Thomas T175, 1700 Repair Manual

Publication No. 49012

REPAIR MANUAL

T175/1700

THOMAS

THOMAS EQUIPMENT LIABILITY WARRANTY

THE WARRANTY IS THE ONLY OBLIGATION OF THOMAS OR A THOMAS DEALER

TO THE PURCHASER OR ANYONE ELSE CONCERNING A PRODUCT, ITS SERVICE,

ITS USE OR PERFORMANCE OR ITS LOSS OF USE OR FAILURE TO PERFORM.

NEITHER THOMAS NOR A THOMAS DEALER HAVE MADE AND NEITHER WILL

MAKE ANY OTHER EXPRESSED OR IMPLIED REPRESENTATION, WARRANTY OR

AGREEMENT CONCERNING A PRODUCT. NEITHER THOMAS NOR A THOMAS

DEALER HAVE MADE OR WILL MAKE ANY REPRESENTATION, WARRANTY OR

AGREEMENT CONCERNING A PRODUCTS MERCHANTABILITY OR OTHER

QUALITY, ITS SUITABILITY FOR PURCHASER’S PURPOSE (EVEN IF A PURCHASER

HAS INFORMED THOMAS OR A THOMAS DEALER OF THAT PURPOSE), ITS

DURABILITY, PERFORMANCE OR OTHER CONDITION.

EVEN IF THOMAS OR A THOMAS DEALER WAS ADVISE OF THE POSSIBILITY OF

SUCH LOSS, NEITHER THOMAS NOR A THOMAS DEALER WILL BE LIABLE TO

PURCHASER OR ANYONE ELSE FOR ANY INDIRECT, INCIDENTAL

CONSEQUENTIAL, PUNITIVE, ECONOMIC, COMMERCIAL, OR SPECIAL LOSS

WHICH IS IN ANY WAY ASSOCIATED WITH A PRODUCT. THIS INCLUDES ANY LOSS

OF USE OR NON-PERFORMANCE OF A PRODUCT, ANY REPLACEMENT RENTAL OR

ACQUISITION COST, ANY LOSS OF REVENUE OR PROFITS, ANY FAILURE TO

REALIZE EXPECTED SAVINGS, ANY INTEREST COSTS, ANY IMPAIRMENT OF OTHER

GOODS, ANY INCONVENIENCE OR ANY LIABILITY OF PURCHASER TO ANY OTHER

PERSON.

PURCHASER MAY NOT ATTEMPT TO ENLARGE ITS RIGHTS UNDER THE

WARRANTY BY MAKING A CLAIM FOR INDEMNITY, FOR BREACH OF CONTRACT,

FOR BREACH OF COLLATERAL WARRANTY, FOR A TORT (INCLUDING

NEGLIGENCE, MISREPRESENTATION OR STRICT LIABILITY) OR BY CLAIMING ANY

OTHER CAUSE OF ACTION.

THE WARRANTY IS A CONDITION OF SALE OF THE PRODUCT TO PURCHASER

AND WILL THEREFORE APPLY EVEN IF PURCHASER ALLEGES THAT THERE IS A

TOTAL FAILURE OF THE PRODUCT.

N.B. Read and practice your Thomas operating and servicing instructions. Failure to do this may

void your warranty.

Publication Number 49012

2

FOREWORD

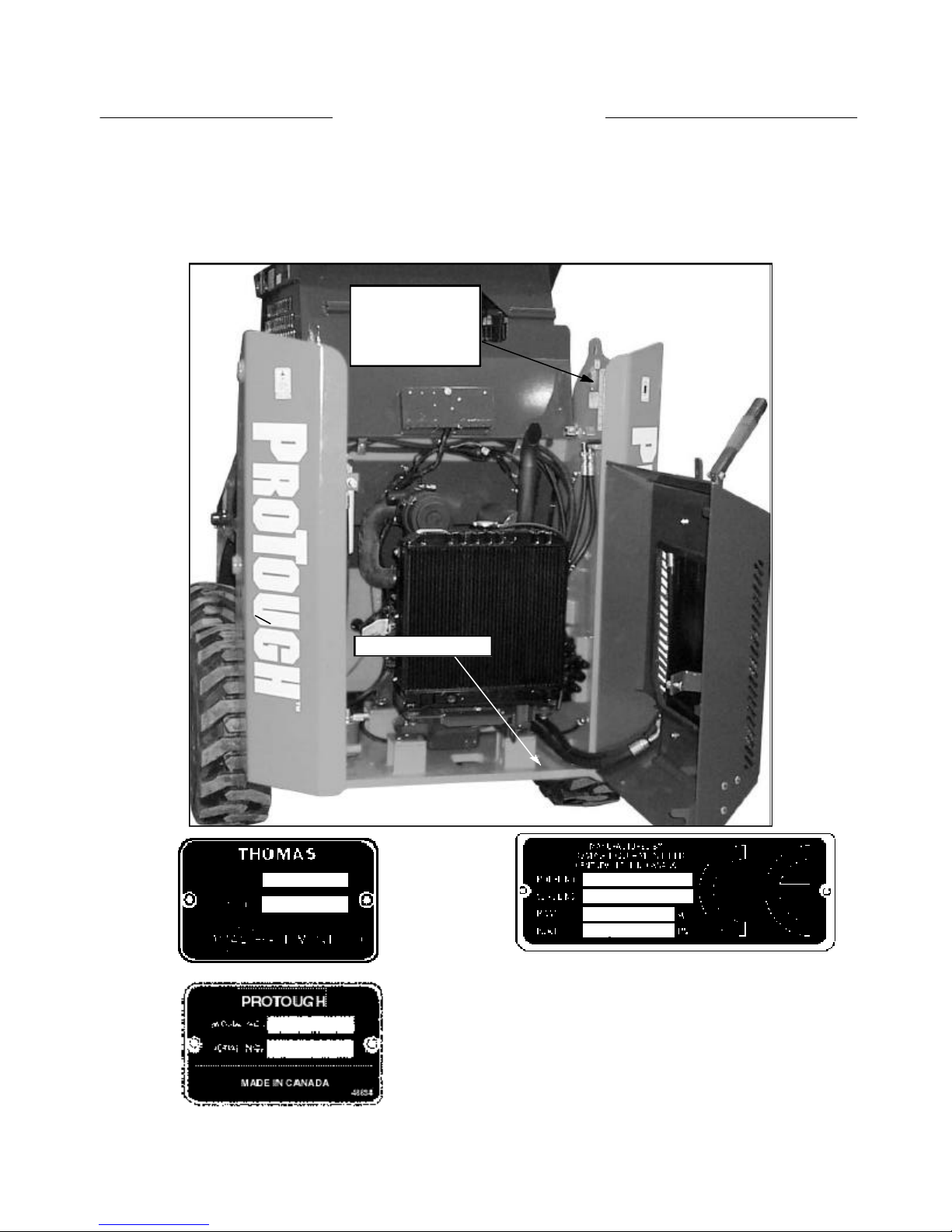

It is important when ordering replacement parts or making a service inquiry to provide both the model number

and serial number of your Thomas loader. The serial number plate is located at the rear of the machine on the

right hand side fuel tank. In the event that the serial number plate is missing, the model number and serial

number are both stamped into the main frame inside the rear door, next to the hydraulic control valve.

S / N Tag location.

Tag is found on

opposite side on

some models

C3313

S / N Stamp location

3

SAFETY PRECAUTIONS

Practically all Service work involves the need to drive the

loader. The Owner’s / Operator’s Manual, supplied with

each loader, contains safety precautions relating to

driving, operating and servicing that loader. These

precautions are as applicable to the service technicians as

they are to the operator and should be read, understood

and practiced by all personnel.

Prior to undertaking any maintenance or repair operations,

make the neccessary safety precautions to prevent

possible personal injury to yourself, or to bystanders.

PERSONAL CONSIDERATIONS

* CLOTHING

The wrong clothing or carelessness in dress can

cause accidents. Check to see that you are

suitably clothed. Some jobs require special

protective equipment.

* SKIN PROTECTION

Avoid long term contact with used motor oil.

Follow work practices that minimize the amount

of skin exposed and length of time used oil stays

on your skin.

* EYEPROTECTION

Injury can be avoided by wearing eye protection

when engaged in chiseling, grinding, welding,

painting and any other task that involves airborne

matter.

falling objects.

* SPECIALCLOTHING

For certain work it may be necessary to wear

flame or acid resistant clothing.

EQUIPMENT CONSIDERATIONS

CAUTION

Avoid injury through incorrect handling of

components. Make sure your are capable of lifting

the object. If in doubt, get help.

* MACHINE GUARDS

Before using any machine, check to ensure that

the machine guards are in position and

serviceable. These guards not only prevent parts

of the body or clothing coming in contact with

the moving parts of the machine but also ward

off objects that might fly off the machine and

cause injury.

* LIFTING APPLIANCES

Always ensure that lifting equipment, such as

chains, slings, lifting brackets, hooks and eyes

are thoroughly checked before use. If in doubt,

select stronger equipment. Never stand under a

suspended load or raised implement.

* BREATHING PROTECTION

Fumes, dust and paint spray are unpleasant and

harmful. These can be avoided by wearing

respiratory protection.

* HEARINGPROTECTION

Loud noise may damage your hearing and the

longer the exposure the greater the risk of

hearing damage. Always wear hearing protection

when working around loud machinery.

* HAND PROTECTION

It is advisable to use a protective cream before

work to prevent irritation and skin

contamination. After work, clean your hands

with soap and water. Solvents such as white

spirits, paraffin, etc. may harm the skin.

* FOOTPROTECTION

Substantial or protective footwear with

reinforced toecaps will protect the feet from

* COMPRESSED AIR

The pressure from a compressed air line is often

as high as 100 PSI (6.9 Bar). Any misuse may

cause injury.

Never use compressed air to blow dust, filing

dirt, etc. away from your work area unless the

correct type of nozzle is fitted.

Compressed air is not a cleaning agent. It will

only move dust etc. from one place to another.

Look around before using an air hose as

bystanders may get grit into their eyes, ears and

skin.

4

SAFETY PRECAUTIONS

* HAND TOOLS

Many cuts, abrasions and injuries are caused by

defective tools. Never use the wrong tool for the

job as this leads either to injury or to a poor job.

Never Use:

A hammer with a loose or split handle.

Spanners or wrenches with spread or worn

jaws.

Wrenches or files as hammers, drills, clevis

pins or bolts as punches.

For removing or replacing hardened pins use a

copper or brass drift.

For dismantling, overhaul and assembly of major

and sub-components always use the Special

Service Tools recommended. These will reduce

the work effort, labor time and the repair cost.

Always keep tools clean and in good working

order.

* ELECTRICITY

Electricity has become so familiar in day to day

usage that it’s potentially dangerous properties

are often overlooked. Misuse of electrical

equipment can endanger life.

Before using any electrical equipment,

particularly portable appliances, make a visual

check to ensure that the cable is not worn or

frayed and that the plugs, sockets etc.are intact.

Make sure you know where the nearest isolating

switch for your equipment is located.

GENERAL CONSIDERATIONS

* SOLVENTS

Use only cleaning fluids and solvents that are

known to be safe. Certain types of fluids can

cause damage to components such as seals, etc.

and can cause skin irritation. Solvents should be

checked that they are suitable not only for the

cleaning of components and individual parts but

also that they do not affect the personal safety of

the user.

* HOUSEKEEPING

Many injuries result from tripping or slipping

over, or on, objects or materials left lying around

by a careless worker.

Prevent these accidents from occurring. If you

notice a hazard, don’t ignore it, remove it.

A clean hazard free place of work improves the

surroundings and daily environment for

everybody.

* FIRE

Fire has no respect for persons or property. The

destruction that a fire can cause is not always

fully realized. Everyone must be constantly on

guard.

- Extinguish matches, cigars, cigarettes etc.

before throwing them away.

- Work cleanly, disposing of waste material into

proper containers.

- Locate all the fire extinguishers and ensure all

personnel know how to operate them.

- Do not panic, warn those near and sound the

alarm.

- Do not allow or use an open flame near the

loader fuel tank, battery or component parts.

* FIRST AID

In the type of work that mechanics are engaged

in, things such as dirt, grease, fine dust etc. all

settle upon the skin and clothing. If a cut,

abrasion or burn is disregarded it may be found

that a septic condition has formed in a short time.

What appears at first to be trivial could become

painful and injurious. It only takes a few minutes

to have a fresh cut dressed but it will take longer

if you neglect it.

* CLEANLINESS

Cleanliness of the loader hydraulic system is

essential for optimum performance. When

carrying out service and repairs, plug all hose

ends and components connections to prevent dirt

entry.

Clean the exterior of all components before

carrying out any form of repair. Dirt and abrasive

dust can reduce the efficiency and working life

of a component and lead to costly replacement.

Use of a high pressure washer or steam cleaner is

5

recommended.

SAFETY PRECAUTIONS

OPERATIONAL CONSIDERATIONS

* Stop the engine, if at all possible, before

performing any service.

* Place a warning sign on loaders which, due to

service or overhaul, would be dangerous to start.

Disconnect the battery leads if leaving such a

unit unattended.

* Do not attempt to start the engine while standing

beside the loader or attempt to bypass the safety

starting system.

* Avoid prolonged running of the engine in a

closed building or in an area with inadequate

ventilation as exhaust fumes are highly toxic.

* Always turn the radiator cap to the first stop to

allow pressure in the system to dissipate when

the coolant is hot.

* Never work beneath a loader which is on soft

ground. Always take the unit to an area which

has a hard working surface, preferably concrete.

* If it is found necessary to raise the loader for

ease of maintenance, make sure that safe and

stable supports are installed beneath the main

frame before commencing work.

* Use footsteps or working platforms when

servicing those areas of the loader that are not

within easy reach.

* Before loosening any hoses or tubes, switch off

the engine, remove all pressure in the lines by

operating the foot pedals several times. This will

remove the danger of personal injury by oil

pressure.

* If high lift attachments are installed on a loader,

beware of overhead power and telephone lines

when travelling. Drop attachment near to ground

level to increase stability and minimize risks.

* Do not park or attempt to service a loader on an

incline. If unavoidable, take extra care and block

the wheels.

* Escaping hydraulic / diesel fluid under pressure

can penetrate the skin causing serious injury. Do

not use your hand to check for leaks. Use a piece

of cardboard or paper to search for leaks. Stop

the engine and relieve pressure before connecting

or disconnecting lines. Tighten all connections

before starting the engine or pressurizing the

lines. If any fluid is injected into the skin, obtain

medical attention immediately.

* Prior to removing wheels and tires from a loader,

check to determine whether additional ballast

(liquid or weight) has been added. Seek

assistance and use suitable equipment to support

the weight of the wheel assembly.

* When inflating tires beware of over inflation;

constantly check the pressure. Over inflation can

cause tires to burst and result in personal injury.

* Safety precautions are very seldom the figment

of someone’s imagination. They are the result of

sad experience where most likely someone has

paid dearly through personal injury.

* Heed these precautions and you will protect

yourself accordingly. Disregard them and you

will duplicate the sad experiences of others.

* Prior to pressure testing, make sure all the hoses

and connectors on both the loader and on the test

machine are in good condition and tightly sealed.

Pressure readings must be taken with the gauges

specified. The correct procedure should be

rigidly observed to prevent damage to the system

or the equipment and to eliminate the possibility

of personal injury.

* Always lower equipment to the ground when

leaving the loader.

6

SAFETY PRECAUTIONS

SERVICE TECHNIQUES

A. SERVICE SAFETY

Appropriate service methods and proper repair

procedures are essential for the safe, reliable

operation of all motor vehicles as well as the

personal safety of the individual doing the work. This

shop manual provides general directions for

accomplishing service and repair work with

tested effective techniques. Following them will help

assure reliability.There are numerous variations in

procedures, techniques, tools and parts for servicing

vehicles as well as in the skill of the individual doing the

work. This manual cannot possibly anticipate all such

variations and provide advice or cautions as to each.

Accordingly, anyone who departs from the instructions

provided in this manual must first establish that he or she

compromises neither his personal safety nor the vehicle

integrity by his choice of methods, tools or parts.

B. SERVICE TECHNIQUES

Clean the exterior of all components before carrying out

any form of repair. Dirt and abrasive dust can reduce the

efficient working life of a component and lead to costly

replacement.

Use cleaning fluids which are known to be safe. Certain

types of fluid can cause damage to O- rings and cause

skin irritation. Solvents should be checked that they are

suitable for the cleaning of components and also that they

do not risk the personal safety of the user.

Time spent on the preparation and cleanliness of working

surfaces will pay dividends in making the job easier and

safer and will result in overhauled components being

more reliable and efficient in operation.

When installing a new hose, loosely connect each end and

make sure the hose takes up the designed position before

tightening the connection. Clamps should be tightened

sufficiently to hold the hose without crushing and to

prevent chafing.

The hoses are the arteries of the unit. Be sure they are in

good condition when carrying out repairs or maintenance.

Otherwise the machines output and productivity may be

affected.

After hose replacement to a moving component, check

that the hose does not foul by moving the component

through the complete range of travel.

Hose connections which are damaged, dented , crushed or

leaking, restrict oil flow and the productivity of the

components being served. Connectors which show signs

of movement from the original swaged position have

failed and will ultimately separate completely.

A hose with a chafed outer cover will allow water entry.

Concealed corrosion of the wire reinforcement will

subsequently occur along the hose length with resultant

hose failure.

Ballooning of the hose indicates an internal leakage due

to structural failure. This condition rapidly deteriorates

and total hose failure soon occurs.

Kinked, crushed, stretched or deformed hoses generally

suffer internal structural damage which results in oil

restriction, a reduction in the speed of operation and

ultimate hose failure.

Free moving, unsupported hoses must never be allowed to

touch each other or related working surfaces. This causes

chafing which reduces hose life.

Replace O rings, seals or gaskets whenever they are

disturbed. Never mix new and old seals and O rings,

regardless of condition. Always lubricate new seals and O

rings with hydraulic oil before installation.

When replacing component parts use the correct tool for

the job.

C. HOSES AND TUBES

Always replace hoses and tubes if the end connections are

damaged. Be sure any hose installed is not kinked or

twisted.

D. PRESSURE TESTING

Prior to pressure testing, be sure all hoses are in good

condition and all connections tight. Pressure readings

must be taken with gauges of specified pressure readings.

The correct procedure should be rigidly observed to

prevent damage to the system or the equipment and to

eliminate the possibility of personal injury.

7

SAFETY PRECAUTIONS

E. BEARINGS

Bearings which are considered suitable for further service

should be cleaned in a suitable solvent and immersed in

clean lubricating oil until required.

Installation of a bearing can be classified into two (2)

ways:

press fit on rotating parts such as shafts and gears,

push fit into static locations such as reduction gear

houses.

Where possible, always install the bearing onto the

rotating components first. Use the correct tools or a press

to install a bearing or bushing. In the absence of the

correct tools or press, heat the bearing and / or casing in

hot oil to assist the installation of the bearing.

When bearings or bushings are removed, always carefully

check that the bearing is free from discoloration and signs

of overheating. Also check for mechanical damage such

as excessive clearance, nicks and scuffing. If in doubt,

replace the bearings or bushings.

Bearings should never be removed unless absolutely

necessary. Always use the recommended puller to reduce

the risk of bearing or related component failure.

These bearings and bushings are subjected, in normal

operation, to high working loads and adverse conditions.

Be sure during normal routine servicing, maintenance or

repair that bearings are given the right attention and are

installed with care.

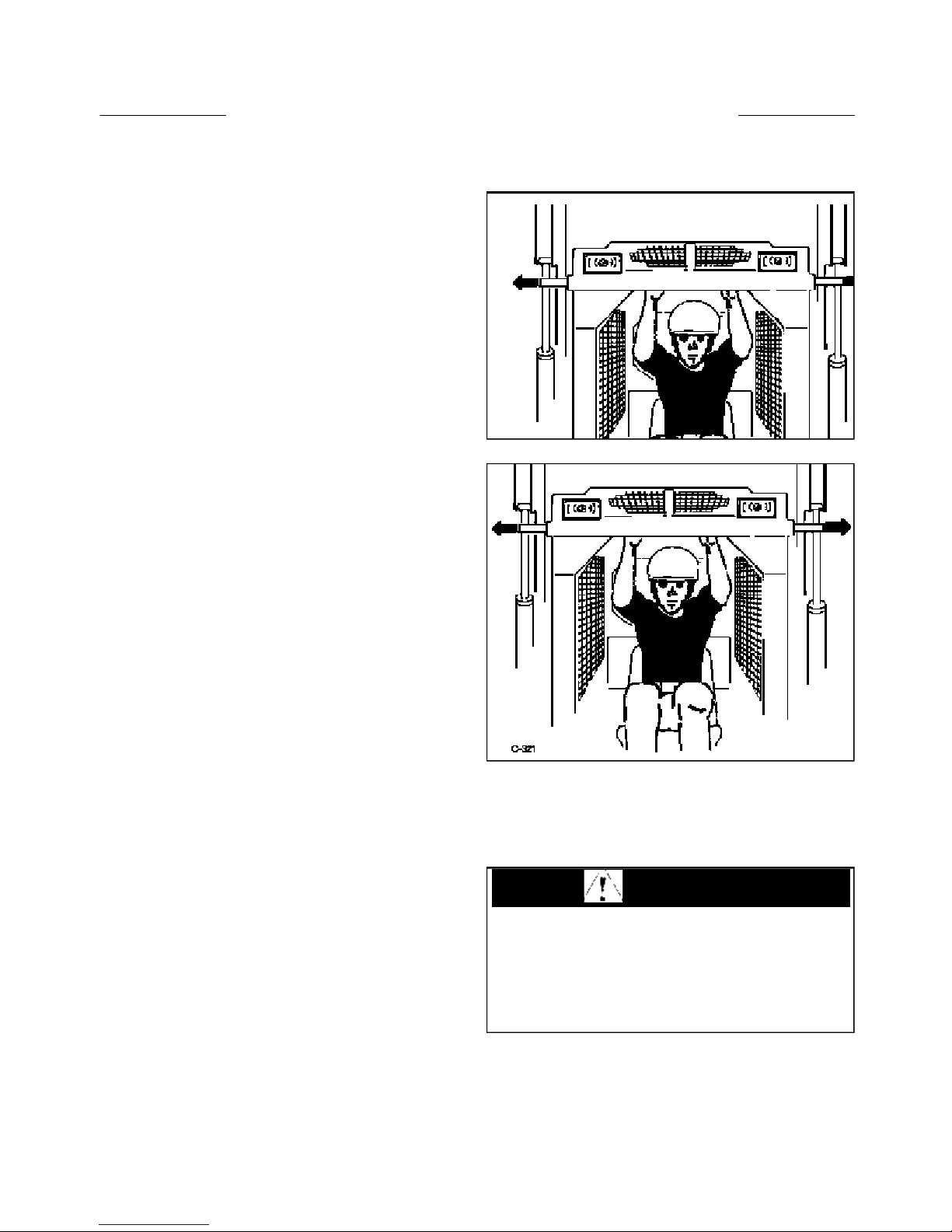

F. BOOM SUPPORTS

For safety while performing regular service or

maintenance work, the loader is equipped with boom

supports.

The boom supports, when extended, prevent the boom

arms from dropping if hydraulic pressure is relieved or

the foot control pedals are accidentally cycled.

To operate the boom supports, first remove any bucket or

attachment from the quick - tach; raise the boom arms to

full height and shut off the engine. Raise the boom

handles up and push out toward the boom arms to extend

the boom supports.

WARNING

To avoid personal injury, service the loader with the

arms down and the bucket or attachment on the

ground. If it is necessary to service the loader with

the boom arms raised be sure to engage the boom

supports. Never work under or around a loader with

raised boom arms without boom supports engaged.

8

TABLE OF CONTENTS

Section 1 Hydraulic System

Hydraulic Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.1

Gear Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2

Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.3

Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5

Oil Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.6

Oil Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.7

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.8

Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.9

Conversion Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.10

Section 2 Hydrostatic Drive System

Specifications.....................................................................................2.1

General Information...........................................................................2.2

Trouble Shooting ...............................................................................2.3

Pressure Tests.....................................................................................2.4

Towing Procedure ..............................................................................2.5

Flushing The Hydraulic System ........................................................2.6

Start - up Procedure ...........................................................................2.7

Gear Pump Replacement...................................................................2.8

Tandem Pump Replacement ..............................................................2.9

Tandem Pump Parts Diagram............................................................2.10

Drive Motor .......................................................................................2.11

Torque Specifications........................................................................2.12

Conversion Chart ...............................................................................2.13

Section 3 Final Drive

Specifications and Maintenance ........................................................3.1

Lubrication .........................................................................................3.2

Drive Chain........................................................................................3.3

Chain Tightener..................................................................................3.4

Drive Motor Sprocket........................................................................3.5

Axle Assembly...................................................................................3.6

Trouble Shooting ...............................................................................3.7

Section 4 Controls

Steering..............................................................................................4.1

Foot Pedals.........................................................................................4.2

Hand Controls ....................................................................................4.3

Throttle...............................................................................................4.4

Restraint Bar......................................................................................4.5

Parking Brake ....................................................................................4.6

Trouble Shooting ...............................................................................4.7

9

TABLE OF CONTENTS

Section 5 Electrical

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.1

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.2

Instrumentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.3

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.4

Engine Glow Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.6

Electrical Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.7

Starter Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.8

Charging Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.9

Safety Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.10

Auxiliary Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.11

Accessory Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.12

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.13

Section 6 Main Frame

Quick - Tach .......................................................................................6.1

Boom Arms........................................................................................6.2

Boom Support....................................................................................6.3

ROPS .................................................................................................6.4

Rear Door...........................................................................................6.5

Section 7 Engine

Maintenance .......................................................................................7.1

Cylinder Head ....................................................................................7.2

Replacement.......................................................................................7.3

Specifications.....................................................................................7.4

Trouble Shooting ...............................................................................7.5

Section 8 Maintenance & Specifications

Maintenance .......................................................................................8.1

Trouble Shooting ...............................................................................8.2

Special Tools ......................................................................................8.3

Specifications.....................................................................................8.4

Decals.................................................................................................8.5

10

SECTION 1 HYDRAULIC SYSTEM

1

Hydraulic Circuit 1.1

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~2

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~4

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~4

Gear Pump 1.2

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg. 1~5

Replacing the Gear Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~6

Gear Pump Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-7 ~ 10

Gear Pump Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-11 ~ 13

Control Valve 1.3

Testing / Adjusting the Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-14 ~ 15

Control Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-15 ~ 16

Exploded Illustration Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-17 ~ 18

Control Valve Disassembly / Repair(175) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-19 ~ 24

Control Valve Dissassembly/Repair(1700) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg. 1-25~28

Hydraulic Cylinders 1.4

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg. 1~29

Testing Piston Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~30

Lift Cylinder Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~31

Tilt Cylinder Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~32

Cylinder Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-33 ~ 34

Cylinder Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-35

Cylinder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-35 ~ 36

Hydraulic Oil Filter 1.5

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~37

Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~37

Hydraulic Oil Cooler 1.6

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg. 1~38

Oil Cooler Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg. 1~38

Hydraulic Oil Reservoir 1.7

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~39

Checking the Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~39

Adding Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~39

Servicing the Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~40

Trouble Shooting 1.8

Trouble Shooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-41 ~ 42

Torque Chart 1.9

Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1~42

Conversion Charts 1.10

Conversion Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg. 1-43 ~ 1-45

1-1

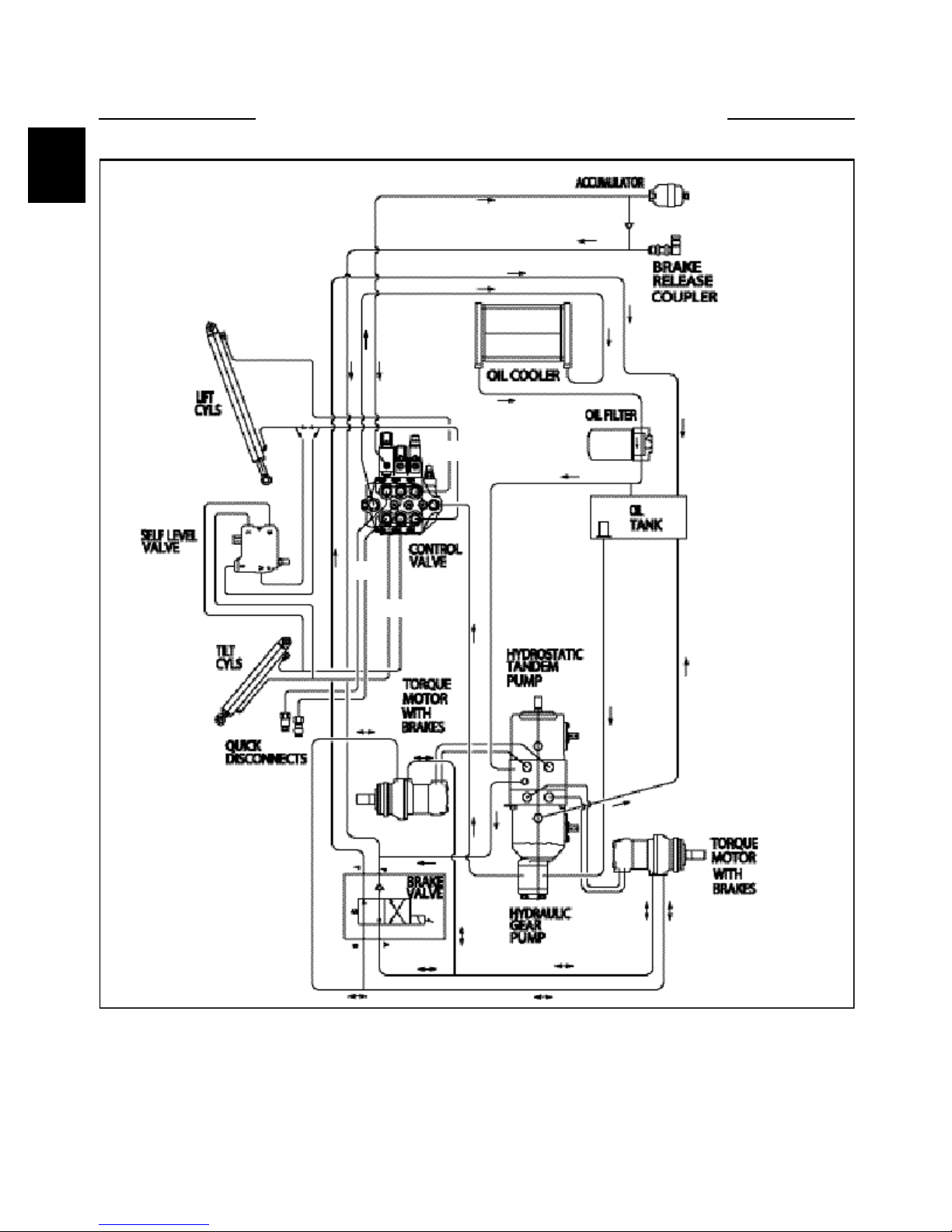

HYDRAULIC LAYOUT 1.1

C C

AA

B B

C4165

A Auxiliary Circuit

B Tilt Circuit

C Lift Circuit

NOTE: Foot pedal control operated machine illustrated.

Items (A3 / B3) are reversed for hand control operated

machines.

Hydraulic fluid comes out the port closest to the spool

end of the valve when the spool is pushed in.

Hydraulic fluid received at the fixed end of the cylinder

pushes it out. When the hydraulic cylinder receives fluid

at the ram (rod) end, it retracts.

1-2

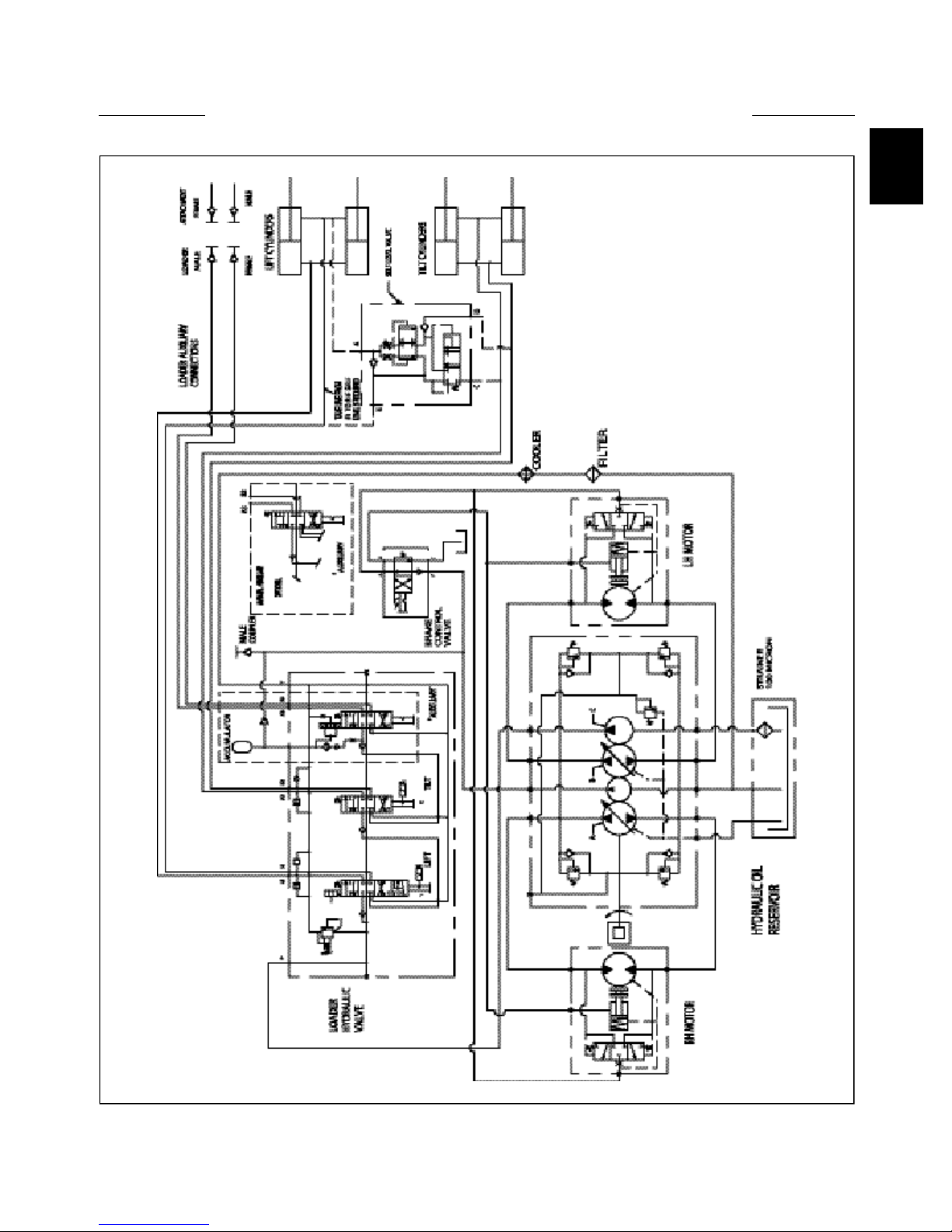

HYDRAULIC SCHEMATIC 1.1

1

C4191

1-3

SPECIFICATIONS & MAINTENANCE 1.1

Hydraulic Specifications

Pump Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gear, 1.37 cu. in. (22.4cc)

Pump Brand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sauer Sundstrand

Pump Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.6 GPM (62.8 LPM)

Rated Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2800 RPM

Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Series Type

Main Relief Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2400 PSI (165.5 Bar) @ Zero Flow

Reservoir Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.8 US Gallons (56 Liters)

Fluid Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10W30 API SJ Oil

Reservoir Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 Micron

System Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Micron

Oil Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650 BTU

Lift Cylinders (STD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (2) 2.5’’ Bore Diameter

Lift Cylinder Rods (STD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5’’ Diameter

Tilt Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (2) 2 1/2’’ Bore Diameter

Tilt Cylinder Rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5’’ Diameter

Lift Cycle Cyl. + / - 1.5 seconds (Up / Down) T175 . . . . . . . . . . . . . . . . . . . . . . . . 5.50 / 3.56

Lift Cycle Cyl. + / - 1.5 seconds (Up / Down) 1700 . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6 / 3.0

Tilt Cycle + / - 1.5 seconds (Up / Down) T175 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.84 / 2.61

Tilt Cycle + / - 1.5 seconds (Up / Down) 1700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.73 / 2.28

Lift & Tilt Cycle Cyl., + / - 1.5 seconds (Up & Out) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.25

Lift & Tilt Cycle Cyl., + / - 1.5 seconds (Down & In) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.55

Allowable Drop, Measured at the Cylinder Rod, Engine Off,

@ Rated Capacity and Operating Temperature . . . . . . . . . . . . . . . . 1.5’’ (38mm) / 3 Minutes

Maintenance Schedule . . . . . . . . . First (HRS) . . . . Every (HRS)

Oil level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 . . . . . . . . . . . . . . . . . . . . . 8

Oil filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 . . . . . . . . . . . . . . . . . . . . 150

Oil cooler clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 . . . . . . . . . . . . . . . . . . . . . 8

General system check

( leaks etc. ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 . . . . . . . . . . . . . . . . . . . . . 8

Cylinders, lubricate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 . . . . . . . . . . . . . . . . . . . . . 8

Control valve relief filter . . . . . . . . . . . . . . . . . . . . . . . 500 . . . . . . . . . . . . . . . . . . . 1000

Reservoir filters change . . . . . . . . . . . . . . . . . . . . . . . 1000 . . . . . . . . . . . . . . . . . . 1000

Hydraulic oil change . . . . . . . . . . . . . . . . . . . . . . . . . 1000 . . . . . . . . . . . . . . . . . . 1000

1-4

GENERAL INFORMATION 1.2

1

Refer to figure C2018 on page 1-2.

Oil is drawn from the hydraulic oil reservoir through a

100 micron element. From there it travels to the main

hydraulic pump.

• The hydraulic pump is a gear type which is driven by a

shaft and coupler through the hydrostatic drive pump at

engine speed. The oil then flows from the gear pump to

the hydraulic control valve.

• The hydraulic control valve is equipped with an

adjustable relief valve which is adjusted to 2400 PSI

(165.5 Bar). The control valve is a series type with 3

spools (banks). The various spools activate the boom,

bucket and auxiliary hydraulic functions.

When the spools are in neutral, oil flows from the

hydraulic gear pump, through the control valve and

returns to the hydraulic cooler, to the 5 micron hydraulic

filter. From the hydraulic filter, the fluid flows to charge

the tandem hydrostatic pump and pressurize the hydraulic

brake release system and then back to the hydraulic

reservoir. As a spool is moved, oil is directed to one of

the valve ports and oil flows out to operate a function.

The return oil coming back from this operation is ported

to the next valve section which allows operation of more

than 1 function at the same time. This is a series type

valve function.

Each spool end contains a centering spring which returns

the spool to neutral when the foot pedal, or control

handle, is released.

• The boom section, on foot control operated loaders, has

a detent mechanism to hold the spool in the float position.

The auxiliary section is operated by foot pedal operation,

or may have an optional electrical solenoid operated

control, and may be engaged momentarily by the control

lever mounted switch, forward or reverse, or by engaging

the dash mounted toggle switch for constant power in the

forward direction only.

The system relief valve operates when ever a hydraulic

function has been restricted or overloaded (fig. C3746).

To protect against excessive pressure build up, the relief

valve opens and allows oil to return to the return outlet.

The system relief valve is adjustable, and is preset at

2400 PSI. (165.5 Bar)

• Load check valves are located between the ports of

each spool circuit. The function of the load check valve is

to hold the boom arms or bucket in position during initial

spool movement (fig. C3717).

Gear pump location

C3426

Control valve location

C3427

Relief Valve

C3746

Check Valve

1-5

C3717

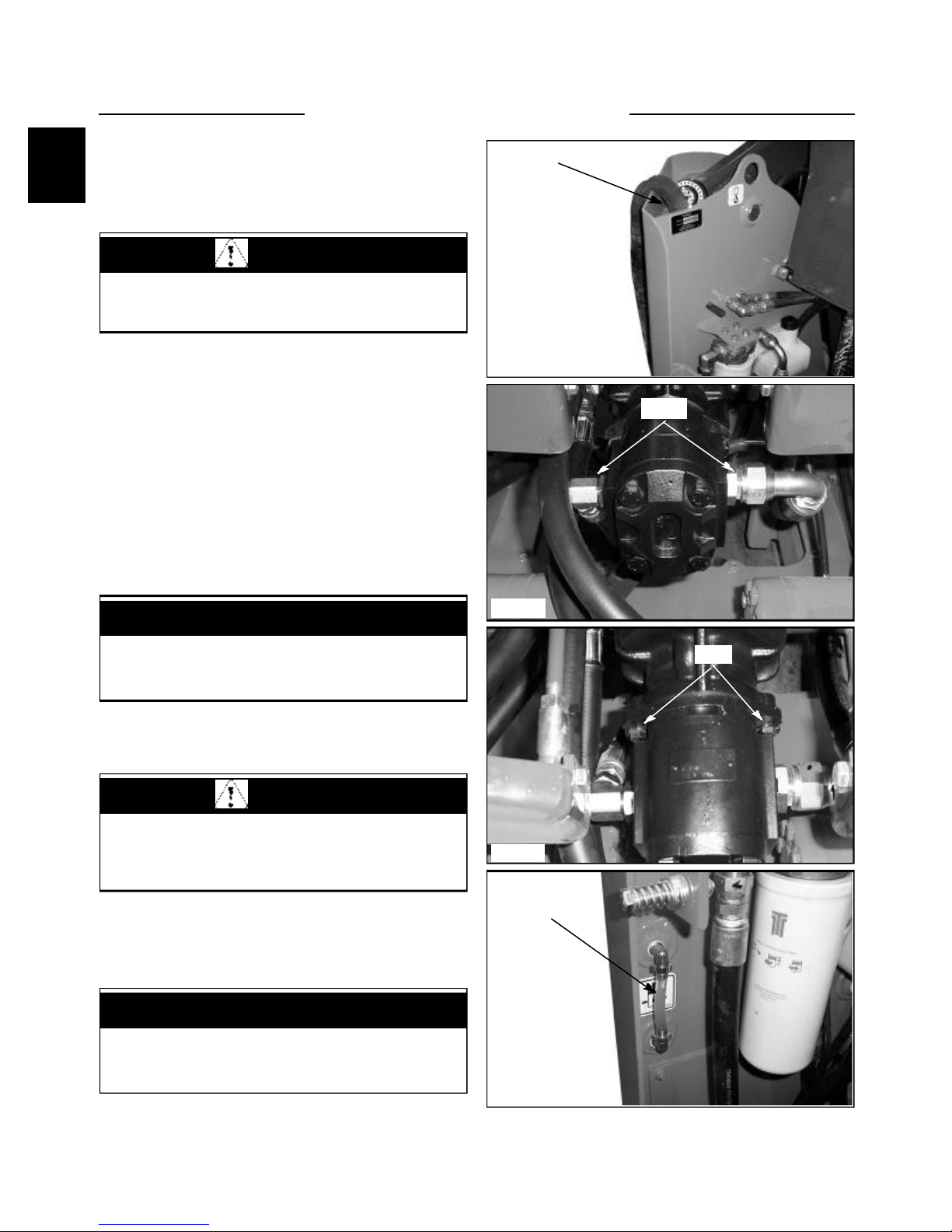

GEAR PUMP 1.2

Replacement

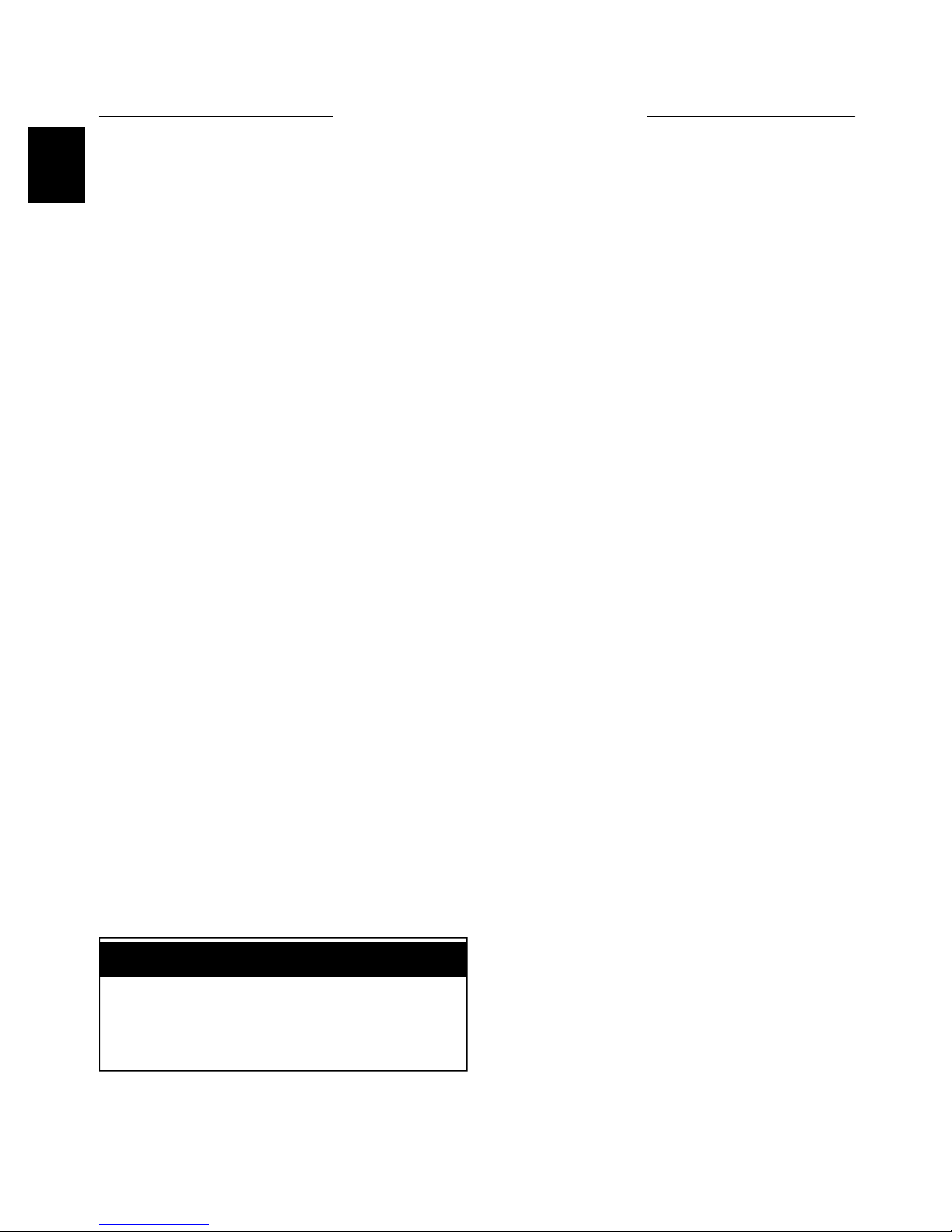

Start the gear pump removal procedure by removing any

attachment, raising the boom arms and engaging the

boom support pins. Shut off the engine.

WARNING

To prevent personal injury do not work under the

boom arms without the boom supports engaged.

1 Remove the seat and hydrostatic shield.

2 Attach a vacuum system to the hydraulic oil reservoir

filler location. ( fig. C3428 ) Or drain the oil reservoir.

Seal the threads on the drain plug, if removed, with teflon

tape or a liquid form of pipe sealant before re - installing.

3 Disconnect the hydraulic hoses from the gear pump.

( fig. C3429 ) Remove the pump fittings. Cap all open

hoses to prevent contamination. After capping ends you

may unhook vacuum system from oil reservoir.

4 Remove the 2 bolts holding the gear pump to the

hydrostatic tandem section. ( fig. C3430) Remove the

gear pump.

5 Replace gear pump in reverse order.

Reservoir filler spout

C3428

Hoses

IMPORTANT

If gear pump replacement is being done because of

failure, the hydraulic system and oil should be

checked for contamination.

6 If the hydraulic system has been contaminated by

pump or other failure you must follow the cleaning

procedure outlined in section 2.7.

WARNING

Use caution when dealing with hydraulic fluid under

pressure. Escaping fluid under pressure can

penetrate the skin and cause serious injury.

7 Start the engine and check for leaks. Do not use your

hands to find leaks.

8 Check the fluid level in the hydraulic oil reservoir

and replenish as required. (fig. C3431)

IMPORTANT

When making repairs to the hydraulic system, keep

the work area and parts clean. Use caps and plugs

on all open lines and ports.

C3429

Bolts

C3430

Oil level

C3431

1-6

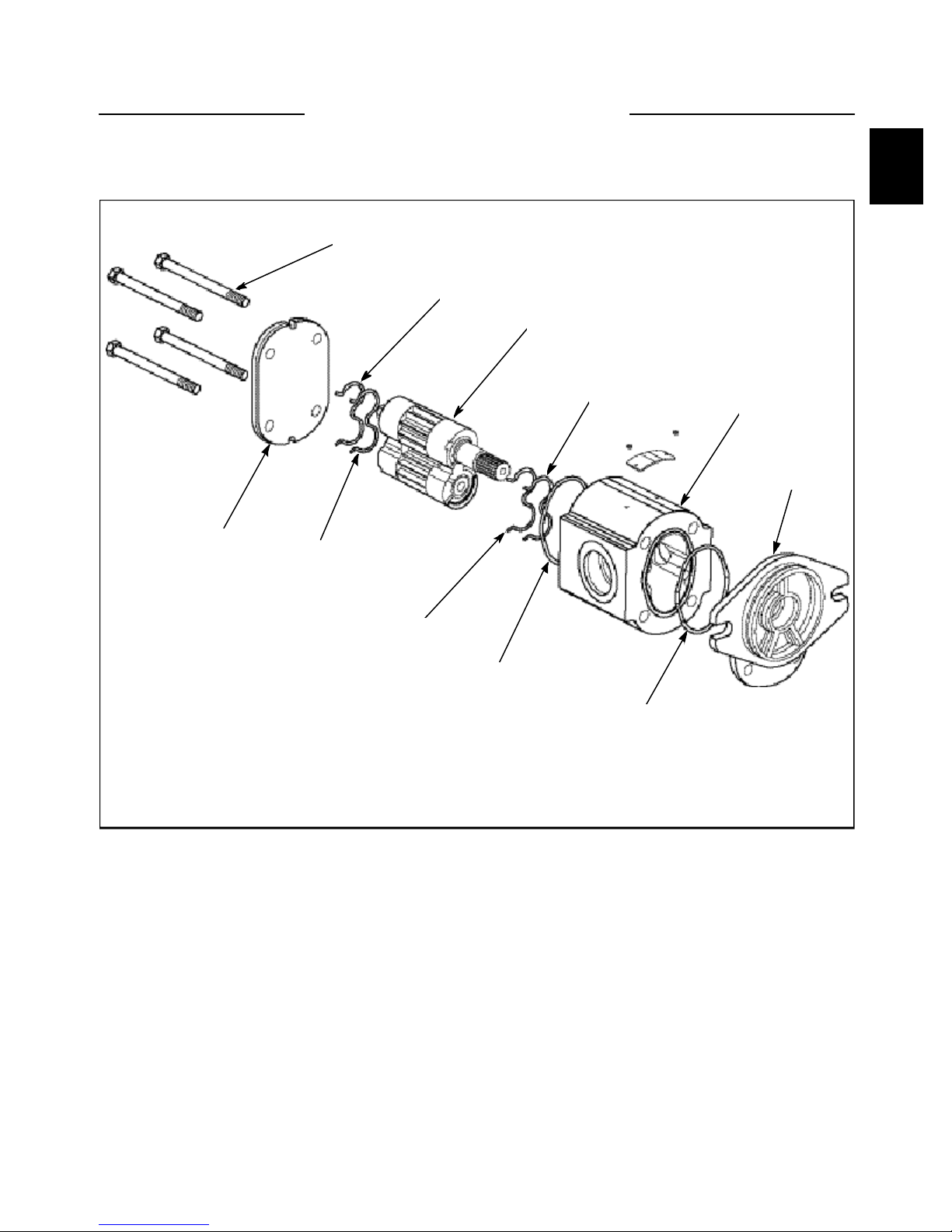

Disassembly

1

GEAR PUMP 1.2

1

3

5

C3835

3

2

4

4

6

6

7

8

1. Screws

2. Rear Cover

3. Backing Strip

4. Moulded Seal

5. Drive Gear

6. O-Ring Seal

7. Body

8. Front Plate

1-7

GEAR PUMP 1.2

Disassembly (continued)

1. General

The following is a detailed procedure for dissambly

and assembly of the SP2.5 pumps. Prior to proceeding it

may be necessary to prepare some subassemblies

seperately. The details for preparing each subassembly are

given in the following section, as well as some general

recommendations.

2. Cleanliness

Cleanliness is the primary factor for reliable pump

performance. Wash the outside of the pump thoroughly

before disassembly and all pieces prior to assembly.

Cleaning parts with clean shop solvent and air drying is

usually adequate.

3. Lubrication Of Moving Parts

During assembly, it is imperative to provide

lubrication with clean hydraulic oil to all the running

parts of the pump. It is also necessary to coat the seals

with grease. The absence of lubrication during assembly

can cause the unit to seize after a few minutes of running.

4. Care Of Surface Treatment

Be careful when handling all the internal surfaces,

especially bearings, gears, and body faces. Do not touch

or score them with metal tools or cutting edges.

5. Marking The Parts

Mark the parts before completely disassembling a

pump. The marks allow components to be reassembled in

the same relative position. This action should be applied

to the body, bearings, and gears. Scribing, bluing, or

using a felt pen to mark the outside of the body on the

inlet side is suggested to indicate the relative position of

the front flange and the rear cover to the body. Mark the

bearing blocks also on the inlet side and the gears

position relative to each other. DO NOT scribe internal

surfaces.

IMPORTANT

Mark all peices during disassembly so that the unit

can be reassembled correctly. Installing components

incorrectly could severly damage the unit and/or

cause it to not function properly.

1-8

GEAR PUMP 1.2

1

Disassembly (continued)

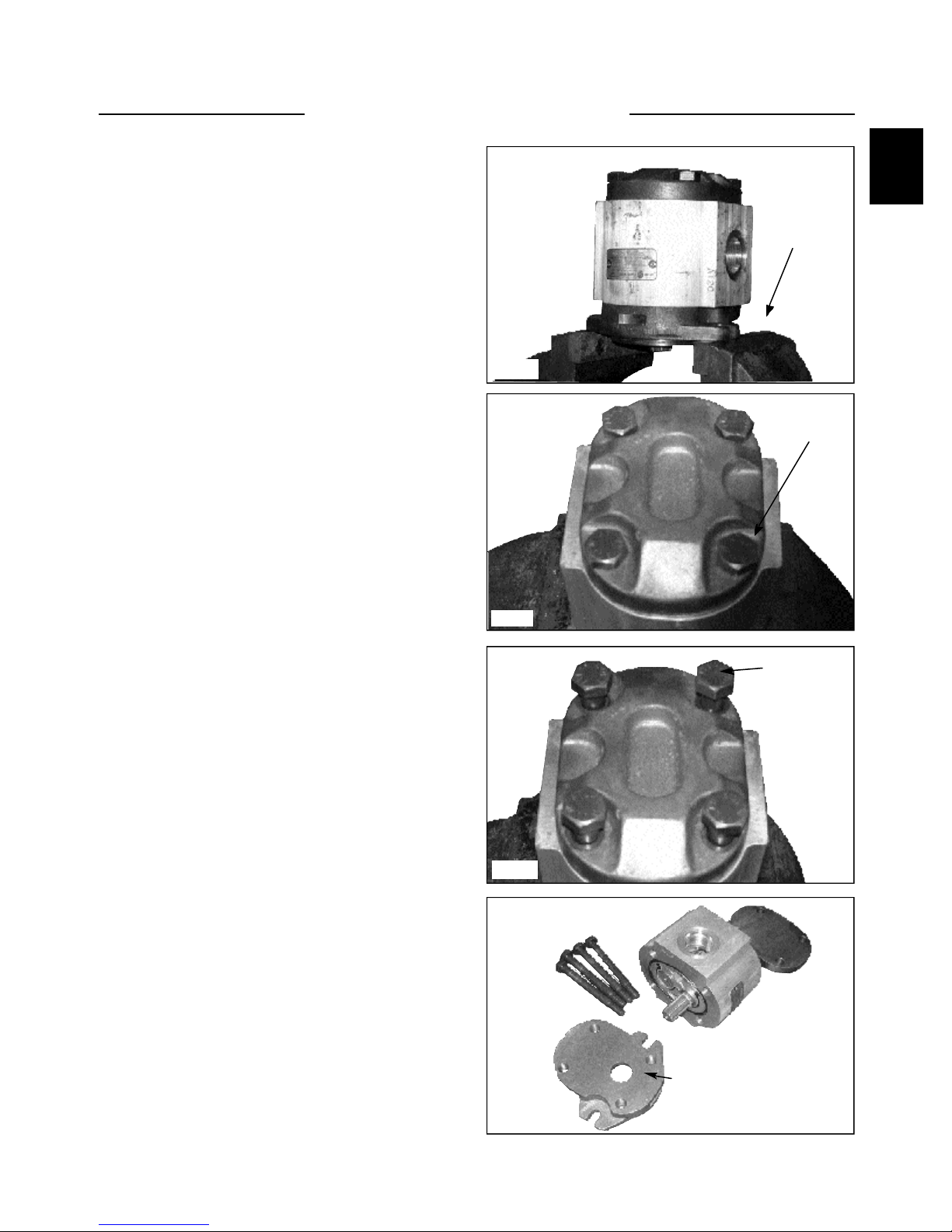

6. Procedure

1. Clamp the unit in a vice from the flange side

(fig. C3973). Make sure the vice jaws are clean and

have smooth surfaces to prevent damage to the

pump. Clamping the pump body is not recommended

because serious damage to the surfaces, on which the

ports are located, may occur.

2. Use a 19mm socket wrench to loosen the four

bolts on the rear cover (fig. C3974). Next completely

unscrew the bolts and remove them. Inspect the

threads for damage (fig. C3975).

3. Place the pump on the table and slowly remove

the front flange (fog. C3976). Note, some units have

a shaft seal and others do not. Should your unit have

the shaft seal, be careful not to damage it when

removing the front flange. Inspect the front flange

and seal area.

Vice

C3973

Bolts

C3974

Remove and

inspect for

damage.

C3975

Front Flange

C3976

1-9

GEAR PUMP 1.2

Disassembly (continued)

6. Procedure

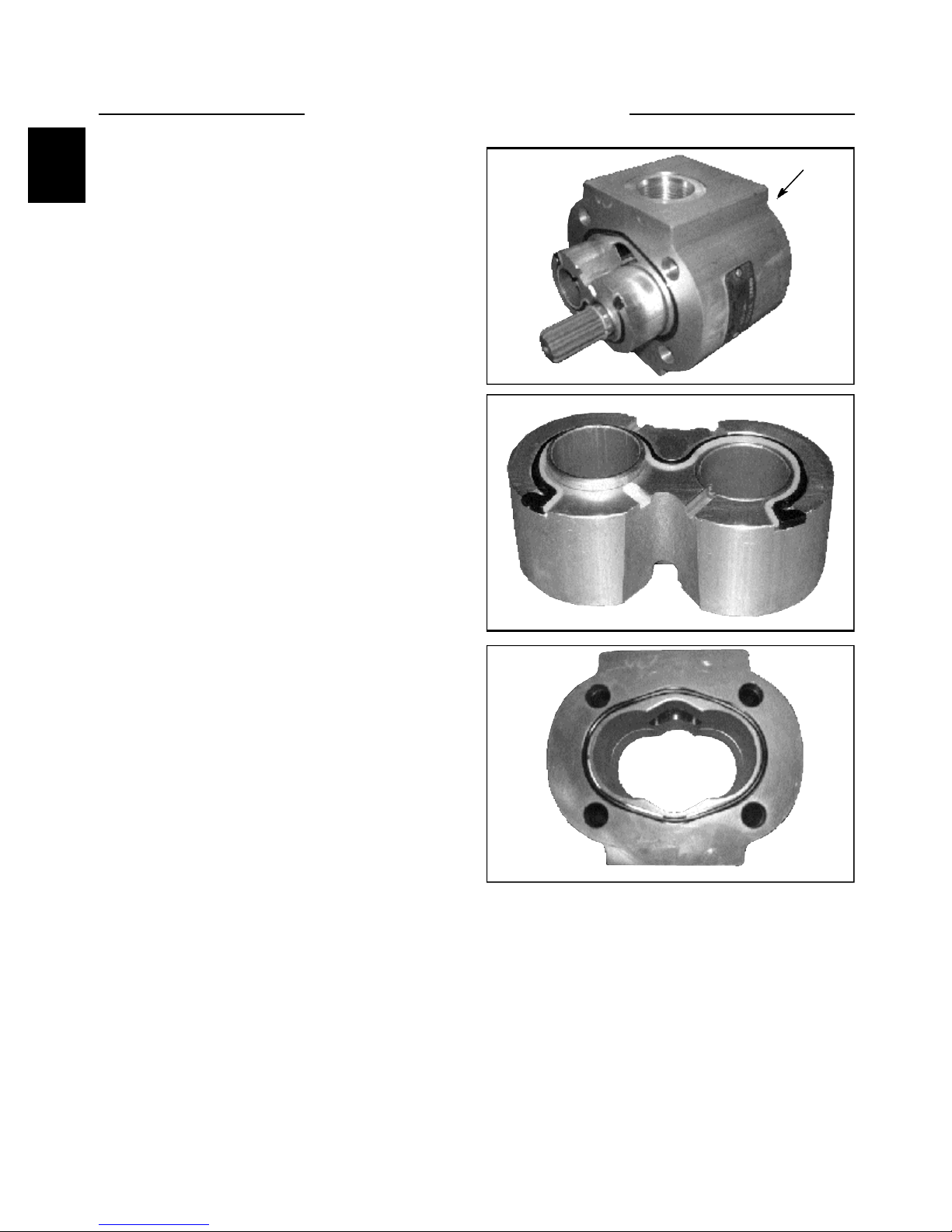

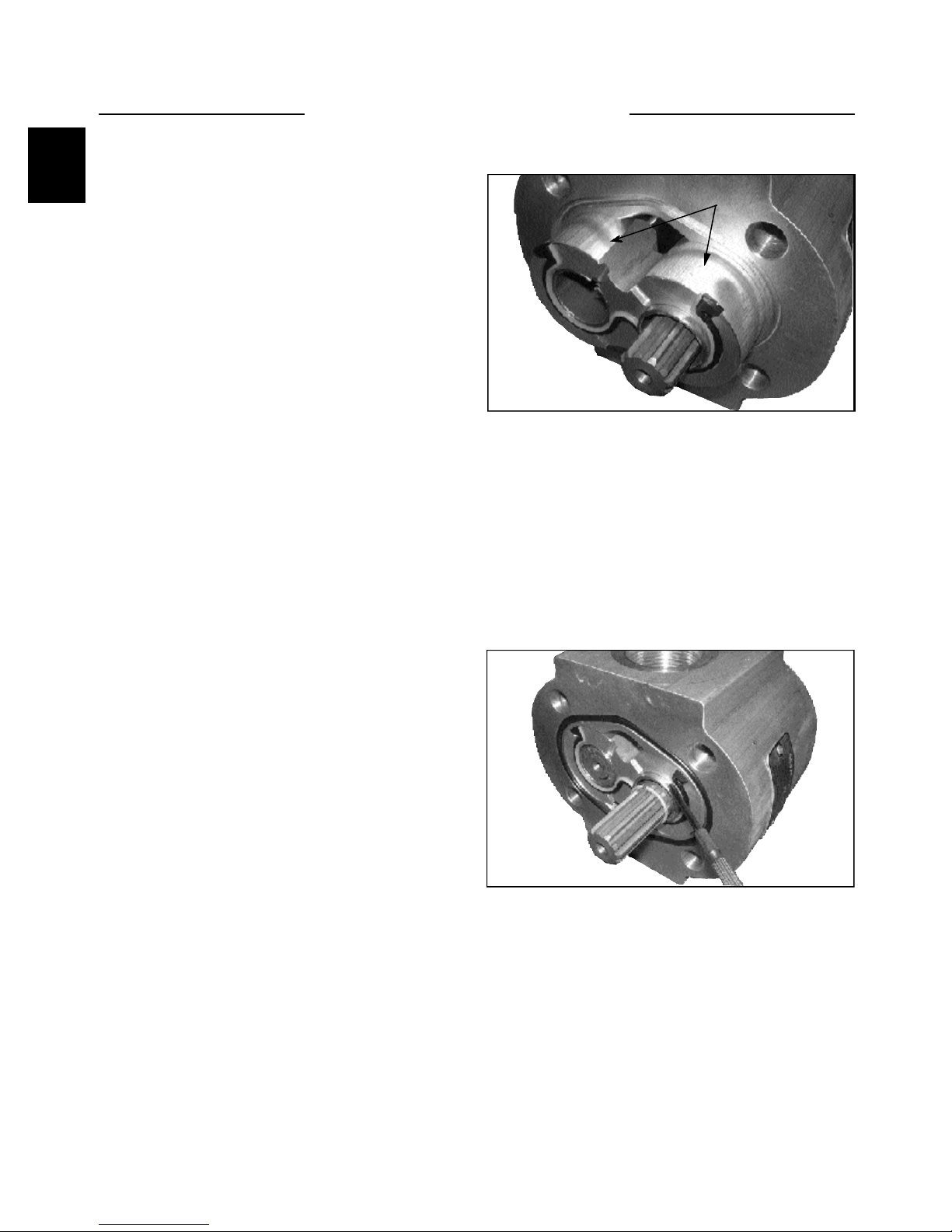

4. Place the pump on it’s side. While disassembling

the unit, you need to mark the relative positions of

the gear mesh (drive gear tooth and idler gear tooth)

and the bearing blocks to the body so they can be

reassembled in the same position. Carefilly remove

the bearing block and gear set (fig. C3977).To

accomplish this, hold the pump body and push with

your fingers on the rear bearing block.

5. Remove the pressure seals taking note how the

pressure seals and teflon back up ring are installed

(fig. C3978). Check the seal quality. Replacement is

recommended whenever there are burrs, evidence of

extrusion, or marks caused by overheating. Carefully

remove the seals from the bearing blocks beginning

with the back up ring then the pressure seal (fig.

C3979). Do not use tools with sharpe edges to

remove the seals, as damage to the bearing blocks

can result. Dispose of any damaged seals.

6. Removal of the outer o-ring seals. Check the

quality of these two seals. If necessary, replace. Do

not use tools with sharp edges to remove the seals, as

damage to the housing may result. Disgard any

damaged seals.

Push

C3977

C3978

7. Remove the shaft seal in the front flange (if

applicable). Place the flange on the work surface.

Using internal snap ring pliers, remove the snap ring.

Check the seal quality and remove it if necessary. To

remove, pry the bottom of the shaft seal and force it

out while rotating the flange to lift it out evenly. Do

not use the flange pilot to gain leverage as damage

may result. Use a plastic rod or wooden dowel as a

fulcrum. After removal, dispose of the damaged seal.

C3979

GEAR PUMP 1.2

1

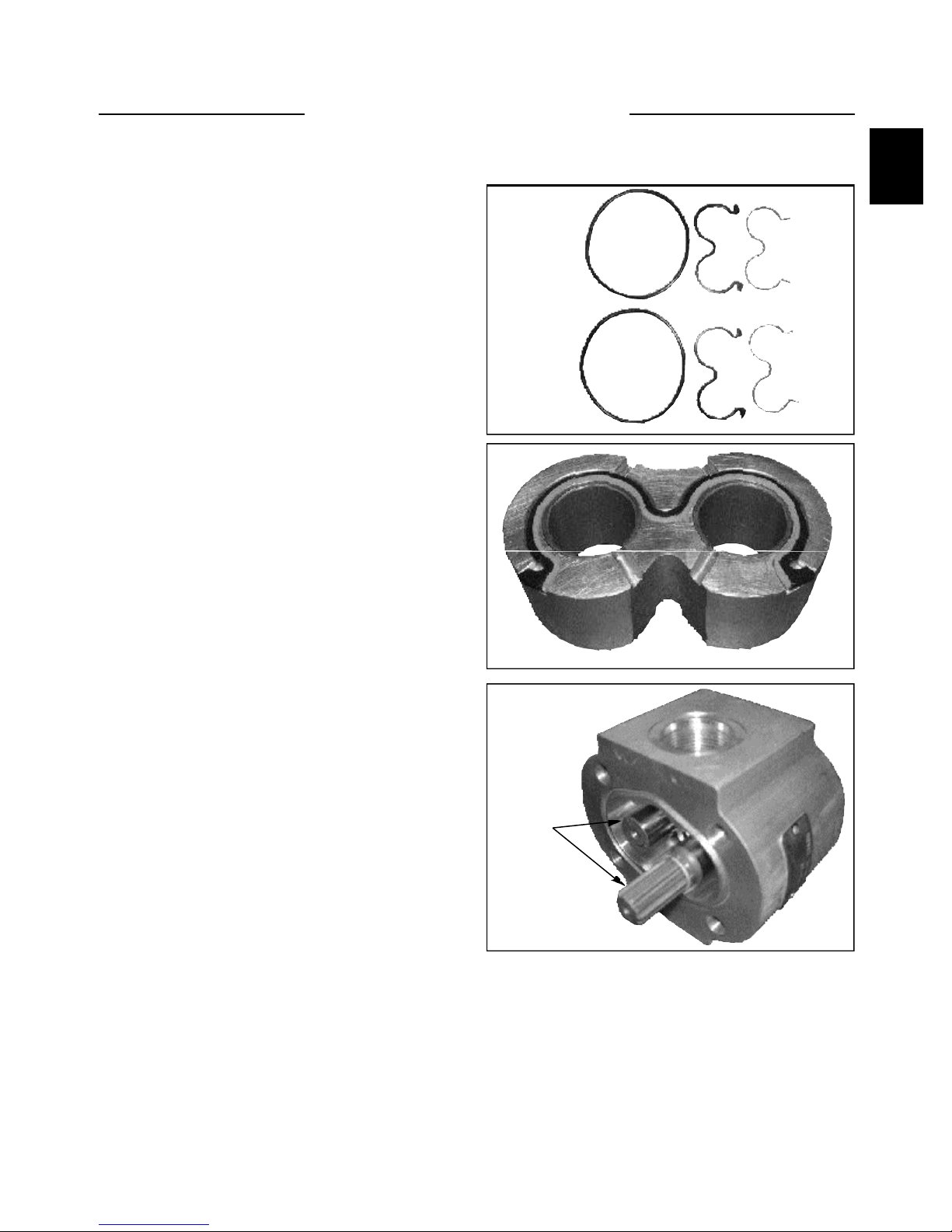

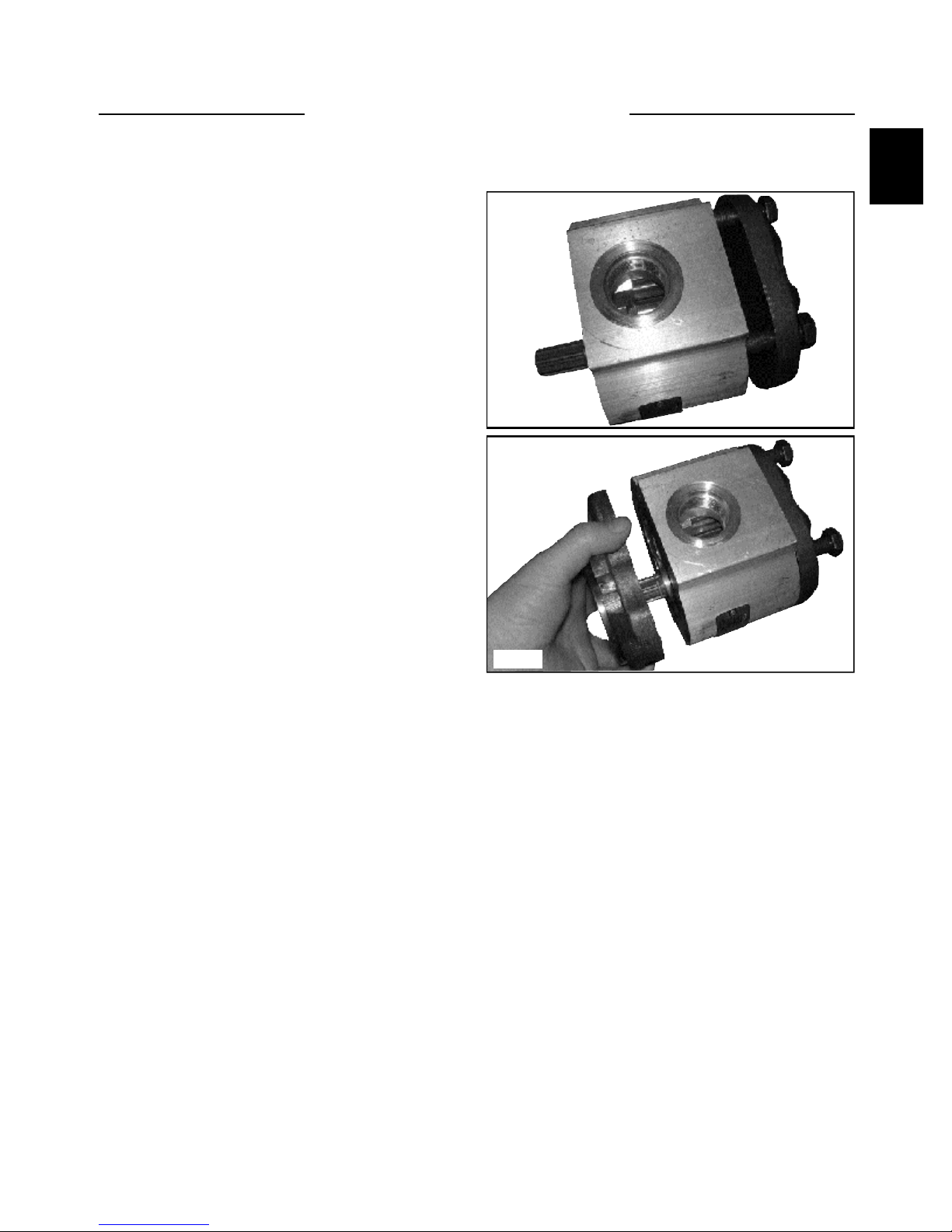

Assembly

1. Have the entire seal kit available and layed out

neatly on the table (fig. C3980). Compare the old

seal kit to the new one to ensure you have the correct

one. Lightly coat all seals with seal grease. The

grease is needed to adhere the sealsin their grooves.

DO NOT INSTALL DRY SEALS!

2. Install the shaft seal into the front flange (if

applicable). Prepare the flange and shaft seal by

lightly lubricating with grease. Seat the seal in the

flange by hand. Then, using a shaft seal installation

tool press the seal until the tool stops on the flange.

This will insure the seal is inserted to the proper

depth.

3. Install the snap ring using internal snap ring

pliers (fig. 3981). Ensure the snap ring fits securely

in its groove. This is necessary to retain the shaft

seal.

C3980

4. Prepare the body by cleaning it. Inspect the

internal and mating surfaces. Ensure the surfaces are

free of burrs and scratches. Check both the bearing

block mating surface and the cut-in path.

5. Prepare the gears (fig. C3982). Caution, the gear

surfaces are superfinished. Residue on hands and

fingers may be corrosive to this surface. DO NOT

TOUCH. Carefully clean the two gears. Inspect the

journals and the flat faces on the top and bottom of

the gears. Ensure these surfaces are free from burrs

or scratches. If scratches are found, clean them with a

flat stone and/or very fine emery paper. Rewash the

gears after this operation.

C3981

Gears

C3982

1-11

Assembly

GEAR PUMP 1.2

6. Prepare the bearing blocks by cleaning both

blocks (fig. C3983). Inspect the flat surfaces of the

bearing blocks for burrs or scratches on the edges. If

necessary, remove burrs with very fine emery paper.

Then rewash the bearings. Inspect the DU bushings

for wear. There should be no bronze showing. Using

clean hydraulic oil, lubricate the internal and external

surfaces of your blocks.

7. Assemble the bearing blocks and gears.

Lubricate the journals and gear faces. Assemble the

bearing blocks and gears in the same orientation that

it was disassembled. Align all marks made during

disassembly. Ensure the front and rear block occupy

the same location with respect tot he housing as they

did before disassembly. Misalignment of the gear

teeth may increase operating noise.

8. Install the gear and block assembly into the body

of the cavity. Align the assembly marks to ensure that

the gear block assembly is installed with the same

orientation as before assembly.

Blocks

C3983

9. Once the gears and the bearing blocks are

installed into the housing, clean the mating surfaces.

Remove any excess lubrication and grease from the

mating surfaces of the pump body. Ensure that these

surfaces are dry and free of contamination before

moving on to the next step. Install the o-rings and

back-up rings on both the bearing blocks and the

housing (fig. C3984).

C3984

1-12

GEAR PUMP 1.2

1

Assembly

10. Remove any axcess lubrication and grease from

the mating surfaces of the front flange and rear cover.

Ensure that these surfaces are dry and free of

contamination before moving on to the next step.

11. Install the four bolts through the rear cover then

slide the assembly onto the rear of the housing (fig.

C3985). Before you slide the cover against the

housing, check to make sure all o-rings and the backup seal are seated properly with no foreign material

on them. If they get pinched or there is foreign

material on an o-ring, you may get internal or

external leakage.

12. Install the front cover (fig. C3986). While

keeping pressure on the front flange and the rear

cover so the o-rings wont move out of place, set the

unit in a vise with the front in the jaws.

13. Torque the four bolts by criss crossing back and

forth a little at a time until you reach the final torque.

C3985

14. After the pump has been disassembled and

reassembled it it suggested that the pump be run in

and tested on an appropriate test stand. This is done

to verify the volumetric efficiency and the integrity

of the unit.

C3986

1-13

CONTROL VALVE 1.3

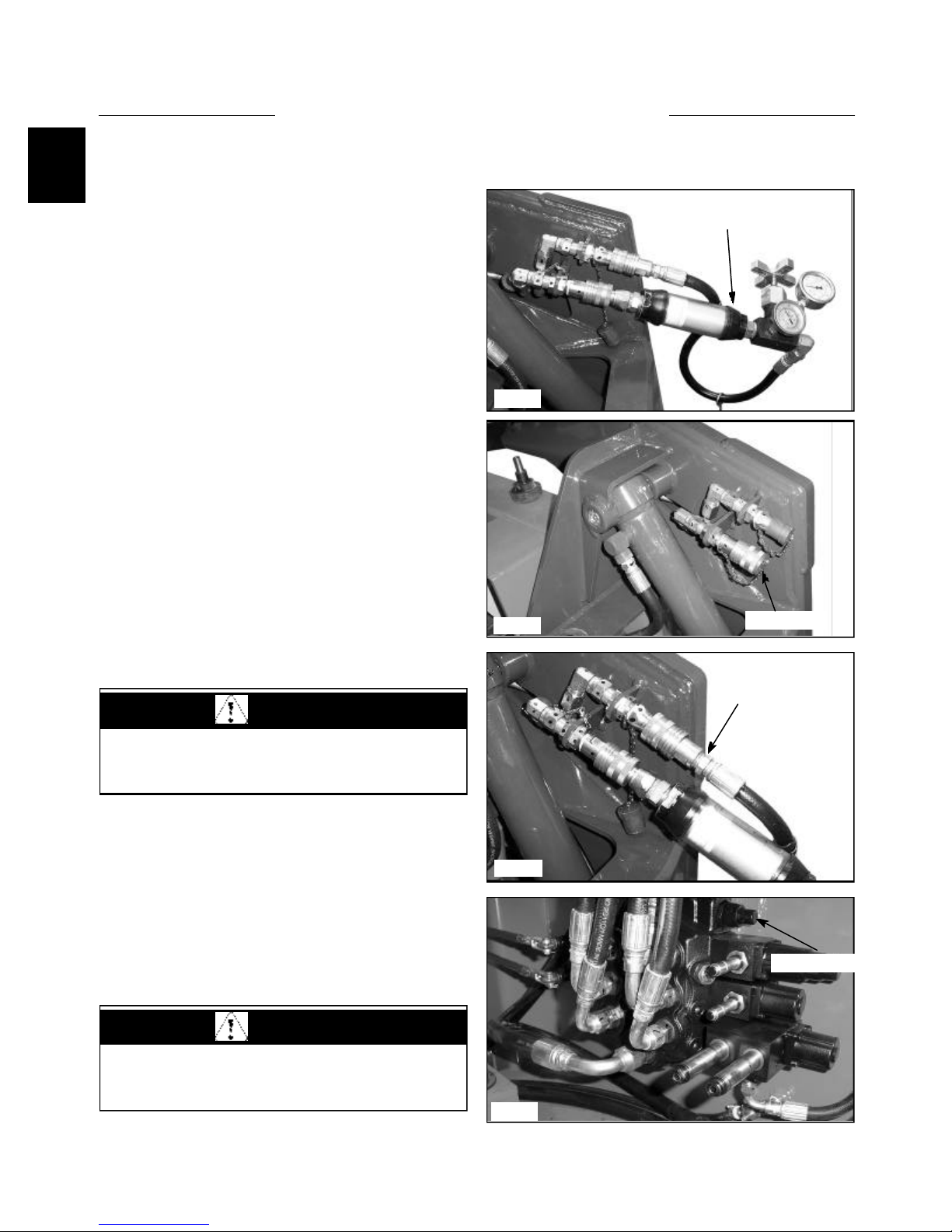

Testing and Adjusting the Relief Valve Pressure

Hoses and gauges required for this test must be capable

of withstanding 5000 PSI (207 Bar) continuous pressure,

and hydraulic flow meter capable of measuring 30 gallons

per minute. (113 LPM) (fig. C3432) This test also

checks the status of the gear pump capacities.

Pressure fluctuations may be caused by restricted oil flow

through the relief valve. The relief valve filter may need

serviced as outlined in the control valve disassembly

section on pages 1-9 through 1-13.

1 Install the flow meter / pressure tester to the auxiliary

hydraulic quick couplers. The female coupler attached to

the loader provides the power out when the auxiliary

control is engaged. (fig, C3646) Connect the flow meter

and pressure gauge inlet side to match the power out of

the female auxiliary coupler to prevent meter and gauge

damage. Be sure to connect a return line to the male

auxiliary hydraulic quick coupler. (fig. C3433)

2 Start the engine and engage the auxiliary hydraulic

system. Increase the engine speed to full operating RPM.

(See Section 7 for checking and adjusting engine speed to

2800 RPM plus or minus 25 RPM)

3 Turn the flow control valve on the flow meter to

restrict the oil flow down to 2 GPM. (7.5 LPM) As you

are turning the flow control valve, watch the pressure

gauge and make sure it does not go over 3000 PSI.(207

Bar) Stop further adjustment immediately if the reading

goes over this setting. Shut off the auxiliary hydraulic

CAUTION

Adjusting the relief valve setting too high may cause

damage to the gear pump.

C3432

C3646

Flow Meter/Pressure Tester

Pressure out

Pressure return

system and shut off the engine. Move to step 6 to make

initial setting.

WARNING

To prevent personal injury or damage to the loader,

do not adjust the relief valve while the engine is

operating.

C3433

Relief valve

C3434

1-14

CONTROL VALVE 1.3

1

4 Repeat steps 2 and 3 if necessary. Allow the loader to

operate at this setting until the oil temperature has

increased to 160° F (71ºC), operating temperature.

5 Turn the flow control valve further to restrict the oil

flow to no flow. (Zero) Correct pressure setting is 2400

PSI +/- 100 PSI. (165 Bar, +/-6.9 Bar)

6 If adjustment is necessary, shut down the auxiliary

hydraulic system, shut off the engine and return the flow

control valve to the open position. Locate the control

valve in the engine compartment.

7 Loosen the jam nut on the relief valve adjusting

screw and turn the screw clockwise, counting the turns,

until the screw bottoms out. (fig. C3435)

8 Turn the screw back out lesser turns than you turned

in to increase pressure, or out more turns to decrease

pressure.

9 Retake the pressure readings by performing steps 2

through 5. If necessary make further adjustments by

repeating steps 6 through 9.

NOTE: If inadequate pressure and / or flow is not

available, the gear pump could be failing, the intake to

the gear pump is restricted, or the filter in the relief

valve is clogged. (See pg. 25 for filter replacement).

Jam nut

Relief valve

C3869

Solenoid coil

mounting nuts

C3436

Control Valve Replacement

1 Remove any attachment and shut off the engine

IMPORTANT

Clean the work area prior to repair. Cap all open

lines, fittings and ports to prevent contamination.

2 Disconnect the control cables, electrical solenoid

spool locks, and electrical auxiliary solenoid wiring

connectors if equipped. (fig. C3436, C3437)

3 Disconnect the the inlet hose coming from the gear

pump.Cap the hose and fitting and remove the adapter

fitting in the control valve. (fig. C3436)

4 Disconnect the 6 hoses going to the boom, bucket

and auxiliary circuits. Marking the hoses as you remove

them is recommended to ease re-assembly and assure the

circuits are functioning properly at restart.(fig. C3434)

5 Disconnect the return line from the control valve and

remove the adapter fitting. Plug and cap all open ports

and hose ends. (fig. C3436)

Cable

cotter pins

C3437

Remove and tag hose location

Solenoid Coils Removed

1-15

C3434

CONTROL VALVE 1.3

6 Remove the 3 nuts holding the control valve to the

mount and remove the control valve.

7 Remove any fittings left in the control valve. Cap all

open ports to prevent contamination. Place these fittings

in the new or repaired control valve. Be sure to check all

fitting flares and o -rings for damage and replace as

required.

IMPORTANT

Follow the hydraulic fitting torque chart in Section

1.10 when connecting fittings and lines.

8 Assemble the control valve to the loader in the

reverse order above. Torque the bolts holding the control

valve to the mount at 15 ft / lbs. (20.4 N.m.)

11 After all connections have been made, including the

control valve electrical connections, check the oil level in

the hydraulic reservoir and top off if necessary.

12 Start the engine and cycle the various hydraulic

functions to check for leaks. Make sure the control valve

lock system is functioning properly. Do not use your

hands to check for leak locations, fluid under operating

pressure can penetrate the skin and cause serious personal

injury.

WARNING

Use extreme caution when checking the hydraulic

system for leaks. Fluid under pressure can penetrate

the skin and cause serious injury.

Valve mount plate

C3438

Check fluid level

C3431

Replenish fluid as required

13 After checking for leaks, you must retest the relief

valve setting as outlined on page 1-6 Testing and

adjusting.

WARNING

All safety switches must be connected and

functioning to prevent possible operator injury.

C1108

1-16

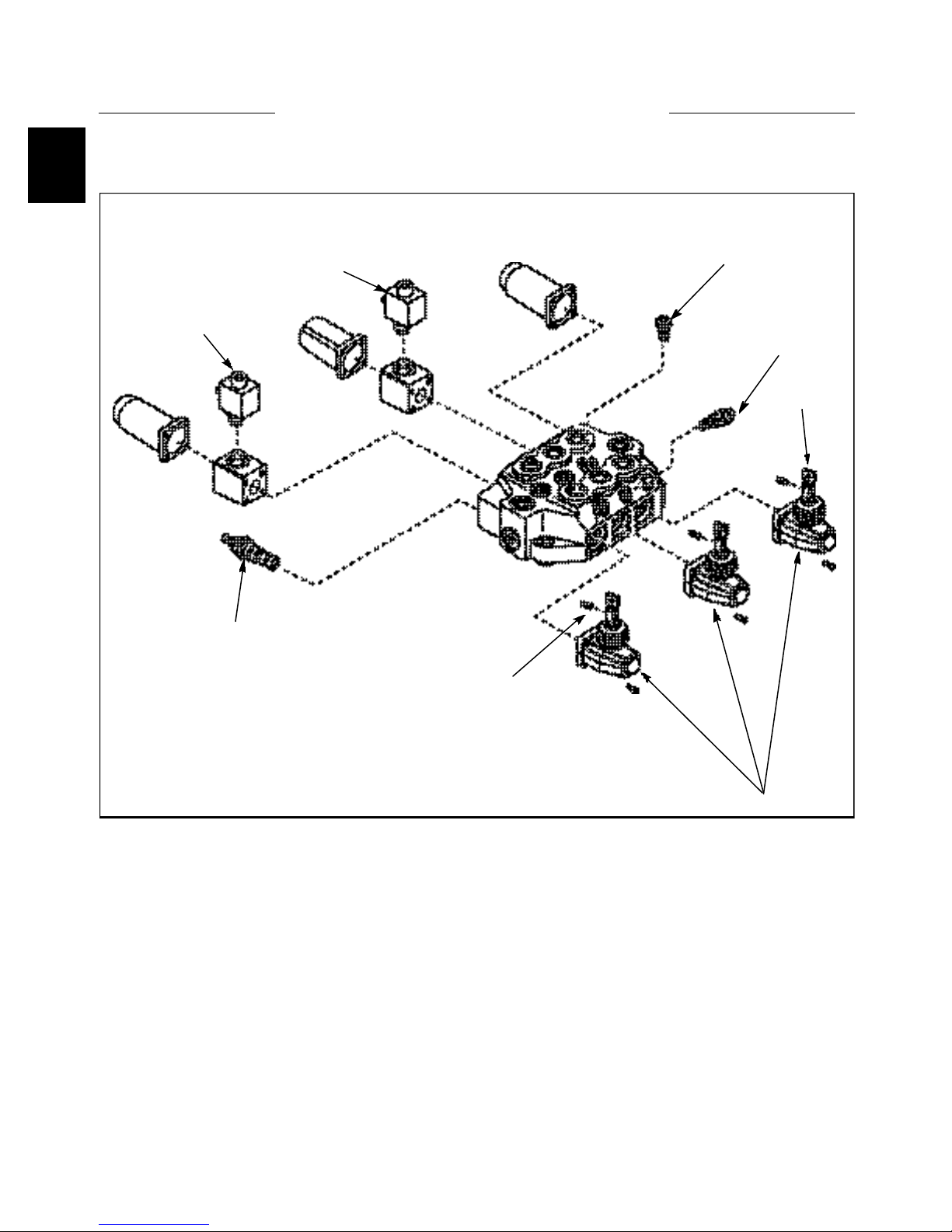

CONTROL VALVE 1.3

1

Control Valve Disassembly (175)

7

6

11

8

6

5

C3240

Diagram Legend

1. Control Box

2. Set Screws

3. Dust Cap Ass’y Kit

4. Check Valve

5. Main relief Valve

6. Lock Solenoid Coil

7. Auxiliary Solenoid Coil

8. Auxiliary Control With Coils

9. Port Relief Valve

10. Bar

11. Dust Cap With Connector For Hand Controls

4

9

3

10

2

1

1-17

CONTROL VALVE 1.3

Control Valve Disassembly (1700)

6

6

5

2

4

3

7

C3303

Diagram Legend

1. Control Box

2. Set Screws

3. Port Relief Valve

4. Check Valve

5. Main Relief Valve

6. Lock Solenoid Coil

7. Bar

1

1-18

CONTROL VALVE 1.3

1

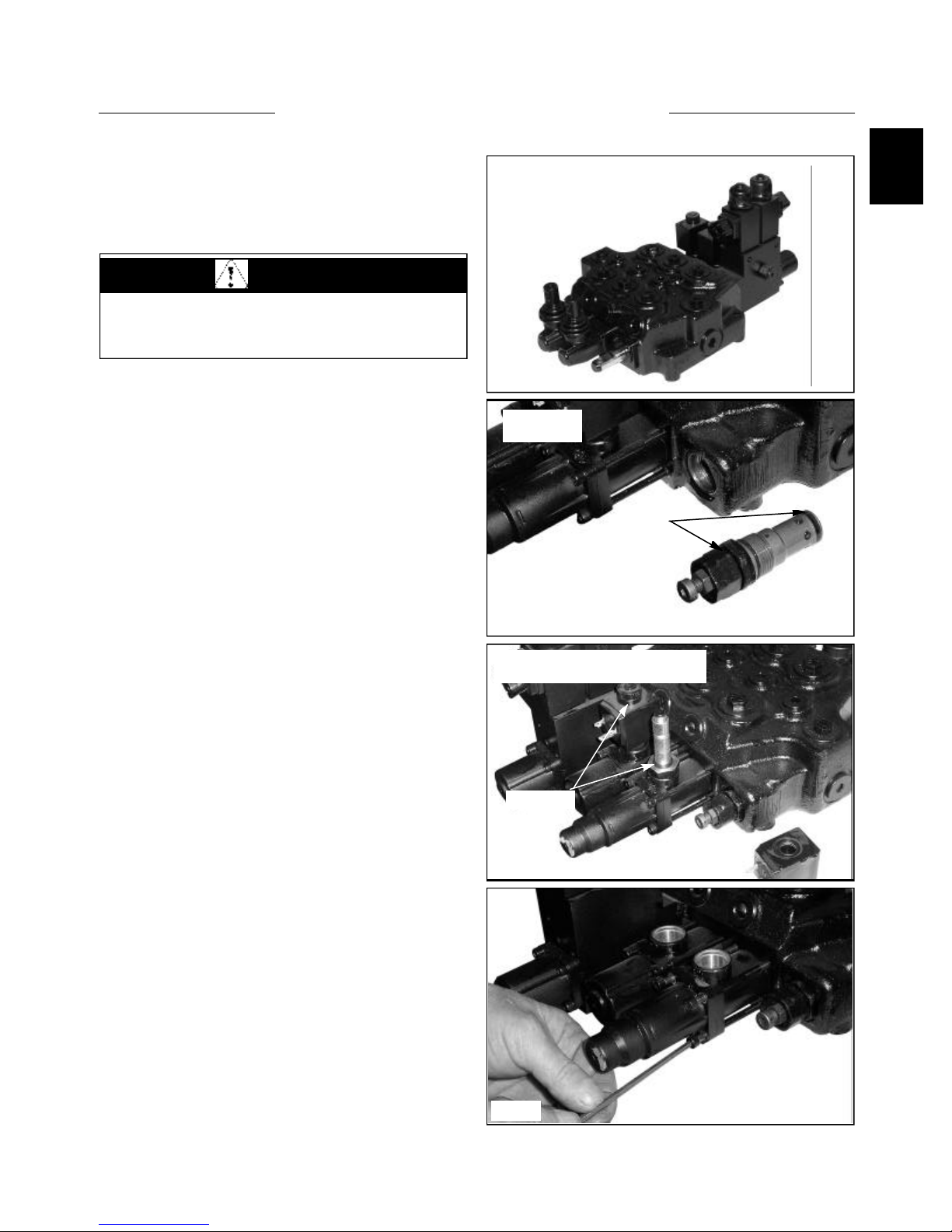

Disassembly / Repair (175)

Before disassembling the hydraulic control valve, clean

the body with a suitable solvent and dry with compressed

air. (fig. C3696)

WARNING

To avoid eye injury, use safety goggles when

cleaning with compressed air.

Ensure all openings are plugged to prevent solvents and

dirt from contaminating the control valve assembly.

1. Remove the pressure relief valve. Discard the Orings. (fig. C3698)

Control Valve

C3696

Removing the

Relief Valve

O Rings

C3698

2. Remove the solenoid coils and locking pin from the

valve lock block. (fig. C3699) There are 2 O-ring seals

located on either side of the solenoid coils.

3 Remove the spring return detent kit and spring center

cap locks. (fig. C3704, C3706)

Removing the solenoid coils from the

spool locks.

O Ring seal

C3699

C3704

1-19

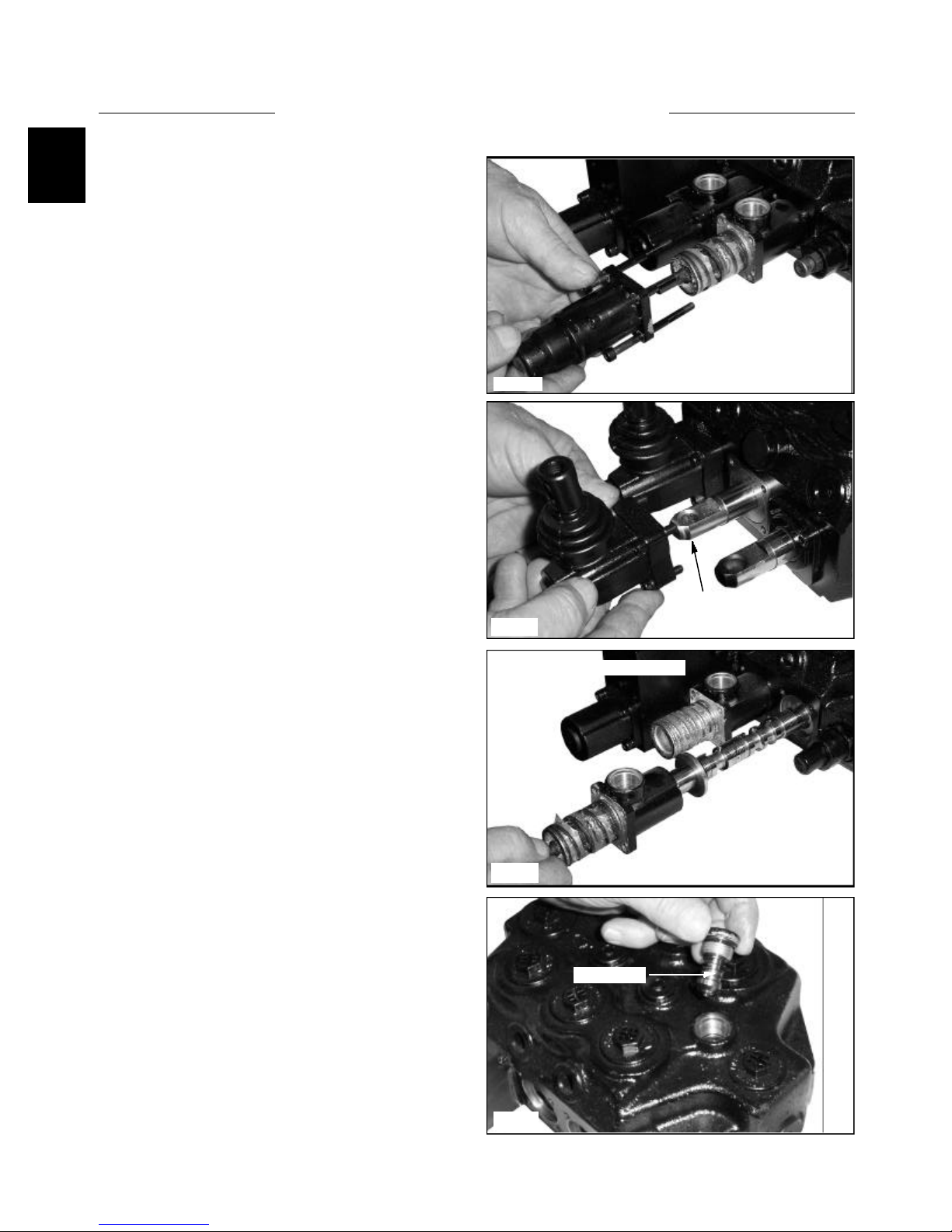

CONTROL VALVE 1.3

Disassembly / Repair 175

(cont’d)

4 Remove the control box from the spool linkage end.

(fig. C3709) The box needs to be tilted upward towards

the valve to release the hardened ball from the hole in the

spool end, and then pull away from the valve.

C3706

5 Pull out the spool. (fig. C3713) As you pull out the

spool, note it’s smooth action as it comes out of the valve

body. The spool should move freely and smoothly in the

bore of the valve body. Check the control valve spool and

bore for scuff marks or abnormal wear. Replace the spool

and or control valve if signs of wear are present.

6 Remove the check valves from control valve body.

(fig. C3717) They are located between the ports of each

section. Check the seat and poppet of the valve body and

check valve. Replace the check valve and or the control

valve if any signs of wear are present.

Spool Linkage

C3709

Removing the spools from the valve.

C3713

Check Valve

C3717

1-20

Loading...

Loading...