Page 1

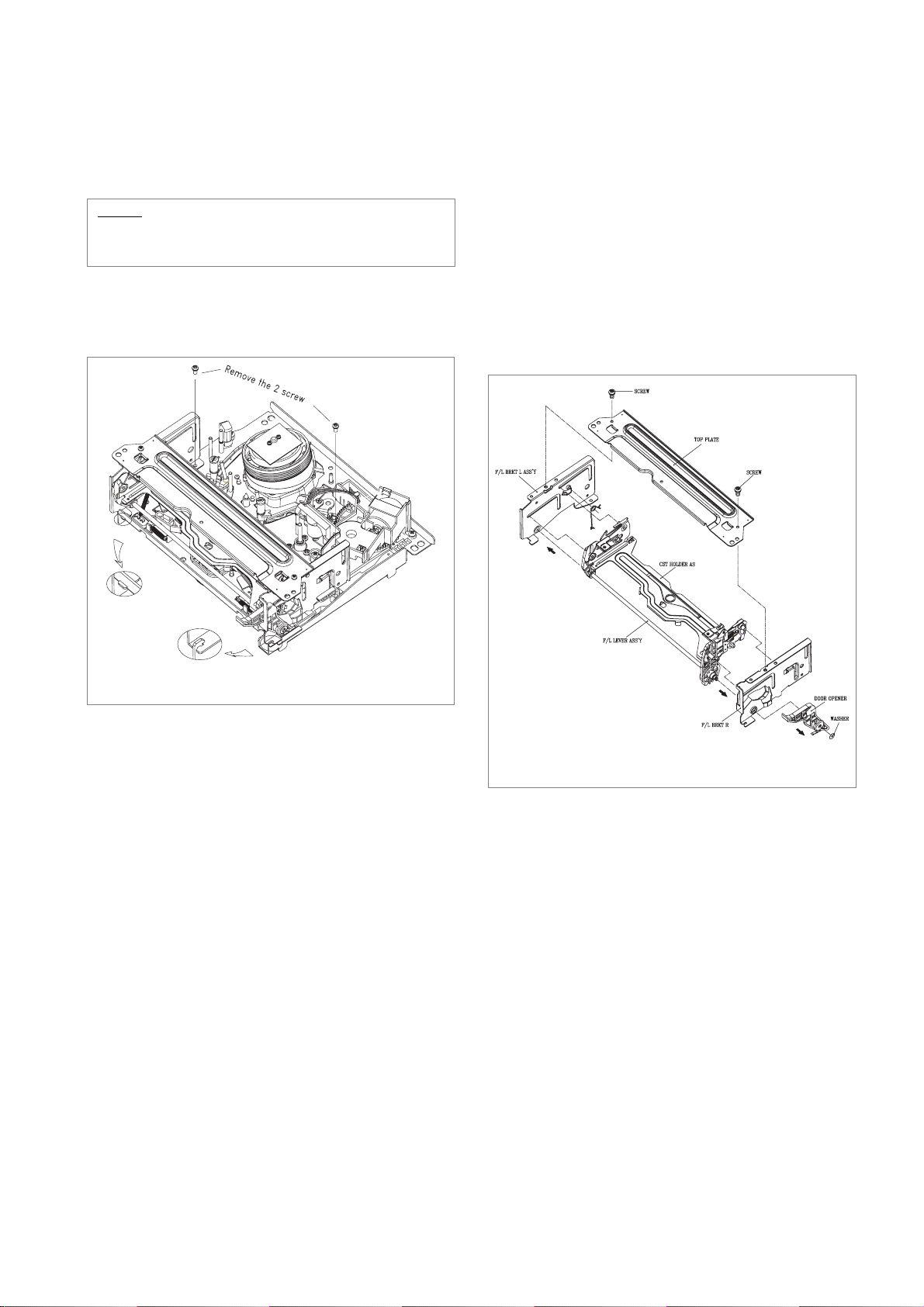

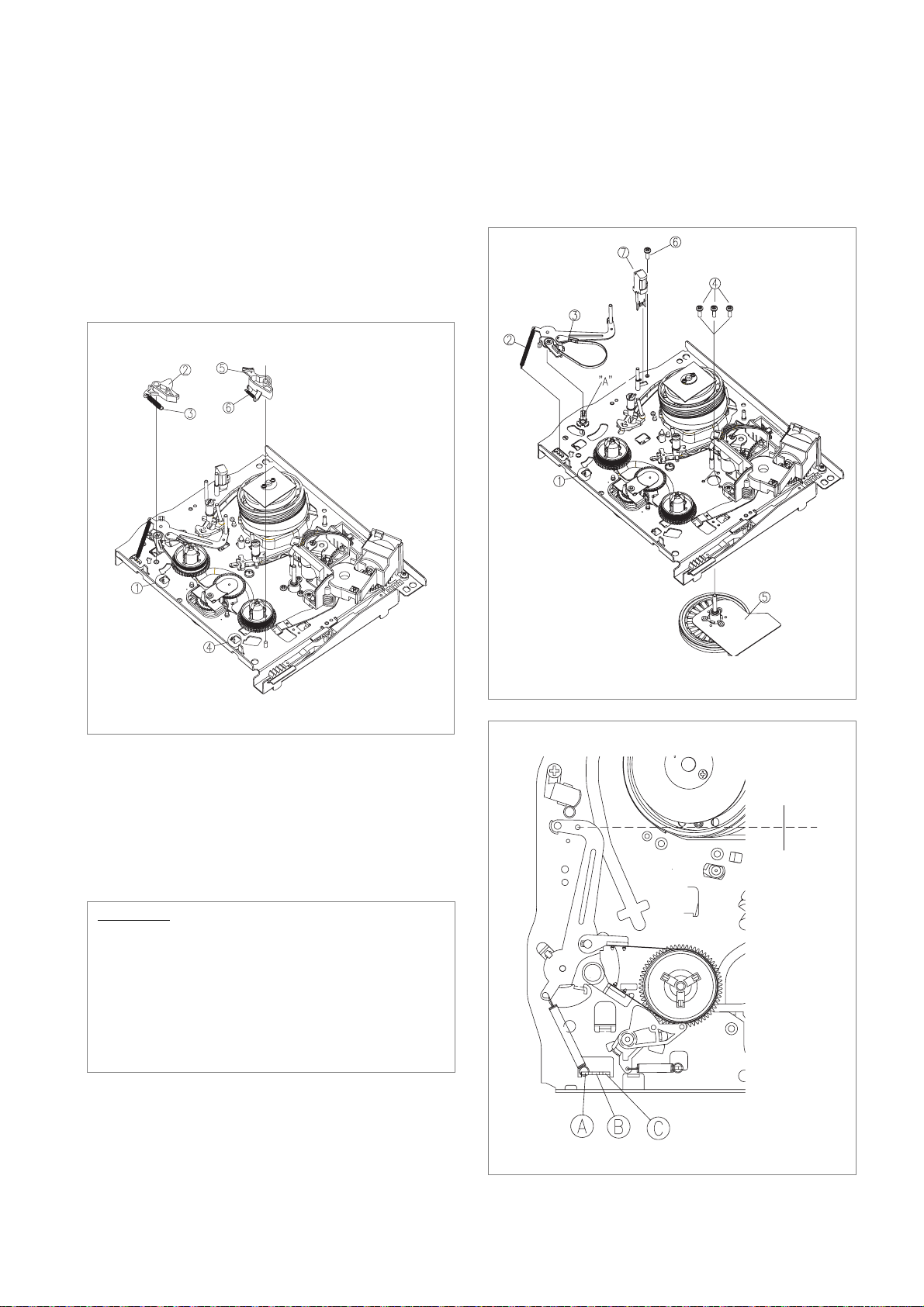

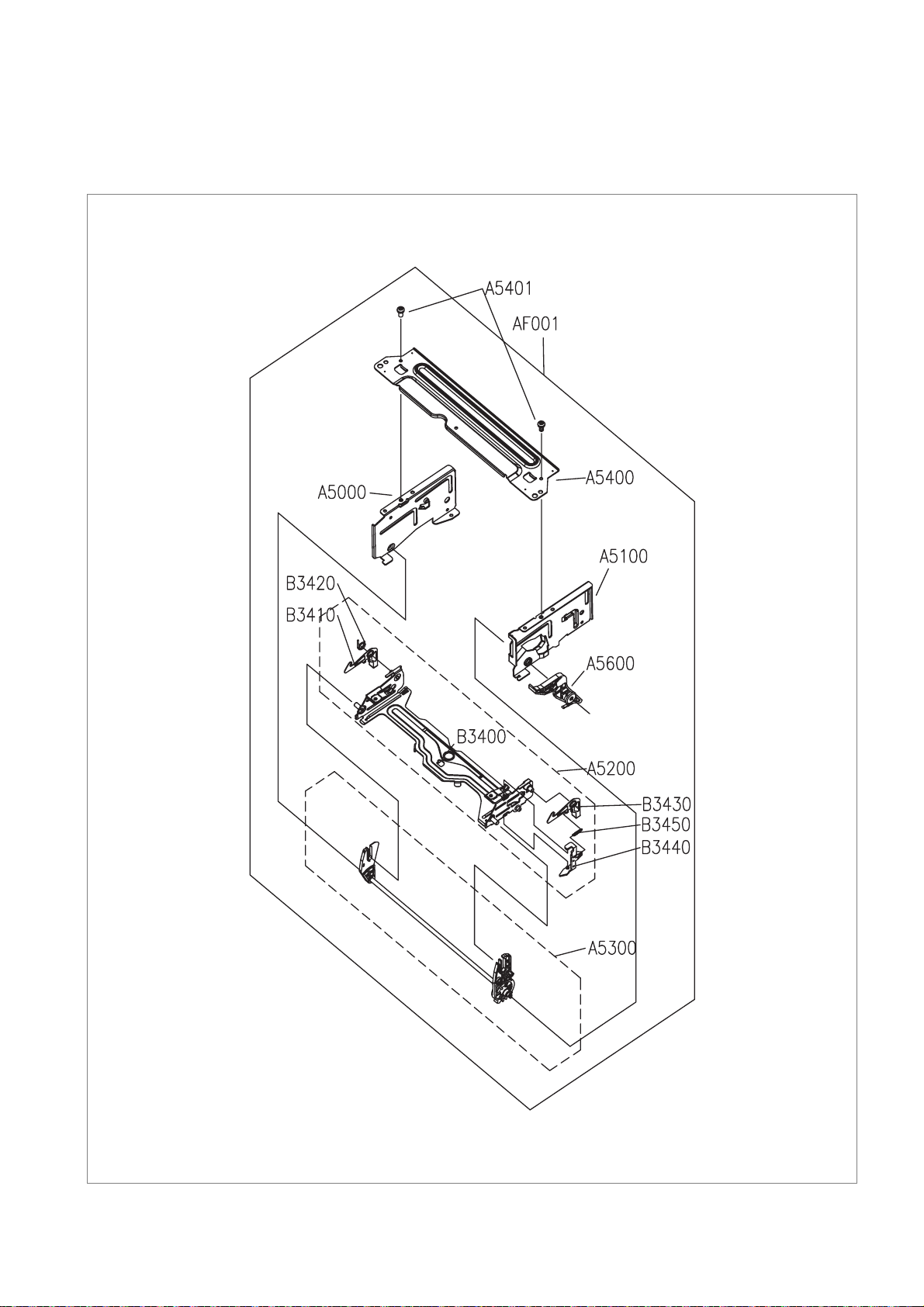

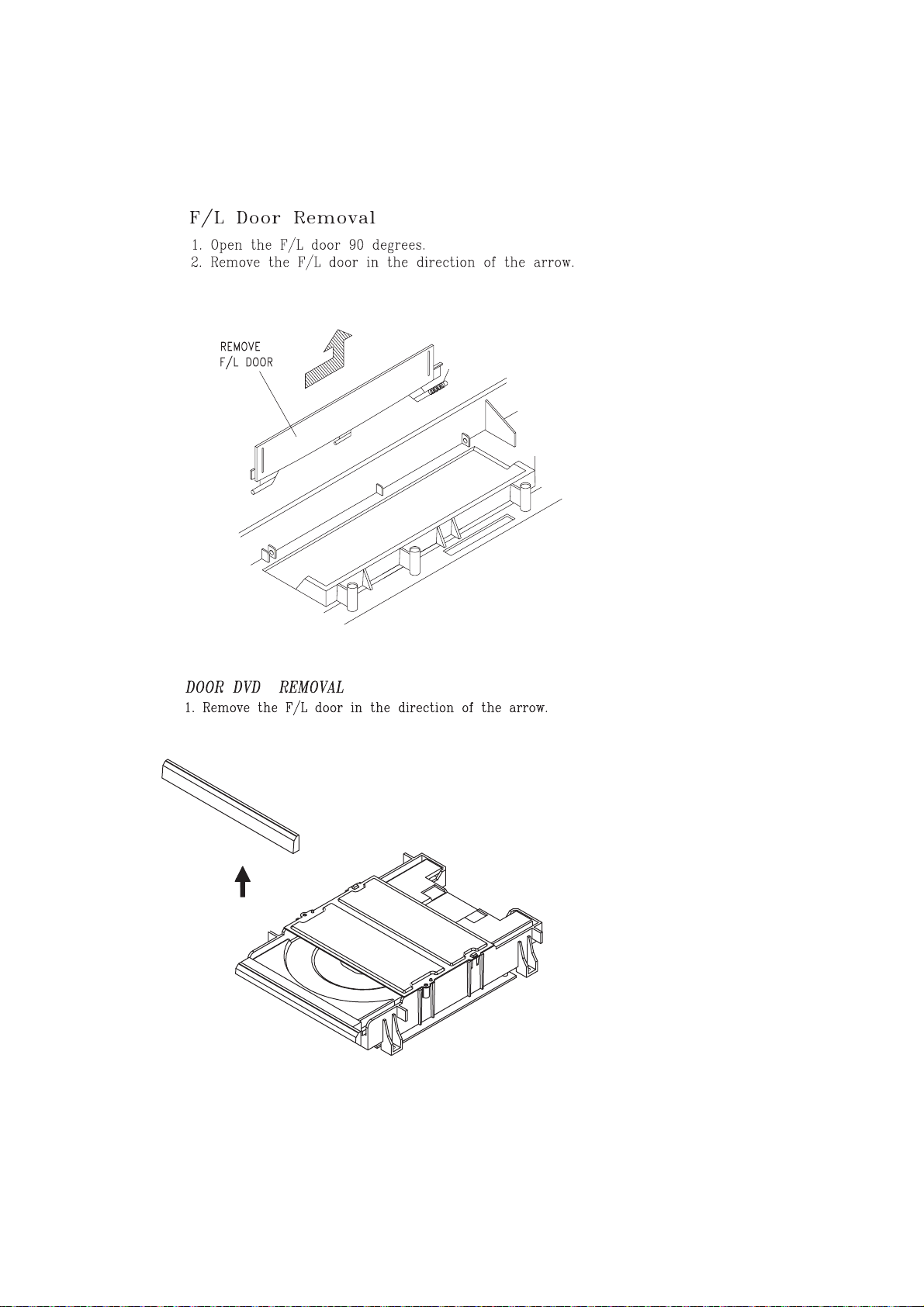

3.1 Removal of the FRONT LOADING Ass’y

(Fig. 3.1)

a. Unscrew the 2 screw holding the F/L.

b. Separate the F/L ASS`Y from the MAIN BASE settling

down point by lifting the rear part of F/L(Screw hole).

3.2 Disassembly of FRONT LOADING Ass’y

(FIg. 3.2~3.5)

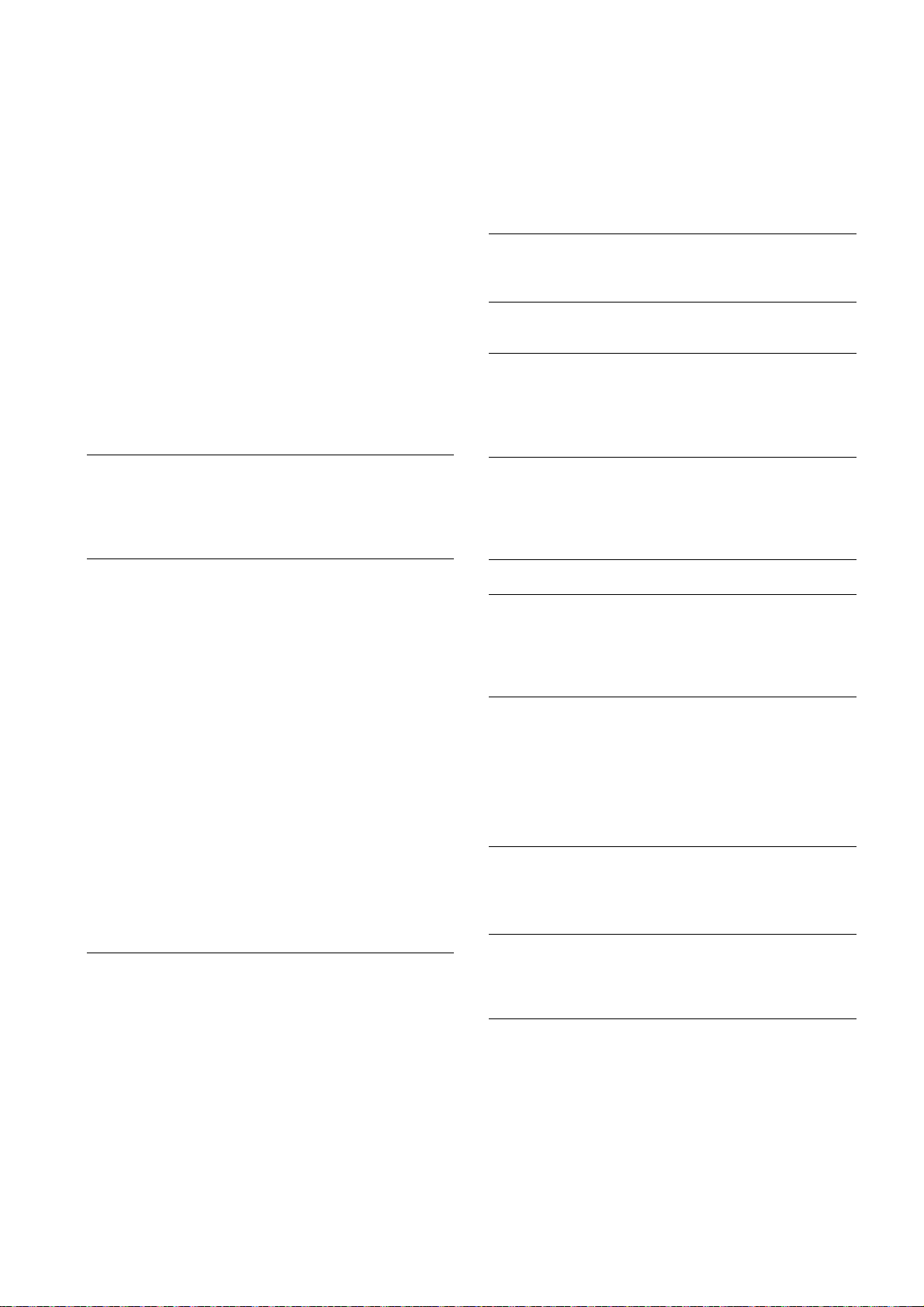

a. Remove the one WASHER for holding the door opener

and separtate F/L Assembly by moving the DOOR

OPENER in the direction of arrow.

b. Remove the 2 screw holding the TOP PLATE and sepa-

rate the CASSETT HOLDER ASS`Y by moving the

FL BRKT L and FL BRKT R in the direction of arrow

(Fig. 3.2)

3. DISASSEMBLY AND REPLACEMENT

NOTE:

REMOVE THE FRONT LOADING ASS`Y IN EJECT

MODE

Fig. 3.1 Diassembly of the FRONT LOADING ASS`Y

Fig. 3.2 Diassembly of the FRONT LOADING ASS`Y

Page 2

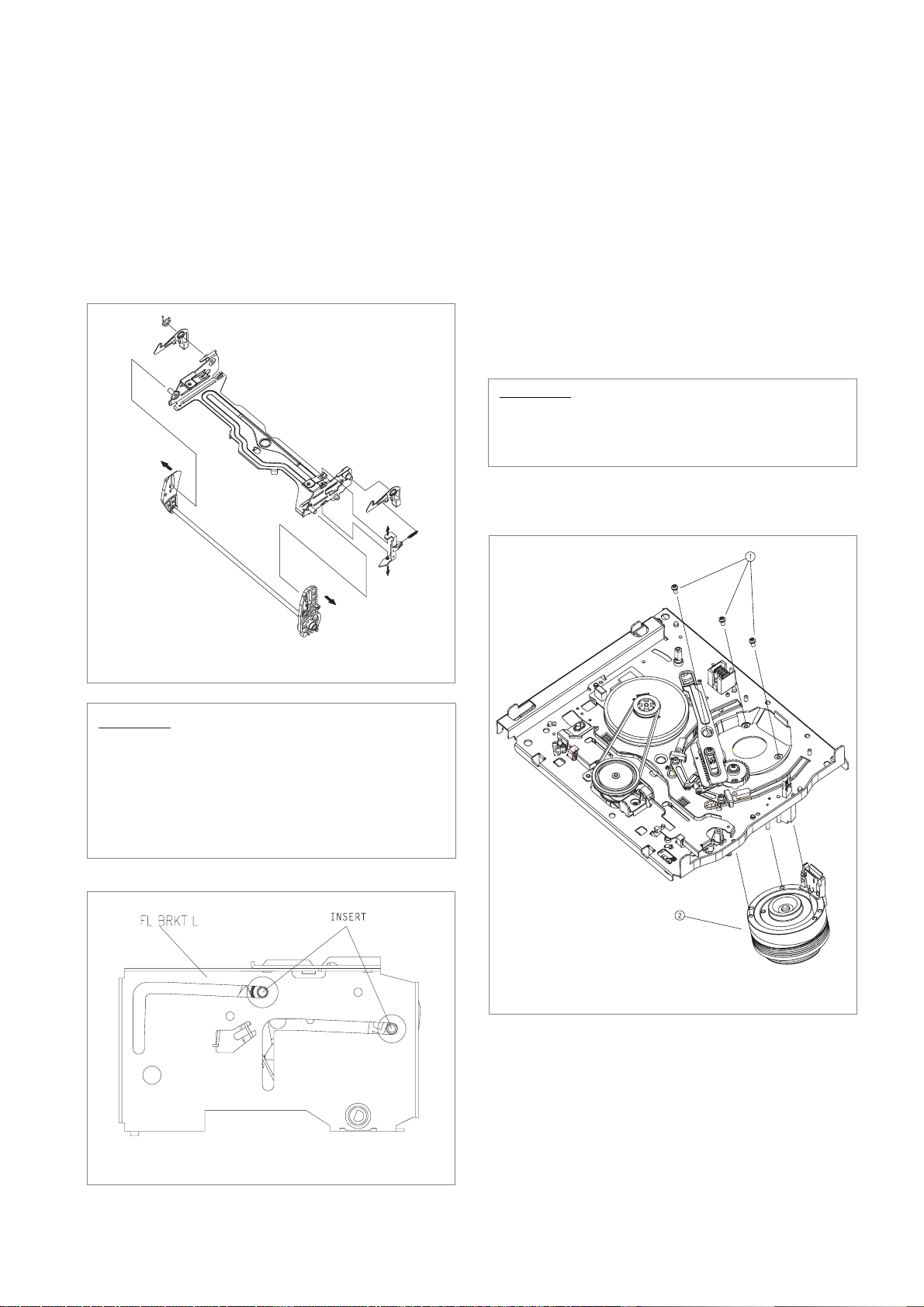

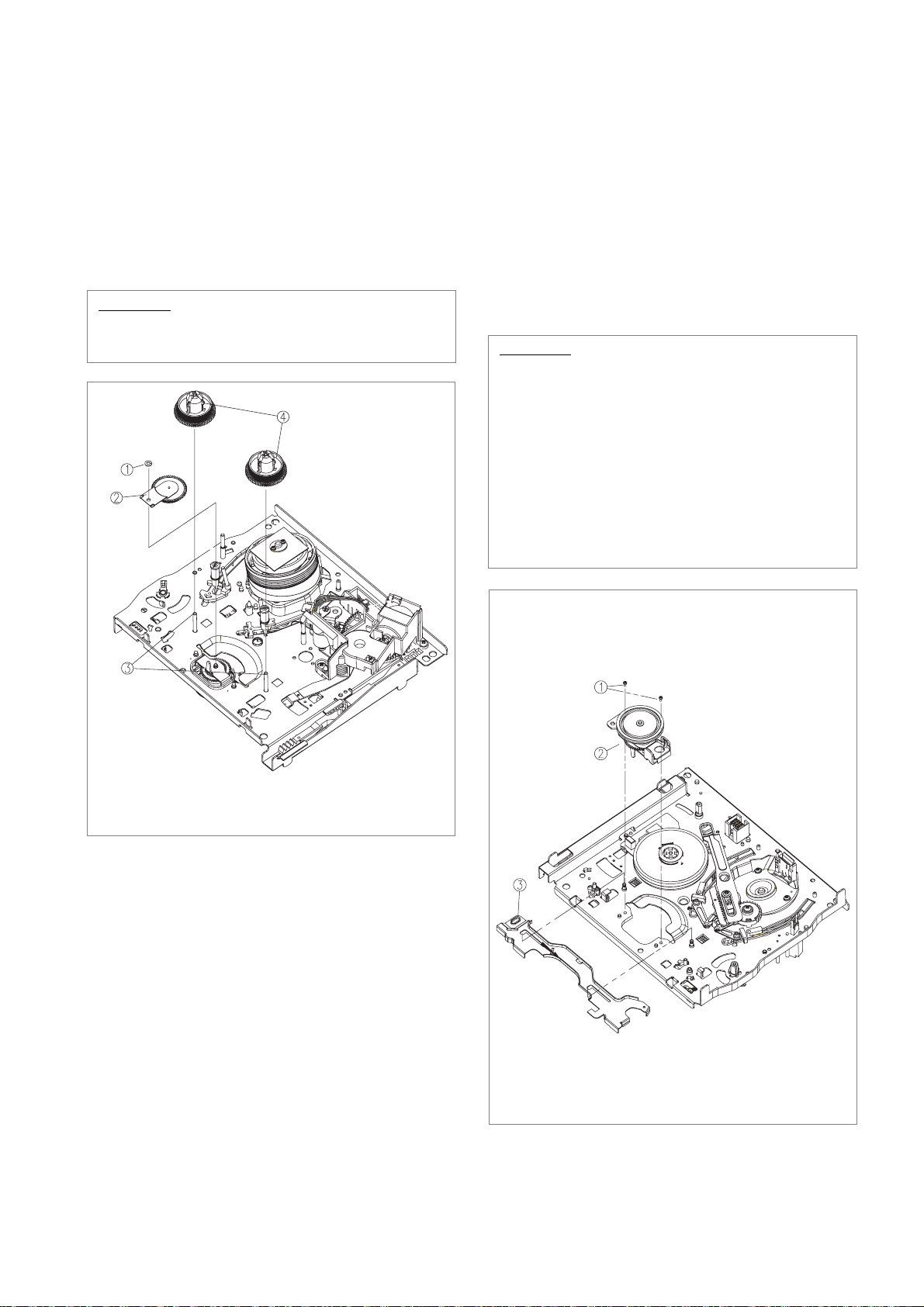

c. Separate the LOADING LEVER ASS`Y by pressing

the connection point from the CASSETTE HOLDER

ASS`Y.(Fig. 3.3)

d. Remove the SAFETY SPRING connecting the SAFETY

LEVER and CASSETTE HOLDER PLATE.(Fig. 3.3)

e. Remove the RELEASE SPRING connecting the

RELEASE LEVER and SAFETY LEVER.(Fig3.3)

3. 3 Disassembly of DRUM Ass’y (Fig. 3.5)

a. Turn over the DECK MECHANISM and holding the

DRUM TOTAL ASS`Y @ with hands , remove the 3

screw holding the drum total assembly with main base.

b. Separatet the DRUM TOTAL ASS`Y from the deck pay-

ing attention there is no damage on the surface of VIDEO

HEAD and DRUM.

c. Assembly step is the reverse way of diassembly.

DISASSEMBLY AND REPLACEMENT (CONTINUED)

CAUTION:

Assemble the FRONT LOADING ASS`Y in the reverse

step of diassembly. Confirm that two bosses on the left

side of the CASSETTE HOLDER ASS`Y are inserted in

the groove on the left side of the top plate. Insert two

bosses on the right side of the CASSETTE HOLDER

ASS`Y into the groove of the F/L BRACKET R.(Fig. 3.4)

FIg. 3.3 Disassembly of the CASSETTE HOLDER Ass’y

FIg. 3.4 Assembly of the FL Ass’y

CAUTION:

• After the assembly of the DRUM TOTAL ASS`Y,

check out if DECK mecahnism operate smoothly and

adjustment of tape transmission section is OK.

FIg. 3.5 Diassembly of DRUM ASS`Y

Page 3

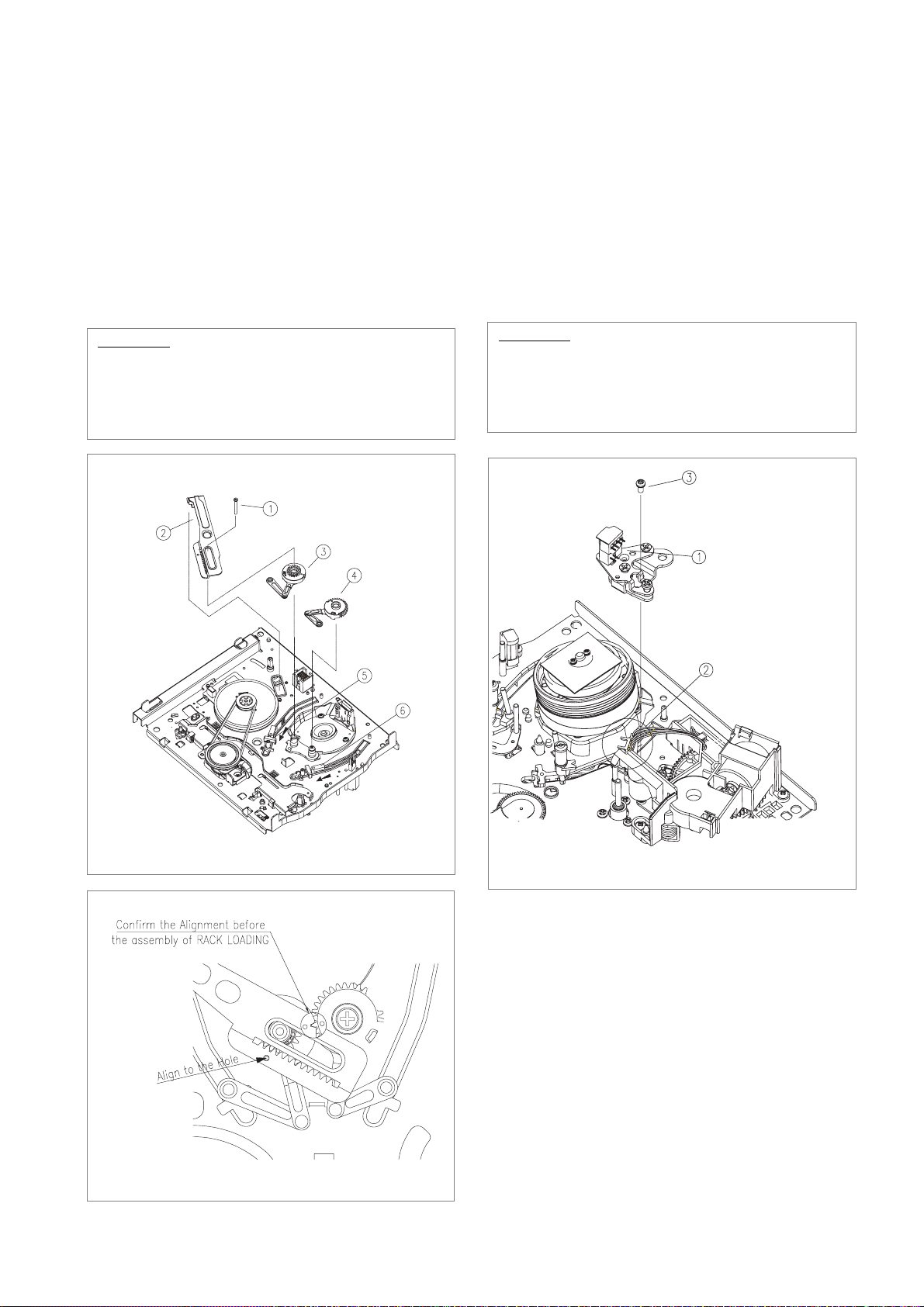

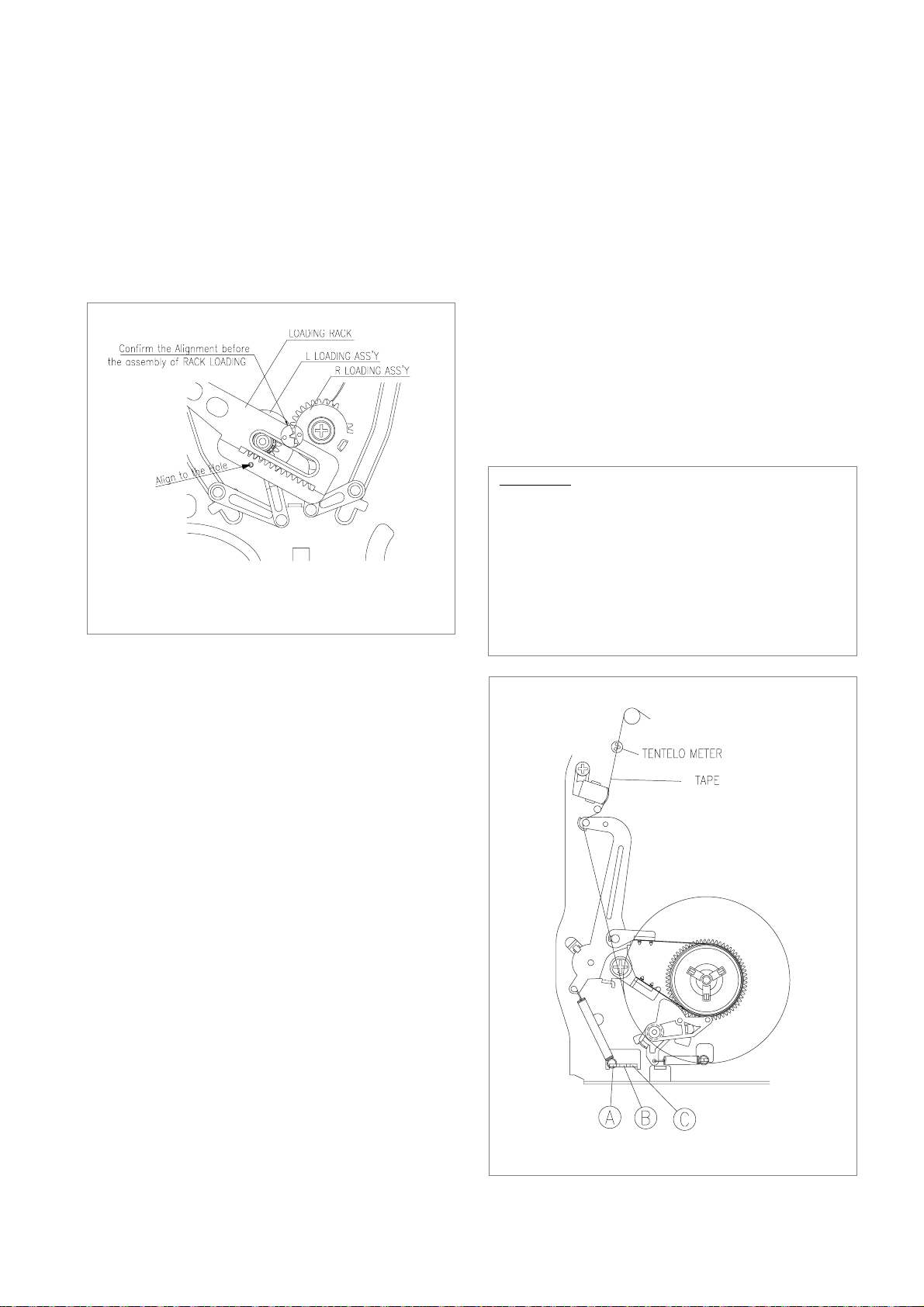

3. 4. Disassembly of LOADING RACK, LOADING

ASS’Y, S/T SLANT POLE ASS’Y (Fig. 3.6, 3.7)

a. Turn out the DECK MECHANISM and remove the

LOADING RACK @ after unscrewing the SCREW .

b. Disintegrate the R LOADING AS # and L LOADING

AS $ .

c. Disintegrate the S SLANT POLE AS % and T SLANT

POLE AS ^ by moving those part in arrow dircetion.

3. 5. Disassembly of the A/C HEAD ASS’Y (Fig. 3.8)

a. Remove the CONNECTOR @ from the AC HEAD

ASS`Y, Watch out that there is no damage in the HEAD

connecting PIN.

b. Separate the AC HEAD ASS`Y ! after unscrewing the-

screw #

DISASSEMBLY AND REPLACEMENT (CONTINUED)

CAUTION:

• Take care GUIDE ROLLER of S/T SLANT POLE AS

and SLANT POLE not to be stained with grease during

assembly.

• Refer to Fig. 3.7 in assembly.

FIg. 3.6 Disassembly of the LOADING RACK, LOADING

ASS’Y and the SLANT POLE ASS’Y

FIg. 3.7 Assembly of the L/R LOADING AS and the

LOADING RACK

CAUTION:

• After the assembly, adjust the tape transmissionsection by refering to the chapter 5.

• After the adjustment of the tape transmission section,

paint the 3 adjustment screw with locking paint.

FIg. 3.8 Disassembly of the AC HEAD ASS’Y

Page 4

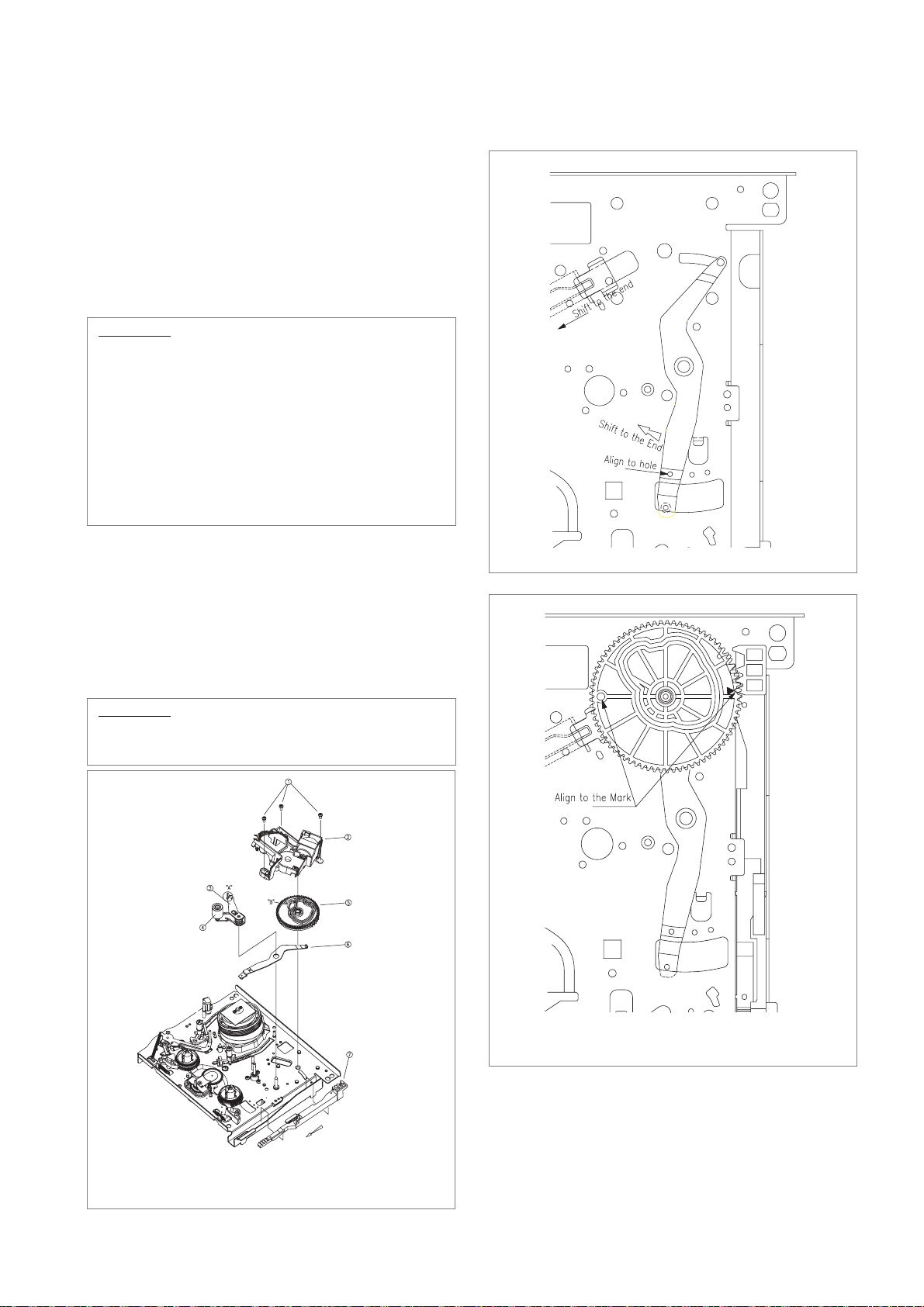

3. 6. Disassembly of the LC BRKT ASS’Y, PINCH

LEVER TOTAL ASS’Y (Fig. 3.9)

a. Separate the LC BRKT Ass’y @ after removing the 3

screws !.

b. Separate the LC BRKT Ass’y @ from the DECK

MECHANISM.

c. Disintegrate the PINCH LEVER TOTAL Ass’y #.

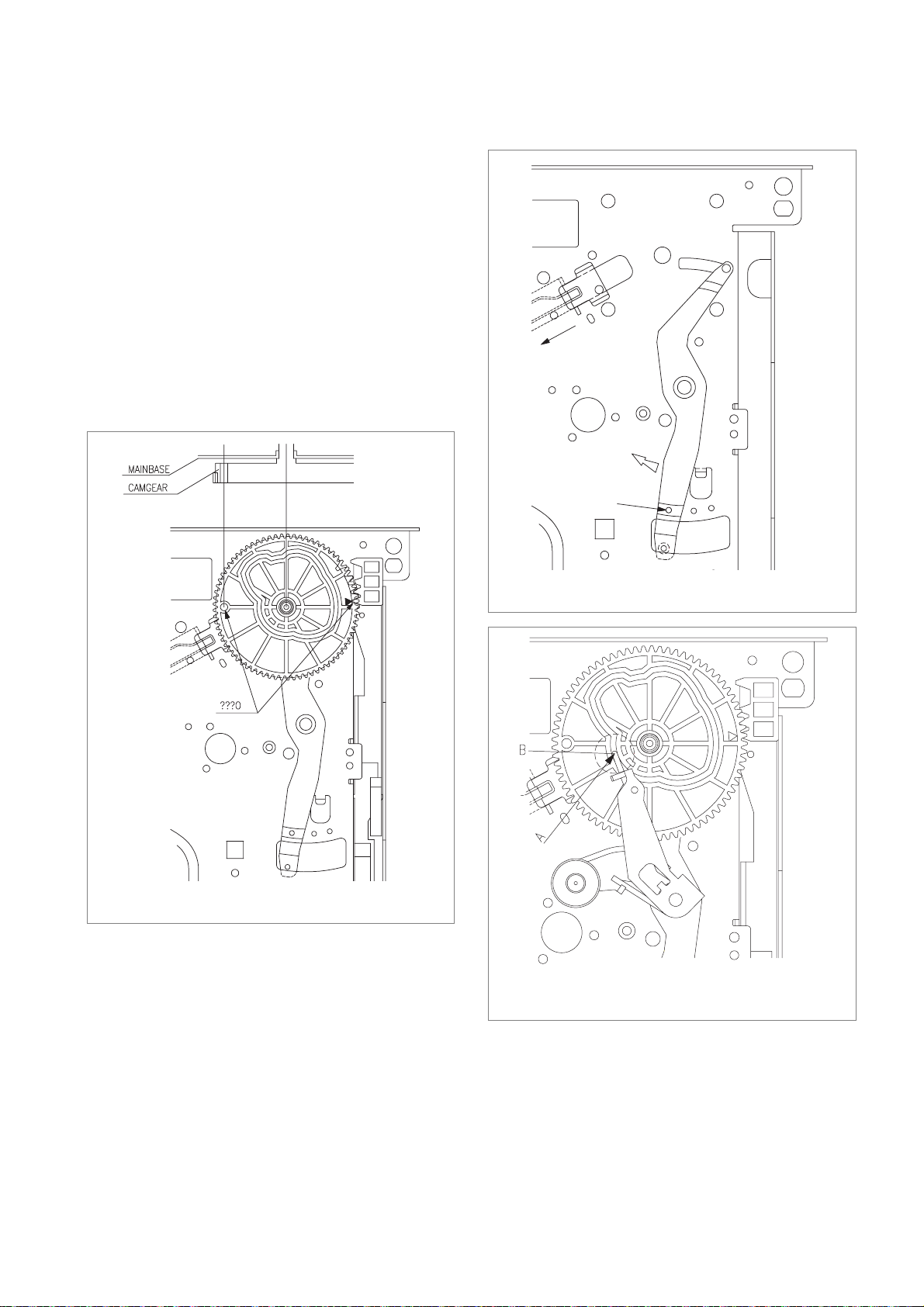

3. 7. Disassembly of the CAM GEAR, RELAY

LEVER, FL RACK (Fig. 3.9)

a. Separate the CAM GEAR % from the MAINBASE.

b. Separate the RELAY LEVER ^ from the MAINBASE.

c. Separate the FL RACK & from MAINBASE by moving

to the arrow direction.

DISASSEMBLY AND REPLACEMENT (CONTINUED)

CAUTION:

• After the assembly of the PINCH LEVER TOTAL

Ass’y, adjust the tape transmission section by refering to

the chapter 5.

• There should be no pollution on the surface of

PINCH ROLLER $ with grease or other foreign

material.

• Make sure if the end of the PINCH SPRINGPINCH

“A” is located at the end of trajectory of CAM GEAR

“B” in assembly (Refer to Fig. 4.3)

CAUTION:

• When reassembling, refer to Fig. 3.10, Fig. 3.11 and

chapter 4.

FIg. 3.9 Disassembly of the LC BRACKET ASS’Y from

the PINCH LEVER TOTAL ASS’Y

FIg. 3.10 Assembly of the CAM GEAR, RELAY LEVER

FIg. 3.11 Assembly of the CAM GEAR, FL RACK

Page 5

3. 8 Disassembly of the S/T BRAKE ASS’Y(Fig. 3.12)

a. Unhook the S BRAKE SPRING # from the MAIN-

BASE HOOK !.

b. Remove the S BRAKE Ass’y @ from the mainbase.

c. Remove the T BRAKE SPRING ^ from the MAIN-

BASE HOOK $.

d. Remove the T BRAKE Ass’y %.

3. 9 Disassembly of the TENSION BAND ASS’Y

(Fig. 3.13)

a. Unhook the TENSION SPRING @ from the MAIN-

BASE HOOK !.

b. Unhook the MAINBASE HOOK “A” and remove the

TENSION BAND Ass’y # from the mainbase.

3. 10 Disassembly of the Capstan Motor (Fig. 3.13)

a. Separate the CAPSTAN MOTOR % after the removal of

3 screws $ holding the capstan motor.

3.11 Disassembly of the FE HEAD (Fig. 3.13)

a. Remove the screw ^ and separate the FE HEAD & from

the MAINBASE.

DISASSEMBLY AND REPLACEMENT (CONTINUED)

CAUTION:

• After the assembly of TENSION BAND Ass’y on the

mainbase, adjust the TENSION POLE location as

shown in Fig. 3.14.

• Avoid getting Grease, Oil or Foreign substance on the

FELT of the BAND BRAKE.

• Take care not to deform the MAINBASE HOOK “A”

when separating the TENSION BAND Ass’y #.

FIg. 3.12 Disassembly of the S/T BRAKE ASS’Y

FIg. 3.13 Disassembly of the TENSION BAND ASS’Y,

CAPSTAN MOTOR and the FE HEAD

FIg. 3.14 Adjustment of the TENSION POLE POSITION

Page 6

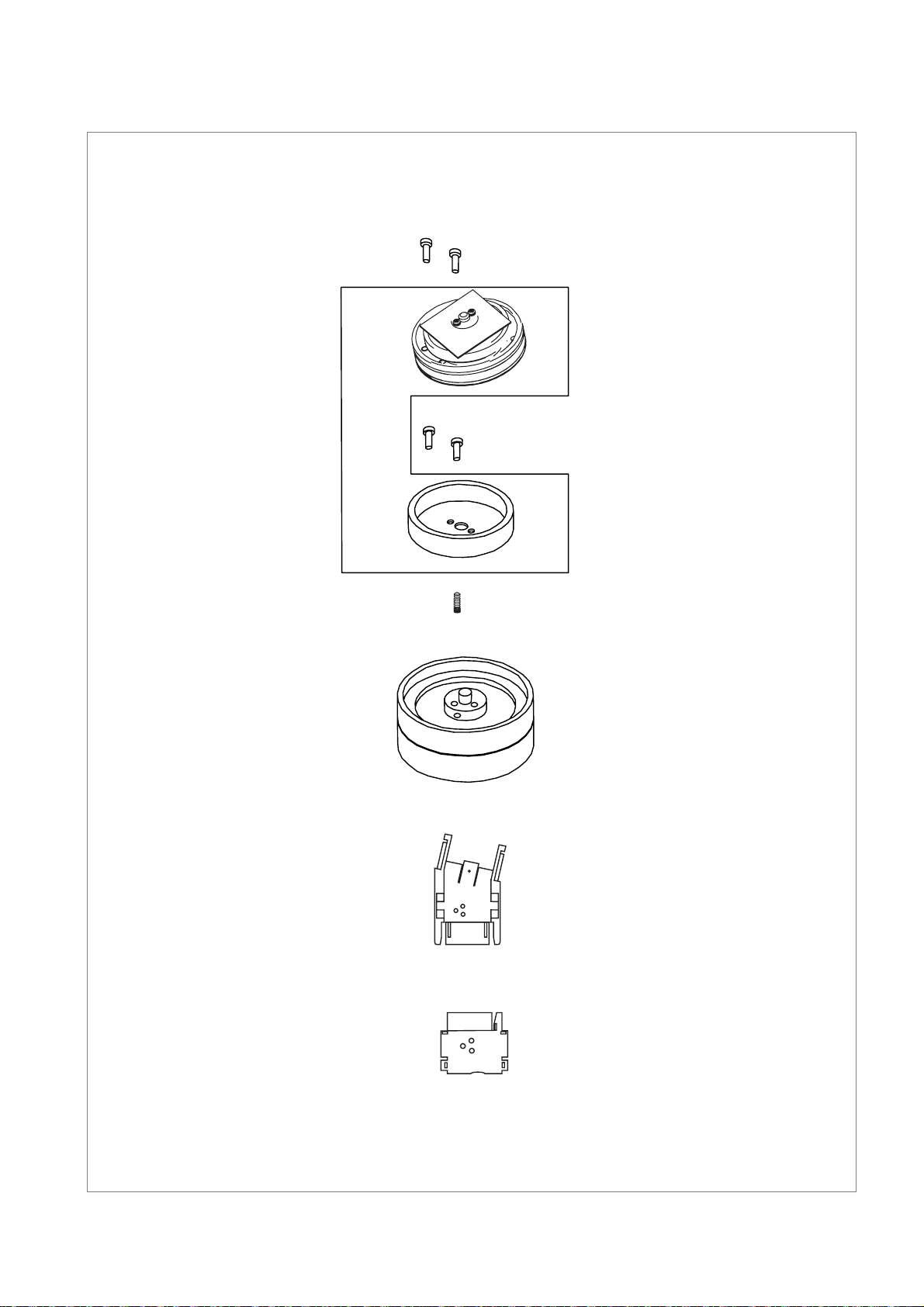

3.12 Disassembly of the REEL T ABLE, IDLER

PLA TE T OTAL ASS’Y (Fig. 3.15)

a. Remove the POLY WASHER ! and separate the

IDLER PLATE TOTAL Ass’y @ from the mainbase.

b. Remove the REEL TABLE $ from the REEL TABLE

POST # of the MAINBASE.

3.13 Disassembly of the REEL BRKT TOTAL

ASS’Y, CONNECT PLATE (Fig. 3.16)

a. Turn over the DECK MECHANISM and remove 2

screws !.

b. Remove the REEL BRKT TOTAL Ass’y @ from the

MAINBASE.

c. Separate the CONNECT PLATE # from the MAIN-

BASE by pushing to the direction of the arrow.

DISASSEMBLY AND REPLACEMENT (CONTINUED)

CAUTION:

• Take care not to deform the IDLER PLATE TOTAL

Ass’y @ when assembling and disassembling.

CAUTION:

• In diassembly of the REEL BRKT TOTAL ASS`Y,

take care REEL BELT and REEL FELT not to be

stained with GREASE, OIL, or foreign substance.

• diassembly of the IDLER ASS`Y should be precede

the diassembly of the REEL BRKT TOTAL ASSY.

• Check the operation of the REEL BRKT TOTAL

ASSY before assembly.

• Check the operation of FF/REW, PLAY, CUE, and

REVIEW work well and existence of noise during

the mode operation..

FIg. 3.15 Disassembly of the REEL TABLE and the IDLER

PLATE TOTAL ASS’Y

FIg. 3.16 Disassembly of the REEL BRKT TOTAL ASS’Y

and the CONNECT PLATE

Page 7

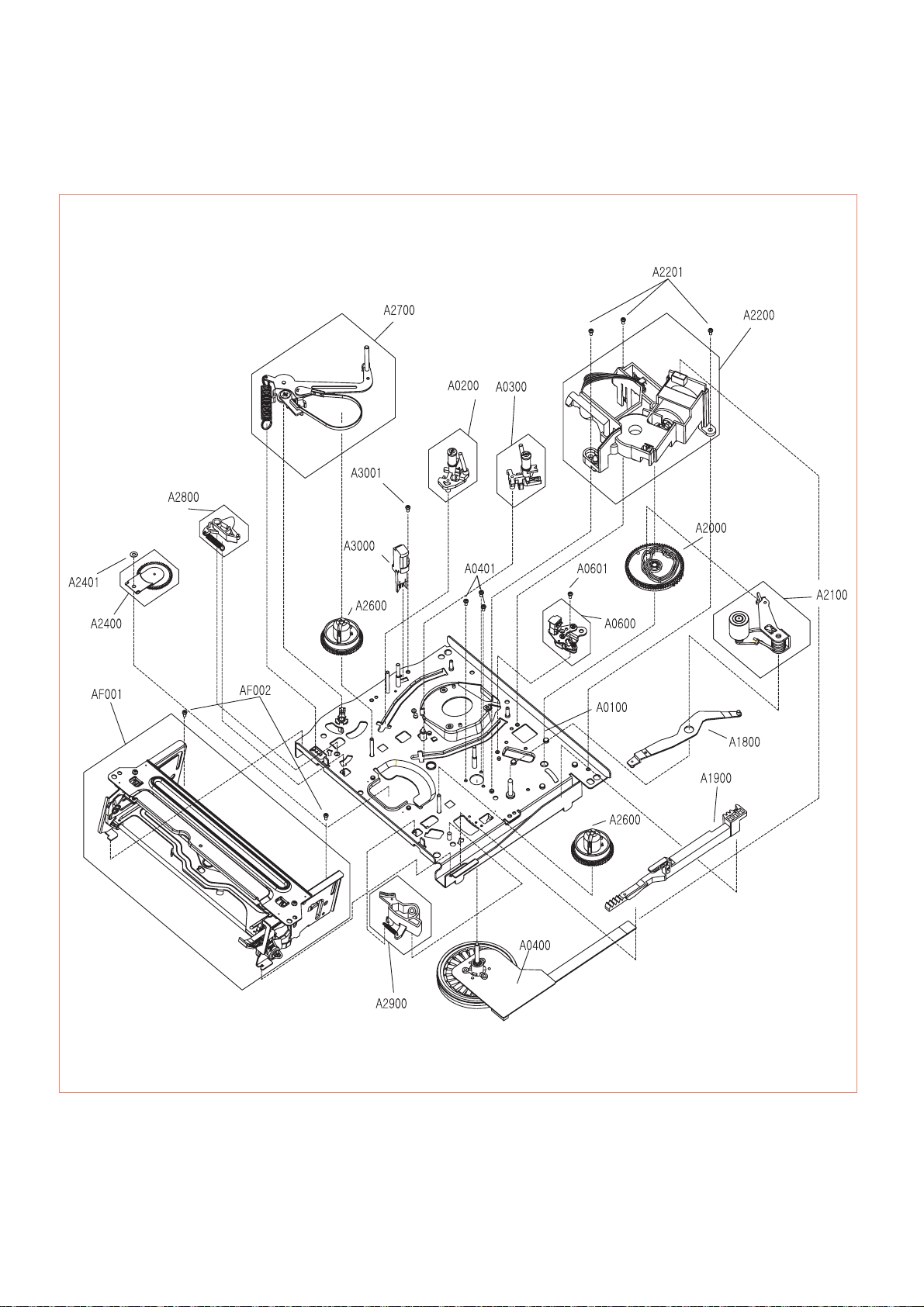

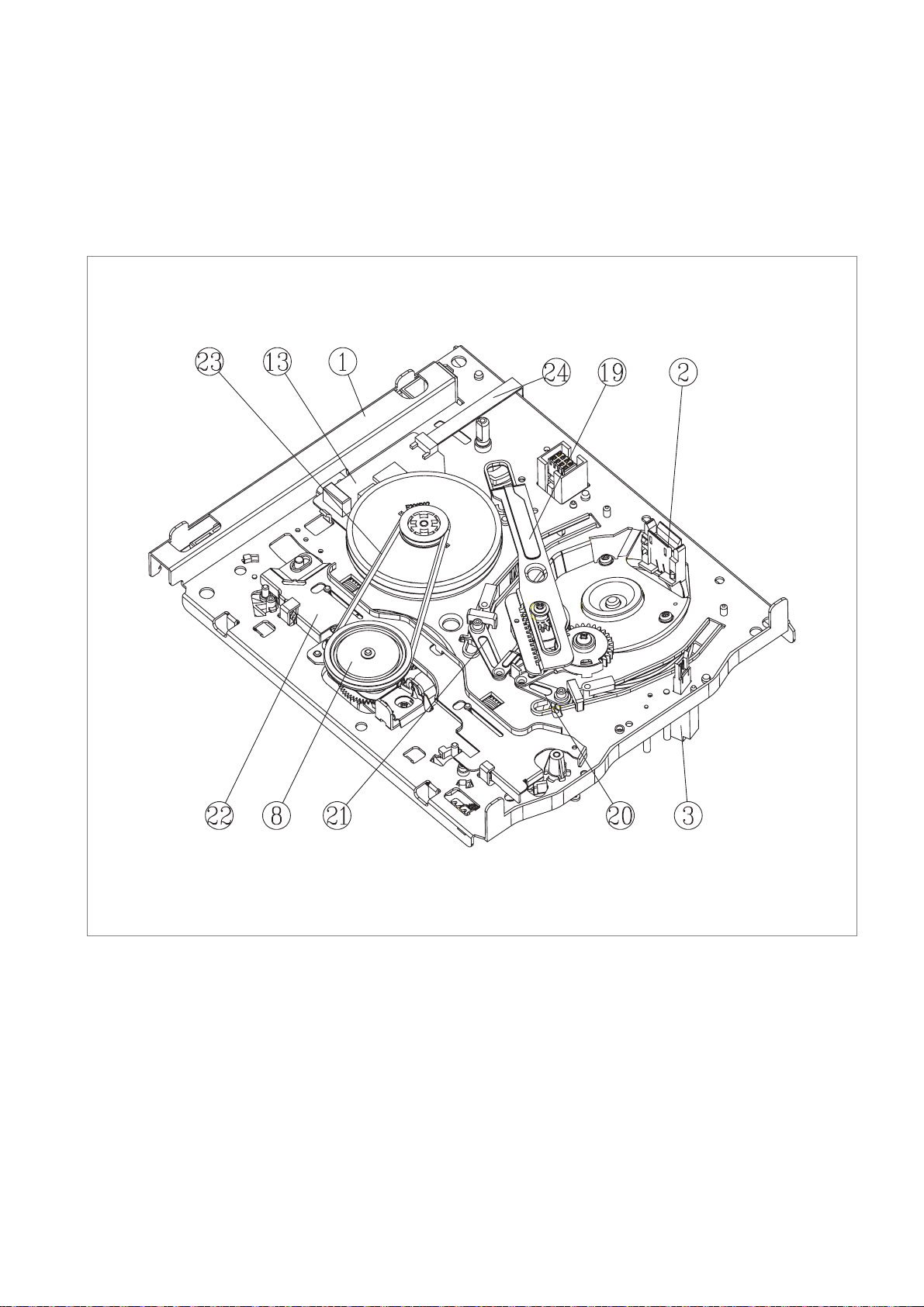

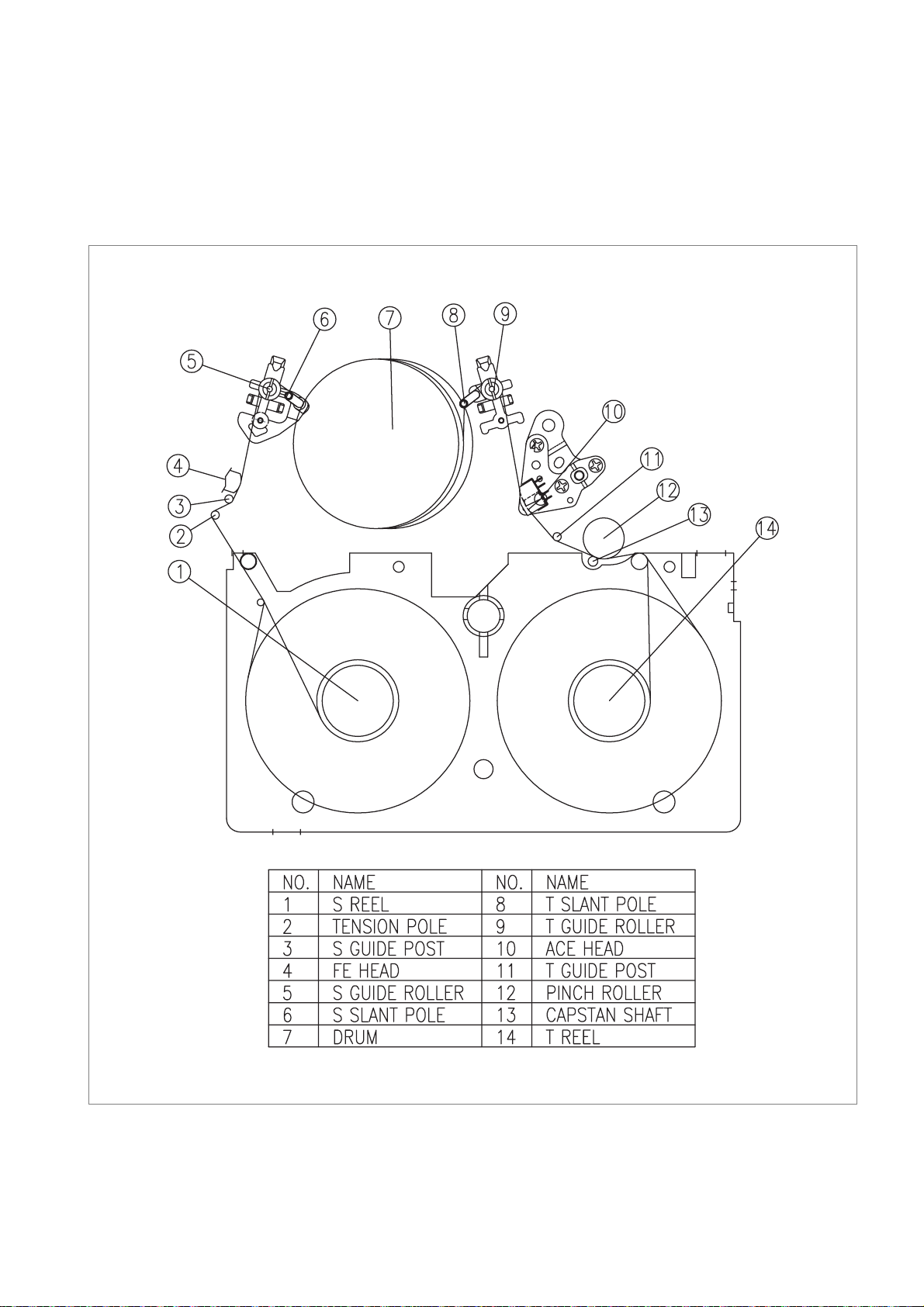

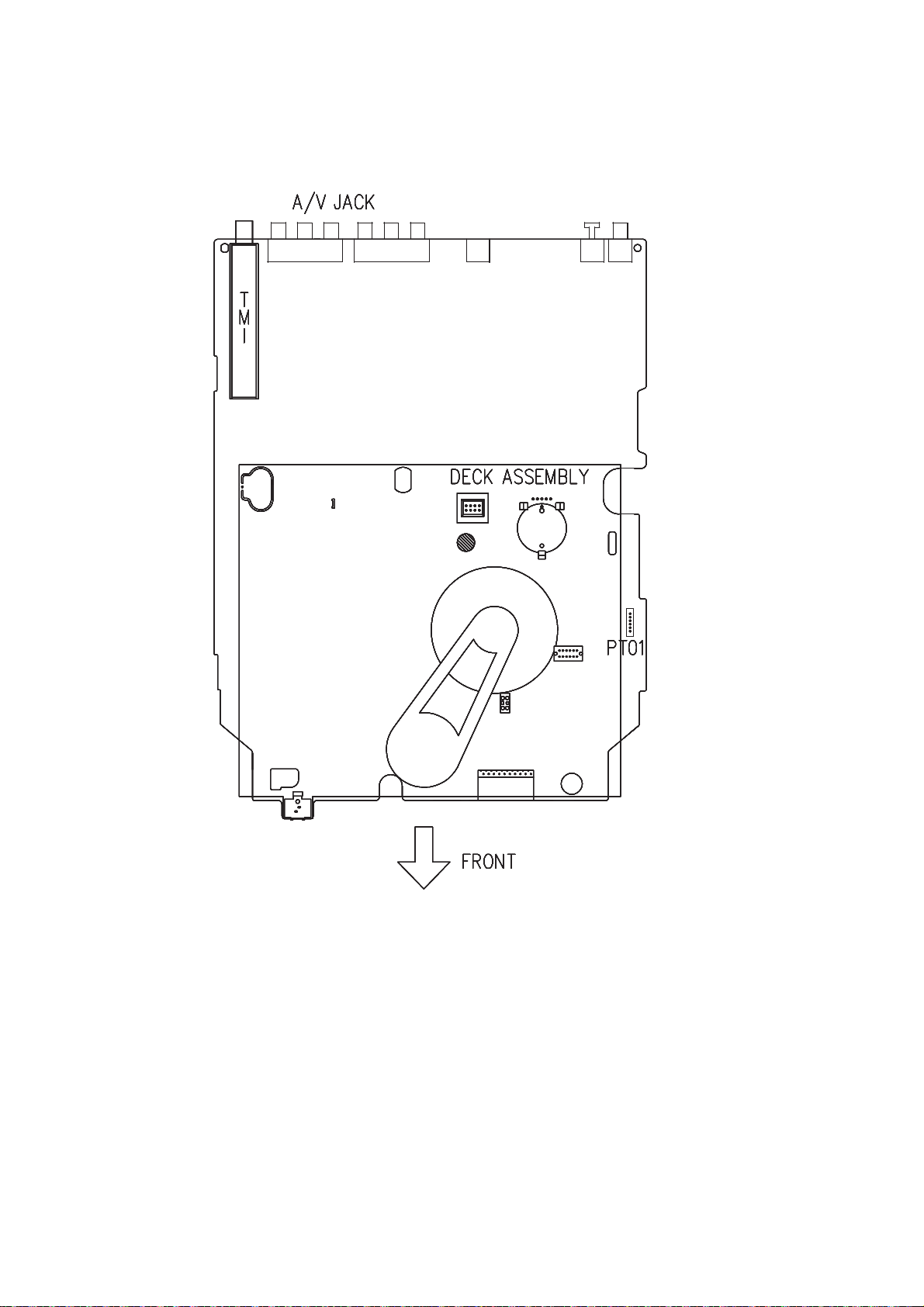

6.1 Exploded view of DECK Ass’y ( Top View)

6. EXPLODED VIEW

Page 8

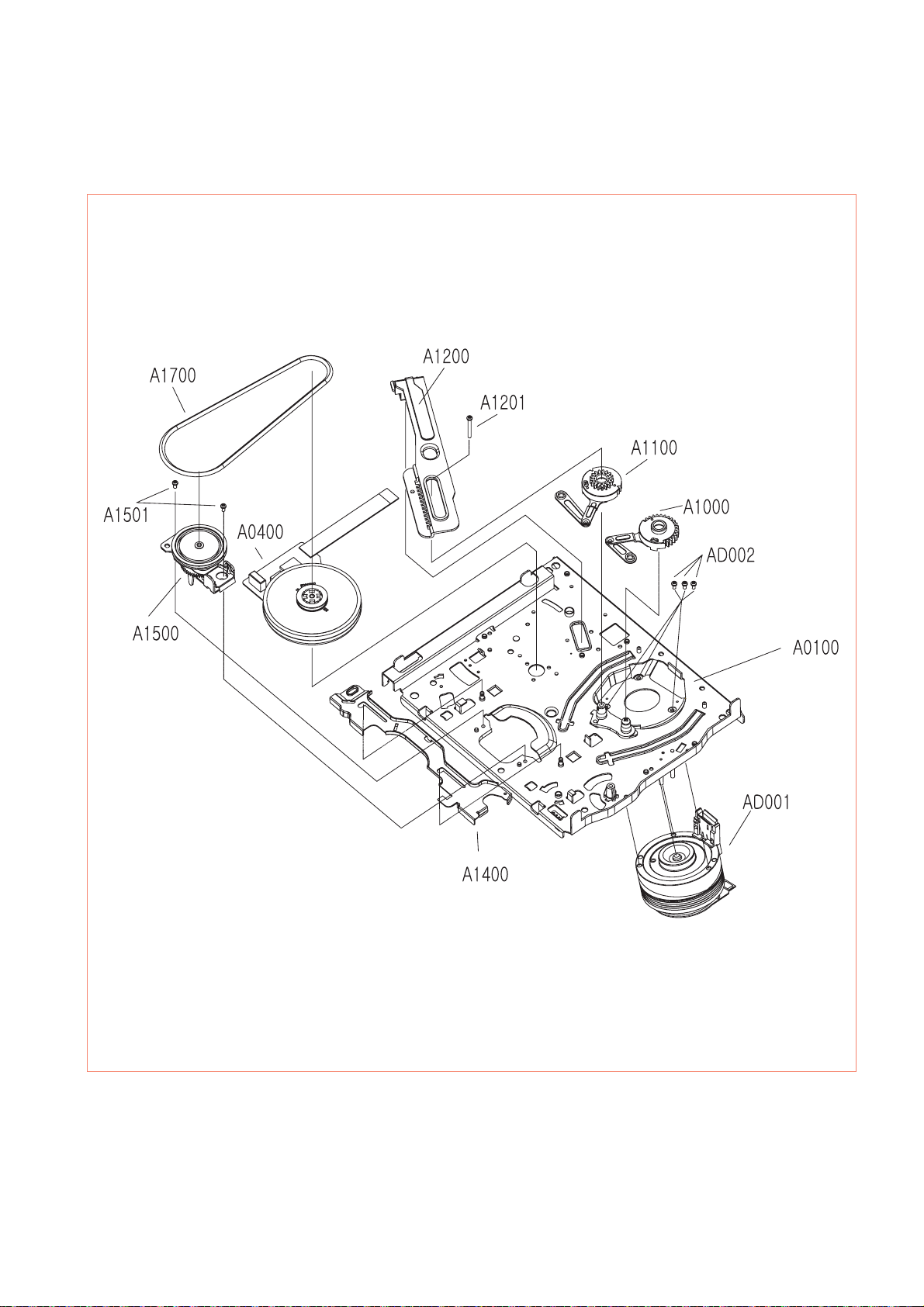

6. 2 Exploded view of DECK Ass’y ( Bottom View)

EXPLODED VIEW (CONTINUED)

Page 9

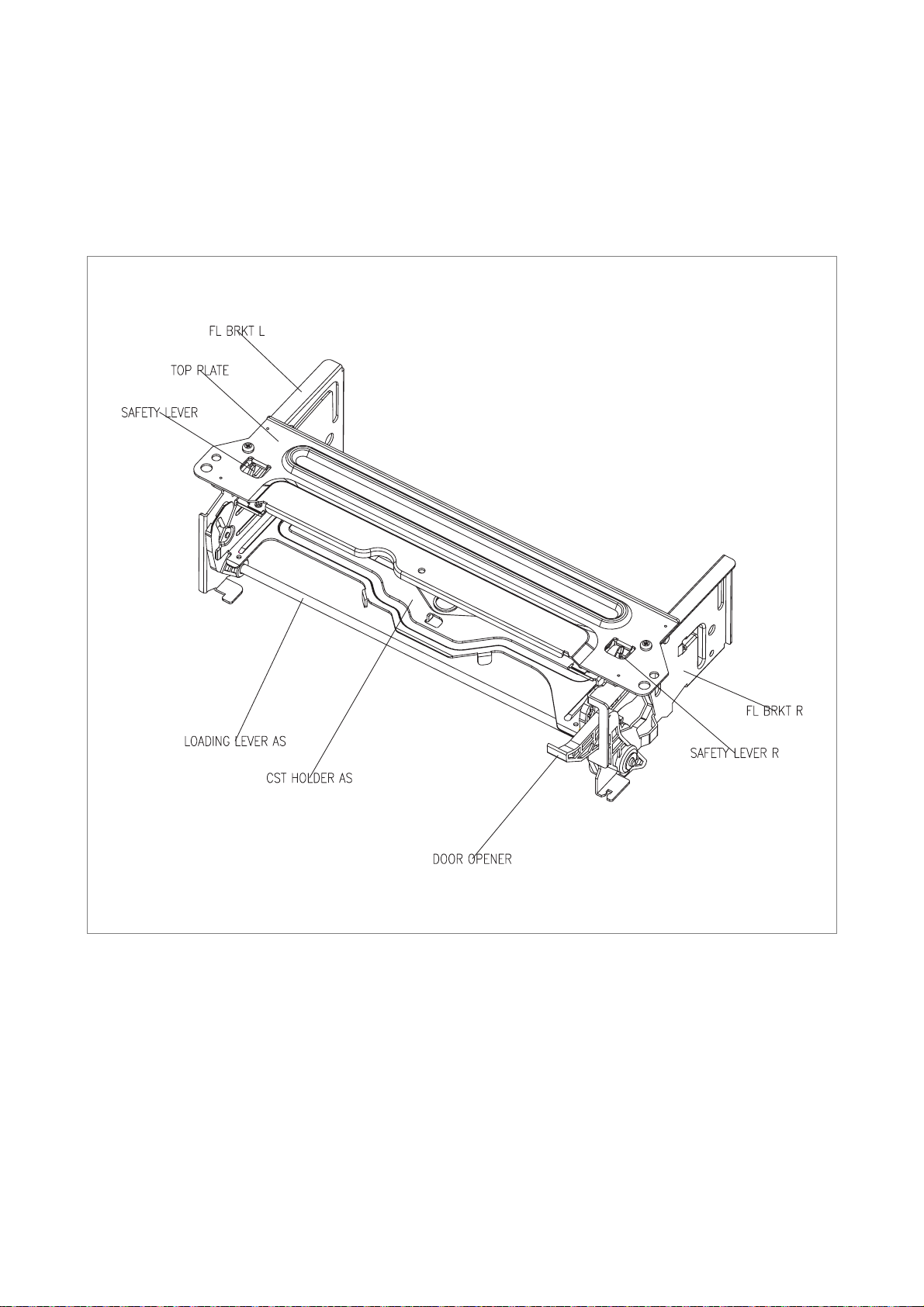

6.3 Exploded view of FL Ass’y

EXPLODED VIEW (CONTINUED)

Page 10

D0040

D0040

D0020

D0050

D0010

D0060

D0070

Page 11

Page 12

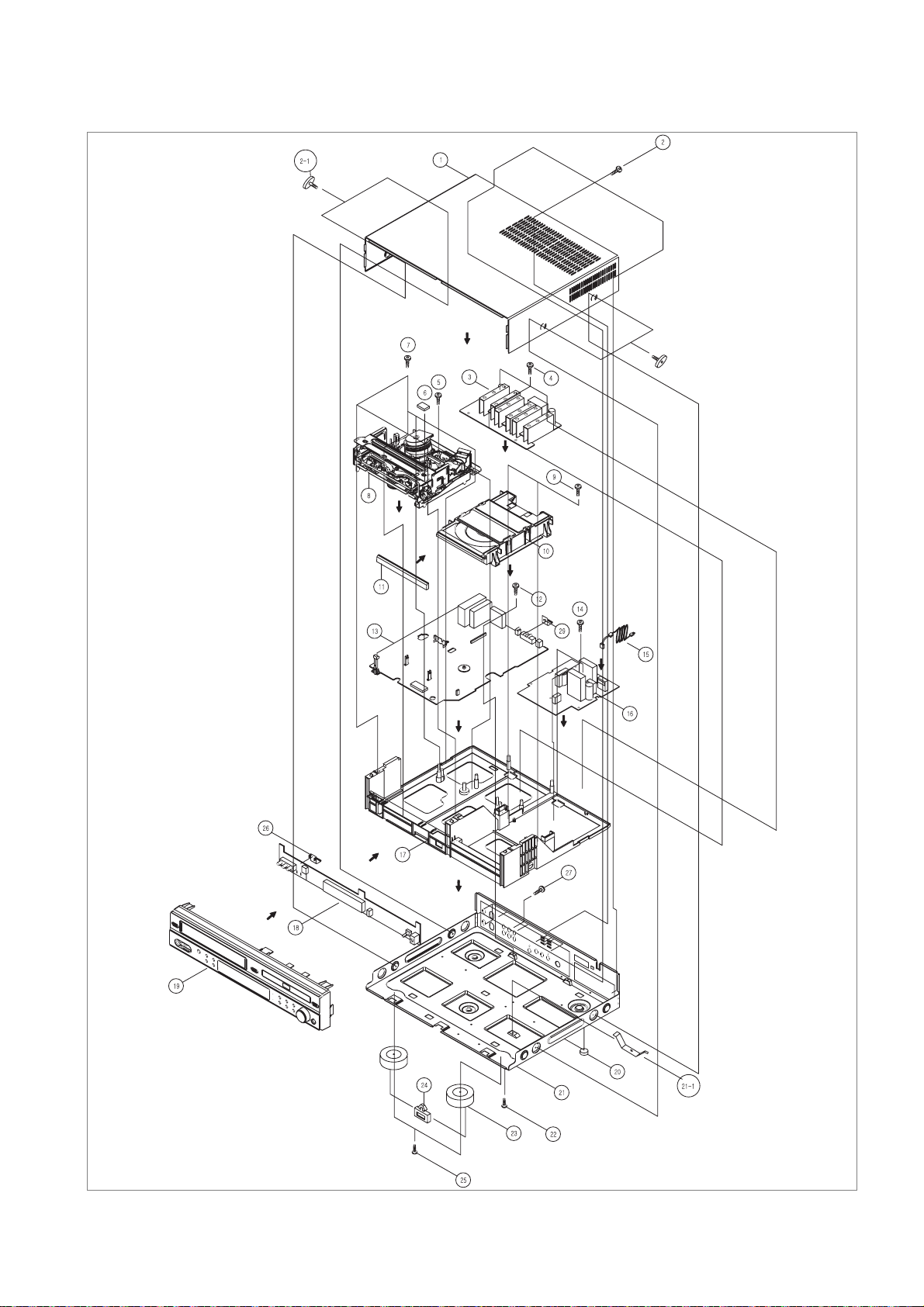

2.1. Assembly diagram

2.1.1. DECK Assembly diagram

A. Upper View

2. ASSEMBLY DIAGRAM AND A/S

1MAIN BASE ASS’Y

2 DRUM ASS’Y

3 FE HEAD

4 S SLANT POLE ASS’Y

5 TENSION BAND ASS’Y

6 S BRAKE ASS’Y

7 REEL TABLE

8 REEL BRKT TOTAL ASS’Y

9 IDLER PLATE TOTAL ASS’Y

10 T BRAKE ASS’Y

11 FL RACK

12 RELAY LEVER

13 CAPSTAN MOTOR

14 LC BRKT ASS’Y

15 PINCH LEVER TOTAL ASS’Y

16 CAM GEAR

17 AC HEAD ASS’Y

18 T SLANT POLE ASS’Y

19 LOADING RACK

20 L LOADING ASS’Y

21 R LOADING ASS’Y

22 CONNECT PLATE

23 REEL BELT

24 CABLE FFC

Page 13

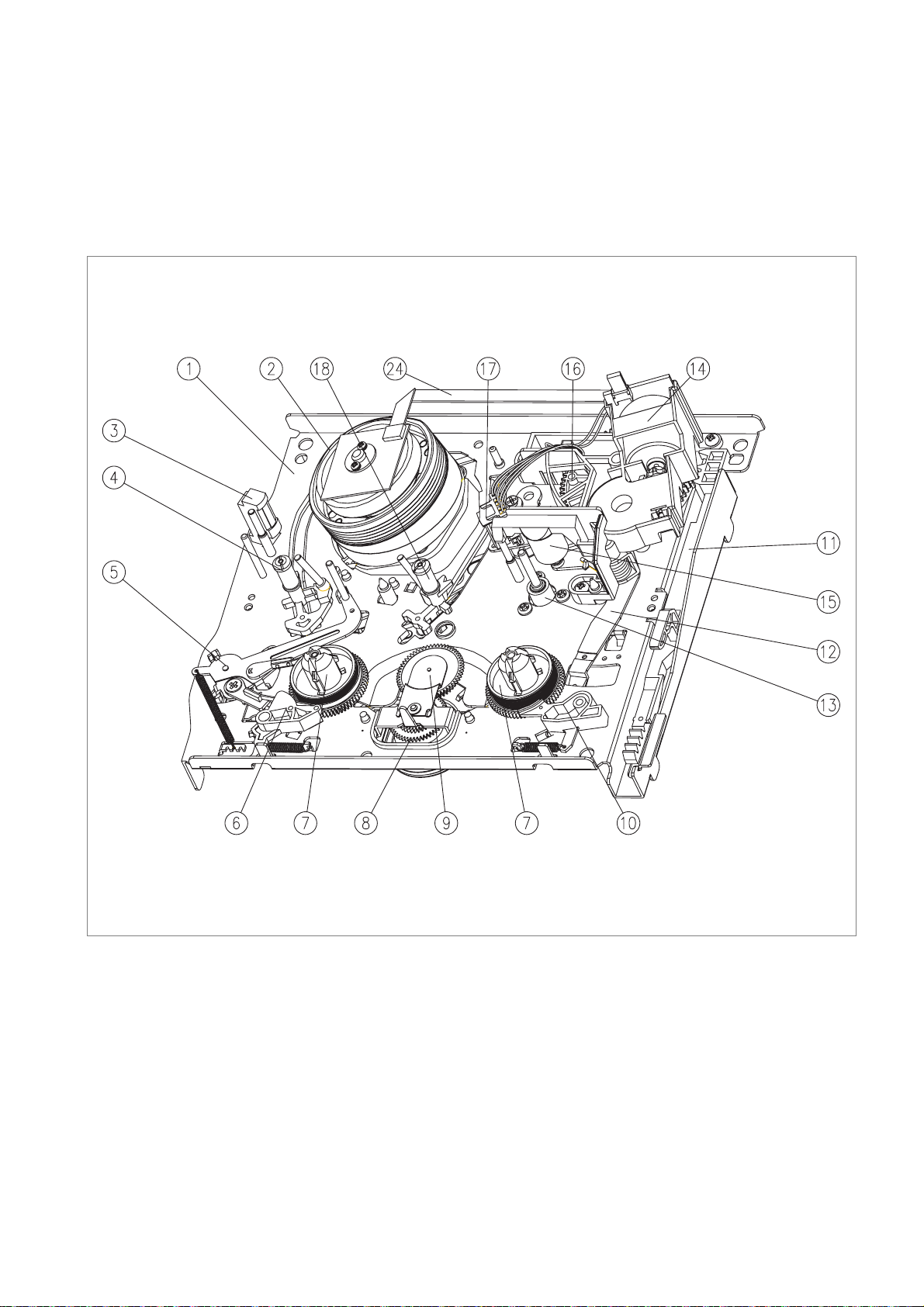

ASSEMBLY DIAGRAM AND A/S(CONTINUED)

B. Lower V iew

1MAIN BASE ASS’Y

2 DRUM ASS’Y

3 FE HEAD

4 S SLANT POLE ASS’Y

5 TENSION BAND ASS’Y

6 S BRAKE ASS’Y

7 REEL TABLE

8 REEL BRKT TOTAL ASS’Y

9 IDLER PLATE TOTAL ASS’Y

10 T BRAKE ASS’Y

11 FL RACK

12 RELAY LEVER

13 CAPSTAN MOTOR

14 LC BRKT ASS’Y

15 PINCH LEVER TOTAL ASS’Y

16 CAM GEAR

17 AC HEAD ASS’Y

18 T SLANT POLE ASS’Y

19 LOADING RACK

20 L LOADING ASS’Y

21 R LOADING ASS’Y

22 CONNECT PLATE

23 REEL BELT

24 CABLE FFC

Page 14

ASSEMBLY DIAGRAM AND A/S(CONTINUED)

2.1.2. FRONT LOADING Assembly diagram

1 FL BRKT L

2 TOP PLATE

3 SAFETY LEVER

4 LOADING LEVER AS4

5 CST HOLDER AS

6 DOOR OPENER

7 SAFETY LEVER R

8 FL BRKT R

Fig.2

Page 15

4. 1 Mechanical Adjustment (Fig. 4.1~4.4)

In case of diassembly and reassembly for fixing the mecanical

problem, check the following check point.

a. Make sure that the DATUM HOLE of the CAM GEAR is

aligned wth the DATUM HOLE in the MAINBASE in

the EJECT mode as shown in Fig. 4-1.

b. Make sure that the ending part “A” of the RELAY

LEVER assembled on the CONNECT PLATE is aligned

with the reference hole “B” of the MAINBASE as shown

in Fig. 4.2.

c. The end point “A” of PINCH SPRING PIN of the

LEVER TOTAL ASS`Y should be located within the

trajectory “B” of the CAM GEAR. (Fig. 4.3)

4. MECHANICAL ADJUSTMENT

FIg. 4.1 Assembly reference between the FL RACK and the

CAM GEAR

TURN TO THE END

ALIGN

FIg. 4.2 Assembly reference between the RELAY LEVER

and the CAM GEAR

FIg. 4.3 Assembly reference of the PINCH LEVER TOTAL

ASS’Ywith the CAM GEAR

Page 16

d. Make sure that the triangular mark “A” of the L LOAD-

ING Ass’y is aligned with the mark “b” of the R LOADING Ass’y. (Fig. 4.4)

e. Reference hole “C” of the LOADING RACK should be

aligned with the reference hole of the R LOADING Ass’y

to make the teeth of the LOADING RACK is aligned as

shown in Fig. 4.4.

4. 2 Adjustment and measurement of the BACK

TENSION (Fig. 4.5, 4.6)

a. Check that the location of the TENSION POLE is in the

right position. if not, adjust that by refering to the “4.4

Adjustment of the TENSION POLE position”.

b. Play back the T-120 TAPE in S-MAX for 20

seconds.(Generally tape transporting section is settled

down in 20 seconds)

c. Measure the BACK TENSION by using the TENTELO

METER (Refer Fig 4.5) The result should be within the

range of 20g ~ 30g.

d. If the BACK TENSION is out of the range, change the

position of the TENSION SPRING of repeat the

process of “4.4 Adjustment of the TENSION POLE

position”.(Fig. 4.6)

MECHANICAL ADJUSTMENT (CONTINUED)

FIg. 4.4 Assembly reference between the LOADING RACK

and the LOADING LEVER ASS’Y

CAUTION:

• If the measurement result greater than the upper limit,

change the hook point of the spring to position “A”

• Confirm that all of the three probes of TENTELO

METER are in contect with the tape.

• During measuring, don`t touch any other parts of the

MECHANISM(i.e. MAINBASE). It is recommended that this measurment be repeated at least three

times for an accurate reading.

FIg. 4.5 Measurement of the BACK TENSION

Page 17

4. 3 Mechanical Mode (Operate without a cassette

tape)

a. Remove the FRONT LOADING MECHANISM from the

DECK MECHANISM

b. Cap the IR LED and pull the FL RACK. This has the same

effect with cassette loading to the deck.

c. If the S,T POLE BASE is loaded, PLAY MODE starts

automatically. If you want other function, press the corresponding button.

d. Turn off the power when the Mechanism is in the desired

position.

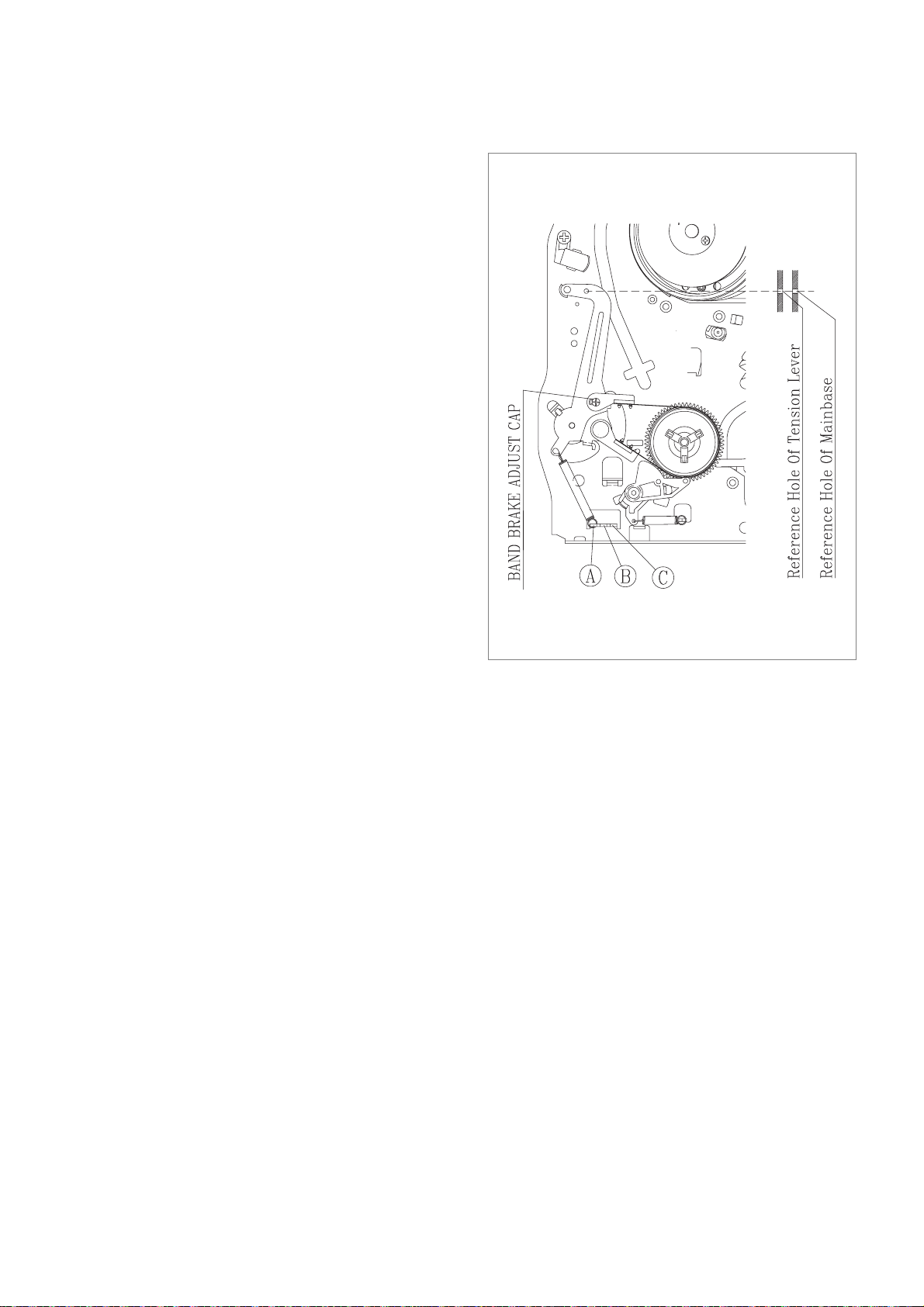

4. 4 Adjustment of the position of the TENSION

POLE (Fig. 4.6)

a. Place the MECHANICAL MODE in the PLAY MODE.

Refer to the above section “4.3 MECHANICAL MODE”

b. Confirm that the TENSION LEVER is aligned with the

datum hole of the MAINBASE.

c. If the requirement “b” is not satisfied. turn the BAND

BRAKE ADJUST CAP clockwise or counterclockwise

until the two datum holes aligns with each other.

MECHANICAL ADJUSTMENT (CONTINUED)

FIg. 4.6 Adjustment of the TENSION POLE POSITION

Page 18

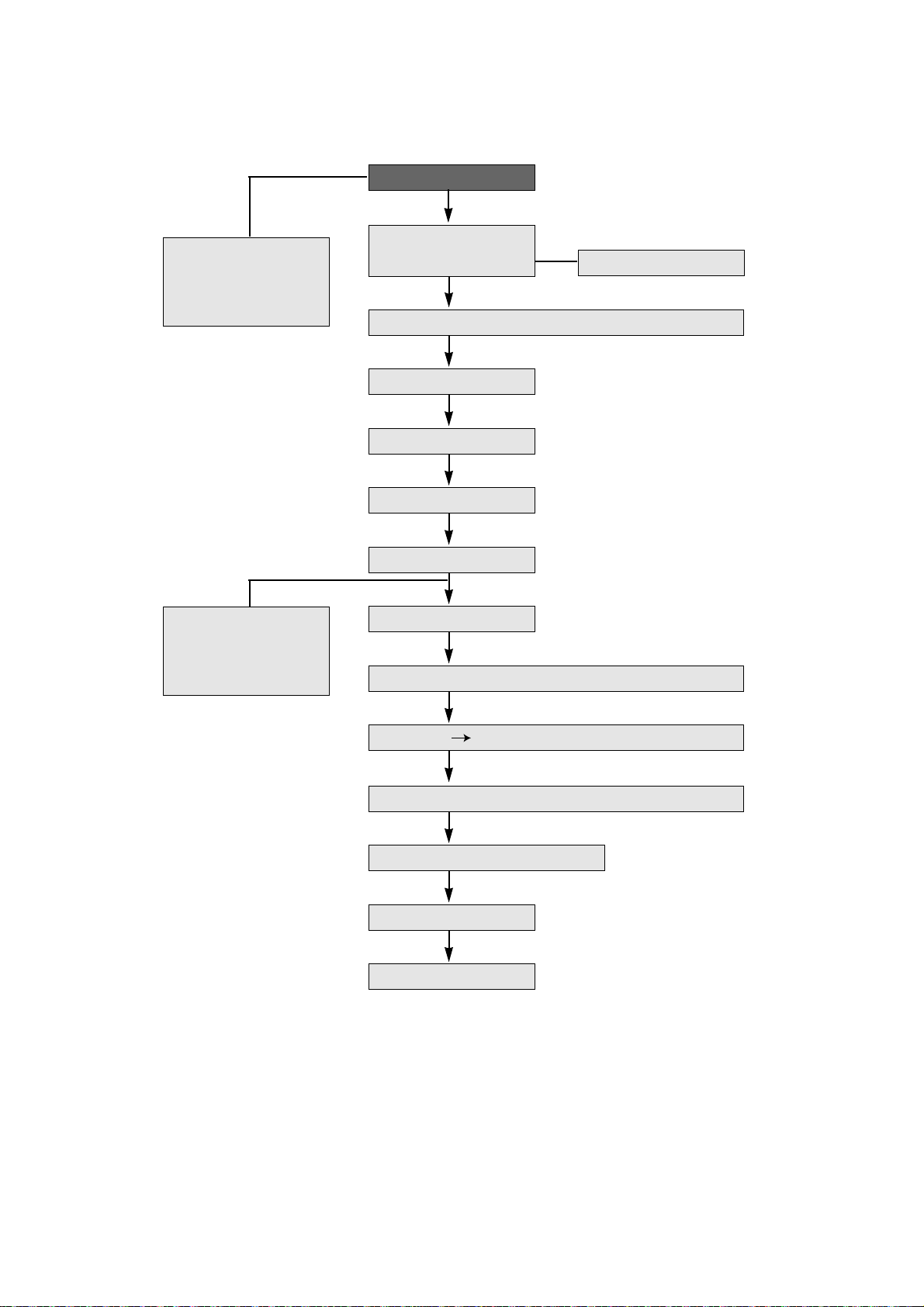

5. ADJUSTMENT OF THE TAPE TRANSPORT SECTION.

Generally, tape transporting section has been precisely adjusted in the factory and does not require the ordinary readjustment.

But there is the case that tape noise or impact on the deck mechanism, tape transporting section readjustment is required. In

adjustment of the tape transmission section consut the following flow chart.

If any components shown in Fig. 5.1, tape transport section are changed. To readjust the tape transporting section.

FIg.5.1 A schematic diagram of the tape transport ing section.

Page 19

S/T GUIDE ROLLER HEIGHT

ADJUSTMENT

•DRUM TOTAL AS

•A/C HEAD AS

•PINCH LEVER TOTAL

AS

S/T GUIDE ROLLER FLUNGE

A/C HEAD AS ADJUSTMENT (TILT ADJUSTMENT)

CLEANING

AUDIO AZIMUTH ADJUSTMENT

A/C HEAD ADJUSTMENT

X-POSITION ADJUSTMENT

PLAYBACK PHASE ADJUSTMENT

LINEARITY ADJUSTMENT

DRUM ENTRANCE/EXIT ENVELOPE FINE TUNING

REVIEW PLAY CHANGING OPERATION CHECK

AUDIO AZIMUTH ADJUSTMENT

AUDIO OUTPUT CHECK (A/C HEAD HEIGHT& TILT ADJUSTMENT)

X-POSITION ADJUSTMENT

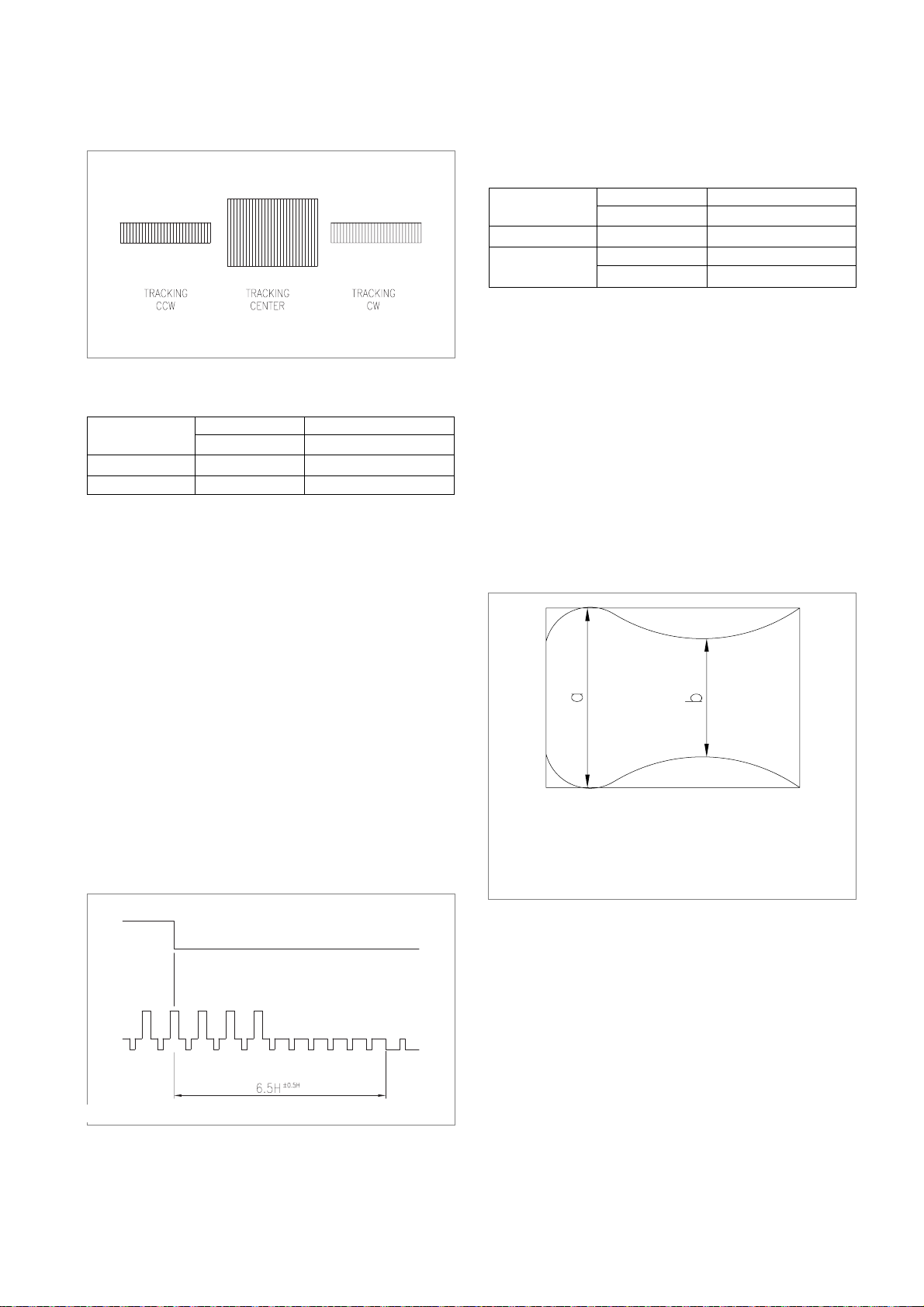

TRACKING

•S SLANT PLOE AS

•T SLANT POLE AS

•TENSION BAND AS

Table.1 Adjustment Flow Diagram of the Tape Transporting System

Page 20

A. Adjustment of the S/T GUIDE ROLLER

A. Adjustment of the S/T GUIDE ROLLER

a. Check the Playing back with a T-120 TAPE.

b. Make sure that excessive tape wrinkle does not occure

ateatch S, T GUIDE ROLLER.

c. If tape wrinkle is observed at the S/T GUIDE ROLLER,

turn the guide roller screw until there is not tape wrinkle.

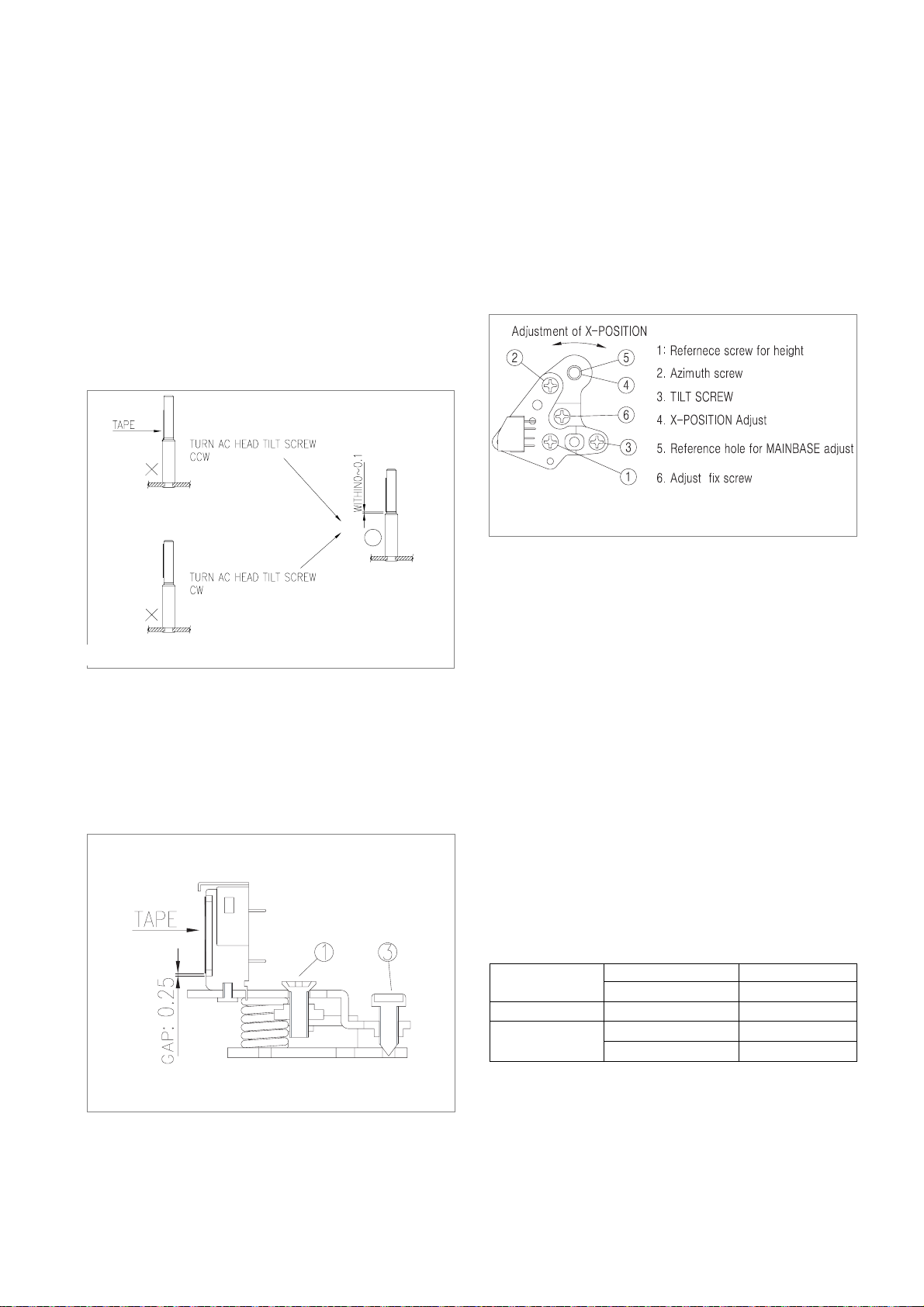

B.Adjustment of the AC HEAD ASS’Y(TILT)

a. Play back a T-120 TAPE and check the running status of

lower side of GUIDE POST.

b. If there is any problem, Turn the AC HEAD TILT

SCREW until the running status improved. (Fig. 5.2)

C.Adjustment of the AC HEAD Height(Fig. 5.3)

a. Play back a T-120 TAPE..

b. Make sure that the gap between the lower end of TAPE

and the AC head is 0.25m.

c. If the measurement of the gap is different from the refer-

ence value 0.25mm, turn the screw ! , # until the

desired gap is obtained.

D.Adjustment of the AUDIO AZIMUTH(Fig. 5.4)

a. Play back the ALIGNMENT TAPE

(DN2 : SP, NTSC,7KHz)

b. Check the AUDIO output with a AUDIO LEVEL

METER.

c. Turn the AC HEAD AZIMUTH SCREW @ until the

maximum AUDIO output(-9dBm ~ -3dBm)is obtained.

E.Adjustment of the X-POSITION(Fig. 5.4 5.5)

a. Connect the PATH ADJ. FIXTURE to the PT01 on the

MAIN CIRCUIT BOARD.

b. Play back the ALIGNMENT TAPE (DN2 : SP MONO-

SCOPE).

c. Connect the S/W pin and ENVE pin of the PATH ADJ.

FIXTURE with the SCOPE PROBE.

d. Insert the adjustment bar in the AC HEAD ADJUST hole

$ and adjust the X-POSITION of the AC HEAD

ASS`Y until the ENVE is maximum when the VR is on

the CENTER.

• There is the possibility that an another TRACKING CENTER can be occur when the AC HEAD ASS`Y turned

completely in the counterclockwise direction, Hence adjust

the X-position with AC HEAD ASS’Y adhering closely

to the right side until the maximum ENVE is obtained.

e. The adjustment of the X-POSITION finished, check

if the AUDIO LEVEL is degraded, then readjustment

of the AUDIO AZIMUTH is required.

ADJUSTMENT OF THE TAPE TRANSPORT SECTION. (CONTINUED)

FIg.5.2 Adjustment of the AC HEAD ASS’Y

FIg.5.3 Adjustment of AC HEAD Height

FIg.5.4 Adjustment of AUDIO AZIMUTH, X-POSITION

S/W PULSE TEST PIN PATH ADJ. FIXTURE

ENVELOPE TEST PIN PATH ADJ.FIXTURE

Measurement Equipment OSILLOSCOPE

VR CONTROL PATH ADJ.FIXTURE

AC HEAD ADJUST HOLE ADJUSTMENT BAR

Test Point

Adjustment

Page 21

F. PLAYBACK PHASE ADJUSTMENT(Fig. 5.6)

PHASE GENERATOR(PG) SHIFTER determine the

VIDEO HEAD SWITCHING POINT when the TAPE is

played back. If an adjustment of the PHASE GENERATOR(PG) SHIFTER is not done precisely, There can be a

HEAD SWITCHING NOISE or a VERTICAL JITTER

problem, vibration of the picture on the screen, not good

quality of picture in special play back.

a. Connect the PT01 on the MAIN CIRCUIT BOARD with

a PATH ADJ. FIXTURE.

b.

Play back an ALIGNMENT TAPE(DN-2 : MON-SCOPE signal)

c. Connect the S/W PULSE TEST PIN on the PATH ADJ.

FIXTURE with a CHANNEL-1 SCOPE PROBE.

d. Connect the VIDEO OUT on the MAIN CIRCUIT

BOARD with a CHANNEL-2 SCOPE PROBE (1V/div).

e. Control the PG VOLUME until the time interval

between the SWITCHING PULSE and the V-SYNC

SIGNAL is within the 6.5H±0.5H as shown in Fig. 5.6.

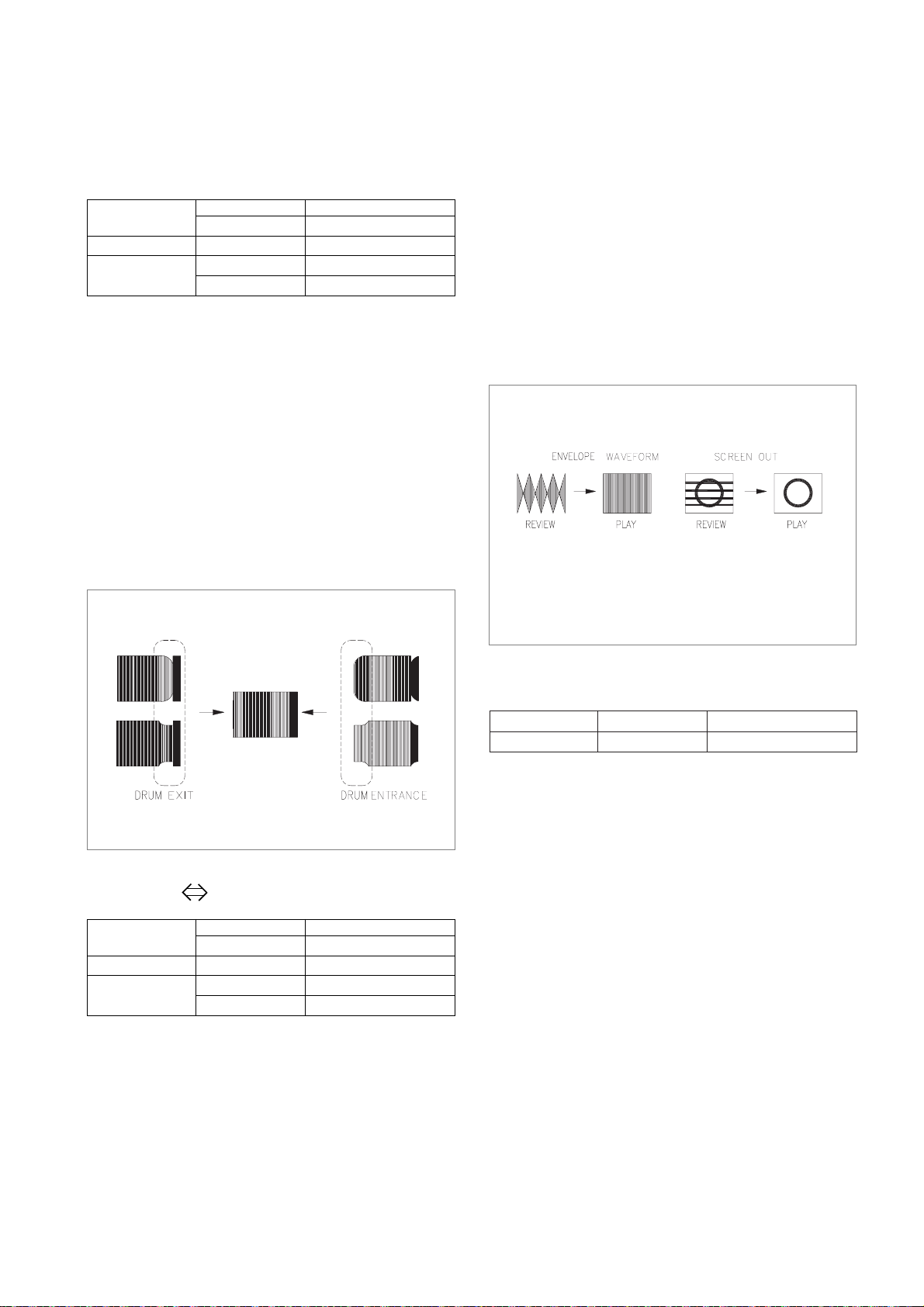

G.Adjustment of the LINEARITY(Fig. 5.7)

a. Connect the PT01 on the MAIN CIRCUIT BOARD with

a PATH ADJ. FIXTURE.

b. Play back an ALIGNMENT TAPE(DN-2 : MONO-

SCOPE Signal).

c. Connect the FIXTURE S/W PULSE TEST PIN on the

PATH ADJ. CHANNEL-1 SCOPE PROBE.

d. Connect the VIDEO OUT on the MAIN CIRCUIT

BOARD with a CHANNEL-2 SCOPE PROBE (1V/div).

e. Adjust the VR CONTROL on the ADJ. FIXTURE until

the ENVELOPE signal is maximum while play back the

ALIGNMENET TAPE.

f. Adjust the S/T GUIDE ROLLER until the envelope signal

waveforms of the entrance and exit sides are as shown in

Fig. 5-7.

ADJUSTMENT OF THE TAPE TRANSPORT SECTION. (CONTINUED)

FIg.5.5 Adjustment of the X-POSITION

S/W PULSE TEST PIN PATH ADJ. FIXTURE

ENVELOPE TEST PIN PATH ADJ.FIXTURE

Measurement Equipment OSILLOSCOPE

VR CONTROL PATH ADJ.FIXTURE

S/T GUIDE ROLLER TAPE TRANSPORT SECTION

Test Point

Adjustment

a: Max Output of Envelope

b: Min Output of Envelope

FIg.5.7 Adjustment of Linearity

Fig.5.6 Playback Phase Adjustment

S/W PULSE TEST PINMAIN CIRCUT BOARD

ENVELOPE TEST PINMAIN CIRCUT BOARD

Measurement Equipment OSILLOSCOPE

VR 595(PG SHIFTER)MAIN CIRCUT BOARD

Test Point

Adjustment

Page 22

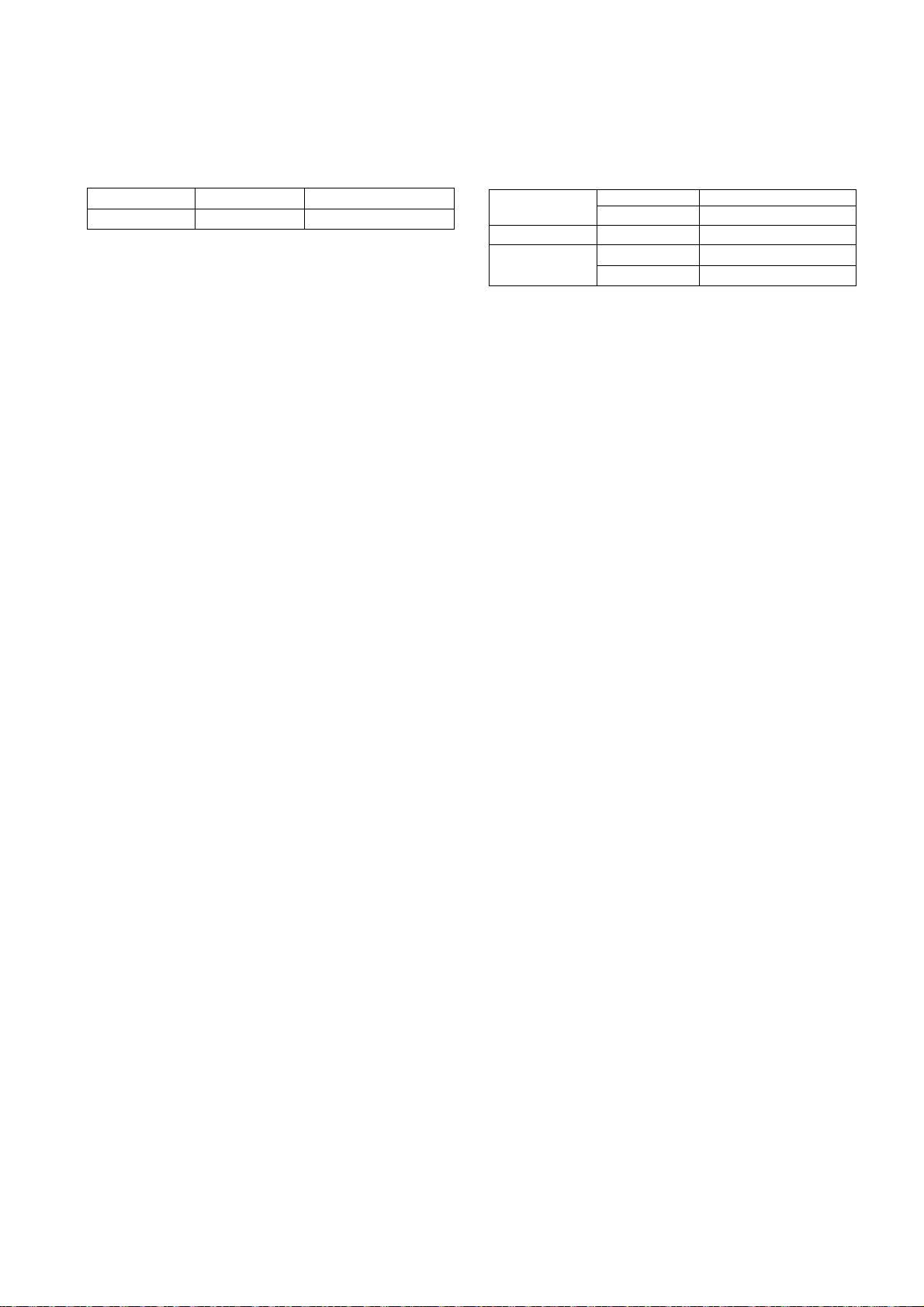

H. Adjustment of the wave form of DRUM Entrance

/ Exit (Fig. 5.8)

a. Connect the PT01 on the MAIN CIRCUIT BOARD with

a PATH ADJ.FIXTURE.

b. Play back an ALIGNMENT TAPE(DN-2 : MONO-

SCOPE signal)

c. Connect the S/W PULSE TEST PIN on the PATH ADJ.

FIXTURE with a CHANNEL-1 SCOPE PROBE.

d. Connect the VIDEO OUT on the MAIN CIRCUIT

BOARD with a CHANNEL-2 SCOPE PROBE(1V/div).

e. Turn the VR CONTROL on the PATH ADJ.FIXTURE

clockwise or counterclockwise until the signal shape of

ENVELOPE has the constant thickness.(Fig.5.8)

f. Adjust the S/T GUIDE ROLLER if the thickness of the

ENVELOPE signal is not uniform.

I. REVIEW PLAY(Fig. 5.9)

a. Connect the PT01 on the MAIN CIRCUIT BOARD with

a PATH ADJ.FIXTURE.

b. Play back an ALIGNMENT TAPE(DN-2 : MONO-

SCOPE signal)

c. Connect the S/W PULSE TEST PIN on the PATH ADJ.

FIXTURE with a CHANNEL-1 SCOPE PROBE.

d. Connect the VIDEO OUT on the MAIN CIRCUIT-

BOARD with a CHANNEL-2 SCOPE PROBE (1V/div).

e. Make the VR CONTROL on the PATH ADJ. FIXTURE

to the center to maximize the ENVELOPE signal.

f. Play back the REVIEW mode about 15 second and alter

the mode to PLAY MODE.

g. Check whether the ENVELOPE waveform restore to its

original form within 3 second when the REVIEW mode is

changed to PLAY mode.

h. If the requirement of “g” is not satisfied, Check the run-

ning status of tape on the lower part of T GUIDE POST

and adjust the S/T GUIDE ROLLER precisely

.

J.Checking AUDIO output waveform (Adjustment

of AC HEAD TILT & Height)

a. Connect the AUDIO output jack with an AUDIO LEVEL

METER.

b. Playback an Alignment Tape (DN-1:Color Bar 1KHz

Signal)

c. Check if the AUDIO output signal level is over -9~-

3dBm.

d. If the requirement of “c” is not satisfied, readjust the AC

HEAD TILT and the HEIGHT until the AUDIO output is

maximized. (Fig. 5.2, 5.3)

ADJUSTMENT OF THE TAPE TRANSPORT SECTION. (CONTINUED)

S/W PULSE TEST PIN PATH ADJ. FIXTURE

ENVELOPE TEST PIN PATH ADJ.FIXTURE

Measurement Equipment OSILLOSCOPE

VR CONTROL PATH ADJ.FIXTURE

S/T GUIDE ROLLER TAPE TRANSPORT SECTION

Test Point

Adjustment

FIg.5.8 Fine adjustment of the ENVELOPE at the DRUM

ENTRANCE/EXIT

S/W PULSE TEST PIN PATH ADJ. FIXTURE

ENVELOPE TEST PIN PATH ADJ.FIXTURE

Measurement Equipment OSILLOSCOPE

VR CONTROL PATH ADJ.FIXTURE

S/T GUIDE ROLLER TAPE TRANSPORT SECTION

Test Point

Adjustment

FIg.5.9 Waveform change when the modealtered

(REVIEW ↔PLAY)

AUDIO OUTPUT AUDIO OUTPUT JACK

AUDIO LEVEL METER

Test Point

Measurement Equipment

Page 23

K.Adjustment of the AUDIO AZIMUTH

a. Connect the AUDIO output JACK with an AUDIO

LEVEL METER.

b. Play back the ALIGNMENT TAPE(DN-2:MONO-

SCOPE 7KHz Signal).

c. Check if the AUDIO output signal level is over : -9 ~-

3dBm.

d. If the requirement of “c” is not satisfied, readjust the

AZIMUTH SCREW of the AC HEAD until the AUDIO

output is maximum.(Fig. 5.4)

e. Repeat the process of “Adjustment of the wave form of

DRUM Entrance/Exit”

L.X-POSITION

a. Connect the PT01 on the MAIN CIRCUIT BOARD with

a PATH ADJ. FIXTURE.

b. Play back an ALIGNMENT TAPE(DN-2 : MONO-

SCOPE Signal).

c. Connect the S/W PULSE TEST PIN on the PATH ADJ.

FIXTURE with a CHANNEL-1 SCOPE PROBE.

d. Connect the VIDEO OUT on the MAIN CIRCUIT

BOARD with a CHANNEL-2 SCOPE PROBE (1V/div).

e. Check if the ENVELOPE is maximum when the VR

CONTROL on the PATH ADJ. FIXTURE is in CENTER

f. If the requirement “e” is not satisfied, readjust the X-POSI-

TION by referring to subitem “E”(Adjustment of the XPOSITION).

g. Repeat the process of subitem “F”(PLAYBACK PHASE

ADJUSTMENT).

ADJUSTMENT OF THE TAPE TRANSPORT SECTION. (CONTINUED)

AUDIO OUTPUT AUDIO OUTPUT JACK

AUDIO LEVEL METER

Test Point

Measurement Equipment

S/W PULSE TEST PIN PATH ADJ. FIXTURE

ENVELOPE TEST PIN PATH ADJ.FIXTURE

Measurement Equipment OSILLOSCOPE

VR CONTROL PATH ADJ.FIXTURE

S/T GUIDE ROLLER

TAPE TRANSMISSION T SECTION

Test Point

Adjustment

Page 24

ELECTRICAL ADJUSTMENT

Fig. 1 Main board test point/control location guide(component)

RTD300

Page 25

ELECTRICAL ADJUSTMENT

PG (Pulse Generator) Shifter Adjustment (Fig. 3)

Test Points: PT01 PIN # Main

Video Out Jack Rear Panel

Adjust: REC SWITCH Main

The Pulse Generator (PG) Shifter determines the video head

switching point during playback. Misadjustment of the PG

Shifter may cause head switching noise in the picture and/or vertical jitter.

1. Load the instrument with an alignment tape and play back

the color bar signal or monoscope signal.

2. Connect Path Fixture to PT01.

3. Connect channel-1 scope probe (1V/div.: 50µ sec/div.) to

PT01 PIN #. Trigger the scope on channel-1.

4. Connect channel-2 scope probe (1V/div.) to the Video Out

Jack.

5. Set the scope to (-) slope and press the REC SW, the alignment is performed automatically. Confirm that the trailing

edge of the SW 30Hz pulse is placed 6.5H±0.5H (horizontal)

lines before the start of vertical sync pulse.

SWITCHING

SW30Hz

PULSE

VIDEO

OUTPUT

V. SYNC

6.5H–0.5

Fig. 3 - Automatic PG Shifter Adjustment

Page 26

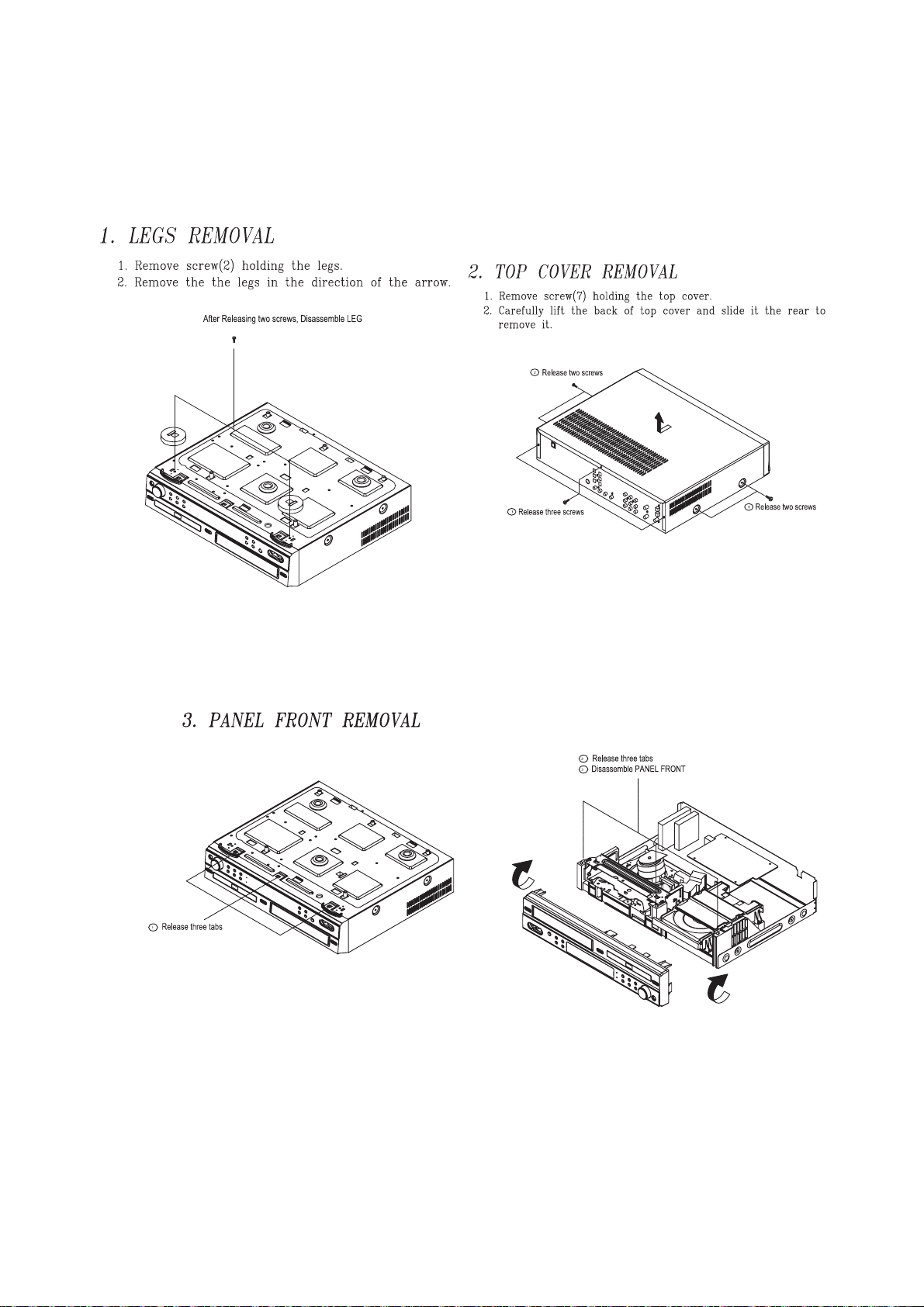

Fig. 1 - Legs Removal

Fig. 2 Top Cover Removal

INSTRUMENT DISASSEMBLY

Perform all disassembly procedures in the order presented. When reassembling, use the reverse procedure. Make sure that all

leads/wiring are routed correctly when reassembling.

PRT_CSYS_DEFyyDEFAULT

zz

xx

Fig. 3 . Panel Front Removal

Page 27

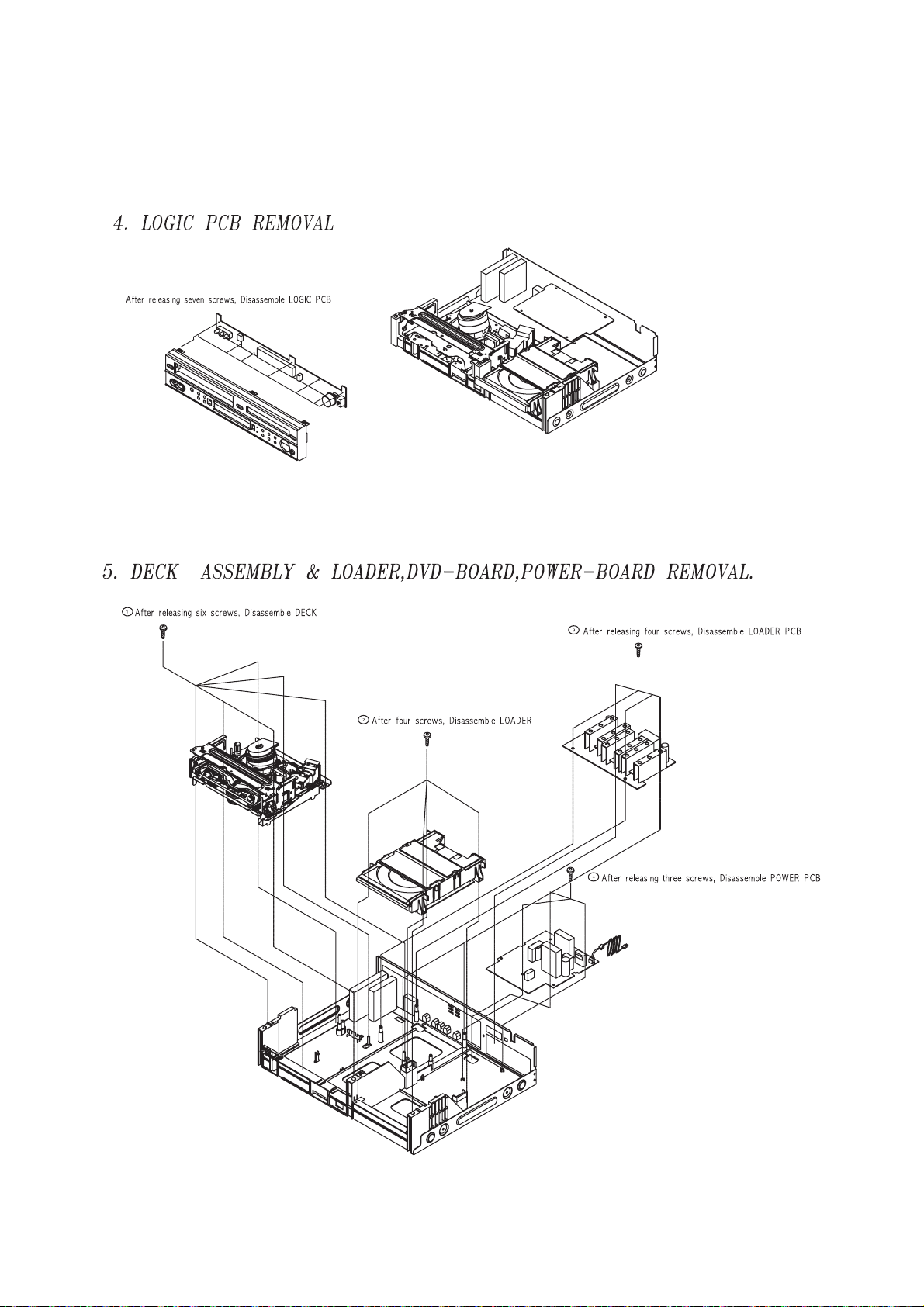

INSTRUMENT DISASSEMBLY (Continued)

Fig. 5 . DECK & LOADER,POWER BOARD Removal

Fig. 4 . LOGIC PCB Removal

Page 28

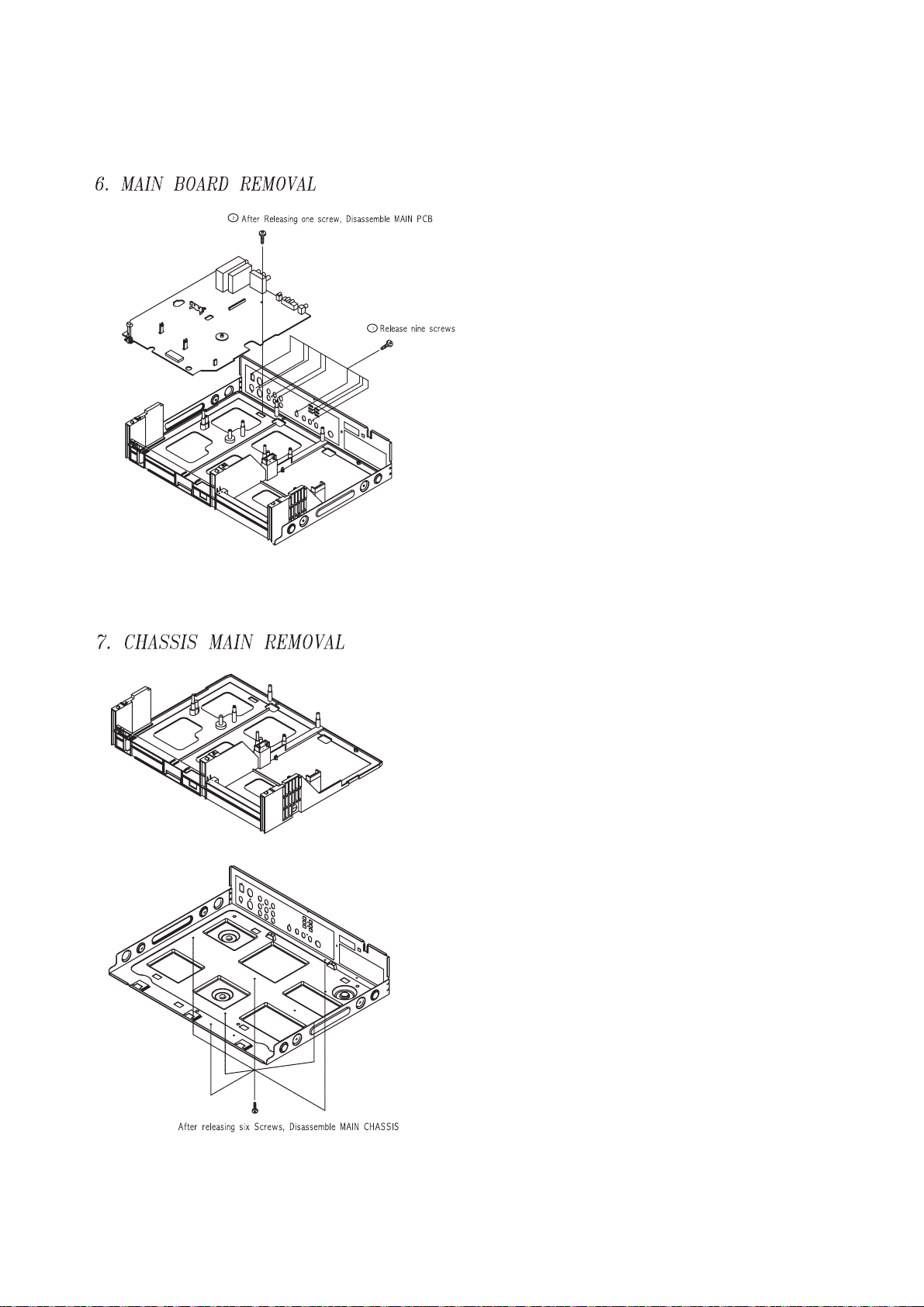

INSTRUMENT DISASSEMBLY (Continued)

Fig. 6. Main Board Removal

Fig. 7. Chassis Main Removal

Page 29

INSTRUMENT DISASSEMBLY (Continued)

Page 30

ABBREVIATIONS

A A or AUD : Audio

A.E. : Audio Erase

AC : Alternating current

ACC : Automatic Color Control

ACS : Auto Clock Set

AFC : Automatic Frequency Control

AFT : Automatic Fine Tuning

AGC : Automatic Gain Control

ALC : Automatic Level Control

AM : Amplitude Modulation

AMP : Amplifier

ANT : Antenna

APC : Automatic phase control

ASS'Y or AS : Assembly

AUTO : Automatic

AV or A/V : Audio/Video

B B : Base, Burst

BAL : Balance

BGP : Burst Gate Pulse

BPF : Bandpass Filter

BW or B/W : Black and White

C C : Capacitor, Chroma, Collector

C Rotary : Color Rotary

C-Sync : Composite Synchronization

CA : Commercial Advance

CAP : Capstan

CAR : Carrier

CATV : Cable Television

CBC : Cable Box Control

CCD : Charge Coupled Devices

CFG : Capstan Frequency Generator

CH : Channel

CHAR : Character

CHROMA : Chrominance

CLK : Clock

CNR : Color Noise Reduction

COMB : Comb Filter

COMP : Comparator, Composite, Compensation

CONV : Converter

CST : Cassette

CTL : Control

CUR : Current

CV : Composite Video

D D : Drum, Digital, Diode, Drain

DC : Direct Current

DD : DC-DC Convert

DEEM or DEEMPH

: Deemphasis

DEMOD : Demodulator

DET : Dectector

DEV : Deviation

DFG : Drum Frequency Generator

DOC : Dropout Compensator

DS : Drain and Source

DSSC : Digital Satellite Set Control

dB : Decibel

E EDS : Extended Data System

ENVE : Envelope

E/V : Envelope/Vertical Sync

G GEN : Generator

GND : Ground

H H : High, Horizontal

HA or HEAD AMP

: Head Amplifier (PreAmp)

HD : Horizontal Drive, Head

HOR : Horizontal

HZ : Hertz

I I/O : Input/Output

IC : Intergrated Circuit

IF : Intermediate Frequency

INS : Insertion

IR : Infrar Red

K KIL : Killer

L L : Low, Left, Coil

LIM : Limit

LM : Loading Motor

LP : Long Play

LPF : Low Pass Filter

M MA : Movie Advance

MAX : Maximum

MIN : Minimum

MIX : Mixer, Mixing

MMV : Monostable Multivibrator

MOD : Modulation, Modulator

MPX : Multiplex

M/T or MTR : Motor

N NC : None Connection

NC or NOICAN : Noise Canceller

NL : None linear

NR : Noise Reduction

O OSC : Oscillator, Oscillation

OSD : On Screen Display

OSP : On Screen Program

OTR : One Touch Record

P P-P : Peak-to-Peak

PB : Playback

PC : Photo Coupler

PCB : Printed Circuit Board

PG : Phase Generator

Page 31

PIC : Picture

PIF : Picture Intermediate Frequency

PLL : Phase Locked Loop

PS : Phase Shift

PWM : Pulse Width Modulator

PWR : Power

Q Q : Transistor

QV : Quasi Vertical

R R : Resistor, Right

REC : Recording

REF : Reference

REG : Regulated, Regulator

REMOCON : Remote Control (Unit)

REV : Reverse

REW : Rewind

RF : Radio Frequency

ROT : Rotary

S SEP : Separation

SHARP : Sharpness

SI or S IN : Serial Input

SO or S OUT : Serial Output

SP : Standard Play

STB : Strobe

SVC : Service

SW or S/W : Switch or Switching Pulse

SYNC : Synchronization

SYSCON : System Control

T TJ : Test Jump

TP : Test Pin

TR : Transistor

TRANS : Transformer

TRK : Tracking

TU : Tuner

U UHF : Ultra High Frequency

V V : Volt, Vertical

V-SYNC : Vertical Synchronization

VCA : Voltage Controlled Adjustor

VCO : Voltage Controlled Oscillator

VCR : Video Cassette Recorder

VD : Vertical Drive

VERT : Vertical

VGC : Voltage Gain Control

VHF : Very High Frequency

VR : Variable Resistor or Volume

W W : Watt

W/D : White and Dark

WF : Wave Form

WHT : White

X X-TAL : Crystal

Y Y FM : Luminance FM Signal

Y Y/C : Luminance/Chrominance

Page 32

SPECIFICATIONS

Cleaning and Lubrication

A. Cleaning the Tape Transport System

The following parts should be cleaned after every 500 hours

of use.

• TENSION POLE

• S-GUIDE POST

• FE HEAD

• S GUIDE ROLLER

• S-SLANT POLE

• VIDEO HEAD/DRUM

• T-SLANT POLE

• T-GUIDE ROLLER

• AC HEAD/AE HEAD

• T-GUIDE POST

• CAPSTAN SHAFT

• PINCH ROLLER

Note: After cleaning with alcohol, allow the parts to dry thor-

oughly before using a cassette tape.

B. Cleaning the Drive System

The following parts should be cleaned after every 500 hours

of use.

• REEL TABLE

• T MAIN BRAKE

• S MAIN BRAKE

• T MAIN BRAKE

• CAPSTAN FLYWHEEL/PULLEY

• REEL PULLEY

C. Lubrication points

The following parts should be cleaned and lubricated after

every 500 hours of use. Apply one (1) or two (2) drops of oil.

Refer to the "Replacement Parts List" for the stock number of

the recommended oil.

• S REEL TABLE POST

• T REEL TABLE POST

• IDLER PULLEY

Power Input:120 Volts AC 60Hzaudio Input:-8.8dBm

Power Consumption :95Watts Audio output (common

Operating Temperature :5 degree C to 35 degree C use of DVD and VCR) : Audio output terminal (2 kinds):

(41 degree F to 95 degree F) -8.8dBm(VCR), 2.0Vrms(DVD)

Storage Temperature : -30 degree C to 65 degree C Audio output (DVD only) : Analogue Audio output(2CH):2.0Vrms

(-22 degree F to 149 degree F)

Installation condition :Horizontal / Relative humidity Audio Input Impedance : More than 47k ohm

under 80% Audio Output Impedance : Less than 1.5k ohm

Weight : 6.45 kg (NET) VHF output : 3 or 4 CH

Playable tape : Very high dense tapes with VHS marks

Dimensions : 430mm Wide X 91mm High Playable disc : DVD,VIDEO-CD,CD(12mm)

X 355.5mm Deep CD(8mm),MP3,CD-R,CD-RW

Tape Speed : SP: 33.35mm/sec.

Recording System SLP : 11.12mm/sec.

4-head Hi Fi : Four video record/playback Maximum Recording Time: T-60: 3 hours/SLP mode

heads T120: 6 hours/SLP mode

Rotary helical scan/luma: FM Fast Forward/Rewind Time: <130sec (T-120 tape)

recording/chroma: converted Tuning System : Auto Program/Cable

subcarrier phase shifted recording Compatible/Frequency

Two audio record/playback Synthesis (FS)

heads Clock display : 12 hrs AM/PM

Rotary helical scan, 2 channels Time Recording : 8 programs a year

FM recording Persistence in power

Received channels :VHF: 2-13 CH / UHF: 14-69 CH failure : 1 min

/ Cable: 1-125 Video S/N (VCR) : Over 45dB(Standard recording)

Video Signal : EIA standard; NTSC color Resolution (VCR) : Over 220 lines (Standard recording)

Antenna : 75 ohm input impedance Resolution (DVD) : Over 500 lines (DVD Disc PLAY)

Video Signal Level : 1Vp-p (140 IRE standard) Audio (VCR) : Over 68dB(Hi-Fi),over 40dB(Mono)

Video output (common use of DVD and VCR): Audio (DVD) : 100dB

VIDEO output terminal, Audio dynamic range : 70dB

1Vp-p (140 IRE standard)

Video output (DVD only):S-VIDEO output

(75 ohm In load Y: 1Vp-p, C:0.286Vp-p)

COMPONENT Progressive output

(75 ohm In load Y:1Vp-p, Pb:0.7Vp-p Pr:0.7Vp-p)

Note : Specifications are subject to change without notice.

CLEANING AND LUBRICATION

Page 33

FIXTURE ITEMDESCRIPTION

Path Adj FixtureUse for X-position adjust/Tape path alignment

Special Driver Use for X-position adjust/Tape path alignment

THE SERVICE FIXTURE

Path Adj Fixture Special Driver

AC Millivolt Meter

Sensitivity: 1.0mVAC–400VAC

Dual-Trace Triggered Oscilloscope–with Lo

–Cap (X10)

and Direct Probes.

Response: DC–20MHz

Sensitivity: 5mV/div.

Max. Sweep Rate: 0.1µsec./div.

Frequency Counter–7 digits

Sensitivity: 25mV-5V

Range: 50Hz–100MHz

DVM

Range: 0.1VDC–1000VD

Accuracy: 0.5%

NTSC Video Signal Generator–Must provide 1V p-p negative

sync video across a 75 ohm load and produce standard NTSC

75% saturated color bars with a 100% white window.

DC Power Supply

Range: 0-50V, 2A well filtered.

Temperature Controlled Soldering Station–Grounded tip

(Tip temperature: 500°F-600°F).

Note: 500 °F Maximum for leadless components.

AC Variac–Continuously variable.

TEST EQUIPMENT REQUIREMENTS

Page 34

1. Preparation for replacement

a. Soldering Iron

Use a pencil-type soldering iron that uses less than 30

watts.

b. Solder

Eutectic solder (Tin 63%, Lead 37%) is recommended.

c. Soldering time

Do not apply heat more than 4 seconds.

d. Preheating

Leadless capacitor must be preheated before installation.

(130°C~150°C, for about two minutes).

2. Removing the leadless component (Resistors, Capacitors)

Grasp the leadless component body with tweezers and alternately apply heat to both electrodes. When the solder on both

electrodes is melted, remove leadless component with a twisting motion.

LEADLESS (CHIP) COMPONENT REMOVAL INSTRUCTION

Note:

a. Leadless component must not be reused after removal.

b. Excessive mechanical stress and rubbing of the compo-

nent electrode must be avoided.

Note:

a. Do not attempt to lift the component off the board until

the component is completely disconnected from the

board by a twisting action.

b. Take care not to break the copper foil on printed board.

• The following procedures are recommended for the replacement of the leadless components used in this unit.

Chip

Tweezers

Soldering lron

PA TH FIXTURE CONNECTION/TEST POINT IDENTIFICATION

Refer to the adjustment of the tape transporting system.

Connect to PT01

!pin-^pin of the

MAIN CIRCUIT BOARD.

CTL pulse test point

GND

S/W pulse test point

ENVE pulse test point

!

^

Page 35

3. Installing the Leadless (chip) Component

a. Presolder the contact points of the circuit board.

b. Press the part downward with tweezers and solder both

electrodes as shown below.

4.Removing of Flat ICs (Recommended procedure)

a. For removing solder chips from IC's pins, use a solder

remover or a wiry solder absorber.

b. Heat the IC's tips evenly by moving the chip IC replacing

tool around them, and detach the IC's leads with a tool in

the way of using a lever.

c. Do not reuse ICs removed once (Discard them)

Note:

Do not glue the replacement leadless component to the

circuit board.

Soldering lron

Presolder

Tweezers

Soldering lron

Chip IC replacing tool

Solder

Page 36

LEADLESS (CHIP) COMPONENT IDENTIFICATION

1. Check the followings before S.M.D Troubleshooting

• Cracked or Chipped Component Body

• Cracked or Separated Solder Joints

• Peeling end Terminations or Fractured Leads

2. S. M. D (Surface Mounted Devices) Identification

a. Chip Resistor Identification

* Standard Chip Resistor Code

b. Chip Capacitor Identification

There is no identification of chip capacitor

REMARK Leadless (CHIP) Components are identified on

schematic by means of "(C)" adjacent to symbol

numbers.

• Rejection of Solder from Copper Pads or Component

• Foreign Matter on Copper Pads

• Solder Bridges

= 12x10

3

(1000) = 12000Ω

= 12KΩ

= 47x10° (1) = 47Ω

XXX

123

470

MULTIPLIER (0-9)

2nd SIG. DIGIT (0-9)

1st SIG. DIGIT (1-9)

Examples

Page 37

1.1 Characteristic of T6-DECK MECHANISM

1) T6-MECHA follows the VHS and the NTSC standard.

2) T6-MECHA uses 3 MOTORS (DRUM MOTOR, CAPSTAN MOTOR, L/C MOTOR).

3) T6-MECHA uses L/C Motor to drive FRONT LOADING.

4) T6-MECHA uses 4-BIT MODE signal to recognize each MODE.

This 4-BIT MODE signal is generated from the cam switch driven by the L/C MOTOR.

5) T6-MECHA has 7MODES (EJECT/INITIAL/REV/IDLE/PLAY,STOP,SLOW/BRAKE/FF&REW) operation.

6) T6-MECHA deduce the MODE changing time by adopting the full loading system which maintains the

tape winding the drum circumference.

7) T6-MECHA can be separated from the main pcb, and be assembled with B-B type connector . This B-B type

connectioning means that CAPSTAN MOTOR, LC MOTOR, AC HEAD, FE HEAD, DRUM are connected

directly without using connector cable.

1. DESCRIPTION OF THE MECHANISM

Page 38

1.2 WIRE DIAGRAM

1.2.1 WIRE DIAGRAM

1.2.2 CONNECTOR PIN ARRANGEMENT

Page 39

RTD300

Symbol Stock Description Circuit Model TypeCode Drawing Notes

1 265596 TOP COVER CABINET ASSEMBLY RTD300 97P0482110

10 265687 DVD MECHANISM W/ SERV/MPEG PCB DVD ASSEMBLY RTD300 97QD020200

11 265602 DVD DOOR CABINET ASSEMBLY RTD300 97PB253300

16 265692 CIRCUIT, SMPS POWER SUPPLY ASSEMBLY RTD300 S 97PD203300

19 265630 FRONT BEZEL CABINET ASSEMBLY RTD300 97PP328210

21 265595 BOTTOM COVER CABINET ASSEMBLY RTD300 97P0482204

A0041 N/S/P SCREW TAPTITE TT2 BIN 3X8 BK CABINET ASSEMBLY RTD300 7173300812

A0042 N/S/P SCREW TAPTITE TT2 FLT 3X8 BSNI CABINET ASSEMBLY RTD300 7175300865

A0051 265598 FOOT CUSHION CABINET ASSEMBLY RTD300 97P4220200

A0052 DISCON_STK SCREW CABINET ASSEMBLY RTD300 7174300811

A0053 DISCON_STK SCREW CABINET ASSEMBLY RTD300 7174300811

A006 N/S/P EARTH BOTTOM SUS 304CSP T0.2 CABINET ASSEMBLY RTD300 97P0991200

A006A N/S/P PLATE EARTH COAXIAL SUS 304 CSP T0.15 CABINET ASSEMBLY RTD300 97P0992300

A006B DISCON_STK SCREW CABINET ASSEMBLY RTD300 7174300811

A0100 N/S/P MAIN BASE AS T4.5-MECHA VCR ASSEMBLY RTD300 97SA332200

A0101 DISCON_STK SCREW 2.6X7 VCR ASSEMBLY RTD300 97S3102000

A013 265631 OVERLAY FOR A/V JACKS CABINET ASSEMBLY RTD300 97P0993000

A0200 248349 LEVER, S GUIDE ASY VCR ASSEMBLY RTD300 97SA316500

A0300 248350 LEVER, T GUIDE ASY VCR ASSEMBLY RTD300 97SA316600

A0400 265629 CAPSTAN MOTOR VCR ASSEMBLY RTD300 97S8104200

A040A N/S/P CUSHION TOP EVA 20X14 CABINET ASSEMBLY RTD300 97P4219500

A040B N/S/P CUSHION TOP PLATE EVA(SOFT) T=1 175*8 CABINET ASSEMBLY RTD300 97P4219700

A0600 248353 HEAD, AC ASY VCR ASSEMBLY RTD300 97SA320500

A0601 N/S/P SCREW MACHINE BIN 3X5 MFZN VCR ASSEMBLY RTD300 7003300511

A080 N/S/P CLAMP WIRE A NYLON 66 CABINET ASSEMBLY RTD300 47P1503600

A1000 248354 ARM, LOADING ASY (L) VCR ASSEMBLY RTD300 97SA316800

A1100 248355 ARM, LOADING ASY (R) VCR ASSEMBLY RTD300 97SA316900

A1200 257436 BRACKET RACK LOADING VCR ASSEMBLY RTD300 97S2709510

A1201 248357 SCREW VCR ASSEMBLY RTD300 7008301911

A1400 253266 BRACKET DECK ASY VCR ASSEMBLY RTD300 97S0904310

A1500 253267 REEL ASY VCR ASSEMBLY RTD300 97SA319410

A1501 N/S/P SCREW TAPPTITE TT3 BIN 3X5 MFZN VCR ASSEMBLY RTD300 7273300511

A1700 235630 BELT, REEL VCR ASSEMBLY RTD300 97S5500400

A1800 248360 LEVER, RELAY VCR ASSEMBLY RTD300 97S2623200

A1900 248361 RACK, FL VCR ASSEMBLY RTD300 97S2709600

A2000 248362 GEAR, CAM VCR ASSEMBLY RTD300 97S2708200

A2100 253269 PINCH LEVER TOP VCR ASSEMBLY RTD300 97SA317150

A2200 257437 BRACKET ASY VCR ASSEMBLY RTD300 97SA318050

A2201 N/S/P SCREW TAPPTITE TT3 BIN 3X6 MFZN VCR ASSEMBLY RTD300 7273300611

A2400 253270 IDLER PLATE VCR ASSEMBLY RTD300 97SA317310

A2401 229769 WASHER VCR ASSEMBLY RTD300 97S3108200

A2600 248368 REEL VCR ASSEMBLY RTD300 97S2909400

A2700 248370 LEVER, TENSION ASY VCR ASSEMBLY RTD300 97SA317200

A2800 248375 BRAKE, S ASY VCR ASSEMBLY RTD300 97SA317400

A2900 253271 BRAKE ASY VCR ASSEMBLY RTD300 97SA317510

A3000 257438 HEAD FE VCR ASSEMBLY RTD300 97S8023700

A3001 DISCON_STK SCREW VCR ASSEMBLY RTD300 7274300811

AD001 265603 VIDEO HEAD/CYLINDER ASSEMBLY VCR ASSEMBLY RTD300 97PA296001

AD002 N/S/P SCREW MACHINE BIN 3X5 MFZN VCR ASSEMBLY RTD300 7003300511

AF001 265604 FRONT LOAD ASSEMBLY VCR ASSEMBLY RTD300 97SA261070

AF002 N/S/P SCREW TAPPTITE TT3 BIN 3X5 MFZN VCR ASSEMBLY RTD300 7273300511

AJ01A N/S/P SCREW TAPTITE TT2 BIN 3X8 BK CABINET ASSEMBLY RTD300 7173300812

AL06 265598 FOOT CUSHION FRONT PANEL ASSEMBLY RTD300 97P4220200

AN002 N/S/P GREASE DELUXE 5221G(NAM-YOUNG) VCR ASSEMBLY RTD300 2291131304

ANTENNA 265531 ANTENNA, AM INCLUDED ACCESSORIES RTD300 97P6800200

ANTENNA 265532 ANTENNA, FM INCLUDED ACCESSORIES RTD300 97P6800100

AP01A N/S/P SCREW TAPPTITE TT2 RND 3*8 MFZN CABINET ASSEMBLY RTD300 7173300811

AZ01A N/S/P SCREW TAPPTITE TT2 RND 3*8 MFZN CABINET ASSEMBLY RTD300 7173300811

AZ03A DISCON_STK SCREW, 3MMD X 10MM CABINET ASSEMBLY RTD300 7174301011

B0610 N/S/P HEAD A/C HVMXA1101A(ALPS) VCR ASSEMBLY RTD300 97SA326800

B1910 N/S/P PINCH ROLLER AS D15(DAEJIN D2.6*D7*T4.5) VCR ASSEMBLY RTD300 97SA481050

B2040 265592 CONNECTOR, 6-PIN VCR ASSEMBLY RTD300 97P885X146

B701 241930 CAP .65 TIN COATING FRONT PANEL ASSEMBLY RTD300 85801065GY

BF241 265626 BEAD, 600 OHM POWER AMP ASSEMBLY RTD300 HLB601M01B

BF242 265626 BEAD, 600 OHM POWER AMP ASSEMBLY RTD300 HLB601M01B

BF243 265626 BEAD, 600 OHM POWER AMP ASSEMBLY RTD300 HLB601M01B

BF244 265626 BEAD, 600 OHM POWER AMP ASSEMBLY RTD300 HLB601M01B

BF245 265626 BEAD, 600 OHM POWER AMP ASSEMBLY RTD300 HLB601M01B

BF246 265626 BEAD, 600 OHM POWER AMP ASSEMBLY RTD300 HLB601M01B

C101 265591 CAP LYTC 470UF 10V MAIN BOARD ASSY RTD300 CEXF1A471V

C102 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C103 187815 CAPCD .1UF Z 50V MAIN BOARD ASSY RTD300 CCZF1H104Z

C104 156245 CAPCD .022UF Z 25V MAIN BOARD ASSY RTD300 CBZF1E223Z

C105 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C106 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C107 257416 CAPCC 50V 8 PF MAIN BOARD ASSY RTD300 HCQK809DBA

C108 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C108A 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C109 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C110 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

Page 1 of 19

Page 40

RTD300

Symbol Stock Description Circuit Model TypeCode Drawing Notes

C111 265560 CAP LYTC 22UF 50V MAIN BOARD ASSY RTD300 CEXF1H220V

C113 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C117 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C118 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C120 187815 CAPCD .1UF Z 50V MAIN BOARD ASSY RTD300 CCZF1H104Z

C121 187815 CAPCD .1UF Z 50V MAIN BOARD ASSY RTD300 CCZF1H104Z

C123 265591 CAP LYTC 470UF 10V MAIN BOARD ASSY RTD300 CEXF1A471V

C132 265591 CAP LYTC 470UF 10V MAIN BOARD ASSY RTD300 CEXF1A471V

C138 265591 CAP LYTC 470UF 10V MAIN BOARD ASSY RTD300 CEXF1A471V

C142 253212 CAPCC 200PF 50V 5% MAIN BOARD ASSY RTD300 HCQK201JBA

C148 265591 CAP LYTC 470UF 10V MAIN BOARD ASSY RTD300 CEXF1A471V

C149 265591 CAP LYTC 470UF 10V MAIN BOARD ASSY RTD300 CEXF1A471V

C200 265591 CAP LYTC 470UF 10V POWER AMP ASSEMBLY RTD300 CEXF1A471V

C201 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C202 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

C203 265550 CAP CC .0027UF 50V X7R MAIN BOARD ASSY RTD300 HCBK272KBA

C204 265551 CAP CC 680PF 50V X7R MAIN BOARD ASSY RTD300 HCBK681KBA

C206 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

C208 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

C209 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C210 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C210 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C211 265563 CAP LYTC 220UF 6.3V POWER AMP ASSEMBLY RTD300 CEXE0J221S

C212 265563 CAP LYTC 220UF 6.3V POWER AMP ASSEMBLY RTD300 CEXE0J221S

C212 178842 CAP LYTC 4.7UF 50V MAIN BOARD ASSY RTD300 CEXF1H479A

C213 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C214 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C215 265563 CAP LYTC 220UF 6.3V POWER AMP ASSEMBLY RTD300 CEXE0J221S

C216 265543 CAP CC 470PF 50V MAIN BOARD ASSY RTD300 HCQK471JBA

C216 265563 CAP LYTC 220UF 6.3V POWER AMP ASSEMBLY RTD300 CEXE0J221S

C217 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C217 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C218 193043 CAP LYTC 47UF 25V MAIN BOARD ASSY RTD300 CEXF1E470V

C219 253199 CAP POLY.015MF 100V 5% MAIN BOARD ASSY RTD300 CMXM2A153J

C220 253200 CAPCC 390PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK391KBA

C221 265542 CAP CC 39PF 50V POWER AMP ASSEMBLY RTD300 HCQK390JBA

C221 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

C222 265542 CAP CC 39PF 50V POWER AMP ASSEMBLY RTD300 HCQK390JBA

C223 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C223 178842 CAP LYTC 4.7UF 50V MAIN BOARD ASSY RTD300 CEXF1H479A

C227 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C228 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C231 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C231 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C232 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C232 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C233 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C234 265544 CAP CC 47PF 50V POWER AMP ASSEMBLY RTD300 HCQK470JBA

C234 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C235 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C236 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C237 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C238 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C239 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C240 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C240 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C241 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C241 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C242 265549 CAP CC .0012UF 50V X7R MAIN BOARD ASSY RTD300 HCBK122KBA

C242 253206 CAPCC 1000PF 50V X7R 10% POWER AMP ASSEMBLY RTD300 HCBK102KBA

C243 265549 CAP CC .0012UF 50V X7R POWER AMP ASSEMBLY RTD300 HCBK122KBA

C243 265549 CAP CC .0012UF 50V X7R MAIN BOARD ASSY RTD300 HCBK122KBA

C244 265535 CAP CC 100PF 50V POWER AMP ASSEMBLY RTD300 HCQK101JBA

C245 265535 CAP CC 100PF 50V POWER AMP ASSEMBLY RTD300 HCQK101JBA

C246 265547 CAP CC .1MF 50V X7R POWER AMP ASSEMBLY RTD300 HCBK104KBA

C247 265553 CAP LYTC 100UF 10V POWER AMP ASSEMBLY RTD300 CEXP1A101A

C248 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C249 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C250 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C251 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C251 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C252 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C252 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C253 178842 CAP LYTC 4.7UF 50V MAIN BOARD ASSY RTD300 CEXF1H479A

C253 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C254 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C254 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C255 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C255 178842 CAP LYTC 4.7UF 50V MAIN BOARD ASSY RTD300 CEXF1H479A

C256 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

Page 2 of 19

Page 41

RTD300

Symbol Stock Description Circuit Model TypeCode Drawing Notes

C256 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C257 265556 CAP LYTC 33UF 16V MAIN BOARD ASSY RTD300 CEXF1C330A

C257 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C258 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C258 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C259 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C259 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

C260 265590 CAPCD .015UF K 50V MAIN BOARD ASSY RTD300 CCZB1H153K

C261 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C262 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C263 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C264 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C265 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C266 188603 CAP LYTC .22MF 50V MAIN BOARD ASSY RTD300 CEXF1H228A

C267 265545 CAP CC .015UF 50V X7R MAIN BOARD ASSY RTD300 HCBK153KBA

C268 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

C269 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C270 265556 CAP LYTC 33UF 16V MAIN BOARD ASSY RTD300 CEXF1C330A

C271 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C272 265563 CAP LYTC 220UF 6.3V MAIN BOARD ASSY RTD300 CEXE0J221S

C273 178842 CAP LYTC 4.7UF 50V MAIN BOARD ASSY RTD300 CEXF1H479A

C274 265534 CAP .047MF Z 50V MAIN BOARD ASSY RTD300 CCZF1H473Z

C275 265558 CAP LYTC 3.3MF 50V MAIN BOARD ASSY RTD300 CEXF1H339A

C276 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C277 187815 CAPCD .1UF Z 50V MAIN BOARD ASSY RTD300 CCZF1H104Z

C278 187815 CAPCD .1UF Z 50V MAIN BOARD ASSY RTD300 CCZF1H104Z

C279 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C280 265550 CAP CC .0027UF 50V X7R MAIN BOARD ASSY RTD300 HCBK272KBA

C281 152242 CAP LYTC 2.2MF 50V MAIN BOARD ASSY RTD300 CEXF1H229A

C282 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C283 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C284 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C285 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C286 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C288 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

C289 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C290 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C291 253201 CAPCC 5600PF X7R 50V 10% MAIN BOARD ASSY RTD300 HCBK562KBA

C292 265546 CAP CC .022UF 50V X7R MAIN BOARD ASSY RTD300 HCBK223KBA

C293 265558 CAP LYTC 3.3MF 50V MAIN BOARD ASSY RTD300 CEXF1H339A

C294 187815 CAPCD .1UF Z 50V MAIN BOARD ASSY RTD300 CCZF1H104Z

C297 265550 CAP CC .0027UF 50V X7R MAIN BOARD ASSY RTD300 HCBK272KBA

C299 187815 CAPCD .1UF Z 50V MAIN BOARD ASSY RTD300 CCZF1H104Z

C300 265562 CAP LYTC 2200UF 50V POWER AMP ASSEMBLY RTD300 CEXF1H222C

C301 265553 CAP LYTC 100UF 10V POWER AMP ASSEMBLY RTD300 CEXP1A101A

C301 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C302 253200 CAPCC 390PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK391KBA

C302 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C303 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C303 187815 CAPCD .1UF Z 50V MAIN BOARD ASSY RTD300 CCZF1H104Z

C304 265537 CAP CC 180PF 50V MAIN BOARD ASSY RTD300 HCQK181JBA

C304 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C305 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C305 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C306 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C306 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C307 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C307 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

C308 265552 CAP TANT 1UF 50V POWER AMP ASSEMBLY RTD300 HCTDK109MC

C308 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C309 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C309 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C310 265552 CAP TANT 1UF 50V POWER AMP ASSEMBLY RTD300 HCTDK109MC

C311 265547 CAP CC .1MF 50V X7R MAIN BOARD ASSY RTD300 HCBK104KBA

C311 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C312 265559 CAP LYTC 1000UF 50V POWER AMP ASSEMBLY RTD300 CEXF1H102V

C312 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C313 265541 CAP CC 330PF 50V POWER AMP ASSEMBLY RTD300 HCQK331JCA

C313 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

C314 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C314 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C315 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C315 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C316 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C316 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C317 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C317 186999 CAPCD .01UF M 16V MAIN BOARD ASSY RTD300 CBZP1C103M

C318 265564 CAP .47MF 63V J POWER AMP ASSEMBLY RTD300 CMXL1J474J

C318 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C320 265541 CAP CC 330PF 50V POWER AMP ASSEMBLY RTD300 HCQK331JCA

Page 3 of 19

Page 42

RTD300

Symbol Stock Description Circuit Model TypeCode Drawing Notes

C321 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C322 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C322 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C323 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C323 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C324 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C324 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C325 156245 CAPCD .022UF Z 25V MAIN BOARD ASSY RTD300 CBZF1E223Z

C326 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

C326 265564 CAP .47MF 63V J POWER AMP ASSEMBLY RTD300 CMXL1J474J

C327 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C328 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C329 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C330 265559 CAP LYTC 1000UF 50V POWER AMP ASSEMBLY RTD300 CEXF1H102V

C330 265534 CAP .047MF Z 50V MAIN BOARD ASSY RTD300 CCZF1H473Z

C331 265534 CAP .047MF Z 50V MAIN BOARD ASSY RTD300 CCZF1H473Z

C331 265553 CAP LYTC 100UF 10V POWER AMP ASSEMBLY RTD300 CEXP1A101A

C332 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C332 265534 CAP .047MF Z 50V MAIN BOARD ASSY RTD300 CCZF1H473Z

C333 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C333 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C334 265552 CAP TANT 1UF 50V POWER AMP ASSEMBLY RTD300 HCTDK109MC

C334 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C335 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C335 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C336 265552 CAP TANT 1UF 50V POWER AMP ASSEMBLY RTD300 HCTDK109MC

C336 253204 CPACC 18PF 50V 5% MAIN BOARD ASSY RTD300 HCQK180JBA

C337 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C337 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C338 265541 CAP CC 330PF 50V POWER AMP ASSEMBLY RTD300 HCQK331JCA

C338 265557 CAP LYTC .47UF 50V MAIN BOARD ASSY RTD300 CEXF1H478A

C339 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C339 186999 CAPCD .01UF M 16V MAIN BOARD ASSY RTD300 CBZP1C103M

C340 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C340 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C341 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C341 186999 CAPCD .01UF M 16V MAIN BOARD ASSY RTD300 CBZP1C103M

C342 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C342 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C343 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C343 265564 CAP .47MF 63V J POWER AMP ASSEMBLY RTD300 CMXL1J474J

C344 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C345 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C346 265541 CAP CC 330PF 50V POWER AMP ASSEMBLY RTD300 HCQK331JCA

C347 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C348 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C349 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C350 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C352 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C353 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C354 265564 CAP .47MF 63V J POWER AMP ASSEMBLY RTD300 CMXL1J474J

C360 265559 CAP LYTC 1000UF 50V POWER AMP ASSEMBLY RTD300 CEXF1H102V

C361 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C362 265553 CAP LYTC 100UF 10V POWER AMP ASSEMBLY RTD300 CEXP1A101A

C363 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C364 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C365 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C366 265552 CAP TANT 1UF 50V POWER AMP ASSEMBLY RTD300 HCTDK109MC

C367 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C368 265552 CAP TANT 1UF 50V POWER AMP ASSEMBLY RTD300 HCTDK109MC

C369 265548 CAP CC .1UF K 50V POWER AMP ASSEMBLY RTD300 HCBK104KCA

C370 265541 CAP CC 330PF 50V POWER AMP ASSEMBLY RTD300 HCQK331JCA

C371 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C372 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C373 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C374 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C375 265564 CAP .47MF 63V J POWER AMP ASSEMBLY RTD300 CMXL1J474J

C376 265541 CAP CC 330PF 50V POWER AMP ASSEMBLY RTD300 HCQK331JCA

C377 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C378 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C379 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C380 230563 CAPCC .1UF Z 50V POWER AMP ASSEMBLY RTD300 HCFK104ZCA

C382 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C383 257417 CAPCC 25V Y5V 0.1MF POWER AMP ASSEMBLY RTD300 HCFH104ZBA

C384 265564 CAP .47MF 63V J POWER AMP ASSEMBLY RTD300 CMXL1J474J

C403 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C404 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C405 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C406 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C603A 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

Page 4 of 19

Page 43

RTD300

Symbol Stock Description Circuit Model TypeCode Drawing Notes

C604 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C608 265547 CAP CC .1MF 50V X7R MAIN BOARD ASSY RTD300 HCBK104KBA

C609 265547 CAP CC .1MF 50V X7R MAIN BOARD ASSY RTD300 HCBK104KBA

C610 265535 CAP CC 100PF 50V MAIN BOARD ASSY RTD300 HCQK101JBA

C611 265535 CAP CC 100PF 50V MAIN BOARD ASSY RTD300 HCQK101JBA

C612 253197 CAPCC 470PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK471KBA

C613 265547 CAP CC .1MF 50V X7R MAIN BOARD ASSY RTD300 HCBK104KBA

C614 265547 CAP CC .1MF 50V X7R MAIN BOARD ASSY RTD300 HCBK104KBA

C615 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C616 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C617 253206 CAPCC 1000PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK102KBA

C618 265546 CAP CC .022UF 50V X7R MAIN BOARD ASSY RTD300 HCBK223KBA

C619 265546 CAP CC .022UF 50V X7R MAIN BOARD ASSY RTD300 HCBK223KBA

C621 265546 CAP CC .022UF 50V X7R MAIN BOARD ASSY RTD300 HCBK223KBA

C622 265546 CAP CC .022UF 50V X7R MAIN BOARD ASSY RTD300 HCBK223KBA

C623 265563 CAP LYTC 220UF 6.3V MAIN BOARD ASSY RTD300 CEXE0J221S

C624 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C625 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C626 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C627 186999 CAPCD .01UF M 16V MAIN BOARD ASSY RTD300 CBZP1C103M

C628 253208 CAPCC 13PF 50V CH 5% MAIN BOARD ASSY RTD300 HCQK130JBA

C629A 265535 CAP CC 100PF 50V MAIN BOARD ASSY RTD300 HCQK101JBA

C630A 265535 CAP CC 100PF 50V MAIN BOARD ASSY RTD300 HCQK101JBA

C631A 265539 CAP CC 24PF 50V MAIN BOARD ASSY RTD300 HCQK240JBA

C651 253205 CAPCC 2200PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK222KBA

C652 253206 CAPCC 1000PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK102KBA

C653 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

C654 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C655 253206 CAPCC 1000PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK102KBA

C656 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C657 265553 CAP LYTC 100UF 10V MAIN BOARD ASSY RTD300 CEXP1A101A

C658 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C659 253205 CAPCC 2200PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK222KBA

C660 253206 CAPCC 1000PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK102KBA

C661 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C662 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

C663 248303 CAP LYTC 47UF 25V MAIN BOARD ASSY RTD300 CEXF1E470A

C664 257415 CAPCC 25V Y5V 0.022MF MAIN BOARD ASSY RTD300 HCFH223ZBA

C665 186999 CAPCD .01UF M 16V MAIN BOARD ASSY RTD300 CBZP1C103M

C666 248303 CAP LYTC 47UF 25V MAIN BOARD ASSY RTD300 CEXF1E470A

C667 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

C668 265550 CAP CC .0027UF 50V X7R MAIN BOARD ASSY RTD300 HCBK272KBA

C701 265533 CAPCD 220PF K 50V FRONT PANEL ASSEMBLY RTD300 CCZB1H221K

C702 265533 CAPCD 220PF K 50V FRONT PANEL ASSEMBLY RTD300 CCZB1H221K

C703 186999 CAPCD .01UF M 16V FRONT PANEL ASSEMBLY RTD300 CBZP1C103M

C704 198559 CAPCD 1000PF K 50V FRONT PANEL ASSEMBLY RTD300 CCZB1H102K

C705 198559 CAPCD 1000PF K 50V FRONT PANEL ASSEMBLY RTD300 CCZB1H102K

C720 186999 CAPCD .01UF M 16V FRONT PANEL ASSEMBLY RTD300 CBZP1C103M

C721 193585 CAP LYTC 47UF 16V FRONT PANEL ASSEMBLY RTD300 CEXF1C470A

C722 187815 CAPCD .1UF Z 50V FRONT PANEL ASSEMBLY RTD300 CCZF1H104Z

C731 193588 CAP LYTC 10UF 16V FRONT PANEL ASSEMBLY RTD300 CEXF1C100A

C851 193043 CAP LYTC 47UF 25V MAIN BOARD ASSY RTD300 CEXF1E470V

C852 193043 CAP LYTC 47UF 25V MAIN BOARD ASSY RTD300 CEXF1E470V

C853 193043 CAP LYTC 47UF 25V MAIN BOARD ASSY RTD300 CEXF1E470V

C854 193043 CAP LYTC 47UF 25V MAIN BOARD ASSY RTD300 CEXF1E470V

C855 193043 CAP LYTC 47UF 25V MAIN BOARD ASSY RTD300 CEXF1E470V

C858 265561 CAP LYTC 47UF 50V MAIN BOARD ASSY RTD300 CEXF1H470V

CABLE 241906 CABLE, RF INCLUDED ACCESSORIES RTD300 97P880RN10

CABLE 265570 CABLE, RCA: L/R AUDIO + VIDEO INCLUDED ACCESSORIES RTD300 97P880P815

CD01 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

CD02 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD03 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD04 265538 CAP CC 220PF 50V MAIN BOARD ASSY RTD300 HCQK221JBA

CD05 253197 CAPCC 470PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK471KBA

CD06 253197 CAPCC 470PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK471KBA

CD07 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD08 253212 CAPCC 200PF 50V 5% MAIN BOARD ASSY RTD300 HCQK201JBA

CD09 253241 CAPCC 2200PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK182KBA

CD10 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD11 265538 CAP CC 220PF 50V MAIN BOARD ASSY RTD300 HCQK221JBA

CD12 253197 CAPCC 470PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK471KBA

CD13 253197 CAPCC 470PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK471KBA

CD14 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD15 253212 CAPCC 200PF 50V 5% MAIN BOARD ASSY RTD300 HCQK201JBA

CD16 253241 CAPCC 2200PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK182KBA

CD17 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

CD18 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CD19 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

CD20 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CD21 265540 CAP CC 330PF 50V MAIN BOARD ASSY RTD300 HCQK331JBA

Page 5 of 19

Page 44

RTD300

Symbol Stock Description Circuit Model TypeCode Drawing Notes

CD22 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

CD23 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

CD26 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

CD27 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CD28 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

CD29 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CD30 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

CD33 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD34 265536 CAP CC 10PF 50V MAIN BOARD ASSY RTD300 HCQK100JBA

CD37 265536 CAP CC 10PF 50V MAIN BOARD ASSY RTD300 HCQK100JBA

CD38 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD41 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD42 265536 CAP CC 10PF 50V MAIN BOARD ASSY RTD300 HCQK100JBA

CD43 253205 CAPCC 2200PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK222KBA

CD44 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

CD45 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CD46 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD47 265536 CAP CC 10PF 50V MAIN BOARD ASSY RTD300 HCQK100JBA

CD48 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD49 253205 CAPCC 2200PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK222KBA

CD50 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

CD51 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CD52 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CD53 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

CD54 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

CD55 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CD56 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

CD69 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

CD70 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CM34 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CM36 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

CM56 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

CM57 193588 CAP LYTC 10UF 16V MAIN BOARD ASSY RTD300 CEXF1C100A

CM58 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CM59 265538 CAP CC 220PF 50V MAIN BOARD ASSY RTD300 HCQK221JBA

CM60 265543 CAP CC 470PF 50V MAIN BOARD ASSY RTD300 HCQK471JBA

CM61 265540 CAP CC 330PF 50V MAIN BOARD ASSY RTD300 HCQK331JBA

CM62 195894 CAP LYTC 100UF 10V MAIN BOARD ASSY RTD300 CEXF1A101V

CM65 265555 CAP LYTC 22UF 16V MAIN BOARD ASSY RTD300 CEXF1C220A

CM66 265538 CAP CC 220PF 50V MAIN BOARD ASSY RTD300 HCQK221JBA

CM67 265543 CAP CC 470PF 50V MAIN BOARD ASSY RTD300 HCQK471JBA

CM68 265540 CAP CC 330PF 50V MAIN BOARD ASSY RTD300 HCQK331JBA

CM69 195894 CAP LYTC 100UF 10V MAIN BOARD ASSY RTD300 CEXF1A101V

CS05 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CS06 253197 CAPCC 470PF 50V X7R 10% MAIN BOARD ASSY RTD300 HCBK471KBA

CS07 257417 CAPCC 25V Y5V 0.1MF MAIN BOARD ASSY RTD300 HCFH104ZBA

CS08 253193 CAPCC .01MF 50V 10% MAIN BOARD ASSY RTD300 HCBK103KBA

CS09 193585 CAP LYTC 47UF 16V MAIN BOARD ASSY RTD300 CEXF1C470A

CS10 193586 CAP LYTC 1UF 50V MAIN BOARD ASSY RTD300 CEXF1H109A

CS11 253212 CAPCC 200PF 50V 5% MAIN BOARD ASSY RTD300 HCQK201JBA

D101 241855 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ5R1BSB

D101A 265601 DIODE, ZENER: 7.5V MAIN BOARD ASSY RTD300 DZUZ7R5BSC

D102A 265601 DIODE, ZENER: 7.5V MAIN BOARD ASSY RTD300 DZUZ7R5BSC

D103 241855 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ5R1BSB

D103A 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D104A 265601 DIODE, ZENER: 7.5V MAIN BOARD ASSY RTD300 DZUZ7R5BSC

D105 241855 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ5R1BSB

D105A 265601 DIODE, ZENER: 7.5V MAIN BOARD ASSY RTD300 DZUZ7R5BSC

D106A 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D107 241855 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ5R1BSB

D107A 265601 DIODE, ZENER: 7.5V MAIN BOARD ASSY RTD300 DZUZ7R5BSC

D108A 265601 DIODE, ZENER: 7.5V MAIN BOARD ASSY RTD300 DZUZ7R5BSC

D109 241855 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ5R1BSB

D109A 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D110A 241863 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ13BSBD111 241855 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ5R1BSB

D111A 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D112 241855 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ5R1BSB

D112A 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D113 241855 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ5R1BSB

D113A 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D114 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D114A 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D223 198599 DIODE POWER AMP ASSEMBLY RTD300 DZN4004--D253 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148---

D601 198599 DIODE MAIN BOARD ASSY RTD300 DZN4004--D602 198599 DIODE MAIN BOARD ASSY RTD300 DZN4004--D603 198599 DIODE MAIN BOARD ASSY RTD300 DZN4004--D604 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D605 DISCON_STK CAP WIRE COPPER 0.6X52MM MAIN BOARD ASSY RTD300 85801060TA

Page 6 of 19

Page 45

RTD300

Symbol Stock Description Circuit Model TypeCode Drawing Notes

D606 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D607 198589 DIODE MAIN BOARD ASSY RTD300 DZN4148--D705 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D706 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D707 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D708 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D709 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D710 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D711 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D720 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D721 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D722 265627 DIODE, LED FRONT PANEL ASSEMBLY RTD300 DSRM5670AD723 265627 DIODE, LED FRONT PANEL ASSEMBLY RTD300 DSRM5670AD731 241855 DIODE ZENER FRONT PANEL ASSEMBLY RTD300 DZUZ5R1BSB

D732 265601 DIODE, ZENER: 7.5V FRONT PANEL ASSEMBLY RTD300 DZUZ7R5BSC

D733 265601 DIODE, ZENER: 7.5V FRONT PANEL ASSEMBLY RTD300 DZUZ7R5BSC

D734 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D735 265601 DIODE, ZENER: 7.5V FRONT PANEL ASSEMBLY RTD300 DZUZ7R5BSC

D736 265601 DIODE, ZENER: 7.5V FRONT PANEL ASSEMBLY RTD300 DZUZ7R5BSC

D737 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D738 265601 DIODE, ZENER: 7.5V FRONT PANEL ASSEMBLY RTD300 DZUZ7R5BSC

D739 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D740 198589 DIODE FRONT PANEL ASSEMBLY RTD300 DZN4148--D851 198599 DIODE MAIN BOARD ASSY RTD300 DZN4004--D852 DISCON_STK CAP WIRE COPPER 0.6X52MM MAIN BOARD ASSY RTD300 85801060TA

D853 DISCON_STK CAP WIRE COPPER 0.6X52MM MAIN BOARD ASSY RTD300 85801060TA

D854 241863 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ13BSBD855 198599 DIODE MAIN BOARD ASSY RTD300 DZN4004--D856 241855 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ5R1BSB

D857 198599 DIODE MAIN BOARD ASSY RTD300 DZN4004--D858 241856 DIODE ZENER MAIN BOARD ASSY RTD300 DZUZ3R9BSA

D859 265600 DIODE, ZENER: 33V MAIN BOARD ASSY RTD300 DZUZ33BSBDVD ASSY 265687 DVD MECHANISM W/ SERV/MPEG PCB DVD ASSEMBLY RTD300 97QD020200

E001 265621 JACK, HEADPHONE FRONT PANEL ASSEMBLY RTD300 97P6316100

FOOT 265628 FOOT CABINET ASSEMBLY RTD300 97Q0804201

FOOT 253259 CLIP CABINET ASSEMBLY RTD300 97P0800602

G701 265599 DISPLAY FRONT PANEL ASSEMBLY RTD300 DHNA12SM56

G701A 265605 HOLDER FOR FRONT DISPLAY FRONT PANEL ASSEMBLY RTD300 97P2348400

G702 265686 SWITCH, ROTARY FRONT PANEL ASSEMBLY RTD300 5S10102001

H701 265619 IC, REMOTE RECEIVER ORC-356HF6 FRONT PANEL ASSEMBLY RTD300 10RC356HF6

I301A N/S/P GREASE SILICON HC-300 POWER AMP ASSEMBLY RTD300 2291130217

I301B N/S/P HEAT SINK AMP AL T1.5 POWER AMP ASSEMBLY RTD300 97P4408900

I301C DISCON_STK SCREW POWER AMP ASSEMBLY RTD300 7174300811

I330A N/S/P GREASE SILICON HC-300 POWER AMP ASSEMBLY RTD300 2291130217

I330B N/S/P HEAT SINK AMP AL T1.5 POWER AMP ASSEMBLY RTD300 97P4408900

I330C DISCON_STK SCREW POWER AMP ASSEMBLY RTD300 7174300811

I360A N/S/P GREASE SILICON HC-300 POWER AMP ASSEMBLY RTD300 2291130217

I360B N/S/P HEAT SINK AMP AL T1.5 POWER AMP ASSEMBLY RTD300 97P4408900

I360C DISCON_STK SCREW POWER AMP ASSEMBLY RTD300 7174300811

IC200 265609 IC, DDX-8000 TQFP POWER AMP ASSEMBLY RTD300 1DDX8000-Q

IC210 265613 IC, 3V REGULATOR RC1117S33T POWER AMP ASSEMBLY RTD300 1RC1117S3C

IC211 265612 IC, 2.5V REGULATOR RC1117S25C POWER AMP ASSEMBLY RTD300 1RC1117S2C

IC220 265611 IC, W78E58BP POWER AMP ASSEMBLY RTD300 1W78E58B-P

IC221 265616 IC, EEPROM CAT24WC08J POWER AMP ASSEMBLY RTD300 14CAT2408J

IC222 265618 IC, S7142 POWER AMP ASSEMBLY RTD300 1S7142---IC251 253561 IC AN3663 MAIN BOARD ASSY RTD300 1AN3663--IC252 265614 IC, HEF4052B MAIN BOARD ASSY RTD300 1HEF4052BD

IC301 265608 IC, POWER AMP: DDX2100-E POWER AMP ASSEMBLY RTD300 1DDX2100-E

IC301 265606 IC, LA71207M MAIN BOARD ASSY RTD300 1LA71207MIC330 265608 IC, POWER AMP: DDX2100-E POWER AMP ASSEMBLY RTD300 1DDX2100-E

IC360 265608 IC, POWER AMP: DDX2100-E POWER AMP ASSEMBLY RTD300 1DDX2100-E

IC401 265610 IC, HEF4053B MAIN BOARD ASSY RTD300 1HEF4053BD

IC601 265617 IC, MICRO M37762M8A-8C6GP MAIN BOARD ASSY RTD300 168KT87DTS

IC603 259394 IC EEPROM S-24C08ADP-01 VCR ASSEMBLY RTD300 14SEK24D08

IC701 265620 IC, PT6315 FRONT PANEL ASSEMBLY RTD300 1PT6315--Q

ICD01 265615 IC, CS4228A-KS MAIN BOARD ASSY RTD300 1CS4228A-B

ICD02 265607 IC, KIA4558F MAIN BOARD ASSY RTD300 1K1A4558FICD03 265607 IC, KIA4558F MAIN BOARD ASSY RTD300 1K1A4558FICD04 259400 IC CHIP AMP NJM4580M MAIN BOARD ASSY RTD300 1NJM4580MC

ICD05 265607 IC, KIA4558F MAIN BOARD ASSY RTD300 1K1A4558FICD06 265607 IC, KIA4558F MAIN BOARD ASSY RTD300 1K1A4558FJ200 265577 CONNECTOR, 6-PIN POWER AMP ASSEMBLY RTD300 97P885X194

J210 265588 CONNECTOR, 5-PIN POWER AMP ASSEMBLY RTD300 97P62A09A5

JK01A N/S/P PLATE EARTH A/V C5210(PBS) T0.2 FRONT PANEL ASSEMBLY RTD300 97P0991600

JK02A N/S/P PLATE EARTH A/V C5210(PBS) T0.2 FRONT PANEL ASSEMBLY RTD300 97P0991600

JK101 265623 JACK VCR ASSEMBLY RTD300 97P6318380

JK102 259405 JACK PIN(CO) DPAM-0011 VCR ASSEMBLY RTD300 97P6318050

JK103 265622 JACK VCR ASSEMBLY RTD300 97P6318370

JK104 259403 JACK PIN(S-VHS)DUAE-9812 VCR ASSEMBLY RTD300 97P6318010