Page 1

www.Thunder-Max.com

309-466 Installation / Setup Guide V2013.09.16

tmaxupport@thunder-max.com

1

Part # 309-366 / 309-466 for V-Rod®

Models

Thank you for purchasing a ThunderMax ECM!

Please read through the following instructions before

beginning the installation procedure. Following these

instructions will ensure that the ECM is installed and

setup properly for optimal results. If you have any

problems or questions, please refer to the SmartLink

Tuning .pdf Manual, included on the CD (Help Menu)

with this package.

Step 1 Insert the SmartLink

CD into your computer.

SmartLink will automatically

open the InstallShield

Wizard when the computer

finds the CD-Rom. Follow

the instructions and install

the software on your

computer. If you do not have a serial port on your

computer for the communication cable, you will need to

use a USB to Serial converter (an inexpensive converter

is available from Zipper’s, #372-000). Install the included

driver disc at this time; follow the instructions given by

the manufacturer of the converter for installation.

Step 2 Install the ThunderMax and AutoTune modules.

(See dielectric grease tip for ECU on bottom of page 7)

Due to the mounting location and space constraints on

the V-Rod® for the ECM, your ThunderMax system is

supplied with a separate AutoTune module. The

ThunderMax ECM mounts in the same location as the

factory ECM; the AutoTune module mounts separately.

2002-2005 MODELS

Step 2a

Remove the

seat, air box

cover and

front frame

side covers

(2) to expose

the airbox

and battery

area.

Remove the

airbox lid with

snorkel.

Installation / Setup

Please Note: This product is Legal in

only for racing vehicles which may never be

upon a highway.

product for his or her use. Installation and use on a pollution-

controlled vehicle constitutes tampering under the U.S. EPA

guidelines and can lead to substantial fines. Review your

application and check your local laws before installing.

The user shall determine suitability of the

Guide

Locate fuse box just

forward of the seat and

remove fuse labeled

POW

“ECM

fuse, right side).

Unplug and remove the

factory ECM from the

motorcycle (located just

behind the steering

stem).

Due to the tight restrictions of the location of the ECM on

2002-2005

Option 1 - The

communication

cable can be

installed into the

communication port

of the ThunderMax

ECM

attached

ECM and stored on

the motorcycle

(how you

route/store

cable is up to you, you can run it through the frame and

along the airbox housing and store it under the seat or

roll it up and store it under one of the side covers), or

Option 2 –(PREFERRED not required) Install

ThunderMax Pigtail Communication Port Harness

( i nc l u d ed) and wire it to the ECM harness plug on

the motorcycle for an alternate port location.

Once option 1 or 2 is performed, install the ThunderMax

ECM to the motorcycle in the stock location. Plug the

main harness into the ECM and reinstall the ECM fuse.

ER” (center

model bikes:

and

remain

to

the

the

California

used

th

e

Page 2

www.Thunder-Max.com

309-466 Installation / Setup Guide V2013.09.16

tmaxupport@thunder-max.com

2

Either

of

these

options

will

allow

Step 2b Remove

2006-UP MODELS

the front and rear

seat, air box cover

and front frame

side covers (2) to

expose the airbox

and battery area.

Remove the airbox

lid with snorkel.

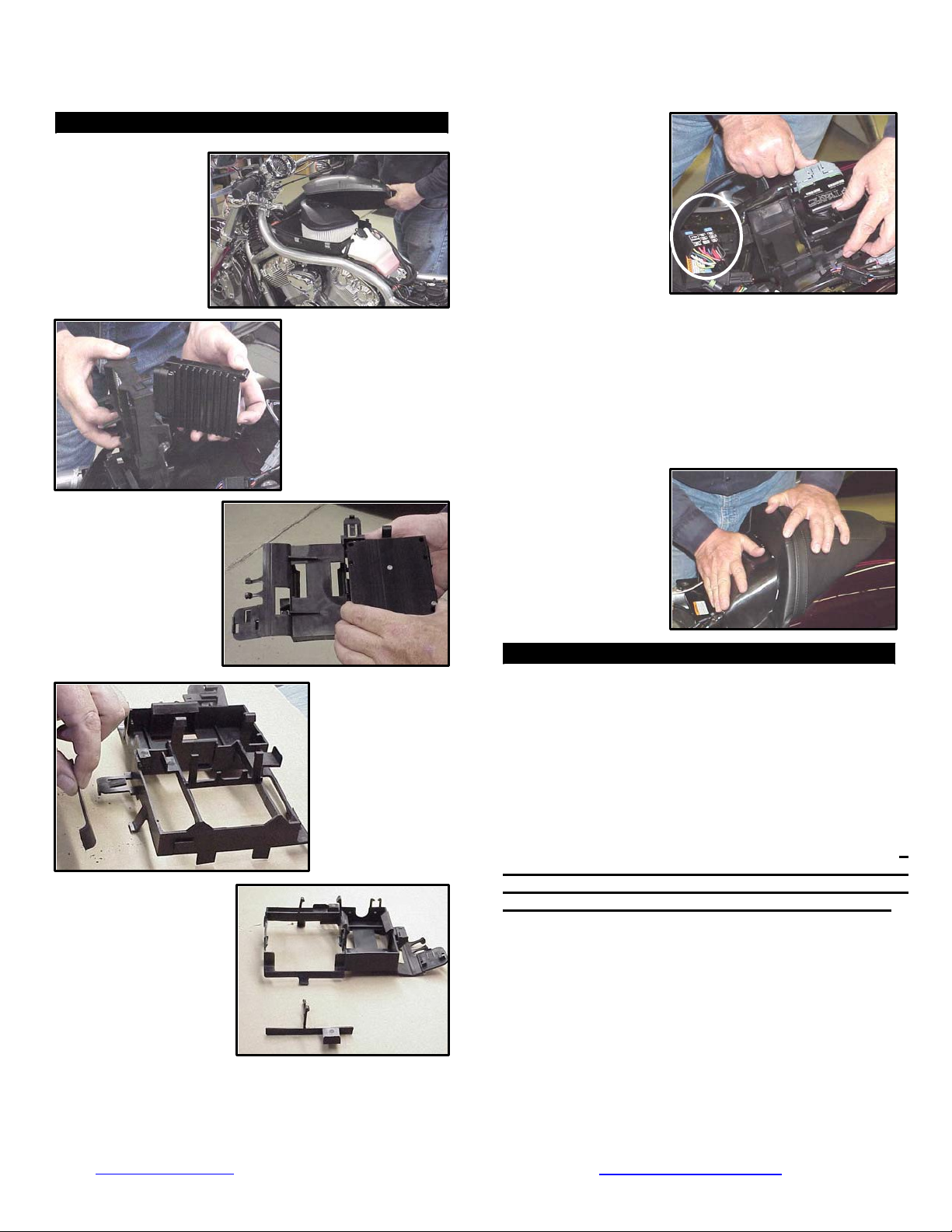

Step 2c Trial fit the

ThunderMax to the

plastic ECM caddy.

Note that some parts

of the caddy will need

to be modified for

proper fit. This is

easily accomplished

with a saw blade.

Cut the caddy in three

places as shown and

remove the ‘T’ shaped

section. Trial fit the

ThunderMax ECM into

the modified caddy; retrim as necessary. Reinstall the caddy with

the ThunderMax ECM

in place.

Locate and remove

the ECM fuse.

Unplug the ECM and

remove the ECM with

the plastic ECM

caddy (unsnap the

caddy from the

fender). Separate the

ECM from the caddy.

Remove the

“loop” from the

left side of the

caddy with a

hacksaw blade or

similar cutting

tool.

Plug the ECM main

harness into

the

ThunderMax and

reinstall

the ECM

fuse. At this point,

you have two options

for linking to

the

ThunderMax with the

supplied

communication

Option 1

cable:

- The

communication cable can be installed into the

communication

port of the ThunderMax ECM and remain

attached to the ECM and kept stored on the motorcycle

under the seat, or

Option 2 – Install t h e ThunderMax Pigtail

Communication Port Harness (included) and wire it to the

ECM harness plug on the motorcycle for an alternate port

location.

quick communication

with the ThunderMax

without removing the

passenger seat to

plug in the cable.

Reinstall the

passenger seat.

ALL

MODELS

Step 2c Install the supplied wide band oxygen sensors

into the exhaust pipes. If your exhaust system is not

equipped with oxygen sensor bungs, they must be

added to the exhaust pipes. The supplied wide band

sensors are longer than the factory sensors. Installation

of the wide band sensors into factory headpipes

equipped with bungs should present no clearance

problems, however, some aftermarket pipes may require

exhaust pipe modification or sensor bung relocation for

interference-free installation. The sen

freely without contacting surrounding components. If

this is not possible, do not attempt to bend or

modify the sensor in any way as it is a sensitive

electronic component and will be damaged if you do.

Modify the pipe if required for clearance.

are available for exhausts systems not equipped with

bungs or if current bungs present clearance issues.

Bungs should be located no more than 3-4” from the

head/pipe connection (for ideal location, refer to the

factory location on 2008-up models).

available from Zipper’s (#272-200, straight; #272-202,

angled). After installation, route the sensor harnesses

through to the left side of the bike as shown.

sors must mount

W

eld-in bungs

W

eld-in bungs are

Page 3

www.Thunder-Max.com

309-466 Installation / Setup Guide V2013.09.16

tmaxupport@thunder-max.com

3

Locate the gray 4-pin data link

port connector near the frame

neck behind the louvered side

panels (left side on ’02-’05, right

side on ’06-up models) and

remove the rubber plug from it.

Install the AutoTune

module flat side up, wires

toward rear. Slip loose wire

ties over front airbox cover

mounting tabs, pull wire ties

tight so that the AutoTune

module is mounted to the

bottom of the bracket as

shown.

Plug the oxygen sensor

harness into the AutoTune

harness plug marked

“FRONT”. Avoid routing

harnesses where engine

movement or moving parts

can contact and damage

the harnesses or connector

plugs.

Loosely loop a wire tie

through each slot in the

supplied AutoTune

module.

Route the oxygen sensor

harness from the front pipe

along the left frame

downtube, across to the

right side of the frame in

front of the cylinder head

cover, away from the

engine and along the frame

when possible.

Plug the 4-pin AutoTune

connector into the gray data

port connector. It is

through the data port that

data from the AutoTune

module is transferred to the

ThunderMax.

Route the rear oxygen

sensor harness between

the engine and fuel tank

under the seat . The

AutoTune harness for the

rear cylinder sensor is

shorter and can be easily

identified by black tracers

on all of its wires; both

plugs are clearly marked for

front/rear use.

poorly! Tie the harnesses

Route the harness along

the upper left frame rail

and

plug

the oxygen

sensor harness into the

AutoTune harness

marked

“REAR”.

It is

very important to install

these correctly

or the

engine will perform

to the frame or existing

plug

component harnesses, taking care to avoid contact with

any vibrating component that may chaff the sheathing or

wires. Some disassembly of bike components may be

required for best harness routing.

Some riders prefer to remove the airbox lid altogether for

increased airflow to the intake. If you chose to leave it

on, the “snout” must be removed due to the AutoTune

W

module mounting.

cutting tool, cut the airbox snout off the airbox lid.

Reinstall the airbox and frame louvered covers.

ith a hacksaw blade or similar

Page 4

www.Thunder-Max.com

309-466 Installation / Setup Guide V2013.09.16

tmaxupport@thunder-max.com

4

Step 3 Load a Base Map to your SmartLink software.

Selecting a base map for your ThunderMax is easy

thanks to the filtering system in the SmartLink software.

Open SmartLink on your computer. The first time the

program opens, you are asked which platform you’ll be

working in, Big Twin or V-Rod. If the program was

opened in standard Zipper’s (Big Twin) configuration,

change the configuration by selecting from the toolbar

[Configure] [Product Configuration] [TMax V-Rod].

From the toolbar choose [EFI Maps] [EFI Map List

ings

/ Definitions]. You should first update the Map

Definitions file to ensure you have the latest available

maps. Close the [Base Map Definitions] window, then

click the [Check Internet For Updates] button (requires

internet connection; follow prompts). After updating,

select [Select BaseMap].

Available base maps will be shown (if the [Show all

Maps] button at the lower left of the screen is

highlighted, click it to clear filtered maps so all maps will be

shown).

Filter the maps to locate a base map that best matches

your application by placing your curser first over any

‘Engine Type’ that matches your engine and right-click it.

All maps that do not match your selection will be filtered

from the screen.

Second, place your curser over the ‘Throttle’ column

and right click your match.

Third, right-click the ‘Exhaust’ type that closest matches

your application.

Fourth, right click the ‘Muffler’ column if further definition

of the exhaust system is required (depends on exhaust

application). Keep right-clicking the application columns

until you have located the best map match (in the case

of identical maps, choose the latest date). Highlight the

map you’ve chosen (left-click; blue bar indicates

selected map) and click [Close] button. This brings you

to the ‘Base Map Name Encoding’ page, from which you

can review the map parameters. Click the [Load

BaseMap] button to load the

From this page you can load the base map into the

software by clicking the [Load Base Map] button.

[Close] this page to view the open map page.

map into the software.

Page 5

www.Thunder-Max.com

309-466 Installation / Setup Guide V2013.09.16

tmaxupport@thunder-max.com

5

V-ROD®

2002-2003

26250

V-ROD®

2004-up

28000

Step 4 From the ‘Tuning Maps’ Tree, click the + sign

next to [Module Configuration], then double-click

‘Basic Settings’. The basic settings page opens.

Check to see if the [Speedo Cal] calibration setting

matches your year and model; if not, click the button,

enter the correct value as shown, then click [Close].

Speedometer

Calibration

Settings

Step 5 Now you are ready to ‘Link’

‘W

and

Attach the communication cable

from your computer to the

ThunderMax module, making

certain that the cable is routed away

from any part of the motorcycle that

generates heat.

Special Note for International Model Bikes with

Active Exhaust Enabled: If your bike is equipped with

a working Active Exhaust Valve, you must unplug the

active exhaust harness before linking to the module, as

the AEV circuitry conflicts with the communication

stream. You can re-connect the harness after unlinking.

If the stock exhaust has been changed, disregard this

step. ThunderMax does not support active exhaust

Step 6 To link to the module, turn the key switch to the

“Ignition” position, making certain the “RUN / OFF”

rocker switch (Kill Switch) on the handlebar controls is in

the “RUN” position. Select the “Link” Button in the

SmartLink software. The button turns green to indicate a

successful link. Answer [No] to the “Do you wish to

READ the module map now” question at this time.

rite’ the map to the ECM.

From the toolbar, click [File] [Write Module Maps and

Settings], answer OK to the message that informs you

that you are about to overwrite the current map in the

module; the transfer bar appears during the map load.

Step 7 Verify Module Settings. Before performing this

W

step, clear any active Diagnostic Code readings.

hile

linked, from the Tuning Tree select [Module

Configuration] [Diagnostic

Codes].

When the Diagnostic Codes window appears, select

[Clear Diagnostic Codes]. After completing this step,

select Basic Settings from the Module Configuration

menu and verify that the speedometer calibration is

correct. After verifying these settings, click [Write Basic

Settings]. If the installation is to be operated in closed

loop mode (with AutoTune module), select

[Configuration] from the toolbar menu and click

[Closed Loop Configuration]. Verify that the [Closed

Loop Processing] and [AutoTune] boxes are che

cked

√ on the left (module) side of the window.

IMPORTANT STEP BEFORE STARTING

Next, ‘Initialize’ the ThunderMax ECM. Initializing

synchronizes ‘home’ positions for the TPS and IAC, and

is a required step any time battery power has been

interrupted or established to the ThunderMax ECM.

With the handlebar switch in the ‘ON’ position, cycle

the key switch on and off 3 times, leaving the

ignition on for 30 seconds, then off for 30 seconds,

each cycle. DO NOT start the engine or move the

throttle during this process. After 3 on/off cycles, make

certain that the motorcycle is in neutral and start the bike

2 times, letting it settle at idle for 10 seconds; the idle

should be smooth and steady. Some engines may

require several on/off engine starts to initialize properly.

This initialization process must be performed any

time battery power is interrupted to the module (after

battery

servicing/winterization,

etc). After initialization,

shut off the engine, but stay linked for step 8.

Page 6

www.Thunder-Max.com

309-466 Installation / Setup Guide V2013.09.16

tmaxupport@thunder-max.com

6

Step 8 Before restarting the engine, from toolbar click

[Monitoring] [Show Gauges]. The “Engine Speed”,

“Engine Head Temp”, “IAC Position”, “AFR Front”, AFR

Rear” and “AFR Target” gauges are automatically

formatted and are shown on the screen. Additional

gauges can be created if desired (see SmartLink Tuning

Manual under Help menu), but the above gauges are

most helpful during initial set up. You may select any

gauges that you deem important; if too many are chosen

your screen may appear cluttered.

Step 9 Select the “Monitor” button to active the gauges.

It is located beside the “Link” button and will turn green

when the monitor gauge functions are live. The gauges

will be displayed if they were not already on the screen.

Step 10 Now select the IAC Stops vs. Engine

Temperature page from “IAC Curves” menu within the

tuning tree. Strike the

spacebar to show the actual values of the tuning block

(use left/right arrow keys to move the block marker).

Make certain that the motorcycle is in neutral and the

engine is cold, and then start the engine. Once the

engine idle is stable after 15- 20 seconds, select the

“IAC-Auto” button (Idle Air Control Auto Adjustment).

Allow the “IAC-Auto” function to run at idle until the

engine head temperature reaches 205 degrees. After

reaching temperature of 205 degrees, the “IAC-Auto”

function automatically shu

ts off. You can terminate this

function at any time, and re-run it at a later time if you

wish.

Step 11 Unlink the SmartLink software from the ECM,

turn off the ignition switch and remove the

communication cable from the ThunderMax ECM. Use

the ‘Save As’ command to create a folder and save the

map to your hard drive. The motorcycle is now ready to

be ridden. Several riding sessions that allow the engine

to reach normal operating temperature should be

completed. During this process, the IAC virtual stops will

automatically be adjusted to the IAC target values set

within the map’s basic settings. This feature

automatically ad justs how the engine comes back to the

specified idle speed. If the IAC stops are set too low, the

engine will dip below the specified idle speed during

certain transient conditions. If the IAC stops are above

the IAC position, the engine will idle above the idle rpm

specified in the i

dle speed vs. engine temperature page.

If it determined that these automatic adjustments have

not resulted in satisfactory operation of the engine,

consult the SmartLink Manual (available under the Help

section of the toolbar), Section 3 (Tuning the

ThunderMax ECM) for further adjustment procedures.

CLOSED LOOP PROCESSING

When equipped with AutoTune, your SmartLink software

will allow you to set Air/Fuel tuning parameters for your

ThunderMax and its installed base map. To set the

AutoTune Limits, go to the toolbar and click [Configure]

[Close Loop MODULE Settings].

The Closed Loop Configuration dialog page opens; the

right side shows the default MAP settings stored in the

MAP file (settings are applied to the installed base map

during the ‘Closed Loop Format’ conversion performed

by SmartLink), while the left side shows what the module

is currently set to (unadjusted, these settings will mirror

MAP’s settings).

The un-highlighted left ‘MODULE’ side of the page

allows editing of those settings within the MODULE for

tuning purposes, while unaffecting the MAP settings. To

edit module settings, click the [Link/Read (Module)]

button (left side highlights/active). You can now edit

Page 7

www.Thunder-Max.com

309-466 Installation / Setup Guide V2013.09.16

tmaxupport@thunder-max.com

7

these settings within the live module should you want to change any of the settings from the MAP default

settings.

Closed Loop Processing (Module) – Check [ON] to enable closed loop AutoTune processing. During closed loop

processing, the ThunderMax module processes feedback from the oxygen sensors to adjust the fuel volume at all

points by creating learned “offset” points from the installed ‘base map’ fuel points. The ‘static’ base map is

dynamically used by the ThunderMax module and the AutoTune’s active (closed loop) feedback system. This

system optimizes the fuel points to fit the target air/fuel ratio through ‘learned offset points’. These ‘learned

offset points’ are stored within the ThunderMax and are used i

n conjunction with the base map. The ‘base map’ fuel

points are not being adjusted by either the AutoTune or ThunderMax modules.

If AutoTune Closed Loop Processing is un-checked, fuel points will be adjusted to the last learned offset points, or if no

learning has occurred, to the original base map points. Stored offset points remain within the module; in the event that

power is interrupted for any reason, the learned offset points remain until re-learned or cleared under the [Map

Editing] toolbar menu.

Air Fuel Ratio Override (Module) – A single Target AFR setting can be applied using this command.

Clicking this box and changing this number overrides ALL ‘Air/Fuel Ratio vs. TPS’ pages at all RPM’s. To

target specific Air/Fuel Ratio RPM ranges and throttle positions, leave this box unchecked and edit the

individual ‘Air/Fuel-TPS @ RPM’ map pages located under the [Tuning Maps] tree. Individual Air/Fuel targets

are pre-set within the base map to provide a good balance between power and

econom

y. Individual cell throttle

position/rpm AFR targets can be viewed and adjusted on these pages. Use the left/right arrow keys to navigate the

individual blocks (strike the spacebar to view the values);

use the up/down arrow keys to adjust the values. Click

the [Monitor] button when linked live and a vertical bar will show the actual throttle position. See the SmartLink

manual for further tuning instructions.

Idle Air Control Override (Module) - Check [OFF]. This setting should not be checked on except for diagnosing a

particular type of supported problem or during tuning on a load cell dyno. Changing this setting will lead to starting

and idling problems.

Maximum CLP Offset (Module) – [Session (Module)] button sets the AFR maximum learning correction from the

base map’s fuel setting per session by percentage (range is 0-10%). A ‘session’ is defined as the period of time from

engine on to engine off (per cycle). [Maximum (Module)] button sets the total AFR maximum learning

correction from the base map’s fuel setting by percentage (regardless of number of sessions; range is 10-25%).

Unless your application is a considerable mismatch to the installed base map, the default settings of 5 and 20

percent are sufficient for most AFR corrections.

You should always pick the best possible map match during the selection of your base map. The theory behind

this is to reduce the range and time the closed loop system needs to learn offsets (corrections) for the target AFR. If

your map selection is a poor match to the application, the amount of learning needed will be significant. Review the

parameters of your base map vs. available base maps under ‘Base Maps Listing ’ to ensure you have the best

map match and the latest version of the map.

TIPS AND GENERAL INFORMATION

A packet of dielectric grease is included with your ThunderMax.

dielectric grease to the inside lip of the ThunderMax ECM (Photo 1) and across the clear case on the 36 pin ECM

connector (Photo 2). Spread the grease across all of the female terminal openings, making sure the grease penetrates

openings. This grease will greatly improve vital

conductivity

between the ThunderMax and the 36 pin connector.

W

hen installing the ECM, apply the provided

Page 8

www.Thunder-Max.com

309-466 Installation / Setup Guide V2013.09.16

tmaxupport@thunder-max.com

8

•

Several support features are located under the

[Help] menu; some require an internet

connection.

•

A comprehensive Tuning Manual in PDF

format is included on the CD for viewing and

printing from your desktop.

•

When the SmartLink program is opened, it

will automatically retrieve and open the last map

that was open.

•

Any time you link to your motorcycle: Read

the map that is installed in the ThunderMax

ECM by selecting [File] then [Read Module

Maps and Settings] on the SmartLink toolbar.

This will synchronize the map file loaded into the

ThunderMax ECM with the SmartLink software.

•

2003 FLT/FLHT models: H-D® used 2 different

speedometer calibrations during the extended

2003 model production. Which calibration you

may need is easily identified by checking the

part number on the back of your factory ECM.

Calibration 20480 is used if the part number

ends in -03, while 4352 is used if the ECM p/n

ends in -02. If your turn signals don’t cancel on

a 2003 model, try the alternate setting.

•

2007-up Big Twin models: There are two

settings in the [Module Configuration] [Basic

Settings] page that should to be set to the

following to enable the 6

function:

Final drive ratio [87; 84 for 06-07 Dyna®]

Gear 6 Min TPS

•

Sportster® models: The [Main Relay Loc]

must be set to “1” under the [Basic Settings]

[Module Configuration] page, or the engine will

not start.

•

Accel Fuel is be used to tune throttle

(go to [Module

•

AFR Correction vs. Engine Temperature page

Configuration]

is used to adjust cold start AFR’s. It is active yet

should be used with extreme caution. Any

changes made to this page affects all maps, at

every throttle position, every 256 RPM’s! See

SmartLink Tuning Manual for procedures.

•

AFR vs. Engine Temperature is active yet at

this time you should be discouraged from

making any changes to this page.

th

gear indicator light to

[40].

response

[Basic Settings]).

•

Air/Fuel-TPS @ RPM These pages reflect

desired targets of AFR to throttle position at

every 256 RPM. Example: if you desire a leaner

mixture for added fuel

econom

y then you can

easily make multi-tiered AFR targets at specific

throttle positions and RPM’s that will be learned

during closed loop processing.

•

During warm-up, the AFR on both cylinders will

be richer than the target AFR at normal

operating temperatures; this is a normal part of

the warm-up map. AutoTune and its targets are

inactive below 200 degrees.

•

Target air/fuel ratios can be viewed on the

Air/Fuel-TPS @ RPM pages. W hen these

pages are open, you can view the target AFR by

clicking on a dot and tapping the space bar to

view the target at a specific throttle position for

that RPM. Use arrow keys to raise/lower targets.

•

Writing new or modified maps to the module

requires the system to be re-initialized (Step 7),

and any existing learned fuel and IAC

adjustments to be cleared (Map Editing, clear).

Linking and editing an existing map within the

module does not require above steps.

•

System Updates are available through

SmartLink with an internet connection.

Software, Firmware and Map updates can be

downloaded; check

•

In-Tank Fuel Filters should be inspected as a

frequently

for updates.

part of routine maintenance. The filter is small

and one bad load of fuel can clog it. The factory

recommended

•

Save your edited maps to your hard drive

service interval is 25K miles.

using the [Save As] command. Document the

changes in [Map Notes] located under [EFI

Maps on the toolbar. These notes are stored

with the saved map; remember to edit them

when making changes for future reference.

•

Oxygen Sensor Care: Items that can damage

or shorten the life of your sensors:

Leaded fuel – Race fuel

Oil deposits from oil

consumption

problems

Excessive moisture exposure

Excessive (extreme) heat

There is no warranty on sensors. Replacement

P/N is 309-355.

Loading...

Loading...