Page 1

Installation and Operation ......................... Par . 1-23 .........Pages 1-18

Check Installation and Start-Up ................. Par . 24 .............. Page 19

Optional Equipment ..................................Par . 25-31 ....... Pages 20-22

Service/Maintenance/Troubleshooting.....Par. 32-42 ....... Pages 23-28

Index by Page

Belt Tension ............................................... 16

Blower/Filter Cabinet (Optional) ...................22

Blower Motor ............................................ 16

Blower Rotation ........................................ 17

Blower Speed Adjustment ......................... 17

Bottom Access ........................................... 23

Burners ................................................ 18, 23

Burner Air Adjustment .............................. 18

Burner Rack Removal ............................... 23

Carryover, Flash ........................................ 25

Check Installation and Start-Up ................ 19

Clearances.................................................... 5

Combustion Air Proving Switch ............... 1 8

Combustion Air ....................................... 5, 6

Confined Space Installation......................... 6

Dimensional Drawings ................................ 3

Disconnect Switch (Optional) ................... 11

Duct Flange (Blower Model Option) ........ 20

INSTALLATION FORM RGM 436 (Version A)

APPLIES TO: Installation/Operation/Service

Table of Contents

Electrical Supply and Connections............ 11

Fan Blade................................................... 25

Fan Control.......................................... 17, 26

Fan Motor .................................................. 16

Gas Piping and Pressures .......................... 10

Guard Options (Blower Model) ................ 22

Hanger Kits (Optional) ................................ 7

Hazard Intensity Levels ............................... 2

Heat Exchanger ......................................... 25

Ignition System.................................... 18, 24

Installation Codes ........................................ 2

Limit Control ....................................... 17, 26

Locating the Heater ..................................... 5

Louvers, Vertical (Optional)...................... 20

Maintenance .............................................. 23

Maintenance Schedule............................... 23

Multiple Heater Control Option ................ 22

Model FE and BE

Gas-Fired, Power-Vented

Unit Heaters

Obsoletes 436-5

Nozzles, Downturn Air (Optional) ............ 20

Optional Equipment .................................. 20

Operating Sequence................................... 19

Orifices, Burner and Pilot.......................... 25

Pilot ..................................................... 18, 24

Polytube Adapter

Service ....................................................... 23

Spark Gap .................................................. 24

Suspending the Unit .................................... 6

Thermostats ............................................... 11

Troubleshooting......................................... 2 7

Uncrating and Preparation........................... 5

Valve, Gas............................................ 18, 26

Venter Motor and Relay ............................ 26

Venting ................................................... 7, 26

Warranty ...................................................... 2

Wiring Diagrams ................................12-15

(Blower Model Option) ..... 21

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

WARNING: Gas-fired appliances are not

designed for use in hazardous atmospheres

containing flammable vapors or combustible

dust, in atmospheres containing chlorinated

or halogenated hydrocarbons, or in applications with airborne silicone substances. See

Hazard Levels, Page 2.

WARNING: Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury or death. Read

the installation, operation, and maintenance

instructions thoroughly before installing or

servicing this equipment.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open

containers in the vicinity of this appliance is

hazardous.

GENERAL

Installation should be done by a qualified agency in accordance

with the instructions in this manual and in compliance with all

codes and requirements of authorities having jurisdiction. The

instructions in this manual apply to the unit heater models shown

on the right.

Model F u el Vent Air Delivery

FE

BE

G as-Fired Power Propeller Fan

Centrifugal Blower (heater

Gas -Fired Po wer

may be attached to

ductwor k)

Mfg P/N 98807 Rev 8, Page 1

Page 2

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal injury or death and/or property damage.

2. WARNING: Failure to comply could result in severe personal injury or death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal injury and/or property damage.

1. Installation Codes

The gas-fired unit heaters covered in this manual are design-certified

by the American Gas Association and approved by the Canadian Gas

Association for use with either natural or propane gas. The type of gas

for which your heater is equipped and the correct firing rate are shown

on the rating plate attached to your unit. Electrical characteristics are

shown on the motor nameplate and on the unit rating plate.

These units must be installed in accordance with local building codes.

In the absence of local codes, in the United States, the unit must be

installed in accordance with the National Fuel Gas Code (latest edition). A Canadian installation must be in accordance with the CAN/

CGA B149.1 and B149.2 Installation Code for Gas Burning Appliances and Equipment. These codes are available from CSA Information Services, 1-800-463-6727. Local authorities having jurisdiction

should be consulted before installation to verify local codes and installation procedure requirements.

Clearances from the heater and vent to combustible construction or

material in storage must conform with the National Fuel Gas Code

ANSI Z223.1a (latest edition) pertaining to gas-burning devices, and

such material must not attain a temperature over 160oF by continued

operation of the heater.

Special Installations (Aircraft Hangars/

Garages)

Installations in aircraft hangars should be in accordance with ANSI/

NFPA No. 409 (latest edition), Standard for Aircraft Hangars; in public garages in accordance with ANSI/NFPA No. 88A (latest edition),

Standard for Parking Structures; and for repair garages in accordance

with ANSI/NFPA No. 88B (latest edition), Standard for Repair Garages. ANSI/NFP A-88 (latest edition) specifies overhead heaters must

be installed at least eight feet above the floor. In Canada, installations

in aircraft hangars should be in accordance with the requirements of

the enforcing authorities, and in public garages in accordance with CAN/

CGA B149 codes.

ANSI/NFP A 409 (latest edition) specifies a clearance of ten feet to the

bottom of the heater from the highest surface of the top of the wing or

engine enclosure of whatever aircraft would be the highest to be housed

in the hangar, and a minimum clearance of eight feet from the floor in

other sections of aircraft hangars, such as the offices, and shops which

communicate with areas used for servicing or storage. The heaters must

be located so as to be protected from damage by aircraft or other objects such as cranes and movable scaffolding. In addition, the heaters

must be located so as to be accessible for servicing, adjustment, etc.

2. Warranty

Refer to limited warranty information on the warranty card in the

"Owner's Envelope".

WARRANTY: Warranty is void if......

a. Unit Heaters are used in atmospheres containing flammable

vapors or atmospheres containing chlorinated or halogenated

hydrocarbons or airborne silicone substances.

b. Wiring is not in accordance with the diagram furnished with

the heater .

c. Unit is installed without proper clearances to combustible ma-

terials or located in a confined space without proper ventilation and air for combustion. (See Paragraphs 6 and 7.)

d. Fan-type unit heater is connected to a duct system.

Form 436, Page 2

Page 3

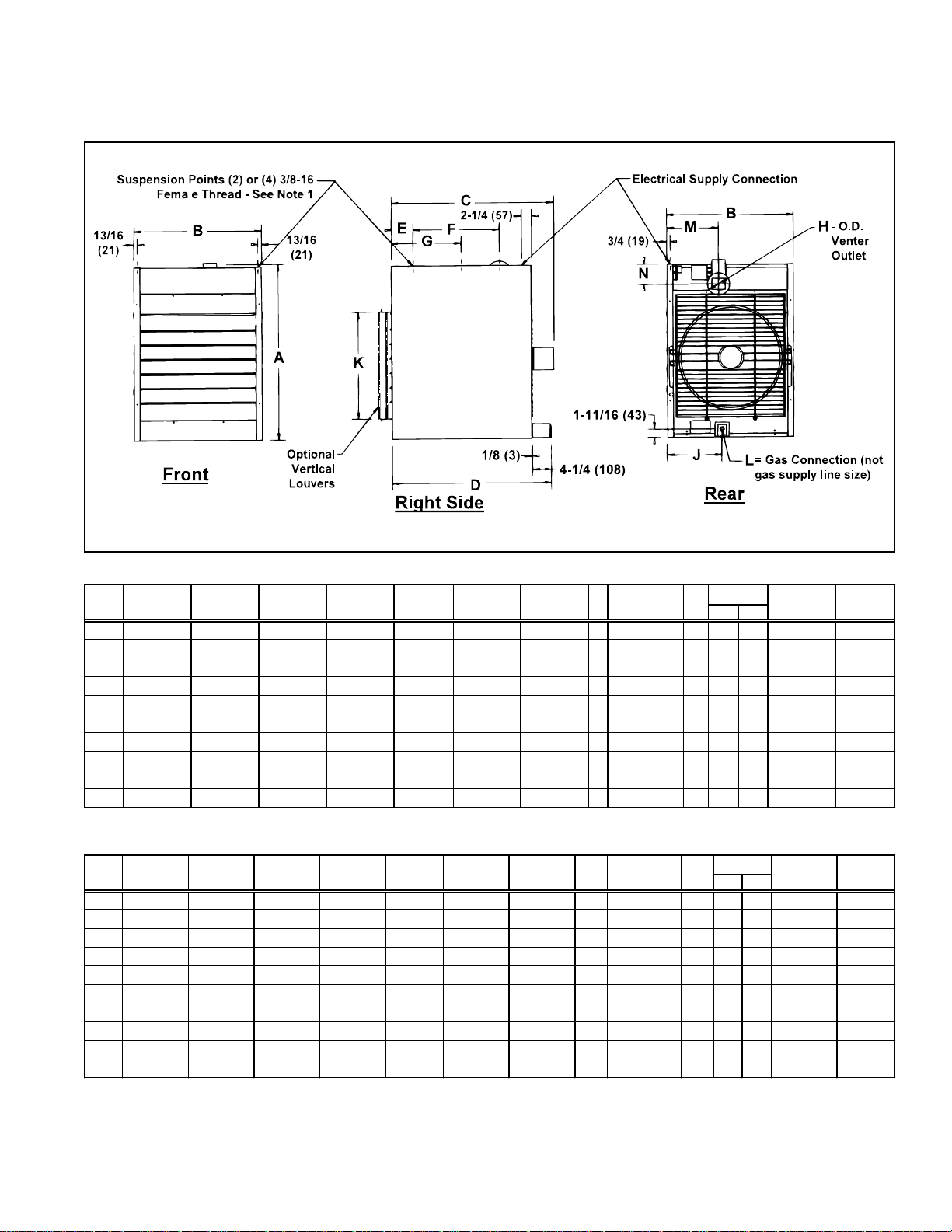

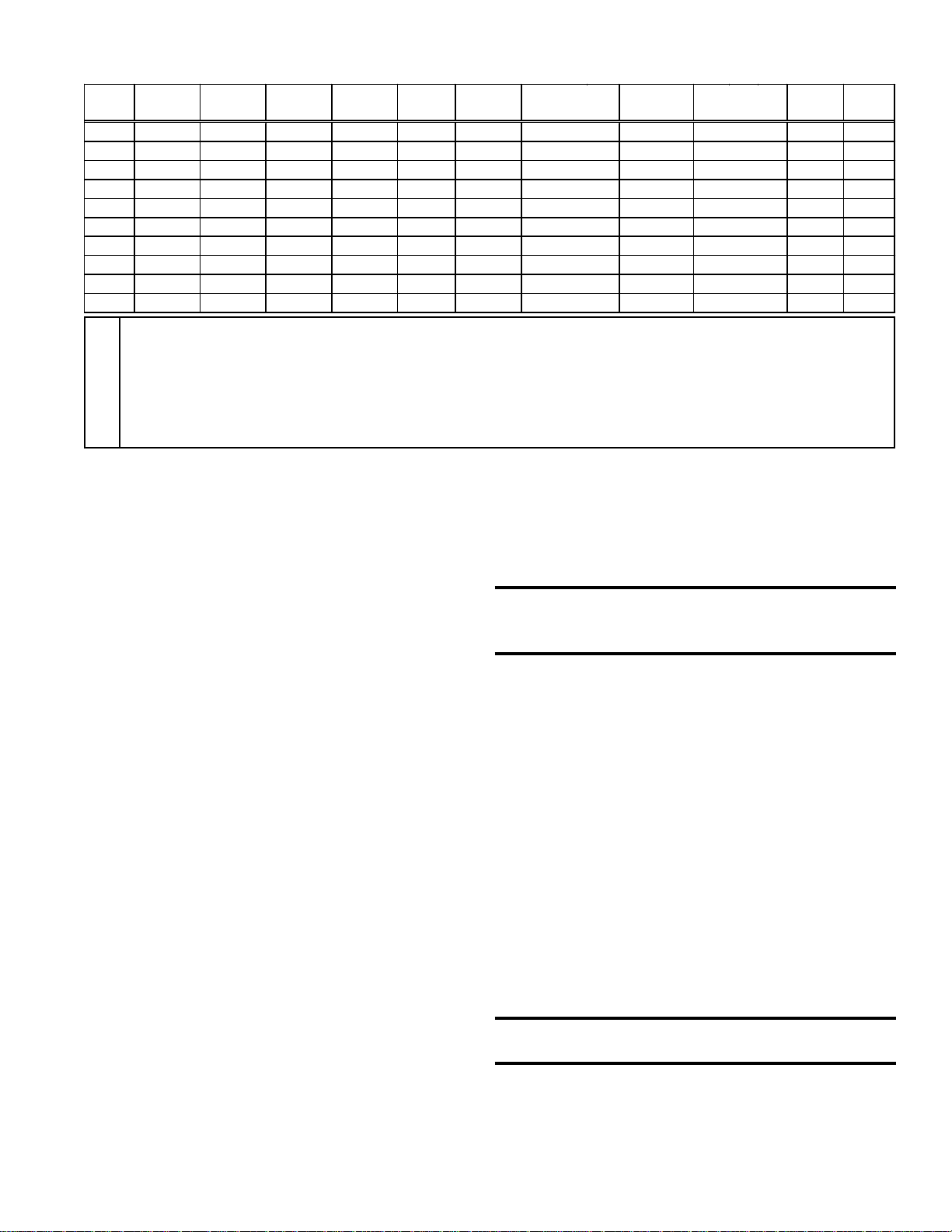

3. Dimensions

Fan-Type, Power-Vented Unit Heater

Dimensions (inches)

SizeABCDEFGHJKLMN

Nat Pro

29-25/32 13-9/16 27-1/16 31-7/ 16 5-27/32 14- 7/16 14-1/32 4 10-9/32 16 1/2 1/2 9-13/16 3

25

29-25/32 13-9/16 27-1/16 31-7/ 16 5-27/32 14- 7/16 14-1/32 4 10-9/32 16 1/2 1/2 9-13/16 3

50

29-25/32 15-9/16 27-1/16 31-7/ 16 5-27/32 14- 7/16 14-1/32 4 10-17/ 3 2 16 1/2 1/2 10-7/16 3

75

29-25/32 17-9/16 30-7/16 31-7/ 16 5-27/32 14- 7/16 14-1/32 4 12-29/ 3 2 16 1/2 1/2 10-7/16 3

100

29-25/32 23-5/16 30-7/16 31-7/ 16 5-27/32 14- 7/16 14-1/32 5 14-7/16 16 1/2 1/2 11-9/16 2-5/8

125

39-15/16 20-5/16 35-7/16 35-15/ 1 6 4-7/8 19-15/32 15-23/32 5 14-9/32 24 1/2 1/2 11-11/16 4- 1 9/32

165

39-15/16 23-5/16 36-3/16 35-15/ 1 6 4-7/8 19-15/32 15-23/32 5 14-13/32 24 1/2 1/2 11-11/16 4-19/ 32

200

39-15/16 28-13/ 1 6 36-3/16 35-15/1 6 4-7/8 19-15/32 15-23/32 5 12-11/ 32 24 1/2 1/2 11-11/16 4-19/ 32

250

39-15/16 28-13/ 1 6 36- 11/16 35-15/ 1 6 4-7/8 19-15/32 15-23/32 6 12-11/32 24 3/4 1/2 11-11/16 3-19/ 32

300

39-15/16 37-1/16 37-5/16 35-15/ 1 6 4-7/8 19-15/32 15-23/32 6 13 24 3/4 1/ 2 11-11/16 3-19/32

400

Dimensions (mm)

SizeABCDEFGHJKLMN

Nat Pro

25

50

75

100

125

165

200

250

300

400

756 344 687 799 148 367 356 102 261 406 13 13 249 76

756 344 687 799 148 367 356 102 261 406 13 13 249 76

756 395 687 799 148 367 356 102 267 406 13 13 265 76

756 446 773 799 148 367 356 102 328 406 13 13 265 76

756 592 773 799 148 367 356 127 367 406 13 13 294 67

1014 516 900 913 124 498 399 127 363 610 13 13 297 117

756 592 919 913 124 498 399 127 366 610 13 13 297 117

756 732 919 913 124 498 399 127 314 610 13 13 297 117

756 732 932 913 124 498 399 152 314 610 19 13 297 91

756 941 948 913 124 498 399 152 330 610 19 13 297 91

Suspension Notes: Use Dimension "G" for two-point suspension and "E" and "F" for four-

point suspension. (Two-point suspension is standard; four-point is optional. Four-point suspension is available either factory or field installed.)

Mfg P/N 98807 Rev 8, Page 3

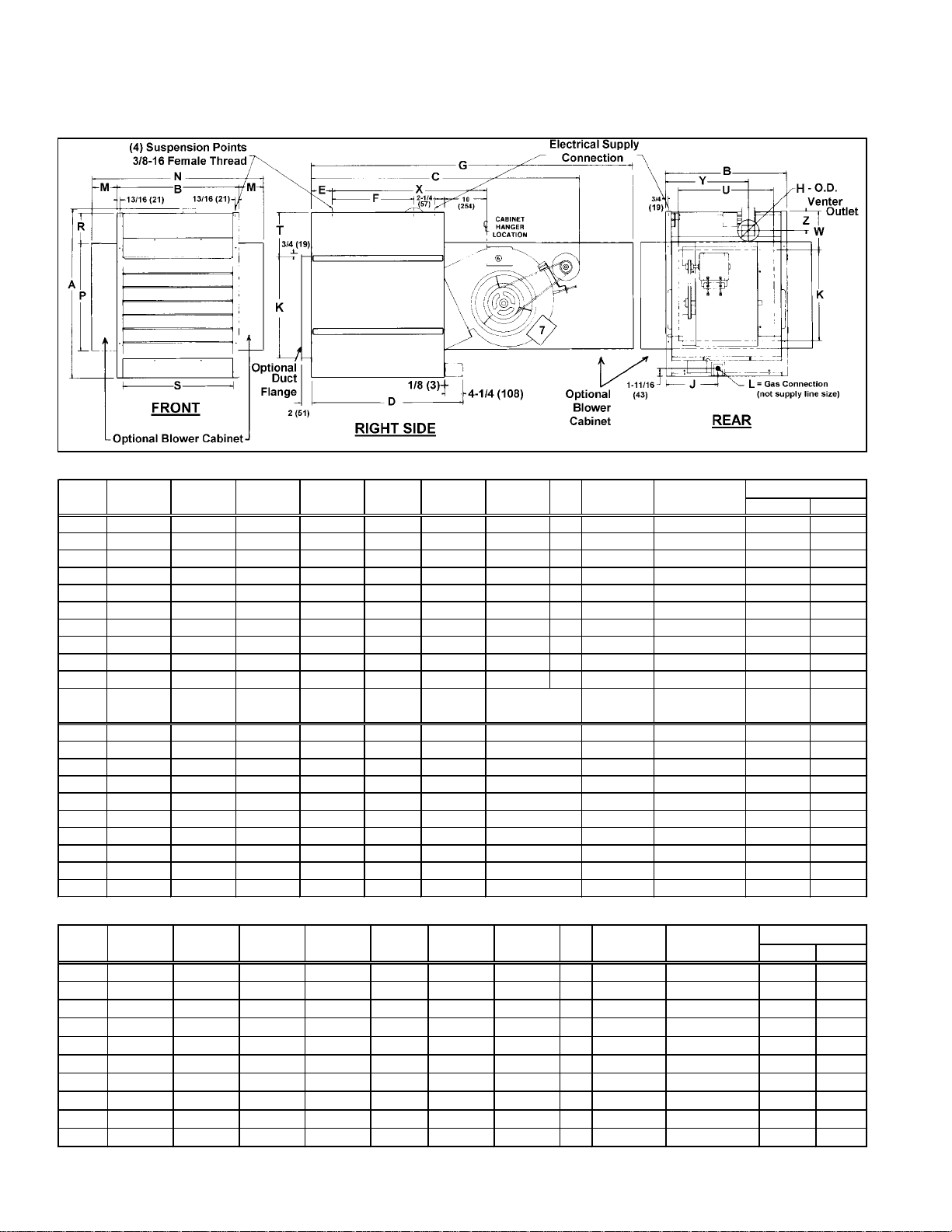

Page 4

3. Dimensions (cont'd)

Blower-Type, Power-Vented Unit Heater

Dimensions (inches)

Size

25

50

75

100

125

165

200

250

300

400

Size

25

50

75

100

125

165

200

250

300

400

Dimensions (mm)

Size

25

50

75

100

125

165

200

250

300

400

Form 436, Page 4

ABCDEF

29-25/32 13-9/16 43-3/8 31-7/16 5-27/32 14-7/16 61-3/8 4 10-9/32 16 1/2 1/2

29-25/32 13-9/16 50 31-7/16 5-27/32 14 -7/16 61-3/8 4 10-9/32 16 1/2 1/2

29-25/32 15-9/16 50 31-7/16 5-27/32 14 -7/16 61-3/8 4 10-17/32 16 1/2 1/2

29-25/32 17-9/16 50 31-7/16 5-27/32 14 -7/16 61-3/8 4 12-29/32 16 1/2 1/2

29-25/32 23-5/16 47-1/2 31-7/16 5-27/32 14-7/16 65-29/32 5 14-7/16 16 1/2 1/2

39-15/16 20-5/16 61 35-15/16 4-7/8 19-15/32 76-1/8 5 14-9/32 24 1/2 1/2

39-15/16 23-5/16 66-1/2 35-15/16 4-7/8 19-15/32 76-1/8 5 14-13/32 24 1/2 1/2

39-15/16 28-13/16 66-1/2 35-15/16 4-7/8 19-15/32 76-1/8 5 12-11/32 24 1/2 1/2

39-15/16 28-13/16 66-1/2 35-15/16 4-7/8 19-15/32 76-1/8 6 12-11/32 24 3/4 1/2

39-15/16 37-1/16 66-1/2 35-15/16 4-7/8 19-15/32 76-1/8 6 13 24 3/4 1/2

MNPRST U W

3-23/32 20-15/16 17-3/4 5-1/4 10-3/4 8-7/16 14-3/4 6-3/16 31-7/32 9-13/16 3

3-23/32 20-15/16 17-3/4 5-1/4 10-3/4 8-7/16 14-3/4 6-3/16 31-7/32 9-13/16 3

2-23/32 20-15/16 17-3/4 5-1/4 12-3/4 8-7/16 14-3/4 6-3/16 31-7/32 10-7/16 3

1-23/32 20-15/16 17-3/4 5-1/4 14-3/4 8-7/16 14-3/4 6-3/16 31-7/32 10-7/16 3

1-11/32 20-15/16 17-3/4 5-1/4 20-1/2 8-7/16 20-1/2 6-3/16 35-3/4 11-9/16 2-5/8

2-27/32 25-15/16 25-1/4 7-1/4 17-1/2 11-7/16 20-1/2 7-15/16 36-11/16 11-11/1 6 4-19/32

1-11/32 25-15/16 25-1/4 7-1/4 20-1/2 11-7/16 20-1/2 7-15/16 36-11/16 11-11/1 6 4-19/32

5-29/32 40-9/16 25-1/4 7-1/4 26 11-7/16 26 7-15/16 36-11/16 11-11/16 4-19/32

5-29/32 40-9/16 25-1/4 7-1/4 26 11-7/16 26 7-15/16 36-11/16 11-11/16 3-19/32

6-25/32 50-9/16 25-1/4 7-1/4 34-1/4 11-7/16 34-1/4 7-15/16 36-11/16 11-11/16 3-19/32

ABCDEF

756 344 1102 799 148 367 1559 102 261 406 13 13

756 344 1270 799 148 367 1559 102 261 406 13 13

756 395 1270 799 148 367 1559 102 267 406 13 13

756 446 1270 799 148 367 1559 102 328 406 13 13

756 592 1207 799 148 367 1674 127 367 406 13 13

1014 516 1549 913 124 495 1934 127 363 610 13 13

1014 592 1689 913 124 495 1934 127 366 610 13 13

1014 732 1689 913 124 495 1934 127 314 610 13 13

1014 732 1689 913 124 495 1934 152 314 610 19 13

1014 914 1689 913 124 495 1934 152 330 610 19 13

Hanger

Hanger

GH J K L

XYZ

Nat Pro

Hanger

GH J K L

Nat Pro

Page 5

Size

25

50

75

100

125

165

200

250

300

400

MNPRST U W

94 532 48 1 133 273 214 375 157 793 249 76

94 532 48 1 133 273 214 375 157 793 249 76

69 532 48 1 133 324 214 375 157 793 265 76

44 532 48 1 133 375 214 375 157 793 265 76

34 532 48 1 133 521 214 521 157 908 294 67

72 659 64 1 184 445 291 521 202 932 297 11 7

34 659 64 1 184 521 291 521 202 932 297 11 7

150 1030 641 184 660 291 660 202 932 297 117

150 1030 641 184 660 291 660 202 932 297 91

172 1284 641 184 870 291 870 202 932 297 91

XYZ

Hanger

When equipped with optional blower cabinet.

When equipped with optional duct flange.

Dimension includes a 3/4" flange on the rear of the blower

cabinet.

NOTES

Use with 4-point suspension without blower cabinet. If

installing hanger kit Option CK19, suspension points

change; see Paragraph 8.

4. Uncrating and Preparation

This unit was test operated and inspected at the factory prior to crating and was in operating condition. If the heater has incurred any

damage in shipment, file a claim with the transporting agency.

Check the rating plate for the gas specifications and electrical characteristics of the heater to be sure that they are compatible with the

gas and electric supplies at the installation site. Read this booklet

and become familiar with the installation requirements of your particular heater. If you do not have knowledge of local requirements,

check with the local gas company or any other local agencies who

might have requirements concerning this installation. Before beginning, make preparations for necessary supplies, tools, and manpower.

Check to see if there are any field-installed options that need to be

assembled to the heater prior to installation. Each of the option packages includes a list of components and step-by-step instructions. For

a brief description of optional hanger kits, refer to Paragraph 8. For a

brief explanation of other frequently specified field-installed options,

see Paragraphs 25-31. After becoming familiar with the instructions,

assemble and install the options that are required for your heater.

If the heater was ordered with a vent cap shipped with the heater

(Option BT2), packaging depends on the size of the heater. Sizes 25

and 50 have the vent cap mounted on a shipping tube that is attached

to the venter housing. Remove the vent cap; remove and discard the

shipping tube. Sizes 100, 165, 200, 250, 300 and 400 have the vent

cap attached directly to the venter housing. Size 125 is shipped with

the vent cap mounted on the crate near the gas valve. Remove the

vent cap for field installation at the vent terminal.

Unless the crate bottom has been removed for option installation,

leave it attached until after the heater has been suspended. If the

crate bottom has been removed, the bottom of the heater must be

supported with plywood or appropriately placed boards. Without

adequate support, the bottom access panel could be damaged.

To protect the unit during shipping, the blower model has special

supports that must be removed before installation. Follow these instructions to remove:

oBlower Support Legs -- Remove the two blower support legs and

screws.

oMotor Shipping Block - Remove the wooden block located under

the motor bracket. Find the two rubber pads shipped in the instruction envelope. Place these pads on the ends of the motor

bracket bolts.

Use with 4-point suspension with blower cabinet.

Contactor is standard on Models 300 and 400; optional on other

sizes.

Contactor location with optional three phase motors on Sizes 50,

75, 100 and 125.

Deduct 6-5/8" on Sizes 50, 75, and 100 when equipped with

direct drive motor.

oMotor Shipping Plate -- Blower models that are equipped with motors

of 3/4 HP or less have a metal shipping plate attached between the

motor and the blower housing. Remove and discard the shipping plate.

Note: On units factory equipped with an optional belt guard, the belt

guard must be removed in order to reach the shipping plate.

5. Unit Heater Location

CAUTION: A void installing a unit heater in extremely

drafty areas. Extreme drafts can shorten the life of the

heat exchanger and/or cause safety problems.

For best results, the heater should be placed with certain rules in mind. In

general, a unit should be located from 8 to 12 feet above the floor. Units

should always be arranged to blow toward or along exposed wall surfaces, if possible. Where two or more units are installed in the same room,

a general scheme of air circulation should be maintained for best results.

Suspended heaters are most effective when located as close to the working zone as possible, and this fact should be kept in mind when determining the mounting heights to be used. However, care should be exercised

to avoid directing the discharged air directly on the room occupants.

Partitions, columns, counters, or other obstructions should be taken into

consideration when locating the unit heater so that a minimum quantity

of airflow will be deflected by such obstacles.

When units are located in the center of the space to be heated, the air

should be discharged toward the exposed walls. In large areas, units should

be located to discharge air along exposed walls with extra units provided

to discharge air in toward the center of the area.

At those points where infiltration of cold air is excessive, such as at entrance doors and shipping doors, it is desirable to locate the unit so that it

will discharge directly toward the source of cold air from a distance of 15

to 20 feet.

Units should not be installed closer than 18 inches from any wall.

CAUTION: Do not locate the heater where it may be

exposed to water spray, rain or dripping water.

6. Clearances & Combustion Air

Units must be installed so that the following clearances are provided for

combustion air space, service and inspection, and for proper spacing from

combustible construction.

Mfg P/N 98807 Rev 8, Page 5

Page 6

6. Clearances and Combustion

Air (cont'd)

Model Required Clearances (inches and mm)

Size Top Flue Sides Bottom Rear

Collector

25-400 6"(152) 6"(152) 18"(457) 12"(305) * 24" (610)**

* When supplied with optional downturn nozzle, bottom clearance is

42"(1067mm). For service purposes, on standard units, bottom clearance exceeding minimum (12" or 305mm) is not required but may

be desirable.

** For servicing purposes only, rear must remain full open.

All fuel-burning equipment must be supplied with the air that enters

into the combustion process and is then vented to the outdoors. Sufficient air must enter the equipment location to replace that exhausted

through the heater vent system. In the past, the infiltration of outside

air assumed in heat loss calculations (one air change per hour) was

assumed to be sufficient. However, current construction methods utilizing more insulation, vapor barriers, tighter fitting and gasketed doors

and windows or weather-stripping, and mechanical exhaust fans may

now require the introduction of outside air through wall openings or

ducts.

The requirements for combustion and ventilation air depend upon

whether the unit is located in a confined or unconfined space. An "unconfined space" is defined as a space whose volume is not less than 50

cubic feet per 1000 BTUH of the installed appliance. Under all condi-

tions, enough air must be provided to ensure there will not be a negative pressure condition within the equipment room or space. For specific requirements for confined space installation, see Paragraph 7.

W ARNING: These power-vented unit heaters ar e

designed to take combustion air from the space

in which the unit is installed and are not designed

for connection to outside combustion air intake

ducts. Connecting outside air ducts voids the

warranty and could cause hazardous operation.

See Hazard Levels, Page 2.

7. Combustion Air Requirements

for a Heater Located in a

Confined Space

Do not install a unit in a confined space without providing wall openings leading to and from the space. Provide openings near the floor

and ceiling for ventilation and air for combustion as shown in Figure

1, depending on the combustion air source as noted in Items 1, 2, and

3 below the illustration.

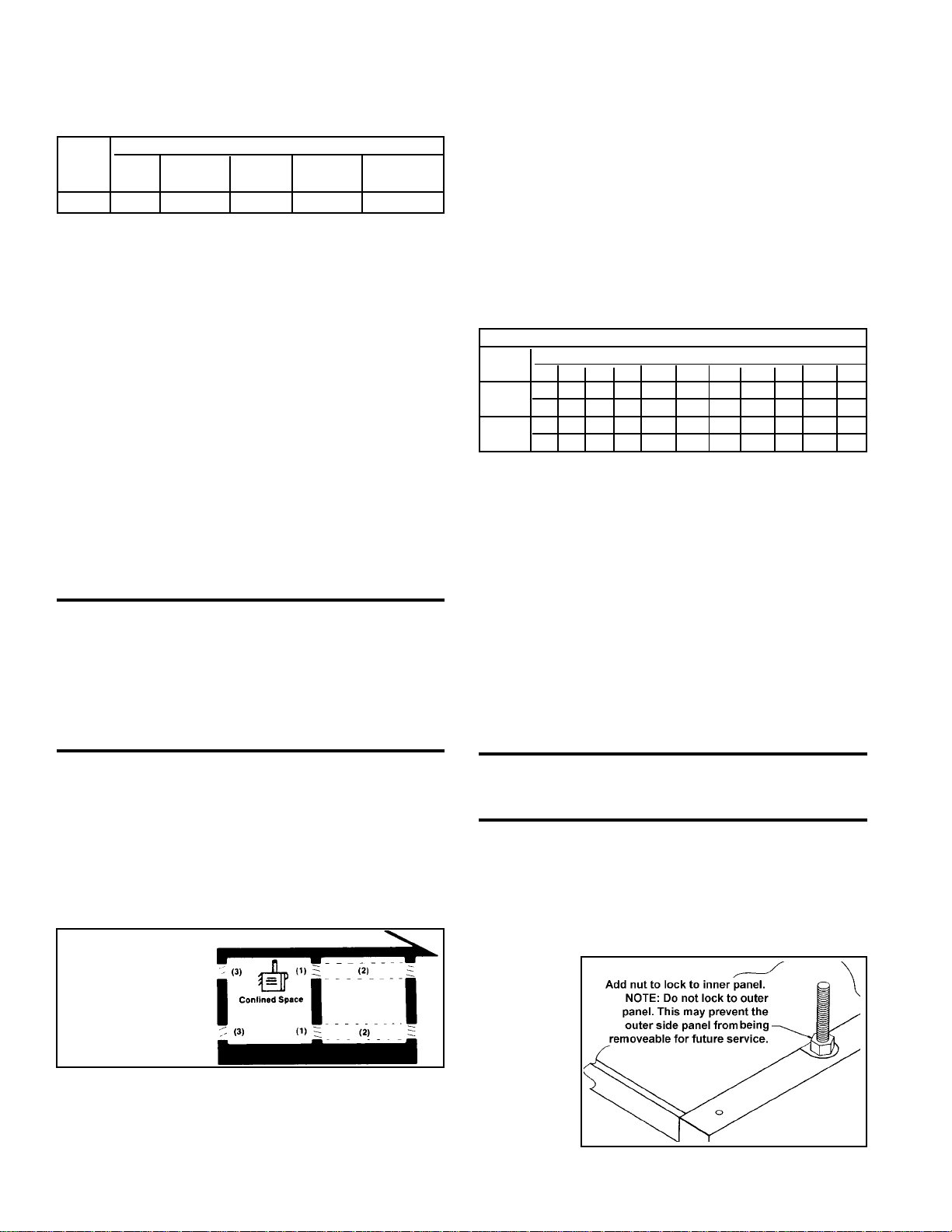

Figure 1 Confined Space: A

space whose volume is

less than 50 cubic feet

per 1000 BTUH of the

installed appliance

input rating

Add total BTUH of all appliances in the confined space and divide by

figures below for square inch free area size of each (top and bottom)

opening.

1. Air from inside the building -- openings 1 square inch free area per

1000 BTUH. Never less than 100 square inches free area for each opening. See (1) in Figure 1.

2. Air from outside through duct -- openings 1 square inch free area

per 2000 BTUH. See (2) in Figure 1.

3. Air direct from outside -- openings 1 square inch free area per 4000

BTUH. See (3) in Figure 1.

NOTE: For further details on supplying combustion air to a confined

space, see the National Fuel Gas Code ANSI Z223.1a (latest edition ).

8. Suspending the Heater

Before suspending the heater, check the supporting structure to be used

to verify that it has sufficient load-carrying capacity to support the weight

of the unit.

Net Weight (lbs and kg)

Model Size

Type 25 50 75 100 125 165 200 250 300 400

Fan lbs 76 83 92 101 132 154 175 209 226 281

kg 34 38 42 46 60 70 79 95 103 127

Blower lbs 97 104 118 130 180 206 240 278 301 395

kg 44 47 54 59 82 93 109 126 137 179

NOTE: If the installation includes an optional stepdown transformer

kit (Option CF or CG), the stepdown transformer bracket is part of the

heater suspension and must be installed prior to hanging the heater.

Follow the instructions on the installation sheet included with the option kit.

A fan-type unit heater is equipped with standard two-point suspen-

sion. A 3/8-16 threaded hanger bracket assembly is located on each

side of the heater. If a fan-type unit has been ordered with optional,

factory-installed, four-point suspension (Option BJ6), it will have two

threaded hanger brackets on each side.

A blower-type heater is equipped with standard four-point suspen-

sion. Two 3/8-16 threaded hanger bracket assemblies are located on

each side of the unit. Each hanger bracket assembly is designed for

threaded rod attachment.

For both "standard" and "optional" suspension point dimensions, see

Dimension Tables in Paragraph 3. (Note: If installing Option CK19

hanger kit, suspension points change; see Figure 4B.)

WARNING: Suspend the heater only from the

threaded hanger brackets. Do not suspend from

the heater side panel.

When the heater is lifted for suspension, the bottom must be protected.

If the wooden crate bottom has been removed, the bottom of the heater

will have to be supported with plywood or other appropriately placed

material. If the bottom is not supported, the bottom access panel could

be damaged. Also, when lifting a blower unit, support the blower and

motor to prevent the unit from tipping.

All blower models have legs that support the blower assembly during

shipping. After

the unit is suspended, these

legs should be

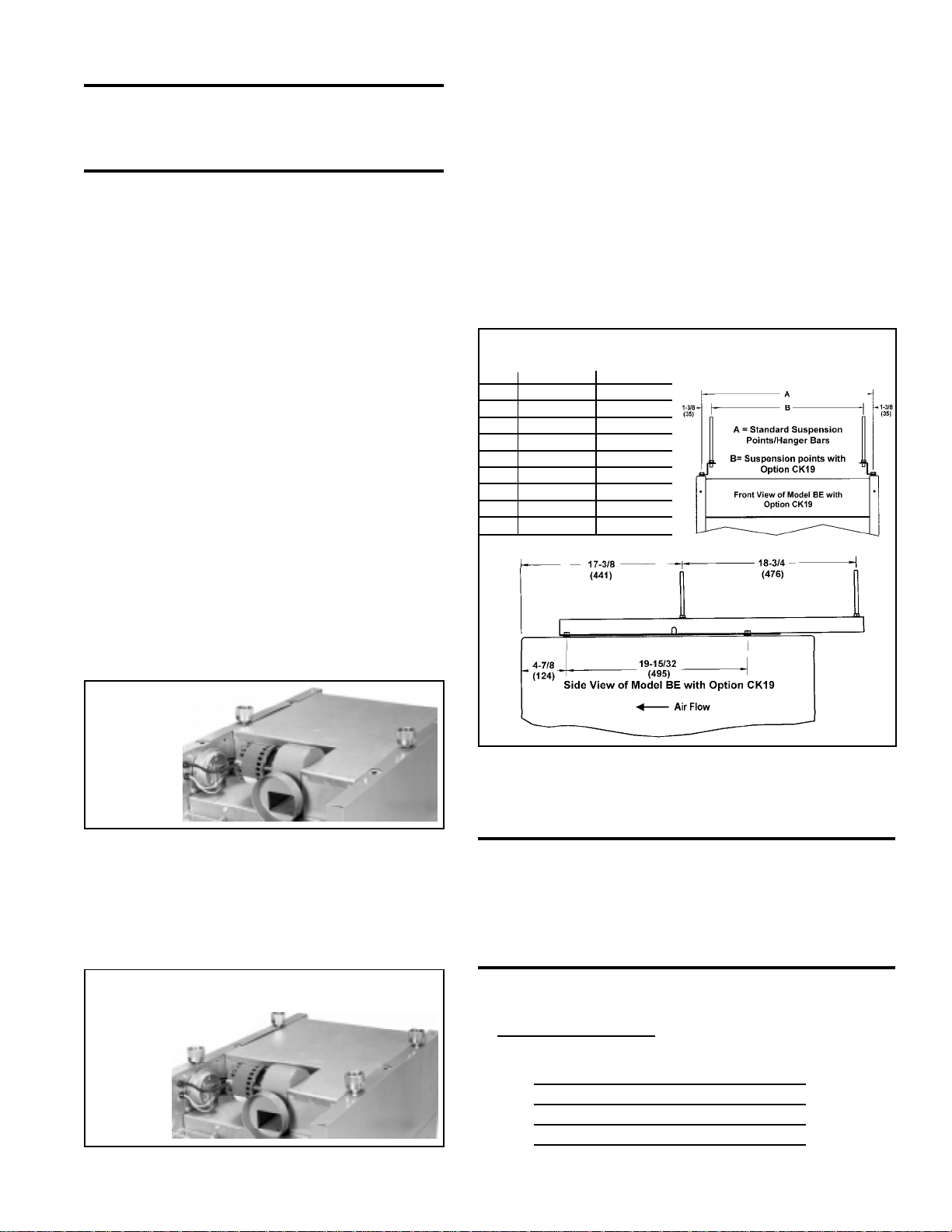

removed.

Be sure that the

threaded hanger

rods are locked

to the heater as

shown in Figure

2.

Figure 2 -

Suspension

Form 436, Page 6

Page 7

WARNING: Unit must be level for proper

operation. Do not place or add additional weight

to the suspended heater. See Hazard Levels, page

2.

If an optional downturn air nozzle is used, the unit must be suspended from four points to ensure level suspension. Two hanger

brackets are included in the downturn option package and must

be field-installed on fan-type units with standard two-point suspension. For additional information, refer to Paragraph 26 and

the instructions that are furnished with the option package.

When blower-type units are equipped with an optional blower/

filter cabinet, there are two suspension points on the blower cabinet hanger bar. Suspend a unit equipped with a blower/filter cabinet from four points, using the two heater hanger bracket assemblies closest to the front of the heater and the two suspension

points on the blower/filter cabinet.

If one of the optional, field-installed hanger kits has been ordered

for your heater, it will have been shipped separately . Each option

package includes a list of components and complete, step-by-step

assembly instructions.

Optional, Field-Installed Hanger Kits:

1) Four-Point Suspension (fan models only) - Option CK7

This option kit is designed to convert a fan-type heater from standard two-point suspension to four-point suspension. The kit contains two additional hanger brackets.

2) Two-Point Swivel Connectors (fan models only) - Option

CK8 (See Figure 3.)

The purpose of this option kit is to adapt the standard hanger

bracket so that the heater can be suspended from 1", threaded,

stationary pipe. The swivel connector screws "into" the threaded

hanger bracket on the heater and "onto" the 1" threaded pipe used

for hanging the heater. The kit includes two swivel hanger connector assemblies and two lock washers.

4) Four-Point Swivel Connectors - Option CK10 (See Figure 4A)

This option package is used on a heater that is already equipped with fourpoint suspension to adapt it for suspension from four 1", threaded, stationary pipes. The kit includes four swivel hanger connector assemblies and

four lock washers.

5) Special Four-Point Suspension with Nearly Equal Loading (applies

to blower models only) - Option CK19

This suspension option is designed for special applications when a suspension system is needed that has nearly equal loading at all four suspension

points. Use this option in installations with spring isolation designed for

seismic protection or when threaded rod hangers are longer than twelve

inches.

Suspension points change with the addition of hanger kit Option CK19; see

Figure 4B.

Figure 4B - Suspension Dimensions (inches and mm) for

Model BE Heater with Hanger Kit Option CK19

Size A B

25-50 11-7/8 (302) 9-1/8 (232)

75 13-7/8 (352) 11-1/8 (283)

100 15-7/8 (403) 13-1/8 (333)

125 21-5/8 (549) 18-7/8 (479)

165 18-5/8 (473) 15-7/8 (403)

200 21-5/8 (549) 18-7/8 (479)

250 27-1/8 (689) 24-3/8 (618)

300 27-1/8 (689) 24-3/8 (618)

400 35-3/8 (897) 32-5/8 (829)

Figure 3 - TwoPoint Suspension

with Swivel

Connections

(fan models

only)

3) Four-Point with Swivel Connectors (fan-models only) Option CK9 (See Figure 4A)

This option package is designed to convert a fan-type heater from

standard two-point suspension to four-point suspension with

swivel connectors. By installing this kit the standard fan-type heater

can be hung from four 1", threaded, stationary pipes. The kit includes two hanger bracket assemblies, four swivel hanger connector assemblies and four lock washers.

Figure 4A - Four-Point Suspension with Swivel

Connections (Applies to both fan

and blower models)

9. Venting

These power-vented unit heaters are designed to operate safely and efficiently with either a horizontal or vertical vent. (Horizontal vent run is recommended for maximum fuel savings.)

WARNING: Units installed in multiples require

individual vent pipe runs and vent caps. Manifolding

of vent runs is not permitted due to possible

recirculation of combustion products into the

building and possible back pressure effects on the

combustion air proving switch.

Specific Venting Requirements (read all before

installing)

1. Venter (Flue) Outlet

Venter Outlet Size:

Model Size Outlet Diameter

25-100 4" (102 mm)

125-250 5" (127 mm)

300-400 6" (152 mm)

Mfg P/N 98807 Rev 8, Page 7

Page 8

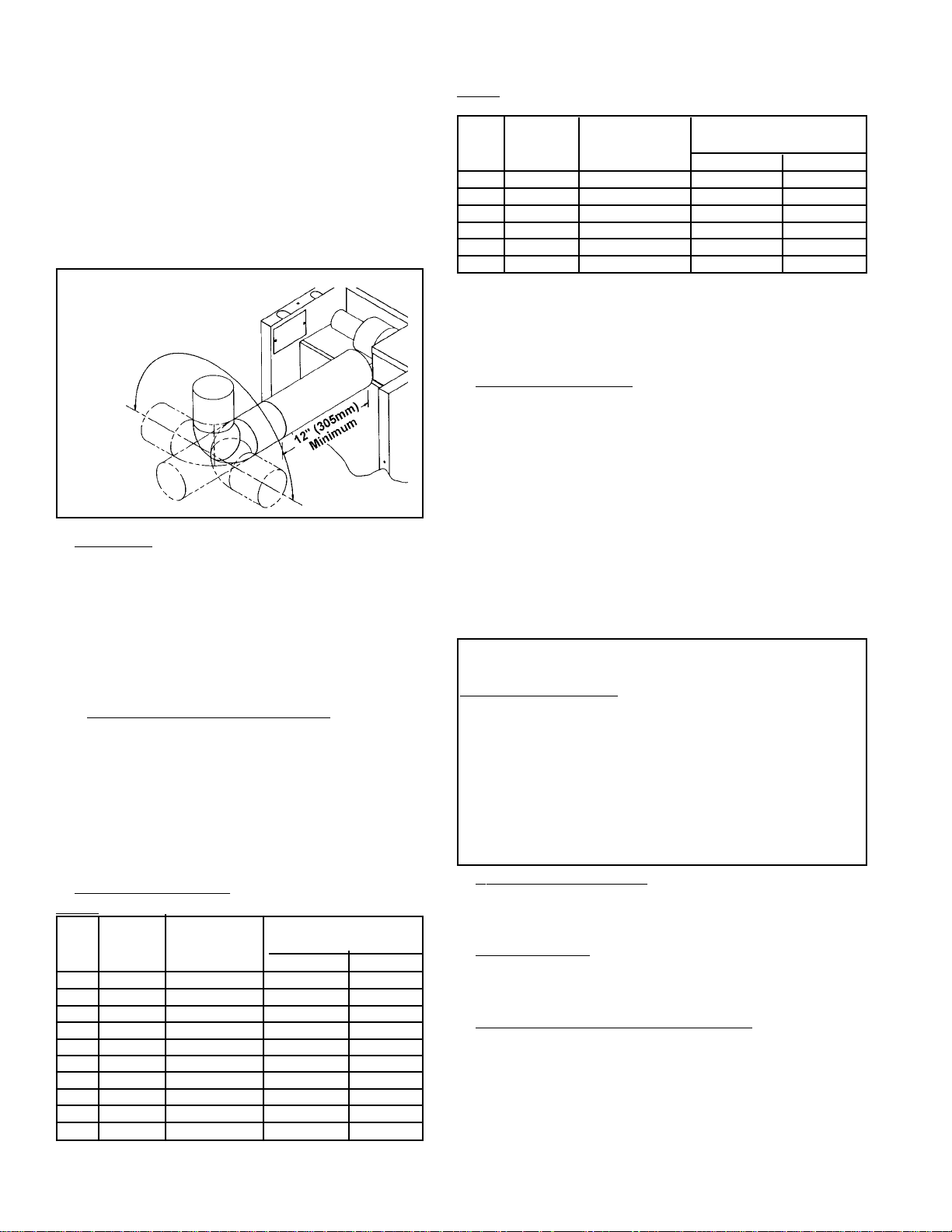

9. Venting (cont'd)

Venter Outlet Attachment Requirements:

• If the pipe used in the vent run is larger than the diameter of the

venter outlet (See Vent Length Table 2), make the transition at

the venter outlet.

• A minimum of 12" of straight pipe is required at the venter

outlet (or transition fitting) before installing an elbow in the

vent system. An elbow should never be attached directly to the

venter. An elbow attached to the straight pipe can be in any

position at or above horizontal. See Figure 5.

Figure 5 - Alternate Vent

Directions (vent in any

position above horizontal;

minimum of 12" of straight

pipe

required

before

an

elbow)

2. Vent Pipe

If installed with a horizontal vent run, use either vent pipe approved

for a Category III heater or appropriately sealed 26-gauge galvanized steel or equivalent single-wall pipe.

If at least half of the equivalent length of the vent system is vertical, vent pipe approved for a Category I heater may be used. Singlewall pipe or double-wall (Type B) vent pipe are suitable for use

with a Category I heater.

Use only one of the flue pipe diameters listed in the Vent Length

Tables for the furnace size being installed.

2A. Vent Pipe Diameter Reduction

If at least half of the equivalent length of the vent system is vertical, the vent pipe diameter may be reduced one inch from the standard diameter listed in Vent Length Table 1. Only single-wall pipe

is suitable for use when reducing the pipe diameter. A taper-type

reducer must be used. The maximum allowable vent length remains

the same. If required, double wall pipe may be used at the terminal

end as shown in Figure 6. (Use the equivalent length for elbows as

shown in Vent Length Table 1 for the standard vent pipe diameter.

All elbows used in the vent system must be considered.)

3. Vent Length Tables

Table 1: Maximum Permissible Vent Lengths

V ent Pipe Maximum Equivalent Straight

Model Diameter Vent Length* Length** - ft (m)

-" (mm) - ft (m) 90o Elbows 45o Elbows

25 4"(102) 30 ft (9.1 m) 3.5' (1 m) 1.8' (.5 m)

50 4"(102) 40 ft (12.2 m) 5' (1.5 m) 2.5' (.8 m)

75 4"(102) 50 ft (15.2 m) 7' (2.1 m) 3.5' (1.1 m)

100 4"(102) 50 ft (15.2 m) 7' (2.1 m) 3.5' (1.1 m)

125 5"(127) 50 ft (15.2 m) 5' (1.5 m) .5' (.8 m)

165 5"(127) 50 ft (15.2 m) 9' (2.7 m) 4.5' (1.4 m)

200 5"(127) 50 ft (15.2 m) 8' (2.4 m) 4.0' (1.2 m)

250 5"(127) 50 ft (15.2 m) 10' (3.0 m) 5' (1.5 m)

300 6"(152) 50 ft (15.2 m) 11' (3.4 m) 5.5' (1.7 m)

400 6"(152) 50 ft (15.2 m) 15' (4.6 m) 7.5' (2.3 m)

Form 436, Page 8

T able 2: Optional Maximum Permissible Vent Lengths

(Requires an increase in vent pipe diameter.)

V ent Pipe Maximum Equivalent Straight

Model Diameter Vent Length* Length** - ft (m)

- " (mm) - ft (m) 90o Elbows 45o Elbows

100 5" (127) 60 ft (18.3 m) 8' (2.4 m) 4.0' (1.2 m)

165 6" (152) 60 ft (18.3 m) 10' (3.0 m) 5.0' (1.5 m)

200 6" (152) 60 ft (18.3 m) 12' (3.7 m) 6.0' (1.8 m)

250 6" (152) 70 ft (21.3 m) 8' (2.4 m) 4.0' (1.2 m)

300 7" (178) 70 ft (21.3 m) 13' (4.0) 6.5' (2.0 m)

400 7" (178) 90 ft (27.4 m) 14' (4.3) 7.0' (2.1)

*Note 1: If the system contains all vertical pipe or a combination of horizontal

and vertical vent pipe, the Maximum Permissible Vent Length shown in Tables 1

and 2 may be increased one foot for each foot vertical rise up to a maximum

increase of 10 feet for model sizes 25 thru 100 and up to 20 feet for model sizes

125 thru 400.

**Reduce the maximum vent length by the amount indicated for each elbow.

4. Vent System Joints

Vent system joints depend on the installation and the type of pipe being

used.

• If using single wall, 26-gauge or heavier galvanized pipe, secure slipfit connections using sheet metal screws or rivets. Seal pipe joints either with tape suitable for 550

o

F (such as Option FA1, P/N 98266) or

high-temperature silicone sealant.

• If using Category III vent pipe, follow pipe manufacturer's instructions

for joining pipe sections. When attaching Category III pipe to the venter outlet or the vent cap, make secure, sealed joints following a procedure that best suits the style of Category III pipe being used.

• If using double-wall (Type B) vent pipe (allowed only if 1/2 of the

equivalent vent length is vertical), follow pipe manufacturer's instructions for joining pipe sections. For joining double-wall pipe to the venter outlet collar, single-wall pipe, and/or the vent cap, follow the instructions below.

Instructions for attaching double-wall (Type B) vent pipe to the venter outlet, a single-wall pipe run, or to the vent cap (use these instructions for either full length double-wall or terminal only):

Hardware and Sealant Required: 3/4" long sheetmetal screws; and a tube of RTV

1) Look for the "flow" arrow on the vent pipe; attach according to the arrow.

Slide the pipe so that the venter outlet, the single-wall pipe, or the vent cap is

inside the double-wall pipe.

2) Drill a hole through the pipe into the outlet collar, the single-wall pipe, or the

vent cap. (Hole should be slightly smaller than the sheet metal screw being used.)

Using a 3/4" long sheet metal screw, attach the pipe. Do not overtighten. Repeat,

drilling and inserting two additional screws evenly spaced (120o apart) around

the pipe.

3) Use RTV to seal any gaps. If there is an annular opening, run a large bead of

RTV in the opening. The bead of RTV must be large enough to seal the opening,

but it is not necessary to fill the full volume of the annular area.

5. Vent System Support

Support lateral runs every six feet, using a non-combustible material such

as strap steel or chain. Do not rely on the heater for support of either horizontal or vertical vent pipe

6. Condensation

Single wall vent pipe exposed to cold air or run through unheated areas

must be insulated. Where extreme conditions are anticipated, install a means

of condensate disposal.

7. Vent Terminal (Pipe and Vent Cap)

The vent system must be terminated with a suitable vent cap that is the

same size as the vent run.

Heaters installed in Canada must be equipped with the vent cap sup-

plied as optional equipment by the heater manufacturer (Option CC1 or

Option BT2). Heaters installed in the United States must be equipped

with the heater manufacturer's vent cap, a Type L Breidert Air-x-hauster

vent cap, or equivalent. Use of a vent cap supplied by the pipe manufac-

®

Page 9

turer is not permitted; the vent cap must be the type approved for use

with this heater. A different style vent cap could cause nuisance problems or unsafe conditions.

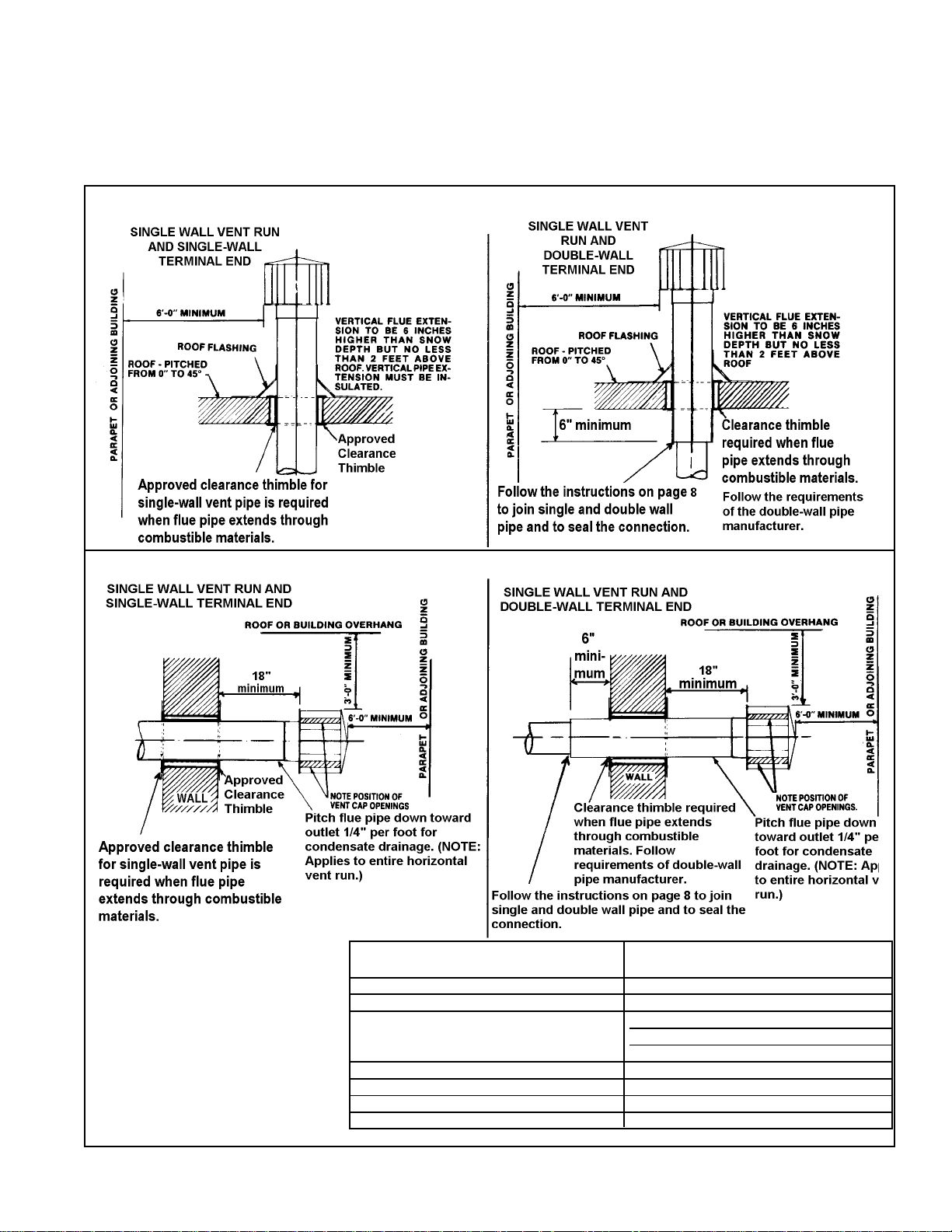

See the illustrations in Figures 6 and 7 for requirements of both vertical and horizontal vent termination. The vent terminal section may be

Figure 6 - Vertical Vent Terminals

either single-wall or double-wall (Type B) vent pipe. If double-wall

pipe is used in the vent terminal with a single-wall vent run, follow the

instructions in No. 4, V ent System Joints, to attach the vent cap and to

connect the double-wall pipe to the single-wall vent pipe run.

Figure 7 - Horizontal Vent Terminals

Horizontal V ent Terminal Clearances:

The location of the termination of the horizontal vent system must be in accordance with

National Fuel Gas Code Z223.1. Required

minimum clearances are listed on the right.

Products of combustion can cause discoloration of some building finishes and deterioration of masonry materials. Applying a clear

silicone sealant that is normally used to protect concrete driveways can protect masonry

materials. If discoloration is an esthetic problem, relocate the vent or install a vertical vent.

Structure Minimum Clearances for V ent Termination

Location (all directions unless specified)

Forced air inlet within 10 ft (3.1m) 3 ft (0.9m) above

Combustion air inlet of another appliance 6 ft (1.8m)

Door, window, or gravity air inlet 4 ft (1.2m) horizontally

(any building opening) 4 ft (1.2m) below

3 ft (0.9m) above

Electric meter, gas meter * and relief equipment 4 ft (1.2m) horizontally

Gas regulator * 3 ft (0.9m)

Adjoining building or parapet 6 ft (1.8m)

Grade (ground level) 7 ft (2.1m) above

*Do not terminate the vent directly above a gas meter or service regulator.

Mfg P/N 98807 Rev 8, Page 9

Page 10

10. Gas Piping and Pressures

WARNING

This appliance is equipped for a maximum gas

supply pressure of 1/2 pound, 8 ounces, or 14

inches water column. Supply pressure higher

than 1/2 pound requires installation of an

additional service regulator external to the unit.

PRESSURE TESTING SUPPLY PIPING

Test Pressures Above 1/2 PSI: Disconnect the heater and manual

valve from the gas supply line which is to be tested. Cap or

plug the supply line.

Test Pressures Below 1/2 PSI: Befor e testing, close the manual

valve on the heater.

All piping must be in accordance with requirements outlined in the

National Fuel Gas Code ANSI/Z223.1a (latest edition), published by

the American Gas Association or CAN/CGA-B149.1 and B149.2, published by the Canadian Gas Association (See Paragraph 1). Gas supply

piping installation should conform with good practice and with local

codes.

Unit heaters for natural gas are orificed for operation with gas having a

heating value of 1000 (+ or - 50) BTUH per cubic ft. If the gas at the

installation does not meet this specification, consult the factory for

proper orificing.

Pipe joint compounds (pipe dope) shall be resistant to the action of

liquefied petroleum gas or any other chemical constituents of the

gas being supplied.

Install a ground joint union and manual shut-off valve upstream of the

unit control system, as shown in Figure 8. The 1/8" plugged tapping in

the shut-off valve provides connection for supply line pressure test

gauge. The National Fuel Gas Code requires the installation of a trap

with a minimum 3" drip leg. Local codes may require a minimum drip

leg longer than 3" (typically 6").

Gas connection sizes are included in the Dimensional Tables in Paragraph 3. After all connections are made, disconnect the pilot supply at

the control valve and bleed the system of air. Reconnect the pilot line

and leak-test all connections by brushing on a soap solution.

Sizing a Gas Supply Line

Ca pa c it y of P i pin g

Cubic Feet per Hour based on 0.3" w .c. Pressure Drop

Sp ecific Grav ity fo r N at ural G as -- 0.6 (N atu ral G as -- 10 0 0 B T U /C u bic Ft )

Specific Gravity for Propane G as -- 1.6 (P ropane Gas -- 2550 BT U /Cubic Ft)

Length Diameter of Pipe

of 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

Pipe Natu ral Propane N atural Pro p ane Natural Pro pane Natural Propane N atural Pro p ane Natural Pro pane

20' 92 56 190 116 350 214 730 445 1100 671 2100 1281

30' 73 45 152 93 285 174 590 360 890 543 1650 1007

40' 63 38 130 79 245 149 500 305 760 464 1450 885

50' 56 34 115 70 215 131 440 268 670 409 1270 775

60' 50 31 105 64 195 119 400 244 610 372 1105 674

70' 46 28 96 59 180 110 370 226 560 342 1050 641

80' 43 26 90 55 170 104 350 214 530 323 990 604

90' 40 24 84 51 160 98 320 195 490 299 930 567

100' 38 23 79 48 150 92 305 186 460 281 870 531

125' 34 21 72 44 130 79 275 168 410 250 780 476

150' 31 19 64 39 120 73 250 153 380 232 710 433

175' 28 17 59 36 110 67 225 137 350 214 650 397

200' 26 16 55 34 100 61 210 128 320 195 610 372

N o t e: W h e n s iz in g s u p p ly lin e s , c o n s id e r p o s s ib ilit ie s o f f u t u r e exp a n s io n a n d in c re a s ed r eq u ir e m e n t s .

Refer to National F uel G as Code for additional information on line siz ing.

Form 436, Page 10

Figure 8 - Supply

Piping Connection

WARNING: All components of a gas supply

system must be leak tested prior to placing

equipment in service. NEVER TEST FOR

LEAKS WITH AN OPEN FLAME. Failure to

comply could result in personal injury , property

damage or death.

Manifold or Orifice Pressure Settings

Measuring manifold gas pressure cannot be done until the heater is in

operation. It is included in the steps of the "Check-Test-Start" proce-

dure in Paragraph 24. The following warnings and instructions apply.

WARNING: Manifold gas pressure must never

exceed 3.5" w.c. for natural gas and 10" w.c. for

propane gas.

For Natural Gas: Manifold gas pressure is regulated by the combina-

tion valve to 3.5" w.c. Inlet pressure to the valve must be a minimum of

5" w.c. or as noted on the rating plate and a maximum of 14" w.c.

For Propane Gas: Manifold gas pressure is regulated by the combination valve to 10" w.c. Inlet pressure to the valve must be a minimum of

11" w.c. and a maximum of 14" w.c.

Page 11

Before attempting to measure or adjust manifold gas pressure,

the inlet (supply) pressure must be within the specified range for

the gas being used both when the heater is in operation and on

standby. Incorrect inlet pressure could cause excessive manifold

gas pressure immediately or at some future time.

Instructions to Check Manifold Pressure:

1) With the manual valve (on the combination valve) positioned

to prevent flow to the main burners, connect a manometer to

the 1/8" pipe outlet pressure tap in the valve. NOTE: A manometer (fluid-filled gauge) is recommended rather than a

spring type gauge due to the difficulty of maintaining calibration of a

spring type gauge.

2) Open the valve and operate the heater. Measure the gas pressure to the

manifold. Normally adjustments should not be necessary to the factory

preset regulator.

If adjustment is necessary, set pressure to correct settings by turning the regulator screw IN (clockwise) to increase pressure. Turn regulator screw OUT

(counterclockwise) to decrease pressure.

Consult the valve manufacturer's literature provided with the heater for more

detailed information.

11. Electrical Supply and Connections

All electrical wiring and connections, including electrical grounding MUST be made in accordance with the National Electric

Code ANSI/NFP A No. 70 (latest edition) or, in Canada, the Canadian Electrical Code, Part I-C.S.A. Standard C22.1. In addition, the installer should be aware of any local ordinances or gas

company requirements that might apply.

Check the rating plate on the heater for the supply voltage and

current requirements. A separate line voltage supply with fused

disconnect switch should be run directly from the main electrical panel to the heater. All external wiring must be within approved conduit and have a minimum temperature rise of 60

Conduit from the disconnect switch must be run so as not to

interfere with the service panels of the heater.

The electrical supply connects at the top back of the heater in the

left corner (left when facing the back of the heater). A threaded

hole is provided for a standard 1/2" electrical fitting.

The wiring access panel is easily removed for field connections.

Consult the wiring diagram supplied with your heater. Replace

the panel after the wiring connections are made.

If the heater has field-installed options that require electrical connections, consult the instruction sheet and wiring diagram supplied in the option package.

A fan-type heater may be equipped with a built-in fused disconnect switch (Option AI-1). If the heater is equipped with a builtin disconnect switch, a two-position toggle (on/off) switch is

located near the electrical supply access panel (See Figures 9A

and 9B). This switch may be used to disconnect the power when

servicing the heater other than in the supply junction box.

Specific wiring diagrams that include standard and factory-installed options are included with the heater. Check the wiring

diagram to identify optional equipment.

o

C.

Field Wiring

from Disconnect

in Conduit

Threaded

Hole for

Standard 1/2"

Fitting

Note: Fan-type

heaters with optional

built-in disconnect

switch, have an on/off

switch located near

the electrical supply

access panel.

Remove

Access

Panel to

make

connections

Figure 9A - Electrical

Connections

WARNINGS: On a heater with

a unit disconnect switch (Option

AI-1), if the power is turned off

at the switch, the supply lead in

the electrical supply junction

box (Figure 9A) remains

energized. If service is to be

done in the supply junction box,

turn off the power at the remote

disconnect switch.

If you turn off the power supply ,

turn off the gas.

The operating sequence of the heater can be

found on the heater wiring diagram and is published in Paragraph 24, Check Installation and

Start-Up. Typical wiring diagrams ar e on the

next four pages, showing standard singlestage heating with spark pilot with and without lockout.

CAUTION: If any of the original wire as

supplied with the appliance must be replaced, it must be replaced with

wiring material having a temperature rating of at least 105

limit control and sensor lead wires which must be 150oC. See Hazard

Levels, page 2.

12. Thermostat and Thermostat

Connections

A thermostat is not standard equipment but is an installation requirement.

Use either an optional thermostat available with the heater or a field-supplied

thermostat. Install according to the thermostat manufacturer's instructions.

Make sure that the heat anticipator setting on the thermostat is in accordance

with the amperage value noted on the

wiring diagram of your heater.

Terminal Strip Connections - The

standard heater is equipped with a twoscrew terminal connector strip (See Figure 10) for easy connection to the low

voltage controls (24V). When factoryinstalled options require two-stage

thermostat control, the heater is

equipped with a SP-ST relay and a

four-screw terminal connector strip

(See Figure 11).

If your heater requires field installation of the four-screw terminal

strip and the relay, follow the instructions packaged with the relay

or thermostat option.

Figure 9B

If equipped

with unitmounted

disconnect

switch, on/

off toggle

switch is

near access

panel to

electrical

supply

junction

box.

Circuit

breaker

button for

Option AI-1

unitmounted

disconnect

switch

o

C, except for

Figure 10 -

Two Screw

Terminal

Connector

Strip for

24-volt

Wiring

Figure 11 -

Four Screw

Terminal

Connector

Strip for 24V olt Wiring

(Paragraph 12 continued on page 16.)

Mfg P/N 98807 Rev 8, Page 11

Page 12

TYPICAL WIRING DIAGRAMS -- Pages 12 - 15

Field Control Wiring Length and Gauge

T otal W ire Distance from MinimumRecommended

Length Unit to Control Wire Gauge

150' (45.7 m) 75' (22.9 m) #18 gauge

250' (76.2 m) 125' (38.1 m) #16 gauge

350' (106.7 m) 175' (53.3 m) #14 gauge

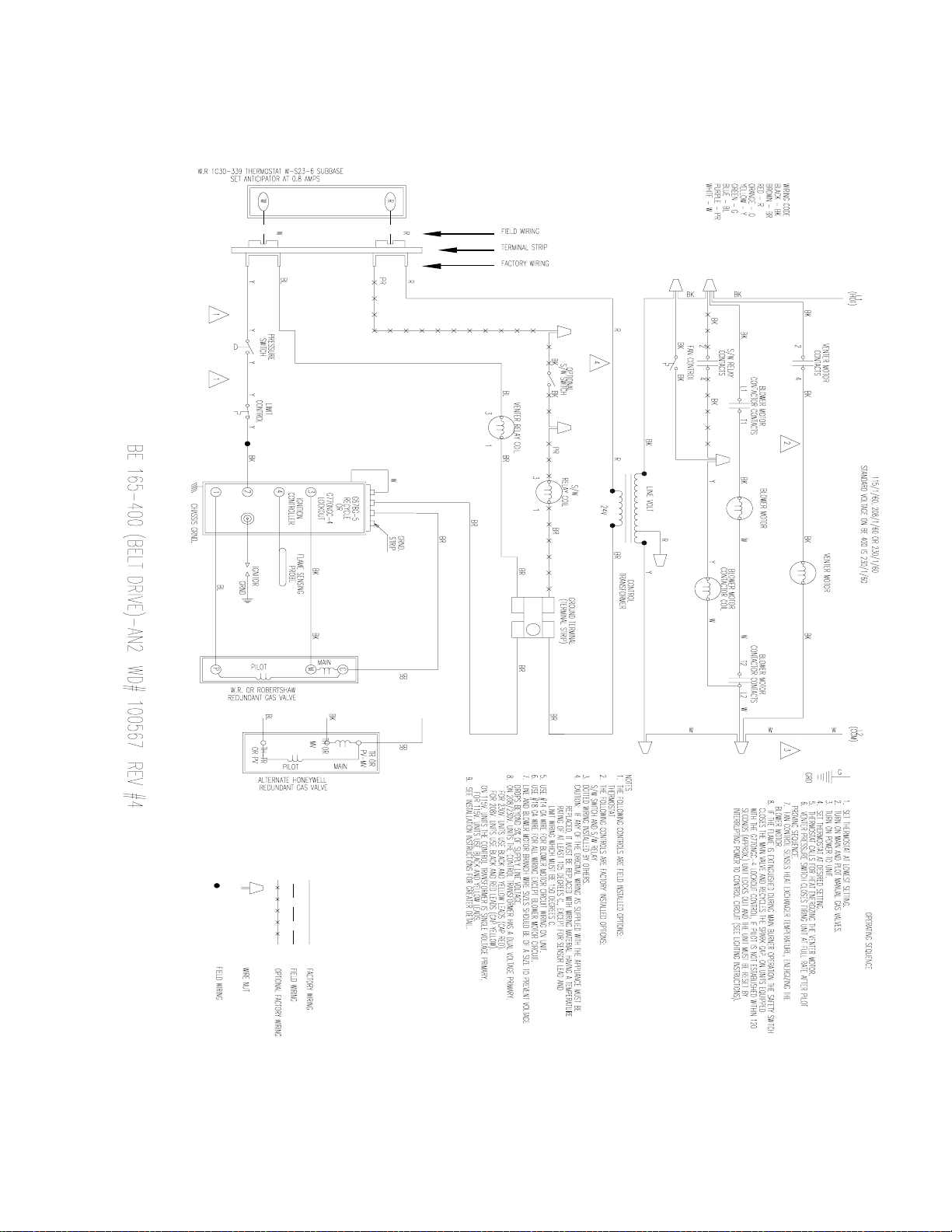

Fan-Type, Power-Vented Model

with Intermittent Spark Pilot,

Single-Stage Heating,

Natural or Propane

OPERATING SEQUENCE

1. SET THERMOSTAT AT LOWEST SETTING.

2. TURN ON MAIN AND PLOT MANUAL GAS VALVES.

3. TURN ON POWER TO UNIT.

4. SET THERMOSTAT AT DESIRED SETTING.

5. THERMOSTAT CALLS FOR HEAT ENERGIZING THE VENTER MOTOR.

6. VENTER PRESSURE SWITCH CLOSES FIRING UNIT AT FULL RATE AFTER PILOT

PROVING SEQUENCE.

7. FAN CONTROL SENSES HEAT EXCHANGER TEMPERATURE, ENERGIZING THE

FAN MOTOR.

8. IF THE FLAME IS EXTINGUISHED DURING MAIN BURNER OPERATION THE SAFETY SWITCH

CLOSES THE MAIN VALVE AND RECYCLES THE SPARK GAP. ON UNITS EQUIPPED

WITH THE G77ONGC-4 LOCKOUT CONTROL, IF PILOT IS NOT ESTABLISHED WITHIN 120

SECONDS (APPROX.) UNIT LOCKS OUT AND THE UNIT MUST BE RESET BY

INTERRUPTING POWER TO CONTROL CIRCUIT (SEE LIGHTING INSTRUCTIONS).

NOTES

1. THE FOLLOWING CONTROLS ARE FIELD INSTALLED OPTIONS:

THERMOSTAT

2. THE FOLLOWING CONTROLS ARE FACTORY INSTALLED OPTIONS:

S/W SWITCH

3. DOTTED WIRING INSTALLED BY OTHERS.

4. CAUTION: IF ANY OF THE ORIGINAL WIRING AS SUPPLIED WITH THE APPLIANCE MUST BE

REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL HAVING A TEMPERATURE

RATING OF AT LEAST 105 DEGREES C., EXCEPT FOR SENSOR LEAD AND

LIMIT WIRING WHICH MUST BE 150 DEGREES C.

5. USE #18 GA WIRE FOR ALL WIRING EXCEPT FAN MOTOR CIRCUIT.

6. LINE AND FAN MOTOR BRANCH WIRE SIZES SHOULD BE OF A SIZE TO PREVENT VOLTAGE

DROPS BEYOND 5% OF SUPPLY LINE VOLTAGE.

7. ON 230V. UNITS THE CONTROL TRANSFORMER HAS A DUAL VOLTAGE PRIMARY.

FOR 230V. UNITS USE BLACK AND YELLOW LEADS (CAP RED).

FOR 208V. UNITS USE BLACK AND RED LEADS (CAP YELLOW).

ON 115V. UNITS THE CONTROL TRANSFORMER IS A SINGLE VOLTAGE PRIMARY.

FOR 115V. UNITS USE BLACK AND YELLOW LEADS.

8. SEE INSTALLATION INSTRUCTIONS FOR GREATER DETAIL.

R

W

SET ANTICIPATOR AT 0.8 AMPS

W.R 1C30-339 THERMOSTAT W-S23-6 SUBBASE

WIRING CODE

BLACK - BK

BROWN - BR

RED - R

ORANGE - O

YELLOW - Y

GREEN - G

BLUE - BL

PURPLE - PR

WHITE - W

L1

(HOT)

VENTER RELAY

CONTACTS

BK BK

2 4

OPTIONAL

S/W SWITCH

BK BK

BK BK

FAN CONTROL

BK

BK

R

8

VENTER RELAY COIL

BL BR

FIELD WIRING

TERMINAL STRIP

FACTORY WIRING

R

R

BL

W

PRESSURE

SWITCH

CONTROL

Y YYY

5 5

FE 25-400 OPT. AH2/AH3 WD #97302 REV #8

31

LIMIT

6

BK

Y

115/1/60, 208/1/60 OR 230/1/60

VENTER MOTOR

BK

BK

R

LINE VOLT

R

BR

24V

BR

BR

5

GRND.

W

STRIP

G67BG-5

RECYCLE

OR

G770NGC-4

LOCKOUT

3

FLAME SENSING

IGNITION

CONTROLLER

4

BK

2

1

CHASSIS GRND.

Y

CONTROL

TRANSFORMER

GROUND TERMINAL

(TERMINAL STRIP)

BR

BK

PROBE

IGNITOR

GRND

BL

FAN MOTOR

FACTORY WIRING

FIELD WIRING

OPTIONAL FACTORY WIRING

WIRE NUT

CRIMP TERMINAL

BK

BK

BKBK

BR

BR

C

MAIN

M

BK

PILOT

W.R. OR ROBERTSHAW

REDUNDANT GAS VALVE

P

BL

L2

(COM)

G

WWW

GRD

7

BR

TR OR

PV-MV

MAIN

TH OR

MV

PILOT

ALTERNATE HONEYWELL

REDUNDANT GAS VALVE

TH-TR

OR PV

CAUTION: If any of the original wire as supplied with

the appliance must be replaced, it must be replaced with

wiring material having a temperature rating of at least

o

105

C, except for limit control and sensor lead wires

which must be 150oC. See Hazard Levels, page 2.

Form 436, Page 12

Page 13

Blower-Type, Power-Vented Model Sizes 25-100 with

Intermittent Spark Pilot,

Single-Stage Heating,

Natural or Propane,

Direct Drive

M odel Size Sp ee d

25 *Medium *Blue and White

L ow Red a nd White

50 *High *Bla ck and White

Medium Blue and White

High Bla c k and White

75 *Medium *Blue and White

L ow Red a nd White

*High *Bl a ck and White

100 Medium Blue and White

L ow Red a nd White

*Factory-wired speed

Use these Two Motor Wires

Mfg P/N 98807 Rev 8, Page 13

Page 14

Blower-Type, Power-Vented Model Sizes 50-250 with Intermittent Spark Pilot, Single-Stage Heating,

Natural or Propane, Belt Drive (NOTE: Belt drive is standard on Sizes 125-250; optional on Sizes 50-

100.)

Form 436, Page 14

Page 15

Blower-Type, Power-Vented Model Sizes 165-400 with Intermittent Spark Pilot, Single-stage

Heating, Natural or Propane, Belt Drive, Motor Contactor (NOTE: Motor contactor is

standard on Sizes 300 and 400; optional on other sizes.

Mfg P/N 98807 Rev 8, Page 15

Page 16

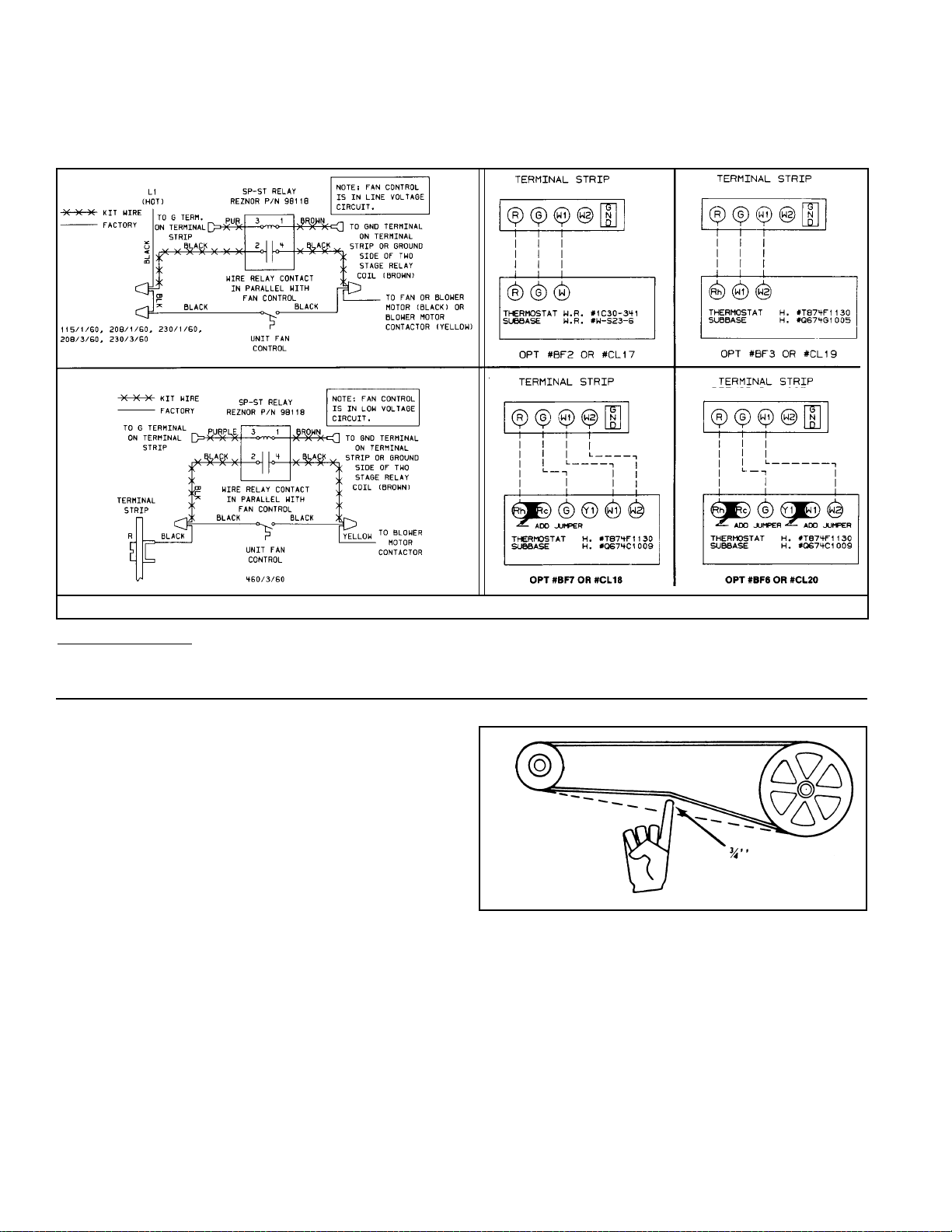

12. Thermostat Connections (cont'd)

There are some unique wiring requirements with the installation of the optional controls (relay and two-stage). Figure 12 illustrates the wiring of the

relay and the connections required for optional thermostat control.

575/3/60

Figure 12 - Wiring Diagrams for Optional Controls

Multiple Heater Control - These unit heaters are not designed for multiple unit connection to one thermostat. If you require that more than one unit

be controlled by a single thermostat, it will be necessary to use relays in the circuit. Options CL31 and CL32 provide the necessary parts and

instructions for multiple heater control. For more information on these options, see Paragraph 30.

13. Fan Motor

Fan motors are equipped with thermal overload protection of the automatic reset type. Should the motor refuse to run, it may be because of

improper current characteristics. Make certain that the correct voltage

is available at the motor.

NOTE: If the unit is equipped with an optional totally enclosed motor,

the horsepower may be larger than the standard motor. Refer to the

motor nameplate to verify horsepower.

14. Blower Motor

Blower Model Sizes 25-100 are standardly equipped with a direct drive

motor; an optional belt drive motor is available on Sizes 50-100. Blower

Model Sizes 125-400 have an adjustable belt drive motor.

As part of the Check/Test/Start (Paragraph 24), check the belt for proper

tension. Proper belt tension is important to the long life of the belt and

motor. A loose belt will cause wear and slippage. Too much tension

will cause excessive motor and blower bearing wear. Adjust the belt

tension by turning the adjusting screw on the motor base until the belt

can be depressed 1/2-3/4". (See Figure 13.) After correct tension is

achieved, re-tighten the locknut on the adjusting screw.

Most blower motors are equipped with thermal overload protection of

the automatic reset type. If a motor is not equipped with thermal overload protection, the unit will be equipped with a starter. The adjustable

setting on the starter will be factory set to match the amp draw of the

Form 436, Page 16

Figure 13 Adjusting Belt

Tension

motor and sealed. No change should be made to starter set unless the

original motor is replaced.

Starters are supplied from the factory for manual reset operation. If an

overload condition is experienced, the condition must be corrected,

and the starter must be manually reset.

After the installation is complete including all ductwork, the amp draw

of the motor should be checked with an amp meter to verify that the

motor amp rating on the motor nameplate is not being exceeded. Amps

may be adjusted downward by reducing blower speed for by increasing the duct system static pressure. The temperature rise must be within

the range specified on the unit rating plate.

Page 17

15. Blower Speed Adjustment

The blower speed may be adjusted to achieve the desired outlet temperature, as long as the adjustment is within the temperature rise and

the static pressure limits shown on the heater rating plate. Direct drive

motors are factory set as indicated in the chart below. Belt drive motors are factory set at the mid-point between maximum and minimum

blower speeds.

If the duct resistance is low, the blower may deliver too high an air

volume; or if the heater is operated without ductwork, it may deliver

sufficient excess air to overload the motor, causing the overload protector to cycle the motor. Reducing the blower speed will correct these

conditions. If ductwork is added to an installation, it may be necessary

to increase the blower speed. Decreasing blower speed will increase

outlet temperature; increasing blower speed will decrease outlet temperature.

Blower Model Sizes 25-100 with Direct

Drive

Direct drive blower motors have multi-speed taps for speed adjustment. If your installation requires an adjustment of the blower speed,

the motor may be re-wired to an alternate tap by following these instructions.

1. Turn off the gas and the electric power.

2. Remove the left (left when facing the back of the unit) outer side

panel of the heater to reveal the wiring connections.

3. Consult the wiring diagram on the heater and follow the below chart

to choose the wire for the desired adjustment. The asterisk(*) indicates the factory-wired speed.

Model Size Speed Use these Two Motor W i res

25 *Medium *Blue and White

Low Red and White

50 *High *Black and White

Medium Blue and White

High Black and White

75 *Medium *Blue and White

Low Red and White

*High *Black and White

100 Medium Blue and White

Low Red and White

4. Cut the crimped cap from the end of the wire that you intend to use

and strip the insulation.

5. Disconnect the factory-wired connection and re-wire, using the

newly stripped wire.

6. Put a wire nut on the end of the blower motor wire that was disconnected.

7. Replace the heater side panel and turn on the gas and the electric.

Blower Model Sizes 50-400 with Belt Drive

The belt drive on these units is equipped with an adjustable pulley

which permits adjustment of the blower speed. Follow these instructions to adjust the blower speed.

1. Turn off the gas and the electric power.

2. Loosen belt tension and remove the belt.

3. Loosen the set screw on the side of the pulley away from the motor.

4. T o increase the blower speed, decreasing outlet temperature, turn

the adjustable half of the pulley inward. To decrease the blower

speed, increasing the outlet temperature, turn the adjustable half

of the pulley outward. One turn of the pulley will change the speed

8-10%.

5. Tighten the set screw on the flat portion of the pulley shaft.

6. Replace the belt and adjust the belt tension. Adjust tension by turning the adjusting screw on the motor base until the belt can be depressed 1/2-3/4". (See Figure 13.) Re-tighten the lock nut on the

adjusting screw.

7. Turn on the gas and electric. Light the heater following the instructions on the lighting instruction plate.

8. Check the motor amps with an amp meter. The maximum motor

amp rating on the motor nameplate must not be exceeded.

CAUTION: An external duct system static

pressure not within the limits shown on the rating

plate or improper adjustment of the motor pulley

or belt may overload the motor.

16. Blower Rotation

Each blower housing is marked for proper rotation. Rotation may be

changed on single-phase motors by re-wiring in the motor terminal

box. Three-phase motors may be reversed by interchanging two wires

on the 3-phase supply connections.

17. Fan Control

1. A fan control provides the following:

(a) Delay of fan or blower operation to prevent the discharge of

cold air.

(b) Fan or blower operation as long as the unit is hot.

2. The fan control provides additional safety by keeping the fan or

blower in operation in the event that the gas valve fails to close

when the thermostat is satisfied.

3. To be sure that the fan or blower can continue to operate, the power

supply to the heater MUST NOT be interrupted except when servicing the unit.

4. If the customer wants the heater off at night, the gas valve circuit

SHOULD BE OPENED by a single pole switch wired in series

with the thermostat. Some thermostats are provided with this feature.

Multiple units controlled from a single thermostat are shut off in the

same manner. For proper operation, be sure the fan control wiring

is observed.

WARNING: If you turn off the power supply,

turn off the gas. See Hazard Levels, page 2.

NOTE: Low ambient temperatures (less than 40oF) may cause false

cycling of the fan/blower. To prevent this, a time delay relay can be

added to the unit (available with single-stage gas valve only) to activate the fan/blower electrically independent of the heat exchanger or

the room temperature. The low ambient fan control relay can be factory installed; Option BF8 will appear on the heater wiring diagram.

Or, the relay can be field installed; order Option CQ3 (P/N 112779).

This relay is in addition to the fan control The fan control is a safety

device and should never be removed from the heater circuit.

18. Limit Control

All models are equipped with an automatic, non-adjustable reset limit

control that acts to interrupt the electric supply to the redundant main

operating valve in case of motor failure or lack of airflow due to restrictions at the inlet or outlet.

Mfg P/N 98807 Rev 8, Page 17

Page 18

19. Combustion Air Proving

Switch

The combustion air proving switch is a pressure sensitive switch that

monitors air pressure to ensure that proper combustion air flow is available. The switch is a single pole - normally open - device which closes

when a decreasing pressure is sensed in the outlet duct of the flue gas

collection box.

On start-up when the heater is cold, the sensing pressure is at the most

negative level, and as the heater and flue system warm up, the sensing

pressure becomes less negative. After the system has reached equilibrium (about 20 minutes), the sensing pressure levels off.

If a restriction or excessive flue length or turns cause the sensing pressure to become less than the switch setpoint, the pressure switch will

function to shut off the main burners. The main burners will remain off

until the system has cooled and/or the flue system resistance is reduced.

The Table on the right lists the approximate water column negative pressure readings and switch setpoints for sea level operating conditions.

Model Start-Up Equilibrium Set Point Set Point

Size Cold "OFF" "ON"

25-400 -1.0" w.c. -0.60" w.c. -0.47" w.c. -0.64"w.c.

DANGER: Safe operation of this unit requires

proper venting flow . NEVER bypass combustion

air proving switch or attempt to operate the unit

without the venter running and the proper flow

in the vent system. Hazardous conditions could

result. See Hazard Levels, page 2.

20. Gas Valve

Main operating valve is powered by the 24-volt control circuit through

thermostat and safety controls. The main control valve is of the diaphragm type with magnetic pilot servo bleed operators, providing regulated gas flow preset at the factory. The valve body also incorporates a

magnetic valve providing pilot gas control for the electronic ignitor system and redundant or dual valve safety shutoff function.

WARNING: The operating valve is the prime

safety shutoff. All gas supply lines must be free of

dirt or scale before connecting the unit to ensure

positive closure. See Hazard Levels, page 2.

is imposed on that metal probe which is electrically isolated from

ground. When the pilot flame impinges on the flame sensing probe,

the flame acts as a conduction path to ground. The pilot flame rectifies and completes the DC circuit. The ignition controller acknowledges the flame and energizes the main gas valve.)

22. Burners

These unit heaters have individually formed steel burners with accurately die-formed ports to give controlled flame stability without lifting or flashback with either natural or propane gas. The burners are

lightweight and factory mounted in an assembly which permits them

to be removed as a unit for inspection or service.

23. Burner Air Adjustment

All sizes of these unit heaters that are equipped with standard aluminized burners are designed to operate without burner air shutters when

fueled with either natural or propane gas. However, Sizes 165 through

400 equipped with optional stainless steel burners (Option AD2) require air shutters (Option AE1) when used with propane gas (Option

AA2).

Optional air shutters, either factory or field installed, are available for

any size model for use where unusual conditions cause excess primary aeration.

Before making any adjustments to the air shutters, allow the heater to

operate for about fifteen minutes. The air shutter adjustment screws

can be reached by opening the bottom panel. (Remove the two screws

located at the rear of the bottom panel and allow the panel to hinge

down from the front.) The adjustment screws for the air shutters are

visible at the rear of the burner rack . See Figure 14.

When making the adjustment, close the air shutters no more than is

necessary to eliminate the problem condition.

Observe the flame for yellow-tipping. A limited amount of yellowtipping is permissible for liquefied petroleum gases. Other fuels should

not display any yellow-tipping.

T wo adjustment screws are used (See Figure 14). Rotating the screws

clockwise closes the shutters, reducing the primary air supply. Counterclockwise rotation opens the shutters, increasing the primary air

supply. The two adjustment screws should be rotated alternately to

open or close the shutters. Attempting to gain adjustment by not alternating between the two screws may cause the shutters to bind.

After proper adjustment has been completed, eliminating the problem

condition, close the bottom panel and replace the retaining screws.

Figure 14 - Air Shutter Adjustment Screws -- Alternate

Turning Screws When Adjusting Shutter

21. Pilot and Ignition System

These unit heaters are equipped with a spark ignited intermittent safety

pilot system that shuts off the pilot gas flow between heat cycles. In

addition, propane units are equipped with a spark pilot system that incorporates a lockout device that stops the gas flow to the pilot if the

pilot fails to light in 120 seconds. The spark pilot with 100% lockout

requires manual reset by interruption of the thermostat circuit. Propane

units require the lockout; natural gas units may be equipped with either

standard spark pilot or spark pilot with lockout (Option AH3). Refer to

the wiring diagram with your heater for pilot system identification and

proper wiring.

The ignition controller in the spark pilot system provides the high voltage spark to ignite the pilot gas and also acts as the flame safety device.

After ignition of the pilot gas, the control electronically senses the pilot

flame. (A separate solid metal probe in the pilot burner assembly is

employed for the flame sensing function. A low voltage electrical signal

Form 436, Page 18

DANGER: Failure to install and/or adjust air

shutters according to directions could cause

property damage, personal injury , and or death.

Page 19

24. Check Installation and Start-Up

Check the installation prior to start-up:

o Check suspension. Unit must be secure and level.

o Blower Model - Check to be sure that all shipping supports

have been removed. Rubber feet must be on the motor bracket

bolts. See Paragraph 4.

o Check clearances from combustibles. Requirements are shown

in Paragraph 6.

o Check vent system to be sure that it is installed according to

the instructions in Paragraph 9.

o Check piping for leaks and proper gas line pressure. Bleed

gas lines of trapped air. See paragraph 10.

o Check electrical wiring. Be sure all wire gauges are as rec-

ommended. A service disconnect switch should be used.

V erify that fusing or circuit breakers are adequate for the load

use.

o Check that any field-installed options have been included in

the installation.

o Blower Model - Check belt tension. See Paragraph 14.

Start-Up -- Typical Operating Sequence:

1. Set thermostat at lowest setting.

2. T urn on main and pilot manual gas valves.

3. Turn on the power to the unit.

4. Set the thermostat to desired setting.

5. Thermostat calls for heat, energizing the venter motor.

6. Venter pressure switch closes, firing the unit, after pilot proving sequence.

7. Fan control senses heat exchanger temperature, energizing

the fan or blower motor.

8. If the flame is extinguished during the main burner operation, the safety switch closes the main valve and recycles the

spark gap.

On units equipped with lockout device, if the pilot is not established within 120 seconds, the unit locks out and must be

reset by interrupting power to the control circuit. (See lighting instructions on the heater.)

Check installation after start-up:

o With the unit in operation, measure manifold gas pressure.

Manifold pressure for natural gas should be 3.5" w.c. and

10" w.c. for propane gas. See Paragraph 10.

o Turn the unit off and on, pausing two minutes between each

cycle. Observe for smooth ignition.

o Blower Model - Check motor amps with an amp meter. The

maximum amp rating on the motor nameplate must not be

exceeded.

o Place 'Owner's Envelope" containing Limited Warranty Card,

this booklet, and any optional information in an accessible

location near the heater. Follow the instructions on the envelope.

DANGER: The gas burner in this gas-fired equipment is designed and equipped to provide safe

and economically controlled complete combustion. However, if the installation does not permit

the burner to receive the proper supply of combustion air, complete combustion may not occur.

The result is incomplete combustion which produces carbon monoxide, a poisonous gas that can

cause death. Safe operation of indirect-fired gas burning equipment r equires a properly operating

vent system which vents all flue products to the outside atmosphere. FAILURE TO PROVIDE

PROPER VENTING WILL RESULT IN A HEALTH HAZARD WHICH COULD CAUSE

SERIOUS PERSONAL INJURY OR DEATH.

Always comply with the combustion air requirements in the installation codes and in Paragraphs

6 and 7. Combustion air at the burner should be regulated only by manufacturer-provided

equipment. NEVER RESTRICT OR OTHERWISE ALTER THE SUPPLY OF COMBUSTION

AIR TO ANY HEATER. Indoor units installed in a confined space must be supplied with air for

combustion as required by Code and in Paragraph 7 of this heater installation manual. MAINT AIN

THE VENT SYSTEM IN STRUCTURALLY SOUND AND PROPERLY OPERATING

CONDITION.

Mfg P/N 98807 Rev 8, Page 19

Page 20

OPTIONAL EQUIPMENT

This section contains a brief description of the more frequently specified field-installed options. All option packages include complete assembly

and installation instructions.

25. Optional Vertical Louvers Option CD1

The purpose of the addition of optional vertical louvers is to increase the air pattern spread. The vertical louver assembly is designed to be field assembled and installed. Refer to the instructions

packaged with Option CD1 for a list of components and step-bystep installation instructions (Do not add optional vertical louvers to

a fan-type heater with downturn nozzle Option CD3. See Paragraph

26.)

CAUTION: To avoid getting burned, adjust

louvers prior to heater operation. If louvers

need re-adjusting after start-up, wear

protective gloves.

Figure 15 Optional

Vertical

Louvers

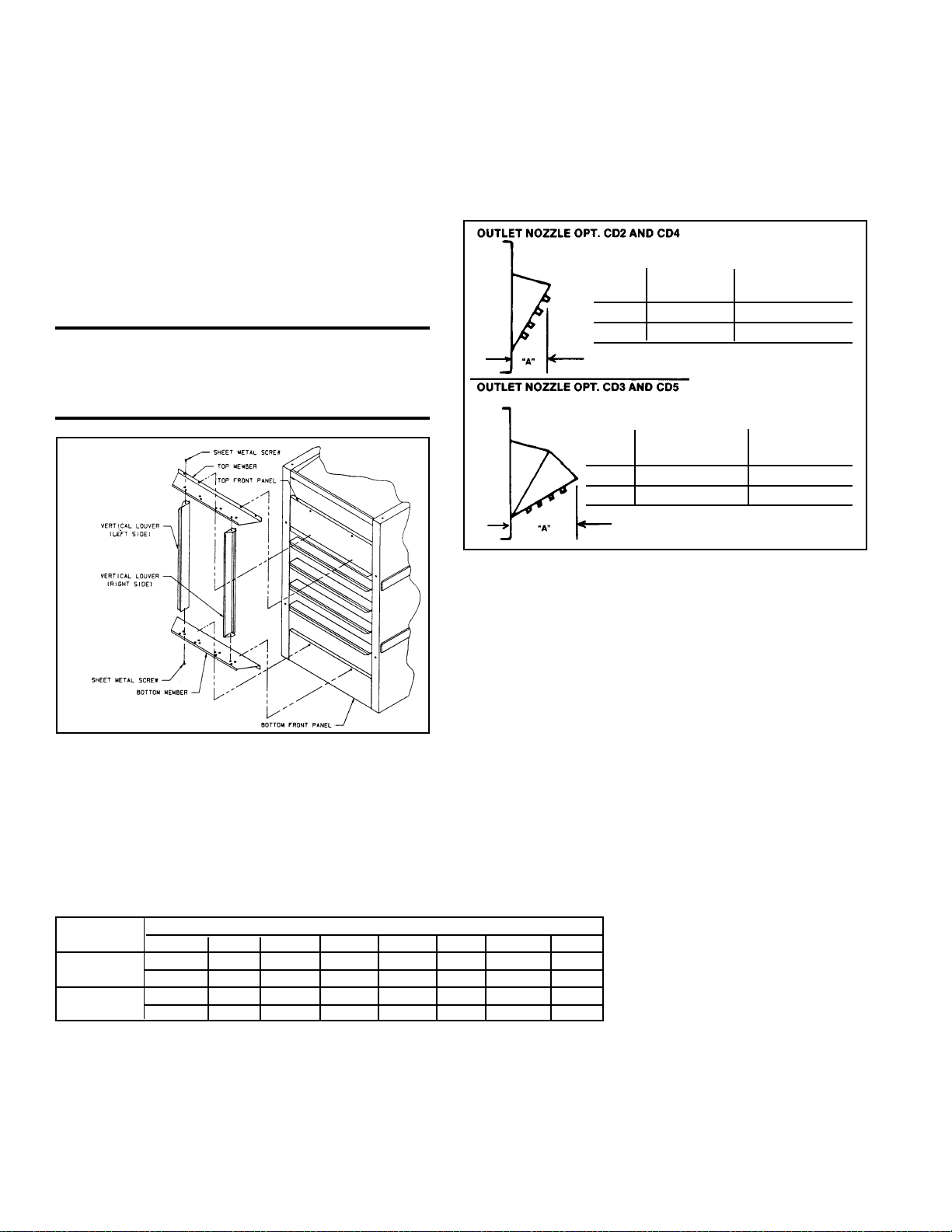

26. Optional Downturn Air Nozzles

- Options CD2, CD3, CD4, & CD5

Sizes "A" Range of

Air Deflection

25-125 9" (229mm) 25o-65

165-400 13" (330mm) 25o-65

Figure 16 - Optional

Downturn Nozzles

Sizes "A" Range of

Air Deflection

25-125 16-1/2" (419mm) 50o-90

165-400 23-1/2" (597mm) 50o-90

Unit heaters may be specified with optional downturn air nozzles to direct

the discharge tempered air. The nozzles are shipped separately for field

assembly and installation. The horizontal louvers are removed from the

heater and re-installed into the outlet of the downturn nozzle.

The addition of a downturn nozzle requires four-point heater suspension.

T wo hanger brackets are included with downturn nozzle options and must

be added to fan-type heaters with standard two-point suspension. Suspension point dimensions are found in Dimension Charts in Paragraph 3. On

fan-type heaters, do not install Option CD5 or use vertical louvers with

Option CD3.

o

o

o

o

27. Optional Duct Flange - Option CD9 (Blower Models only)

Blower-type unit heaters may be connected to ductwork. The duct flange option is designed to adapt

the heater outlet (supply side) for connection to ductwork.

Ductwork connection sizes are shown in the chart below.

Follow the installation instructions included with the option package.

Model BE Duct Connection Sizes (inches and mm) with Optional Duct Flange

Size 25-50 75 100 125 165 200 250-300 400

Height 15-7/8 15-7/8 15-7/8 15-7/8 23-7/8 23-7/8 23-7/8 23-7/8

403 403 403 403 606 606 606 606

Width 10-3/4 12-3/4 14-3/4 20-1/2 17-1/2 20-1/2 26 34-1/4

273 324 375 521 445 521 660 870

Form 436, Page 20

Page 21

28. Optional Polytube Adapter - Options CD6, CD8, and CD11

(Blower Models only)

The polytube adapter option is designed to adapt this blowertype heater for use with polytube ductwork. The use of