Thor Audio TA-1000 Mk2 Brochure

|

|

|

Page 1 |

Thor Audio News |

|

|

|

||

|

|

|

||

|

|

|

|

|

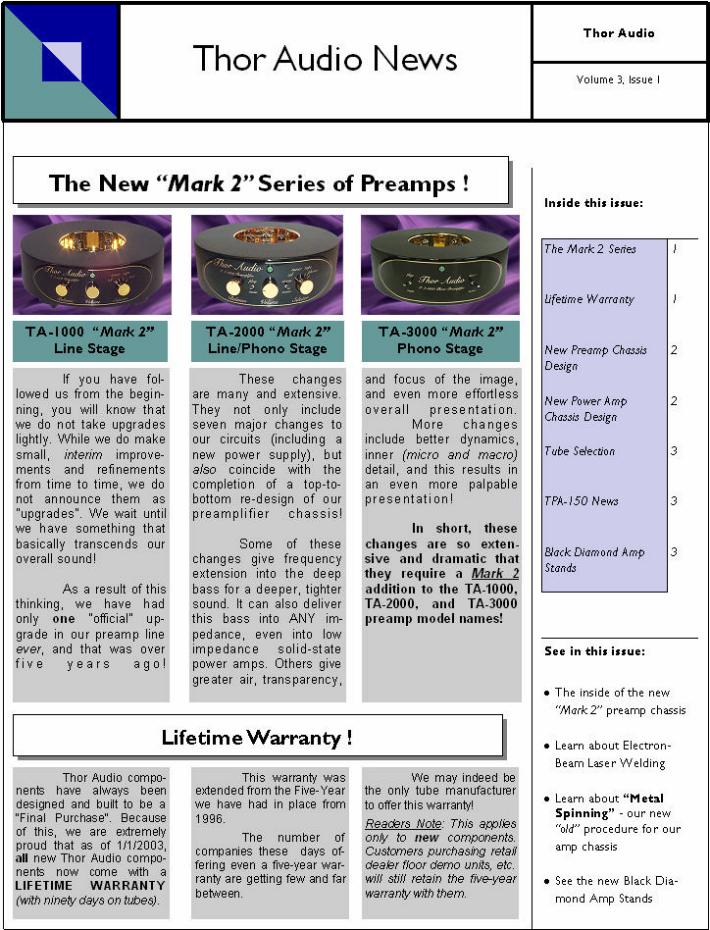

Inside view (upside down) of the bored 1" (25.4 mm) thick Top Plate

(used in our TA-1000, TA2000, & TA-3000 preamps)

Black Diamond Racing

“Pucks” & “Cones”.

New Preamp Chassis !

The new preamp chassis is basically bored from solid blocks of pristine aircraft-quality aluminum and now features a massive 1" thick top plate!

In addition, the sides of the chassis are now a full 1/2" thick. All RCA jacks in the back are recessed into oversized holes counterbored from the outside showing the true thic k- ness of the outside wall.

We will continue to use the Black Diamond

"Pucks and Cones" combination (see picture) for stability and height underneath all of our power amplifiers.

However, as a result of this re-design, the preamp chassis is so massive and rigid that it will handle any sound-robbing

(preamp level) vibrations with ease. Because it no longer needs as much mechanical clamping/damping of the bottom, we have removed the "pucks".

Note that we will continue to use the pyramid

cone feet as before.

Another added benefit is that removal of the pucks will also lower the overall height of the preamp from 5 1/2" to 4 3/4". This lower height also makes it useable with many more audio racks.

Readers Note: Some of the best news is that while these chassis are much more expensive to produce, we will not be increasing our retail prices until next year!

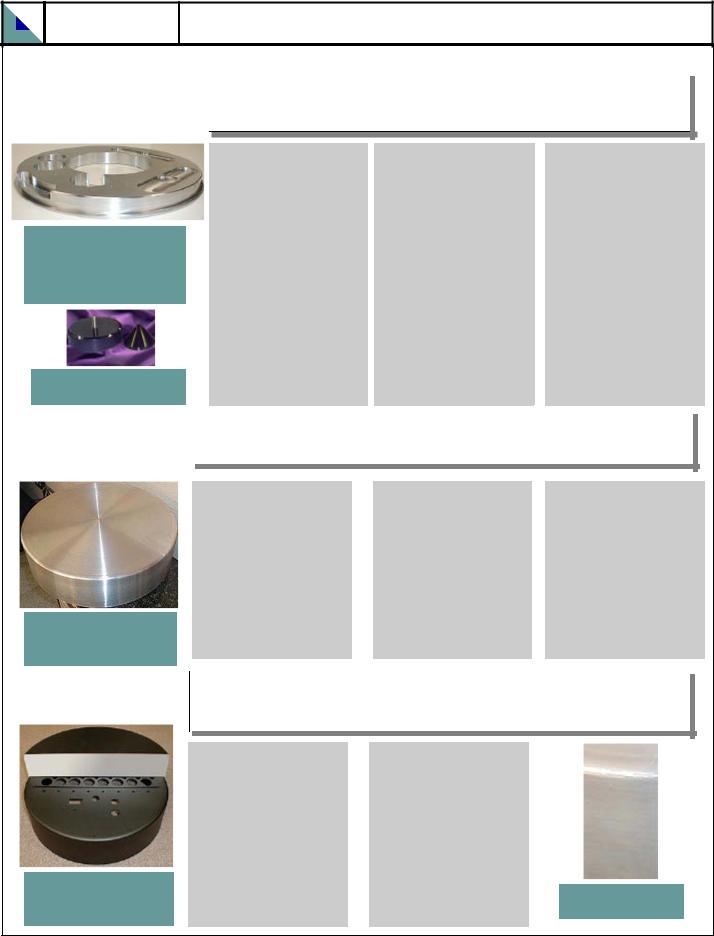

A one-piece “spun” bare metal of a TPA-150 main/ bottom chassis.

New Power Amp Chassis !

“Metal Spinning” is a procedure that dates back well over 100 years. Surprisingly, most people in the metal fabrication business these days have never even heard of it!

While others may have heard of it, there are only a couple of dozen people in the entire US that can

actually do it, and this is because it was handed down from father to son!

This procedure (soon to be seen in it’s entirety on our web site) makes a one-piece round chassis (see picture).

If you want a truly round chassis, AND have it be only one piece, this is the

only way to do it.

The chassis are so structurally strong and inert that they handle any soundrobbing vibrations with ease and gives the best look we have seen to our amp chassis. Even the TPA-30 and the TPA-60 chassis will be back-engineered to accommodate this new design!

Powder coated chassis shown with the ElectronBeam Laser-welded Top

Electron-Beam Laser-Welded Chassis !

A perfect marriage of “old and new” -

We start with a perfectly “spun” chassis. (see above picture)

Then, any welds that are necessary are done using the very latest in “Space-Age” technology— The Electron-Beam Laser

Welder.

This makes the chassis itself (and especially the electrical earth ground) totally contiguous and gives an invisible seem to the outside of the chassis.

Additionally, it is so strong that it becomes even harder than the metal itself. This is why it can be used for spacecrafts and the like.

The invisible laser-weld on the side of an amp chassis.

Loading...

Loading...