.(22dm'z)

Weight: - -: o"0gt

Motor: :3 -29 09-07A

Airfoii:tr.3-15

No.4344

Warranty

This

kit is

guaranteed

to be free from defects

in material and

workmanship atthe date of

purchase.

It

does

not co,.'er anyr

damage caused by use

or modification.

The warranty does

not extend beyond

the

product

iisetf

and

is limited only to the original

cost of the

kit. By the act of building

this user-

assembled

kit the user accepts all

resulting in liability

for damage caused

by the final

product.

lf the

buyer

is

not

prepared

to accept

this liability, it can be

returned

new

and

unused to the

place

of

purchase

for a refund.

Neither

your

dealer

nor Thunder Tiger

Distributors, can accept

kits for

return if

construction has begun.

Notice: Adult Super

Vision

Required

This

is not a toy. Assembly and

flying of this

product

requires adult

supervision.

Read through this

book completely and

become familiar

with the assembly

and

flight of this airplane.

Inspect all

parts

for completeness

and damage.

Browse

www. thundertiger.

com

for

customer

service

if

you

encounter

any

problems.

J E6926

Page 2

INTRODUGTION

*g4''u/ffu

Introd

u ctio

n

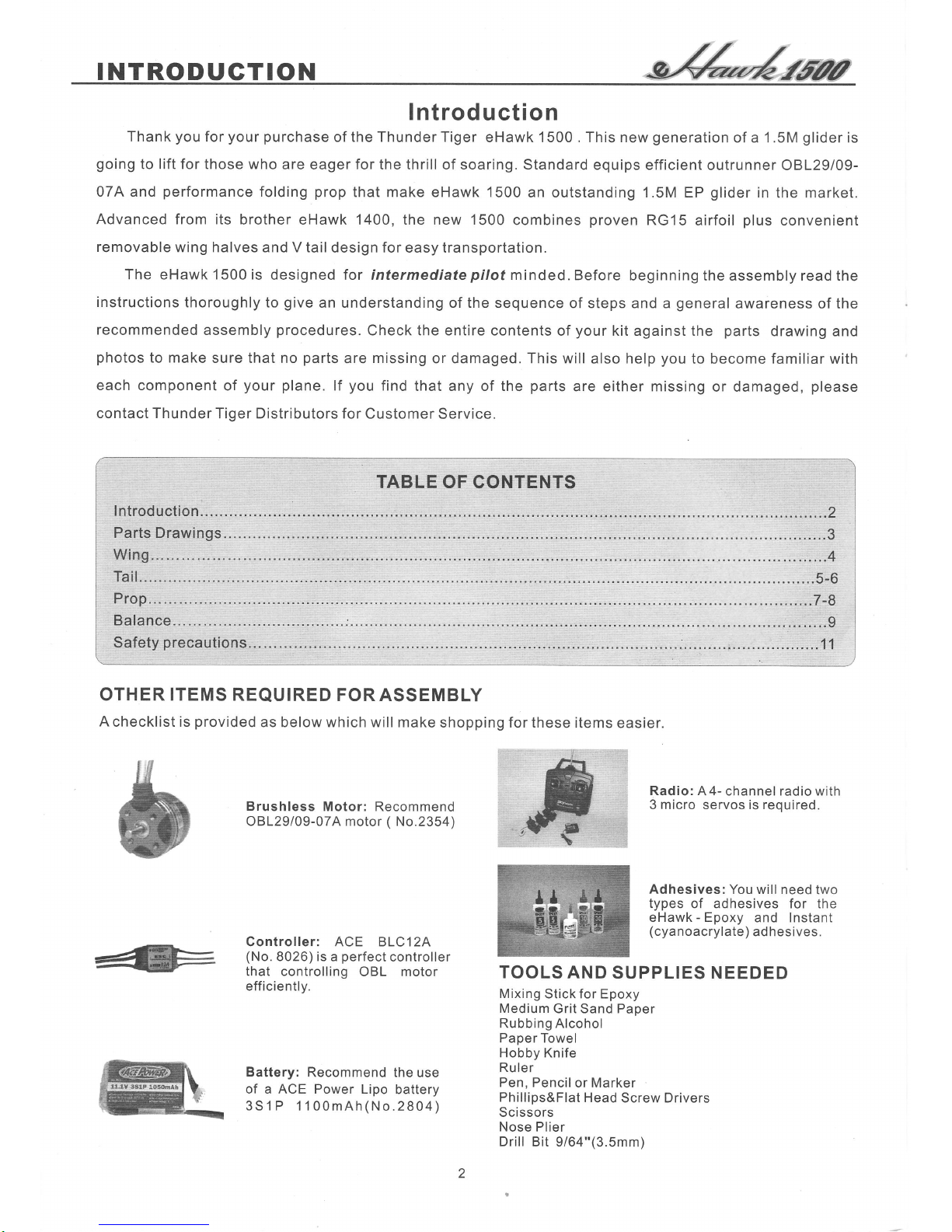

Thank

you

for

your purchase

of the Thunder Tiger

eHawk 1500 . This new

generation

of a 1 .5M

glider

is

going

to

lift

for those who are

eager

for

the thrill of soaring. Standard

equips efficient outrunner

OBL29/09-

07A and

performance

folding

prop

that make eHawk 1500

an outstanding 1.5M EP

glider

in

the market.

Advanced from its

brother eHawk 1400, the new 1500

combines

proven

RG15

airfoil

plus

convenient

removable

wing halves and V tail

design for easy transportation.

The eHawk 1500 is

designed for intermediate

pilot

minded.

Before

beginning the assembly read the

instructions

thoroughly to

give

an understanding of the sequence

of steps and a

general

awareness of the

recommended

assembly

procedures.

Check the entire contents

of

your

kit against the

parts

drawing and

photos

to make

sure that no

parts

are

missing

or damaged. This will

also help

you

to become familiar

with

each component

of

your plane.

lf

you

find

that any of the

parts

are either missing

or damaged,

please

contact Thunder

Tiger Distributors for

Customer Service.

OTHER ITEMS REQUIRED

FOR ASSEMBLY

A

checklist is

provided

as below which will make

shopping for these

items

easier.

Brushless

Motor: Recommend

OBL29/09-074 motor ( No.2354)

Radio: A 4-

channel radio with

3 micro servos is reouired.

Adhesives:

You will need

two

types of adhesives

for the

eHawk - Epoxy

and Instant

(cyanoacrylate)

adhesives.

Gontroller: ACE BLC12A

(No.

8026) is a

perfect

controller

that controlling

OBL motor

efficientlv.

Battery:

Recommend the

use

of a ACE Power Lipo

battery

3Sl P'1100mAh(No.2804)

TOOLS AND

SUPPLIES NEEDED

Mixing

Stick for Epoxy

Medium

Grit Sand Paoer

Rubbing Alcohol

Paoer Towel

Hobby Knife

Ruler

Pen, Pencil

or Marker

Phillios&Flat

Head

Screw Drivers

Scissors

Nose Plier

Drill Bit

9/64"(3.5mm)

Page 3

lTiffiundm

PARTS DRAWINGS

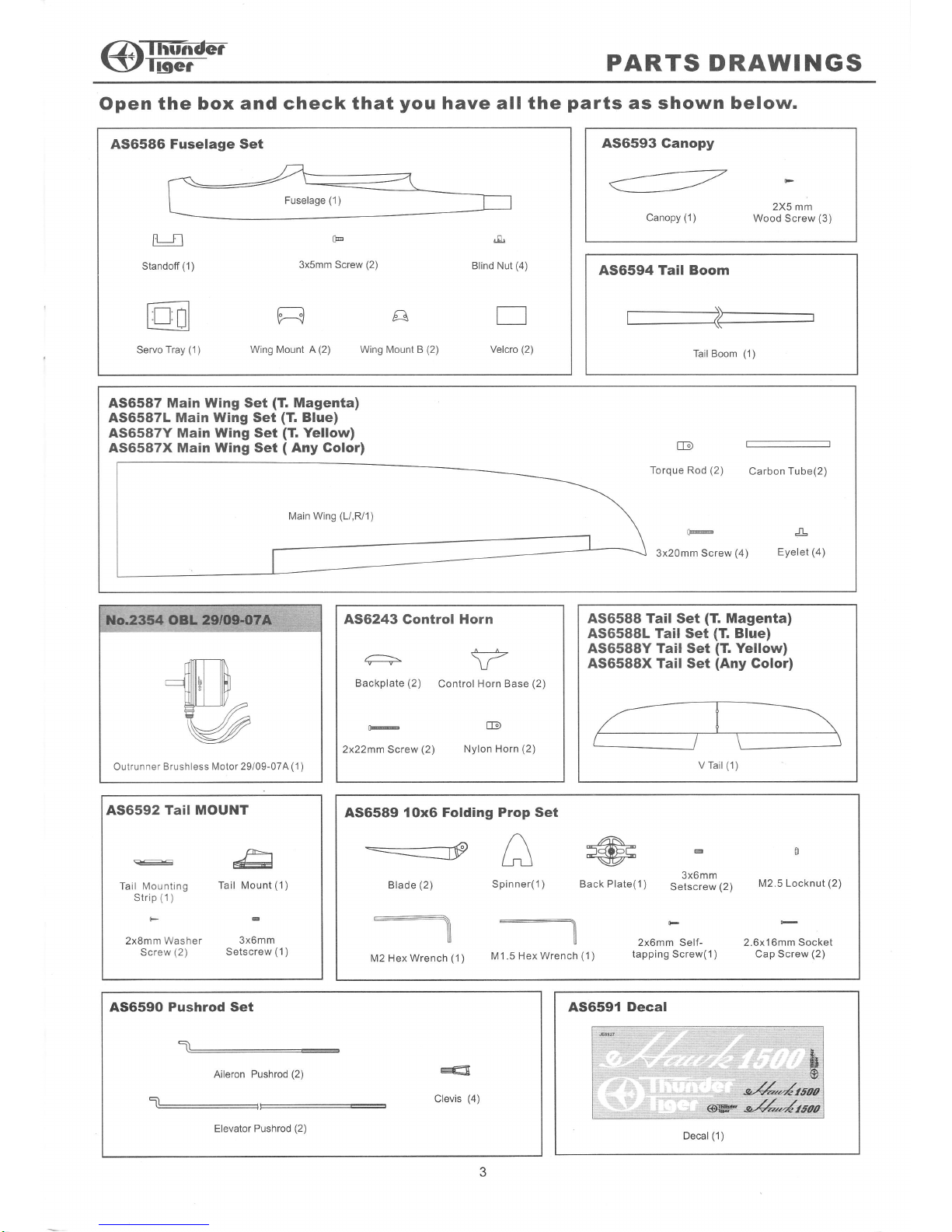

Open the

box and check that

you

have all the

parts

as shown below.

A36586 Fuselage Set

Standoff

(1

)

l't I nl

t'L--l't tl

i-l

Servo Tray

(1

)

@

3x5mm Screw

(2)

t2-J

A

Wing Mount A

(2)

Wing Mount B

(2)

,-E

Blind Nut

(4)

r

Velcro

(2)

A56594

Tail Boom

Tail Boom

(1)

2X5 mm

Wood Screw

(3)

A56593

Ganopy

:

Canopy

(1

)

A56587 Main Wing Set

(T.

Magenta)

AS6587L Main

Wing

Set

(T.

Blue)

AS6587Y Main

Wing

Set

(T.

Yellow)

AS6587X Main Wing Set

(

Any Golor)

Torque

Rod

(2)

Carbon

Tube(2)

Main Wing

(L/,R/1)

A56243

Gontrol

Horn

';------

Backplate

(2)

Con

2x22mm

Screw

(2)

\r

trol Horn Bas

@

Nylon Horn

(2)

e

(2)

Outrunner

Brushless Motor 29l09-07A

(1

)

A56592

Tail MOUNT

R-€

Tail

Mounting

T

Strip

(1)

F

2x8mm Washer

Screw

(2)

G

#

ail Mount

(1)

3x6mm

Setscrew

(1

)

A56588 Tail

Set

(T.

Magenta)

AS6588L Tail Set

(T.

Blue)

AS6588Y

Tail Set

(T.

Yellow)

AS6588X Tail Set

(Any

Golor)

AS6591

Decal

Decal

(1

)

A56589 {OxG

Folding Prop Set

-=.__---xp

/_\

Lfu

M1.5 Hex Wrench

(1)

@

ack

Plate(1

)

oS

3x6mm

Setscrew

(2)

M2 5 Locknut

(2)

F

2x6mm Self- 2.6x16mm Sockel

tapping Screw(1) Cap Screw

(2)

:

M2 Hex

Wrench

(1)

AS6590 Pushrod Set

5_

Aileron

Pushrod

(2)

Elevator Pushrod

(2)

Clevis

(4)

?

Page 4

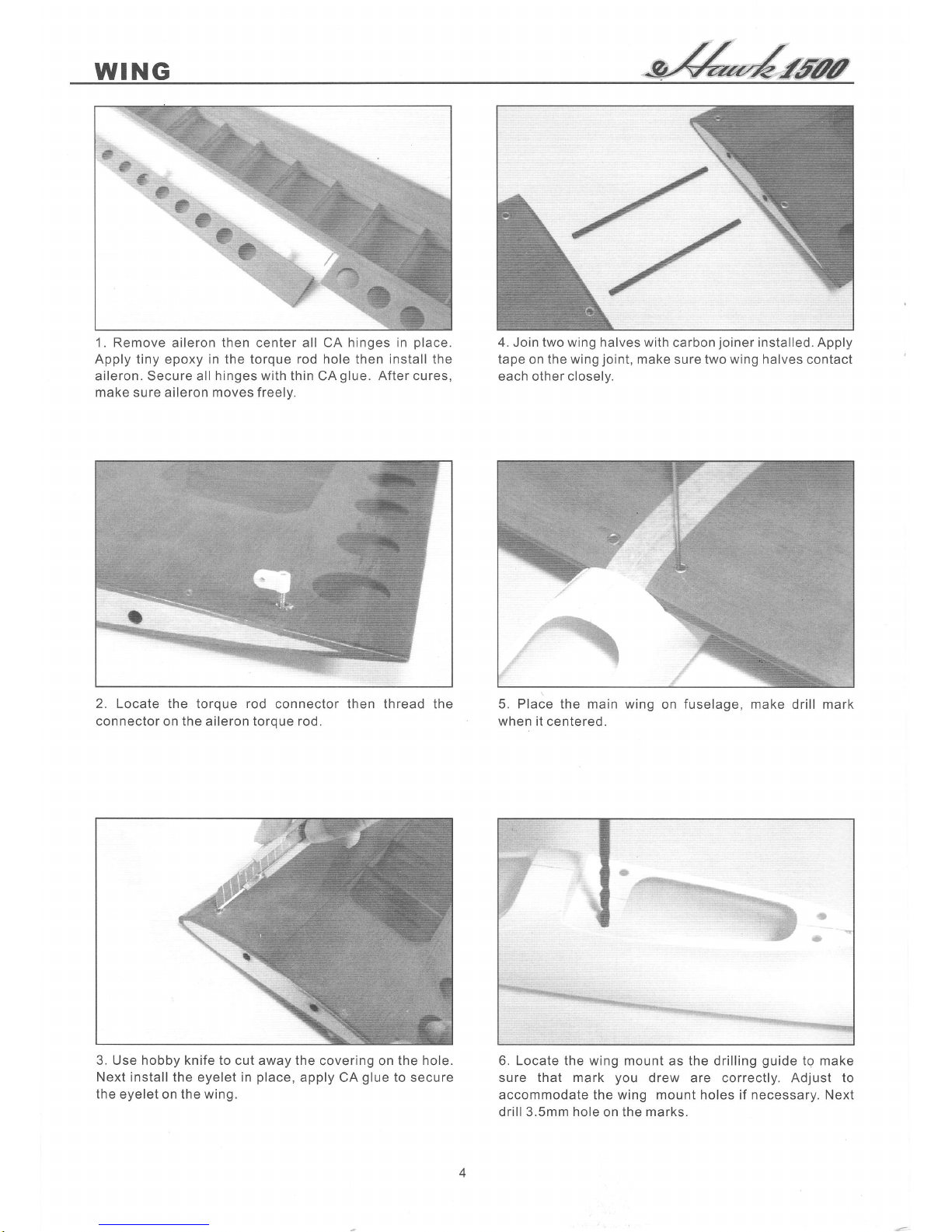

1. Remove

aileron

then

center

all CA hinges in

place.

Apply

tiny epoxy

in the torque rod hole then install the

aileron. Secure all

hinges with

thin CA

glue.

After

cures,

make sure aileron moves freelv.

2. Locate the torque rod

connector then thread the

connector on the aileron torque rod.

3. Use hobby knife to cut

away

the

covering on the

hole.

Next install the eyelet in

place,

apply CA

glue

to secure

the eyelet on the wing.

4.

Join

two wing halves with

carbon

joiner

installed. Apply

tape

on the

wing

joint,

make sure two

wing

halves contact

each other closelv.

5. Place the main

when it

centered.

wing

on

fuselage,

make drill mark

6. Locate the wing mount as the drilling

guide

tg make

sure that mark

you

drew are correctly. Adjust to

accommodate the wing mount holes if necessary. Next

drill

3.5mm hole

on the

marks.

Page 5

@lPr..-

TAIL

rt

.1

,,.

r.

.i

gl

',s{

'E

G

a_ ts

I'f:l

brd

:ffi

'

t..

7.

Installthe

blind nut on the wing mounts

as shown.

8. Glue

wing

mounts in

place.

You may need to sand the

glue

area to enhance the

adhesion.

Make

sure there is

no

glue

in the blind nut.

i.irf

I

il

I

"

1"

.l

10. Secure the

servo

with the

grommet,

eyelets and wood

screws

which

come

with

the servo as

photo

shown. Note

the orientation of the servos.

a

j

11.

Glue the servo tray in

fuselage.

Note: do not

push

in

too much as it might brake the fiberglass. Recommend

the servo tray edge is 1-112"

(40mm)

to the fuselage

wing leading edge.

12. Locate

and

install

elevator control

horn then thread

the connector as shown.

9. Glue the servo

standoff on

the

servo tray as shown.

Page 6

TAI L

I

13.

Cut away the mounting

hole covering with hobby knife.

lron

the center mounting

area if necessary.

14. Locate the

tail boom and

the tail mount.

Secure the

tail mount in

olace

with

3x6mm set screw as shown.

Note that the

pushrod

exit holes are

level with the mount

16. Thread the

clevis on the

pushrod,

note the

orientation

of Z-bend

end and clevis.

17. Insert

the Z-bend

end of the

pushrod

to the exit hole as

shown. Do not

snap on the clevis

at this moment.

18. Locate

the

servo

horn,

insert the Z-bend

end at the

second hole. Trim

away the excess

portion

of the servo

horn

as

it

will contact

the fuselage.

15. Bend

the horizontal tail

then

next

secure the tail on the

tail

and 2X8mm washer screws.

olace

the tail

on the

mount

mount with mounting

strip

Page 7

@ffiF

PROP

t)t

19. Attach the tail

boom then reach two

pushrods

on the

servo.

Make

sure the

oushrod

should

be cross to each

other.

That

is to say the left elevator

servo controls the

right elevator. Secure the

servo

horn with

servo screw

when servo is in neutral

oosition.

20. Temporally install main wing on fuselage with four

3x20mm screws. Adjust the tail boom make sure V tail is

at

the same angle to the main wing next

glue

the tail

boom in

place.

22. Remove the main wing, install

the aileron servo horn

and

pushrod.

Thread

the clevis on the

pushrod.

23. Install the main wing again, adjust the

clevis and snap

it onto the control horn when

servo is in neutral oosition.

24. Secure the

motor ( recommend Thunder Tiger

OBL29/09-07A)

with 3x5mm screw. Make

sure

the wires

do not contact to the motor can. Tape the wires if

necessary.Locate the Folding Prop

accessories as shown.

21. Adjust the clevis and snap on the elevator control horn.

Page 8

PROP

-sZL-r{6aa

1

*l

f"\"

25. Install

the blade

holder

on

the motor with two 3x6mm

set

screws.

Make sure the holder does not contact the

screw but as close as oossible to the fuselace.

26. Install the folding

prop

with the 2.6x16mm

socket

screws

and

M2.6 locknut. Do not

over

tighten the

screw

make

sure

it

can

fold

back

freelv.

28. Locate Velcro

and cut

it into

two oieces.

Attach

the

Velcro to

battery

pack

and attach the other

halves

of

Velcro to the fuselage. Refer to manufacturer's Receiver

and ESC manual then connect all connectors

properly

and setup V-tail function. The ESC and RX are located

as snown.

,

--ti

29. Thread the antenna through the

aileron exit

hole

then

tape it on the boom

to the tail.

27. Installthe

spinner with 2xOmm self-tapping screw

as snown.

30. Trim the canopy

alone

with the molded line.

Cut away

the

air

inlet for

cooling

?

/

.,:',1

''iil

'

''

t;!'

'

*..,i

.\

t

Q

Page 9

@lP,"..-

BALANGE

31. Position the canopy in

place.

You may

use tape

the canopy in

place.

Or

you

may drill three 1/16"

(

holes then secure the canopy with furnished

wooo screws.

IMPORTANT-Do not fly

your

model

before completing

this

very important

section. A model that is not

properly

balanced will

be

unstable could cause

serious damage and/or injury.

1.Turn the wing(and

plane

if assembled) up

side down

and measure about 2-1l8"(53mm)from

the

Leading

Edge

of the wing root then make a mark with

your

felt-tip

pen.

This is the

balance

point.

2.With

your

model

fully assembled turn the model upright

and

pick

it

up

with

one

finger

at each of the balance marks

you

made

earlier. lf balanced

properly

the

plane

will

hang horizontally.

2-118"(53mm)

Pick

up

model

at arrows.

Balancing

your

model is very important and must not

be

overlooked. The

center of

gravity

(CG)

is

2-118"

behind

the leading edge of the wing near

the wing

root,

parallel

with

the fuselage. You can adjust the battery

pack

forward

or backward to

reach the riqht

CG.

FIRST FLGHTS

to tape

1.5mm)

2x5mm

Make sure the direction of servo moves

correctly.

lf

not,

switch

the

reversing switch on the transmitter. Adjust

the

control

throws as

following

suggested.

__---r3t8"'vnn

{,^".u,n-

5/8".l5mm

Before

you

attempt to

some final checks:

1 . Fully charge

your

the manufactures

fly

your

model

you

should

perform

radio and flight

batteries

following

instructions.

114",6nm

l/4",6mm

2.Check the direction of travel of

your

control surfaces

and the ooeration

of

the motor

controller oer the

manufacturers instructions.

3.Range check

your

radio

system

per

the

manufactu rers i nstructions.

4.Double

check

that

you

have installed the screws in

the servo control arms and that the clevises are

snapped tightly on the control horns.

We

strongly

recommend that

you get

help from an

experienced R/C

pilot

if

you

are

just

beginning. You

should be able to

find

help at

your

local

dealer or

club field.

First

of all,

if

you

are flying with other flyers, check to

make

sure

they are not operating on the same frequency

as

you.

lf they

are,

do

not turn on

your

radio until they

have

safely

landed and have turned their radio off.

3/8",9mm

3/8",9mm

Aileron-Low

Rate

Aileron-High Rate

Elevator/Rudder

-Low

Elevator/Rudder

-High

Rate

Page 10

FIRST FLIGHT

Secondly, even though the eHawk

1500 is

very easy

to

fly, if

you

are a novice modeler/pilot, we

highly

recommend that

you

seek the help of an experienced

modeler for

your

first few flights. He can save

you

a

lot

of time and

possible

disappointment by

helping

you get

your

model in the air safely and

getting

it trimmed out

for

you.

lmportant:The radio control system

is

set up to operate

the control surfaces

just

lick a real airplanes as

if the

pilot(you)

are sitting

in cockpit

controlling the airplane.

When

you

want the

plane

to dive,

you push

the elevator

stick forward

(up),

to climb

you pull

the stick back

(down),

to turn

right,

you

move

the aileron

stick

to right

with

elevator up and

vise

versa.

When

you

want to turn

the motor on

you push

the throttle stick forward

and

when

you

want to turn the motor off

you pull

the stick

back.

lt is

the turning

that

causes

the most

problems

with novice

pilots

because when the

plane

is

flying

towards

you

a

right turn

command

on the transmitter

cause the

plane

to turn to

your

left

(which

is

the

planes

right). Get the

picture?

Fortunately the up and down

commands do

not change. The easiest way to conquer

this

problem

is

to

try and

always

face

your

body

near

the direction the

planes

are flying. This means that

you

will

have

to look over

your

shoulder

at times, but many

modelers find this an easy way to learn.

THE

FIRST FLIGHTS

You should

always

use

the

first few flights to

get

accustomed to

your

new airplane and

its flying

characteristics. Keep the model upwind and climb

to a

good

comfortable altitude to cut off

the motor and trim

your

eHawk 1500 for a

glide.

At altitude cut the

motor

and start

your glide.

Have

an

experienced modeler

adjust the trims of the transmitter

for

you

until the

plane

will

glide

straight

and level without any

other

control

input.

Once the trims are set

practice

making smooth

turns in

both directions

while losing as little

altitude

as

possible.

When the eHawk 1500 starts to

get

too

low

for

comfort turn the

motor

back on and

climb

back

uo to

altitude. Practice

this

climbing

and

gliding

until

you

are comfortable with the airplane.

Depending

on

the

battery

you

use

the

eHawk

1500 will

make 5 to

6

good

climbs up to a nice thermal searching

altitude

from

single

battery

charge. Once the

ESC

shuts off the

power

to the motor

you

will need to set up

for

your

landing. Continue to

make

smooth

gently

turns while lining up the

eHawk

1500 with

your

landing

strip. Once

you

are set up to land

keep

the wings

level

and let the model settle in for

an

nice

gentle

landing

while adding up elevator to keep the nose up slightly as

the

plane

slows

down. Make

several

flights like this to

really familiarize

yourself

with

the characteristics of

your

model

and to

learn

the

glide

and distance covering

abilities

of

the eHawk 1500. Once

you

have mastered

a

good

"comfort

level"

you

are

ready to

start searching

for thermals which

will really

increase

your

flight times.

THERMALS

Thermal soaring is one of the most interesting and

challenging types of flying there is. Believe it or

not,

your

eHawk 1

500

is capable

of

flights thousands of feet

high, lasting for

several

hours,

and covering dozens of

miles. The following

paragraphs

will help explain how

to

take advantage

of

natures

energy sources

called

thermals.

"Thermal"

is the term applied to

columns

of rising air.

This air is rising

because

it is warmer

than

the

surrounding air. A dust devil is simply a

thermal

which

ahs

picked

up some dust. Even a tornado is very

similar to a thermal, but of course much stronger.

Thermals occur when

the

sun, or other

heat

source,

heat

the air in one location faster and/or

warmer

than

the surrounding air. Darker surfaces

(plowed

fields,

asphalt

parking

lots, etc.) absorb the sun's energy

faster than lighter

colored and

are

generally good

thermal

generators.

This warmer air

is lighter

(less

dense)

than the

cooler air

and thus rises. The rising air

naturally starts to rotate,

much

like

water

going

down a

drain, and forms

an

inverted funnel shaped

column

that usually

gets

larger

with

altitude.

This

warmer

air

often contains water vapor which condenses as

it

reaches the

cooler air

high

above

the earth forming big

puffy

Cumulus clouds

that

experienced sailplane

flyers

willwatch to determine where the thermals are forming.

Thermals vary in

strength, but often

contain

air

that is

rising at speeds over 1200 feet

per

minute.

Some

thermals are

so strong

they

can even

rip

a sailplane

apart, especially if the

plane

is flying

fast

when

it

passes

through

the

thermal.

THERMAL

SOARING

It takes

lots

of

oractice

and

concentration to thermal

soar

like the

Hawks and Eagles. Since the

pilot

is

not

sitting inside

an

model sailplane, he cannot

feel

the

thermal,

he

can only see

his

sailplane's

reaction

to

the

thermal. Therefore, the majority of the time,

unless

the

pilot

is

paying

careful attention to the

plane,

he

may

not even realize that

plane

is near a thermal. Since

most thermals

are relatively small, less than a hundred

feet in diameter near the

ground,

the sailplane will

rarely

fly

directly into the thermal and

start

rising.

More likely,

it will fly near a thermal and the wing

closest to the

thermal

will rise

turning

the

plane

away

from the thermal. So as

you

can see, an inexperienced

pilot

may

bounce around between

the thermals with

ever

knowing

that he is encountering rising air.

In

order

to

take advantage of thermals,

you

need

to fly

smoothly with

as

few

control

inputs

as

possible.

Watch

the sailplane carefully and it will tell

you

what the air

around it is

doing.

When a sailplane does fly

directly

into a thermal it

will

either start rising

or

stop

sinking at

its

normal

rate.

Either case is reason enough to explore further.

Continue flying straight ahead until

you

have

obviously

passed

through the area

of strongest

lift. Now start

circling

in fairly

tight, but smooth circles. Because

of

the thermals inverted funnel shape, the lower the

planes

altitude, the tighter

the

circles need to be. As

the

plane

gains

altitude, the diameter of

the

circles

can

be increased. lf

you

see the

plane

falling

off

on one

side

of the

turn,

move the

circle over

into the stronger

lift. Thermals

are swept

along

by the

wind

so allow

10

Page 11

ZlTn-ifrdm

\)tf

locr

SAFETY PREGAUTIONS

your

circle

to

drift downwind

with the

thermal. Be

careful when following a thermal downwind though as

you

still

have to be able to make it back to

the field!

lf the sailplane is flying along and all of a sudden turns

by itself, it has

probably

flown near a thermal. Keep in

mind

that thermal

will have

tendency to turn the

plane

away, so

make

a 180 degree turn and fly back towards

the thermal . lf

you

don't

quickly

encounter lift

start

searching around that area. lf

you

find the

thermal,

follow the

procedure

outlined

above to take advantage

of it.

Thermals can be

generated

at any time

of the day, but

the strangest thermals are usually

produced

when the

sun

is

directly overhead 10:00am to 2:00pm

seems to

be the best time to find the strongest thermals.

lf

you

find

yourself getting

too high or

you're

having

trouble

getting

out of a strong thermal. DO

NOT dive

the

plane

to lose

altitude.

This

will very

quickly

over-

stress the airframe and blow the wings

off the

pla

The easiest

and safest

way

to

qulckly

lose

altitude

i

apply full rudder

(either

right

or

left)

and full up

eleva

This will

put

the

plane

into a tight spin that will

normally

not over-stress the airframe. This is

especially useful if

the sailplane

gets

sucked into a cloud

or

gets

too high

to see. The

spinning action

will

give

the

sun a better

chance of reflecting off of the wing

and catching

your

attention.

As

you

might

expect,

with

all this rising

air, there must

also be some sinking

air.

This

sinking air is the

sailplane

pilots

enemy and

one of

the

factors that really

make

eHawk

1500

challenging.

"Sink"

as it is referred

to, is usually not as strong

as

the

nearby thermals, but

is

can

quickly put

a sailplane on the

ground.

Sink in

one

of the reasons,

you

have to be very

careful when

chasing a thermal downwind.

lf

you

encounter sink,

immediately

turn and fly 90 degrees to the

direction of

the wind. Apply a little down elevator to

pick

up some

speed and

get

out of the bad

air as

quickly

as

possible.

You as the

pilot

of this radio

controlled model are

responsible for

any accidents that may

occur during its

use. We recommend

that

you

fly

your

model at a model

club

field

which is specially set up for modelflying.

But

always be sure that

you

operate the model in a

safe and

careful manner and read the

Safety Cautions which

enclosed in the kit

as

following.

Now that

you

have

completed the

assembly of

your

eHawk 1500 model we feel

that have a very

capable

and

good

looklng

2-meter electric

sailplane. We hope

that

you

will enjoy this model

and

get

many hours

of

flying

pleasure

from

its use. Thank

you

for

purchasing

this eHawk 1500 from Thunder

Tiger and we look

forward

to

providing

you

with other

great

RiC

products

in the future.

@ffiF

R/C Model

Airplane

Wffi

THUNDER TIGER CORPORATION

http://www.thunderti

ger.com

@E

€N

11

Loading...

Loading...